Patents

Literature

544 results about "Pre stretching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-layer, elastic articles

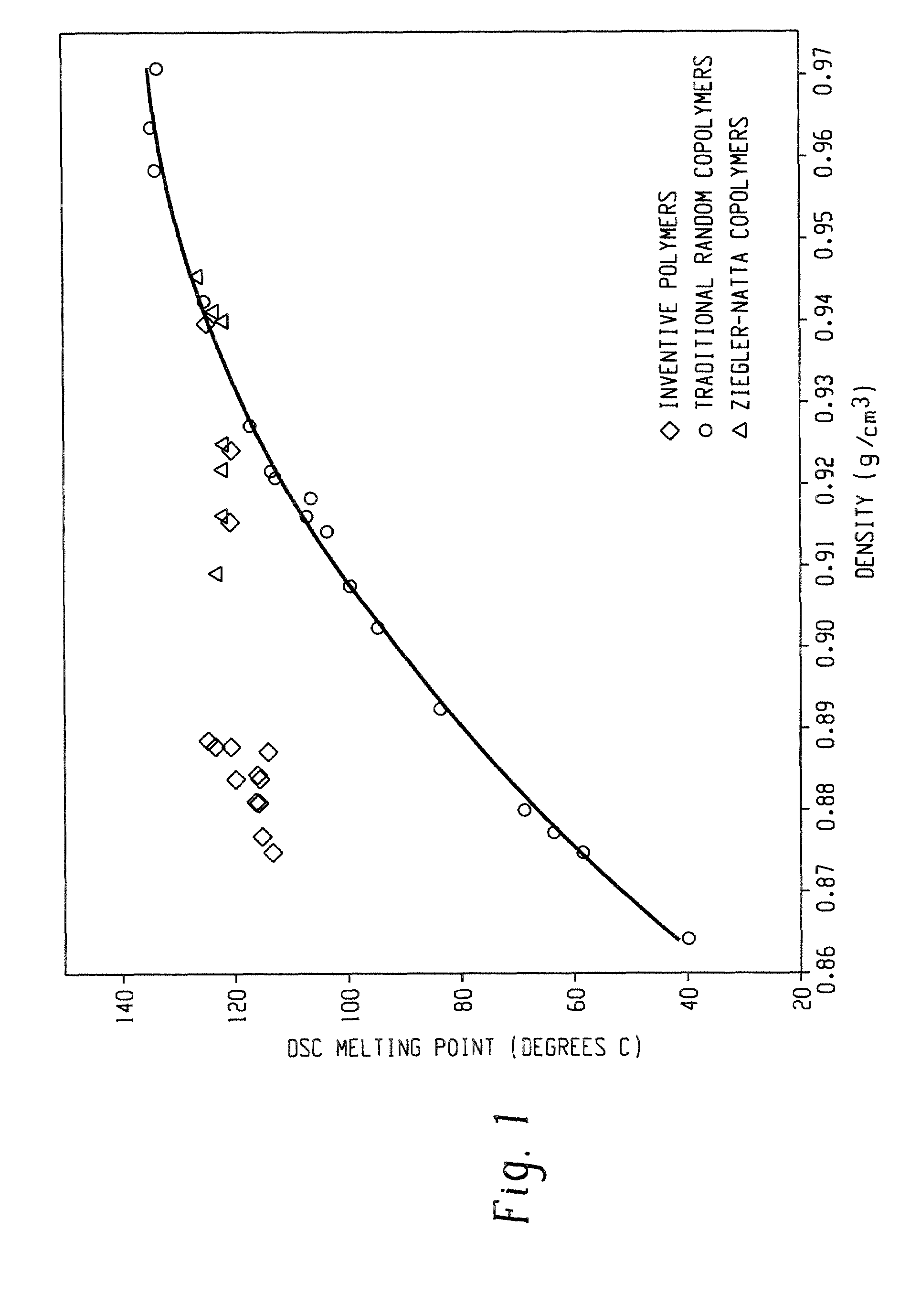

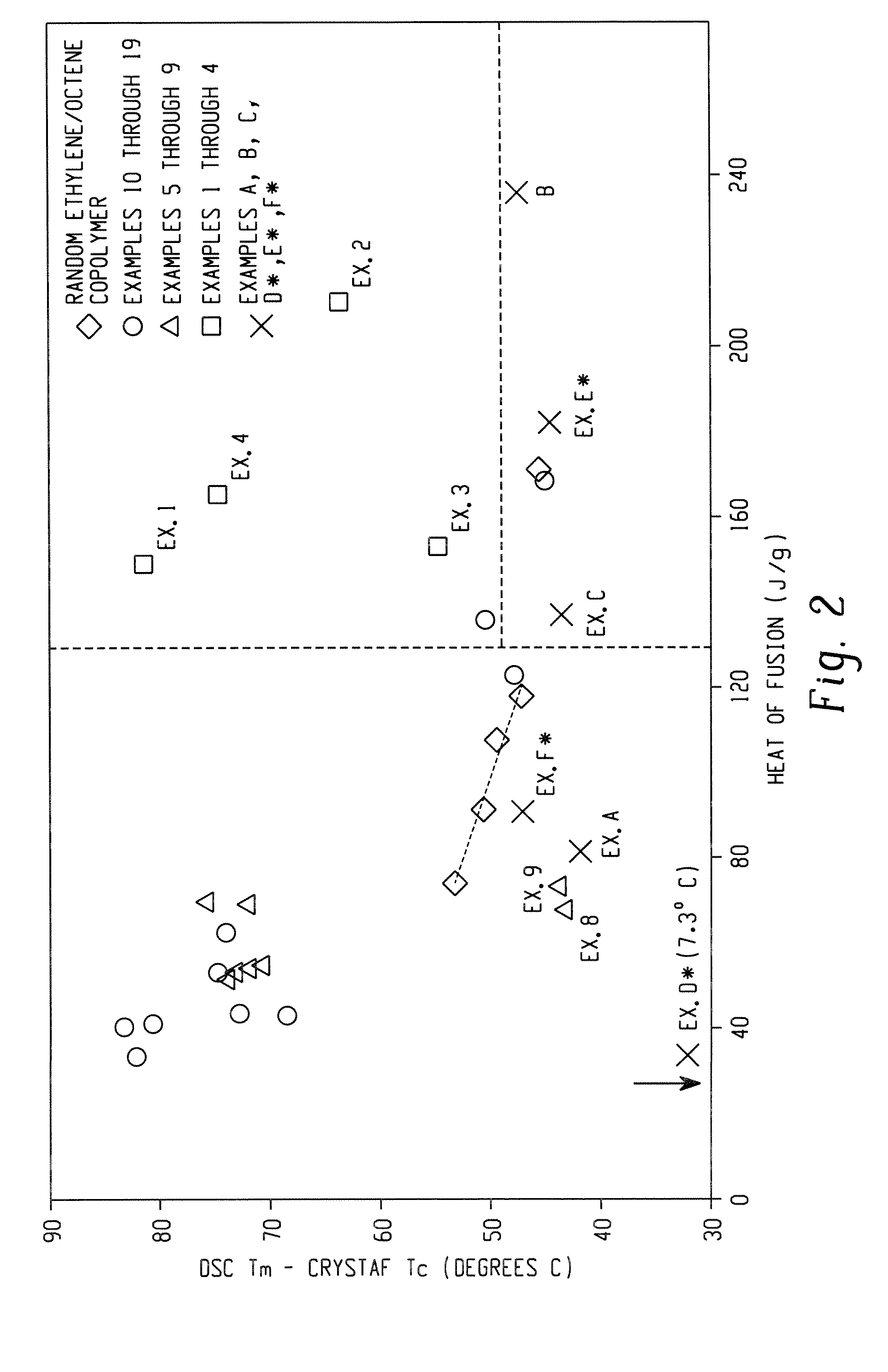

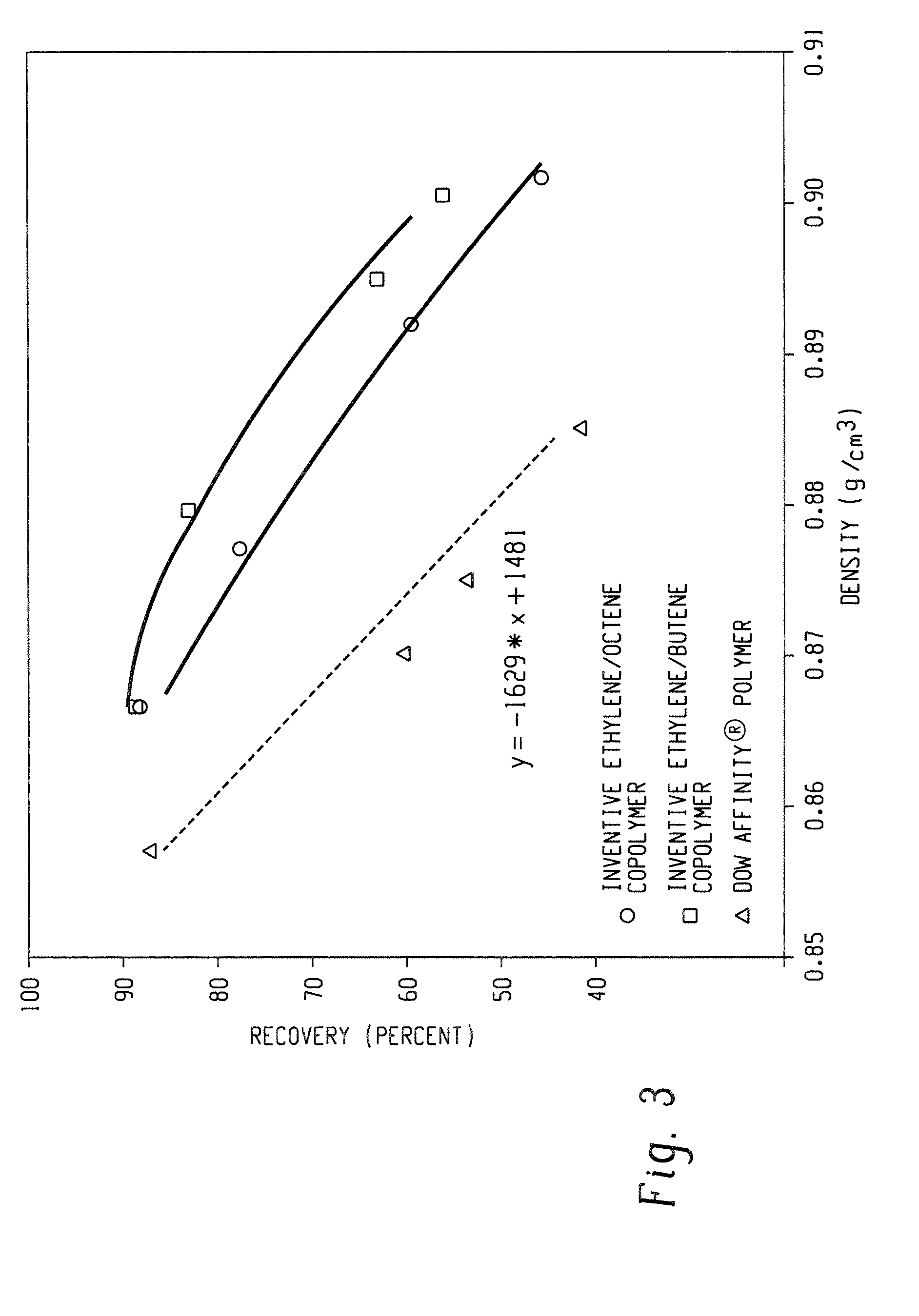

The invention is an article comprising at least two layers, a low crystallinity layer and a high crystallinity layer. One or both layers is capable of being elongated so that a pre-stretched article is capable of being formed.

