Preparation method of barrier layer yttrium oxide-doped bismuth oxide of solid oxide fuel cell

A solid oxide, fuel cell technology, used in fuel cell parts, fuel cells, chemical instruments and methods, etc., can solve the problems of poor compatibility of zirconium-based electrolytes, increase interface resistance, etc., to reduce interface resistance, The effect of stress relief and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

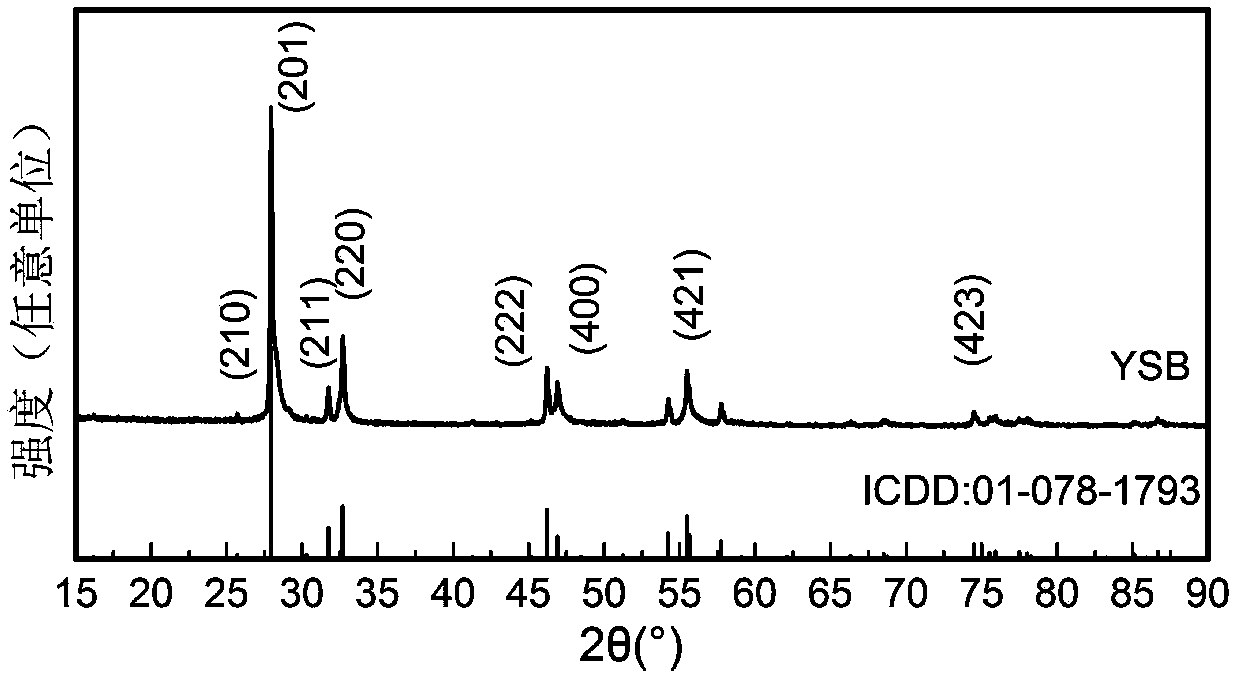

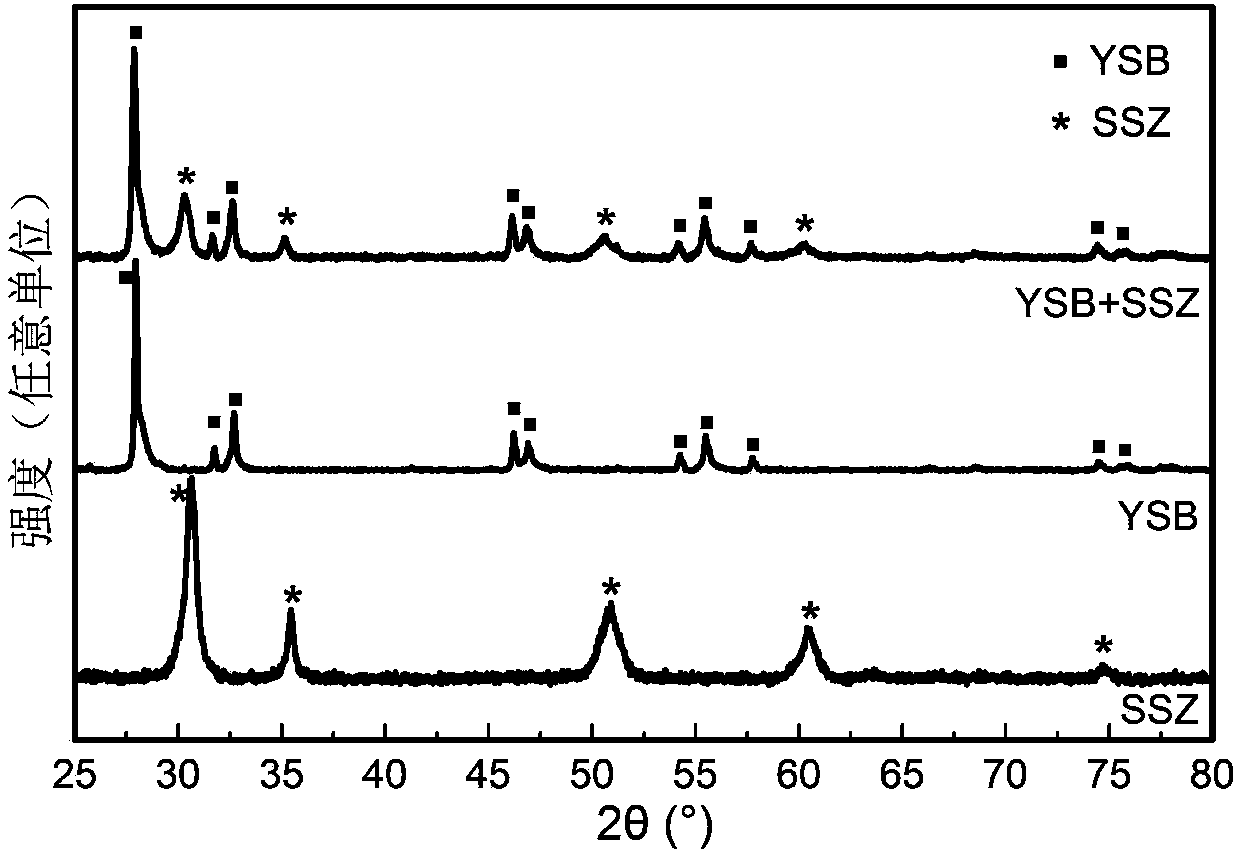

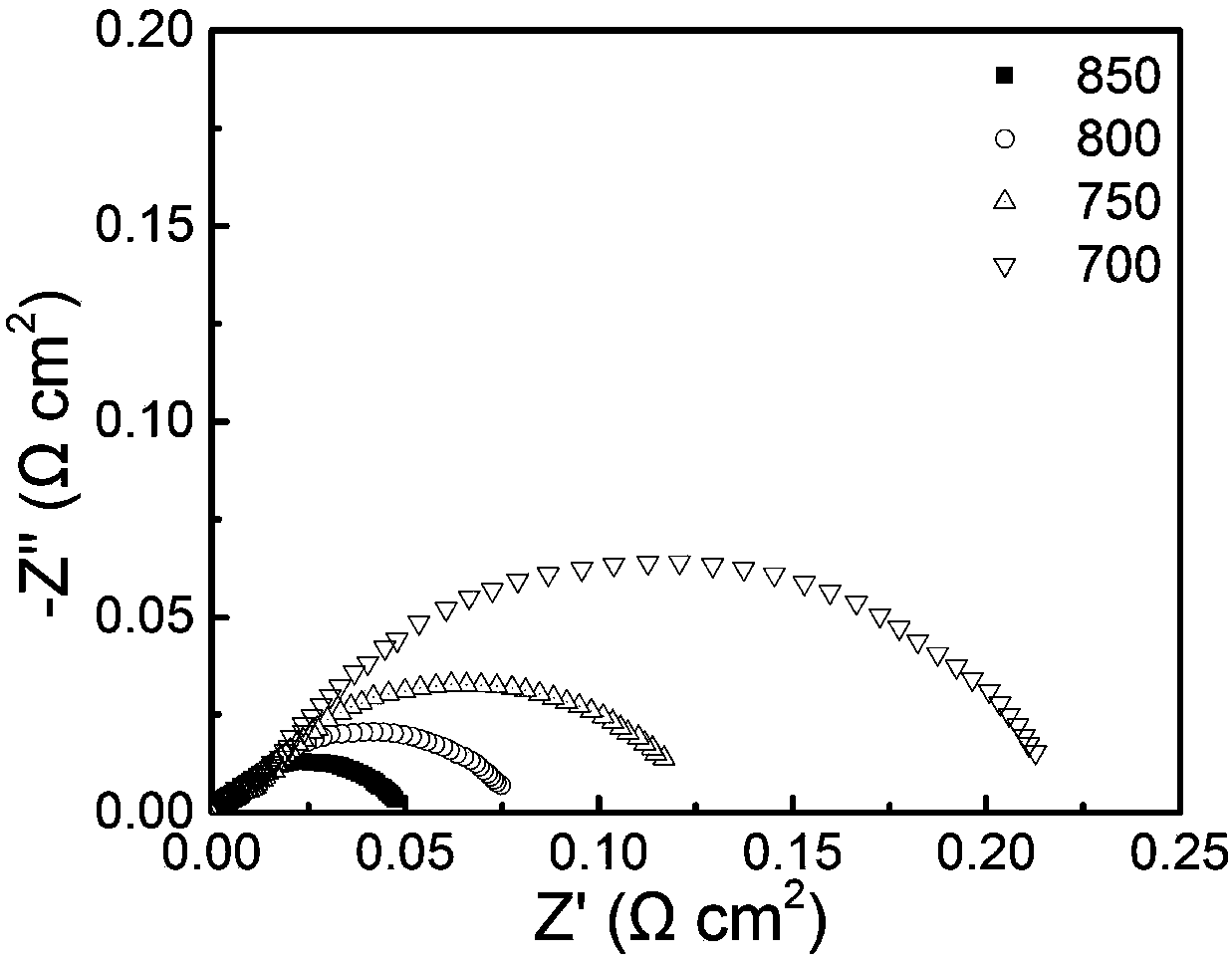

[0021] Embodiment 1: This embodiment records a method for preparing a solid oxide fuel cell barrier layer doped with yttrium oxide and bismuth oxide. The specific steps of the method are as follows:

[0022] Step 1: Add ethyl cellulose as pore forming agent and binder to Y x Bi 2-x o 3 , get Y x Bi 2-x o 3 Powder;

[0023] Step 2: Drop terpineol into the Y obtained in step 1 as a dispersantx Bi 2-x o 3 In the powder, grind for 10-30min with an agate mortar;

