Water-soluble gold and silver inks, and preparation method

A water-soluble, gold-and-silver technology, applied in inks, household utensils, applications, etc., can solve the problems of non-toxic, tasteless, waterproof, and mildew-proof inks, and achieve the effect of simple material application process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

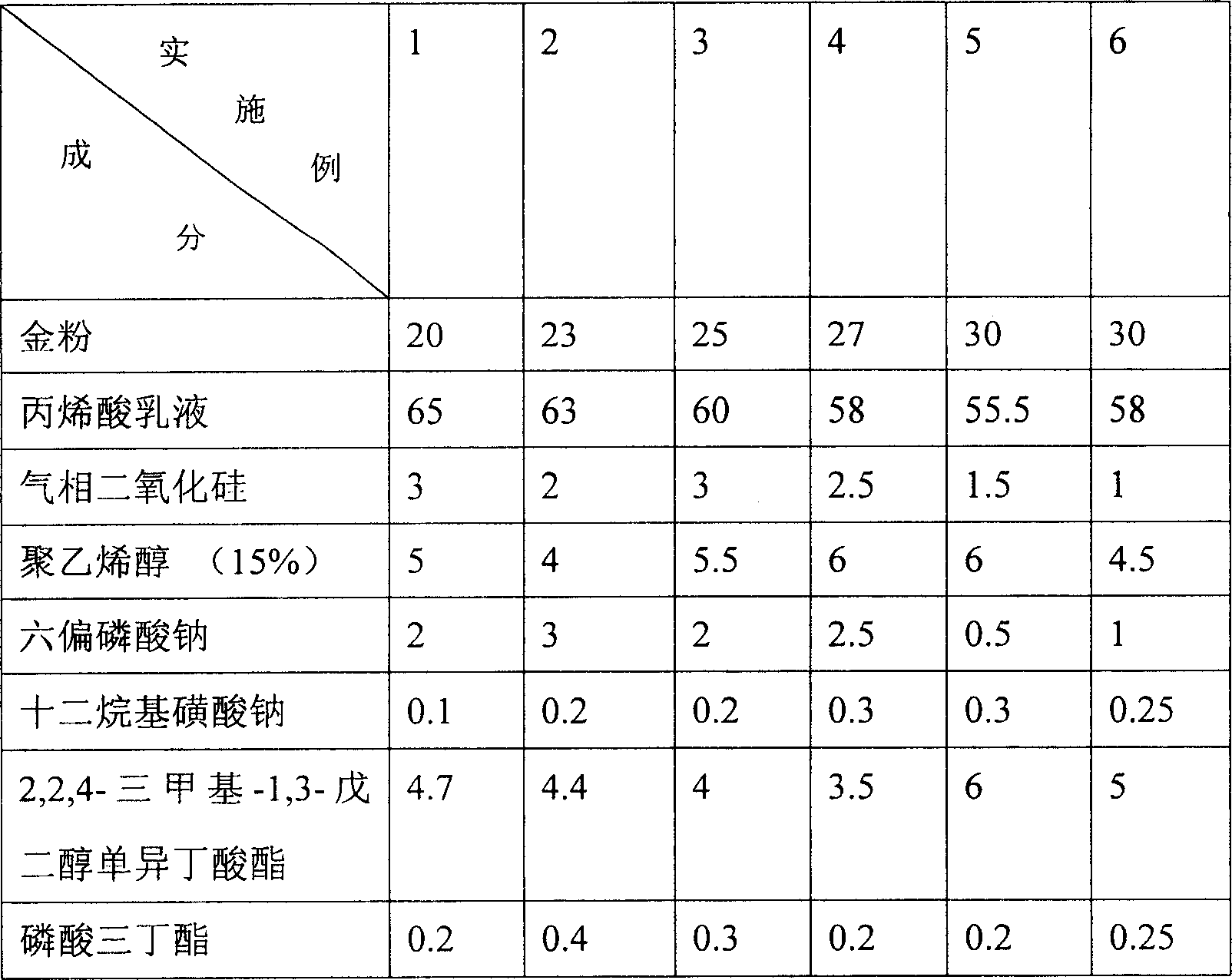

Embodiment 1-6

[0040]

[0041]

Embodiment 7-12

[0043]

[0044] silver powder

20

23

25

27

30

30

acrylic emulsion

65

63

60

58

55.5

58

3

2

3

2.5

1.5

1

Polyvinyl alcohol (15%)

5

4

5.5

6

6

4.5

Hexametaphosphate

2

3

2

2.5

0.5

1

0.1

0.2

0.2

0.3

0.3

0.25

2,2,4-Trimethyl-1,3-pentane

Glycol monoisobutyrate

4.7

4.4

4

3.5

6

5

0.2

0.4

0.3

0.2

0.2

0.25

[0045] The water-soluble gold and silver ink waterproof anti-seepage mechanism of the present invention is as follows: the acrylic resin that exists in the emulsifier is compounded with nano-scale silicon dioxide to form a colloid, and this colloid is mixed with gold and silver powder and various auxiliary agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com