Owner:DOW GLOBAL TECH LLC

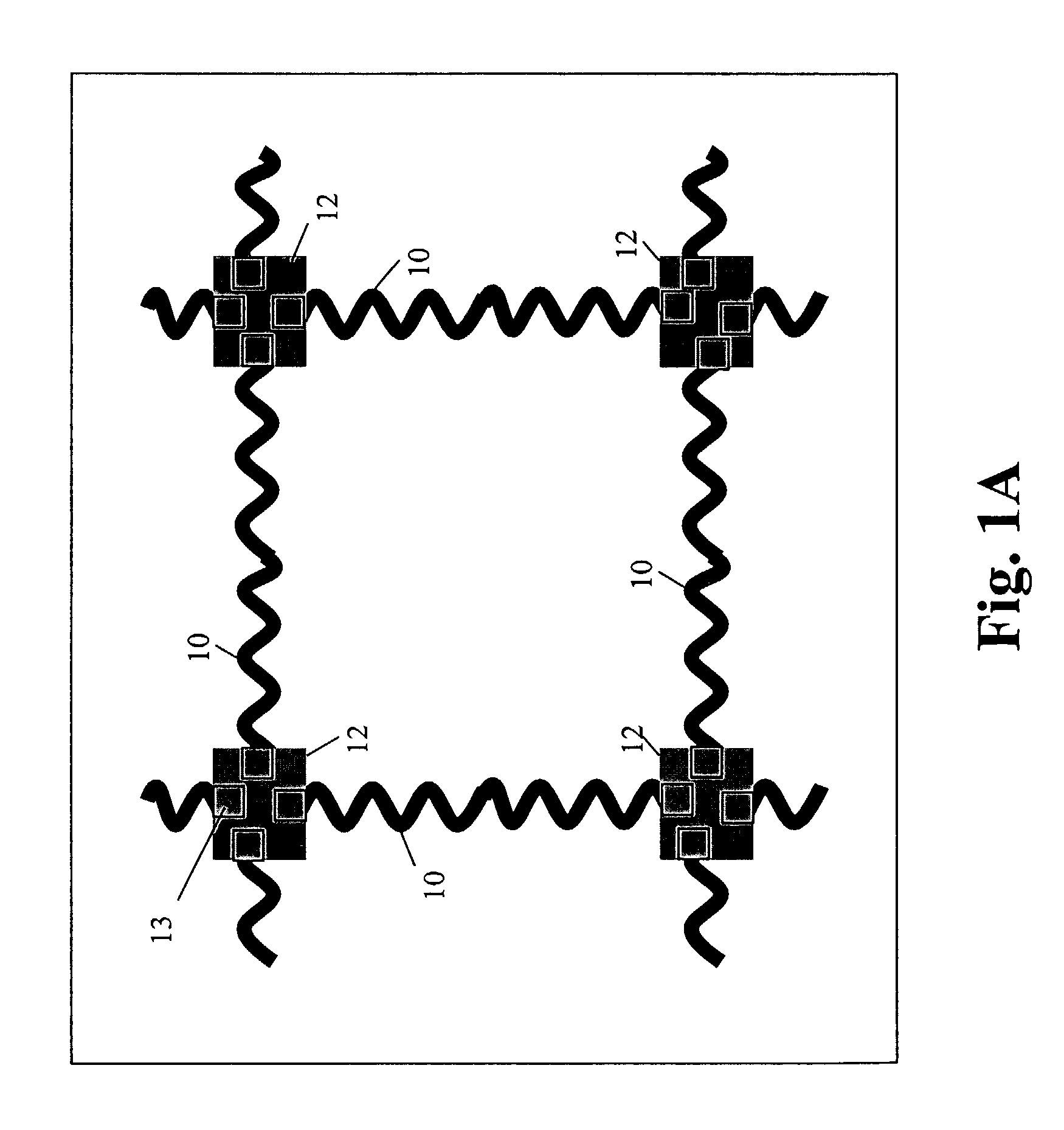

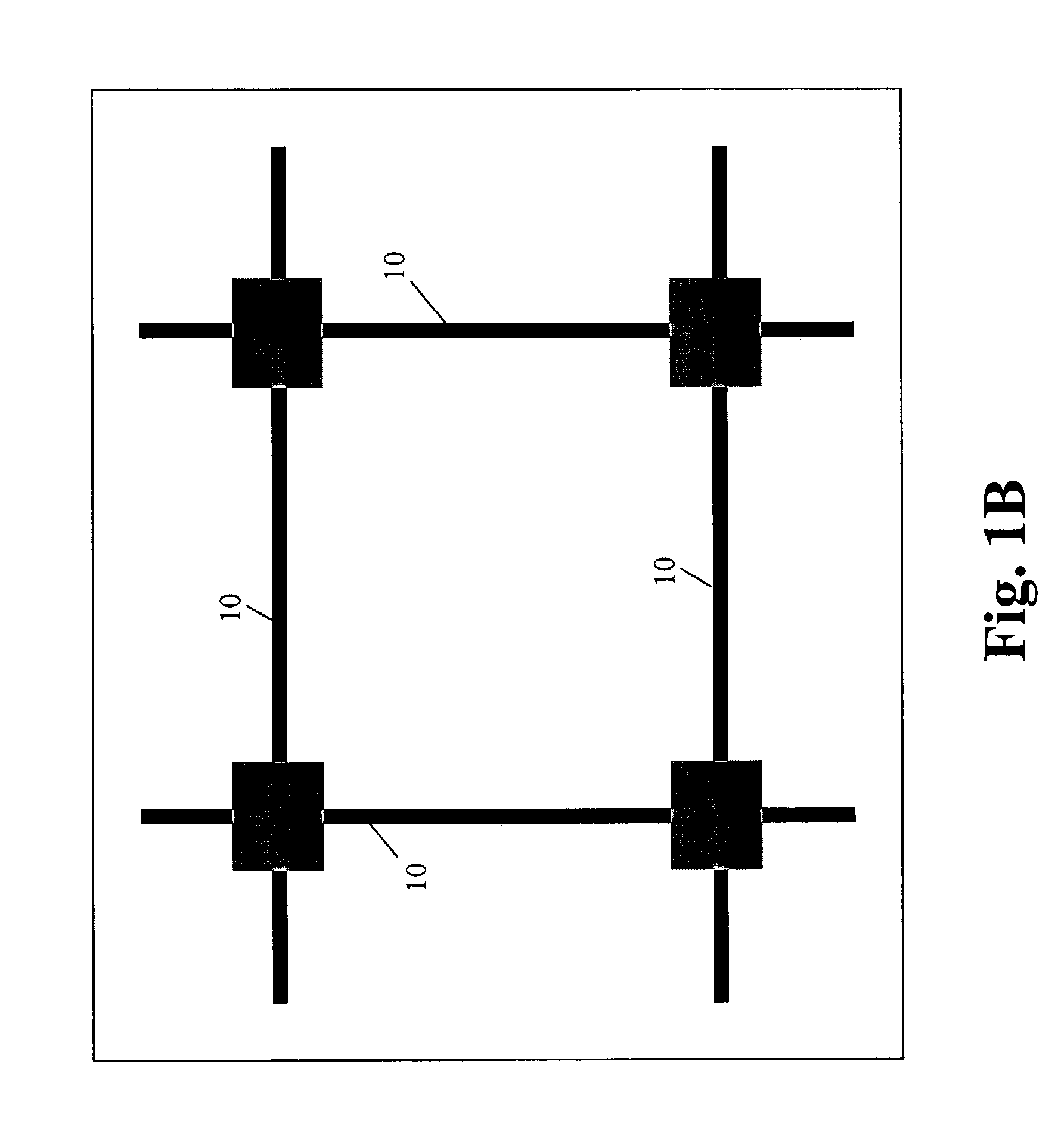

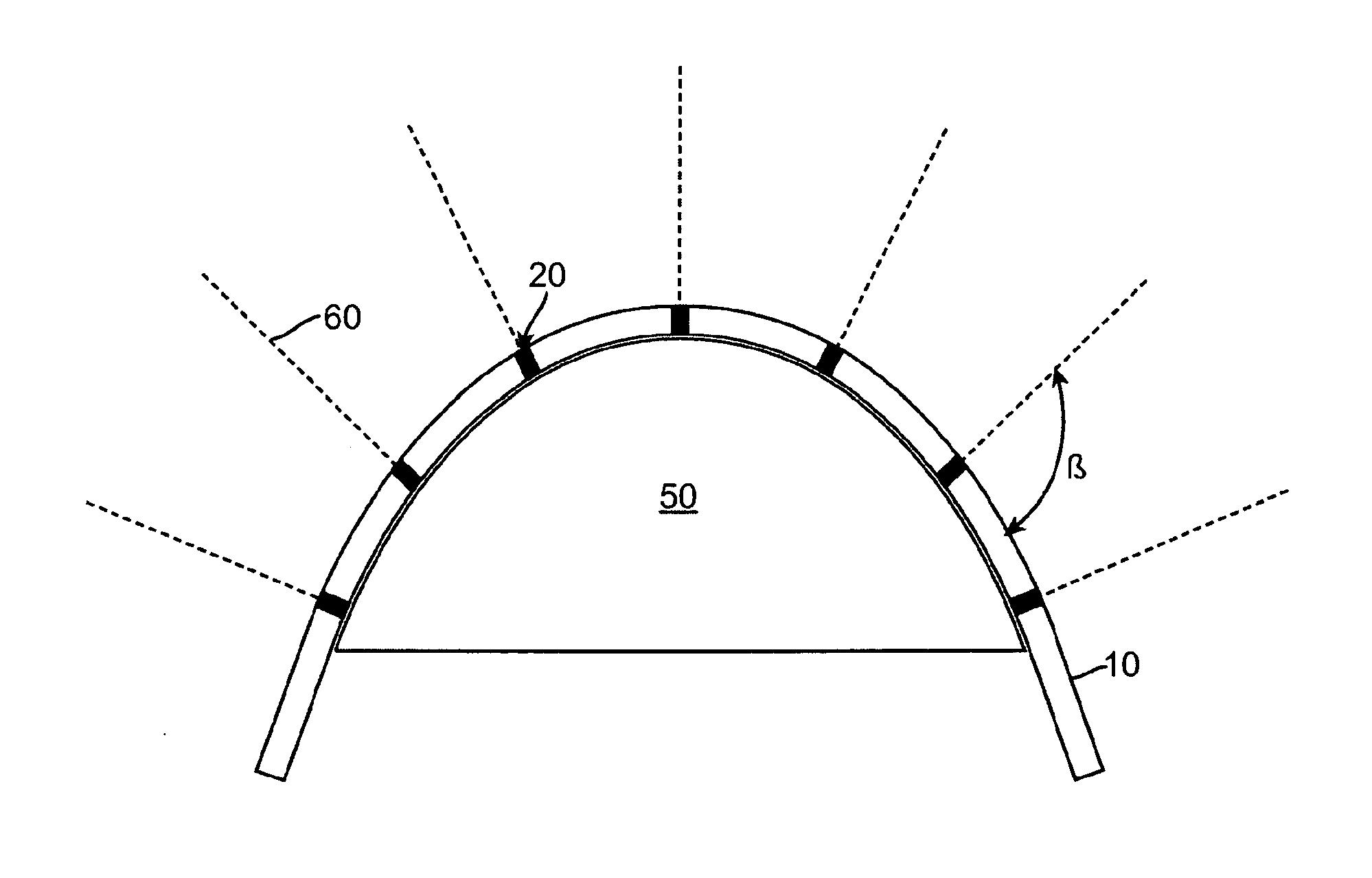

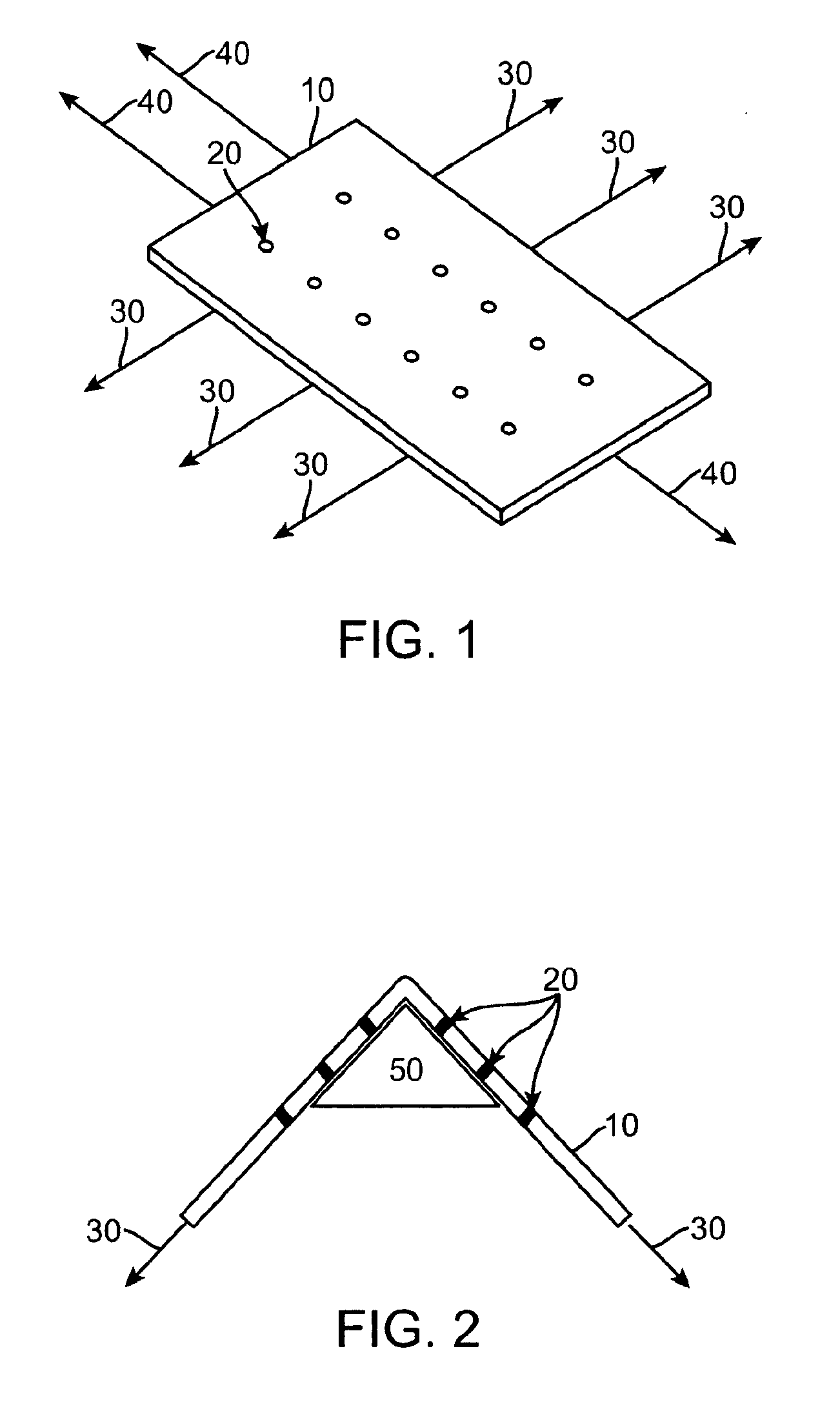

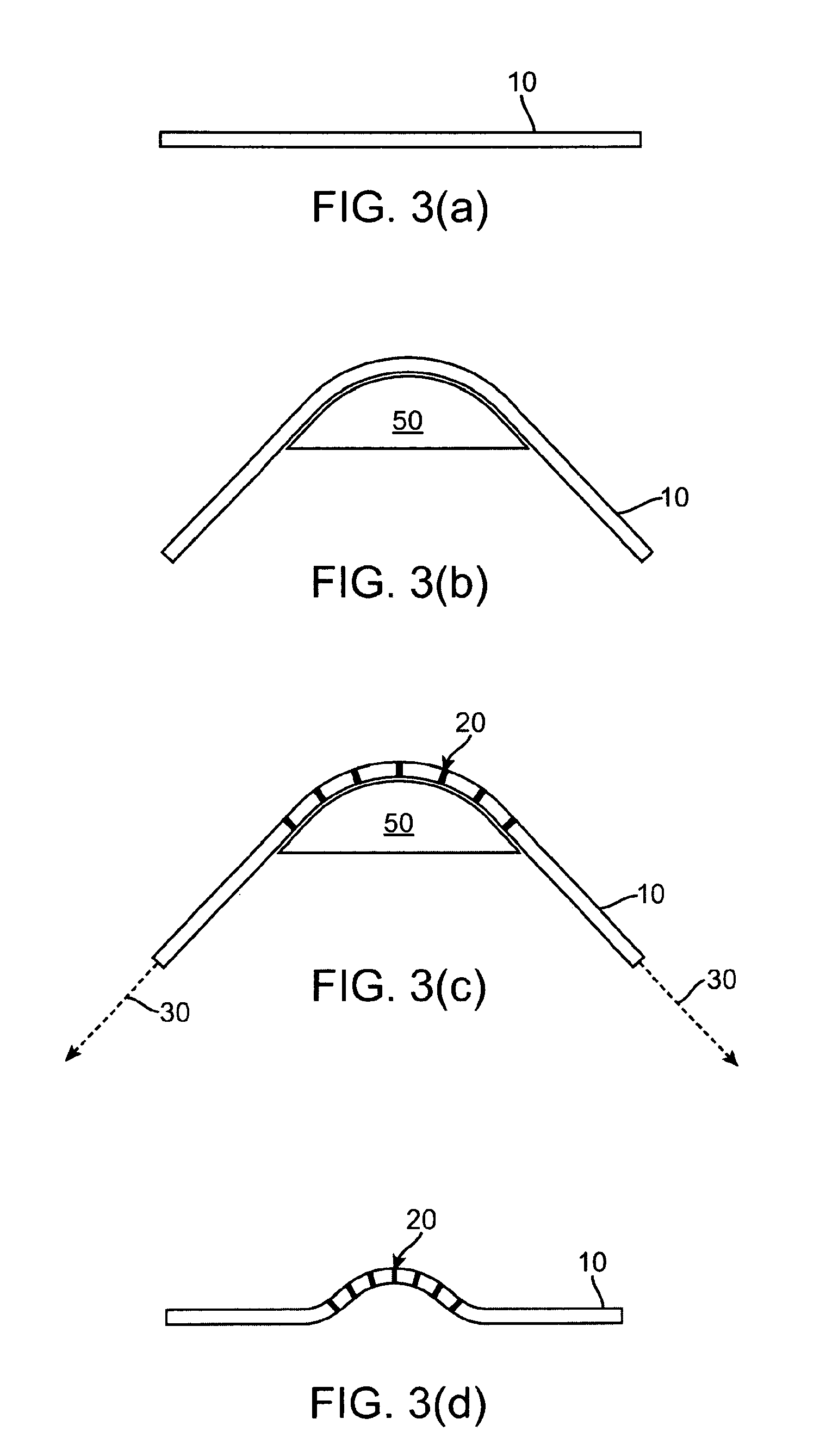

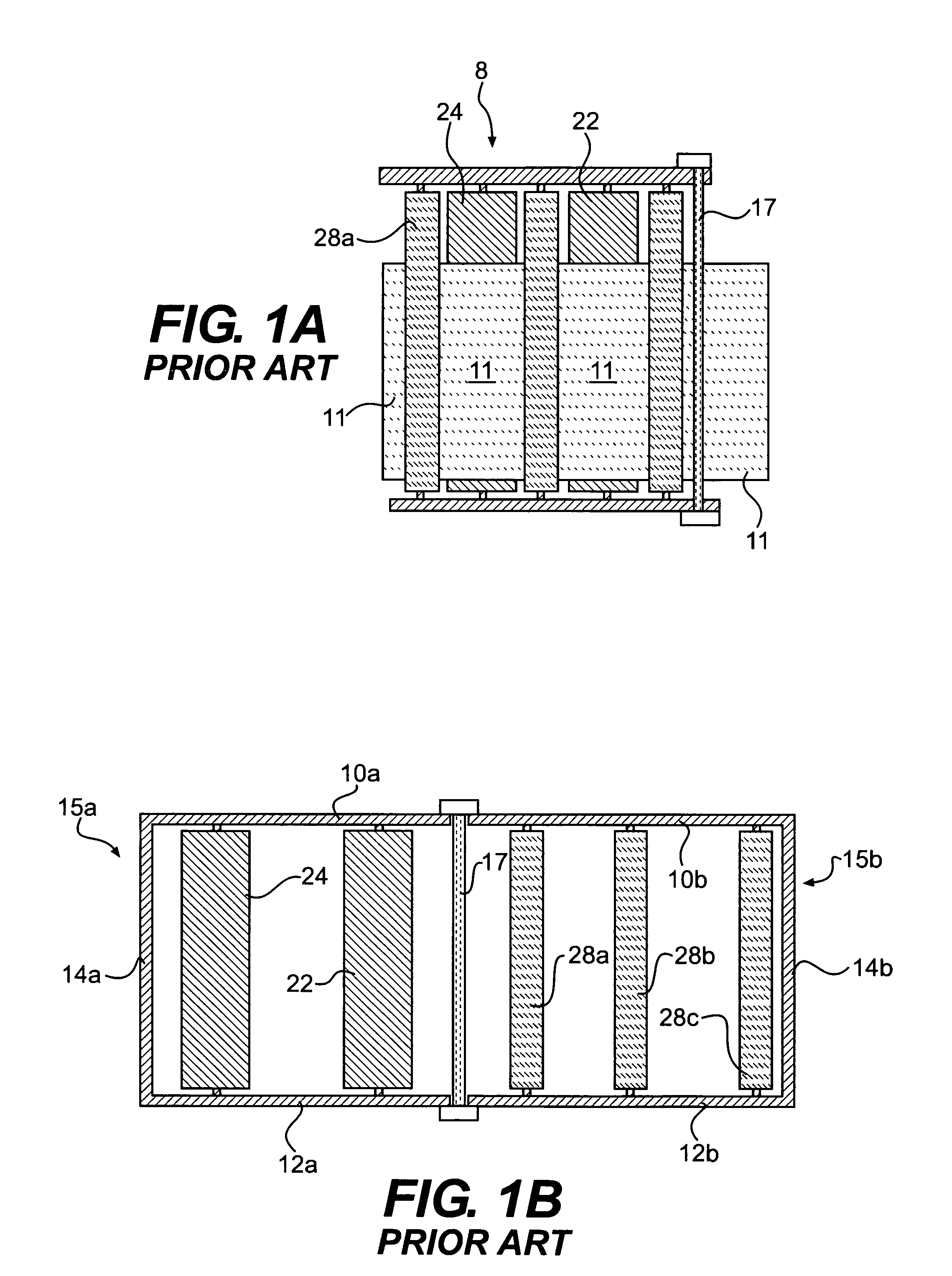

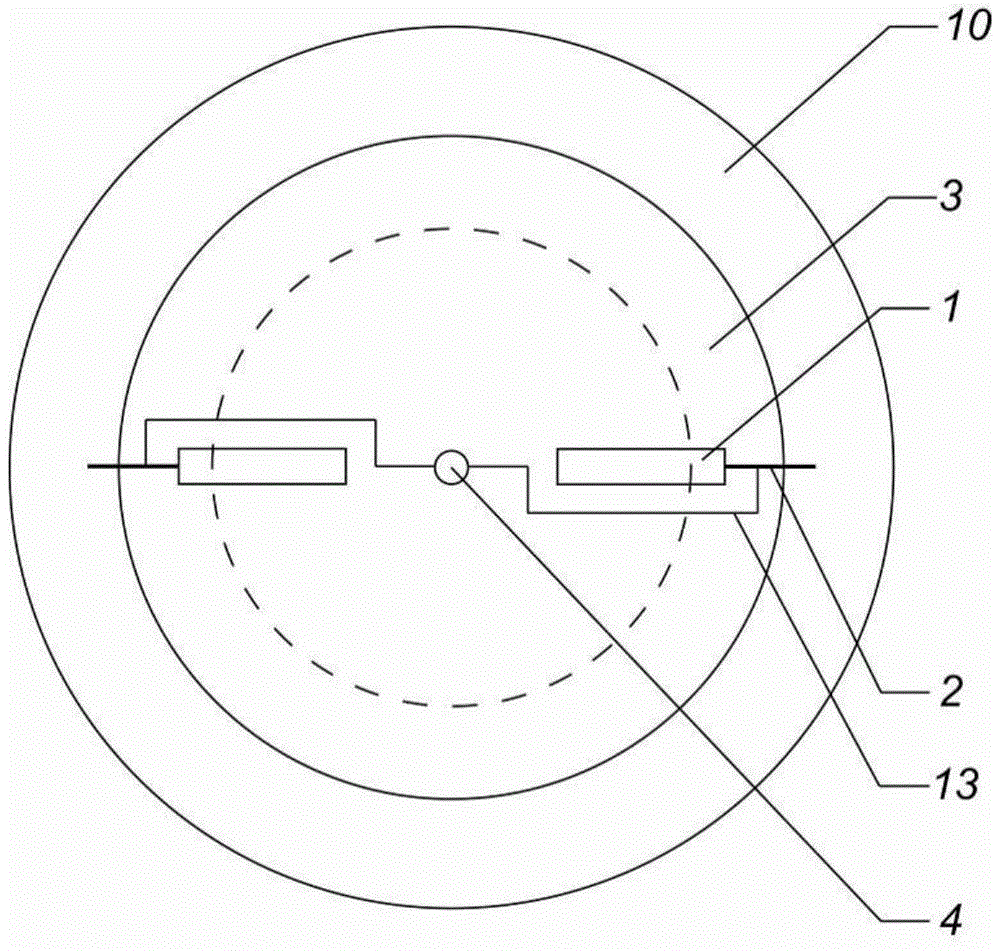

Stretchable and elastic interconnects

InactiveUS7491892B2Reduce mechanical stressSave spaceCircuit bendability/stretchabilityTwo-part coupling devicesElastomerPlastic materials

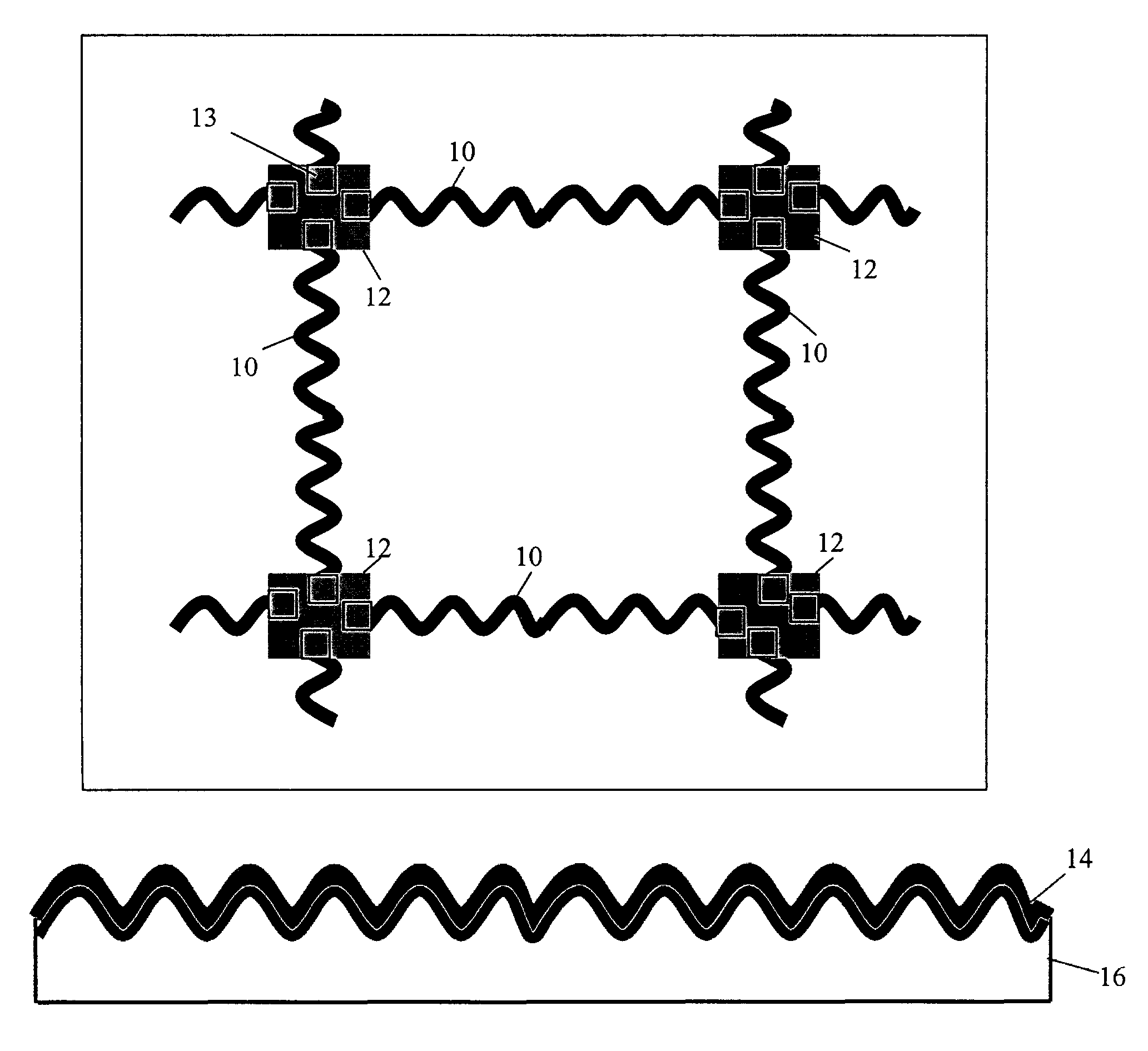

The present invention relates to stretchable interconnects which can be made in various geometric configurations, depending on the intended application. The stretchable interconnects can be formed of an electrically conducting film or an elastomer material to provide elastic properties in which the interconnects can be reversibly stretched in order to stretch and relax the elastomer material to its original configuration. Alternatively, stretchable interconnects can be formed of an electrically conducting film or a plastic material to provide stretching of the material to a stretched position and retaining the stretched configuration. The stretchable interconnect can be formed of a flat 2-dimensional conductive film covering an elastomeric or plastic substrate. When this structure is stretched in one or two dimensions, it retains electrical conduction in both dimensions. Alternatively, the stretchable and / or elastic interconnects can be formed of a film or stripe that is formed on an elastomeric or plastic substrate such that it is buckled randomly, or organized in waves with long-range periodicity. The buckling or waves can be induced by various techniques, including: release of built-in stress of the conductive film or conductive stripe; pre-stretching the substrate prior to the fabrication of the conductive film or conductive stripe; and patterning of the surface of the substrate prior to the fabrication of the metal film. The stretchable interconnect can be formed of a plurality of conductive films or conductive stripes embedded between a plurality of layers of a substrate formed of an elastomer or plastic.

Owner:PRINCETON UNIV

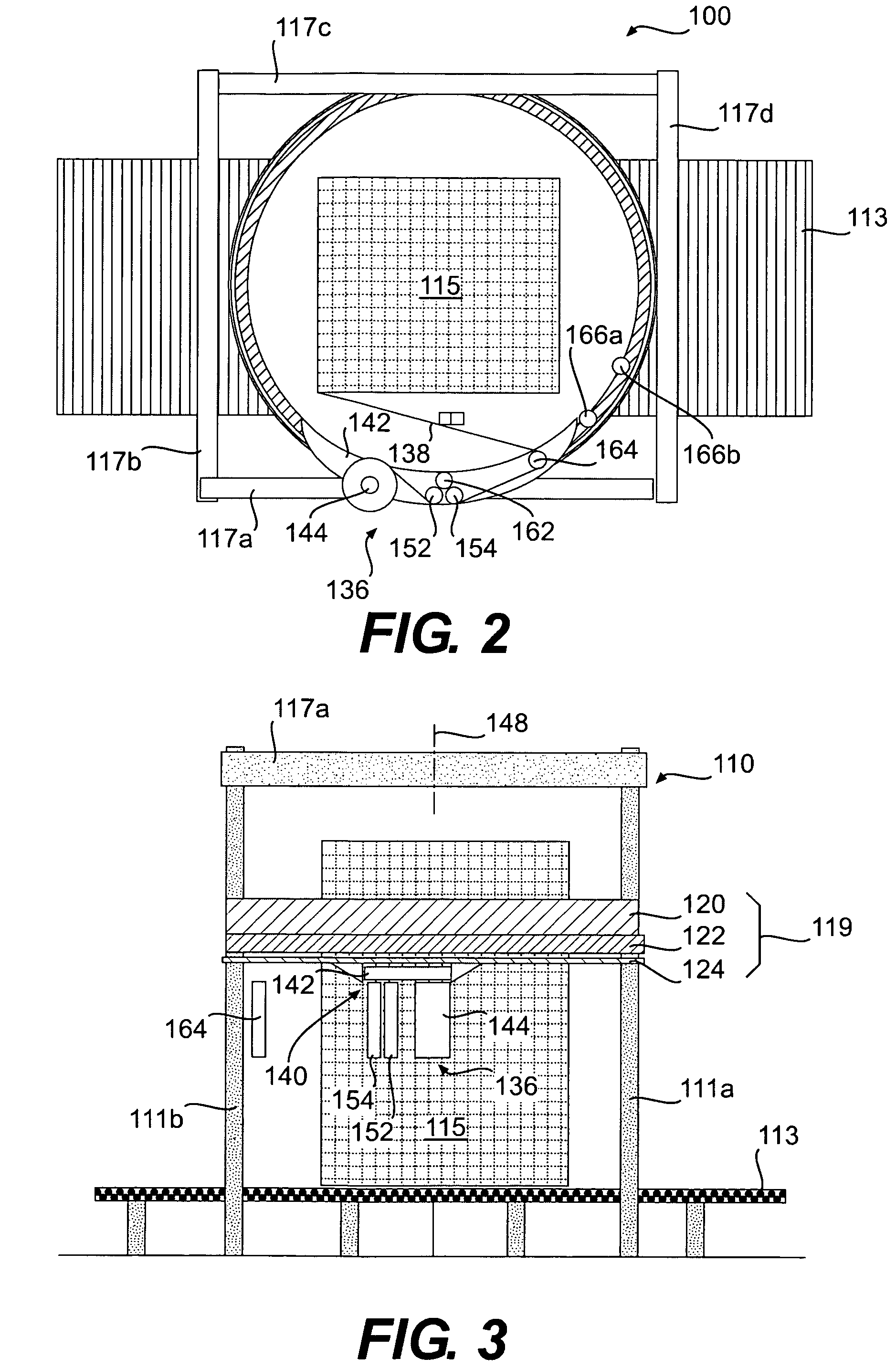

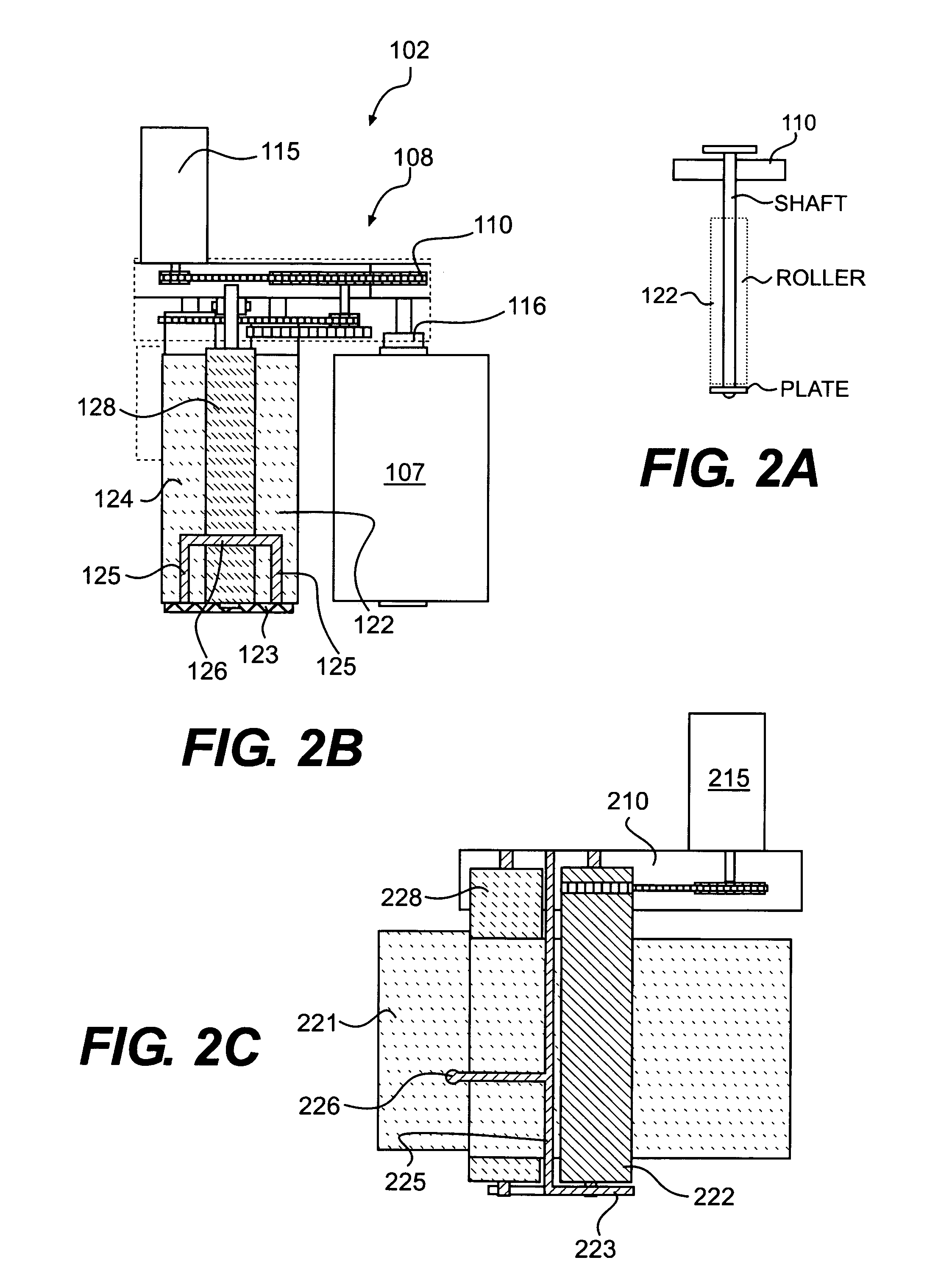

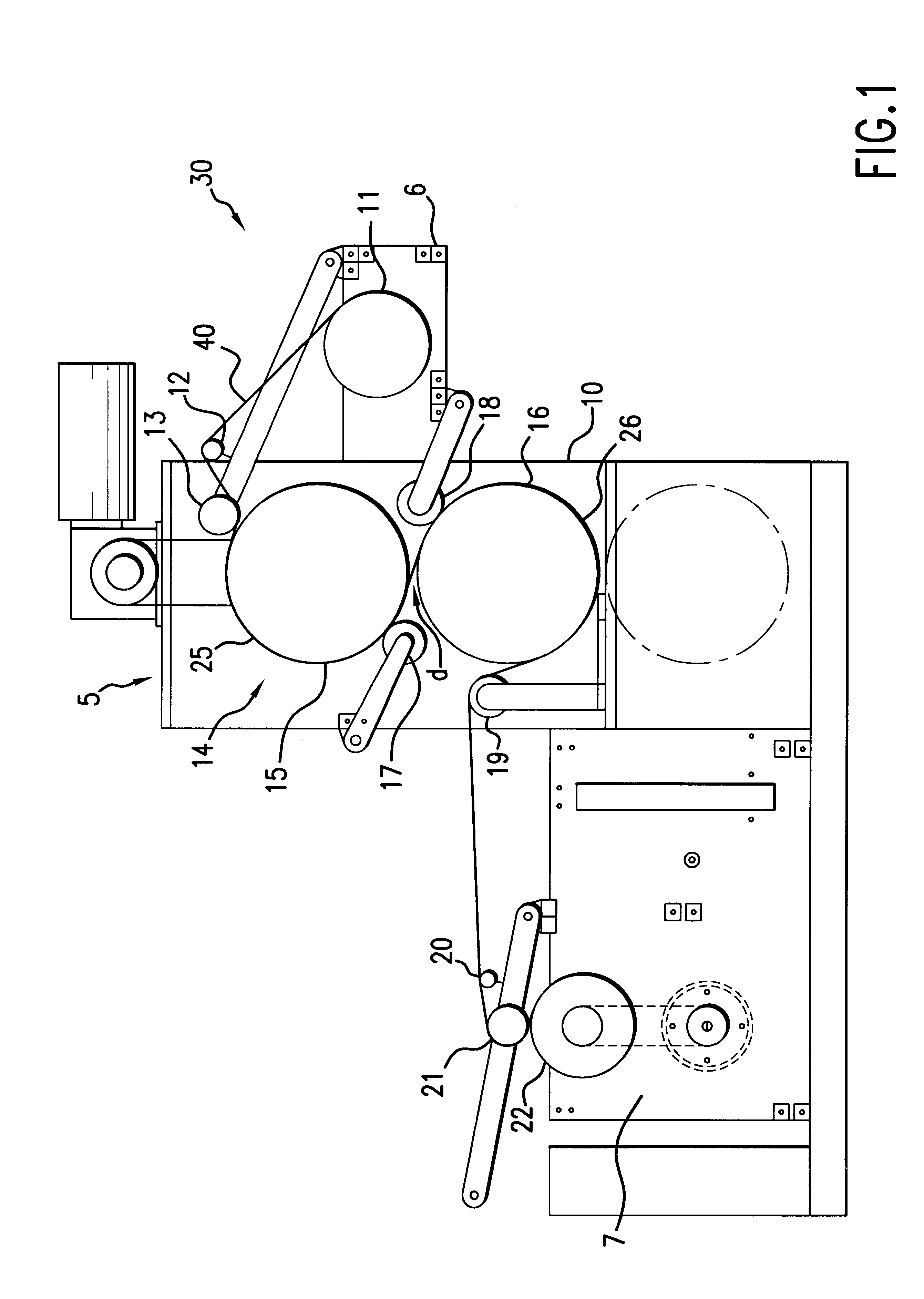

Method for dispensing a predetermined amount of film relative to load girth

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched film based upon load girth. A non-rotating ring carries a belt. A film dispenser is mounted on a rotating ring, and the rotating ring includes a pulley that connects to the belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched film to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum film use is obtained by dispensing a length of pre-stretched film that is between approximately 100% and approximately 130% of load girth. Once the amount of film to be dispensed per revolution is determined, a mechanical ratio of ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / ring rotation) can be set. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of film is dispensed and wrapped around the load.

Owner:LANTECH COM

Wrapping apparatus including metered pre-stretch film delivery assembly and method of using

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched packaging material based upon load girth. A non-rotating ring carries a belt driven by a motor. A packaging material dispenser is mounted on a rotating ring, and the rotating ring may include a pulley that connects to the band, such that the rotating ring is driven by the drive belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum packaging material use is obtained by dispensing a length of pre-stretched packaging material that is between approximately 90% and approximately 120% of load girth. Once the amount of packaging material to be dispensed per revolution is determined, a ratio of rotating ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / rotating ring rotation) can be set and mechanically controlled. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of packaging material is dispensed and wrapped around the load. In an alternative embodiment, the ratio is electronically controlled.

