Patents

Literature

32results about How to "Eliminate the effects of thermal deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

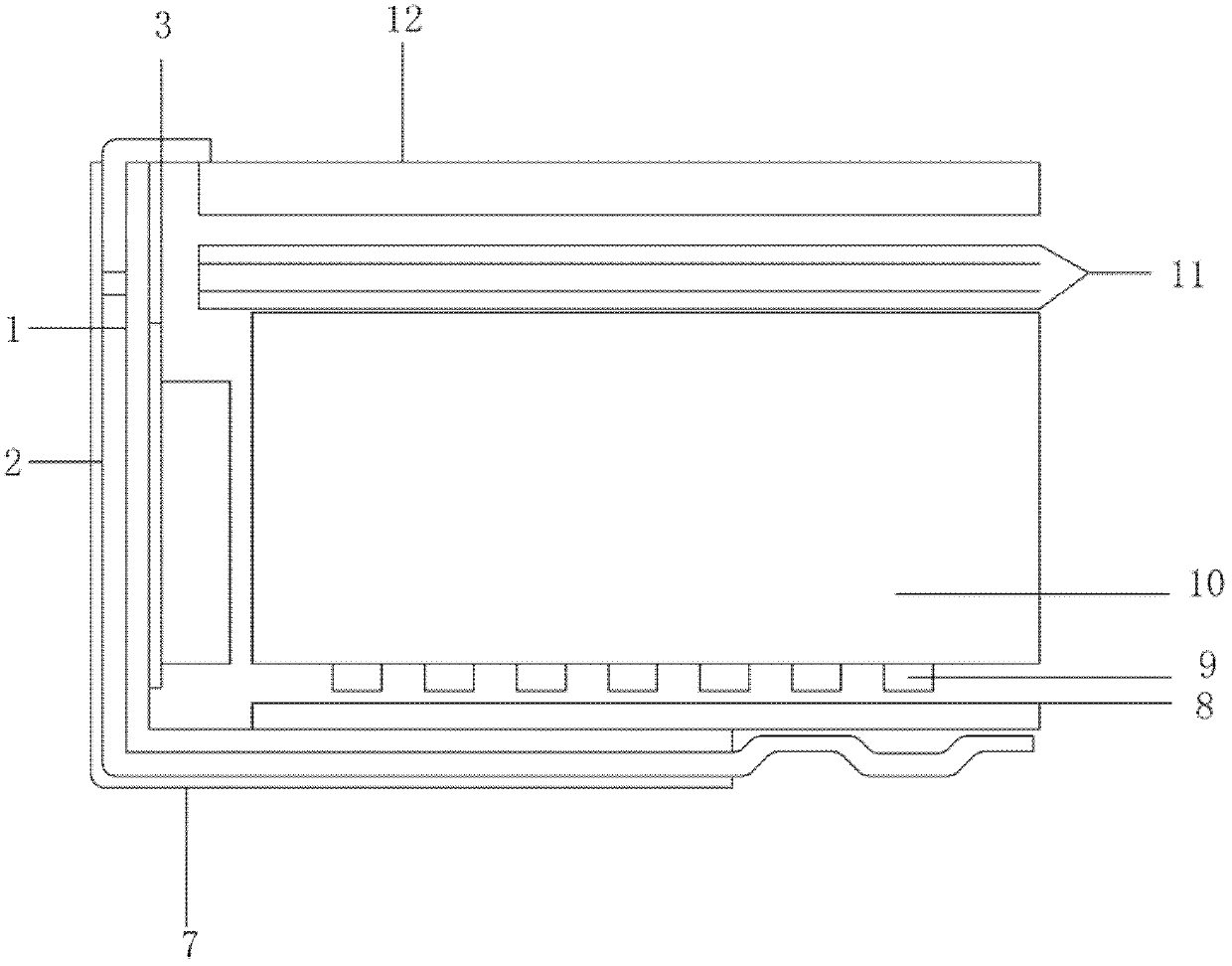

Modified acrylate heat-dissipation powder coating as well as preparation method and application thereof

ActiveCN102618141AExcellent heat transfer and cooling efficiencyReduced clusteringPoint-like light sourceLighting heating/cooling arrangementsSolventIn situ polymerization

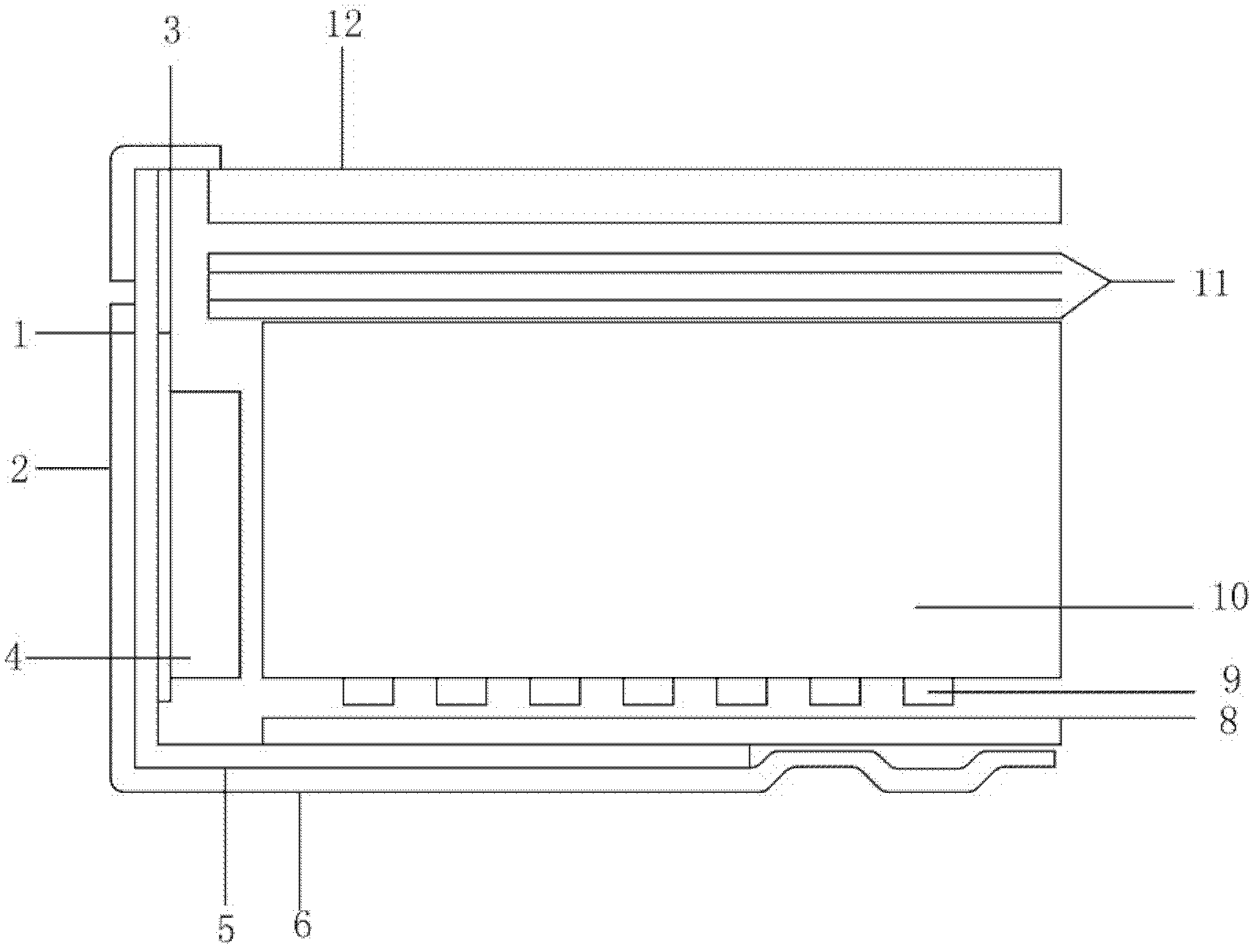

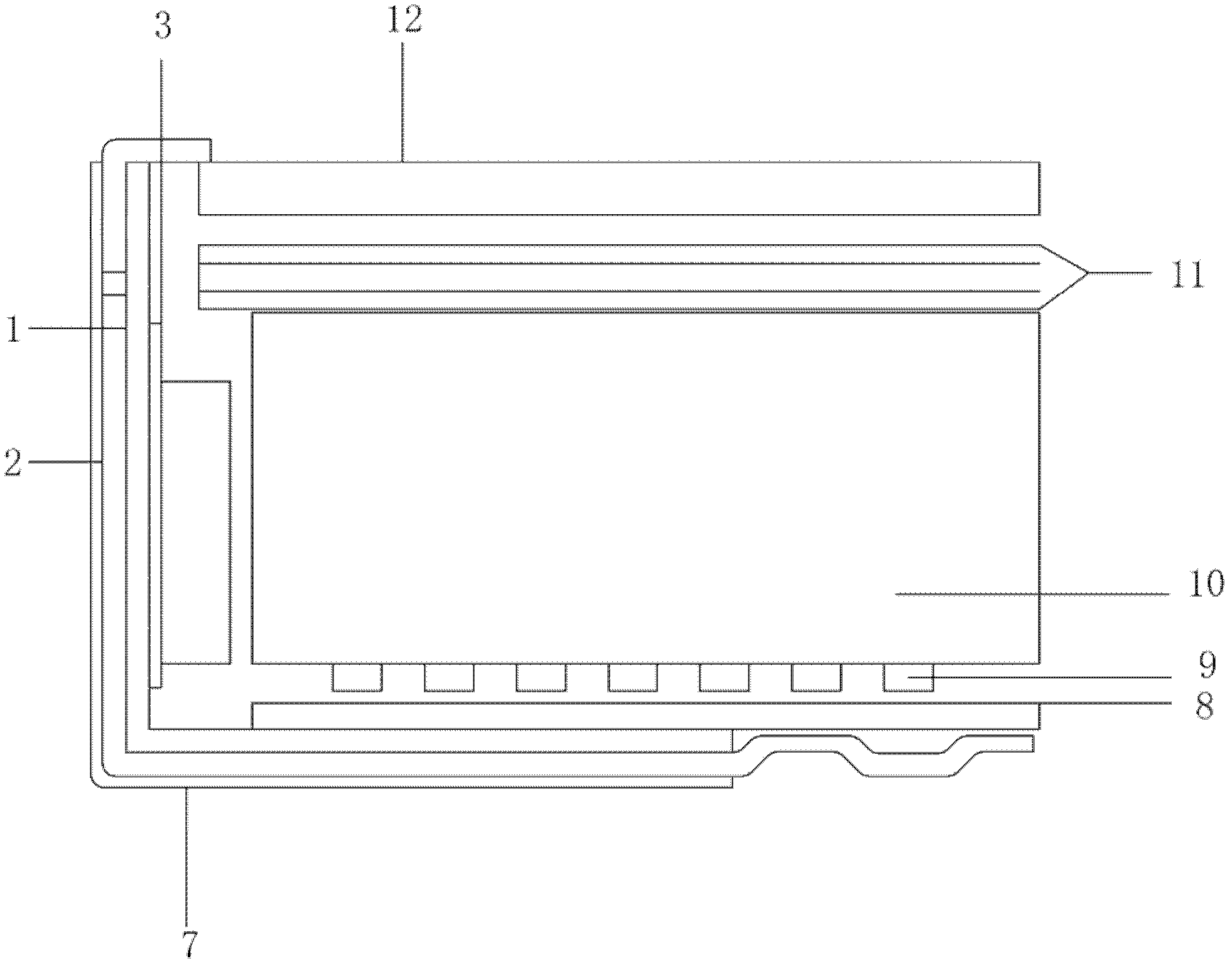

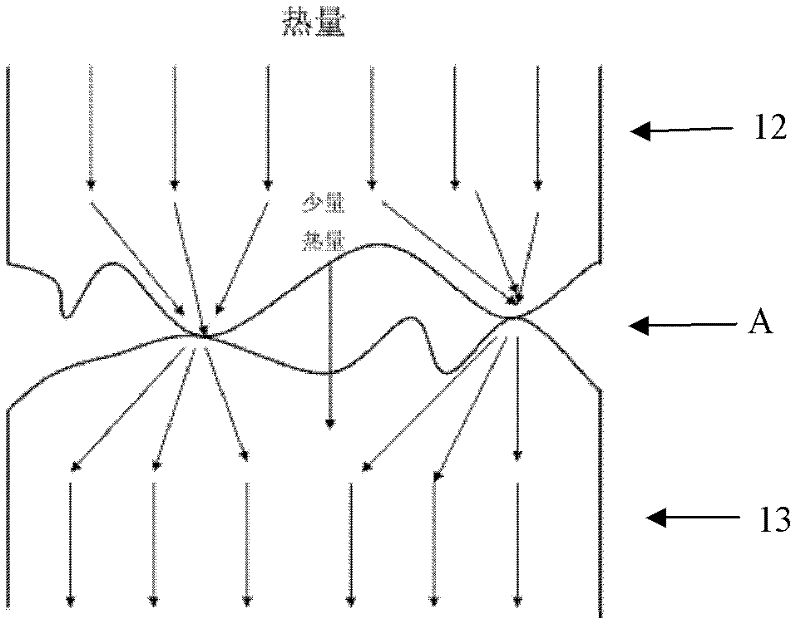

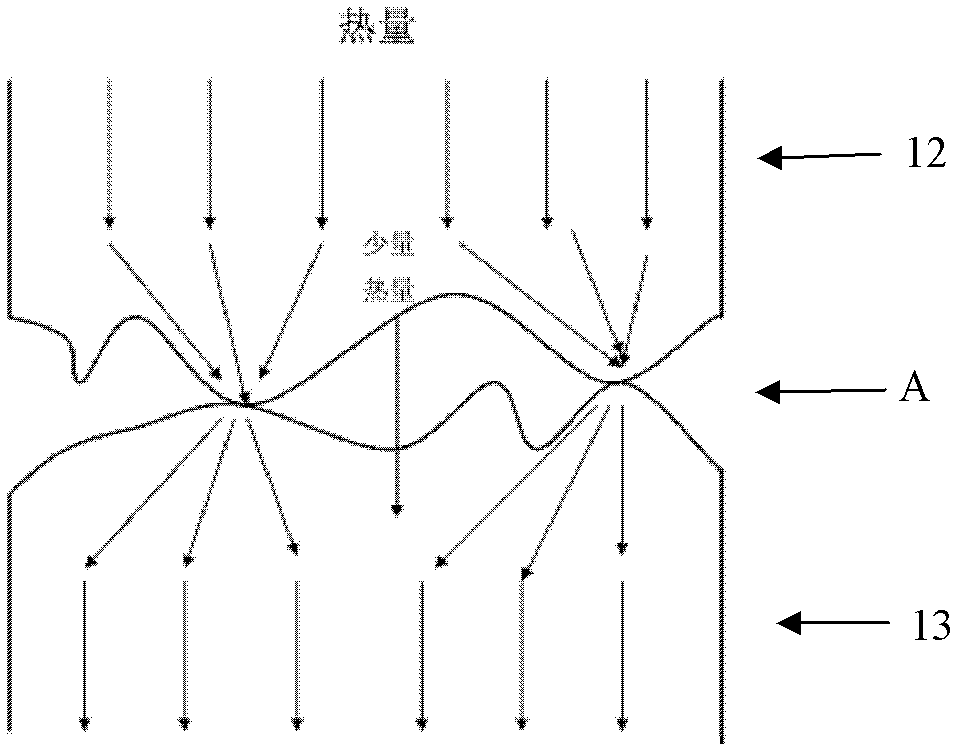

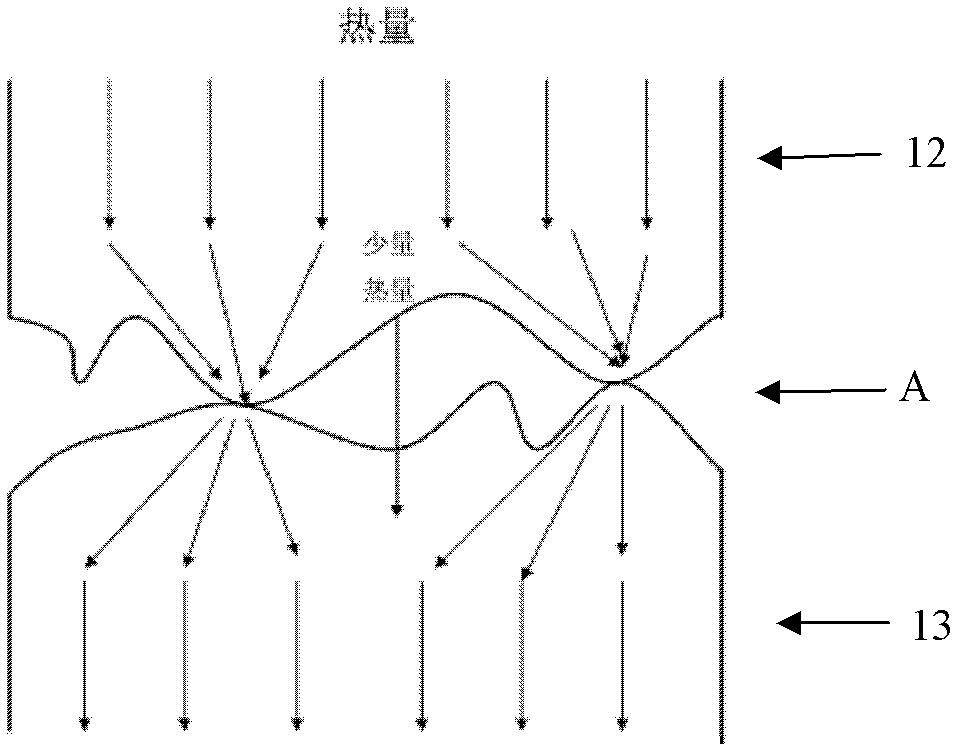

The invention provides a modified acrylate heat-dissipation powder coating material which is prepared in a way that heat-dissipation agent is dispersed in a monomer solution, subjected to in-situ polymerization and then treated through desolventizing agent, wherein the weight ratio of the heat-dissipation agent to monomer is (1-25) to (7.5-9); the heat-dissipation agent comprises 82-90 percent of carbon fiber and 10-20 percent of nanometer material; and the monomer is one or more of styrene, methacrylic acid, glycidyl ester, acrylic acid-2-ethyl hexyl ester, methyl methacrylate and methyl acrylate. According to the invention, as the heat-dissipation coating material dispersed uniformly and added with the carbon fiber and nanometer material compound heat-dissipation particles is obtained by adopting solution in-situ polymerization, the heat transmission efficiency and the heat dissipation efficiency can be increased; and the heat-dissipation coating material can be coated as a heat-dissipation coating on the surface of a back plate of an LED LCM (liquid crystal model) to dissipate part of the heat generated by LEDs in a infrared radiation manner, so that the heat dissipation performance of the LED LCM is enhanced, and the heat dissipating capacity and the heat dissipation efficiency are improved in the same heat dissipation area.

Owner:HISENSE VISUAL TECH CO LTD

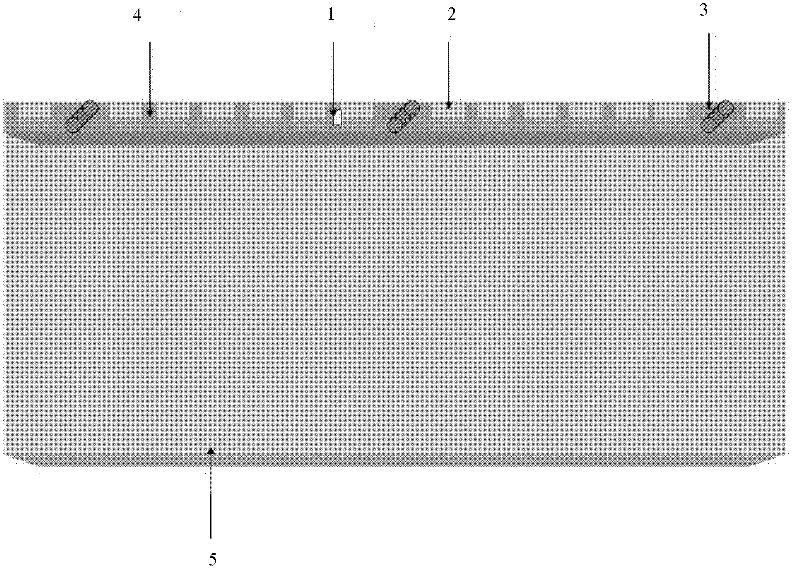

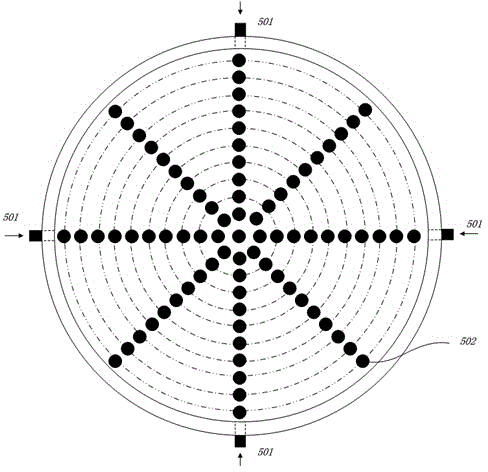

Substrate-free pressure-sensitive acrylic thermal conductive adhesive, preparation method and application thereof

InactiveCN102391799AConnectivityPlay a thermal conductivityNon-macromolecular adhesive additivesFilm/foil adhesivesFiberCarbon fibers

The invention provides a substrate-free pressure-sensitive acrylic thermal conductive adhesive. A thermal conductive agent is dispersed in a monomer solution, and the thermal conductive adhesive is formed by curing and cross-linking after in situ polymerization; the consumption ratio of the thermal conductive agent to the monomer is (1-4): (6-9); the thermal conductive agent consists of 75 to 90 percent of carbon fibers and 10 to 25 percent of carbon nano tubes; and the monomer is acrylic acid and / or acrylate. Because the thermal conductive agent of specific components is uniformly dispersed in the acrylic polymerization monomer to form a stable three-dimensional netlike thermal conductive structure, so that the thermal conductive adhesive is good in thermal conductive performance and good in environment friendliness. The thermal conductive adhesive can be applied between a light emitting diode (LED) light bar and an aluminum alloy profile, between the aluminum alloy profile and a back plate, between the LED light bar and the back plate or between a chip and a radiator, is used as a double-sided adhesive tape, and is used under the condition of a big gap between two contact faces of liquid crystal modules.

