Application of activated aluminum oxide defluorination adsorbing material with different surface features

A surface feature and adsorption material technology, applied in the direction of adsorption water/sewage treatment, other chemical processes, combustible gas purification, etc., can solve the problems of difference in fluoride ion adsorption effect, large reactor, high project investment, etc., to achieve improved fluorine removal adsorption The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

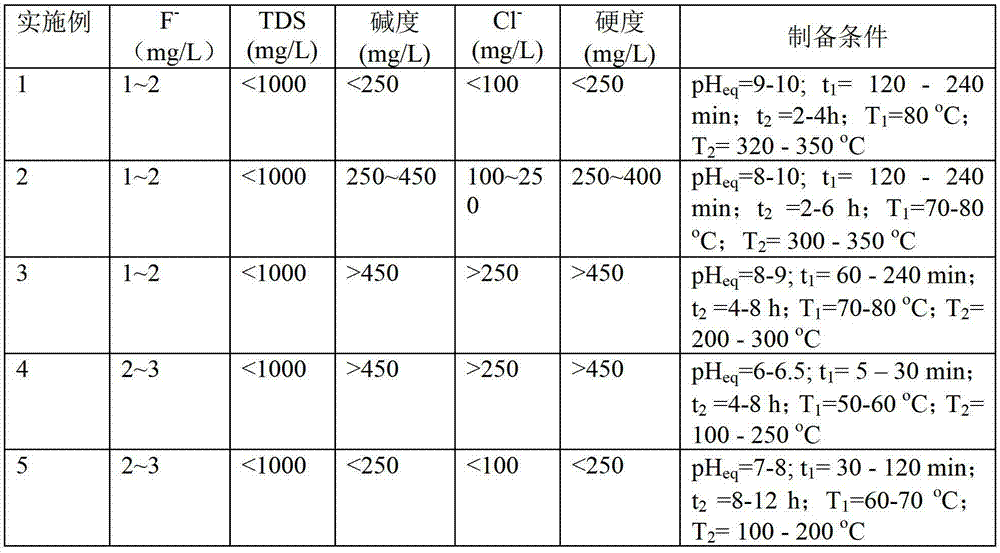

[0048] Fluorine (F - ) concentration, total dissolved solids (TDS), alkalinity, Cl - Concentration, hardness and other different water quality chemical characteristics, determined the specific process parameters for the preparation of active aluminum oxide fluorine removal adsorption materials with different surface characteristics, as shown in Table 1:

[0049] Table 1

[0050]

[0051] The preparation method of the active aluminum oxide fluorine removal adsorption material with different surface characteristics is as follows:

[0052] (1) The prepared concentration is 12Kg / m 3 Al 2 (SO 4 ) 3 Aqueous solution with a concentration of 0.5Kg / m 3 NaCl aqueous solution is mixed to obtain Al 2 (SO 4 ) 3 An aqueous solution mixed with NaCl (the molar ratio of aluminum to chlorine in the mixed aqueous solution is 8.2:1), and the concentration is 2.5Kg / m 3 NaOH aqueous solution; under the condition of full stirring, slowly add NaOH aqueous solution to Al 2 SO 4 Fully mi...

Embodiment 6

[0057] Fluorine (F - ) concentration is 1~2mg / L, total dissolved solids (TDS) is 450mg / L, Cl - The concentration is >250mg / L, the hardness is >450mg / L, according to the water quality conditions, the preparation conditions of active aluminum oxide fluorine removal adsorption materials with different surface characteristics are as follows:

[0058] (1) The preparation concentration is 15Kg / m 3 KOH aqueous solution; the prepared concentration is 1Kg / m 3 MgCl 2 Aqueous solution and 20Kg / m 3 AlCl 3 aqueous solution is mixed to obtain MgCl 2 and AlCl 3 Mixed aqueous solution (the molar ratio of aluminum to chlorine in the mixed aqueous solution is 0.32:1); under fully stirred conditions, slowly add KOH aqueous solution to MgCl 2 and AlCl 3 Fully mix in the mixed aqueous solution to obtain a reaction system, and slowly add the KOH aqueous solution to the MgCl 2 and AlCl 3 Monitor the pH value of the reaction system during the mixing of the mixed aqueous solution, when the e...

Embodiment 7

[0063] Fluorine (F - ) concentration is 2~3mg / L, total dissolved solids (TDS) is - The concentration is <100mg / L, and the hardness is <250mg / L. According to the water quality conditions, the preparation conditions of active aluminum oxide fluorine removal adsorption materials with different surface characteristics are as follows:

[0064] (1) The preparation concentration is 15Kg / m 3 KOH aqueous solution; the prepared concentration is 1Kg / m 3 MgCl 2 Aqueous solution and 20Kg / m 3 AlCl 3 aqueous solution is mixed to obtain MgCl 2 and AlCl 3 Mixed aqueous solution (the molar ratio of aluminum element to chlorine element in the mixed aqueous solution is 0.32:1); under the condition of full stirring, MgCl 2 and AlCl 3 The mixed aqueous solution is slowly added to the KOH aqueous solution and fully mixed to obtain a reaction system, and the MgCl 2 and AlCl 3 The mixed aqueous solution is slowly added to the KOH aqueous solution and the pH value of the reaction system is mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com