Owner:LANTECH COM

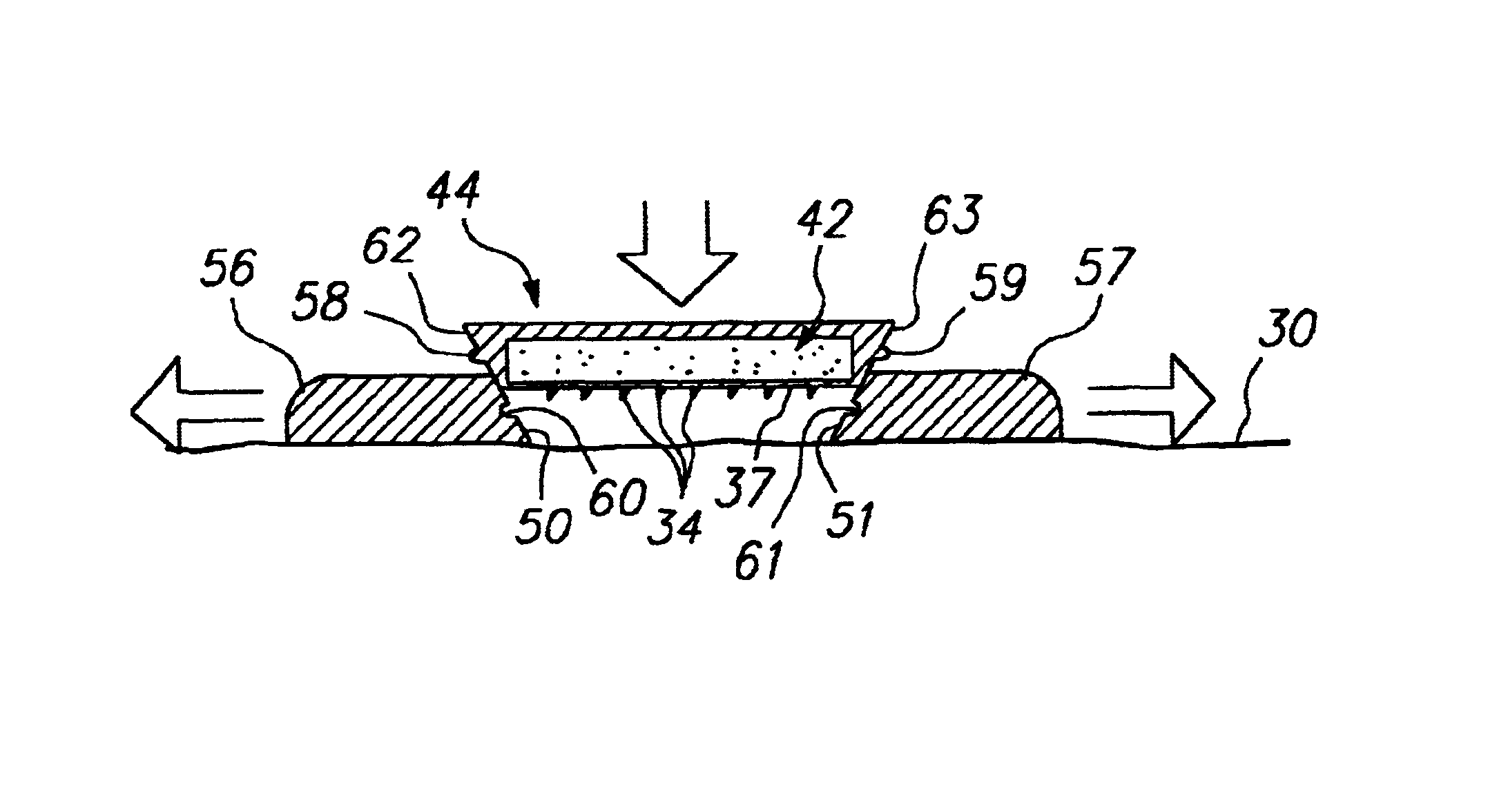

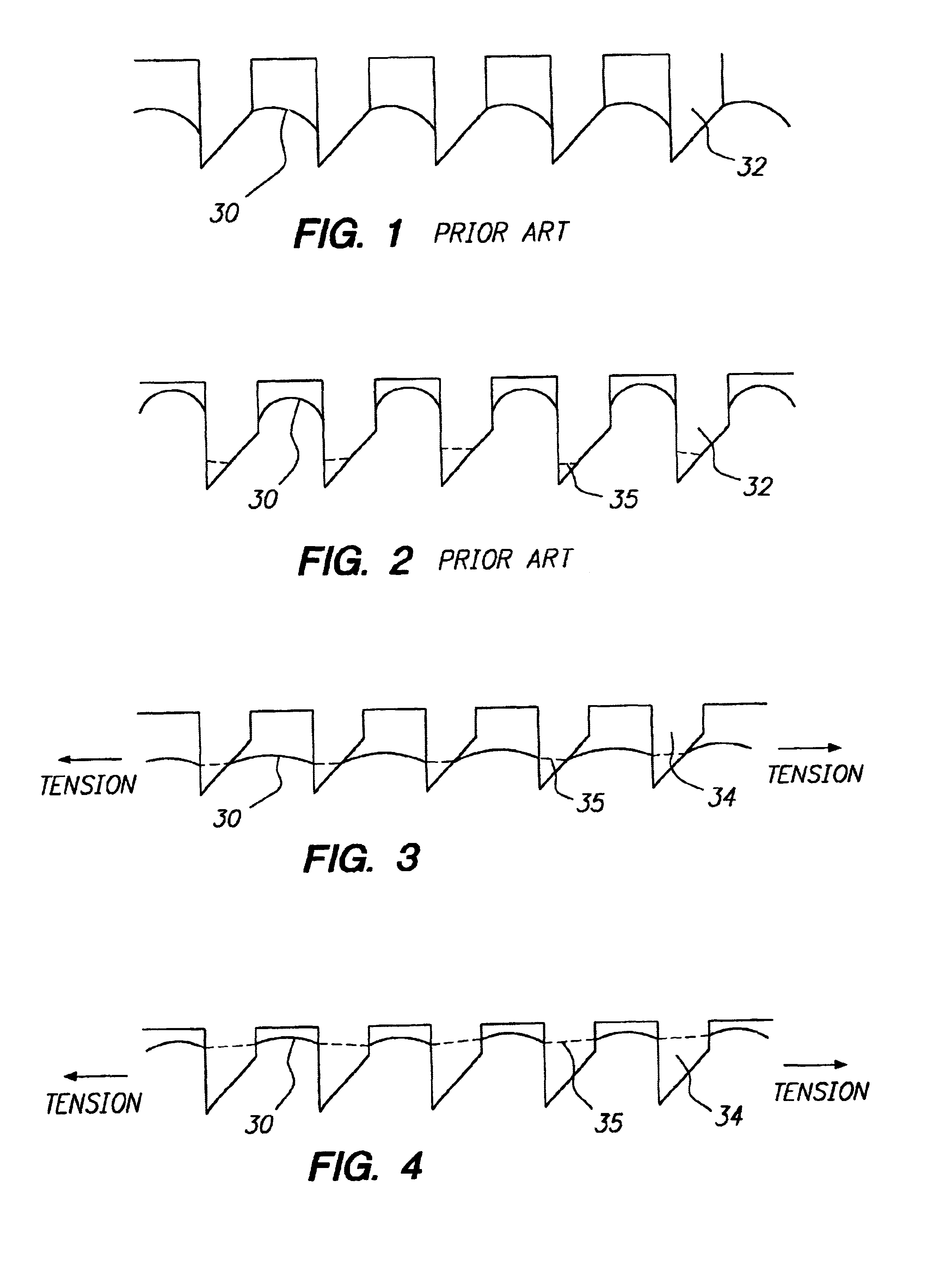

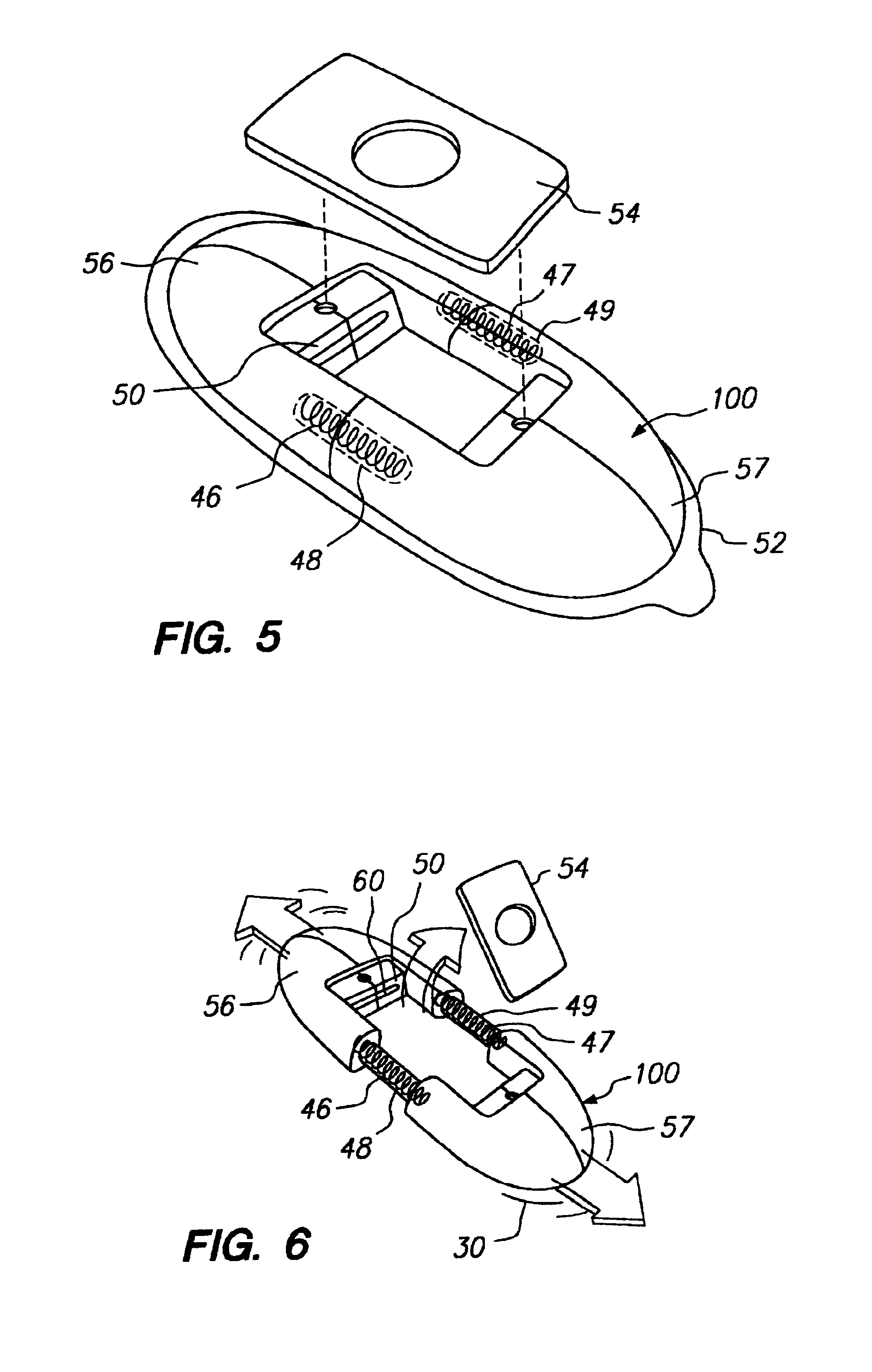

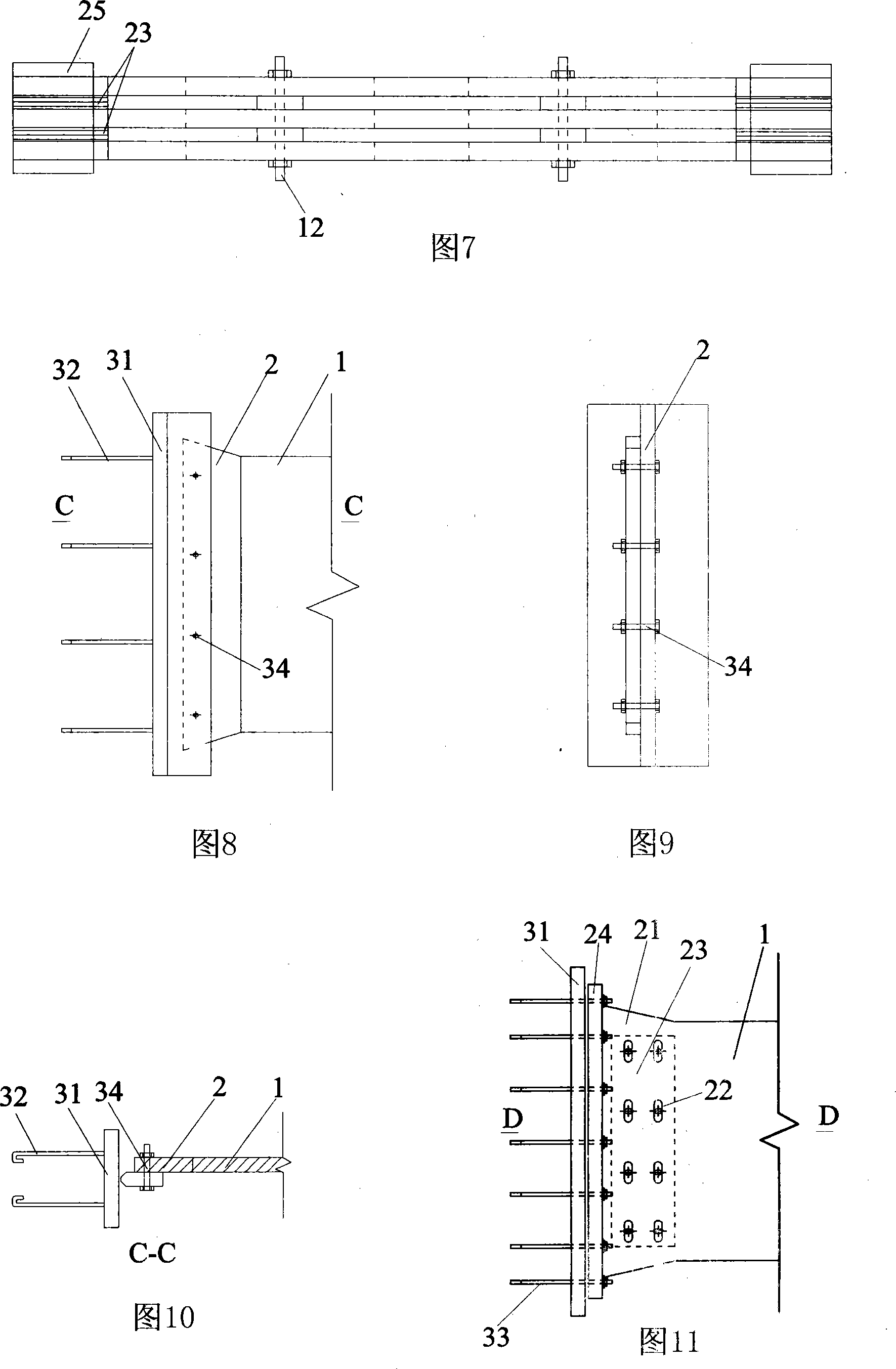

Device and method for enhancing skin piercing by microprotrusions

InactiveUS7087035B2Uniform penetrationCreate tensionElectrotherapyJet injection syringesSkin stretchingSkin surface

A device and method for enhancing skin piercing by microprotrusions involves pre-stretching the skin to enhance pathway formation when the microprotrusions are pressed into the skin. An expandable device includes skin engaging opposite ends that contact the skin surface so that when the device is expanded the skin is stretched. The skin is placed under a tension of about 0.01 to about 10 megapascals, preferably about 0.05 to 2 megapascals. The device has a plurality of microprotrusions which penetrate the skin while the skin is being stretched by the expanded device. Another stretching device employs suction for skin stretching.

Owner:ALZA CORP

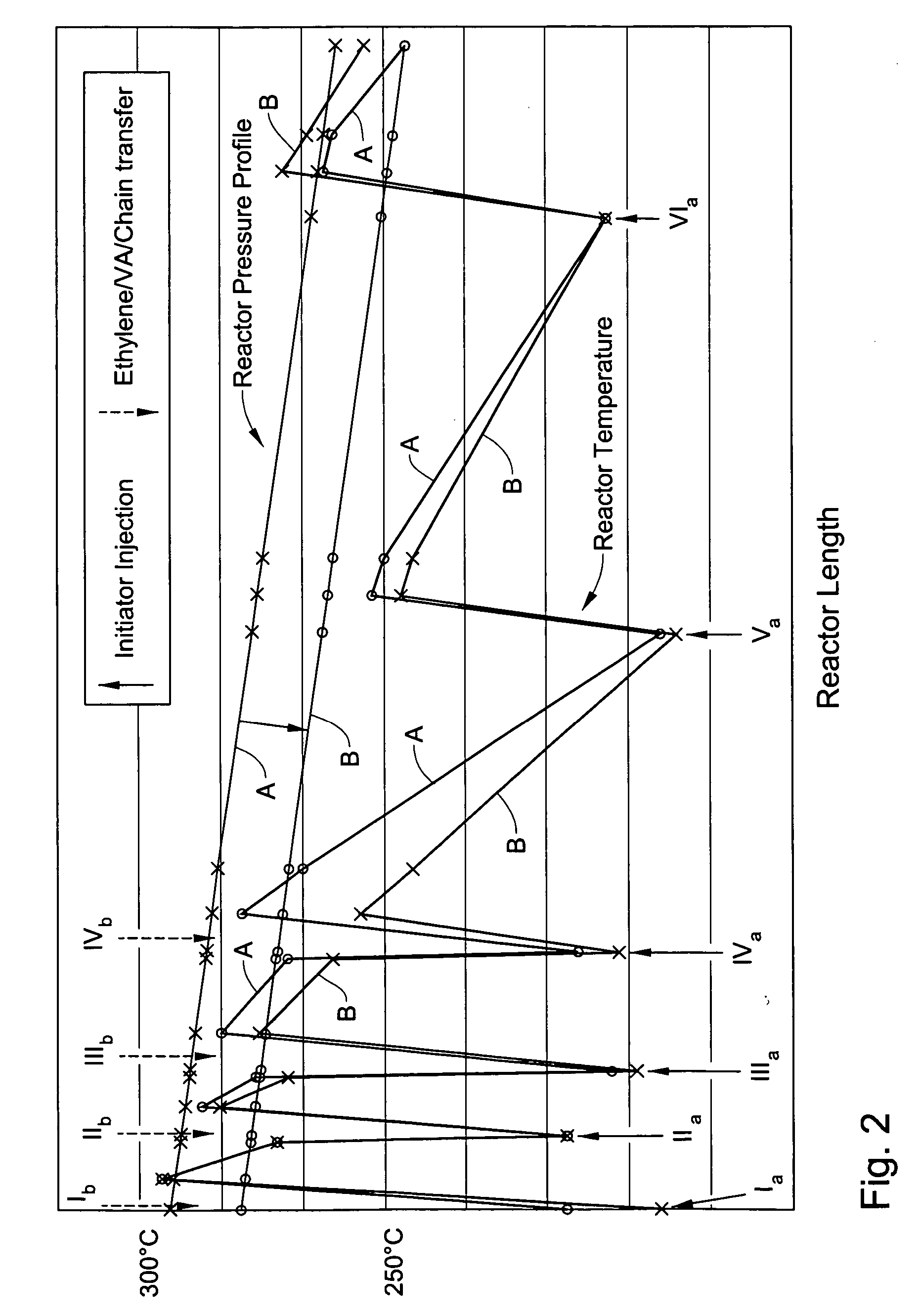

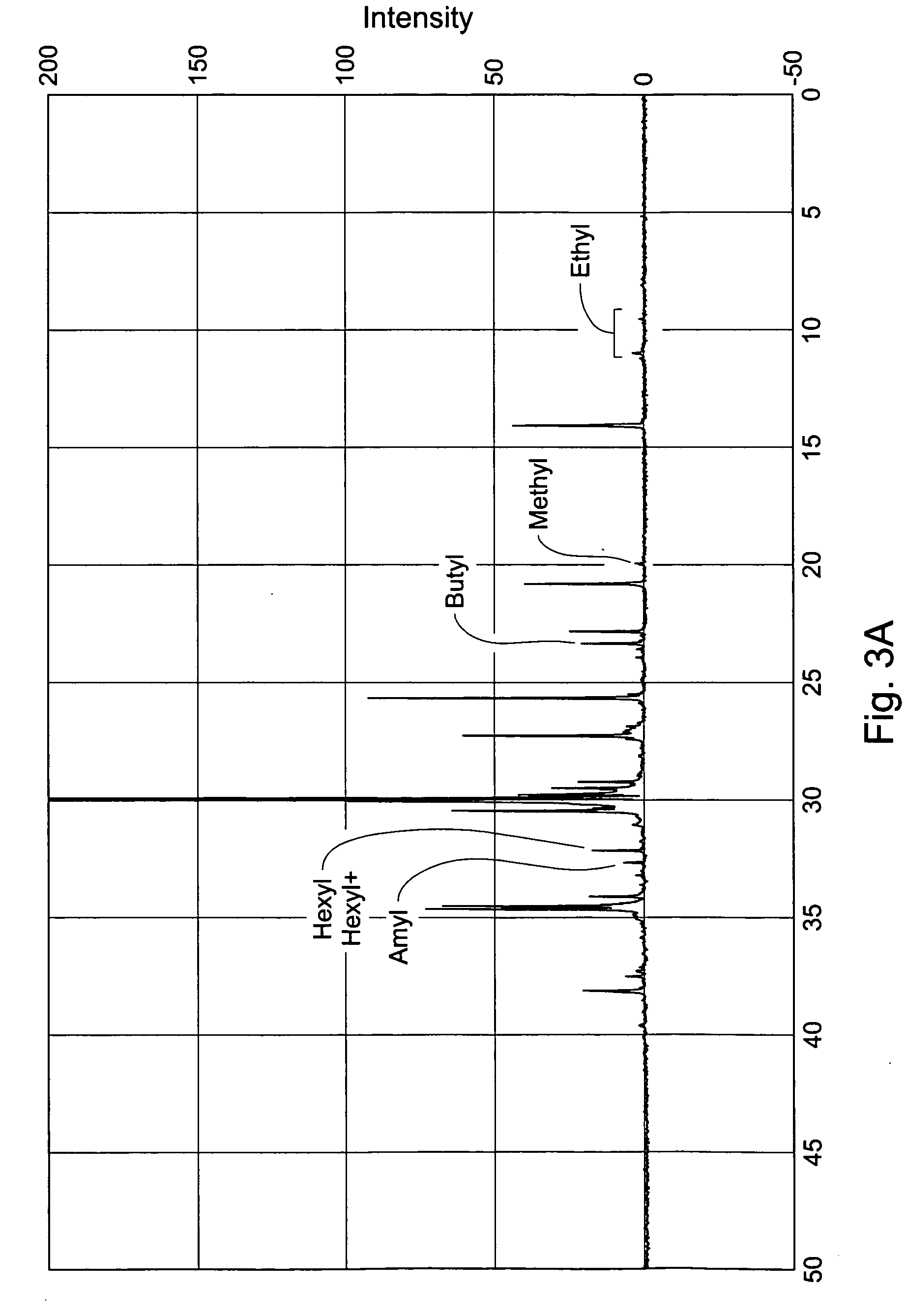

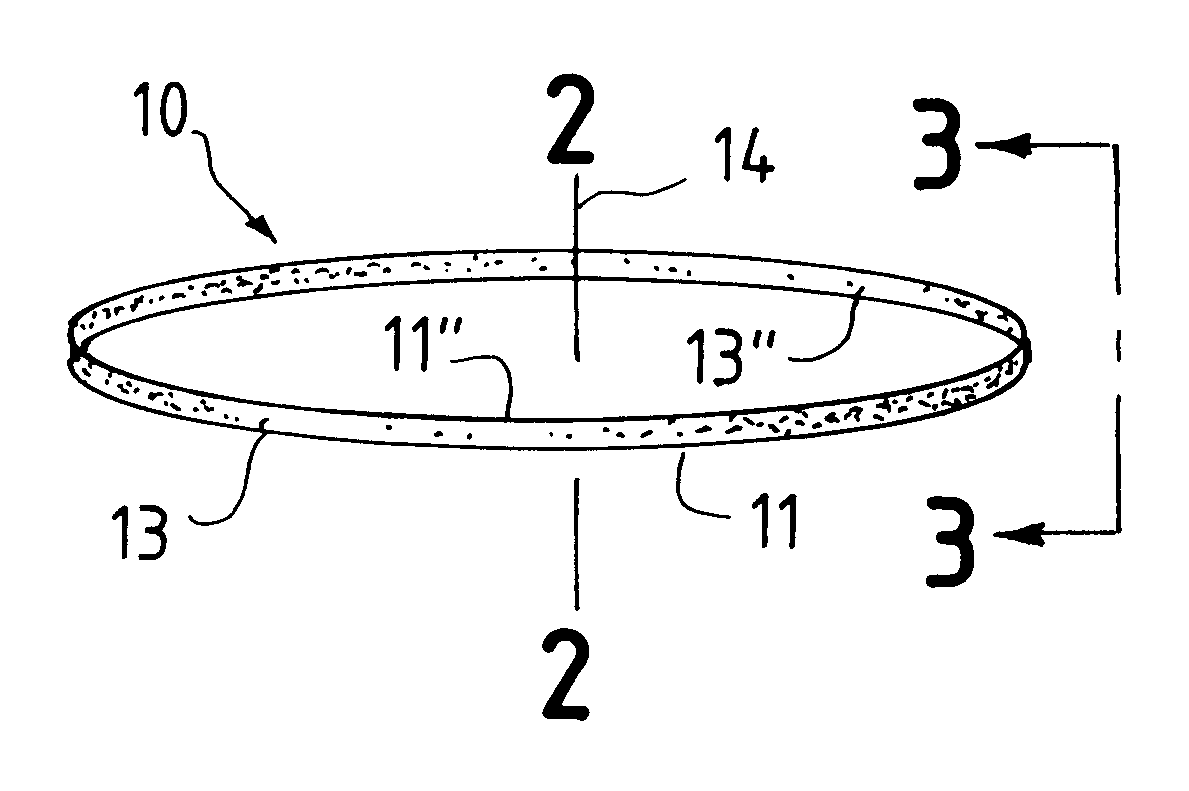

Polymers of ethylene and, optionally, copolymerizable esters, films using such polymers and stretch hood packaging processes using such films

ActiveUS20050037219A1Excellent film performanceSynthetic resin layered productsDomestic containersParticulatesMelt flow index

The invention relates to a polymer comprising units derived from ethylene, said polymer having: a) a Melt Index of from 0.05 to 20 g / 10 min as determined by ASTM-1238 Condition E; b) at least 10 per 1000 C-atoms of short chain branches, containing five carbon atoms or less, as determined by C13 NMR, and less than 3.5 mol %, of units derived from a copolymerizable ethylenically unsaturated ester, c) a density of from 0.90 to 0.94 g / cm3, preferably 0.91 to 0.935 g / cm3, especially 0.92 to 0.93 g / cm3 as determined by ASTM D1505, and d) a relaxation time as described herein of at least 10 s. Such polymers are obtainable by polymerization by free radical polymerization using a chain transfer agent that incorporates into the polymer chain such as an alpha-olefin, preferably propylene, as a chain transfer agent, preferably in a tubular reactor under circumstances to favor LCB formation in a down stream part of the tubular reactor. The polymer may be used for stretch hood film, preferably as a blown film coextruded tube comprising: a) a core of the above polymer; and b) a skin layer, on each side of the core which may be of the same or different composition, comprising at least 60 wt % of an LLDPE having density of 0.91 to 0.94 g / cm3 as determined by ASTM-D 1238 Condition E and hexane extractables less than 1.5 wt %, said skin layer containing less than 7500 ppm of anti-block particulates and said film having an elastic recovery after a 100% stretch of at least 40% and providing a normalized holding force per 100 μm thickness pre-stretch at 85% stretch after an initial stretch of 100% of at least 20 N / 50 mm at a deformation rate of less than 10% of the starting length per second.

