Bar stock pneumatic radial impact blanking method with high-efficiency and precision

A technology of precision blanking and bar material, applied in the field of low energy consumption, near net and high efficiency precision forming, can solve the problems of low material utilization rate, low production efficiency, poor cutting section quality, etc., and achieve good section quality, wide processing range, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

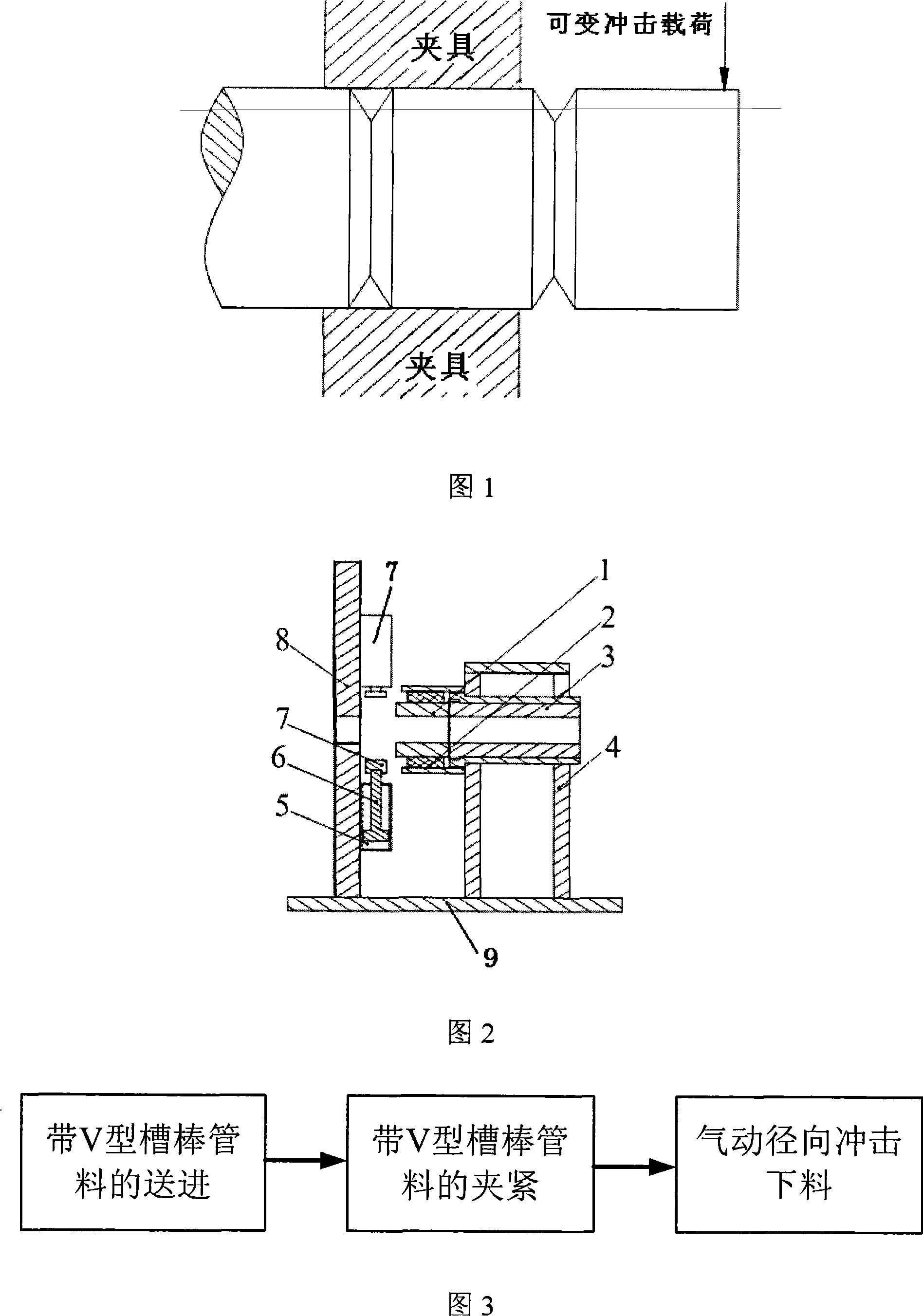

[0011] The pneumatic radial impact high-efficiency and precise blanking method of the bar material of the present invention utilizes the fatigue fracture mechanism of the bar material, and the blanking mold is driven by the cylinder to compress and load the bar material radially. The working contour curve of the blanking mold adopts a cycloid, driven by the cylinder piston, it makes a radial impact movement. The bar is fixed and still, and the 7 impact cylinders arranged evenly and the 7 blanking molds driven by it are moved in sequence, so that the load is continuously applied along the radial direction of the bar, which promotes the generation and expansion of the fatigue crack of the bar, thus Complete precision blanking. In order to realize blanking of bars with different diameters, replaceable blanking molds are used.

[0012] The blanking device of the present invention is shown in Figure 1, and this pneumatic radial impact precision blanking device comprises base 9, is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com