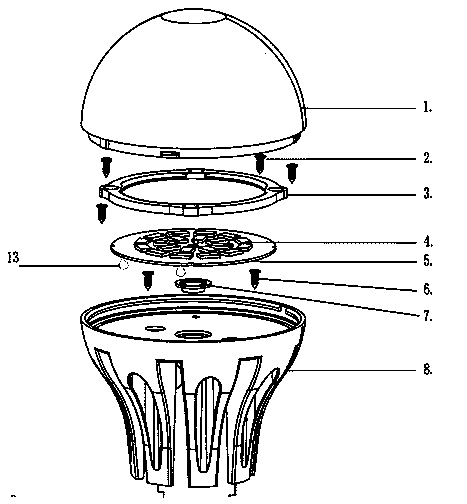

Novel LED lamp

An LED lamp, a new type of technology, used in adhesive types, cooling/heating devices for lighting devices, lighting and heating equipment, etc. Reduce the influence of thermal deformation, facilitate the conduction of heat, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 1) 0.05kg initiator and 5kg solvent are mixed into initiator solution;

[0064] 2) 10kg heat conducting agent, 60kg parts by weight of monomer and solvent of 75kg parts by weight are prepared into monomer solution;

[0065] 3) Then add the initiator solution dropwise to the monomer solution at 70-90°C to carry out in-situ polymerization, the initiator solution in the polymerization reaction is added dropwise several times, and the time interval between each two drops is 0.5 hours , adding 1 / 6 of the total amount each time. After the dropwise addition, continue to react for 0.5-2 hours to obtain a thermally conductive adhesive solution;

[0066] 4) It is obtained by removing the solvent from the thermally conductive adhesive solution.

[0067] The LED lamp coated with heat-conducting adhesive was tested to evaluate the heat conduction effect, and the temperature of the temperature measurement point was 63.1°C.

Embodiment 2

[0069] 1) 0.7kg initiator and 50kg solvent are mixed into initiator solution;

[0070] 2) Prepare 40kg heat transfer agent, 90kg monomer and 200kg solvent to make monomer solution;

[0071] 3) Then add the initiator solution dropwise to the monomer solution at 70-90°C to carry out in-situ polymerization reaction. After the dropwise addition, continue the reaction for 2 hours. The time interval between the two drops is 0.5-2 hours, and the total amount of 14 is added each time to obtain the thermally conductive adhesive solution;

[0072] 4) It is obtained by removing the solvent from the thermally conductive adhesive solution.

[0073] The thermal conductivity test was carried out with the aforementioned method, and the temperature of the temperature measurement point was 64.7°C.

Embodiment 3

[0075] 1) 0.1kg initiator and 10kg solvent are mixed into initiator solution;

[0076] 2) Prepare 15kg heat transfer agent, 80kg monomer and 75kg solvent to make monomer solution;

[0077] 3) Then add the initiator solution dropwise to the monomer solution at 70-90°C to carry out in-situ polymerization, the initiator solution in the polymerization reaction is added dropwise several times, and the time interval between each two drops is 0.5 hours , add 1 / 3 of the total amount dropwise each time, after the dropwise addition is completed, continue to react for 0.5-2 hours to obtain a thermally conductive adhesive solution;

[0078] 4) It is obtained by removing the solvent from the thermally conductive adhesive solution.

[0079] The thermal conductivity test was carried out with the aforementioned method, and the temperature of the temperature measurement point was 66.7°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com