Palladium/ceramic composite film

A ceramic composite and composite thin film technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of palladium film failure, pinhole defects, grain growth and coarsening of palladium film, etc. The effect of reducing thermal expansion mismatch, improving high temperature structural stability, increasing the difficulty of high temperature grain growth and coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

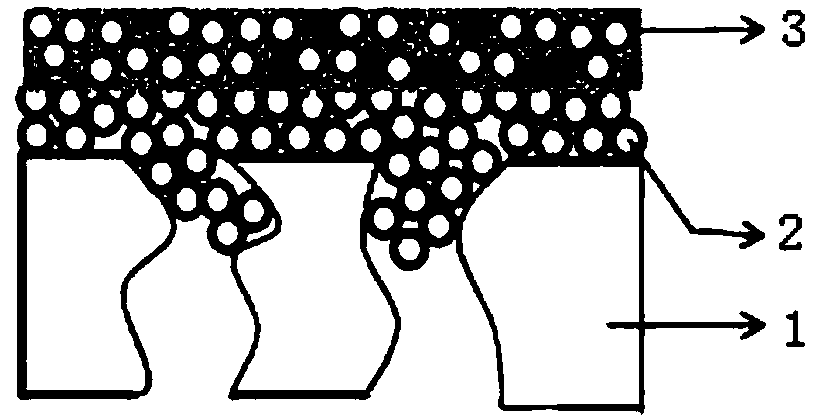

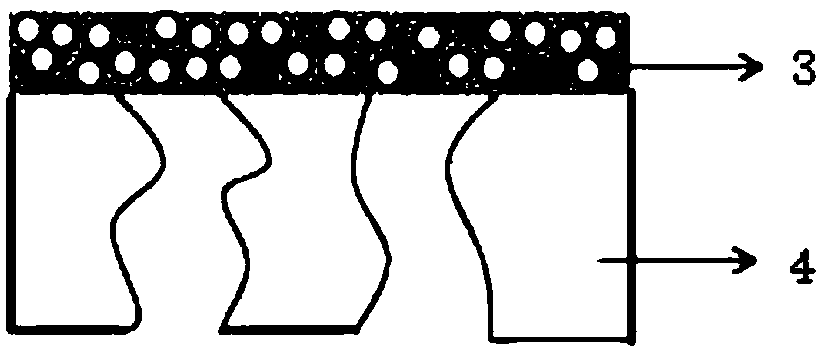

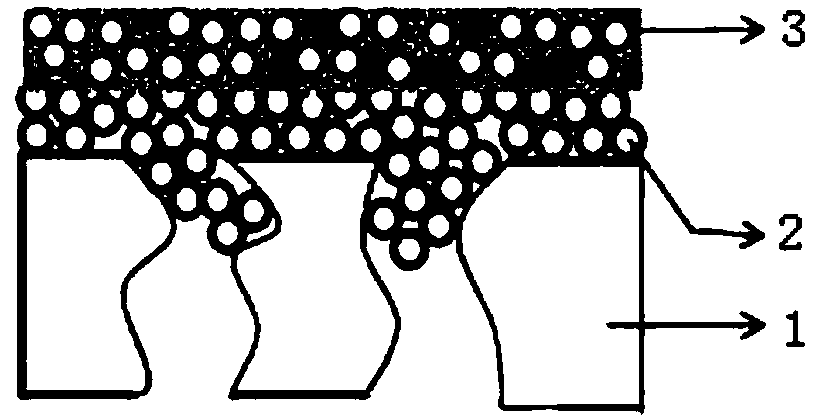

Image

Examples

Embodiment 1

[0019] Preparation of Pd / Alumina Composite Thin Films on Porous Alumina

[0020] Palladium / alumina composite films were prepared on 3-inch porous alumina sheets. Metal palladium and alumina targets are used, metal palladium is powered by DC power supply, alumina is powered by radio frequency power supply, and Ar is used as the starting gas. When the back vacuum is better than 2×10 - 4 After Pa, clean with Ar plasma bombardment for 15 min in the sputtering chamber. The palladium / alumina composite thin film was obtained by sputtering the palladium target and the alumina target at the same time. for 2 hours. The thickness of the palladium / aluminum oxide composite thin film is 2.5 micrometers, and the volume content of metal palladium is 95%.

[0021] The prepared palladium / alumina composite film was kept in a hydrogen atmosphere at 700°C for 72 hours. The composite film had no defects such as pinholes and cracks, and the helium leakage rate was better than 10 -9 Pa·m 3 / ...

Embodiment 2

[0023] Preparation of Pd-Cu / ZrO Composite Thin Films on Porous Stainless Steel

[0024] A palladium-copper / alumina composite film was prepared on a 3-inch porous stainless steel sheet, and the copper content in the palladium-copper alloy was 40wt%. Palladium-copper alloy (copper content 40wt%) and alumina target material are used, the palladium-copper alloy is powered by a DC power supply, the alumina is powered by a radio frequency power supply, and Ar is used as a glow gas. When the back vacuum is better than 2×10 -4 After Pa, clean with Ar plasma bombardment for 15 min in the sputtering chamber. The palladium-copper / alumina composite film was obtained by sputtering palladium-copper and alumina targets at the same time. The sputtering chamber pressure was 0.85Pa, the target base distance was 100mm, the palladium-copper sputtering power was 250W, and the alumina sputtering power was 150W. The deposition time was 5 hours. The thickness of the palladium-copper / aluminum oxi...

Embodiment 3

[0027] Preparation of Pd-Ag / CrO Composite Thin Films on Porous Glass

[0028] A palladium-silver / chromium oxide composite film was prepared on a 3-inch porous glass sheet, and the silver content in the palladium-silver alloy was 23wt%. Palladium-silver alloy (silver content 40wt%) and chromium oxide target material are used, the palladium-silver alloy is powered by a DC power supply, the chromium oxide is powered by a radio frequency power supply, and Ar is used as an initiating gas. When the back vacuum is better than 2×10 -4 After Pa, clean with Ar plasma bombardment for 15 min in the sputtering chamber. The palladium-silver / chromium oxide composite film was obtained by sputtering palladium-silver and chromium oxide targets at the same time. The sputtering chamber pressure was 0.85Pa, the target base distance was 100mm, the sputtering power of palladium-silver was 100W, and the sputtering power of chromium oxide was 250W. The deposition time was 5 hours. The thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com