Owner:HISENSE VISUAL TECH CO LTD

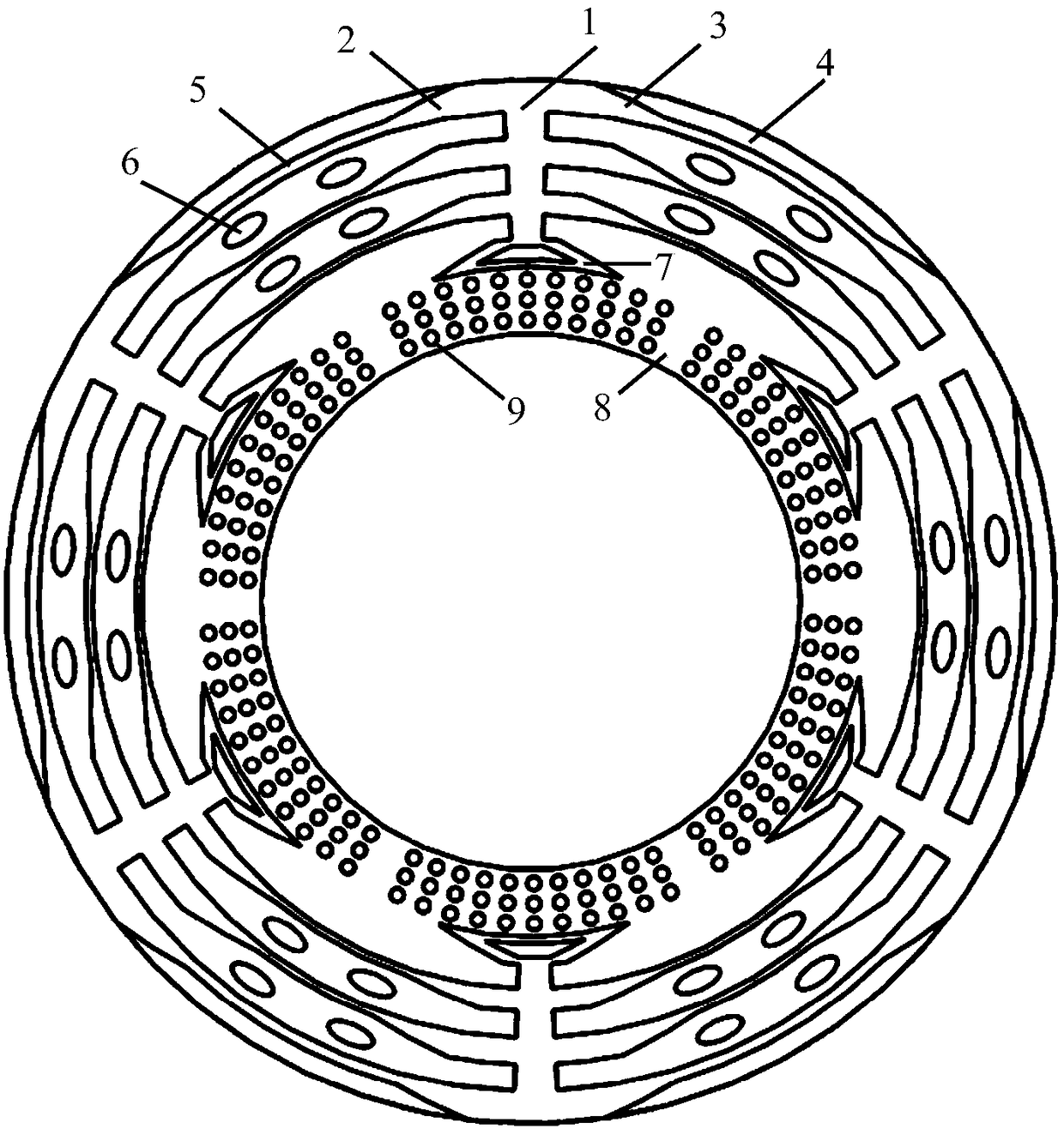

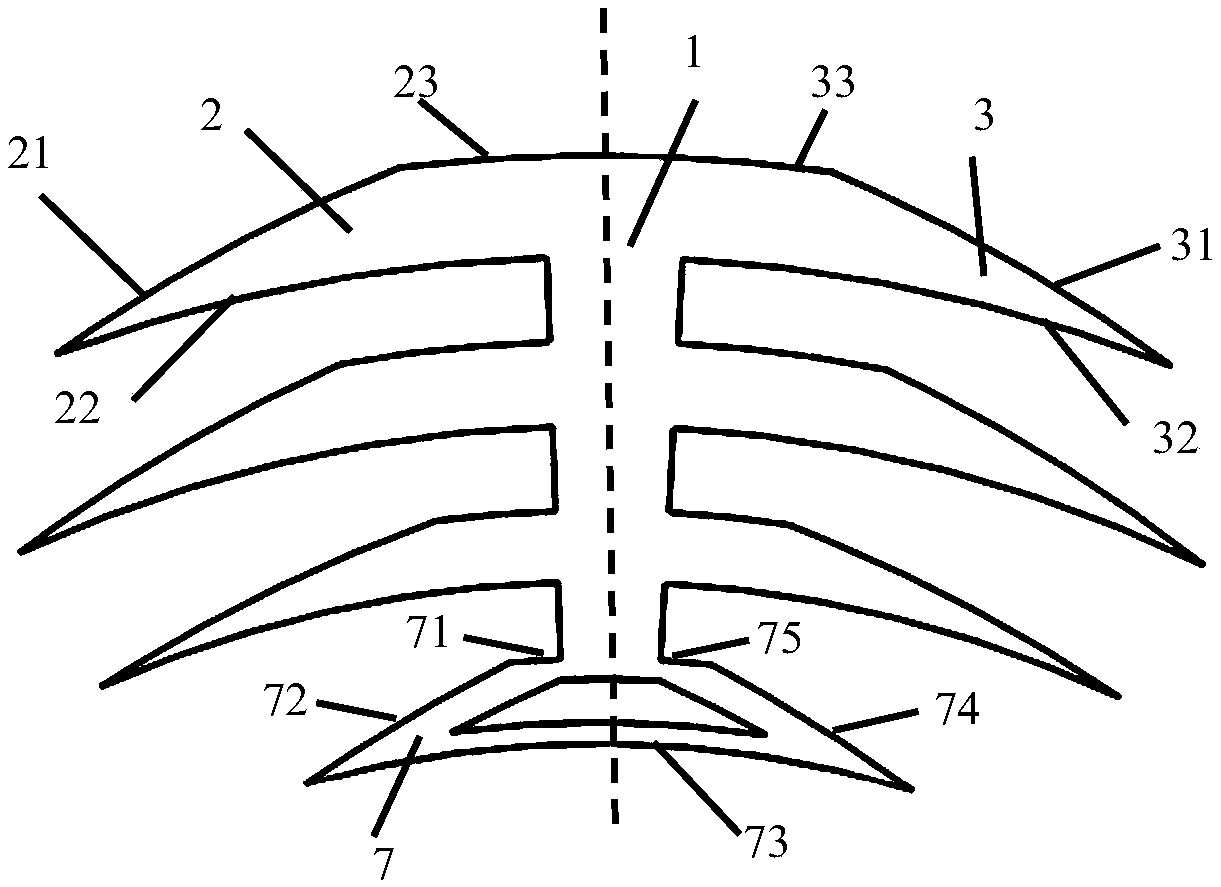

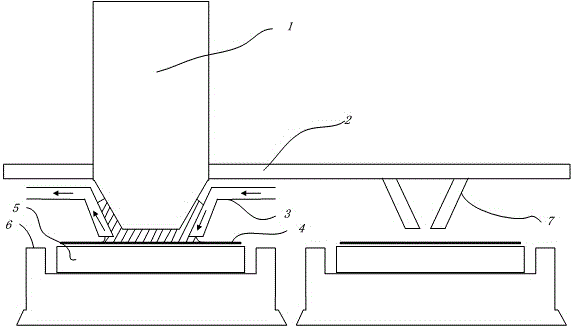

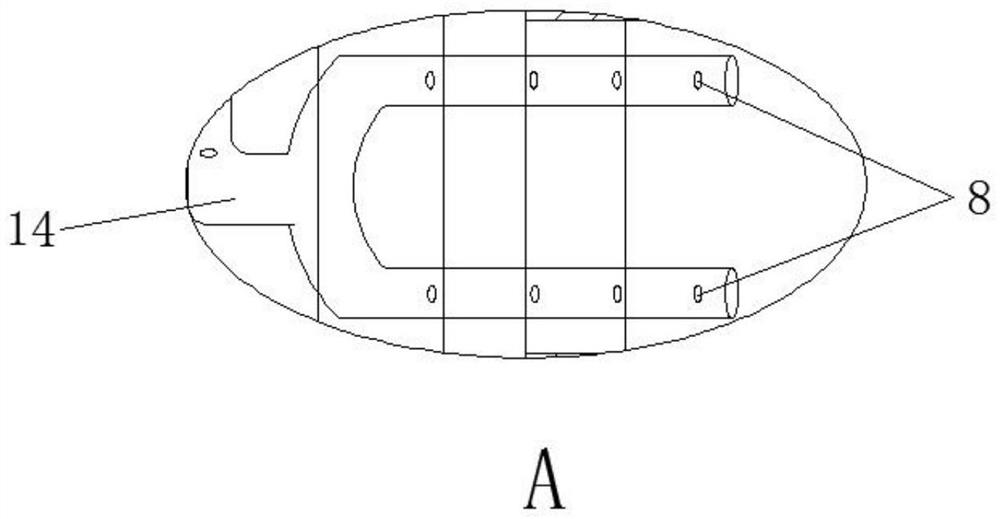

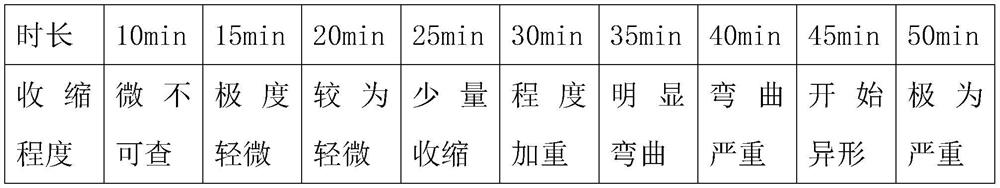

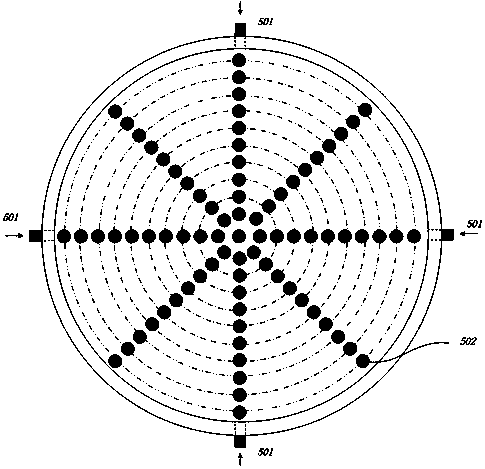

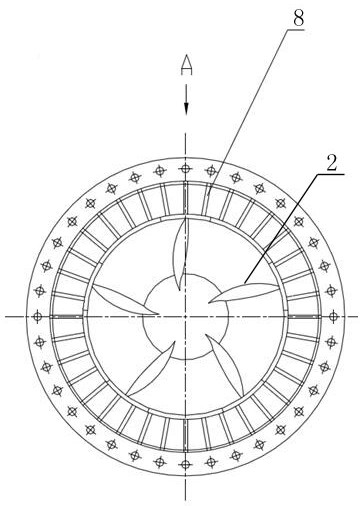

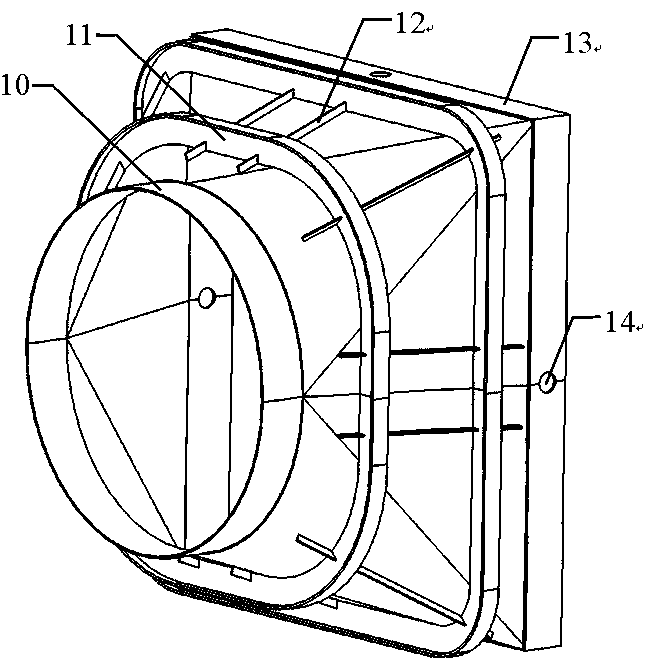

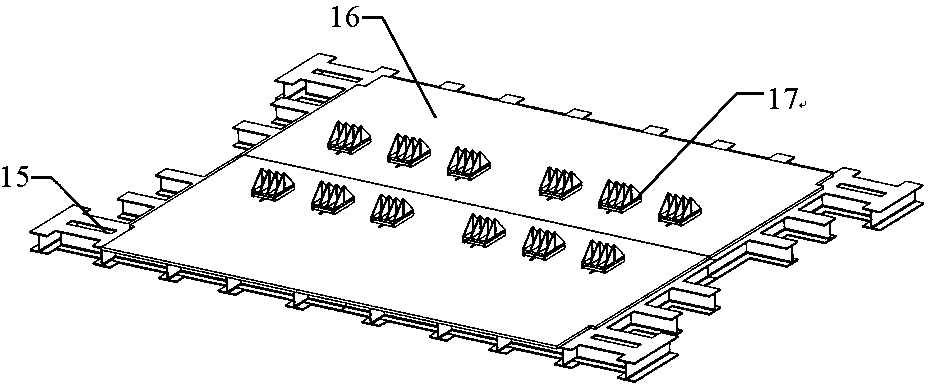

Fishbone simulation type dry gas seal structure

ActiveCN108506494AEnhance the dynamic pressure effectImprove lubrication statusEngine sealsDry gas sealHigh pressure

The invention discloses a fishbone simulation type dry gas seal structure. The fishbone simulation type dry gas seal structure comprises a moving ring and a static ring, wherein a seal inlet is formedin the outer diameter side, namely the high-pressure side, of the moving ring, a seal inlet is formed in the outer diameter side, namely the high-pressure side, of the static ring, a seal outlet is formed in the inner diameter side, namely the low-pressure side, of the moving ring, and a seal outlet is formed in the inner diameter side, namely the low-pressure side, of the static ring. A plurality of fishbone simulation type grooves are evenly distributed on the high-pressure side of at least one end face of the moving ring in the circumferential direction, and a plurality of fishbone simulation type grooves are evenly distributed on the high-pressure side of at least one end face of the static ring in the circumferential direction. A non-hole area between every two adjacent fishbone simulation type grooves in the circumferential direction is a sealing weir 4. Annular sealing dams 8 are arranged below the fishbone simulation type grooves. The fishbone simulation type dry gas seal structure has the remarkable advantages of being high in opening capacity, high in stability, low in leakage quantity, less in sealing end face deformation and capable of carrying out two-way rotation, and the like, and thereby having broad market prospect.

Owner:XI AN JIAOTONG UNIV

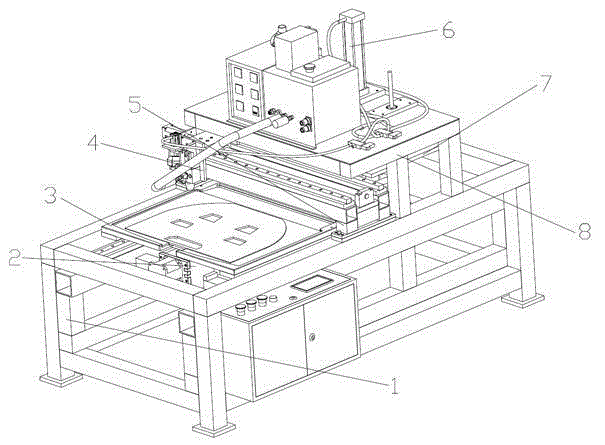

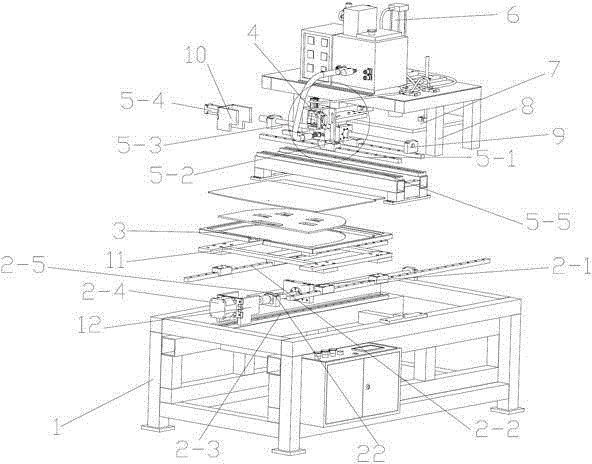

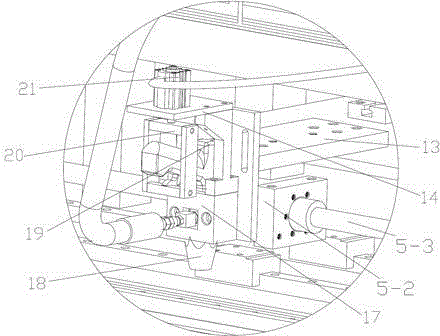

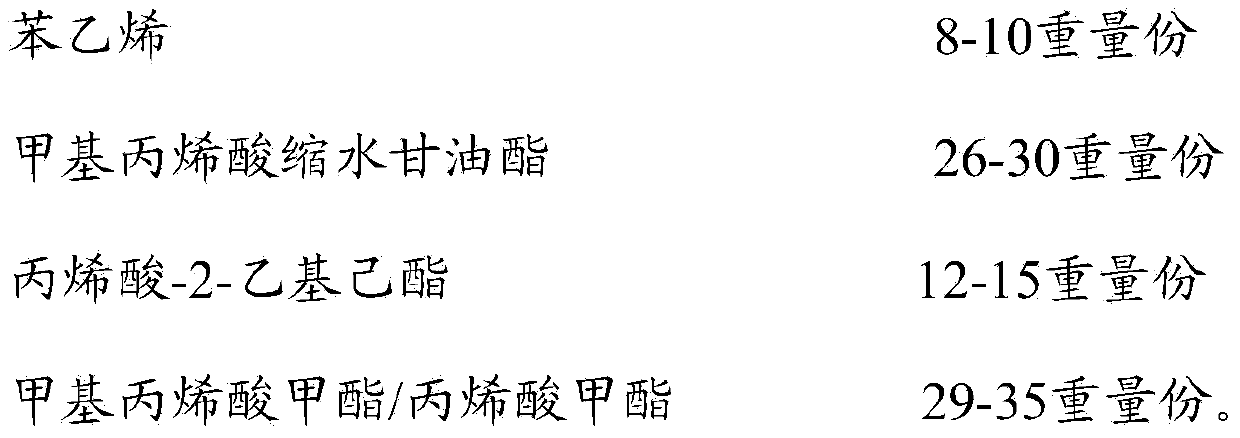

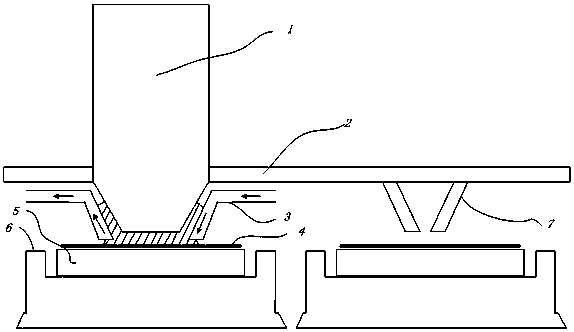

Automatic glue spraying and compounding all-in-one machine and manufacturing method for automobile trunk carpet production

ActiveCN104527203AConform to designFit for useLaminationLamination apparatusEngineeringVertical displacement

The invention discloses an automatic glue spraying and compounding all-in-one machine and a manufacturing method for automobile trunk carpet production. A template of the automatic glue spraying and compounding all-in-one machine is moved by a horizontal sliding mechanism so that the purpose of horizontal displacement glue spraying of a polypropylene cellular board on the template can be achieved through a glue spraying device. The glue spraying device is moved by a vertical sliding mechanism so that the purpose of vertical displacement glue spraying of the polypropylene cellular board on the template can be achieved through the glue spraying device. Meanwhile, the glue sprayed polypropylene cellular board on the template is glued to a sound insulation felt. The glued sound insulation felt and the polypropylene cellular board on the template are quickly transferred to the position below a pressing plate by the horizontal sliding mechanism. The pressing plate is automatically activated and quickly pushed by a power unit so that further pressing, compounding and molding can be carried out on the glued sound insulation felt and the polypropylene cellular board. According to the automatic glue spraying and compounding all-in-one machine and the manufacturing method for the automobile trunk carpet production, the compounding fastness and the production efficiency of an automobile trunk carpet are improved, and the compounded and molded automobile trunk carpet is good in operation performance.

Owner:NINGBO SUNLIGHT MOTOR PARTS

Modified acrylate heat-dissipation powder coating as well as preparation method and application thereof

ActiveCN102618141BImprove heat transfer efficiencyImprove cooling efficiencyPoint-like light sourceLighting heating/cooling arrangementsFiberGlycidyl methacrylate

The invention provides a modified acrylate heat-dissipation powder coating material which is prepared in a way that heat-dissipation agent is dispersed in a monomer solution, subjected to in-situ polymerization and then treated through desolventizing agent, wherein the weight ratio of the heat-dissipation agent to monomer is (1-25) to (7.5-9); the heat-dissipation agent comprises 82-90 percent of carbon fiber and 10-20 percent of nanometer material; and the monomer is one or more of styrene, methacrylic acid, glycidyl ester, acrylic acid-2-ethyl hexyl ester, methyl methacrylate and methyl acrylate. According to the invention, as the heat-dissipation coating material dispersed uniformly and added with the carbon fiber and nanometer material compound heat-dissipation particles is obtained by adopting solution in-situ polymerization, the heat transmission efficiency and the heat dissipation efficiency can be increased; and the heat-dissipation coating material can be coated as a heat-dissipation coating on the surface of a back plate of an LED LCM (liquid crystal model) to dissipate part of the heat generated by LEDs in a infrared radiation manner, so that the heat dissipation performance of the LED LCM is enhanced, and the heat dissipating capacity and the heat dissipation efficiency are improved in the same heat dissipation area.

Owner:HISENSE VISUAL TECH CO LTD

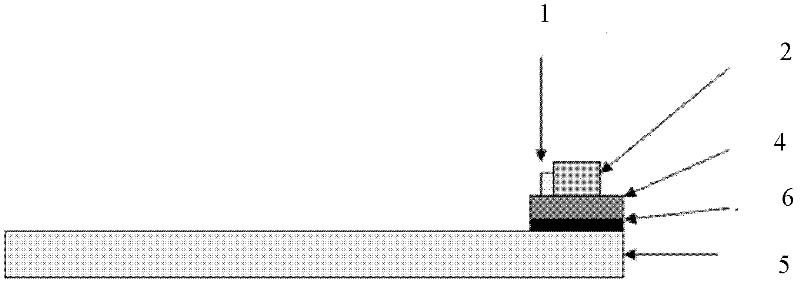

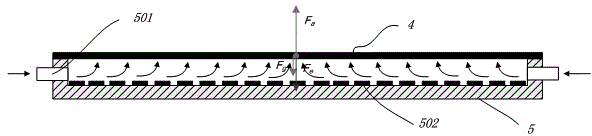

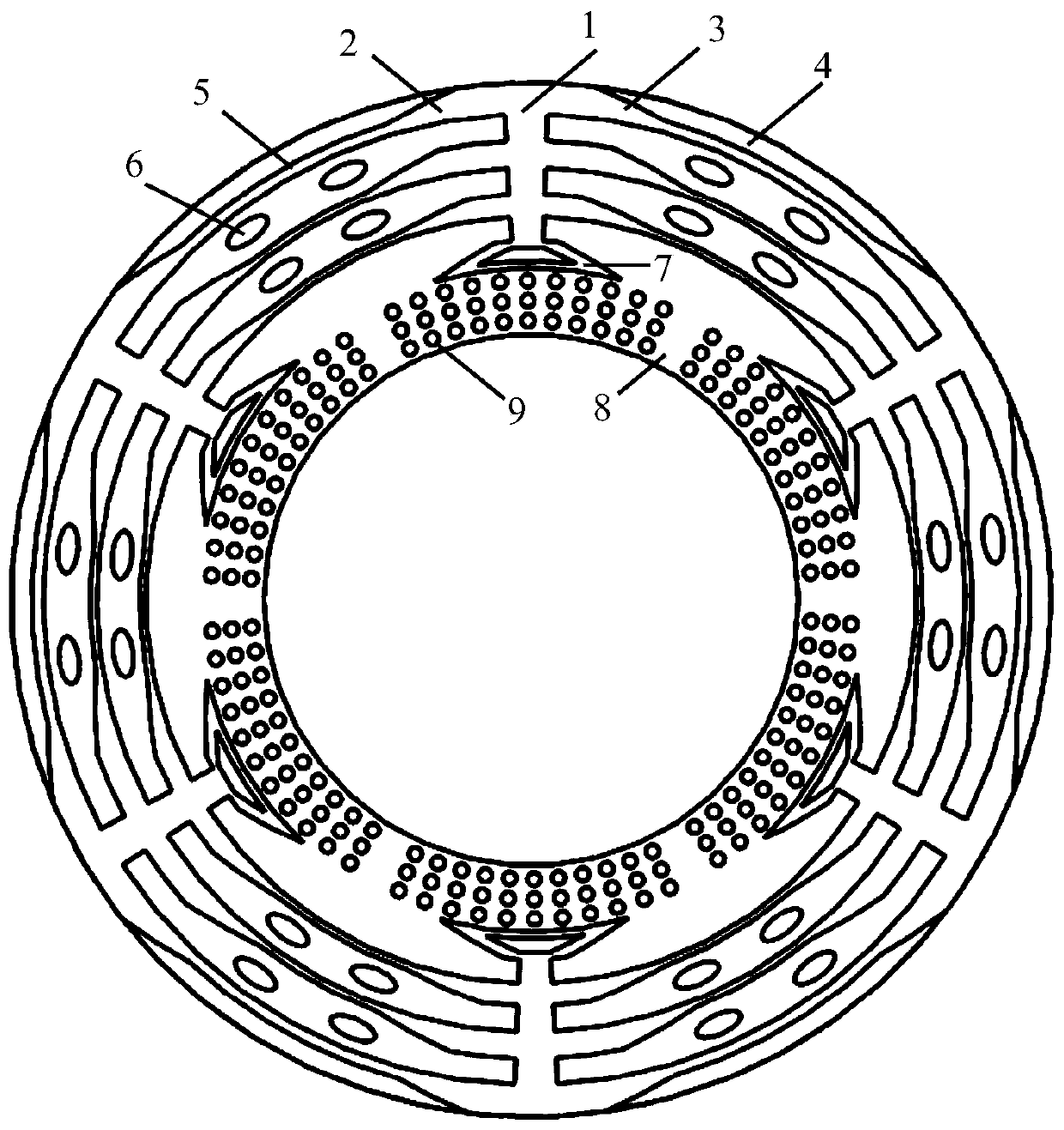

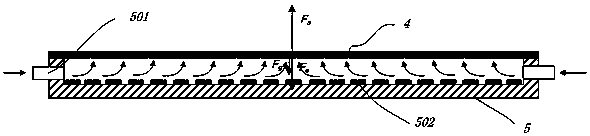

Non-contact silicon chip deformation compensation apparatus and method based on electrostatic effect

ActiveCN105717749AAvoid exposure to contaminationReal-time correction of the effects of thermal deformationPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringSilicon chip

The invention discloses a non-contact silicon chip deformation compensation apparatus, comprising a forward air floatation unit and an electrostatic adsorption unit, wherein the forward air floatation unit comprises a shell and a groove, a stationary electrode array is arranged at the bottom of the inner side of the groove, and the forward air floatation unit further comprises a plurality of air inlets formed in the shell an used for guiding in compressed air.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Automatic glue spraying and compounding machine for automobile trunk carpet production and production method

ActiveCN104527203BReduce meltingReduce the temperatureLaminationLamination apparatusEngineeringVertical displacement

The invention discloses an automatic glue spraying and compounding all-in-one machine and a manufacturing method for automobile trunk carpet production. A template of the automatic glue spraying and compounding all-in-one machine is moved by a horizontal sliding mechanism so that the purpose of horizontal displacement glue spraying of a polypropylene cellular board on the template can be achieved through a glue spraying device. The glue spraying device is moved by a vertical sliding mechanism so that the purpose of vertical displacement glue spraying of the polypropylene cellular board on the template can be achieved through the glue spraying device. Meanwhile, the glue sprayed polypropylene cellular board on the template is glued to a sound insulation felt. The glued sound insulation felt and the polypropylene cellular board on the template are quickly transferred to the position below a pressing plate by the horizontal sliding mechanism. The pressing plate is automatically activated and quickly pushed by a power unit so that further pressing, compounding and molding can be carried out on the glued sound insulation felt and the polypropylene cellular board. According to the automatic glue spraying and compounding all-in-one machine and the manufacturing method for the automobile trunk carpet production, the compounding fastness and the production efficiency of an automobile trunk carpet are improved, and the compounded and molded automobile trunk carpet is good in operation performance.