Owner:EXXONMOBIL CHEM PAT INC

Drilling in stretched substrates

InactiveUS20100276505A1Facilitate formation of aerosolMinimize impactBurnersSpray nozzlesEngineeringPre stretching

Owner:ARADIGM

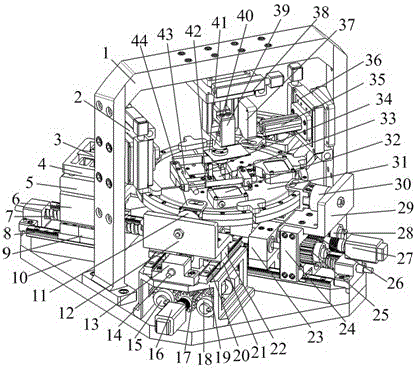

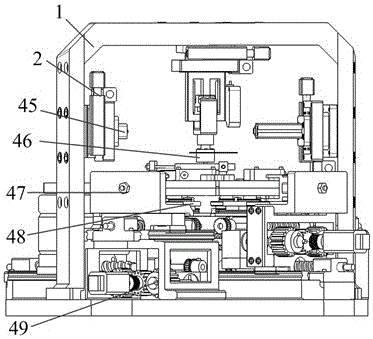

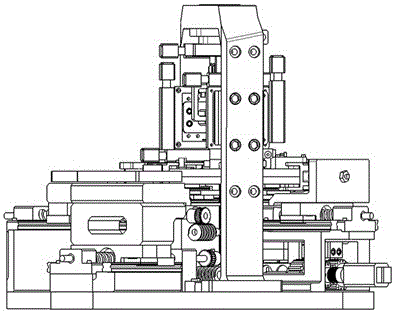

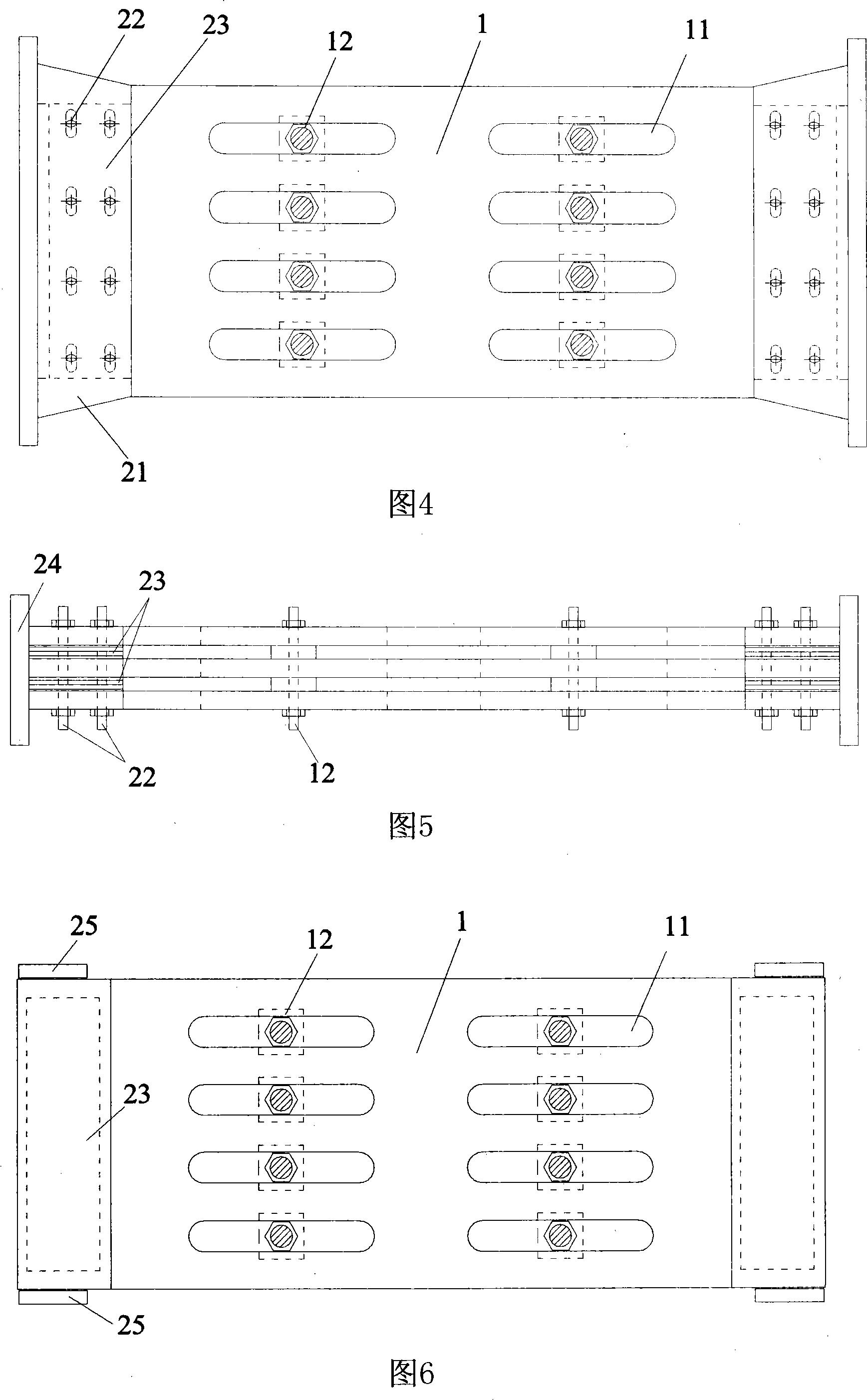

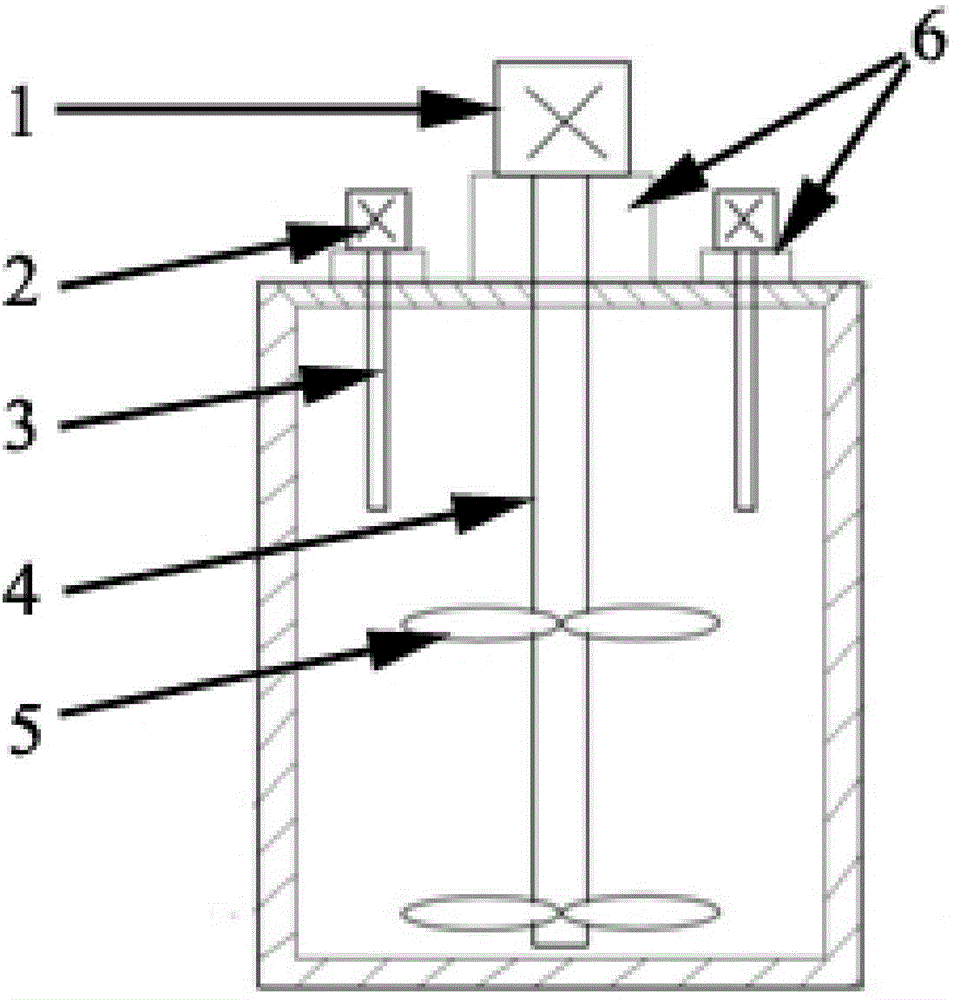

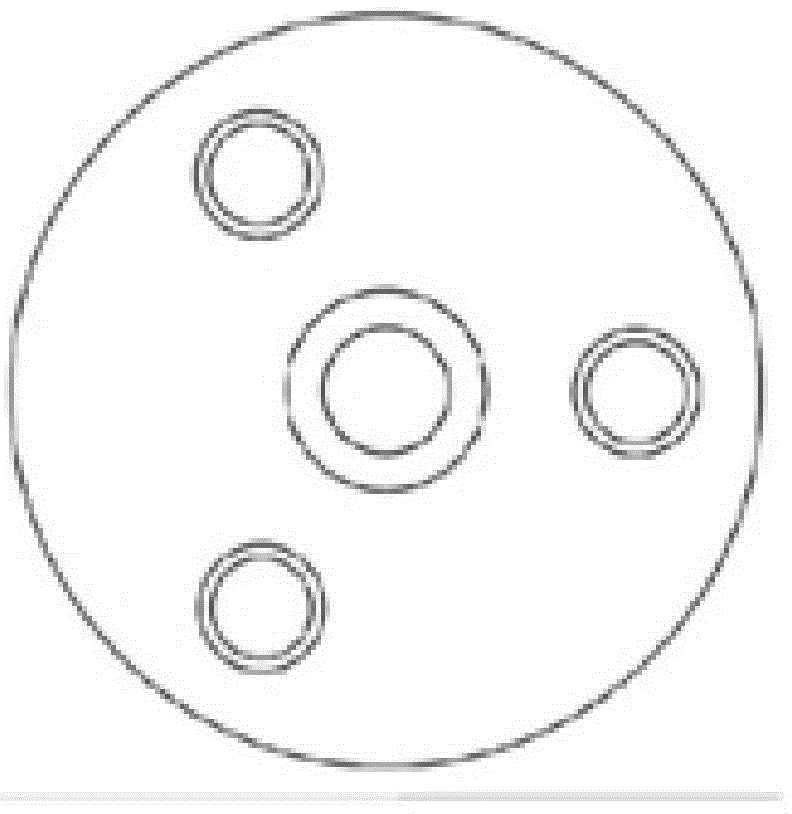

Material mechanical property in-situ testing system and method in dynamic and static load spectrum

ActiveCN106226152AImprove compatibilityCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesEngineeringMultiple modes

The invention relates to a material mechanical property in-situ testing system and method in a dynamic and static load spectrum, and belongs to the field of mechanical tests. The system integrates the following functions: a static testing function of biaxial drawing and shearing in an orthogonal plane, a shearing static testing function, a double shaft pull-pull mode fatigue testing function, and a static / dynamic press testing function. A complicated static / dynamic load spectrum can be established. Multi-mode composite load mechanical property evaluation can be performed on a film material or a block material, for example: high-cycle fatigue tests based on double-shaft pre-stretching load and impact press tests based on double-shaft stretching-shearing pre-load. At the same time, special defects are pre-fabricated on the central area and cross shaped arm area of a test piece; the analysis functions of a variable-zoom optical imaging system or a digital speckle strain analysis system can be utilized; the provided system and method can also be used to research the deformation behavior and cracking expansion rules of micro defects in a component under a multi-dimensional stress, and an evaluation tool is provided for performance degradation rules of products and optimized preparation method of materials.

