Device for measuring thermal elongation of ram based on material thermal elongation difference characteristics

A technology of thermal elongation and ram, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., and can solve the problems of increased equipment cost and high cost of Invar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

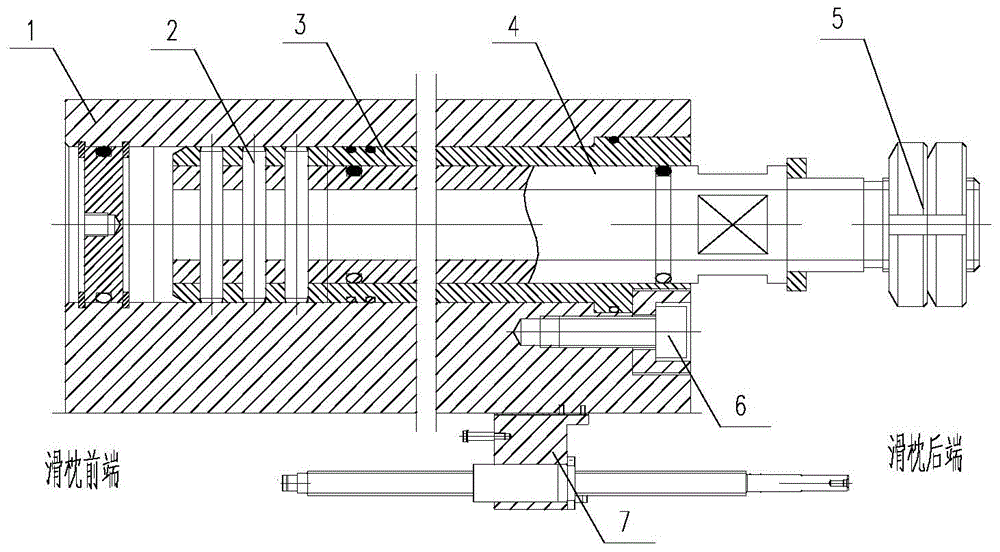

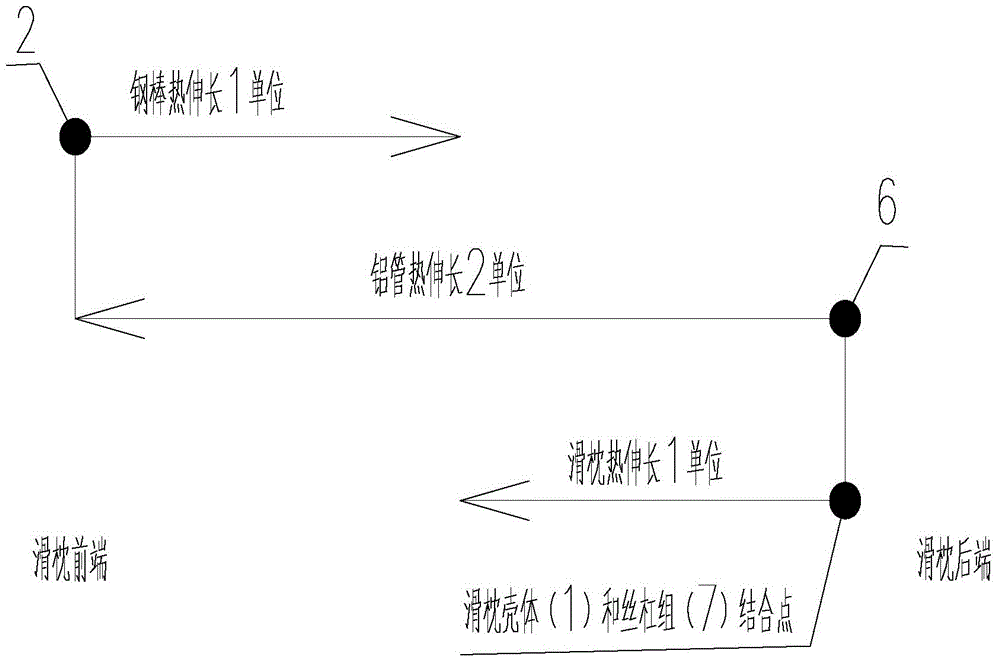

[0009] In order to monitor the thermal elongation variation of the ram, it is necessary to give the ram a relative reference object to realize the measurement of the thermal elongation variable of the ram. In order to reduce costs, the technical measure of the present invention to replace zero-degree Invar is: measure based on the thermal elongation difference characteristics of the material, the thermal expansion coefficient (1 / °C) of steel: 0.0000118 per 1 degree of temperature rise, and the thermal expansion coefficient of aluminum (1 / °C): 0.0000236 for every 1 degree of temperature rise, and the unit meter is 0.0000236, using the characteristic that the thermal expansion coefficient of aluminum is twice that of steel, the structural principle of the design see figure 2 As shown, the characteristic of metal materials is that when one end of the material is fixed, it will expand to the free end when its temperature changes. When the temperature of the steel ram shell chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com