Owner:NINGBO SUNLIGHT MOTOR PARTS

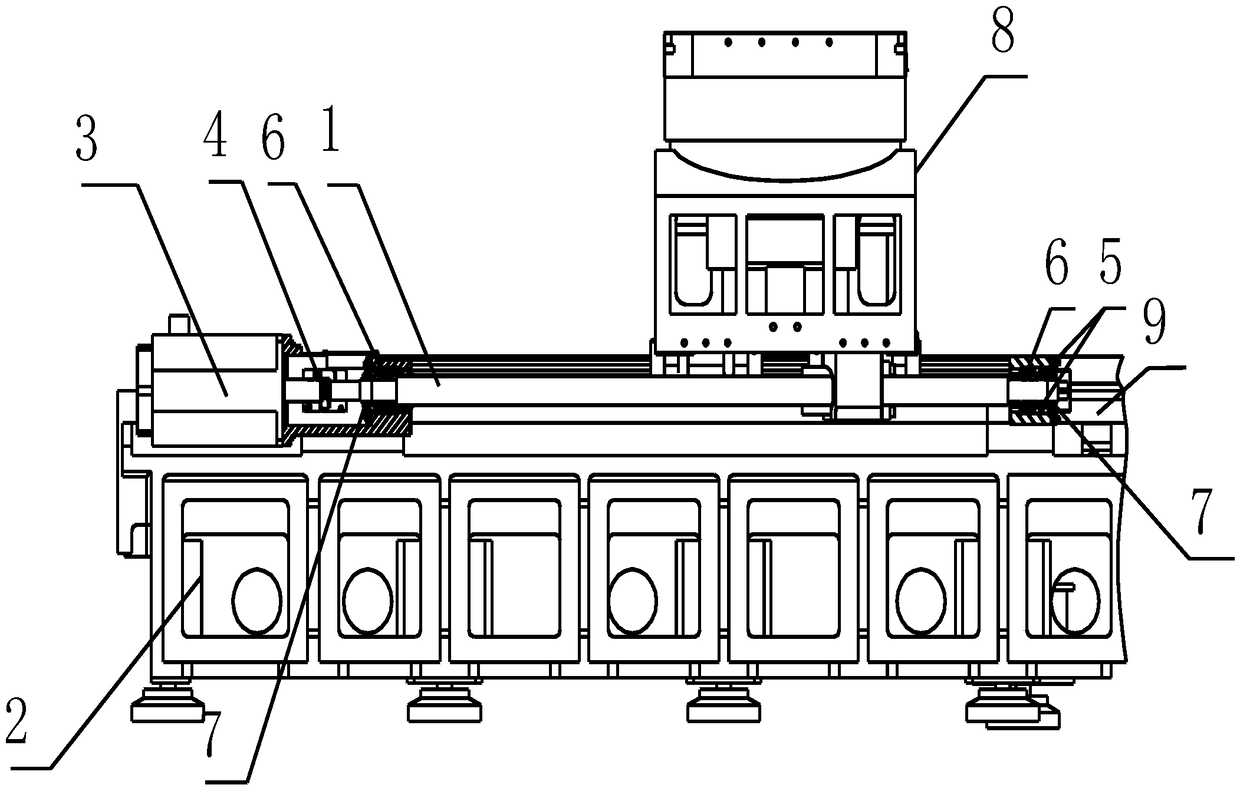

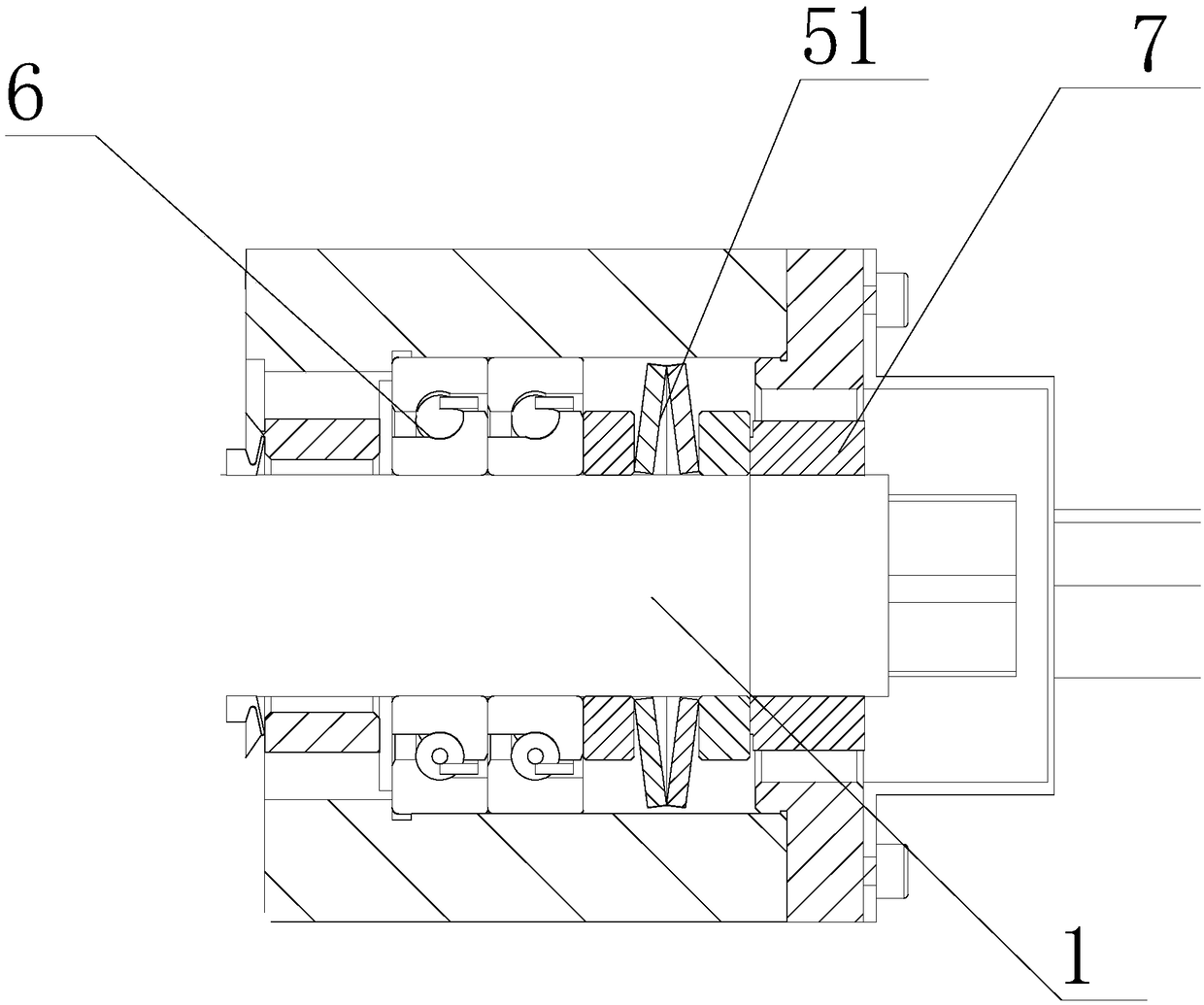

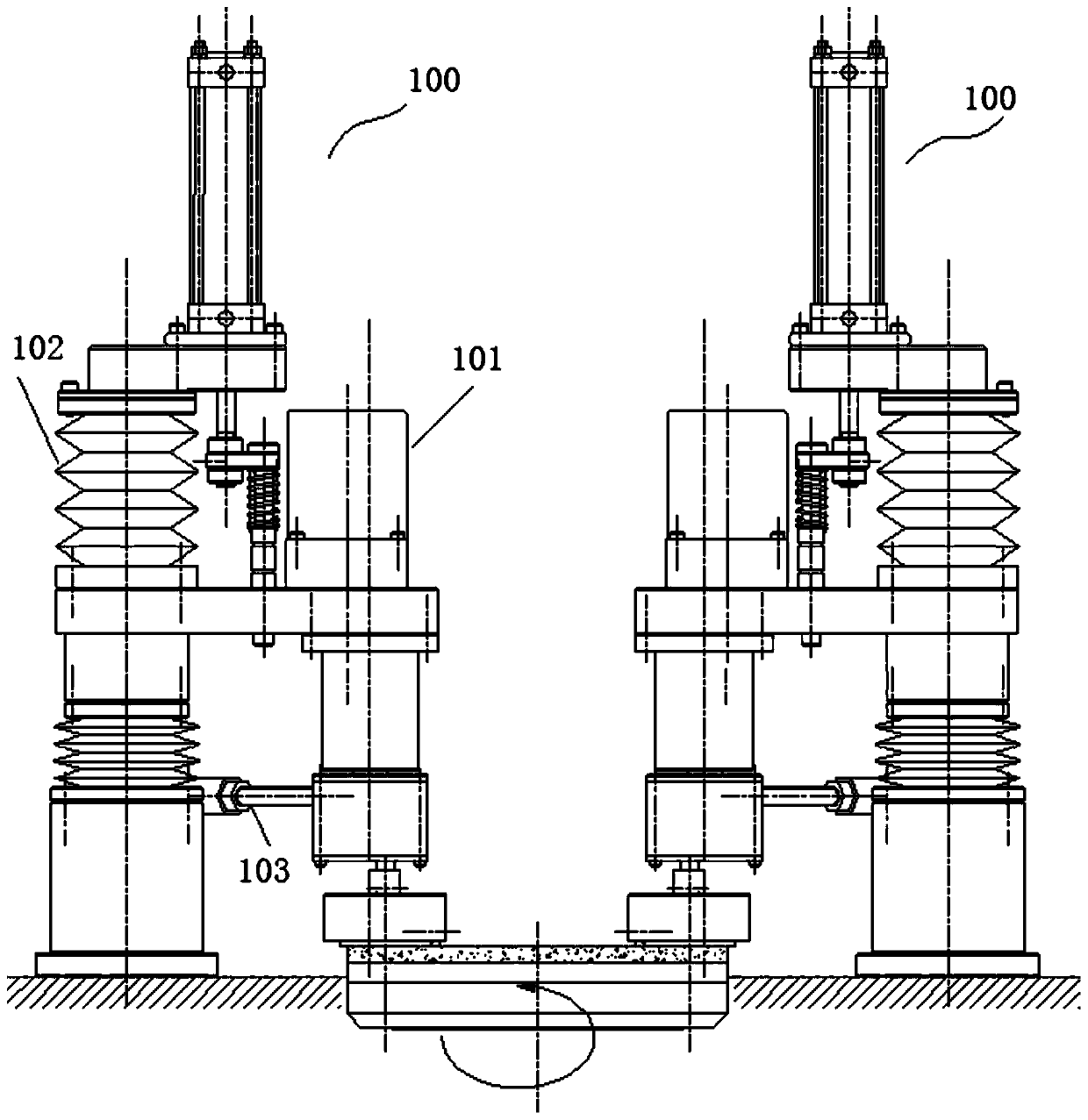

Pre-stretching lead screw

PendingCN109458438AGuaranteed transmission accuracyIncrease stiffnessGearingThermal deformationPre stretching

The invention discloses a pre-stretching lead screw. The lead screw is installed on a fixing bracket; one end of the fixing bracket is provided with a driving device; a shaft coupler is arranged between the driving device and the lead screw; the shaft coupler is used for connecting the driving device with the lead screw; the driving device is used for driving the lead screw to rotate through the shaft coupler; the other end of the lead screw is provided with a pre-stretching device; the pre-stretching device is pre-tightened and fixed to one side of the lead screw; and the pre-stretching device is used for providing pre-stretching force for the lead screw. One end of the pre-stretching lead screw disclosed by the invention is provided with the pre-stretching device for balancing the elongation, generated by the generation of heat by friction, of the lead screw; the pre-stretching device is pre-tightened and fixed for providing pre-stretching force for the lead screw; after the lead screw is thermally elongated, the pre-stretching force is reduced without generating stroke errors of the lead screw, and thus the transmission precision of the lead screw is guaranteed. Compared with the lead screw in the prior art, the lead screw, which is additionally provided with the pre-stretching device, disclosed by the invention can eliminate thermal deformation influences generated in quickmovement, and thus the rigidity, the precision and the reliability of the lead screw can be improved.

Owner:NANTONG MACHINE TOOLS GROUP +1

Direct-driven swing head air cooling system

PendingCN113732813AIncrease heat transfer range and heat transfer areaRapid coolingMeasurement/indication equipmentsMaintainance and safety accessoriesPhysicsAir cooling system

The invention discloses a direct-drive swing head air cooling system, and relates to the technical field of direct-drive swing head cooling. The direct-drive swing head air cooling system comprises a C shaft, an A shaft, an electric spindle, a spindle box, an A shaft shell, an air conditioner and cooling pipelines, the electric spindle is installed in the spindle box, the A shaft is installed in the A shaft shell, the C shaft and the A shaft are both of a hollow structure, one ends of the cooling pipelines are connected with the air conditioner, the other ends of the cooling pipelines penetrate through the interior of the C shaft and extends into the A shaft from the interior of the A shaft shell, and air holes are formed in the portions, located in the C shaft, the A shaft and the spindle box, of the cooling pipelines. The cooling pipelines are arranged in the C shaft, the A shaft and the A shaft shell, and the air holes are formed in the cooling pipelines, so that parts in the C shaft, the A shaft and the A shaft shell can be rapidly cooled, the heat exchange range and the heat exchange area can be enlarged through arrangement of a first branch pipe and a second branch pipe, rapid cooling is facilitated, the heat dissipation efficiency is improved, and the thermal deformation influence is reduced.

Owner:宁波天控五轴数控技术有限公司

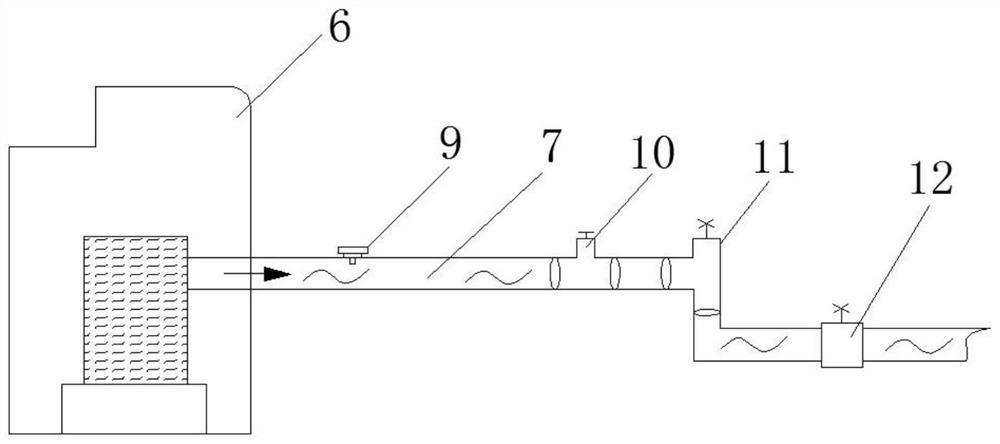

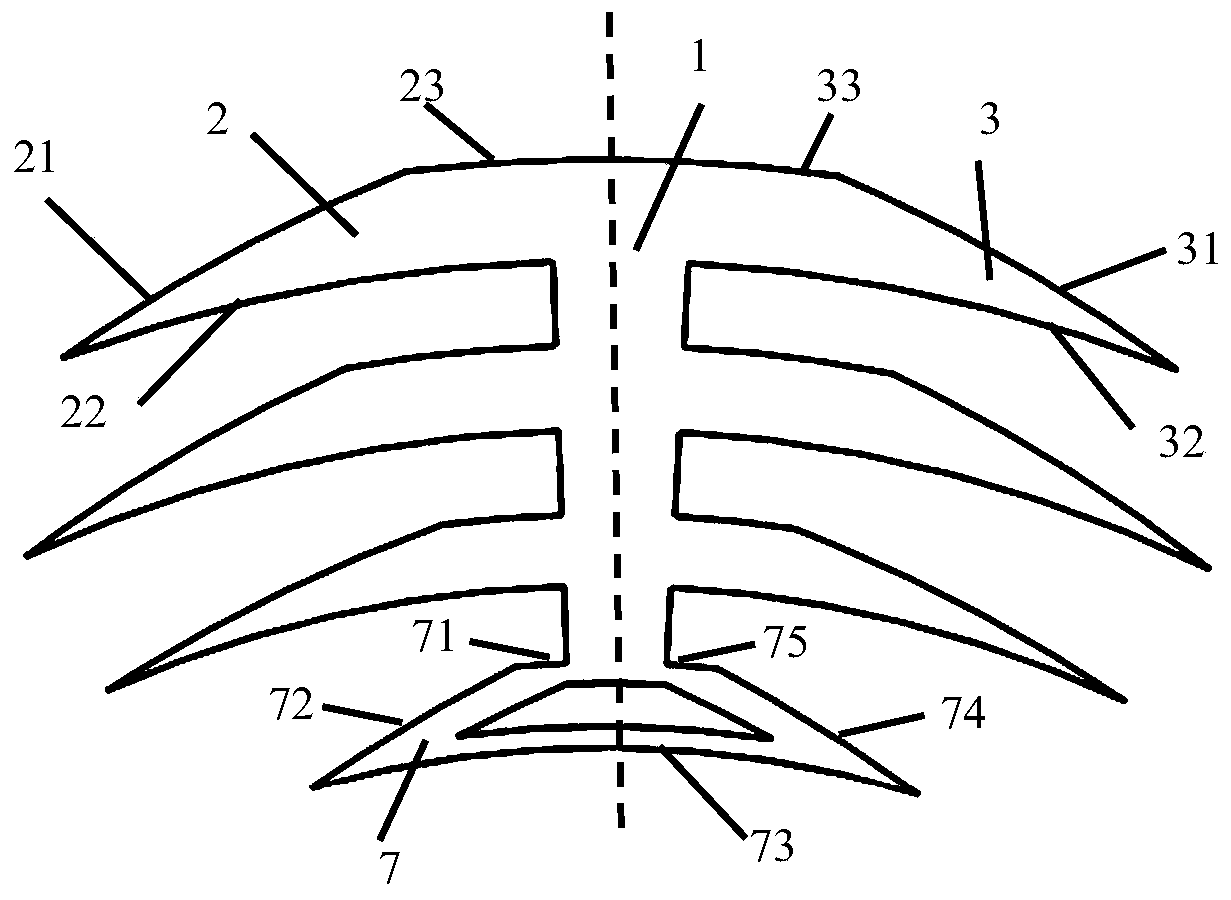

Method for testing thermal shrinkage performance of silane crosslinked polyethylene cable material

PendingCN113267526AGuarantee stabilityFine and rigorous testing processMaterial thermal coefficient of expansionPreparing sample for investigationCross-linked polyethylenePolymer chemistry

The invention discloses a method for testing thermal shrinkage performance of a silane crosslinked polyethylene cable material, and particularly relates to the technical field of cable production. Fixed-length cutting is performed on the silane crosslinked polyethylene cable material, so that the influence of specification difference of silane crosslinked polyethylene cable material samples on a test result is reduced, the sample is firstly soaked with clear water, so that the sample adapts to the soaking condition, meanwhile, the influence of the thermal deformation condition during direct heating is reduced, the influence on the silane crosslinked polyethylene cable material due to long-time contact with water is effectively reduced by soaking the sample in a resin solution and pouring a trace of higher fatty acid and a metal oxide reagent into the solution, the stability of the testing process is greatly guaranteed, the whole thermal shrinkage testing process is fine and rigorous enough by performing thermal shrinkage testing on a single sample for multiple times in different time periods and performing centralized comprehensive testing on multiple samples, and the reliability of a testing result is greatly guaranteed.

Owner:今化科技(武汉)有限公司

A fishbone-like dry gas seal structure

ActiveCN108506494BStrong opening abilityUniform end face pressure distributionEngine sealsDry gas sealEngineering

The invention discloses a fishbone simulation type dry gas seal structure. The fishbone simulation type dry gas seal structure comprises a moving ring and a static ring, wherein a seal inlet is formedin the outer diameter side, namely the high-pressure side, of the moving ring, a seal inlet is formed in the outer diameter side, namely the high-pressure side, of the static ring, a seal outlet is formed in the inner diameter side, namely the low-pressure side, of the moving ring, and a seal outlet is formed in the inner diameter side, namely the low-pressure side, of the static ring. A plurality of fishbone simulation type grooves are evenly distributed on the high-pressure side of at least one end face of the moving ring in the circumferential direction, and a plurality of fishbone simulation type grooves are evenly distributed on the high-pressure side of at least one end face of the static ring in the circumferential direction. A non-hole area between every two adjacent fishbone simulation type grooves in the circumferential direction is a sealing weir 4. Annular sealing dams 8 are arranged below the fishbone simulation type grooves. The fishbone simulation type dry gas seal structure has the remarkable advantages of being high in opening capacity, high in stability, low in leakage quantity, less in sealing end face deformation and capable of carrying out two-way rotation, and the like, and thereby having broad market prospect.

