A Cooler for Large Diameter Hypersonic Wind Tunnel

A hypersonic, cooler technology, used in the testing of instruments, machines/structural components, measuring devices, etc., can solve the problems of large volume, inability to block, and difficulty in transportation and installation, to ensure the flow area, Reduced pressure loss and easy procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

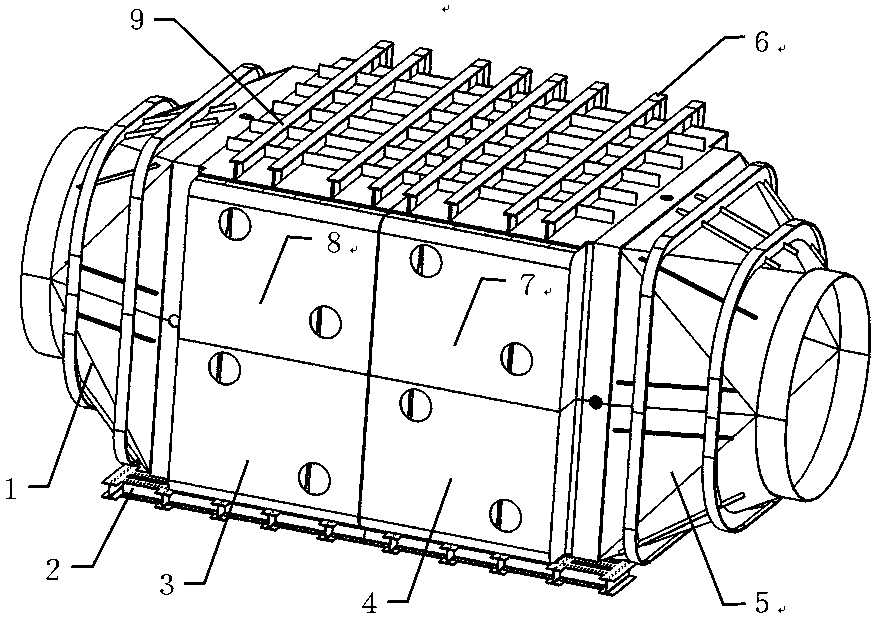

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings.

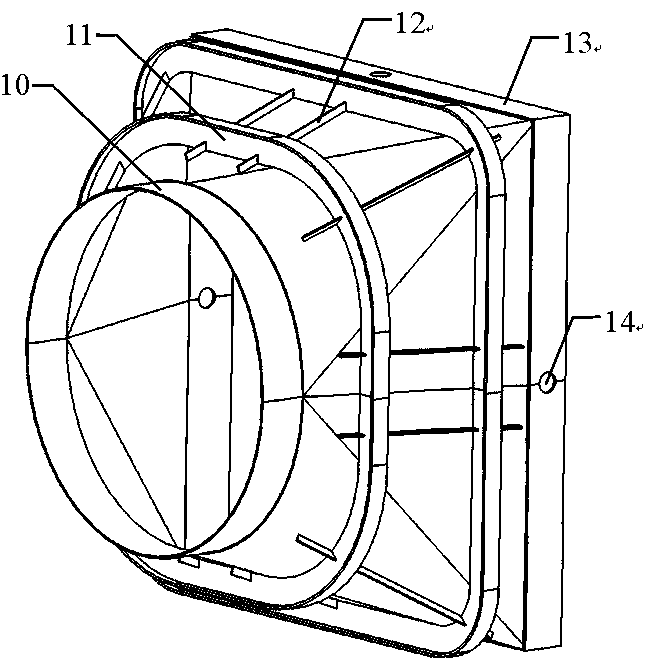

[0037] Such as figure 1As shown, the cooler for a large-diameter hypersonic wind tunnel includes a front transition section 1, a tube box, a base 2, a rear transition section 5, a side shell 6, and an upper shell 9; the tube box is placed on the base 2 , the upper surface of the pipe box is welded to the upper shell 9, the front end of the pipe box is welded to the transition section square interface 13 of the front transition section 1, the rear end of the pipe box is welded to the square interface of the rear transition section 5; the left side of the pipe box is fixed Water tank, the right side of the pipe box is an active water tank, the side shell 6 covers the outer surface of the active water tank and leaves a gap with the active water tank, and the side shell 6 and the upper shell 9 are welded at the joint;

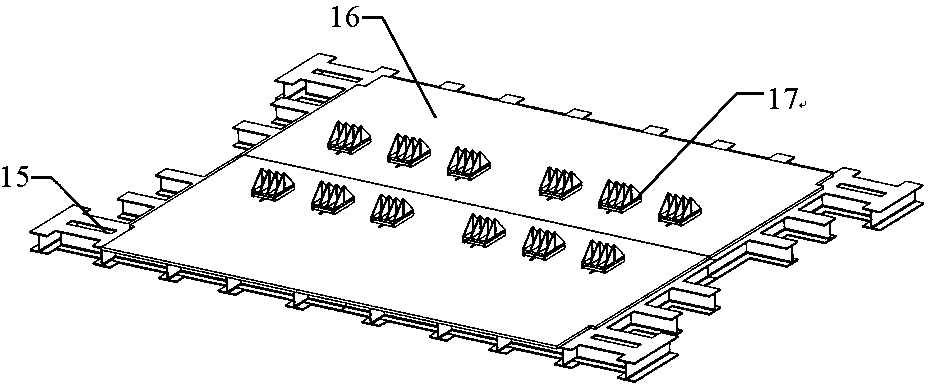

[0038] The pipe box is composed of an array of pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com