Owner:JILIN UNIV

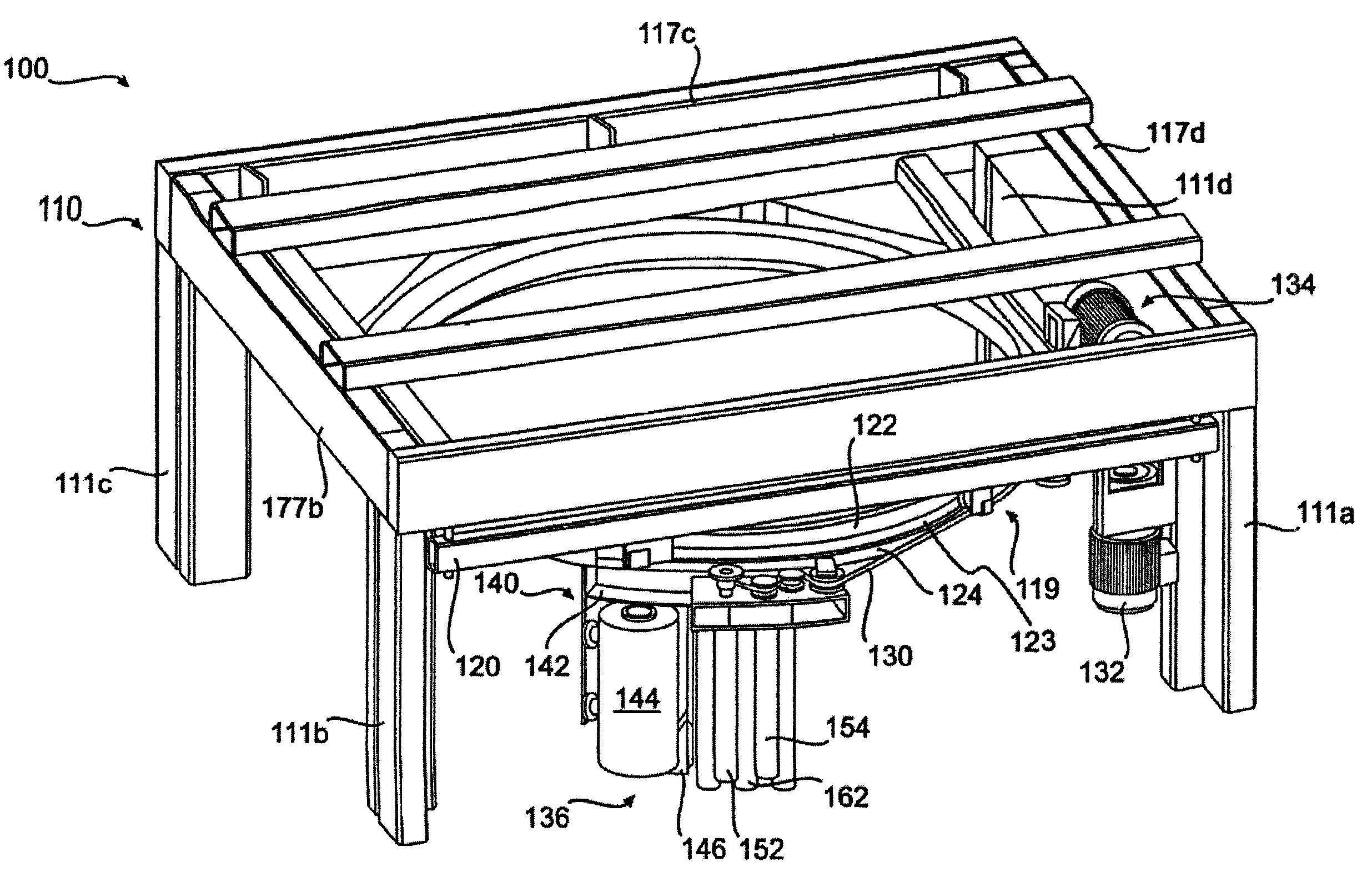

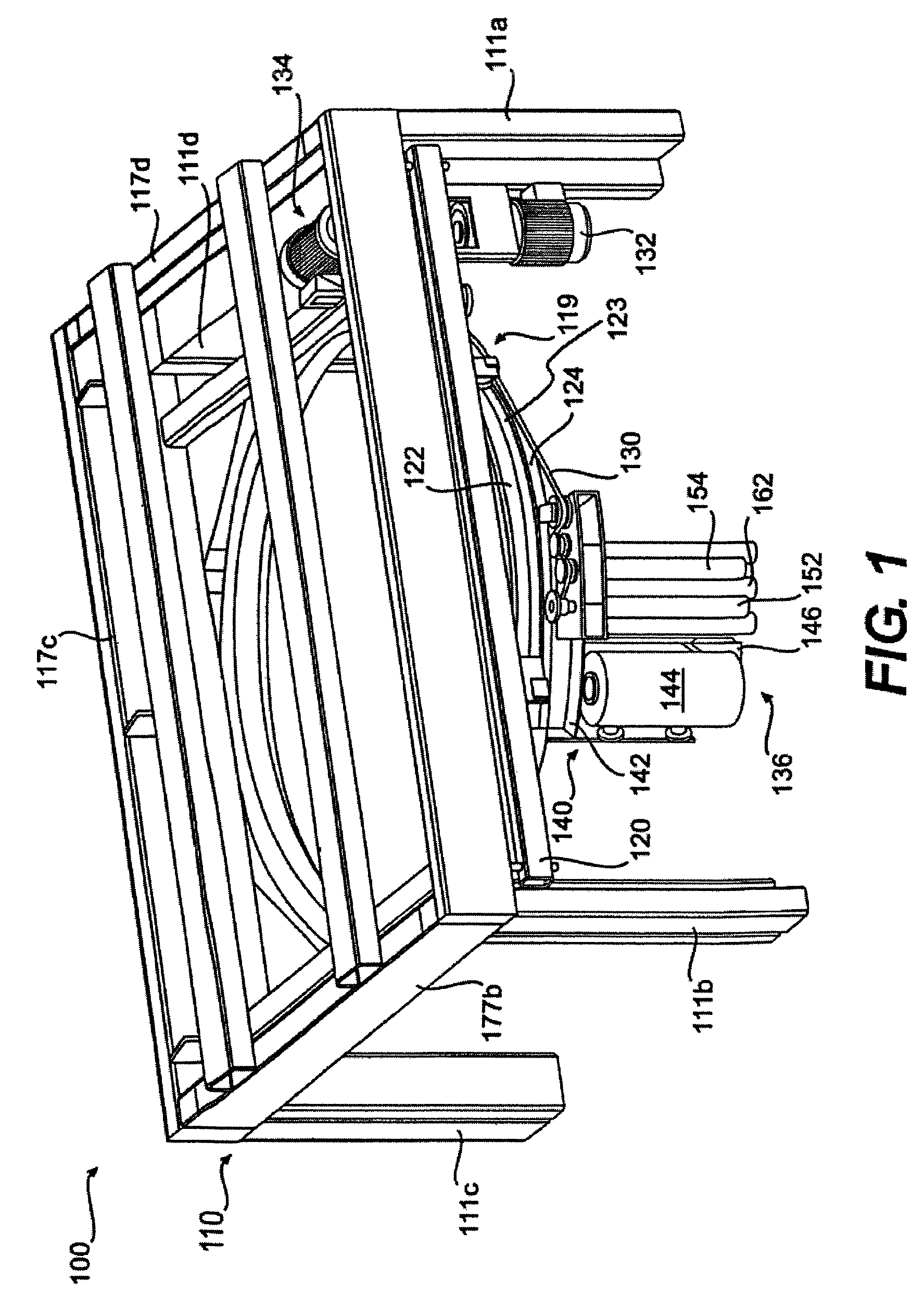

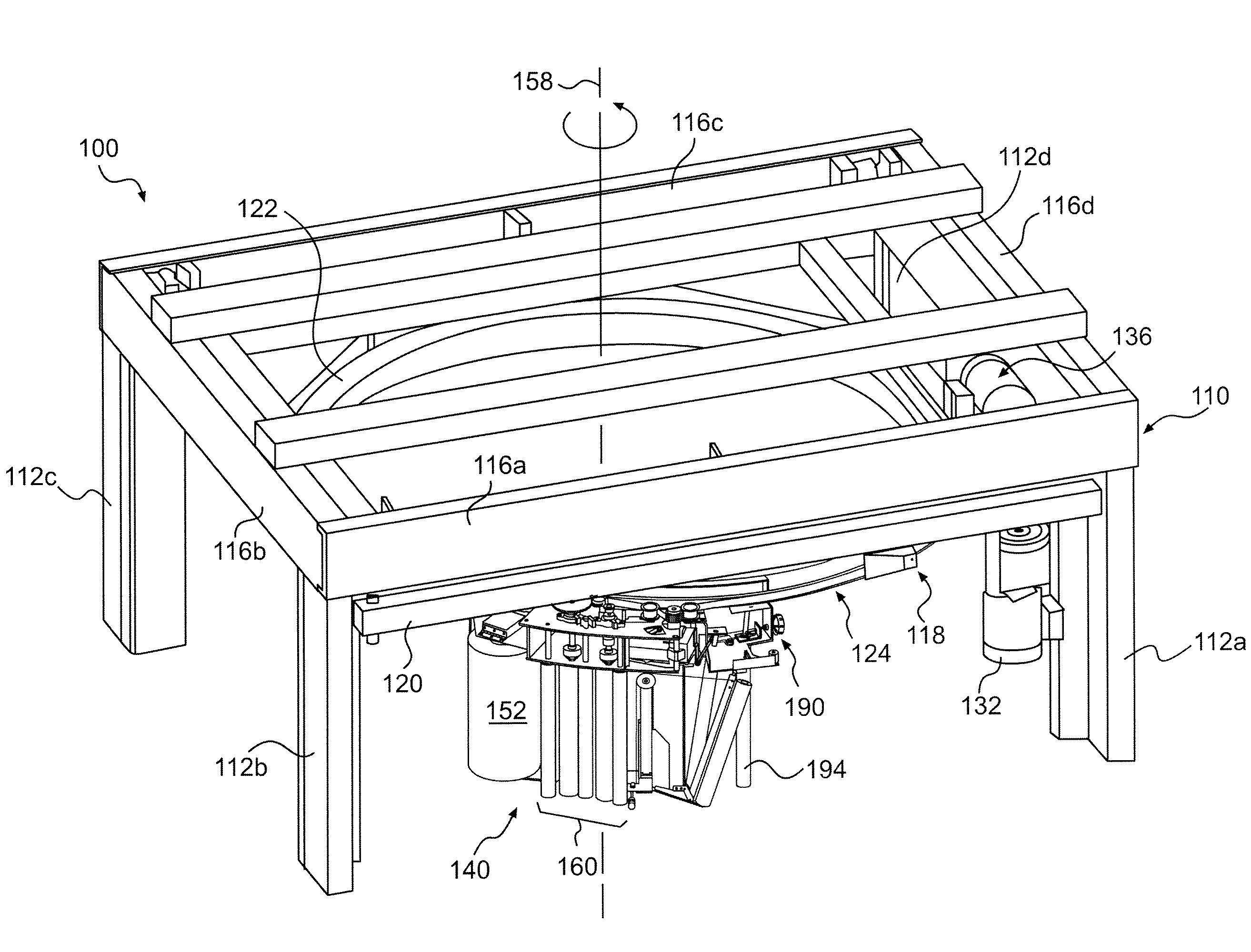

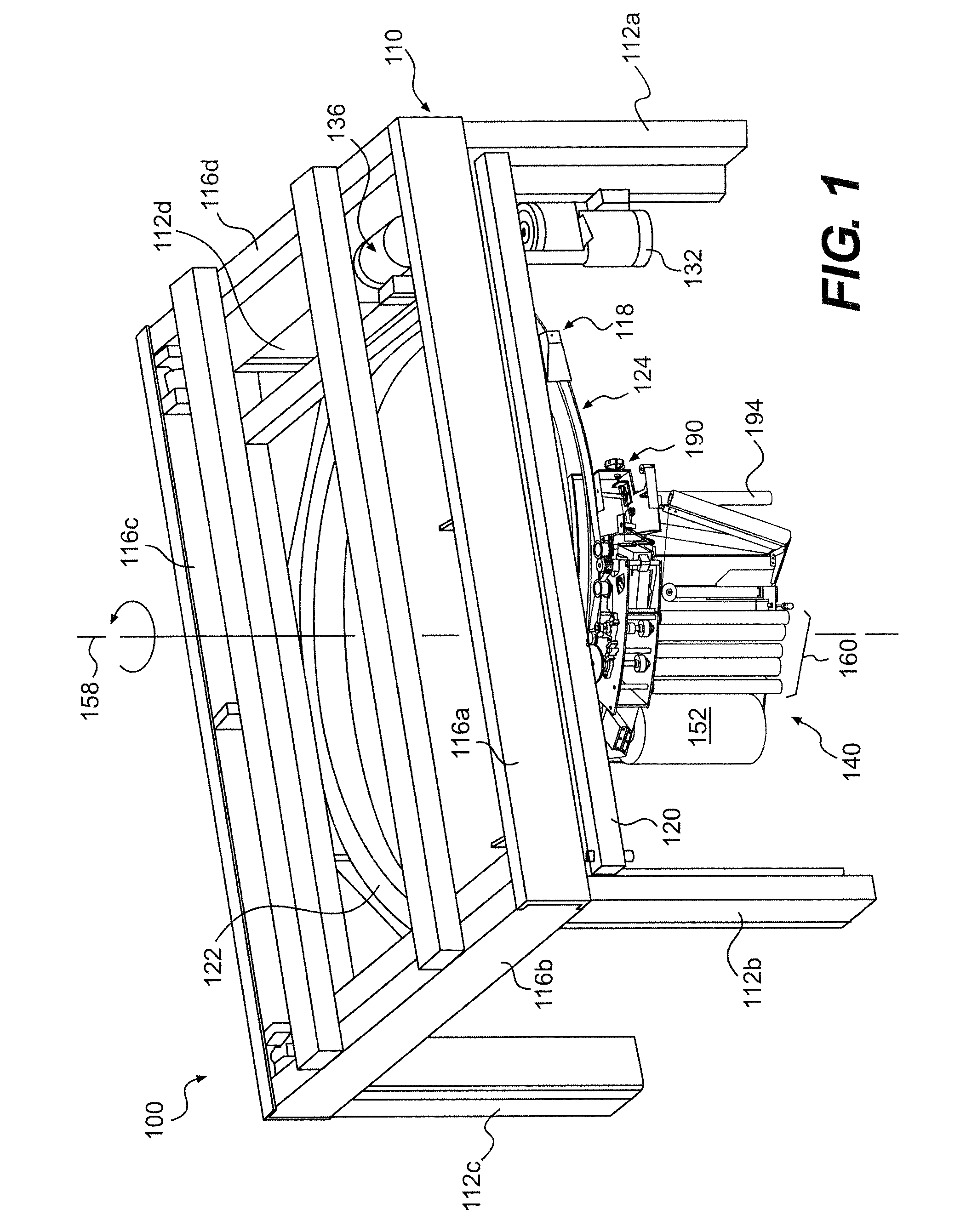

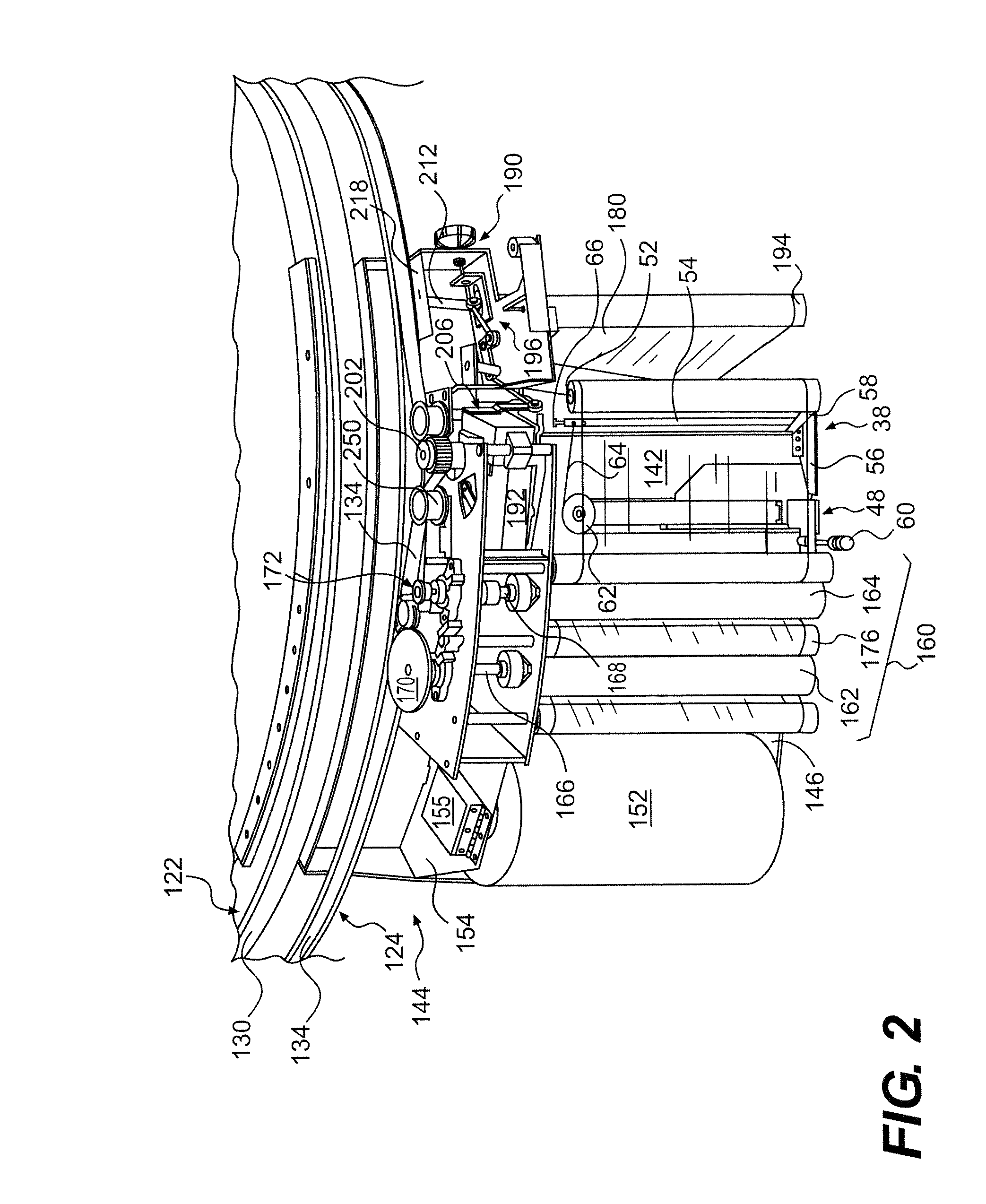

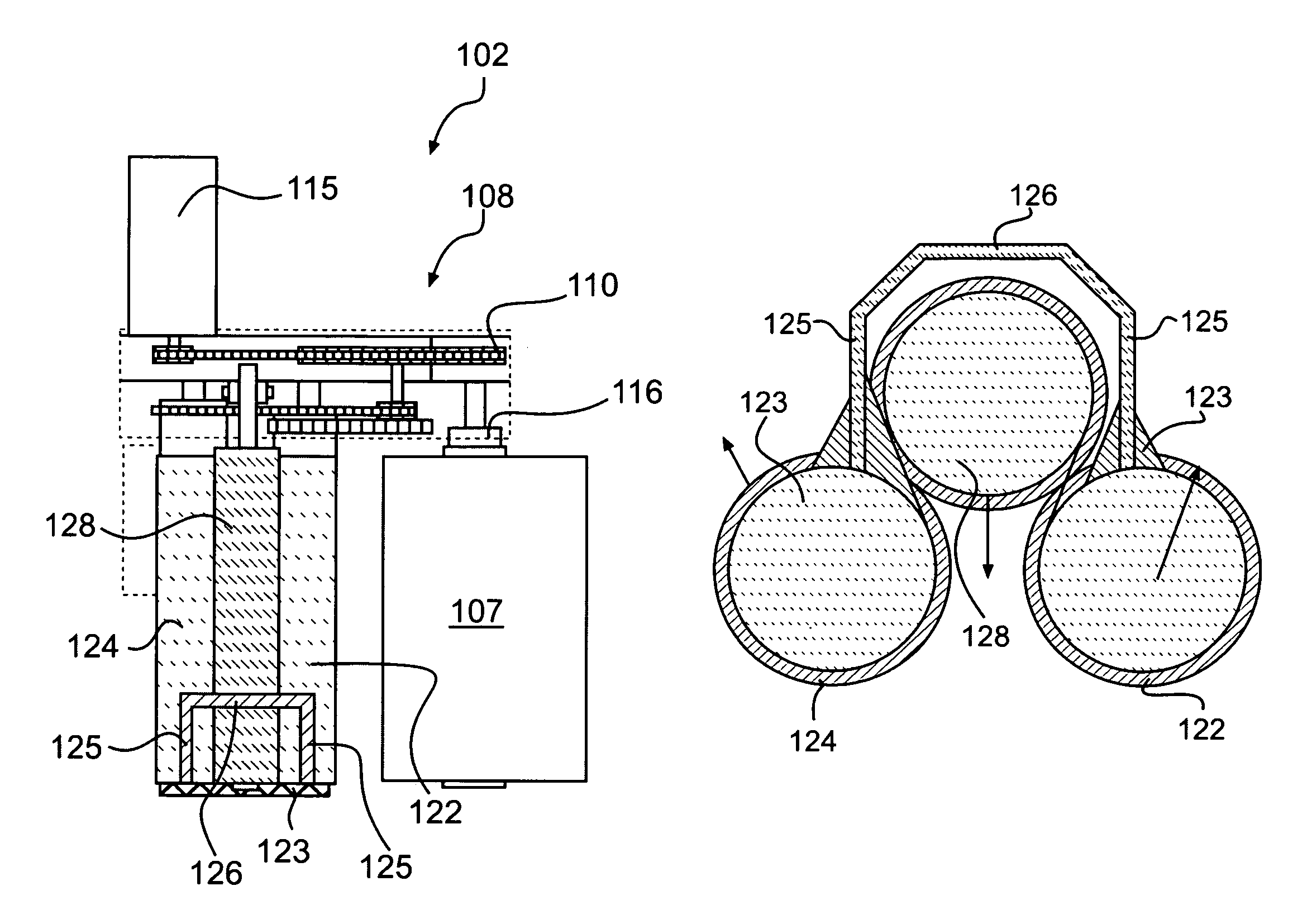

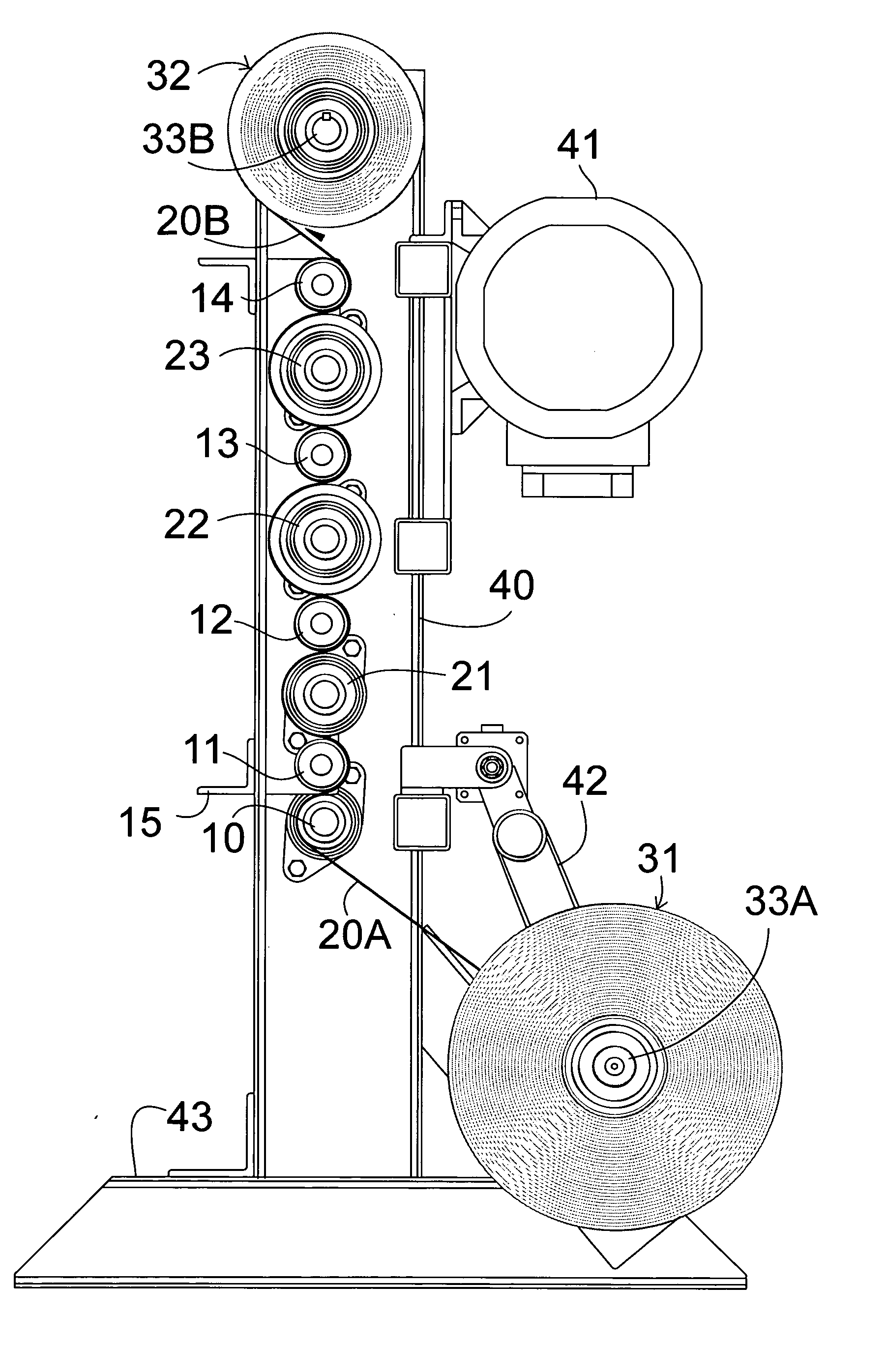

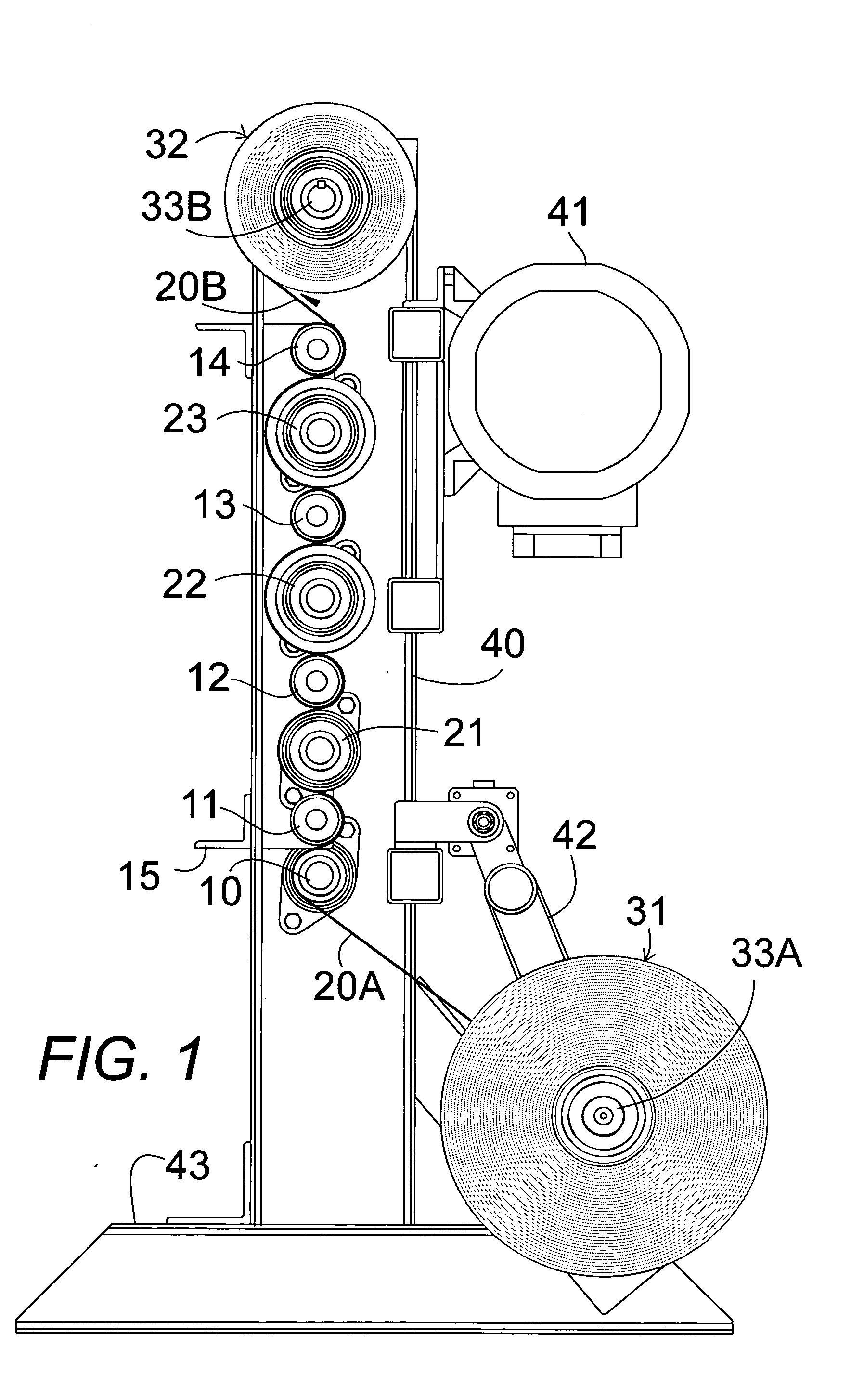

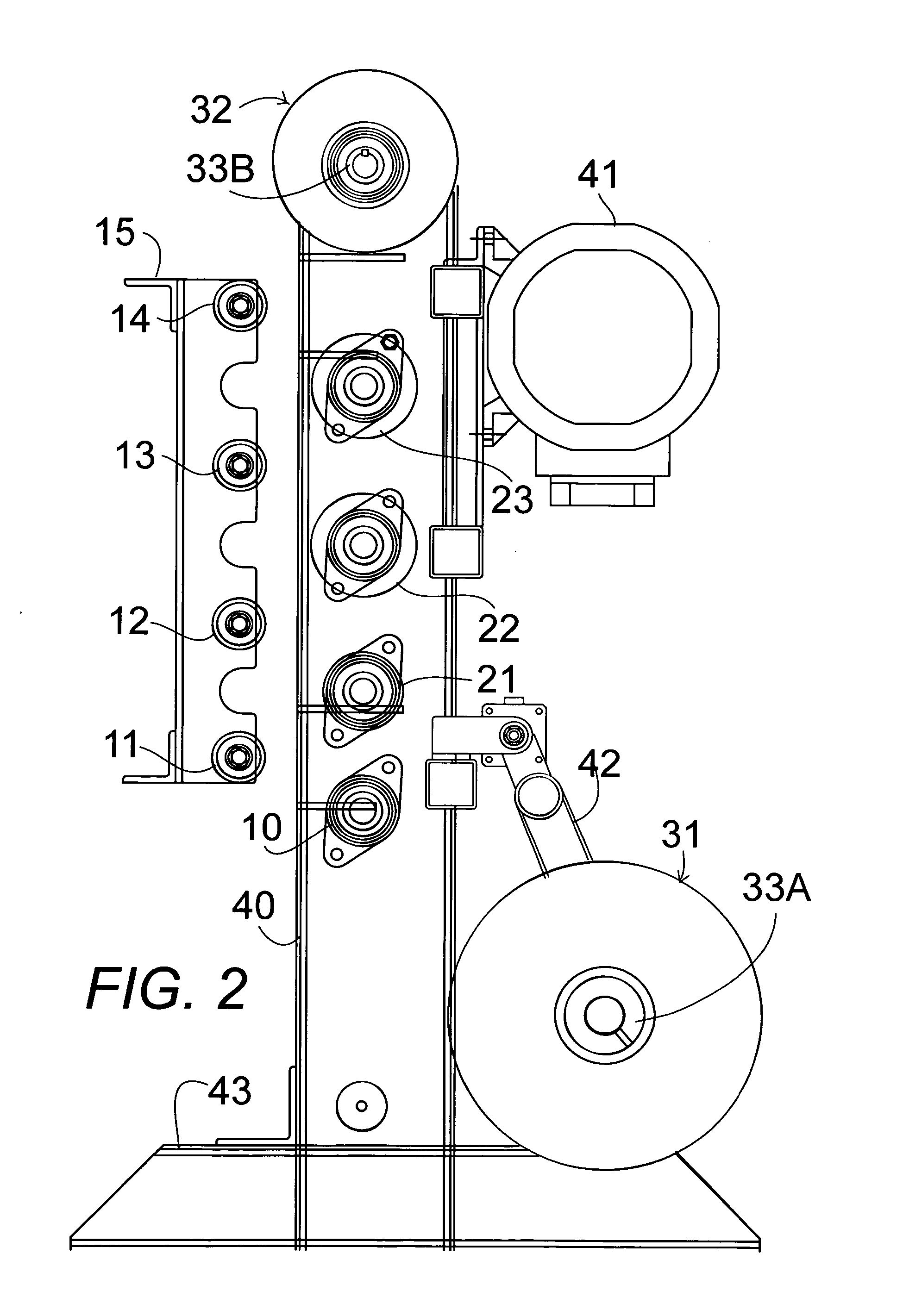

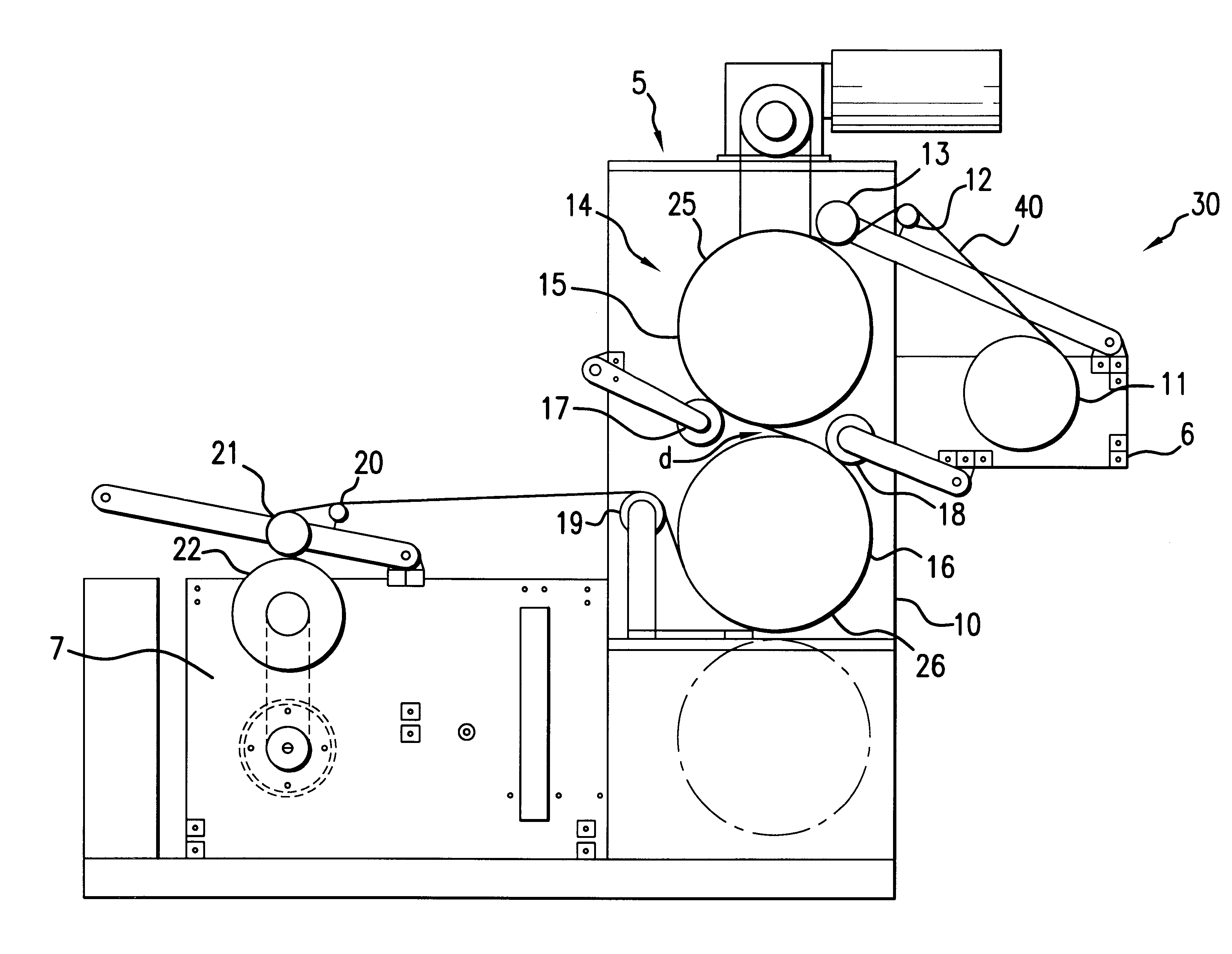

Film dispenser with pre-stretch assembly

A film dispenser for a stretch wrapping apparatus is provided. The film dispenser includes a pre-stretch assembly having a top portion mounted to and extending downwardly from a drive plate of a roll carriage frame. The pre-stretch assembly includes two pre-stretch rollers having first ends connected to the roll carriage frame and second ends connected to one another. The pre-stretch rollers may be coated. The pre-stretch assembly further includes a cantilevered idle roller mounted to the drive plate and positioned between the pre-stretch rollers. A film path is defined by the space between the pre-stretch rollers and the idle roller. The film path is easily accessible via the bottom end of the pre-stretch assembly.

Owner:LANTECH COM

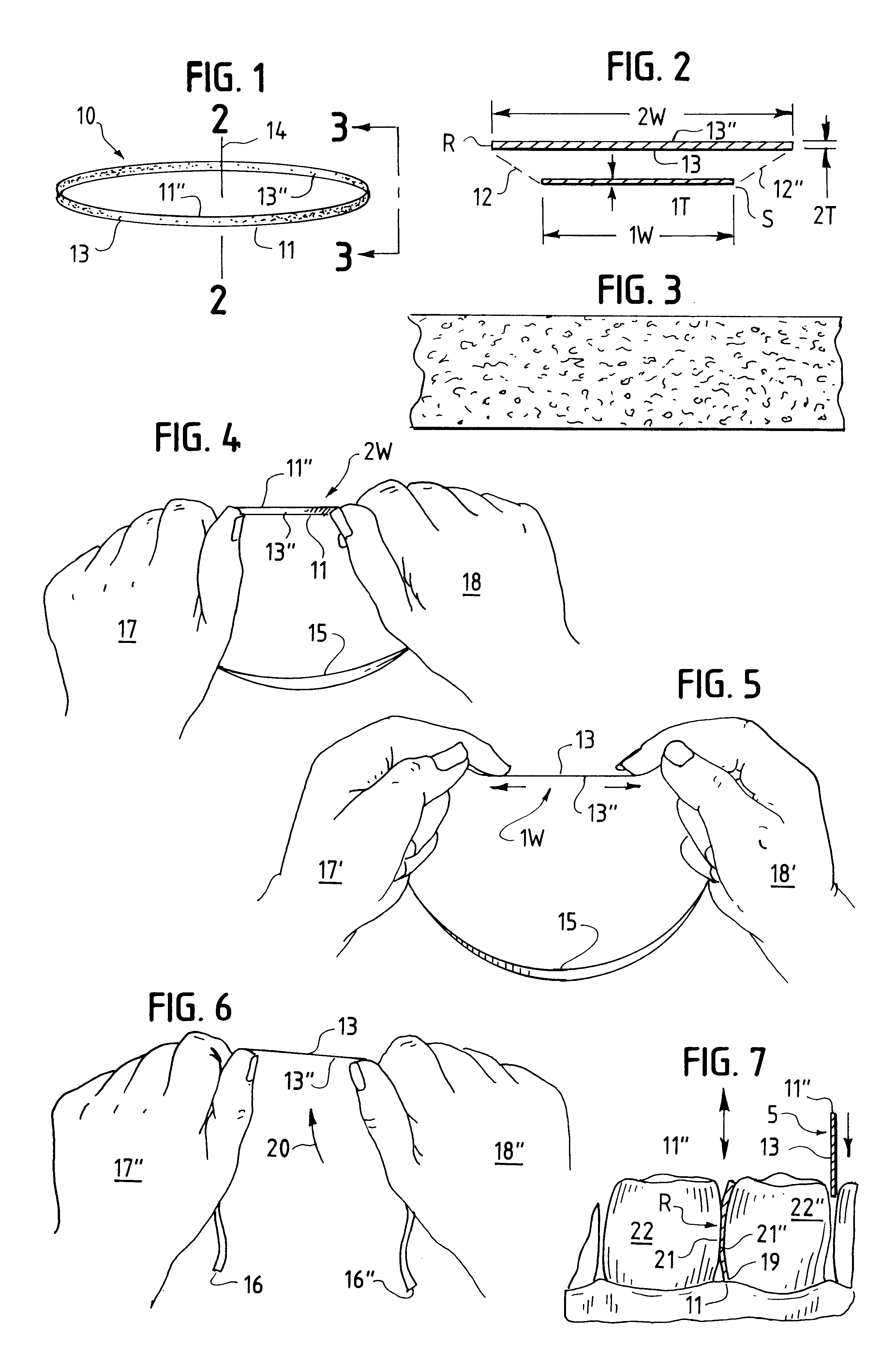

Variable-guage tooth-flossing loops

Embodied in the flexile forms of both an endless-loop and as a linear-tape, a unique tooth flossing device for cleaning away bacteria between the teeth is set forth. Comprised of a nontoxic extrusion-molded thermo-plastic polyurethane having particular properties of excellent elasticity, almost film-like guage of thickness, and a natural random surface-texture serving to aid the flossing procedure. In use, a FLOSS-LOOP(TM) is simply held in the user's thumb-&-forefinger of both hands, so as to pre-stretch "thin" that portion to be slid vertically between the teeth. The exceptionally high stretched tensile-strength of this device enables it to endure the duress of insertion between the teeth, yet once interposed interstitially adjacent the gum-line, the release of excess tension upon the tensioned segment of the loop enables it to resume it's natural thickness-guage of approximately 0.325 mm(0.0128-inch). This novel variable-guage capability of the device, making it able to more effectively burnish away substances from the tooth and sulcus of the gum-tissue during it's thicker guage modality; then again be retensioned to approximately only 0.200 mm-guage for easy interstitial removal. Either version of the device may be coated with various agents effective in combating diseases of the teeth and gums.