Owner:XI AN JIAOTONG UNIV

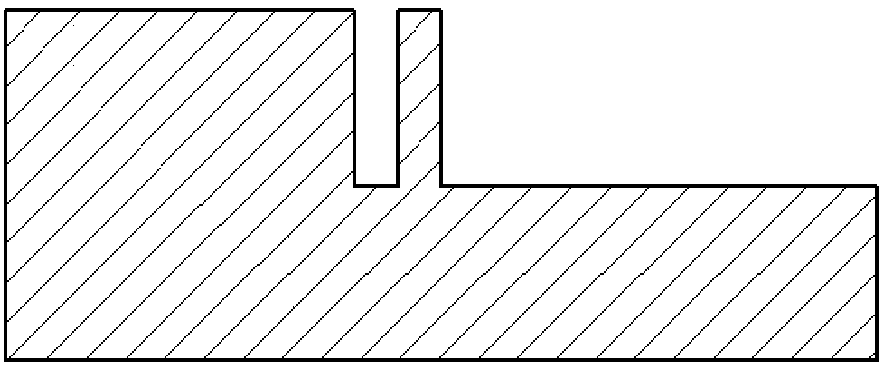

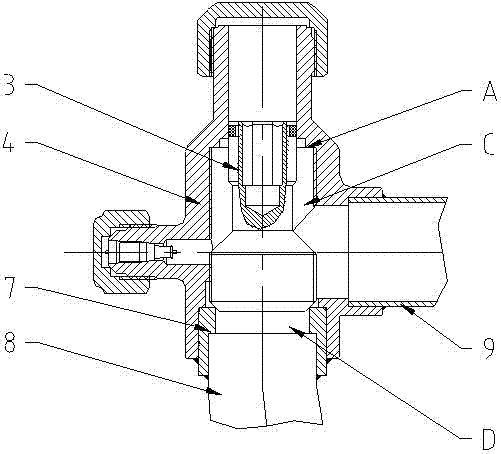

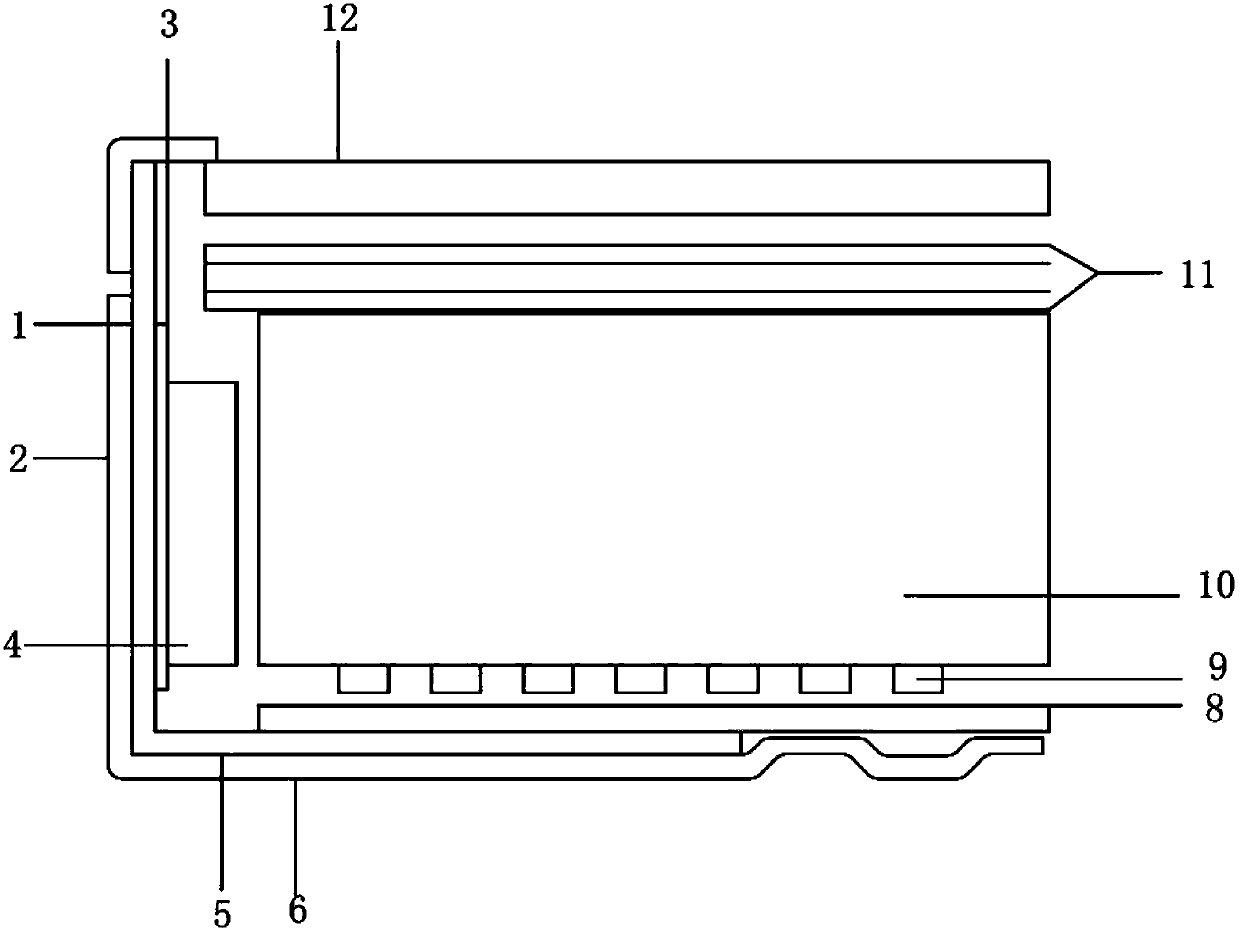

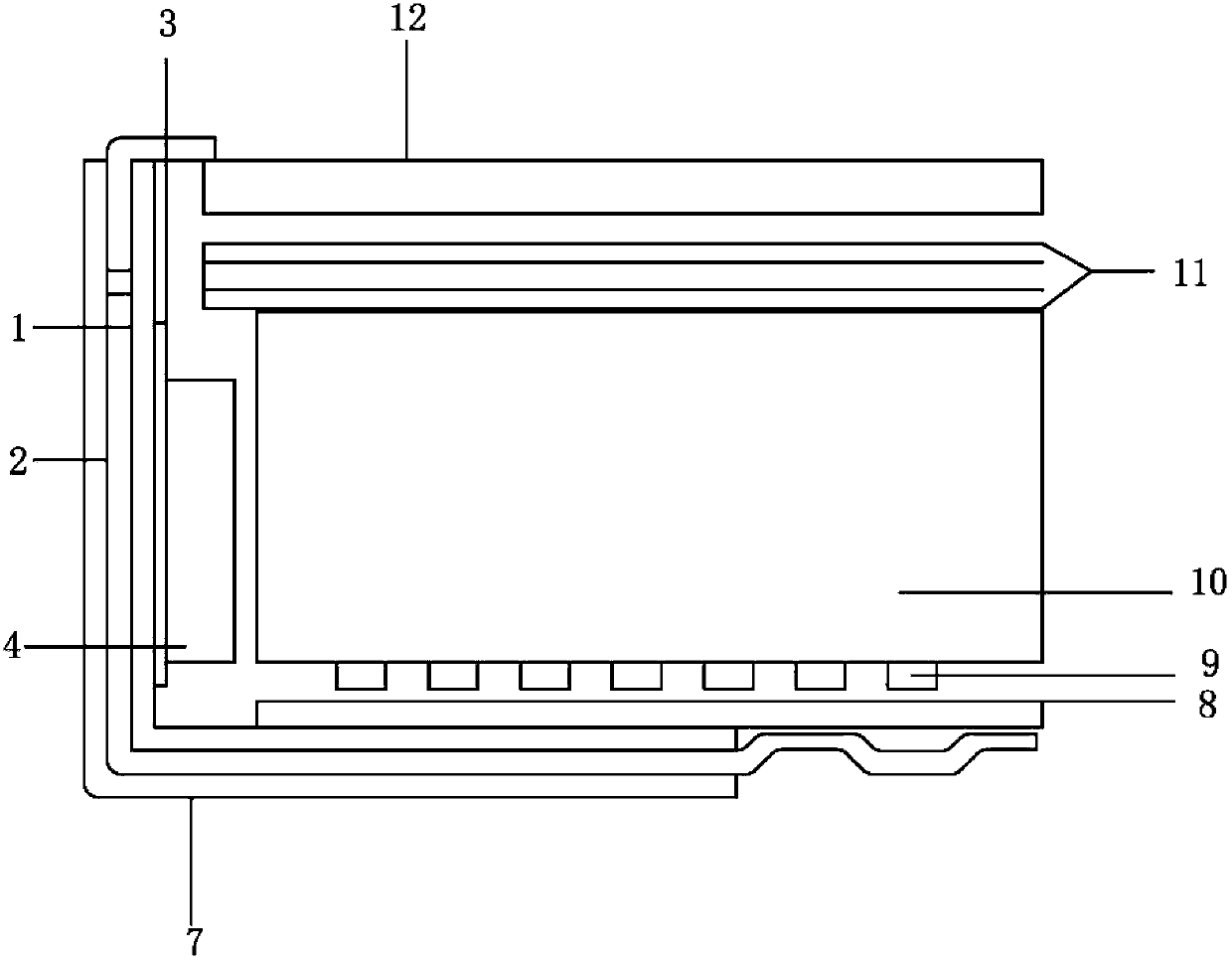

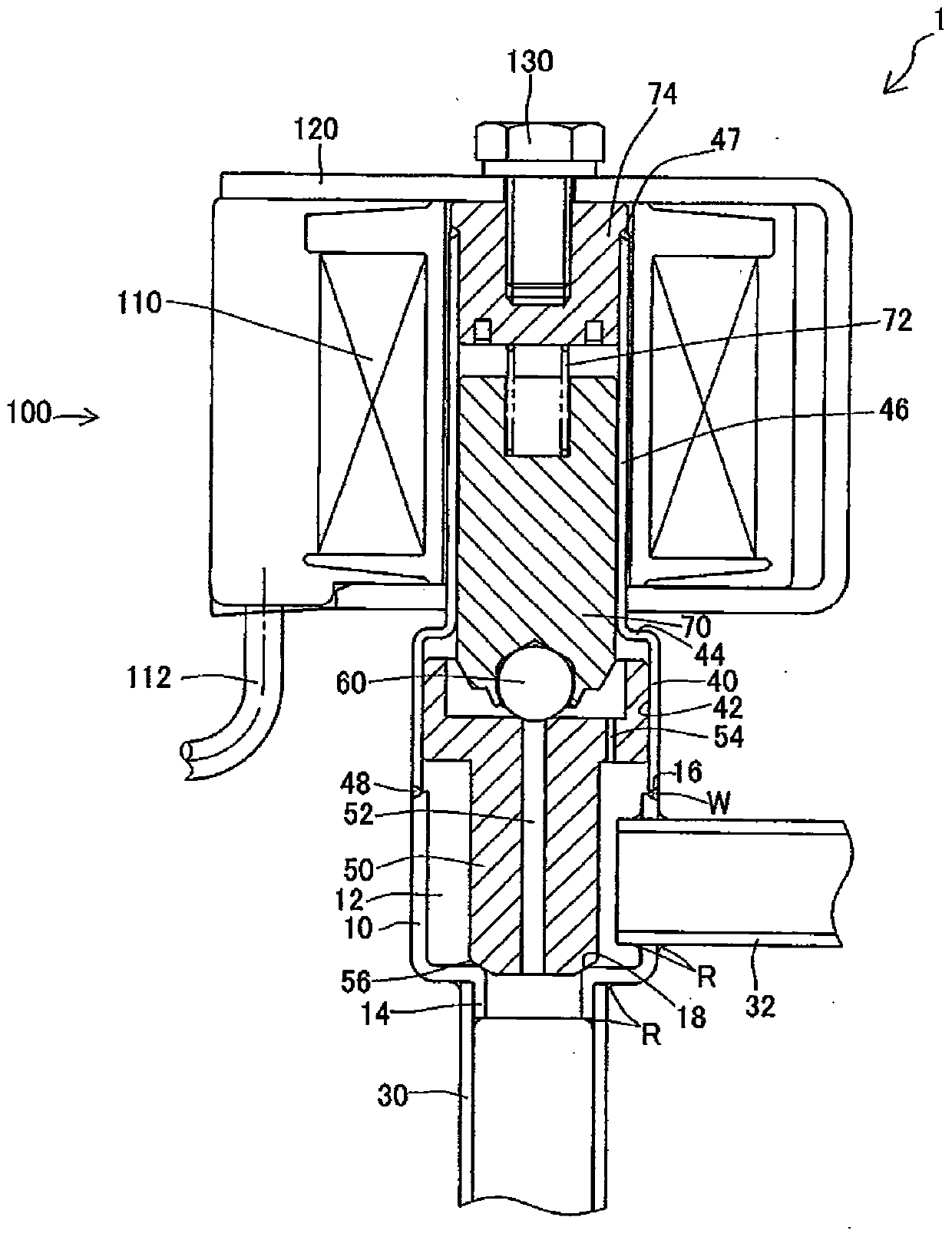

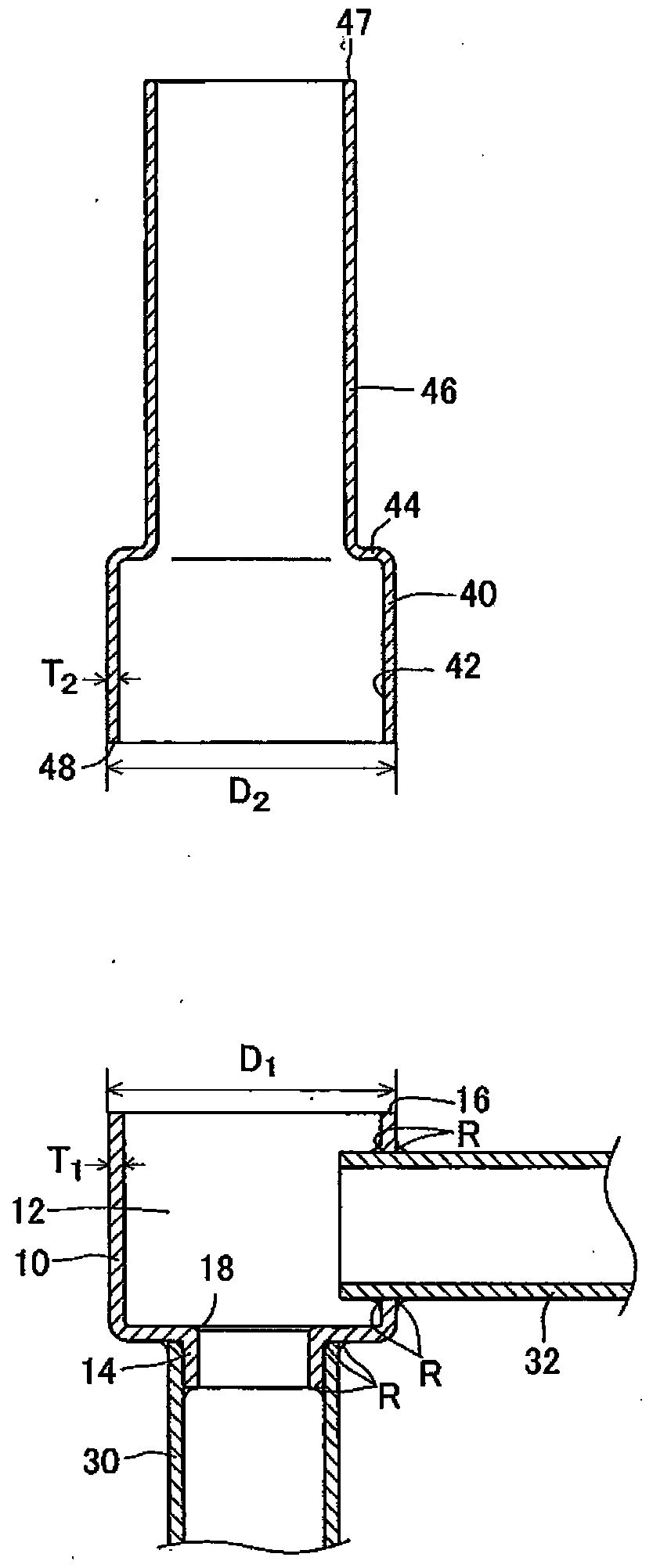

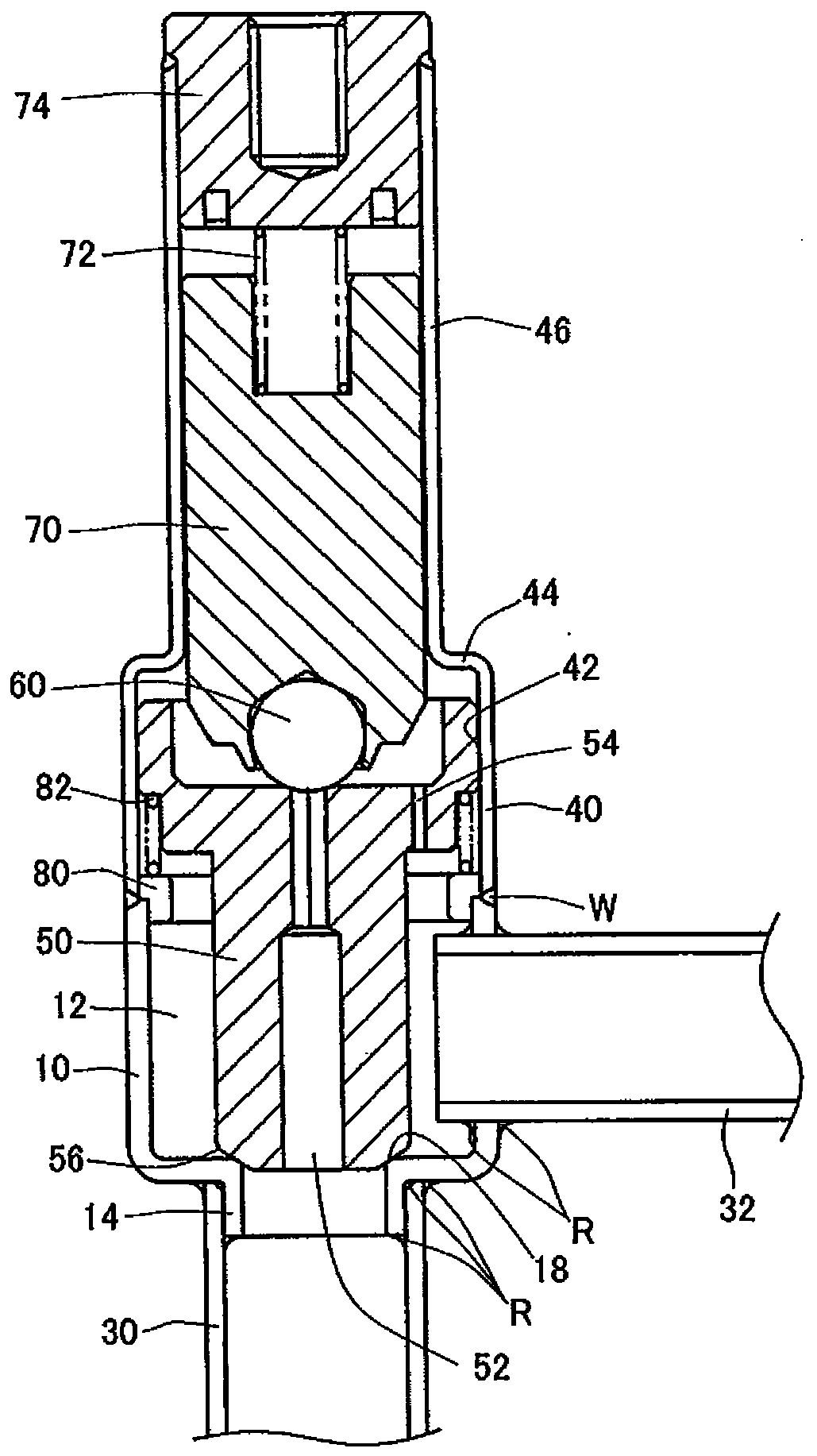

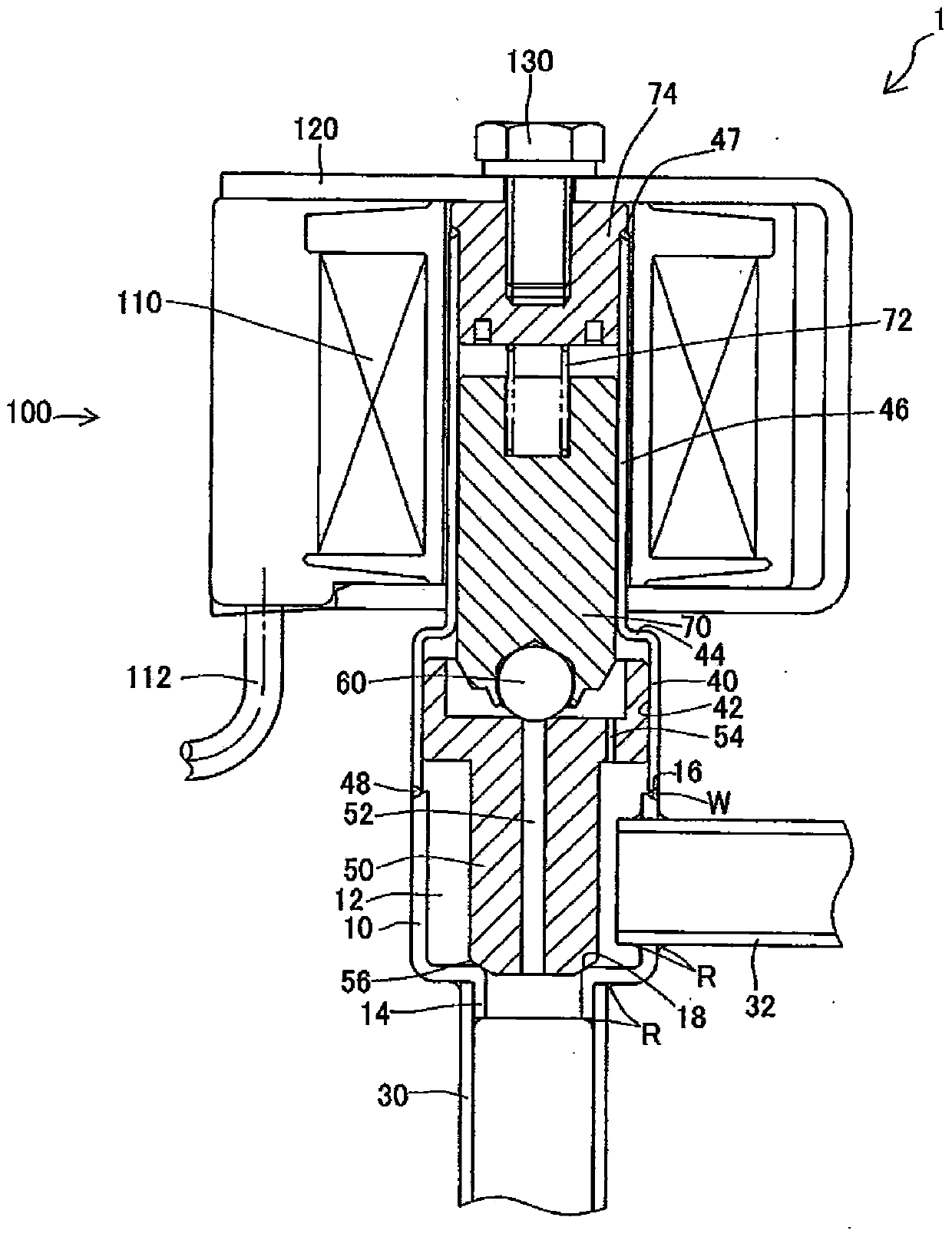

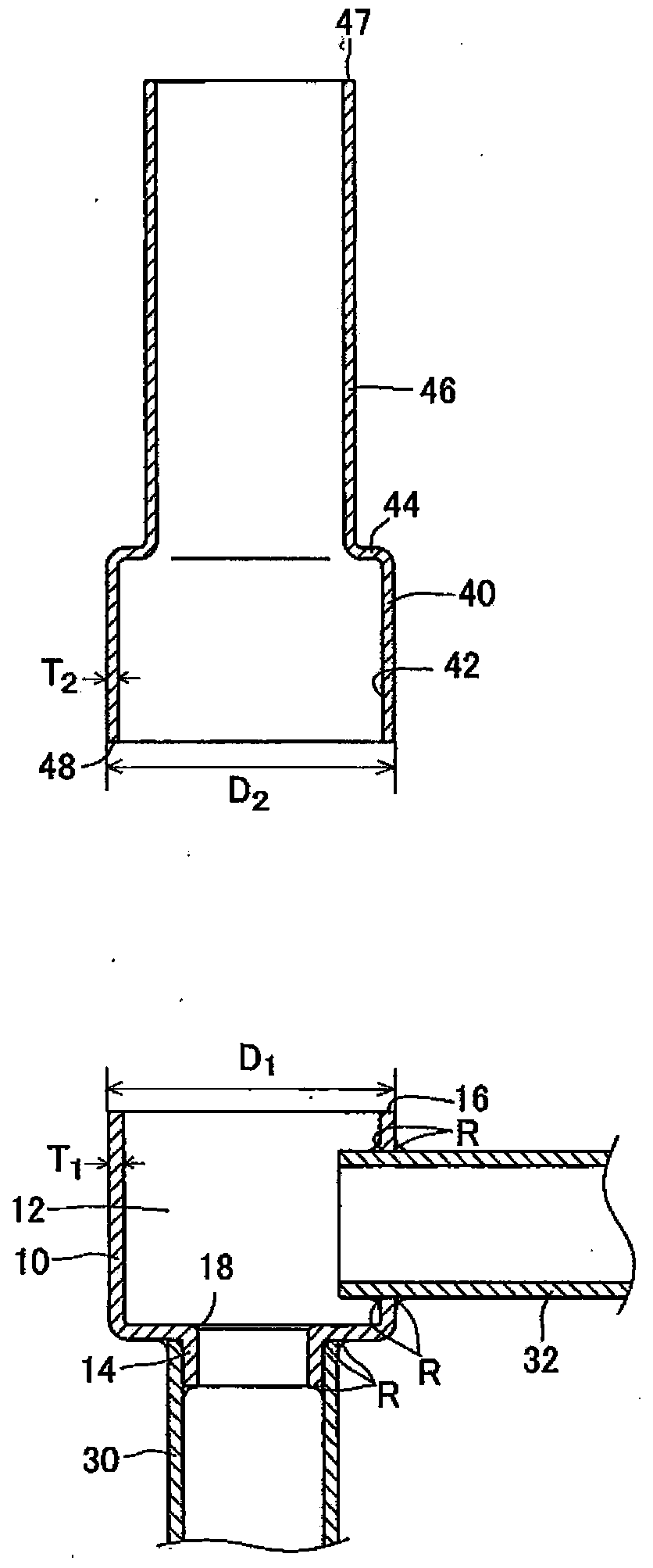

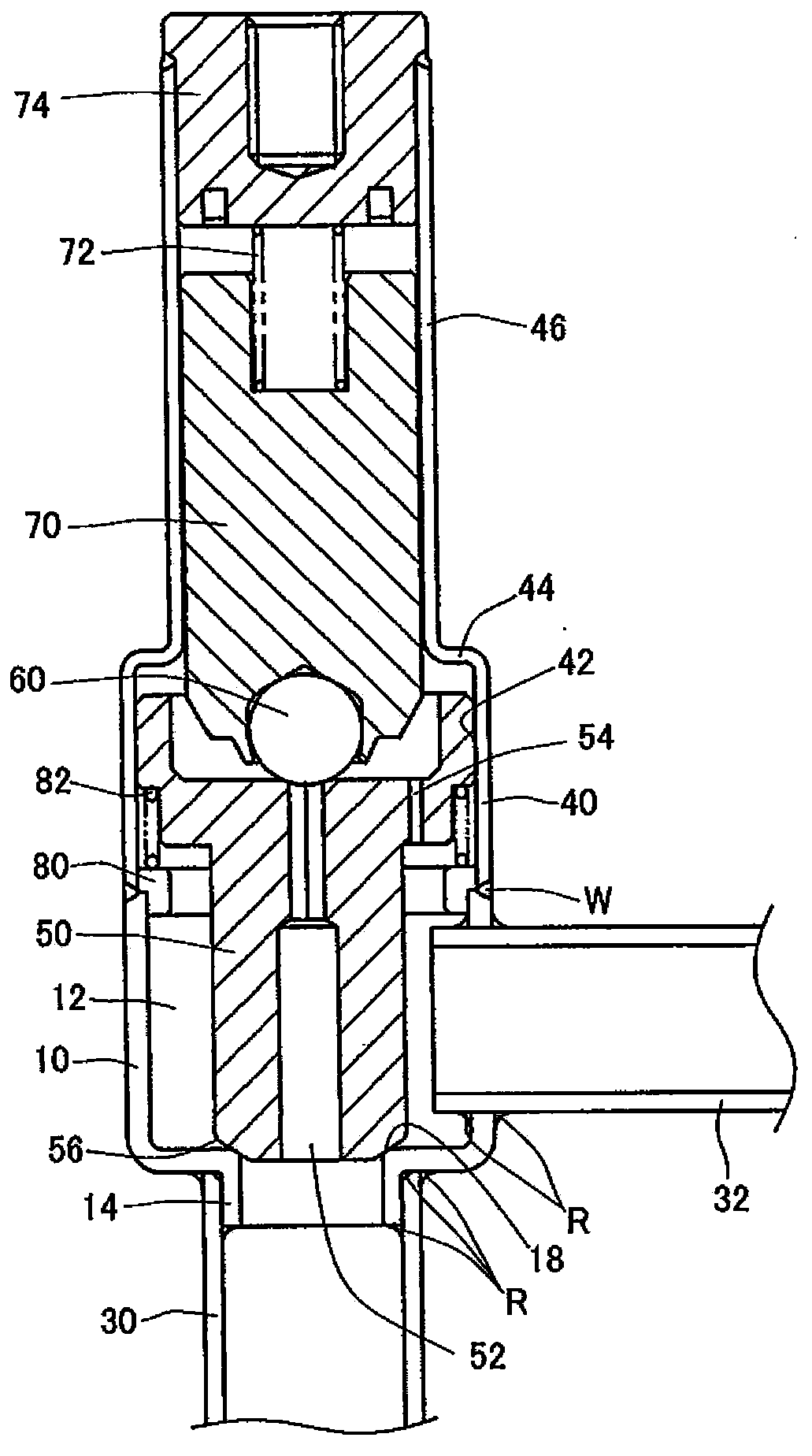

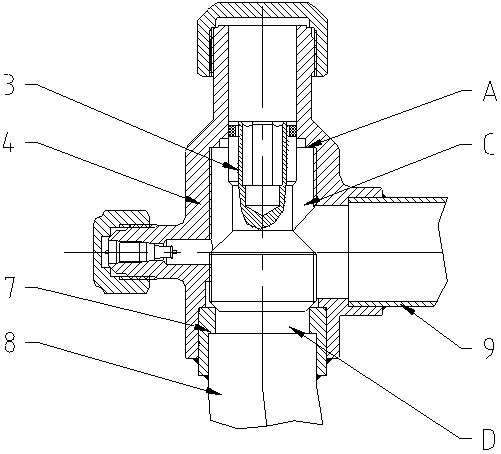

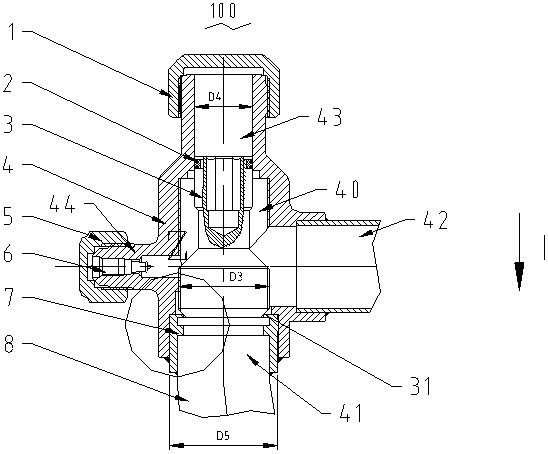

a shut-off valve

ActiveCN103968080BIncrease cooling areaEliminate the effects of thermal deformationValve members for heating/coolingLift valvePore diameterThermal distortion

The invention discloses a stop valve. The stop valve comprises a cavity and a lantern ring, wherein the cavity is defined by assembled a valve seat and a valve element; the lantern ring is mounted on the valve seat; the valve seat comprises a medium inlet and a medium outlet; a first sealing ring part located between the medium inlet and the medium outlet is arranged on the lantern ring; the valve core is located between the medium inlet and the medium outlet, and can coordinate with the first sealing ring part to switch on / off the medium inlet and the medium outlet; the stop valve is characterized in that a conical surface matched with the first sealing ring part is arranged on the valve element; the lantern ring is of normal pore diameter, normal inner wall thickness and a second pore diameter forming the first sealing ring part; the second pore diameter is smaller than the normal pore diameter; a radiating ring part which is in interval with the first sealing ring part is further arranged on the lantern ring. The two ring parts are arranged on the lantern ring of the stop valve, so that the radiating area can be effectively increased, the influence scope of thermal distortion can be reduced, and the stable sealing effect can be achieved.

Owner:ZHEJIANG DUNAN MASCH CO LTD

Non-contact silicon wafer deformation compensation device and method based on electrostatic effect

ActiveCN105717749BAvoid exposure to contaminationReal-time correction of the effects of thermal deformationPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringContact type

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

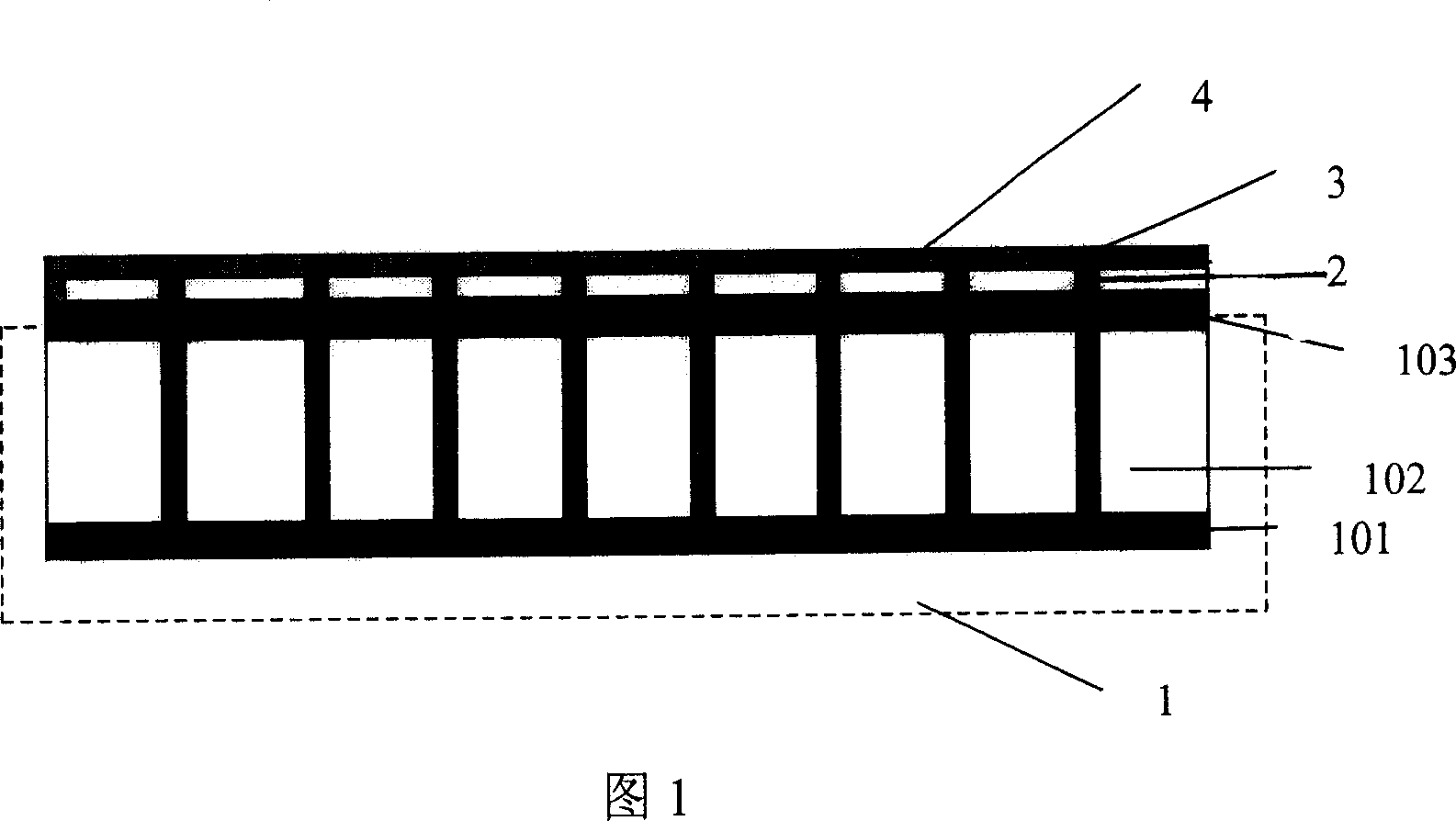

Light weight large-bore compound reflector

ActiveCN1327252CDifficulty avoiding uneven thicknessEliminate the effects of thermal deformationMirrorsEpoxyCarbon fibers

The invention discloses a kind of weight reduced, large-bore, and compound reflector. It includes a compound lens which is composed of folded graphite fiber / wreath oxygen resin or graphite fiber / cyanic acid fat panel + beehive interlayer + graphite fiber / wreath oxygen resin or graphite fiber / cyanic acid fat panel. It has these characteristics: On the lens, there are a microlite cylinder array and a tiny glass reflection base which are both fixed by wreath oxygen resin; On the microlite reflection base, a metallic reflection layer which is plated in vacuum exists. The advantages of the invention are as follows: It takes the microlite cylinder array as the join linking the carbon fiber compound material lens and the microlites reflection base so that the compound material lens can match the microlites reflection base's coefficient of heat expansion well and the problem of the mirror surface's anamorphic caused by heat can be solved. Moreover, the fact that the microlites reflection base has a good optical surface guarantees the reflector's heat stability and chemical stability.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

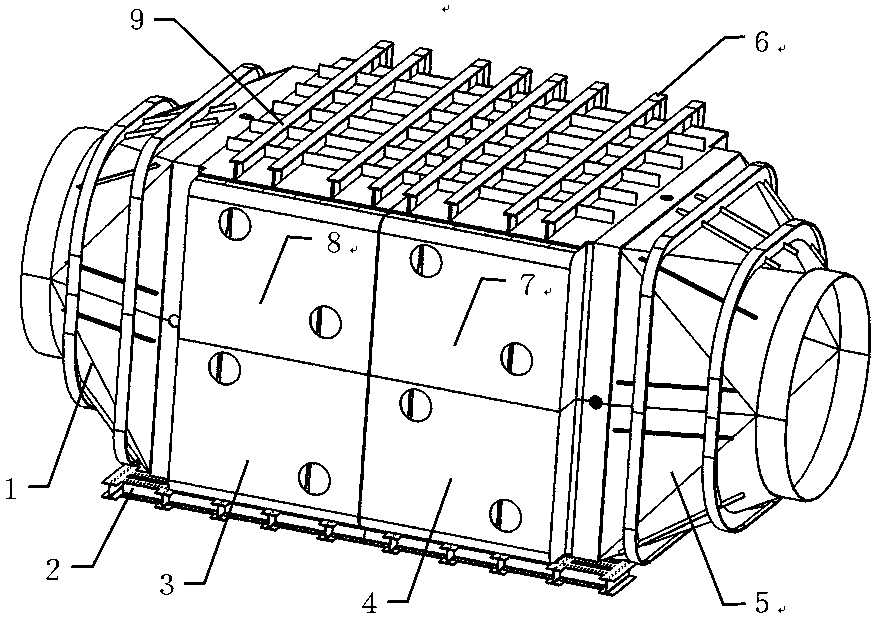

Method for manufacturing front guide cylinder of large-size tubular pump

PendingCN114799590AImprove deformation resistanceIntegrity guaranteedPump componentsWelding/cutting auxillary devicesImpellerMachining