[0024] Step 3: Grinding the Y obtained in Step 2 x Bi 2-x o 3 The paste is screen printed onto the electrolyte;

[0025] Step 4: Print the Y x Bi 2-x o 3 Electrolyte drying of slurry;

[0026] Step 5: Repeat Step 3 and Step 4 1-3 times to get Y with different thickness x Bi 2-x o 3 barrier layer;

[0027] Step 6: Printed on the Y x Bi 2-x o 3 The electrolyte of the barrier layer is heat-treated.

specific Embodiment approach 2

[0028] Specific embodiment two: the preparation method of a solid oxide fuel cell barrier layer yttrium oxide doped bismuth oxide described in specific embodiment one, in step one, the Y x Bi 2-x o 3 Synthesized by co-precipitation method, the specific synthesis steps are as follows:

[0029] (1) Weigh the corresponding mass of Bi(NO 3 )·5H 2 O and Y (NO 3 )·6H 2 O, add into nitric acid and stir to dissolve, so that the total concentration of metal ions is 0.1-0.5mol / L;

[0030] (2) Distilled water is added to the nitric acid solution of (1) metal ions for dilution, and the volume ratio of the nitric acid solution to distilled water is 1:1-2;

[0031] (3) Add ammonia water dropwise to the solution obtained in (2), adjust the pH=8-11, and continue to stir for 2-6h;

[0032] (4) suction filter the mixture obtained in (3), and wash with distilled water 3-5 times to obtain a white precipitate;

[0033] (5) Put the above-mentioned white precipitate into an oven, and dry at ...

specific Embodiment approach 3

[0035] Specific embodiment three: the preparation method of a kind of solid oxide fuel cell barrier layer yttrium oxide doped bismuth oxide described in specific embodiment one, in step one, the addition amount of described ethyl cellulose is Y x Bi 2-x o 3 5%-15% of mass.

[0036] Embodiment 4: A method for preparing a solid oxide fuel cell barrier layer of yttrium oxide doped bismuth oxide according to Embodiment 1. In step 1, the Y x Bi 2-x o 3 The particle size of the powder is 60-100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com