Leadless low-melting glass production method

A low-melting point glass and production method technology, applied in the field of materials, can solve the problems of difficult mother liquor handling, environmental and safety impacts, poor product stability, etc., achieve material stability, reduce sealing temperature, and enhance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

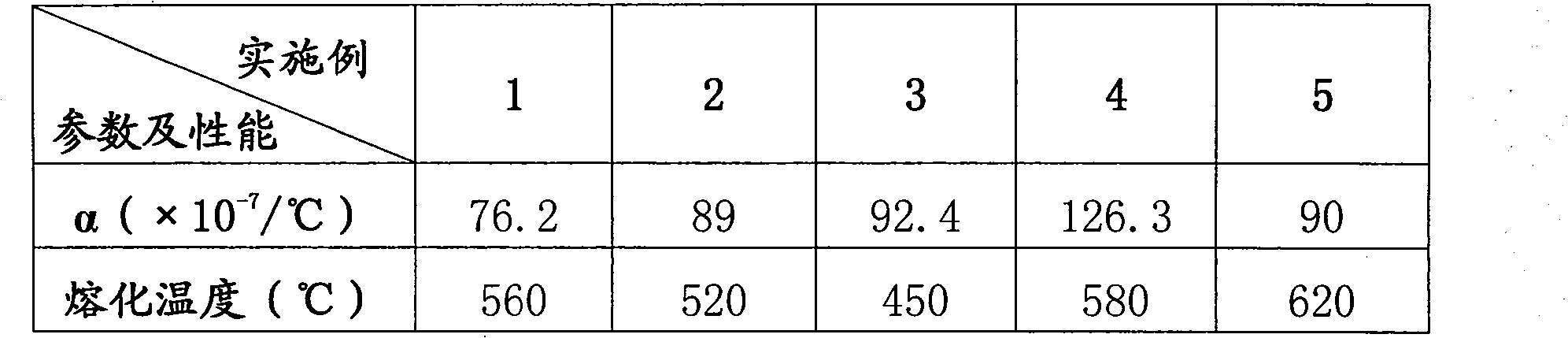

Examples

Embodiment 1

[0021] A method for producing lead-free low-melting glass, comprising the following steps:

[0022] (1) Preparation of glass front matrix:

[0023] a. Measure raw materials according to the following quality:

[0024] Na 4 P 2 o 7 165g, SnCl 2 150g, BaCl 2 24g, ZnCl 2 6g, AlCl 3 4.5g, SrCl 2 3.5g, CaCl 2 9g.

[0025] b. Set the temperature of the water bath at 60°C, prepare a sodium pyrophosphate solution with a mass concentration of 20%, and heat it in the water bath;

[0026] c. Dissolve the above chloride with 180ml of HCl solution with a mass concentration of 15% and add 60ml of pure water to dilute it. When the temperature of the sodium pyrophosphate solution reaches 55°C, add the solution dropwise to the sodium pyrophosphate solution to react and keep stirring. Acceleration rate 15ml / min, stirring rate 100rad / s;

[0027] d. Continue stirring for 50 minutes after the dropwise addition, and heat preservation and aging for 60 minutes;

[0028] f. After aging, r...

Embodiment 2

[0034] A method for producing lead-free low-melting glass, comprising the following steps:

[0035] (1) Preparation of glass front matrix:

[0036] a. Measure raw materials according to the following quality:

[0037] Na 4 P 2 o 7 350g, SnCl 2 250g, BaCl 2 57g, ZnCl 2 13g, AlCl 3 7g, SrCl 2 8g, CuCl7.5g, CaCl 2 7g.

[0038] b. Set the temperature of the water bath at 70°C, prepare a sodium pyrophosphate solution with a mass concentration of 30% and heat it in the water bath;

[0039] c. Dissolve the above chlorides with 320ml of HCl solution with a mass concentration of 15% and dilute with 110ml of pure water. When the temperature of the sodium pyrophosphate solution reaches 55°C, add the solution dropwise to the sodium pyrophosphate solution to react and keep stirring. Acceleration rate 20ml / min, stirring rate 100rad / s;

[0040] d. Continue to stir for 50 minutes after the dropwise addition, and keep warm for 120 minutes;

[0041] f. After aging, rinse with pure ...

Embodiment 3

[0047] A method for producing lead-free low-melting glass, comprising the following steps:

[0048] (1) Preparation of glass front matrix:

[0049] a. Measure raw materials according to the following quality:

[0050] Na 4 P 2 o 7 325g, SnCl 2 250g, BaCl 2 40g, ZnCl 2 11g, AlCl 3 8g, SrCl 2 6.5g, CuCl5g, CaCl 2 6.5g.

[0051] b. Set the temperature of the water bath at 55°C, prepare a 30% sodium pyrophosphate solution and heat it in the water bath;

[0052] c. Dissolve the above chloride with 300ml of HCl solution with a mass concentration of 20% and dilute with 100ml of pure water. When the temperature of the sodium pyrophosphate solution reaches 55°C, add the solution dropwise to the sodium pyrophosphate solution to react and keep stirring. Dropping rate 20ml / min, stirring rate 150rad / s;

[0053] d. Continue to stir for 50 minutes after the dropwise addition, and heat preservation and aging for 140 minutes;

[0054] f. After aging, rinse with pure water for 3 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com