Owner:LOOPS L L C

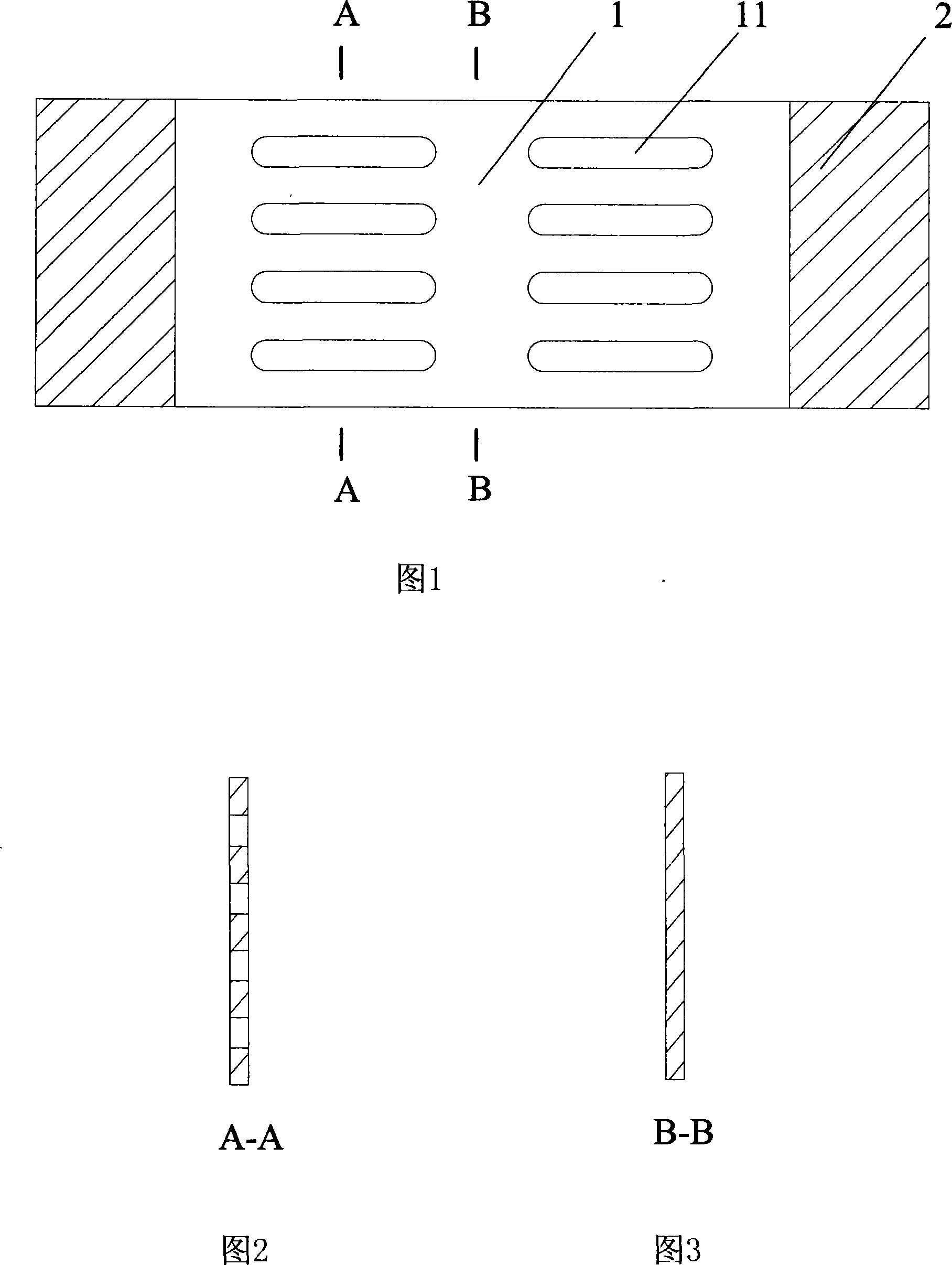

Coupled shearing force wall energy-dissipation beam-coupled steel plate damper and its using method

InactiveCN101173535AReduce the difficulty of reinforcementReduce the difficulty of structural designShock proofingPlastic yieldingWhole body

The invention discloses a damper and the application method, in particular to a braced shear wall coupling beam energy dissipating damper and the application method. The damper comprises a mutual connection plastic yield energy dissipating work area and a keeping approximate rigidity partial fixing area, two or more than two column strip-shaped holes are arranged in work area; non-sharp corner processing is adopted at the upper ends of the strip-shaped hole. The application method of the damper for shear wall coupling beam energy dissipating comprises: the reinforced concrete coupling beam is replaced by one or more than one damper; or one or more damper is adhered to the reinforced concrete coupling beam and is positioned at the coupling beam of the shear wall. Each damper work area is provided with anti out-plane instability bolt to prevent the out-plane of each damper from instability; each damper partial fixing area is pre-stretched by high strength bolt, or each damper is welded into a whole body by cap cover plate.

Owner:滕军

Pre-stretched wrapping film roll with entrapped air and method

InactiveUS20060243842A1Easy and fast loadingLayered productsFunction indicatorsLinear low-density polyethyleneAir entrainment

A pre-stretched film roll of a mono orientated linear low density polyethylene (LLDPE) is stretched between 30% and 320% depending on the final product that is required. Stretching is in the machine direction (MD) at a controlled rate in two stages. Differentially rewinding the film entraps air between the layers of the roll and creates soft overlapping edges around the roll to produce a spongy, “soft” roll that prevents and resists drop damage due to its shock absorbent characteristic.

Owner:MARTIN GUILLERMO DURAN ESPINOZA & ANGEL GERARDO SANTILLAN DIAZ DE LEON

Aviation aluminum alloy pre-stretching plate and production method thereof

InactiveCN101037747AAvoid deformationReduce residual stressTemperature control deviceAviationQuenching

The invention relates to aluminium alloy pretensioning plates for aviation and a method for producing the same in order to solve the problem that the existing aluminium alloy plates are easy to be deformed in the machining and machining yield is low. The aliminium alloy pretensioning plates for aviation comprise, based on weight shares, Si of 0.20, Fe of 0.3, Cu of 1.7, Mn of 0.10, Cr of 0.22, Ti of 0.06, Mg of 2.5, Zn of 5.6, and the residuel of Al, the total of 100. The method for producing the aliminium alloy pretensioning plates for aviation includes the steps of : 1) admixture; 2) casting; 3) soak heating treat; 4) heating, hor rolling and cutting; 5) quenching, straightening; 6) pretensioning, ageing, sawing the plates according to the requirement of the product to produce aliminium alloy pretensioning plates for aviation. The plates product of the invention is steady without deforming in machining.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Method for carrying out ultrasonic inspection on residual stress of aluminium alloy pre-stretching board by water immersion

ActiveCN103543206AGood for non-destructive evaluationThe detection process is fastAnalysing solids using sonic/ultrasonic/infrasonic wavesStress measurementWater immersion

The invention provides a method for carrying out ultrasonic inspection on residual stress of an aluminium alloy pre-stretching board by water immersion, belonging to the field of non-destructive inspection. The method comprises the following steps of preparing a reference block; carrying out measurement and calibration; measuring the residual stress. In the method, the water immersion method is adopted, and the temperatures in stress calibration and stress measurement processes can be ensured to be consistent by controlling the water temperature not to be changed, thus eliminating the effects of temperature difference on the ultrasonic wave speed and eliminating temperature errors; besides, an automatic scanning frame is adopted instead of manual scanning, so that the distance between a probe and the surface of a material to be measured in the measurement process can be ensured not to be changed, thus eliminating the effects of coupling condition difference on sound propagation time and eliminating the coupling errors. The method is beneficial to non-destructive evaluation of the near surface residual stress of the aluminium alloy pre-stretching board.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method to make tube-in-tube balloon

A tube-in-tube assembled parison for preparation of an elongated medical device. The parison if formed by assembling in tube-in-tube fashion a first tube of orientable polymer material and a second tube formed of orientable polymer material disposed around the first tube, with an adhesive tie layer disposed between the first and second tubes. The tubes are brought into contact to form a unitary parison. The adhesive may allow movement between the polymer layers during balloon blowing. The first tube, or the second tube, or both, may have been longitudinally pre-stretched after formation thereof but before assembly of the parison.

Owner:BOSTON SCI SCIMED INC

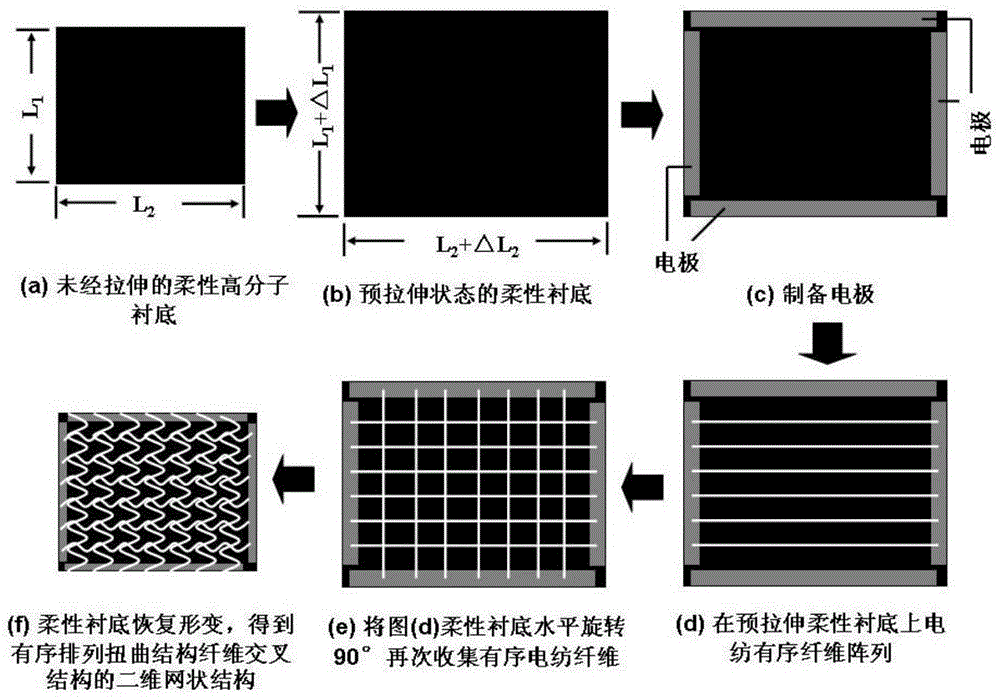

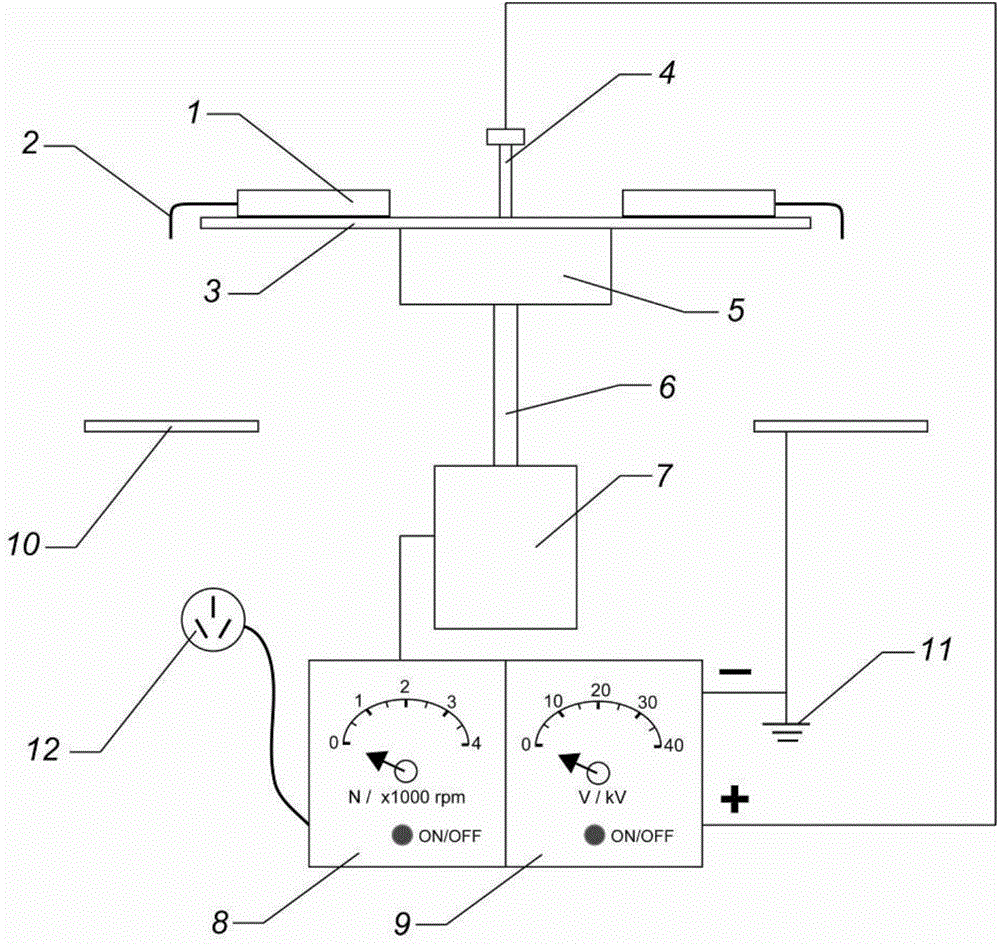

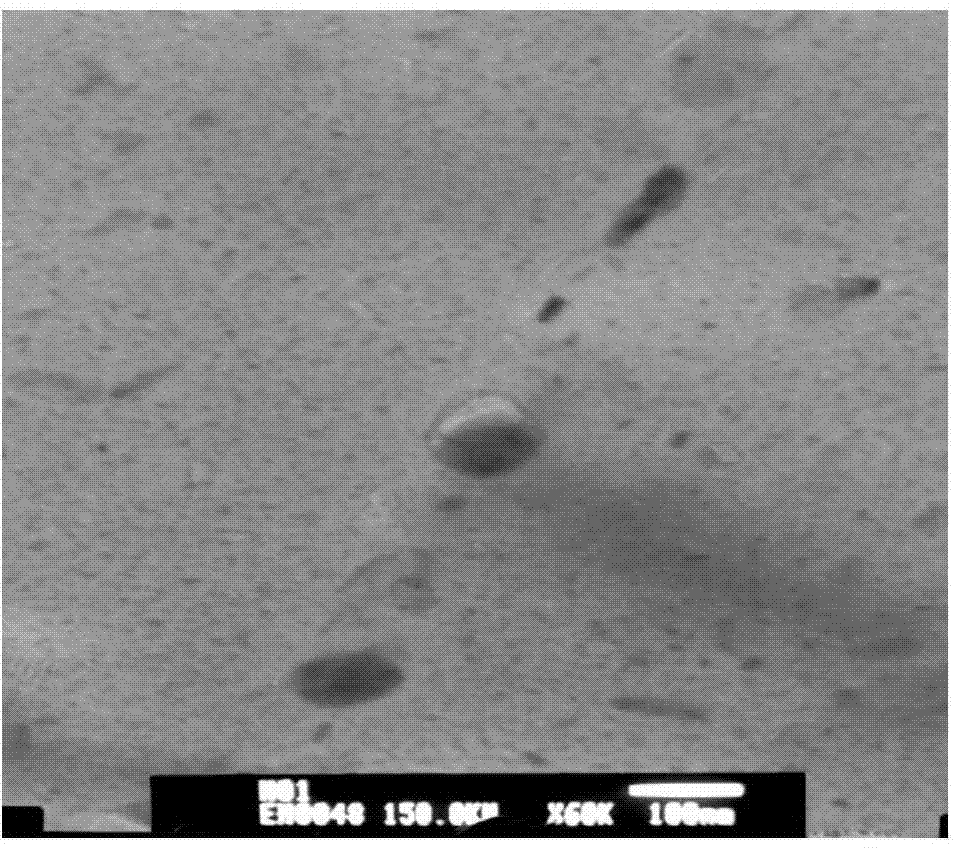

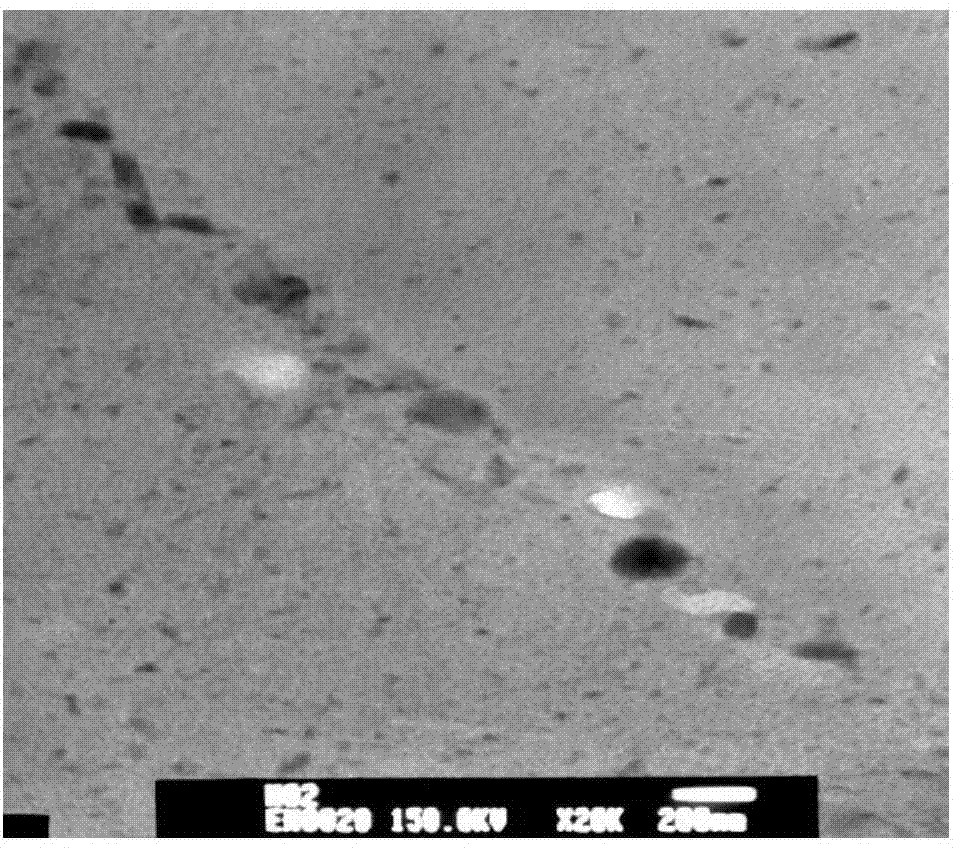

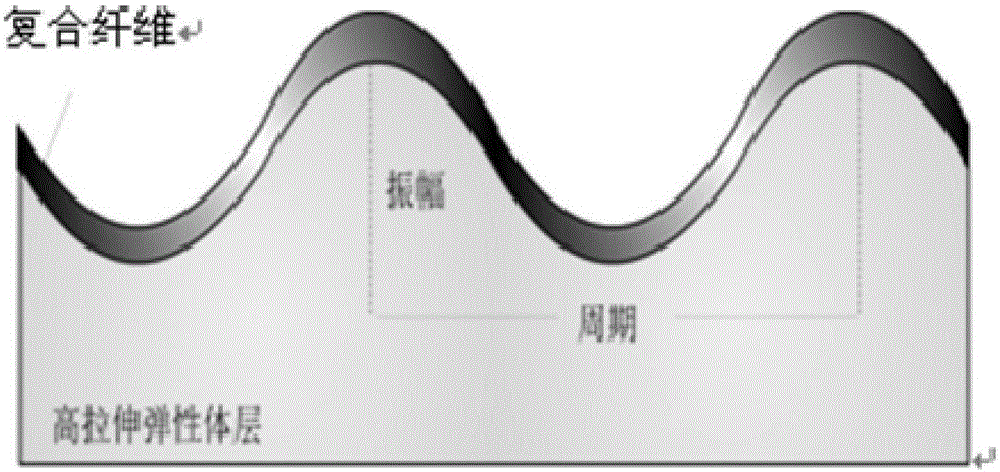

Method for manufacturing flexible stretchable device based on ordered arrangement torsion structure

InactiveCN104153128AAccurate realization of pre-strain controlAchieve pre-strain controlNew-spun product collectionFilament/thread formingPre strainElectrospinning

The invention belongs to the technical field of flexible device manufacturing, and relates to a method for manufacturing a flexible stretchable device based on an ordered arrangement torsion structure. The method includes the steps that firstly, a flexible macromolecule substrate is pre-stretched to be fixed to a glass sheet, and electrodes are manufactured at the four edges of the pre-stretched flexible macromolecule substrate; secondly, the flexible macromolecule substrate is placed on an annular metal collector connected with the negative electrode of a power source to serve as a collecting substrate, and a machined hollow stainless steel needle serves as a spinning spraying head; a spinning solution is injected into a spinning solution container for electrospinning; the flexible macromolecule substrate is horizontally rotated by 90 degrees for continuous electrospinning and then taken down from the glass sheet, and the flexible stretchable device based on an ordered arrangement torsion structure is obtained. The method is simple in manufacturing process and convenient to operate; the manufactured flexible stretchable device can be stressed and tensioned in one or two of the two-dimensional directions respectively, pre-strain control over materials in the two directions can be accurately achieved, and the application range is wide.

Owner:QINGDAO UNIV

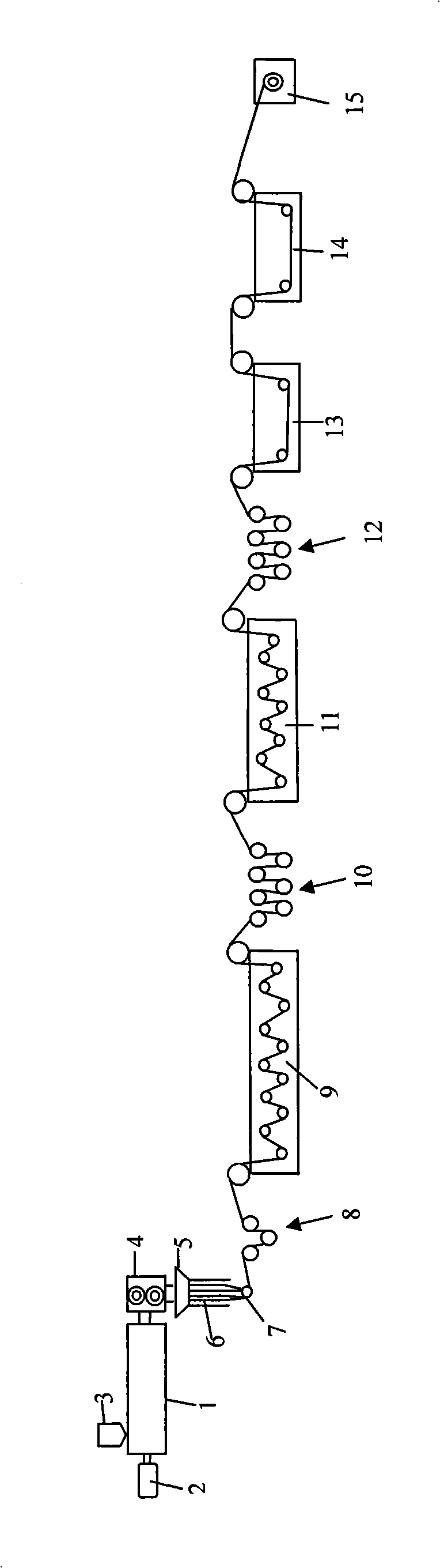

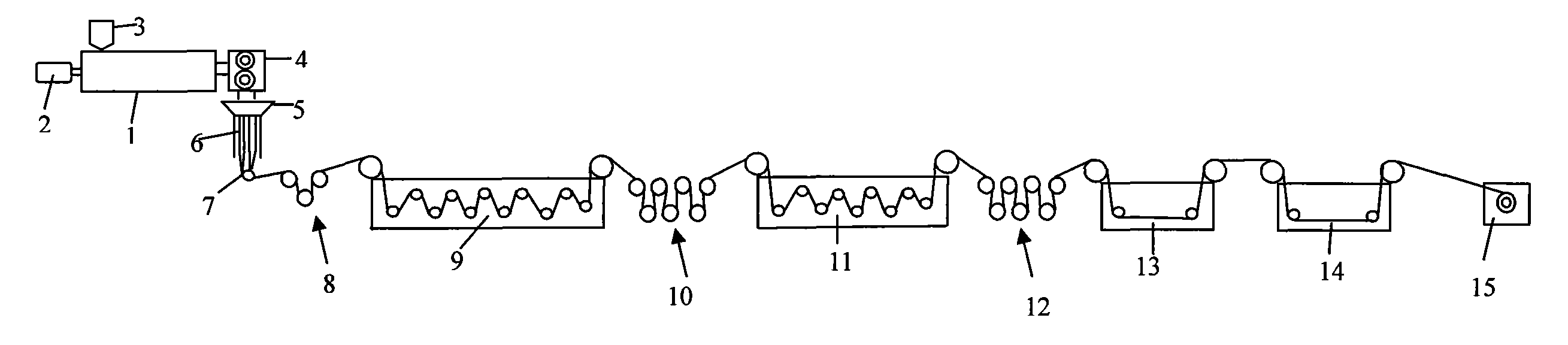

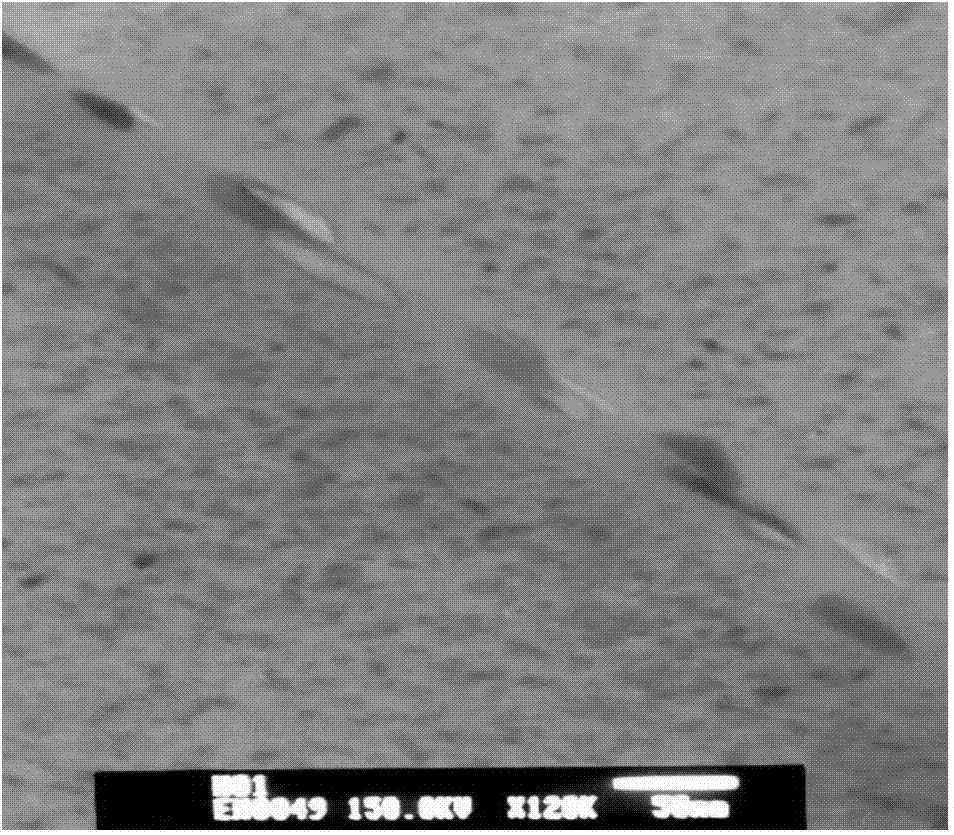

Method and equipment for preparing ultrahigh molecular weight polyethylene fibers

InactiveCN101935894AContinuous productionShort processArtificial thread manufacturing machinesMelt spinning methodsFiberYarn

The invention discloses a method and equipment for preparing ultrahigh molecular weight polyethylene fibers. The method comprises the following steps of: blending and melting ultrahigh molecular weight polyethylene and a modifier to prepare a granular or powdery modified ultrahigh molecular weight polyethylene raw material; melting and extruding the raw material by using an extruder to form melt of which a flow rate is 0.01 to 0.2 grams per 10 minutes, feeding the melt to a spinning mould by using a melt pump to form melt strips, and cooling and pre-stretching the melt strips to obtain primary yarns; and stretching the primary yarns in a plurality of stages to obtain the ultrahigh molecular weight polyethylene fibers. The equipment comprises the extruder, the melt pump, the spinning mould, a cooling channel, a three-roller tractor, a primary hot-stretching box, a first seven-roller tractor, a secondary hot-stretching box, a second seven-roller tractor, a rinsing trough, a drying box and a winder which are arranged sequentially. The method and the equipment have the characteristics of continuous production capability, relatively shorter process flow, relatively fewer equipment components, no need of solvent, low production cost and the like.

