Light weight large-bore compound reflector

A compound mirror and large-caliber technology, applied in the field of optical mirrors, can solve the problems of uneven adhesive layer thickness, fiber printing, and difficult process, so as to reduce the mismatch of thermal expansion coefficient, ensure rigidity and strength, reduce The effect of small thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

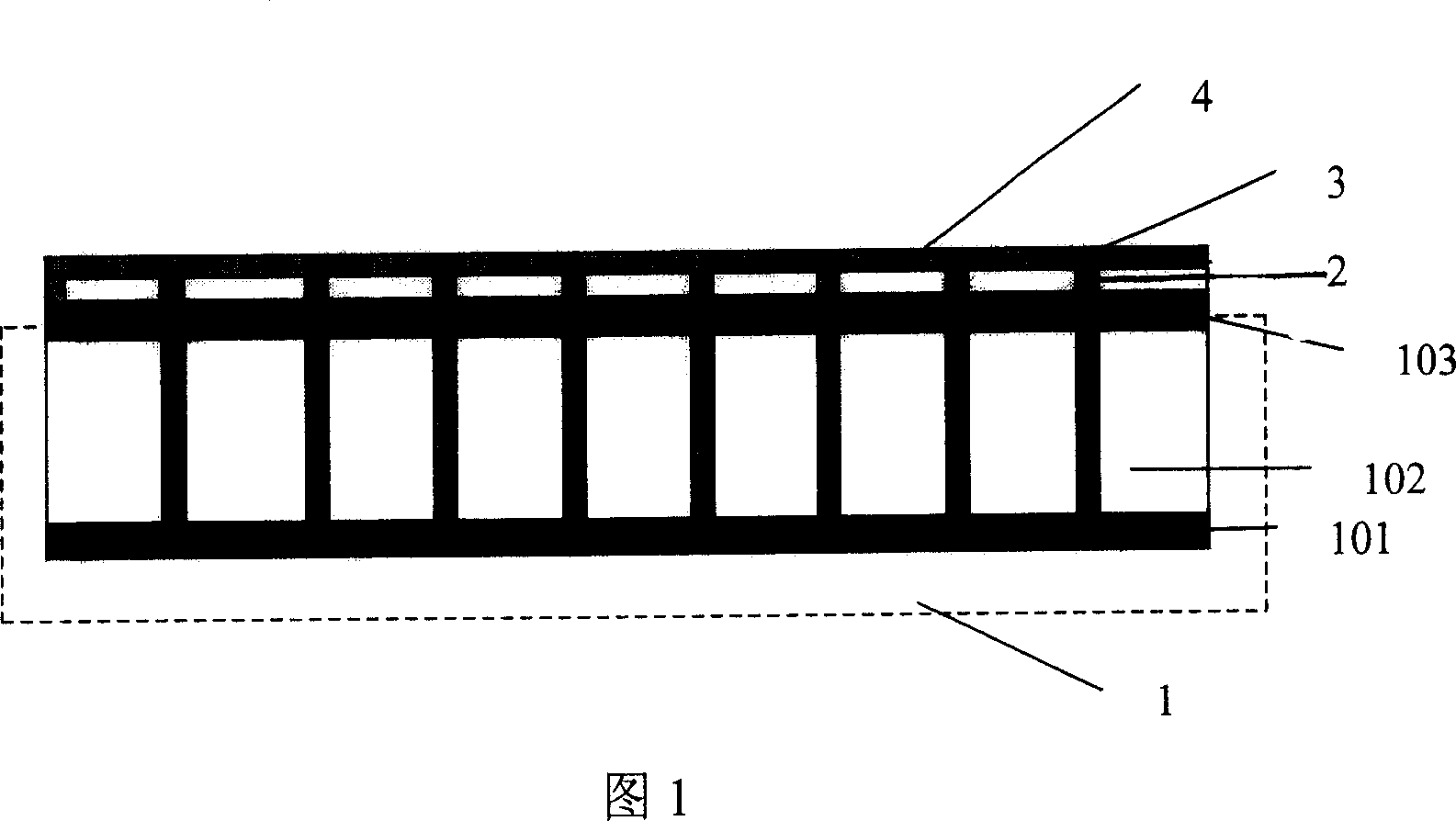

[0011] Below in conjunction with accompanying drawing, the specific embodiment of composite reflector of the present invention is described in detail:

[0012] The composite reflector of the present invention includes: a composite mirror blank made of successively stacked first panels 101, honeycomb interlayers 102, and second panels 103, wherein the first panel and the second panel are made of graphite fiber, epoxy resin or graphite Composed of fiber and cyanate ester; on the mirror blank, there are micromirror glass column arrays 2 fixed by epoxy resin and micromirror glass reflective substrates 3; Coated metal reflective layer 4.

[0013] The graphite fiber / epoxy resin or graphite fiber / cyanate panel is composed of multiple layers of graphite fiber cloth impregnated in epoxy resin or cyanate, and epoxy resin is sandwiched in the middle of the radial direction of the cloth at 45 degrees. The resin layers are cross-laid. Said honeycomb interlayer is a paper honeycomb interl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com