The invention discloses a manufacturing method of a front guide cylinder of a large-size tubular pump. The manufacturing method comprises the steps of machining of a plate frame structure, installation of the plate frame structure and cast guide vanes, installation of the plate frame structure and a mask and machining of the front guide cylinder. Pairing and rough machining of the plate frame structure are completed through a thickened auxiliary process flange, and pairing welding of the plate frame structure and the cast guide vane is carried out with the auxiliary process flange as the reference; after the front guide cylinder is completely welded, the auxiliary process flange is removed, and the flange connecting end face of the axial rib plate is machined with the center and the end face of an impeller hub as the benchmark; welding the corrosion-resistant flange and the axial rib plate to ensure the concentricity of the impeller hub and the corrosion-resistant flange and the planeness of the end surface of the flange, and finally, finely machining the end surface, the inner circle and the outer circle of the corrosion-resistant flange by taking the center and the end surface of the impeller hub as references to ensure the thickness required by the design of the corrosion-resistant flange. The method is easy to implement, little in cost and construction period increase and capable of effectively reducing the difficulty of the overall manufacturing process of the guide cylinder.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

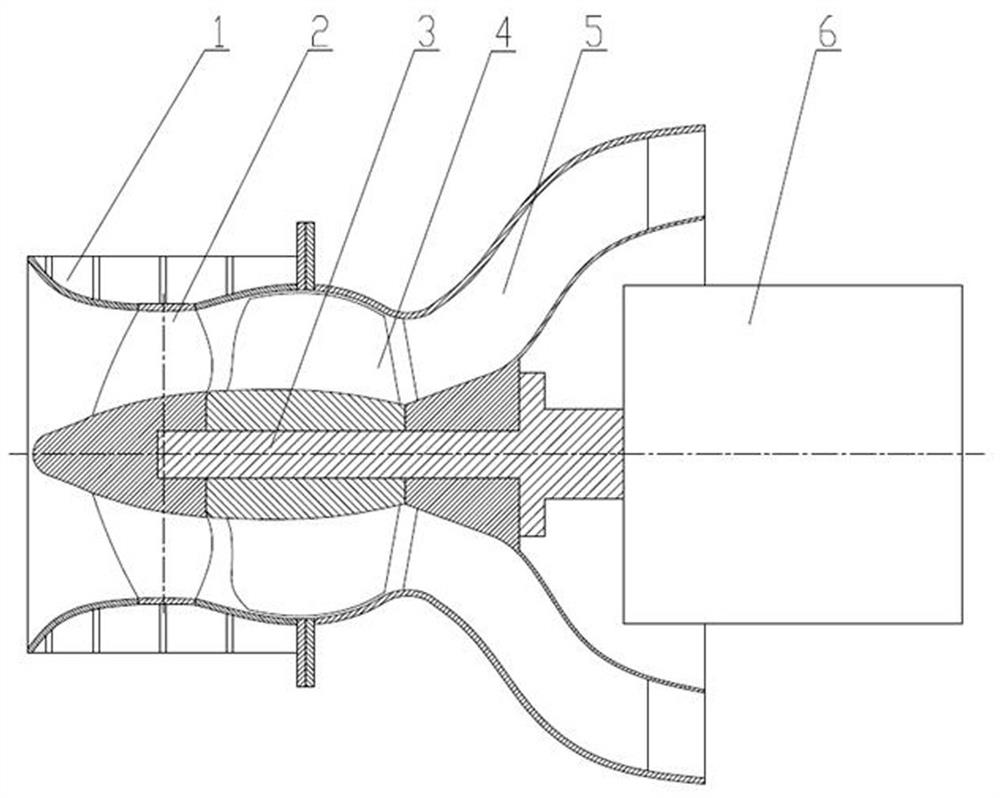

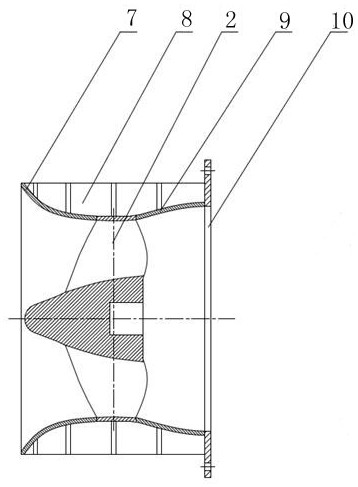

A Cooler for Large Diameter Hypersonic Wind Tunnel

ActiveCN106197939BGuaranteed circulation areaIncreased pressure lossAerodynamic testingButt jointEngineering

The invention provides a cooler for a large-aperture hypersonic wind tunnel. A pedestal of the cooler is provided with a channel. The upper part of the channel is welded with an upper shell. The front end of the channel is welded with a square interface of a front transition segment. The rear end of the channel is welded with a square interface of a rear transition segment. The left side of the channel is a fixed water tank and the right side of the channel is a movable water tank. A side shell covers the outer surface of the movable water tank and reserves a gap with the movable water tank. The side shell and the upper shell are welded at a butt joint position. The channel is formed by combining channel modules of the same structure in arrays, and installation and welding are carried out by using a cordwood system stacking mode of from left to right and from bottom to top. Alternatively-arranged finned tubes are arranged between fixed water tank tube plates and movable water tank tube plates, and the finned tubes serve as heat exchange tubes to increase the heat exchange area. The cooler adopts a mode of a high temperature air flow and cooling water horizontally cross flow, and thus the heat exchange efficiency is raised. The cooler is advantaged by being compact in structure and high in heat exchange efficiency, and capable of meeting operation requirements of the large-aperture hypersonic wind tunnel.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Solvent acrylic ester heat dissipation coating, and preparation method and application thereof

ActiveCN102676010BImprove heat transfer efficiencyImprove cooling efficiencyPoint-like light sourceLighting heating/cooling arrangementsFiberCarbon fibers

Owner:HISENSE VISUAL TECH CO LTD

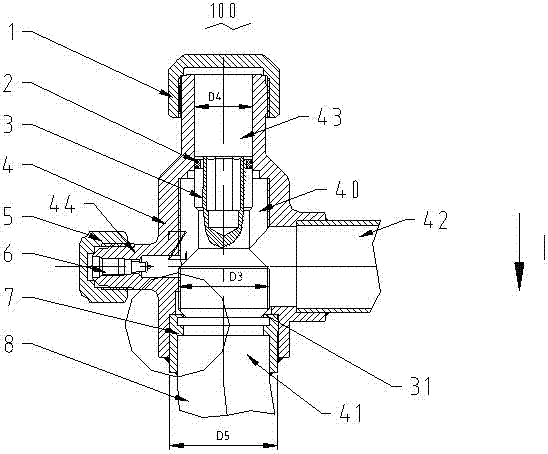

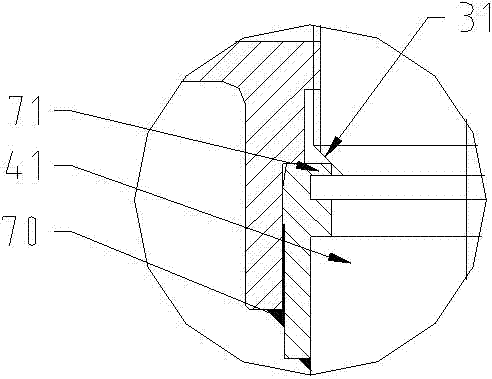

electric drive valve

A valve body of a solenoid valve (1) is formed by jointing a second valve body (10) and a first valve body (4) through fusion welding. Pipes (30, 32) are jointed with the second valve body through brazing (R). A valve core (50) is guided to slide by an internal circumferencial surface (42) of the first valve body (40). The first valve body (40) is not influenced by thermal deformation of brazing (R), so that good sliding performance of built-in components is guaranteed. According to the electric driving valve, thermal deformation of the sliding surface is avoided when the pipes are jointed with the valve body through brazing.