Owner:王庆昭

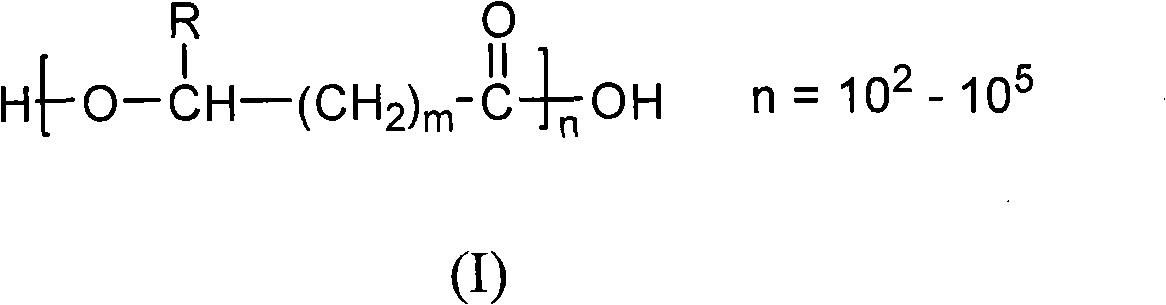

Polyhydroxyalkanoates fiber and preparation method thereof

InactiveCN101538750AArrange straight and neatHigh crystallinityMonocomponent copolyesters artificial filamentConjugated synthetic polymer artificial filamentsFiberBiocompatibility Testing

The invention relates to a fiber and a preparation method thereof, in particular to a degradable fiber and a preparation method thereof. The fiber contains polyhydroxyalkanoates, and the preparation method thereof comprises the steps of melting and extruding a base material, obtaining a sample band, cold-stretching or pre-stretching the sample band, quenching, performing isothermal crystallization and the like. The fiber disclosed by the invention has the advantages of good biocompatibility, biodegradability, high strength and / or good toughness.

Owner:TIANJIN GREENBIO MATERIAL CO LTD +1

Cotton-simulated terylene short fiber and preparation method thereof

ActiveCN101831727AGuaranteed spinnabilitySimple processHollow filament manufactureFilament manufacturePolyesterState of art

The invention provides a cotton-simulated terylene short fiber. Concave pits are formed on the surface of the cotton-simulated terylene short fiber; and the cotton-simulated terylene short fiber comprises 0-1 percent by weight of calcium sulphate, 1-10 percent by weight of PEG (Polyethylene Glycol) and 1-10 percent by weight of ECDP (Easy Cationic Dyeable Polyester). The invention also provides a preparation method of the cotton-simulated terylene short fiber, comprising the following steps of: slicing the PET; drying a mixture of the calcium sulphate, the ECDP and the PEG and fusing and spinning the mixture into a terylene raw filament at 270-280DEG C by using a profile spinneret; carrying out winding, doffing, balanced bundle collection, wire guiding, pre-stretching and oiling; after primary or secondary stretching, dissolving out partial calcium sulphate in the soaking process by alkali treatment to form mocropores on the surfaces of fibers; and finally carrying out tense heat setting, curling, loosed heat setting, cutting and packaging to obtain the cotton-simulated terylene short fiber. The invention solves the problems that a compound spinning process in the prior art is not only complicated, but also has low yield and makes up the defects that the terylene has poor hydrophilicity and the textile is humid and muggy to wear.

Owner:XUZHOU SILK FIBER TECH

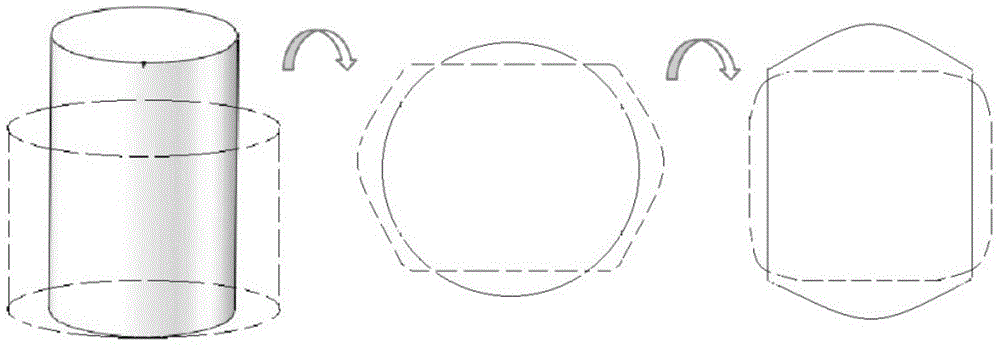

Microscale Al-containing rare earth wrought magnesium alloy and preparation method thereof

The invention relates to a microscale Al-containing rare earth wrought magnesium alloy and its preparation method and belongs to the scope of industrial magnesium alloy. The magnesium alloy comprises, by weight, 6.5-15.0% of Gd, 3.0-5.5% of Y, 2.0-4.0% of Zn, 0.3-1.5% of Nd, 0.3-0.9% of Zr, 0.4-1.0% of Al and the balance of Mg. The preparation method of the magnesium alloy comprises the steps as follows: raw material preparation, alloy melting, alloy semi-solid extrusion, homogenization treatment, redeformation, cooling and pre-stretching treatment, ageing strengthening treatment and the like. By fully utilizing the defect that Al is preferentially combined with rare earth and Zr in alloy to form a stable phase, Zn element is added to make up insufficiencies and the wrought magnesium alloy with high performance is prepared. The recovery effect of rare earth elements is enhanced, and semi-solid forming and solid plastic forming are combined.

Owner:GRIMAT ENG INST CO LTD

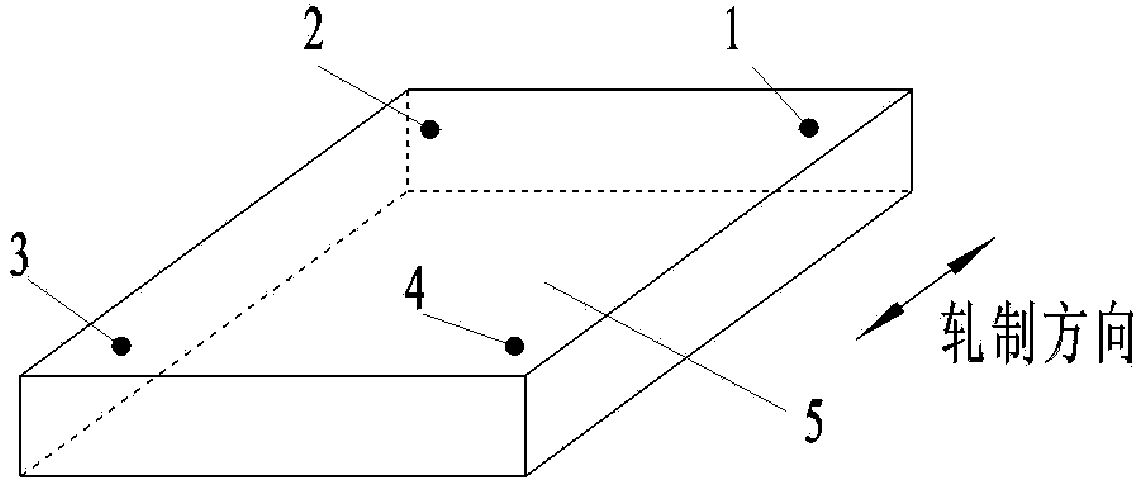

Method for preparing wide magnesium alloy sheet

ActiveCN103316915AGive full play to shapingEasy to shapeRoll mill control devicesMetal rolling arrangementsInternal stressMaterials science

The invention relates to a method for preparing a wide magnesium alloy sheet. According to the method, a fine-grain and homogeneous magnesium alloy slab with low internal stress is homogenized and then reversibly hot-rolled at a high speed, the sheet is hugely pressed down and deformed by combining multiple pony-roughing pass high-temperature pre-annealing with vertical roller rolling and pre-stretching in the reversible high-speed hot-rolling process, and a magnesium alloy medium-thickness sheet can be obtained after multi-pass hot-rolling. After ends of the medium-thickness sheet are cropped and the edge of the medium-thickness sheet is sheared, the surface of the medium-thickness sheet is grinded and polished, the medium-thickness sheet is precisely rolled after heating and annealing, and the sheet is hugely pressed down and deformed by combining multiple pony-roughing pass high-temperature pre-annealing with repeated bending deformation and high-speed asymmetrical rolling in the precision rolling process, so that the high-precision magnesium alloy sheet is obtained. The method is simple in process, easy to operate and suitable for large-scale industrial production, sheet cracking rate is greatly reduced, and the yield of the magnesium alloy sheet is remarkably improved.

Owner:NORTHEASTERN UNIV

Aluminum alloy for 480 MPa-class aluminum alloy oil pipe and pipe manufacturing method thereof

The invention discloses an aluminum alloy for a 480 MPa-class aluminum alloy oil pipe. The aluminum alloy comprises the following components by weight percent: 5.10-6.90% of Zn, 1.10-1.80% of Mg, 0.05-0.20% of Cu, 0.10-0.30% of Mn, 0.10-0.30% of Cr, 0.01-0.02% of Ti, 0.15-0.2% of Zr and the balance of Al and unavoidable impurities, wherein in the unavoidable impurities, the content of the Si is not greater than 0.15 of the total weight of the aluminum alloy and the content of Fe is not greater than 0.15 of the total weight of the aluminum alloy. The manufacture method of the aluminum alloy pipe comprises the following steps: (1) smelting the raw materials according to the weight percentage, performing external refining and casting to obtain a pipe blank; (2) performing three-stage homogenization treatment; (3) squeezing under high temperature; (4) performing twin-stage solid solution treatment, quenching and cooling; (5) prestretching and deforming; and (6) performing twin-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

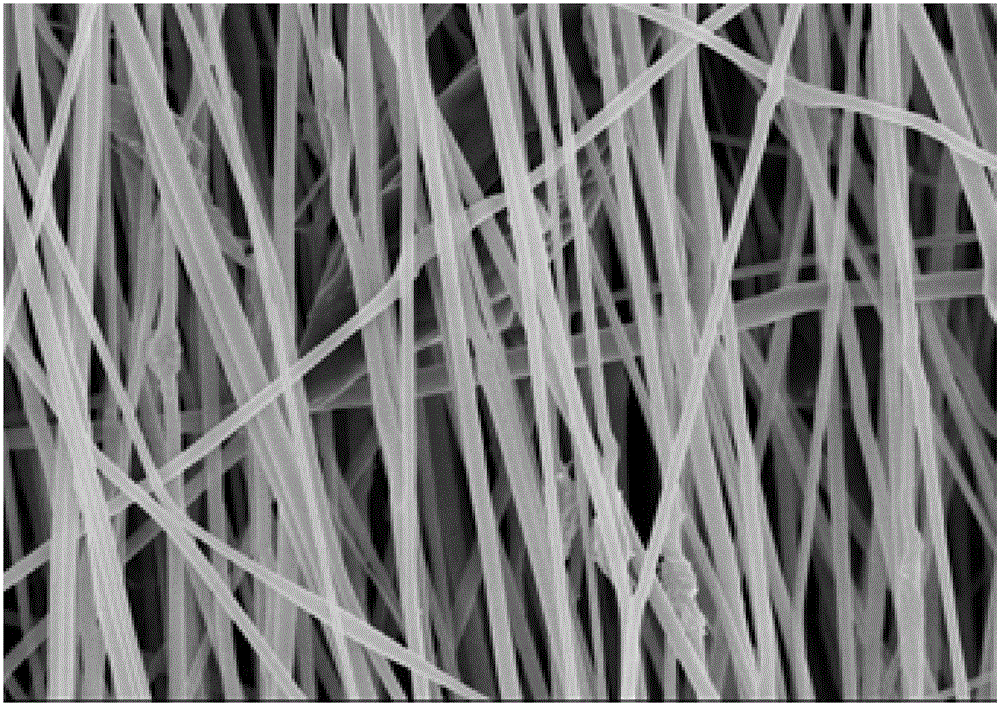

Preparation method and application of stretchable polymer composite material

InactiveCN105970350AElectroconductive/antistatic filament manufactureElectro-spinningFiberPolymer science

The invention relates to a preparation method of a polymer composite material capable of being stretched in a wide range and in particular relates to a preparation method and application of a stretchable polymer composite material based on super-aligned orderly fibers. Aligned ultrathin nanofibers are deposited on a rubber base pre-stretched by 200-400% (the length after stretching is 2-4 times the original rubber length) by adopting the electrostatic spinning technology and utilizing a roller collection method, and a folded structure is formed after rubber recovers, thus preparing the stretchable composite material.

Owner:CHANGZHOU UNIV +1

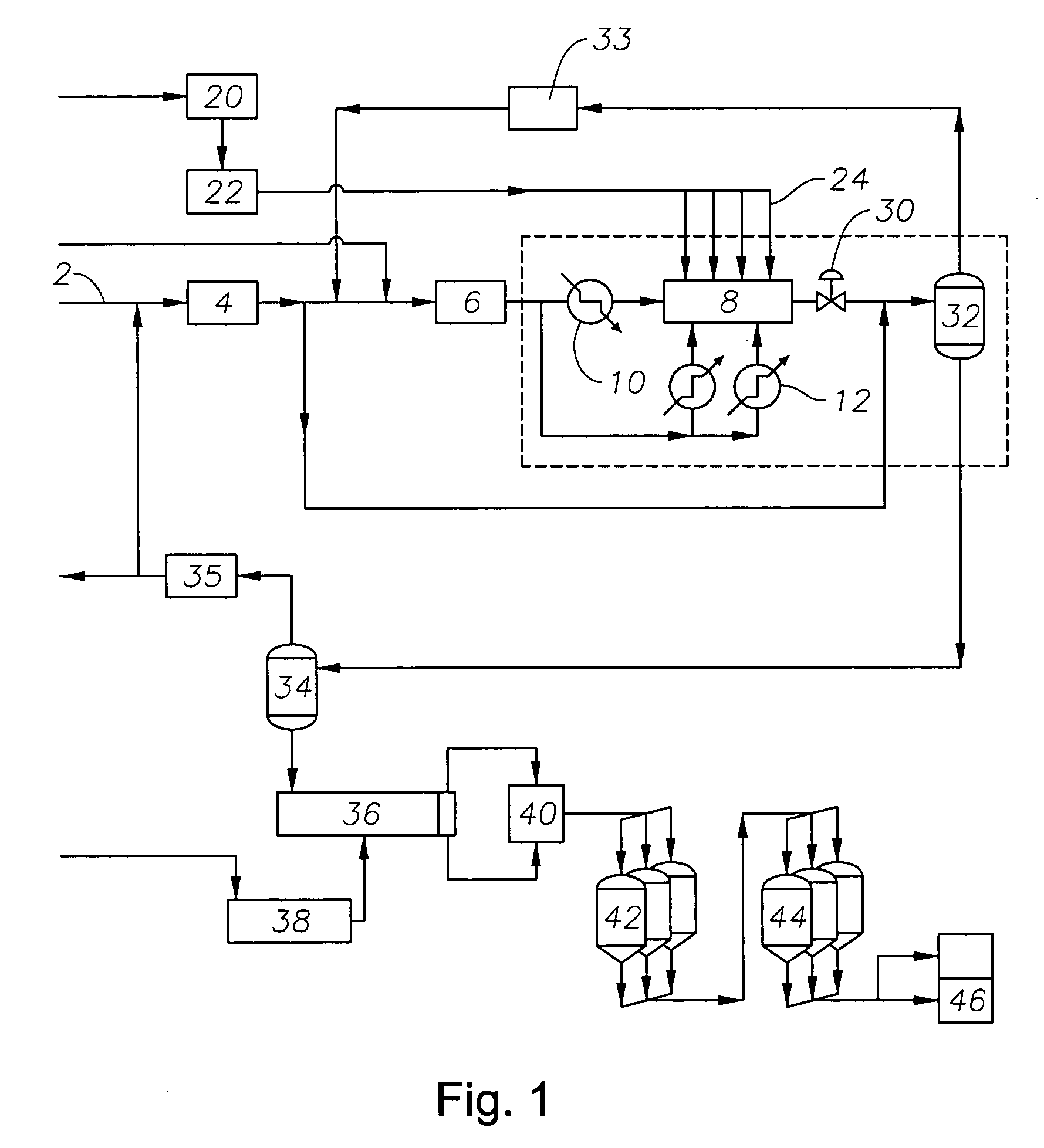

Apparatus and high speed process for making highly stretched film

InactiveUS6375781B1Maximize contactMinimize neck-inMechanical working/deformationLaminationElectrical and Electronics engineeringPre stretching

An apparatus and high speed process for heating and stretching a film having a bridle mechanism comprising a first heated roll and a second heated roll. The film is stretched as the film is transferred from the first heated roll to the second heated roll which rotates at a speed greater than the speed at which the first heated roll rotates. The film is fed into the bridle mechanism at a rate of about 1,500 fpm to about 2,500 fpm wherein it is stretched to a length that is up to about 450% greater than its initial, pre-stretched length. The increased contact between the large diameter heated rolls and the film and the short draw gap between the two heated rolls result in a highly stretched film having minimal neck-in.

Owner:ILLINOIS TOOL WORKS INC

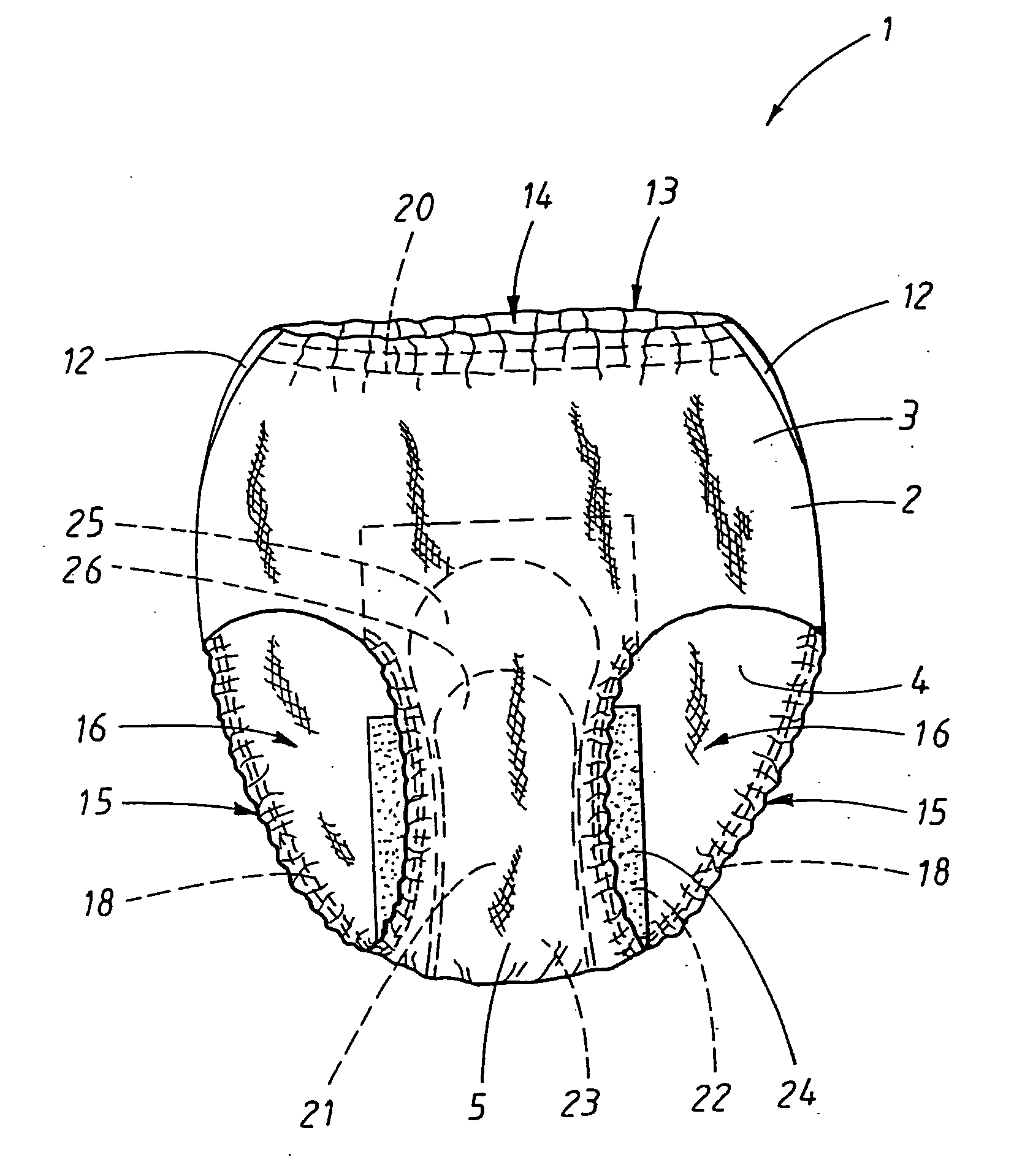

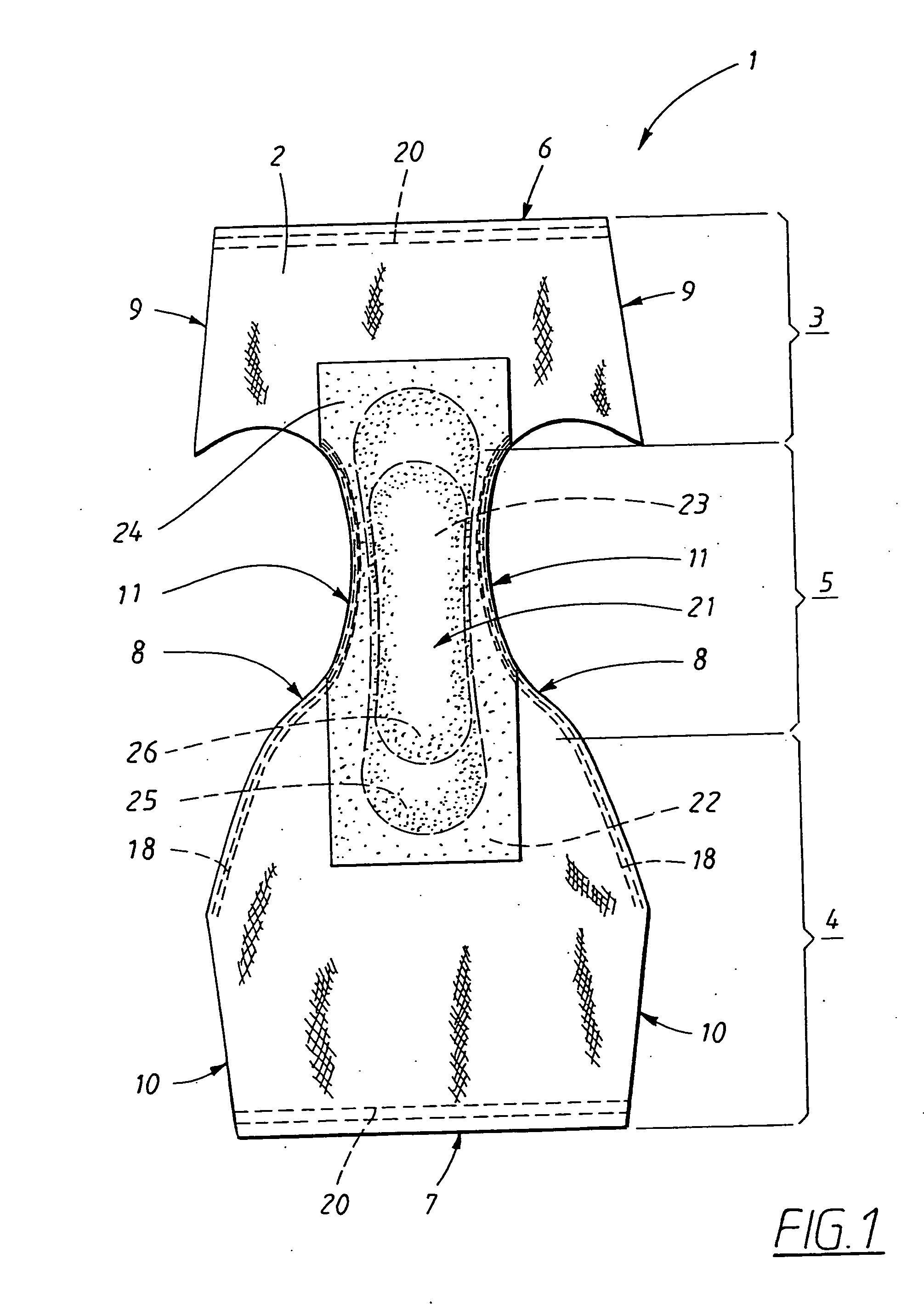

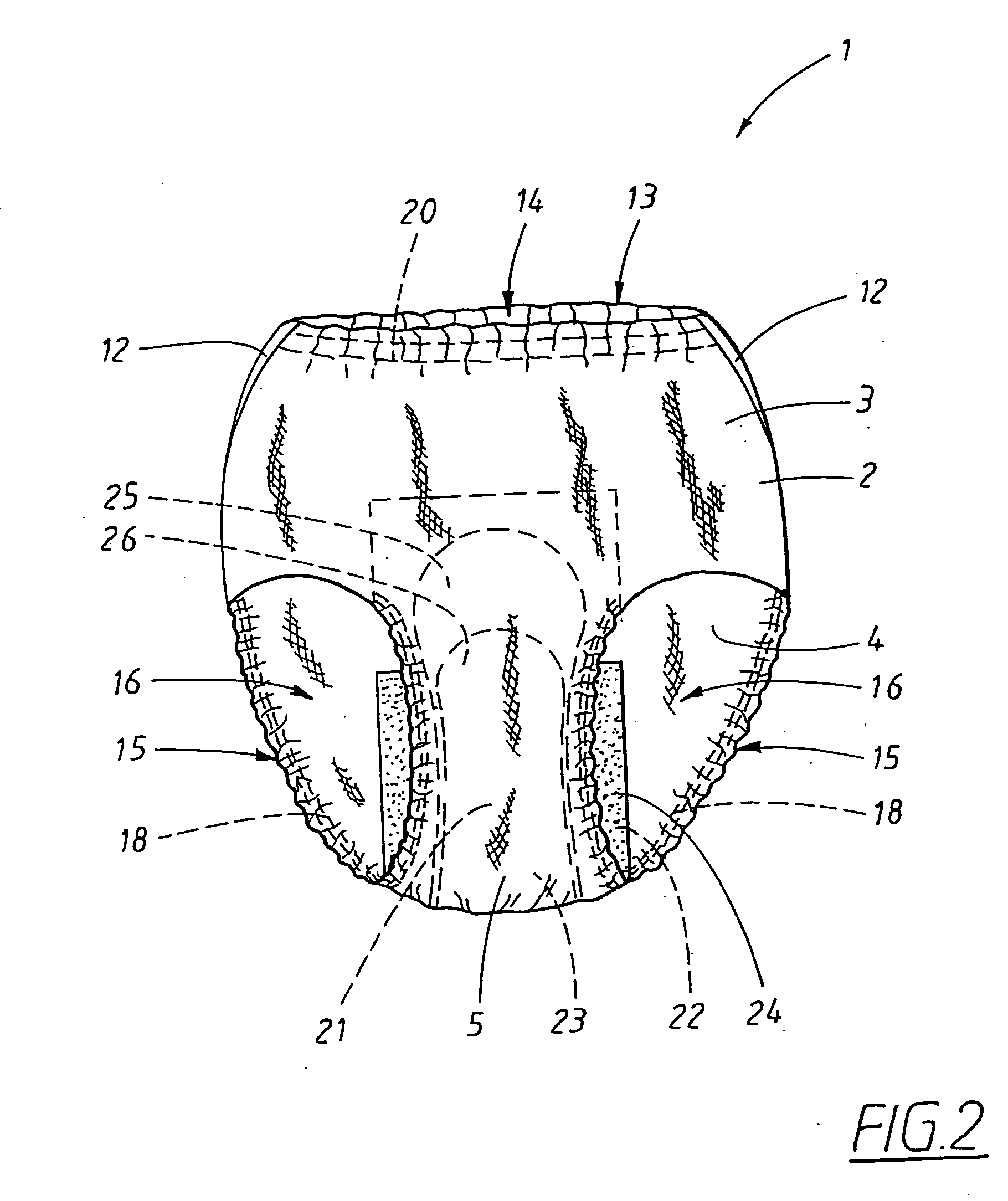

Pant-shaped article with improved fit

ActiveUS20080161767A1Eliminate pressureEliminate riskBaby linensTamponsEngineeringMechanical engineering

A pant shaped garment having a rear portion, a front portion, and a crotch portion, a waist opening with a waist edge and two leg openings bordered by a leg edge having a front part located generally on the front portion and a rear part located generally on the rear portion and on the crotch portion. Front and rear portions are mutually connected in two side joins which run from the waist opening to each leg opening. An elongated elastic element is pre-stretched along the rear part of the leg edge of each leg opening. The front portion comprises an elastically extensible material and the elongated elastic element constricts the rear part of the leg edge, thereby stretching the elastic material along the front part of the leg edge. The side joins exhibit a curvature in a direction towards the rear portion that increases in a direction from the waist opening towards the leg opening.

