Digitally controlled multifunctional sewing machine

A sewing machine and multi-functional technology, which is applied in the direction of sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems of single processing pattern, inability to discharge materials at the same time, small processing range, etc., and achieve simplified operation process, convenient operation, The effect of improving sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

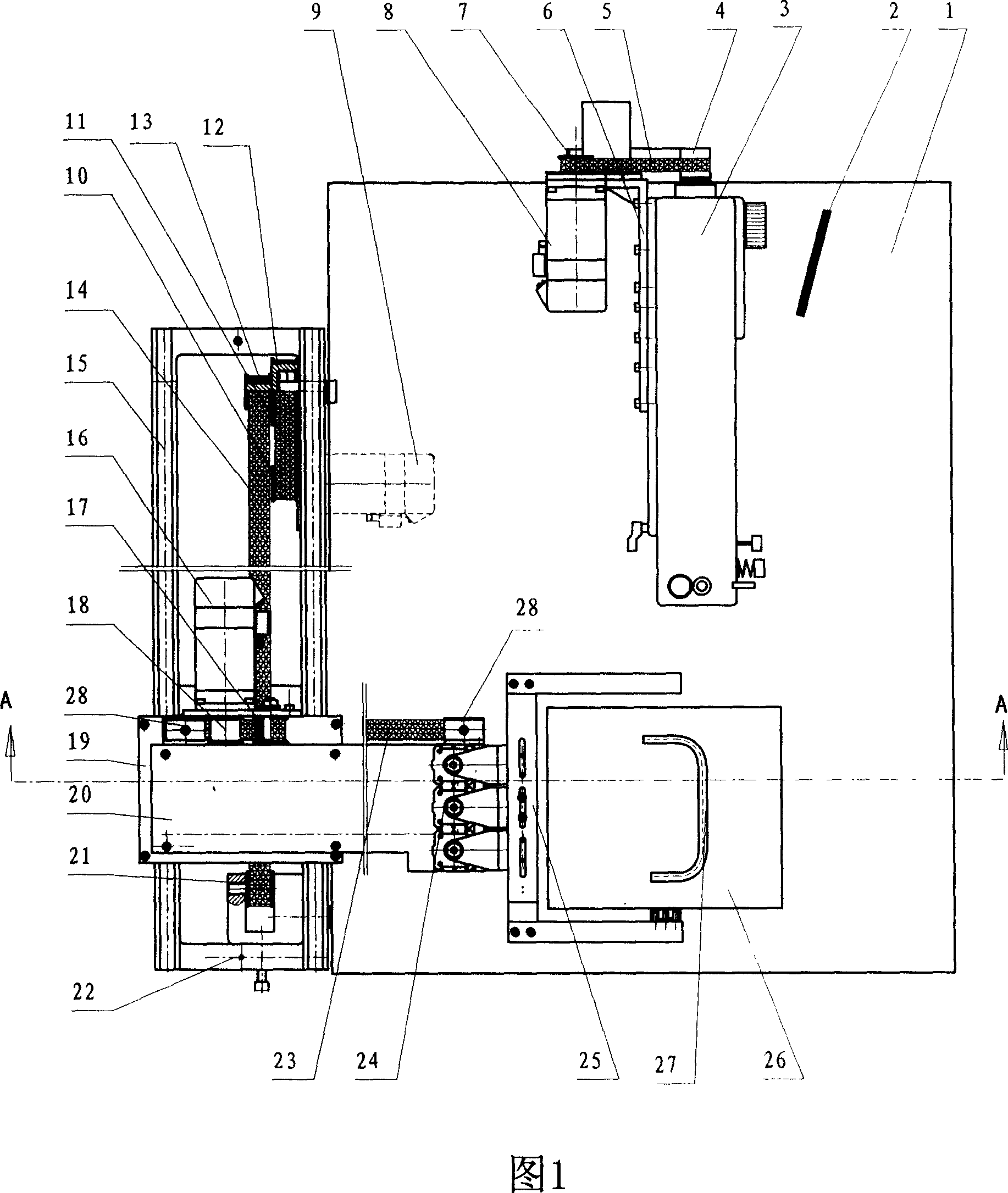

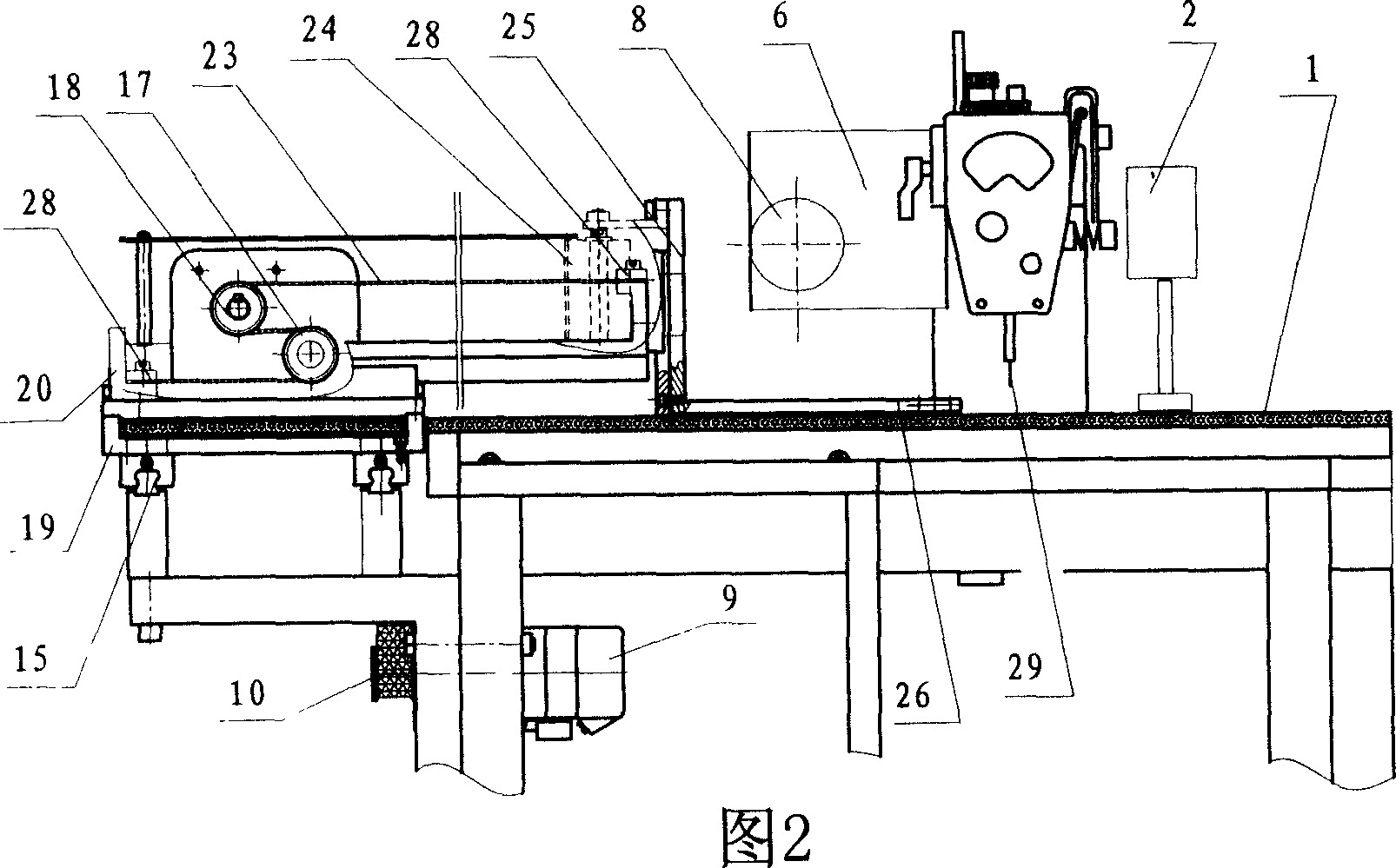

[0015] The present invention mainly includes three parts: a control system 2 placed on a working platform 1, a sewing machine body 3 with a machine body motor 8, an X-Y direction slide mechanism, and a presser foot mechanism.

[0016] The X-Y slide mechanism consists of a Y slide base 22 placed on one side of the working platform 1 with a Y support guide rail 15, a Y slide motor 9 with a Y drive mechanism placed on the Y slide base 22, and The Y-direction transmission mechanism is connected to the Y-direction slide table 19 that can move on the Y-direction support guide rail 15, and the X-direction slide table motor 16 with the X-direction transmission mechanism is placed on the Y-direction slide table 19, and the X-direction slide table motor 16 connected with the X-direction transmission mechanism is connected to the Y-direction transmission mechanism. Consists of slide table 20 and the like. Body motor 8, Y-direction slide motor 9, X-direction slide motor 16 are connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com