Owner:FUJIKOKI MFG CO LTD

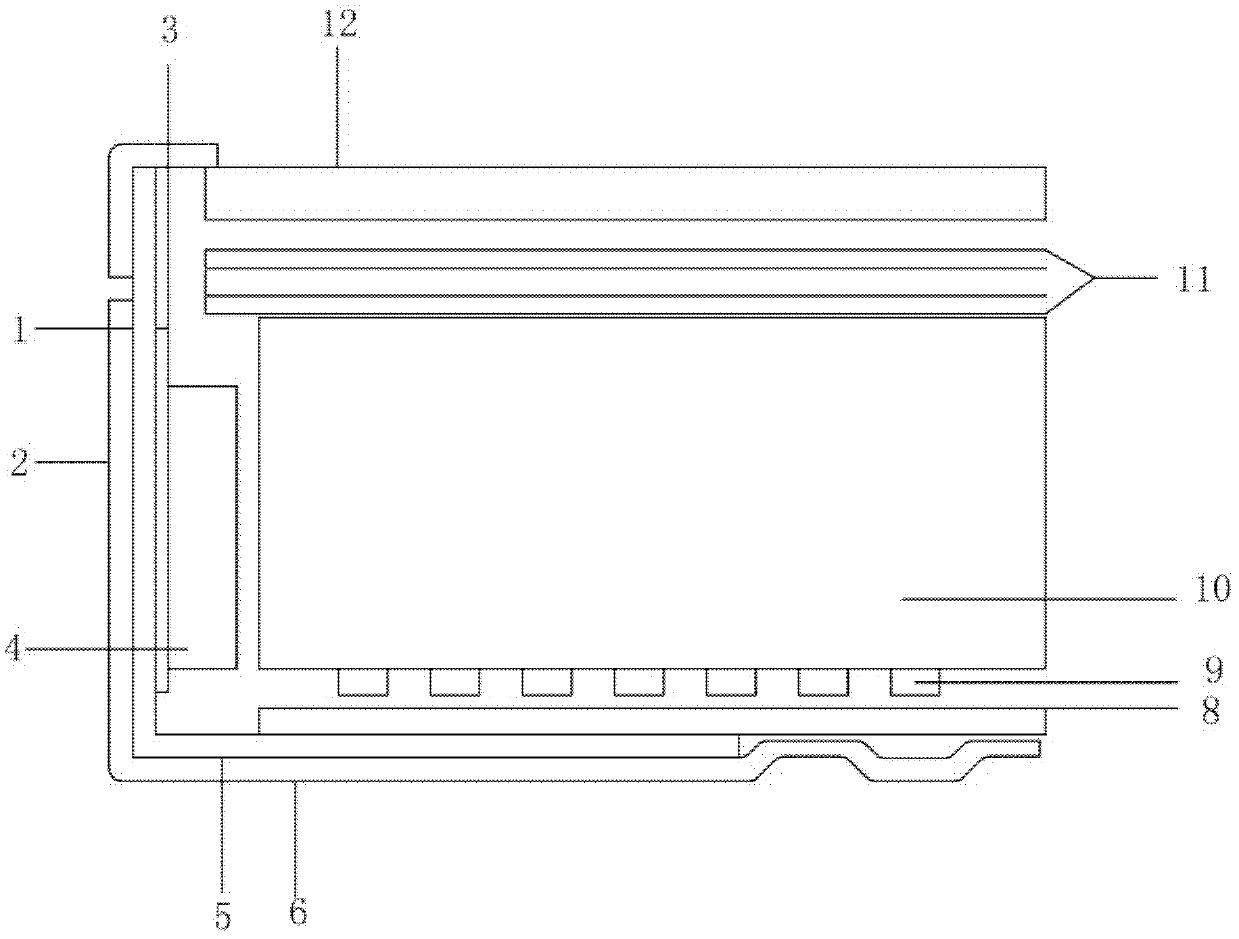

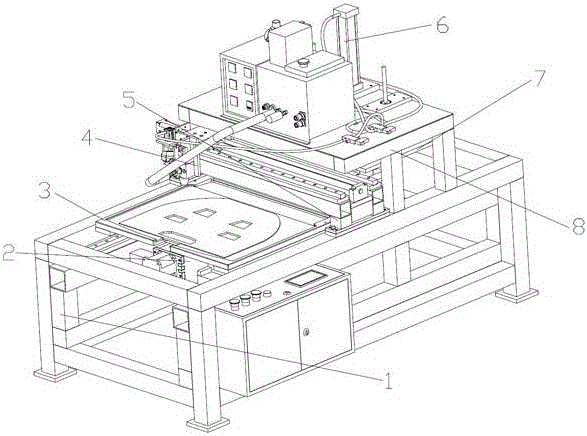

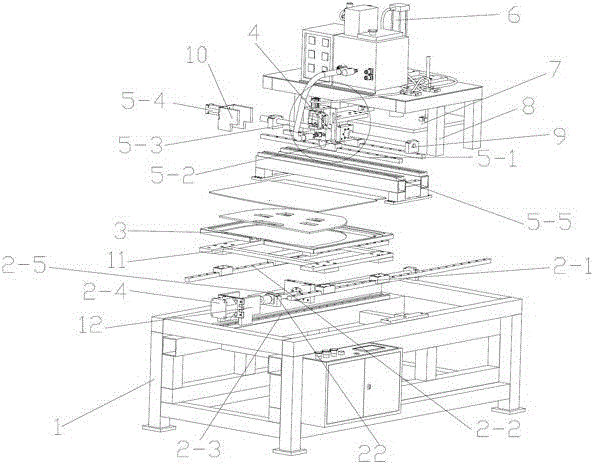

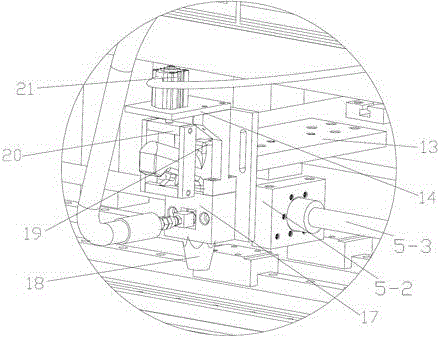

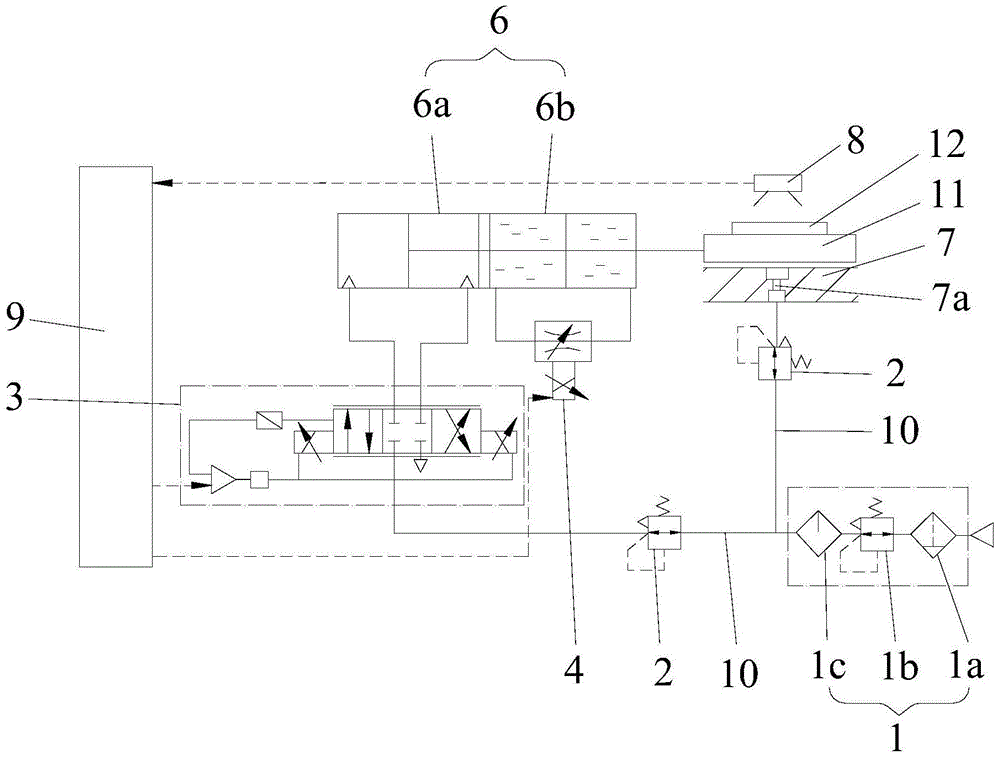

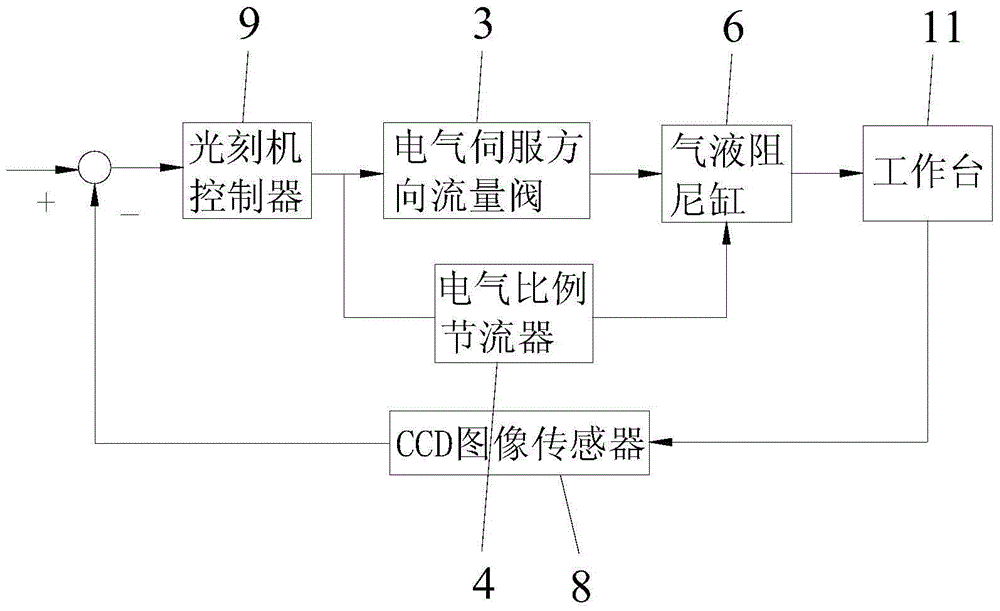

Electrical servo alignment control system and control method for lithography machine

ActiveCN104460240BEliminate frictionEliminate the effects of thermal deformationPhotomechanical exposure apparatusMicrolithography exposure apparatusHydraulic cylinderControl system

The invention discloses an electrical servo position alignment control system and an electrical servo position alignment control method of a photoetching machine. The control system comprises a pneumatic triple element connected with an air source, an electrical servo direction flow valve, an electrical proportion flow regulator, an air-hydraulic damping cylinder formed by a servo cylinder and a hydraulic cylinder through series connection, a static-pressure air-floatation guide rail of a support workbench, a CCD (Charge Coupled Device) image sensor located above the workbench, and a photoetching machine controller, wherein the pneumatic triple element is connected with the electrical servo direction flow valve and the static-pressure air-floatation guide rail by two pipelines respectively, the electrical servo direction flow valve is connected with the servo cylinder, the electrical proportion flow regulator is connected with the hydraulic cylinder, a push rod of the hydraulic cylinder is connected to the workbench, and the photoetching machine controller is connected with the electrical servo direction flow valve, the electrical proportion flow regulator and the CCD image sensor. According to the electrical servo position alignment control system and the electrical servo position alignment control method of the photoetching machine, the homeostatic control precision of the system can be improved, and the position of the workbench can be accurately controlled.

Owner:ZHISHENG SCI & TECH GUANGZHOU

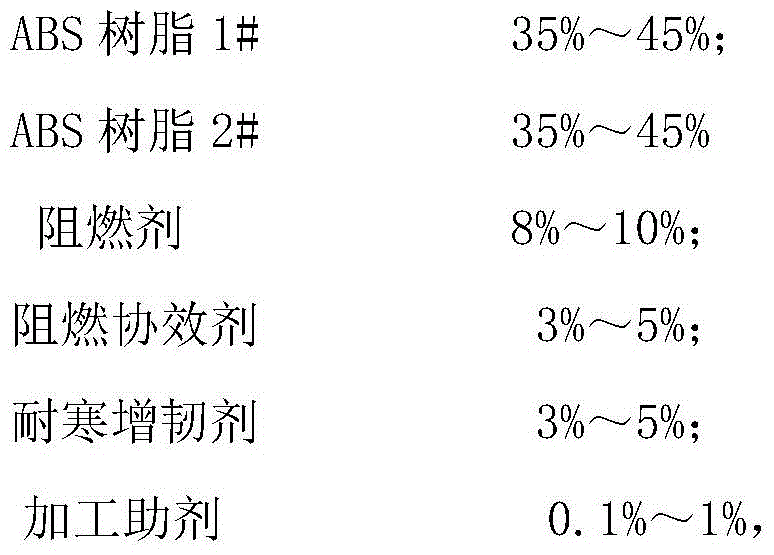

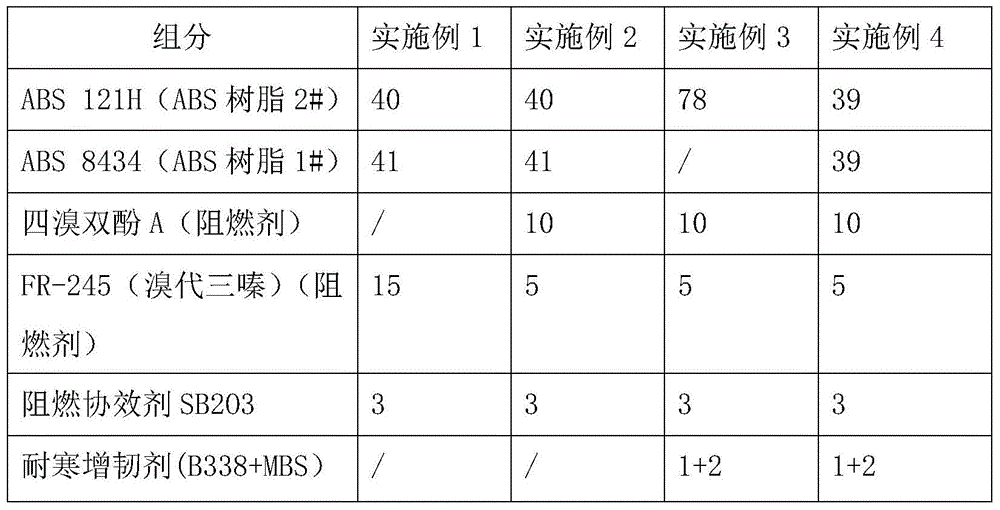

Low-temperature-resistant flame-retarding ABS material and preparation method thereof

InactiveCN105733170ASpecial core-shell structureImprove impact performanceFire retardantProcessing aid

The invention provides a low-temperature-resistant flame-retarding ABS material, which is composed of, by mass percentage concentration, 35-45% of 1# ABS resin, 35-45% of 2# ABS resin, 8-10% of a flame retardant, 3-5% of a flame retardant synergist, 3-5% of a cold-resistant flexibilizer, and 0.1-1% of a processing aid. The invention also provides a preparation method of the low-temperature-resistant flame-retarding ABS material, wherein the method includes the steps of: uniformly mixing the raw materials and performing extrusion granulation in a double screw extrusion machine, water-cooling the granulated material, cutting the material into granules and drying the granules to prepare the ABS material. The ABS material has high impact resistant and impact resistant at 40-50 DEG C, has very low influence on other mechanical performances and has excellent comprehensive performances.

Owner:SHANGHAI SHENGNAN COMPOSITE MATERIALS CO LTD

Electric driving valve

A valve body of a solenoid valve (1) is formed by jointing a second valve body (10) and a first valve body (4) through fusion welding. Pipes (30, 32) are jointed with the second valve body through brazing (R). A valve core (50) is guided to slide by an internal circumferencial surface (42) of the first valve body (40). The first valve body (40) is not influenced by thermal deformation of brazing (R), so that good sliding performance of built-in components is guaranteed. According to the electric driving valve, thermal deformation of the sliding surface is avoided when the pipes are jointed with the valve body through brazing.

Owner:FUJIKOKI MFG CO LTD

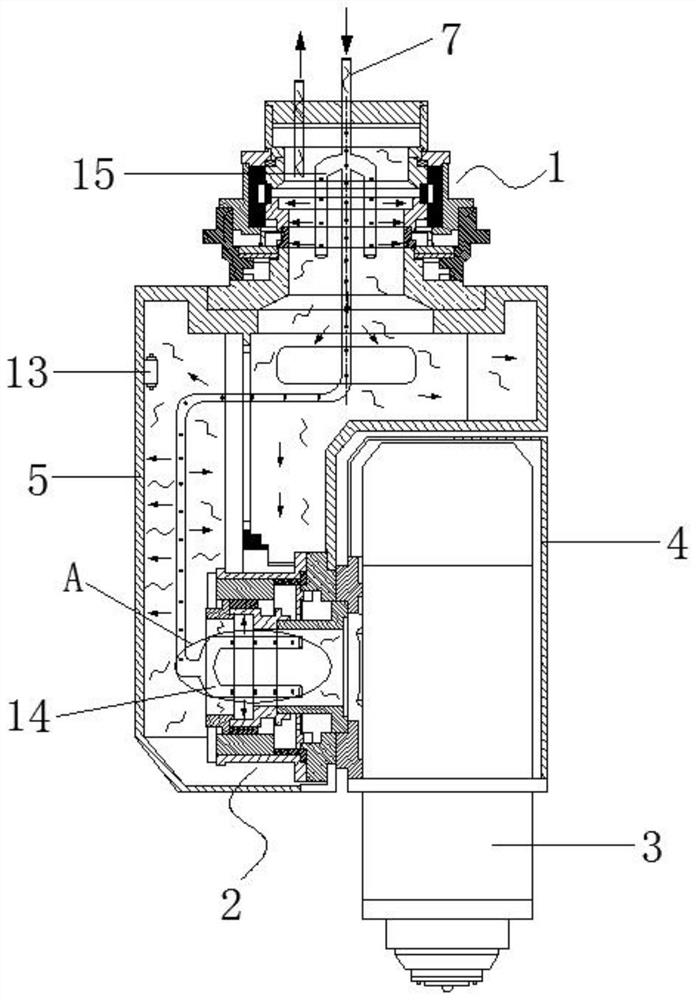

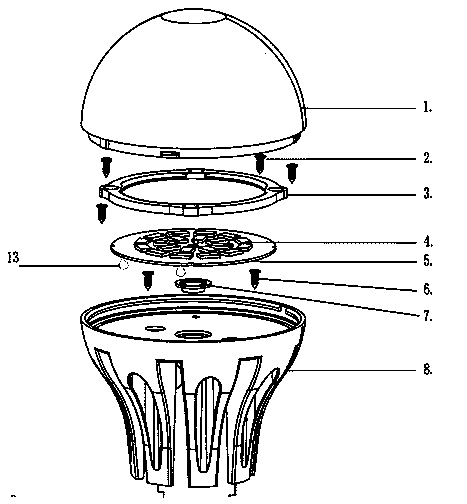

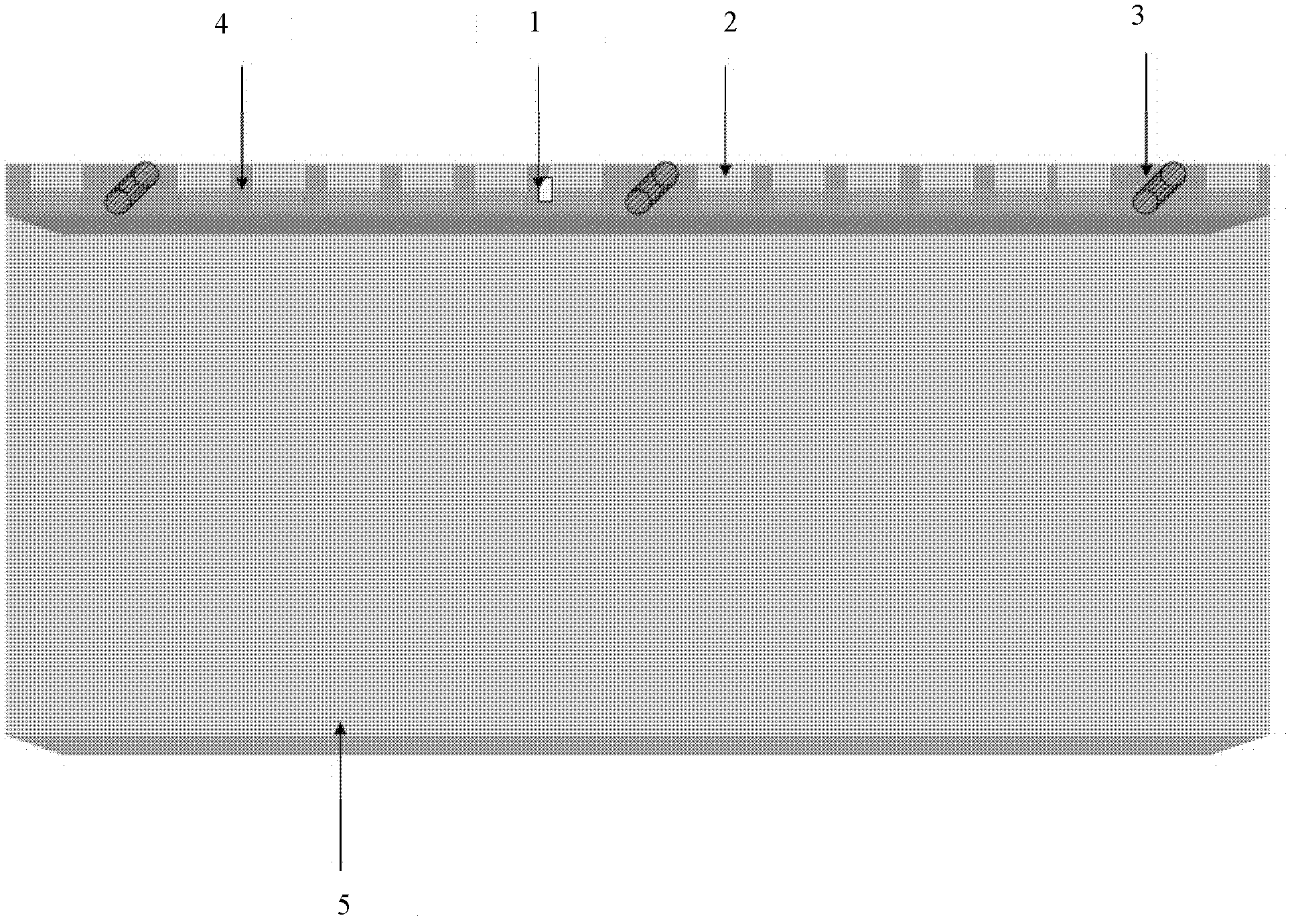

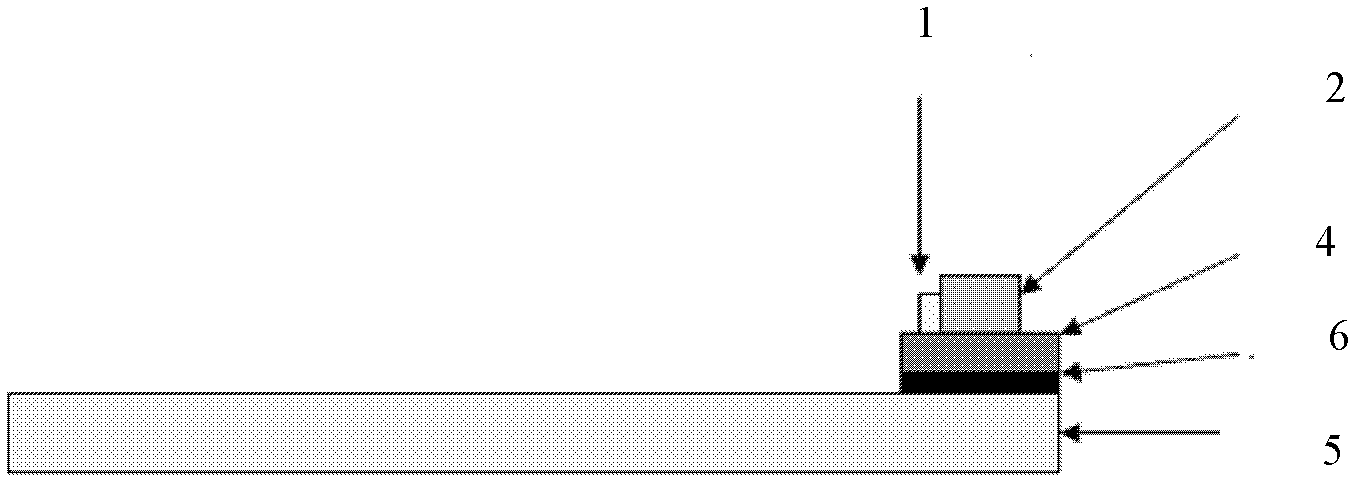

Novel LED lamp

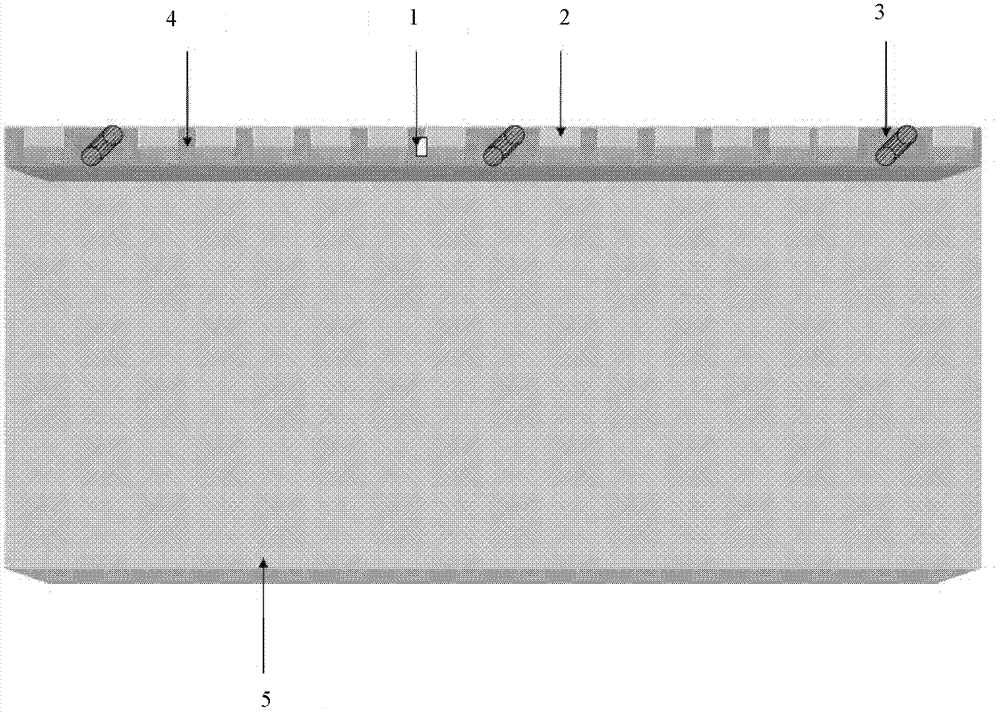

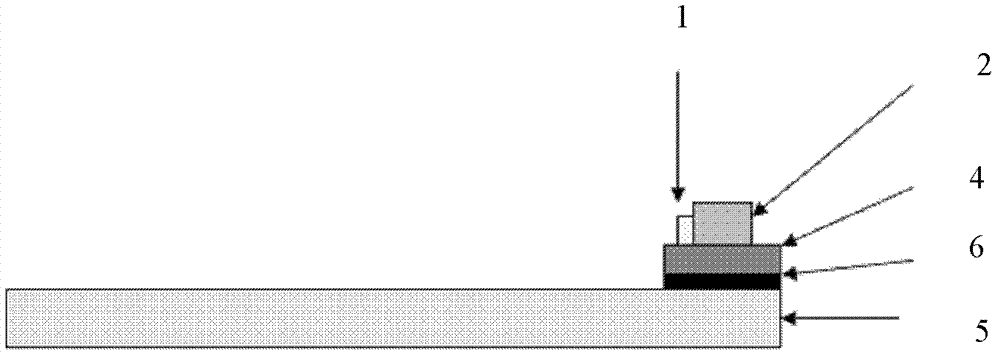

InactiveCN103292289BAnti-staticStable three-dimensional heat conduction structureNon-macromolecular adhesive additivesPoint-like light sourceHeat conductingEngineering

The invention provides a novel LED lamp which comprises an LED lamp heat-dissipating aluminum cup (8), a lamp disc (5) and a lamp shade (1). The novel LED lamp is characterized by further comprising a pressing ring (3) arranged on the lamp disc (5), and a plastic isolating ring (7) arranged between the heat-dissipating aluminum cup (8) and the lamp disc (5). A round hole matched with the plastic isolating ring (7) is formed in the center of the heat-dissipating aluminum cup (8) so that the plastic isolating ring (7) can be buckled to the heat-dissipating aluminum cup (8) conveniently. The pressing ring (3), the lamp disc (5) and the heat-dissipating aluminum cup (8) are connected and fixed through screws (2). The edge of the pressing ring (3) is provided with threads corresponding to the screws (2). The inner edge of the heat-dissipating aluminum cup (8) is provided with small symmetrically-arranged holes. Threads corresponding to screws (6) are arranged inside the small holes. The heat-dissipating aluminum cup (8) and the lamp disc (5) are connected through heat-conducting glue (13).

Owner:杭州亿达照明电器有限公司

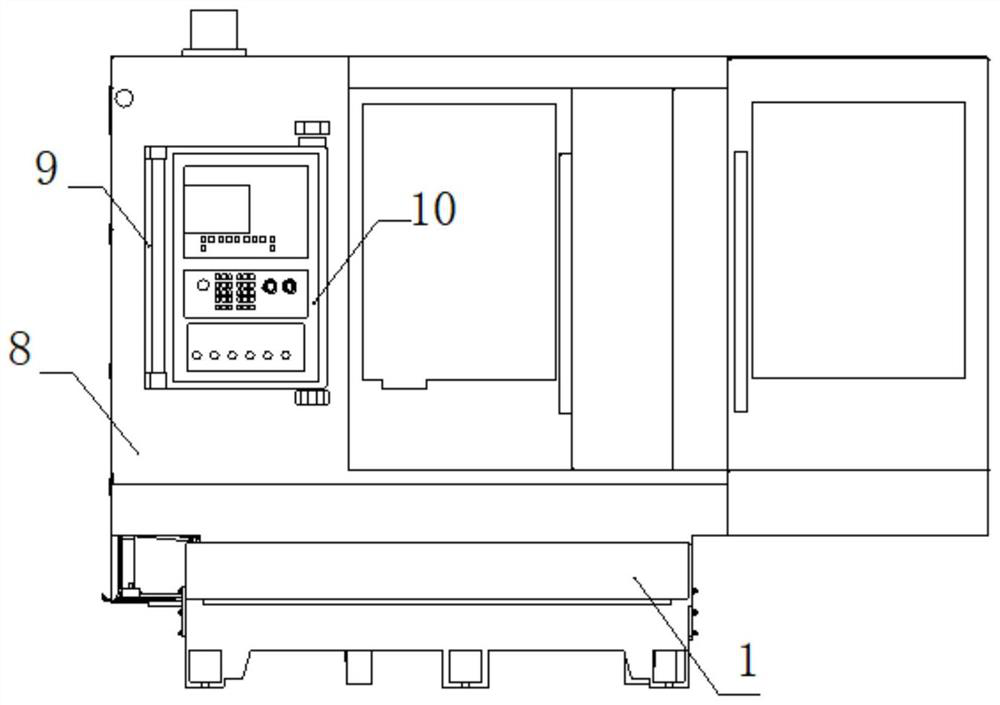

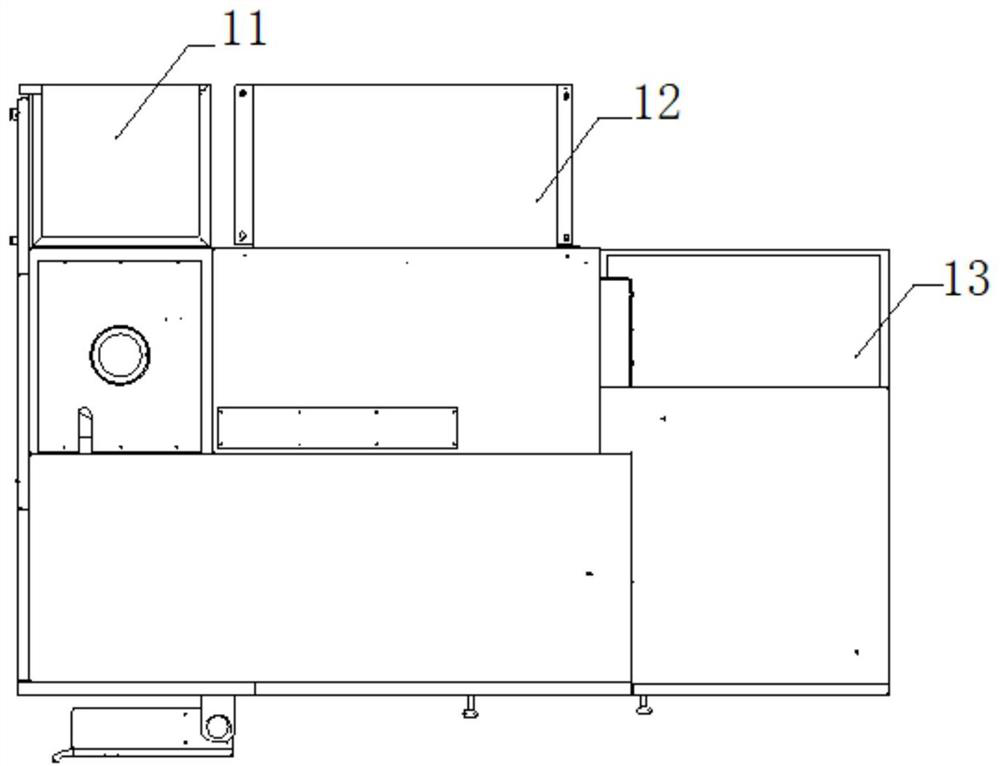

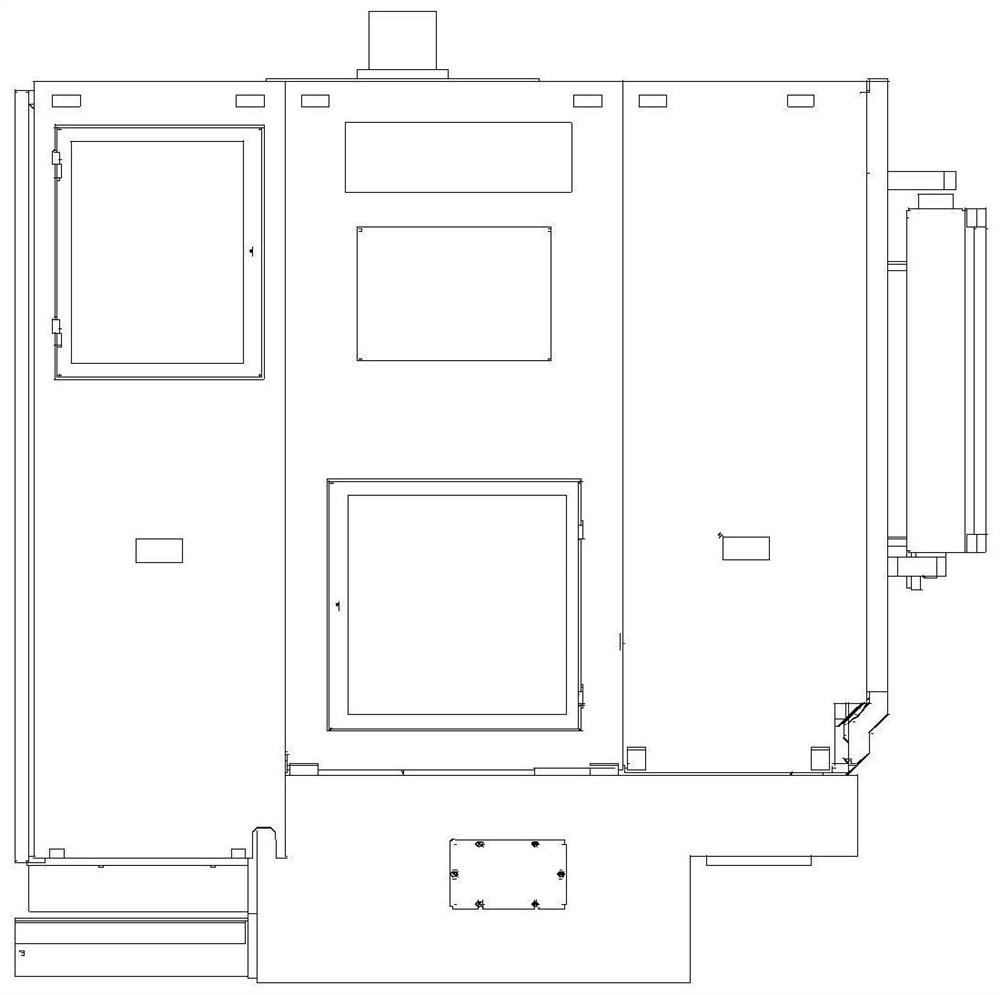

A high-precision workpiece processing system and processing method thereof

ActiveCN112894031BImprove thermal stabilityImprove machining accuracyFeeding apparatusLarge fixed membersHobbingHeadframe

Owner:浙江鑫佳硕科技有限公司

Polycrystalline diamond compact surface polishing machine with adaptive temperature and pressure

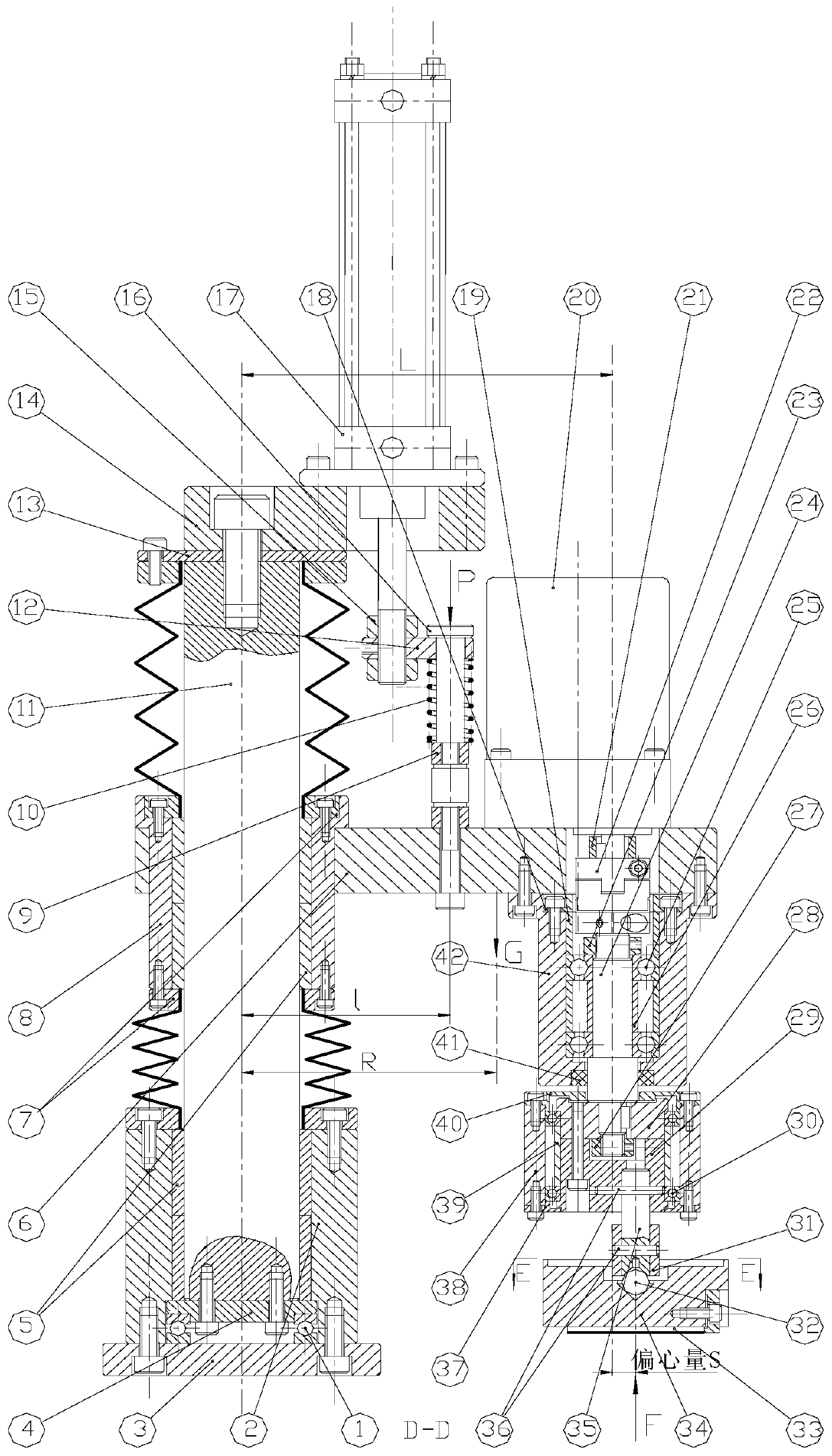

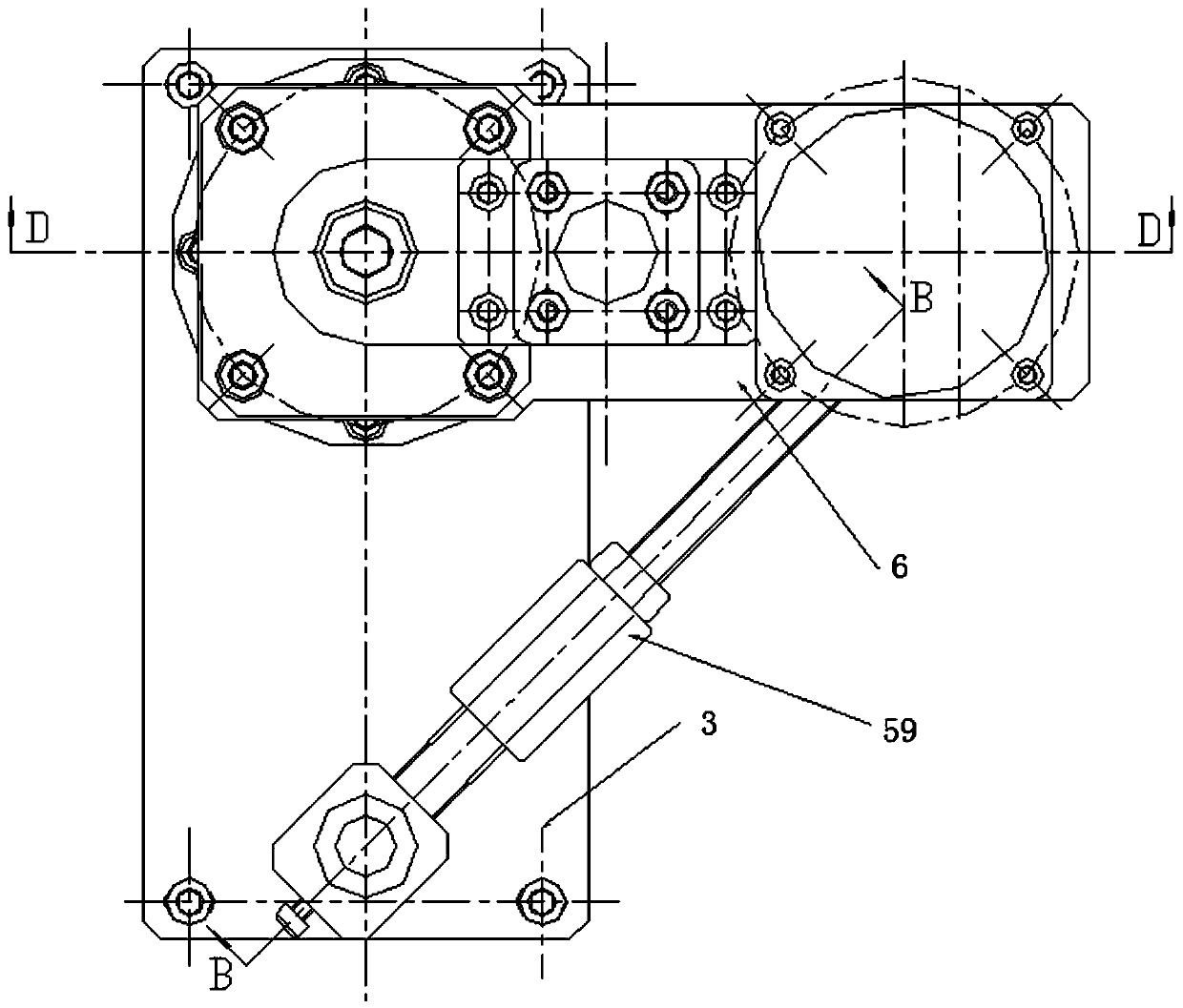

PendingCN111037444AContinuous and stable eccentric rotationReduce deformation stressPolishing machinesGrinding drivesPolishingPolycrystalline diamond

The invention discloses a polycrystalline diamond compact surface polishing machine with adaptive temperature and pressure. The polishing machine comprises a grinding wheel device, a detection device,an execution device, a control device and at least one eccentric rotary polishing device corresponding to the grinding wheel device; and the grinding wheel device, the detection device, the executiondevice and each eccentric rotary polishing device are respectively connected with a control device. The polishing machine not only has the advantages of a double-rocker swing mechanism, but also canrealize the rotation of a polycrystalline diamond compact in the polishing process and continuously and stably eccentrically rotate on the end surface of the grinding wheel, the polished surface is prevented from being scratched; and moreover, the polishing machine realizes self-adaptive control of polishing pressure, temperature and load current of a grinding wheel driving motor, improves polishing efficiency and quality, reduces stress deformation and thermal deformation influence of a large-area (even super-large-area) of the polycrystalline diamond compact, and solves the problem of immediate dressing of a polishing and grinding wheel.

Owner:北京迪蒙吉意超硬材料技术有限公司

Stop valve

ActiveCN103968080AIncrease cooling areaEliminate the effects of thermal deformationValve members for heating/coolingLift valvePore diameterEngineering

The invention discloses a stop valve. The stop valve comprises a cavity and a lantern ring, wherein the cavity is defined by assembled a valve seat and a valve element; the lantern ring is mounted on the valve seat; the valve seat comprises a medium inlet and a medium outlet; a first sealing ring part located between the medium inlet and the medium outlet is arranged on the lantern ring; the valve core is located between the medium inlet and the medium outlet, and can coordinate with the first sealing ring part to switch on / off the medium inlet and the medium outlet; the stop valve is characterized in that a conical surface matched with the first sealing ring part is arranged on the valve element; the lantern ring is of normal pore diameter, normal inner wall thickness and a second pore diameter forming the first sealing ring part; the second pore diameter is smaller than the normal pore diameter; a radiating ring part which is in interval with the first sealing ring part is further arranged on the lantern ring. The two ring parts are arranged on the lantern ring of the stop valve, so that the radiating area can be effectively increased, the influence scope of thermal distortion can be reduced, and the stable sealing effect can be achieved.

Owner:ZHEJIANG DUNAN MASCH CO LTD

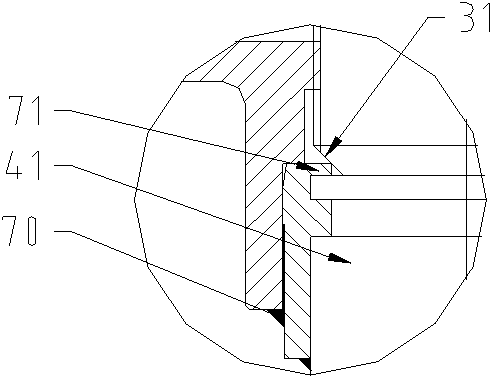

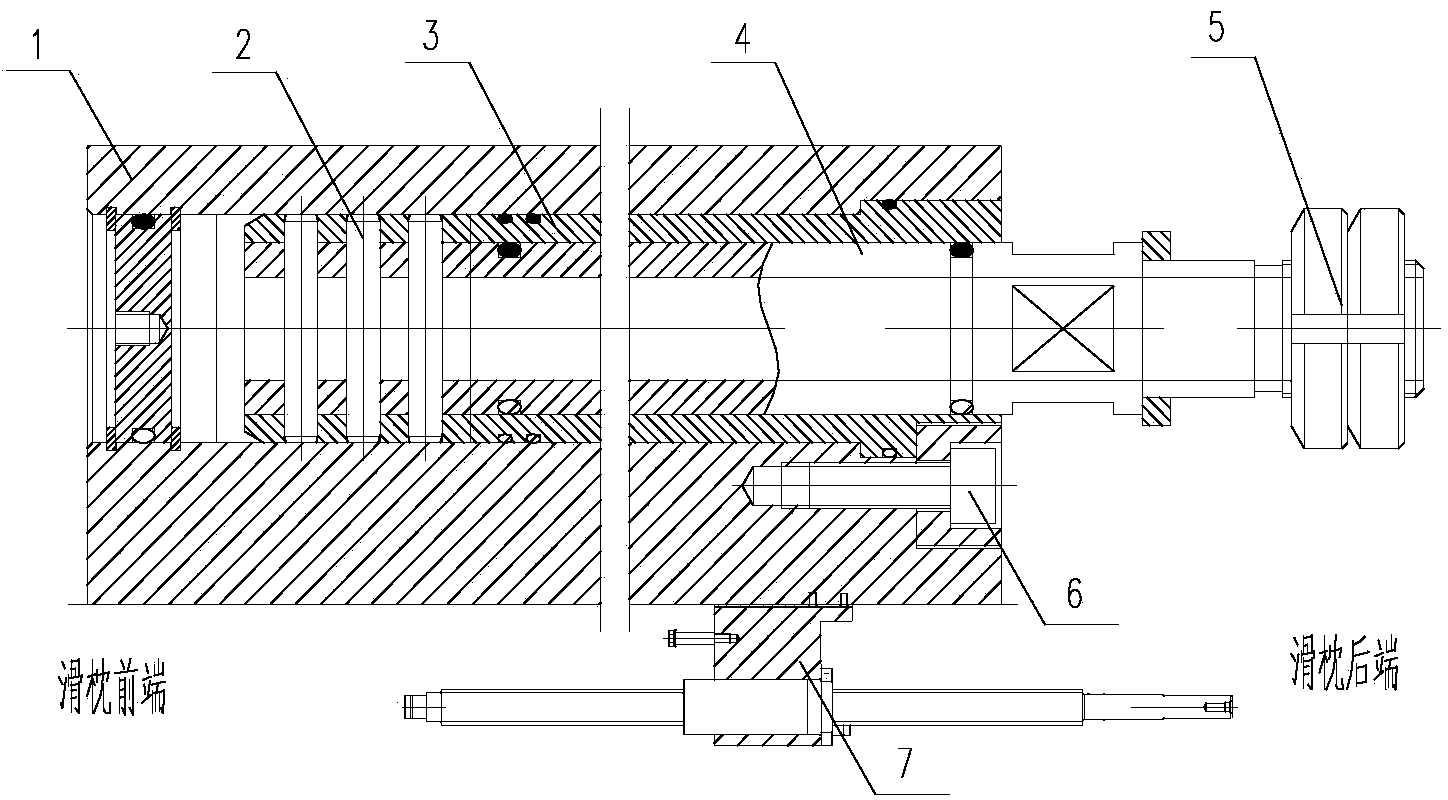

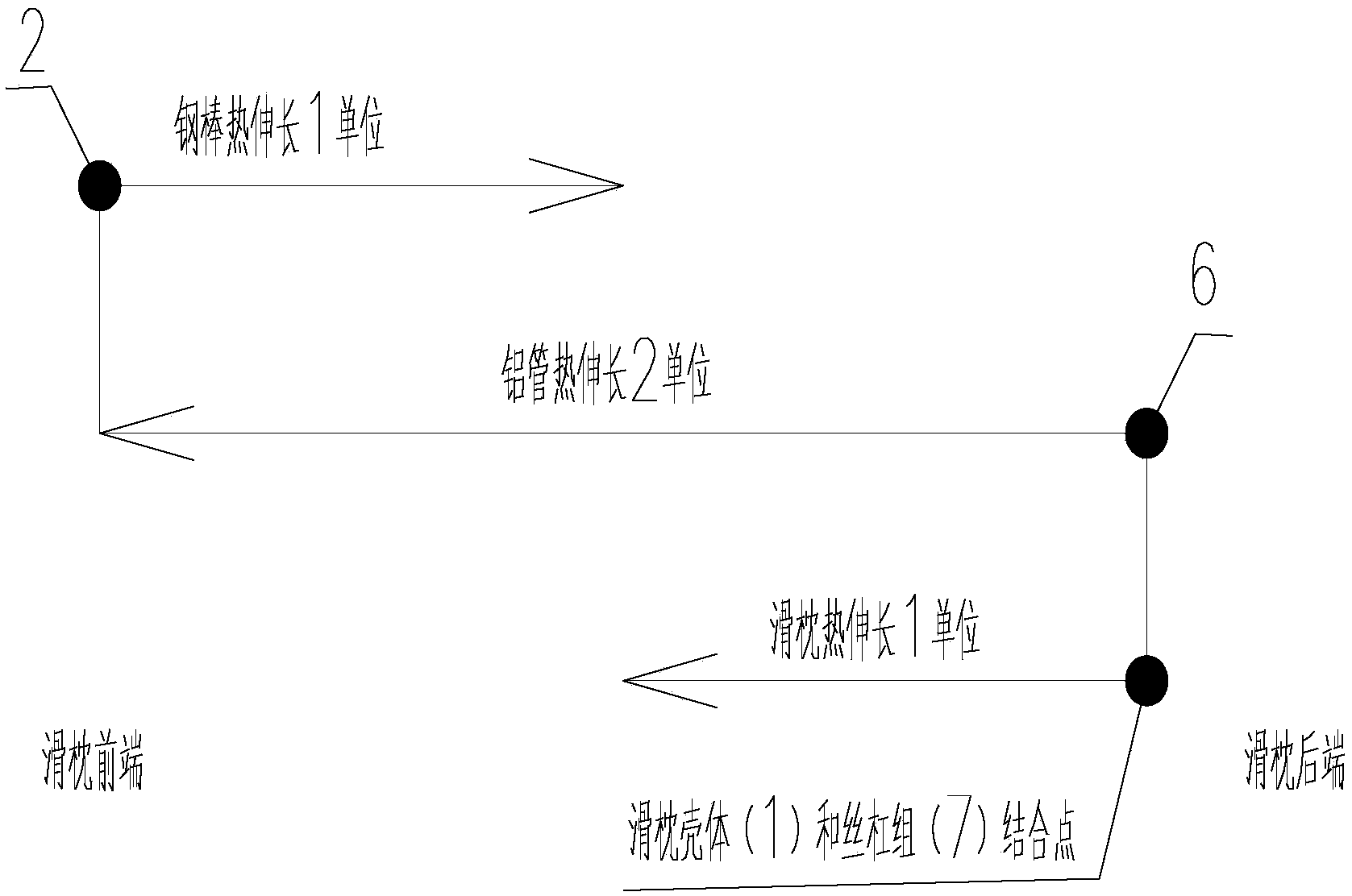

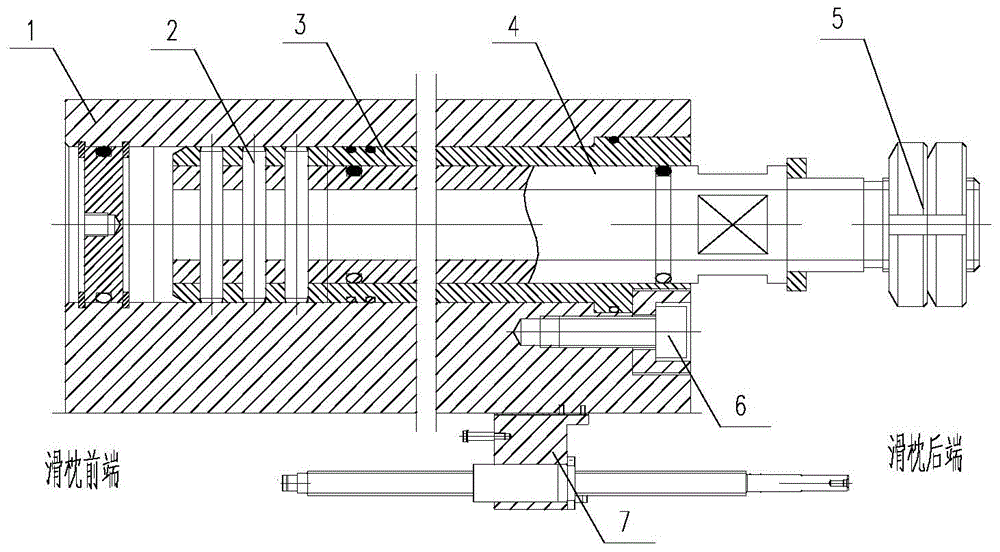

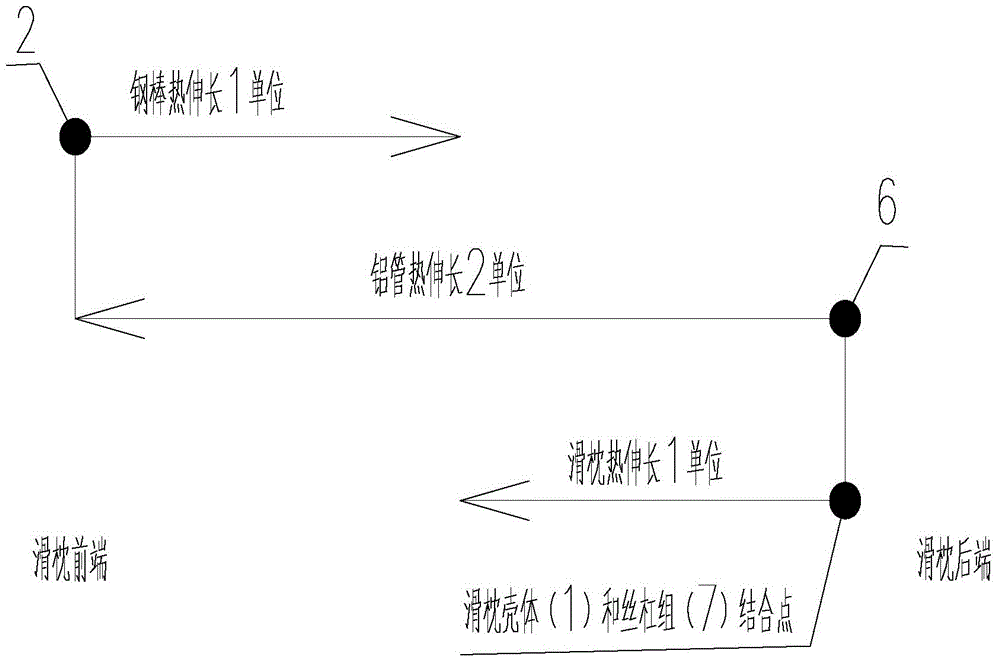

Device for measuring thermal elongation of ram based on texture thermal elongation difference property

ActiveCN103624631AEliminate the effects of thermal deformationSmall heat transfer gradientMeasurement/indication equipmentsMeasurement deviceThermal expansion

The invention provides a device for measuring thermal elongation of a ram based on a texture thermal elongation difference property. According to the device, a bonding point of a ram shell and a screw rod set is arranged at the fixed rear end of the ram. The device is structurally characterized in that the rear end of the ram is joined with the rear end of an aluminum pipe; the aluminum pipe and the front end of a steel rod are joined on a fixed part of the aluminum pipe and the steel rod; the rear end of the steel rod is connected with a measuring device; a design is that the thermal expansion coefficient of aluminum is two times as much as that of steel; when the temperature is changed, the ram shell extends for one thermal elongation unit along the positive direction, the aluminum pipe extends for two times along the positive direction and the steel rod is moved for two times along the positive direction; however, the steel rod extends for one thermal elongation unit along the negative direction and the sum of the thermal elongation unit and the thermal elongation of the ram is equal to the thermal elongation amount of the aluminum pipe; a reference object of the thermal displacement of the ram is compounded; and a numerical value collected by the measuring device at the rear end of the steel rod is the thermal displacement of the ram, so that expensive mark post invar steel is replaced and the production cost of equipment is reduced obviously.

Owner:沈阳机床中捷友谊厂有限公司

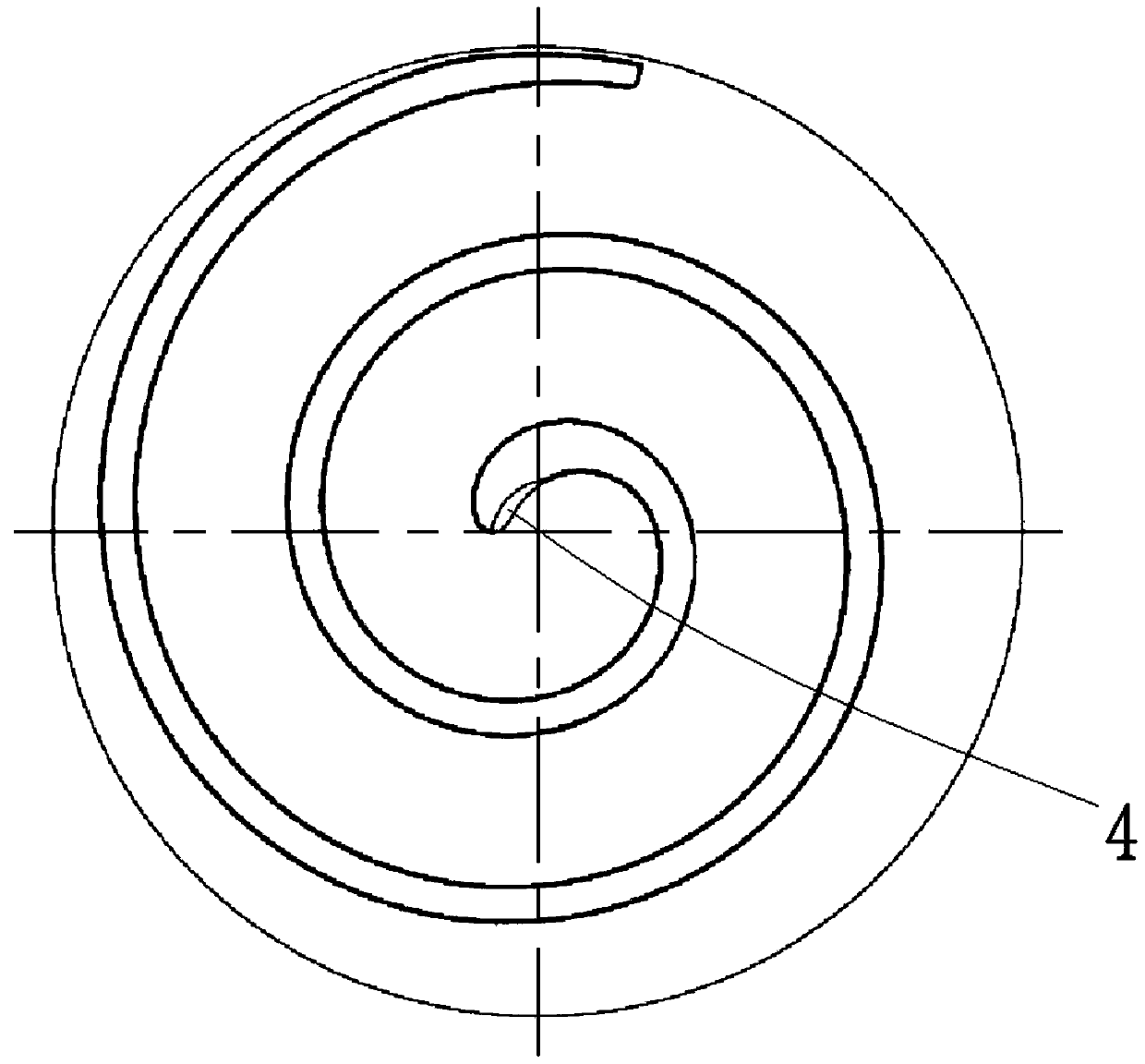

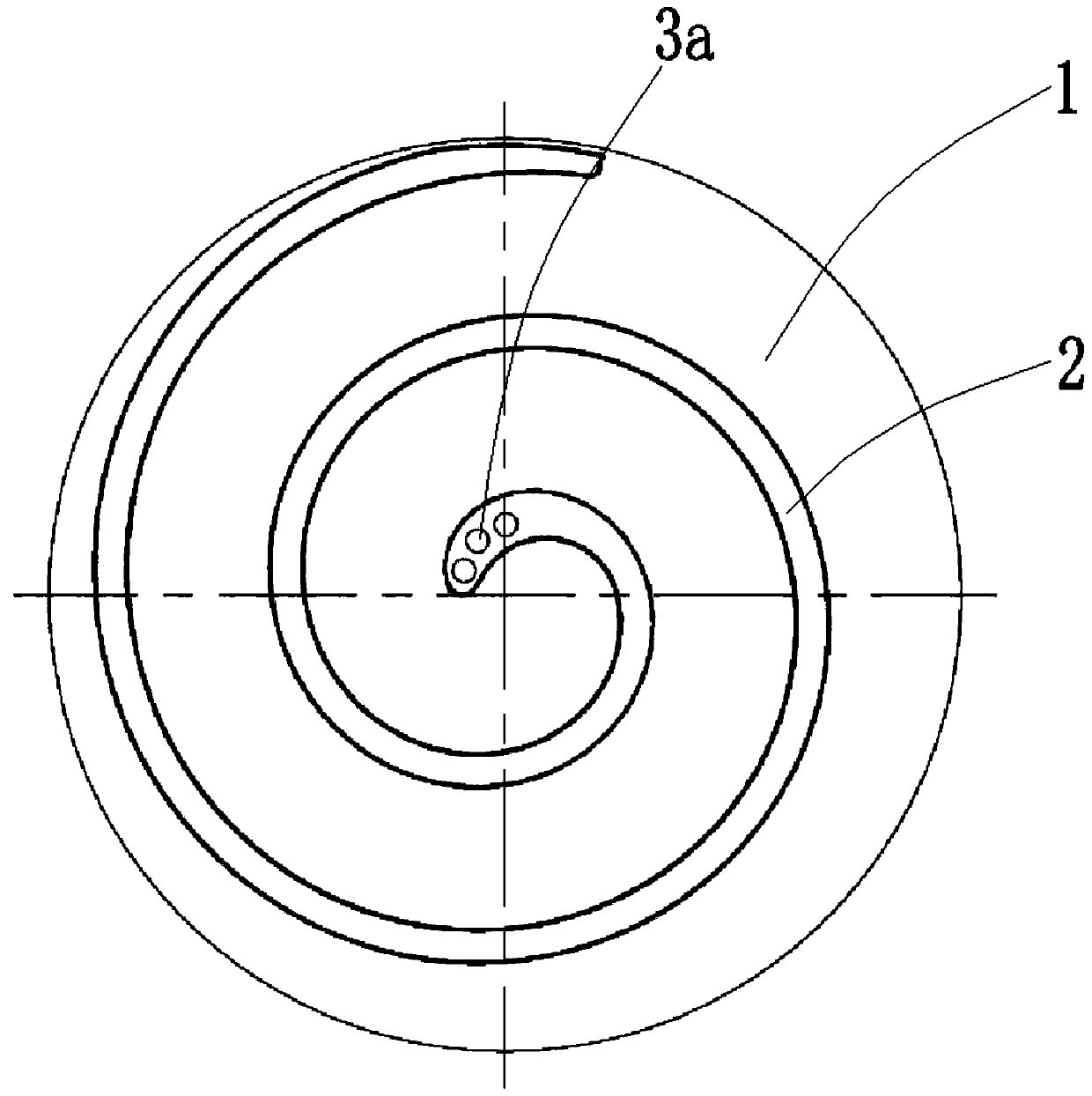

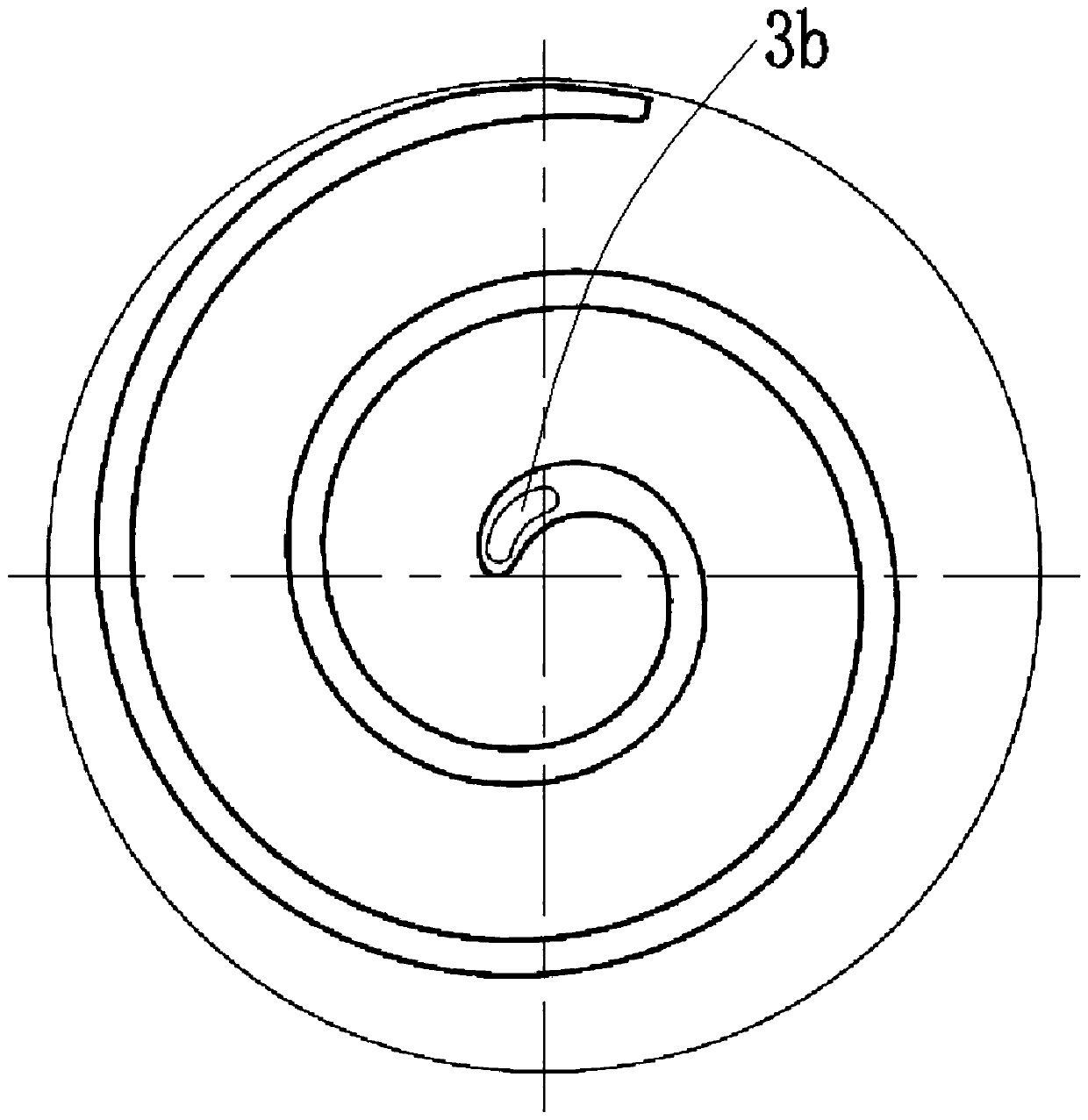

Scroll compressor vortex plate, compressor adopting scroll compressor vortex plate and air conditioner

PendingCN110792600AImprove lubricityReduce wearRotary piston pumpsRotary piston liquid enginesPhysicsThermal deformation

The invention relates to the technical field of compressor vortex plates and provides a scroll compressor vortex plate, a compressor adopting the scroll compressor vortex plate and an air conditioner.The problem that reliability is abnormal due to thermal deformation of the center of a molded line in the prior art is solved. The scroll compressor vortex plate comprises a vortex end plate and a vortex blade arranged on one end face of the vortex end plate. At least one oil storage hole is formed in the end face of the vortex blade, the oil storage holes are formed in the high-pressure sectionof the vortex blade, and the hole diameter of the oil storage holes is smaller than the thickness wall of the vortex blade. The vortex compressor vortex plate is adopted in the compressor, and the compressor adopting the vortex compressor vortex plate is adopted in the air conditioner. Compared with the prior art, after the oil storage holes are additionally formed in the end face of the high-pressure section of the vortex blade of the scroll compressor vortex plate, the heat deformation influences of the vortex blade can be reduced, the lubricating capability is improved, the temperature of the high-pressure section and the center is effectively reduced, the problem of abnormal reliability caused by the thermal deformation of the center of the existing molded line can be lowered, and thehigh-temperature-resisting use capability of the electric compressor is improved.

Owner:ZHUHAI LANDA COMPRESSOR +1

Device for measuring thermal elongation of ram based on material thermal elongation difference characteristics

ActiveCN103624631BEliminate the effects of thermal deformationSmall heat transfer gradientMeasurement/indication equipmentsMeasurement deviceThermal expansion

The invention provides a device for measuring thermal elongation of a ram based on a texture thermal elongation difference property. According to the device, a bonding point of a ram shell and a screw rod set is arranged at the fixed rear end of the ram. The device is structurally characterized in that the rear end of the ram is joined with the rear end of an aluminum pipe; the aluminum pipe and the front end of a steel rod are joined on a fixed part of the aluminum pipe and the steel rod; the rear end of the steel rod is connected with a measuring device; a design is that the thermal expansion coefficient of aluminum is two times as much as that of steel; when the temperature is changed, the ram shell extends for one thermal elongation unit along the positive direction, the aluminum pipe extends for two times along the positive direction and the steel rod is moved for two times along the positive direction; however, the steel rod extends for one thermal elongation unit along the negative direction and the sum of the thermal elongation unit and the thermal elongation of the ram is equal to the thermal elongation amount of the aluminum pipe; a reference object of the thermal displacement of the ram is compounded; and a numerical value collected by the measuring device at the rear end of the steel rod is the thermal displacement of the ram, so that expensive mark post invar steel is replaced and the production cost of equipment is reduced obviously.

Owner:沈阳机床中捷友谊厂有限公司

Pressure-sensitive acrylic acid thermally conductive adhesive, preparation method for same and application thereof

InactiveCN102433092BImprove performanceStable three-dimensional heat conduction structureNon-macromolecular adhesive additivesFilm/foil adhesivesCarbon fibersIn situ polymerization

Owner:HISENSE VISUAL TECH CO LTD

Substrate-free pressure-sensitive acrylic thermal conductive adhesive, preparation method and application thereof

InactiveCN102391799BWeaken the "cluster phenomenon"Reduce clusteringNon-macromolecular adhesive additivesFilm/foil adhesivesFiberCarbon fibers

Owner:HISENSE VISUAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com