Owner:ESSITY HYGIENE & HEALTH AB

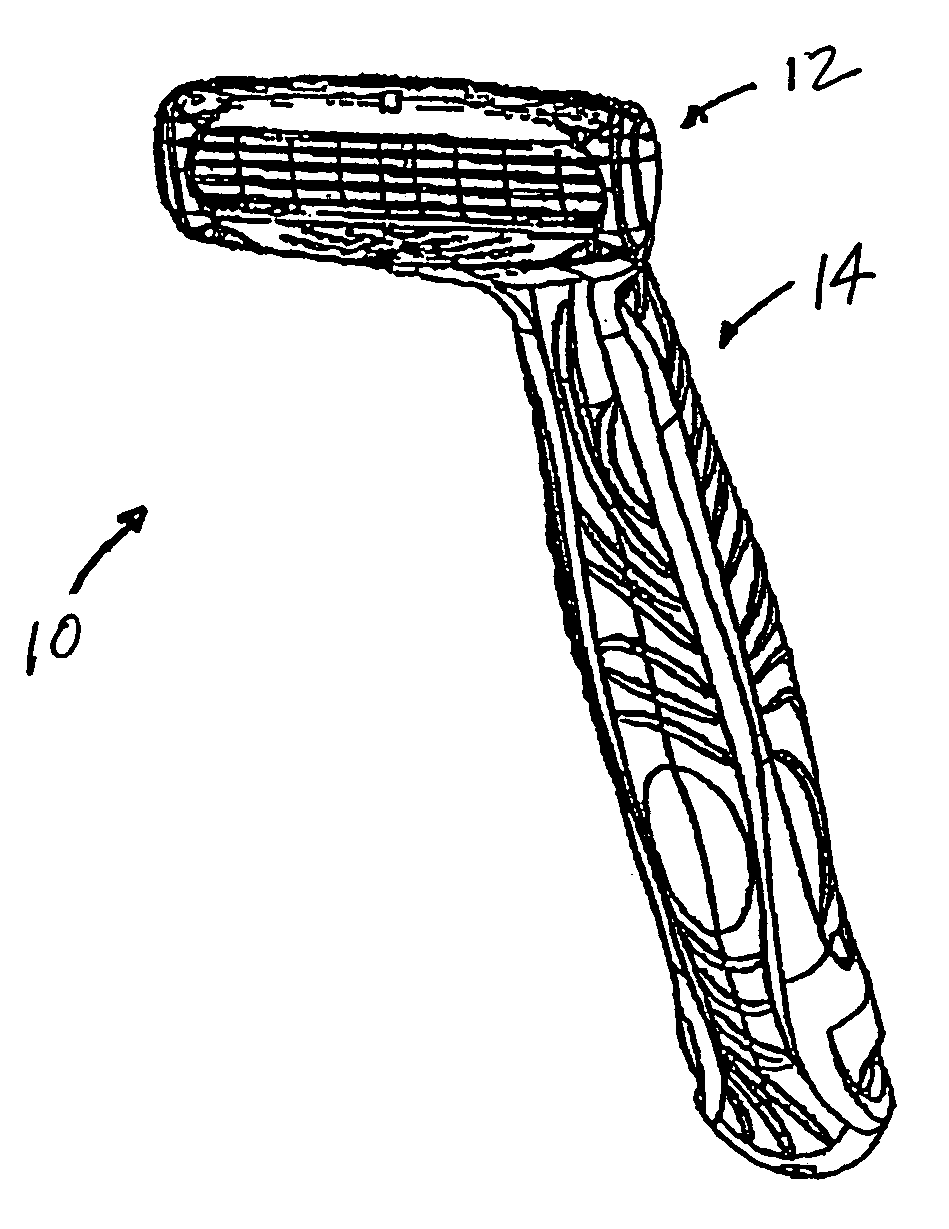

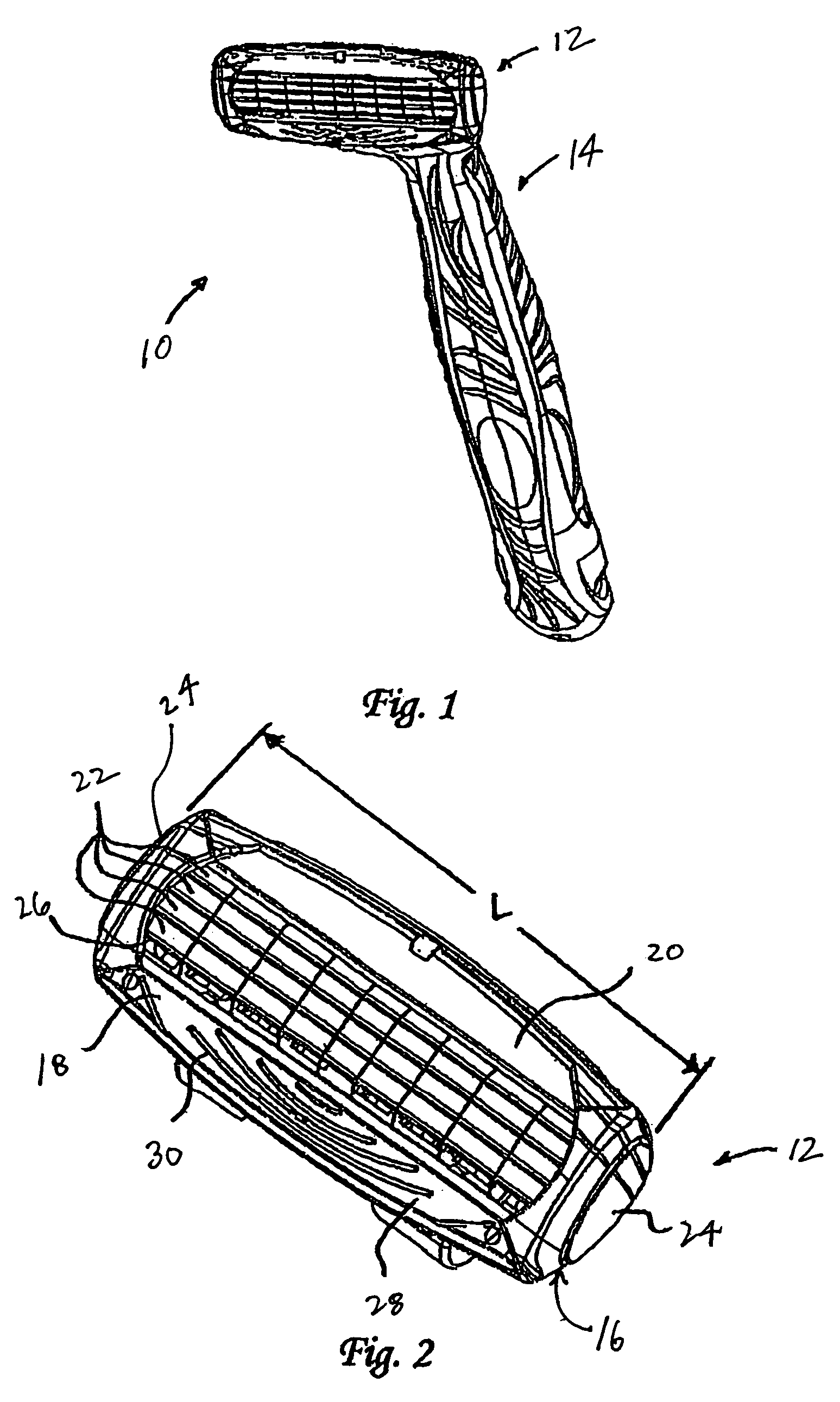

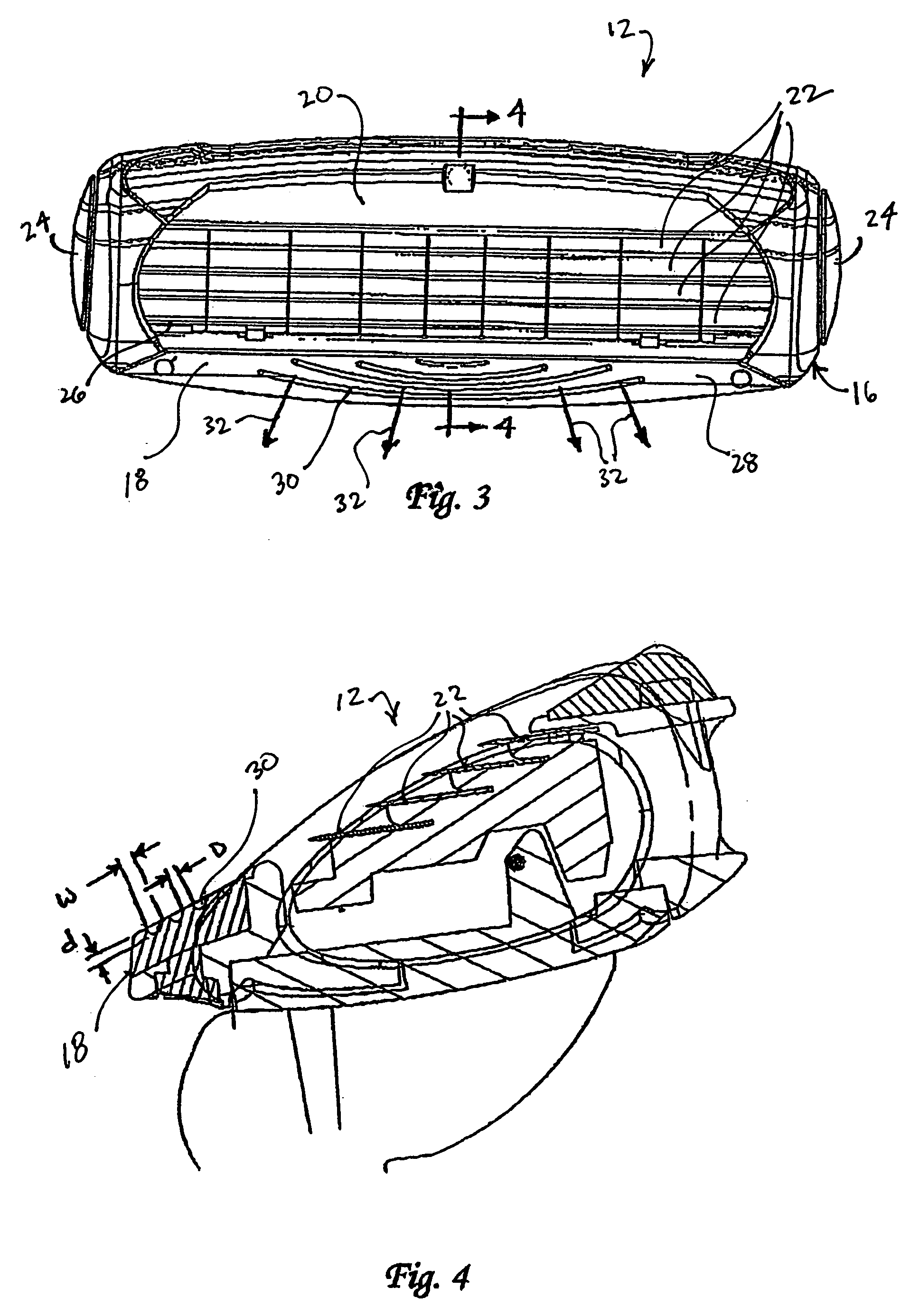

Shaving implement

InactiveUS20060070240A1Facilitate close cuttingSmoothly shavedMetal working apparatusEngineeringKnife blades

A guard for a razor cartridge has a skin-engaging surface and a plurality of arcuate channels formed therein that, when the guard is incorporated into a shaving implement and used to shave, pre-stretch the skin in directions forward of razor blades of the cartridge and outward towards the edges of the cartridge. A razor cartridge has a plurality of skin-engaging elements mounted on a frame having two ends, the skin-engaging elements including at least one blade having a sharpened cutting edge; a cap positioned aft of the at least one blade; and a guard positioned forward of the at least one blade, the guard having a skin-engaging surface and a plurality of arcuate channels that pre-stretch the skin and distribute water and / or shaving aid material along the cutting edge of the blade. A wet shaving system has a handle and the razor cartridge mounted thereon.

Owner:EVEREADY BATTERY CO INC

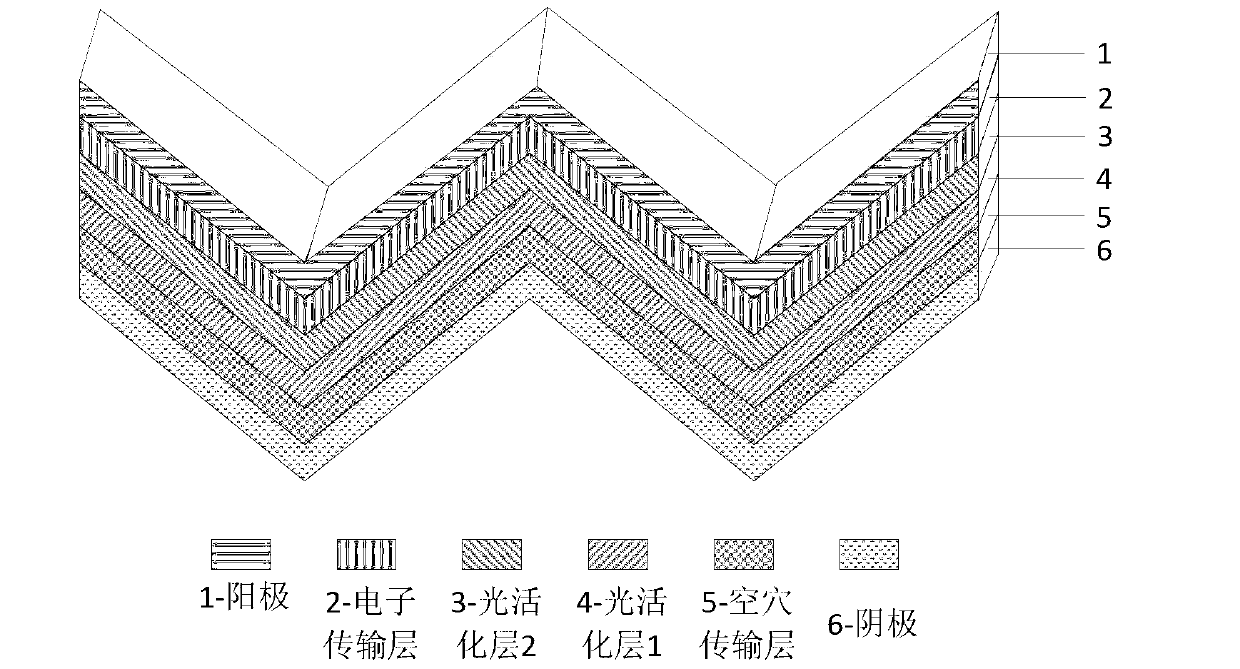

Flexible polymer solar battery with wrinkling structure and preparation method thereof

InactiveCN103219467AImprove the utilization rate of sunlightImprove photoelectric conversion efficiencySolid-state devicesSemiconductor/solid-state device manufacturingComposite filmPolyethylene terephthalate glycol

The invention relates to a flexible polymer solar battery with a wrinkling structure, comprising a transparent electrode, a cavity transporting layer, photo-activation layer materials, an electron transporting layer and a metal electrode, wherein the photo-activation layer materials comprise a donor material and an acceptor material; the transparent electrode is made of graphene / PEDOT(poly(3,4-ethylenedioxythiophene):PSS(polystyrene sulfonate) / PET(polyethylene terephthalate) composite film; the hole transporting layer is made of a PEDOT:PSS film; an electron donor is made of P3HT; an electron acceptor is made of graphene / PEDOT:PSS composite particles; the electron transporting layer is made of a zinc-oxide film; and the metal electrode is made is silver. The flexible polymer solar battery is prepared by the following steps of: adopting an ink-jet printer to print a graphene / PEDOT:PSS transparent conducting layer, the hole transporting layer, active-layer materials, the electron transporting layer and metal slurry on a pre-stretched PET film in sequence, carrying out drying treatment on the materials under the temperature being 50-100 DEG C, then removing pre-stretching force and obtaining the flexible polymer solar battery with the wrinkling structure. The flexible polymer solar battery has the advantages that the sunlight utilization rate is high, the photoelectric conversion efficiency is high, the preparation process is simple and convenient, the mechanical stability is good, large-scale industrial preparation can be realized and the application prospect is wide.

Owner:PEKING UNIV

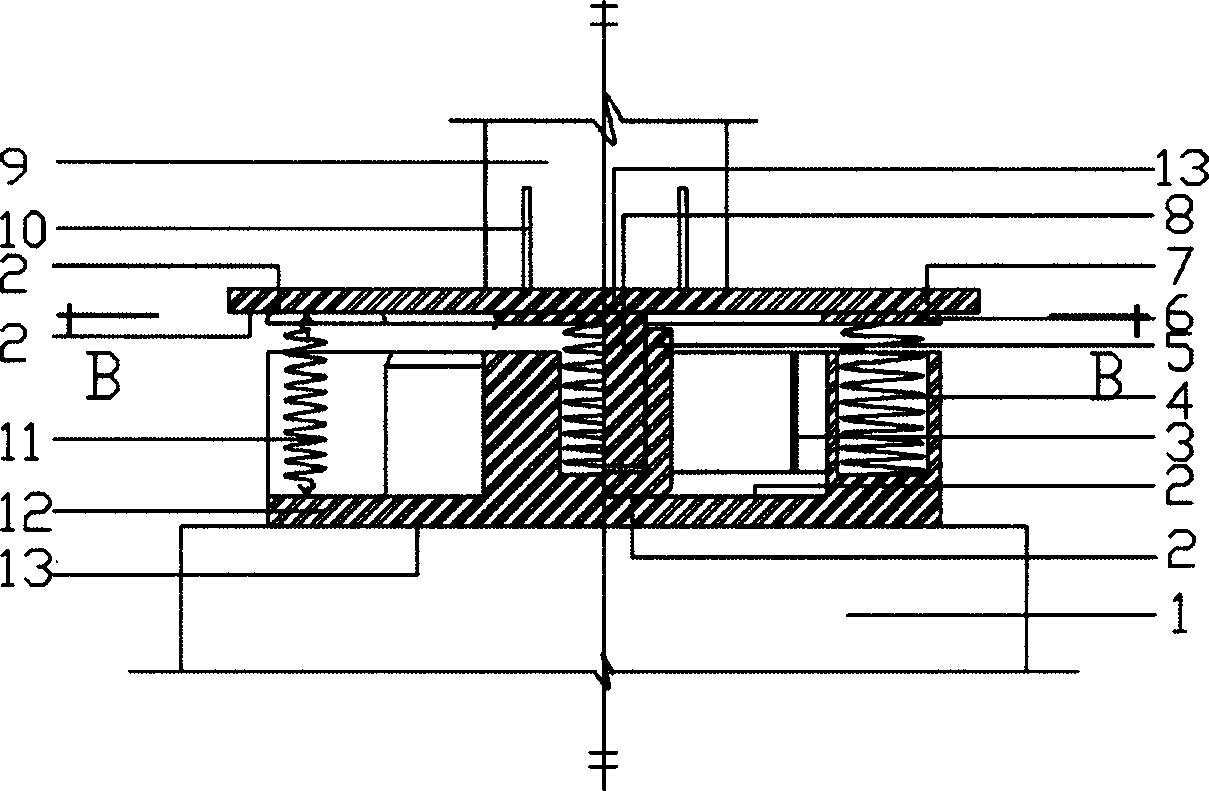

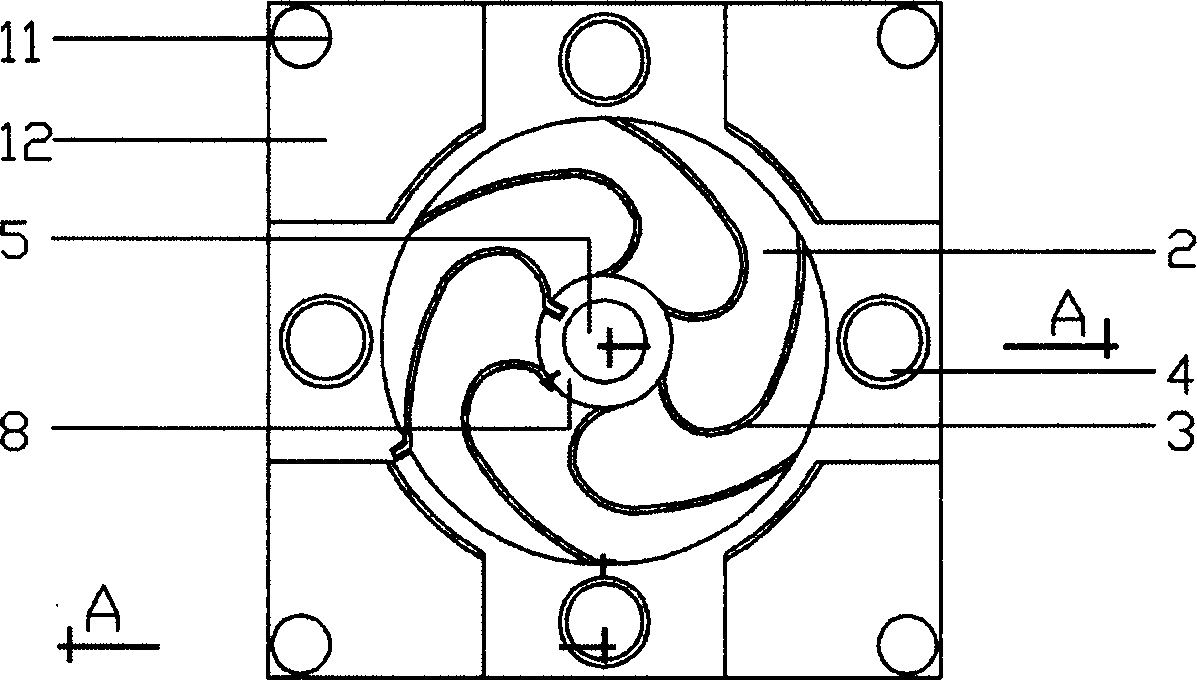

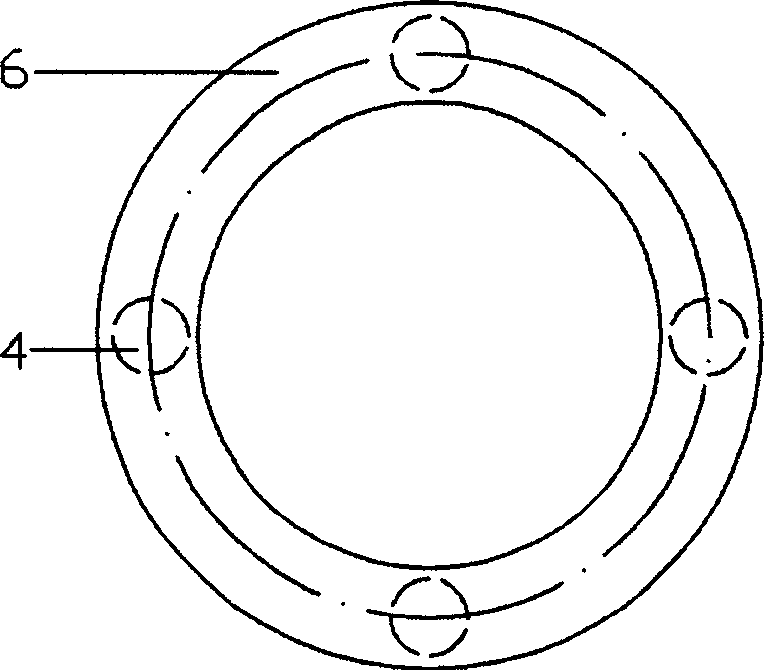

Slide type multiple dimension shock-proof device

InactiveCN1715574ASimple structureGood shock isolation and energy consumptionProtective buildings/sheltersShock proofingSlide plateWeld seam

The present invention provides a kind of sliding multidimensional vibration isolator, and belongs to the field of shockproof technology for civil engineering building. The sliding multidimensional vibration isolator consists of lower vibration isolating seat board, coating layer of low friction coefficient material, energy consuming steel plate, pre-pressing spring, round steel sliding block, ring sliding plate, upper vibration isolating seat board, upper round steel connecting block, anchor rib, pre-stretching spring and welding seam. The present invention has the advantages of simple structure, low cost, high durability, high vibration isolating and energy consuming effect, easy construction and other advantages, and may be used widely in building, structure and bridge structure.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

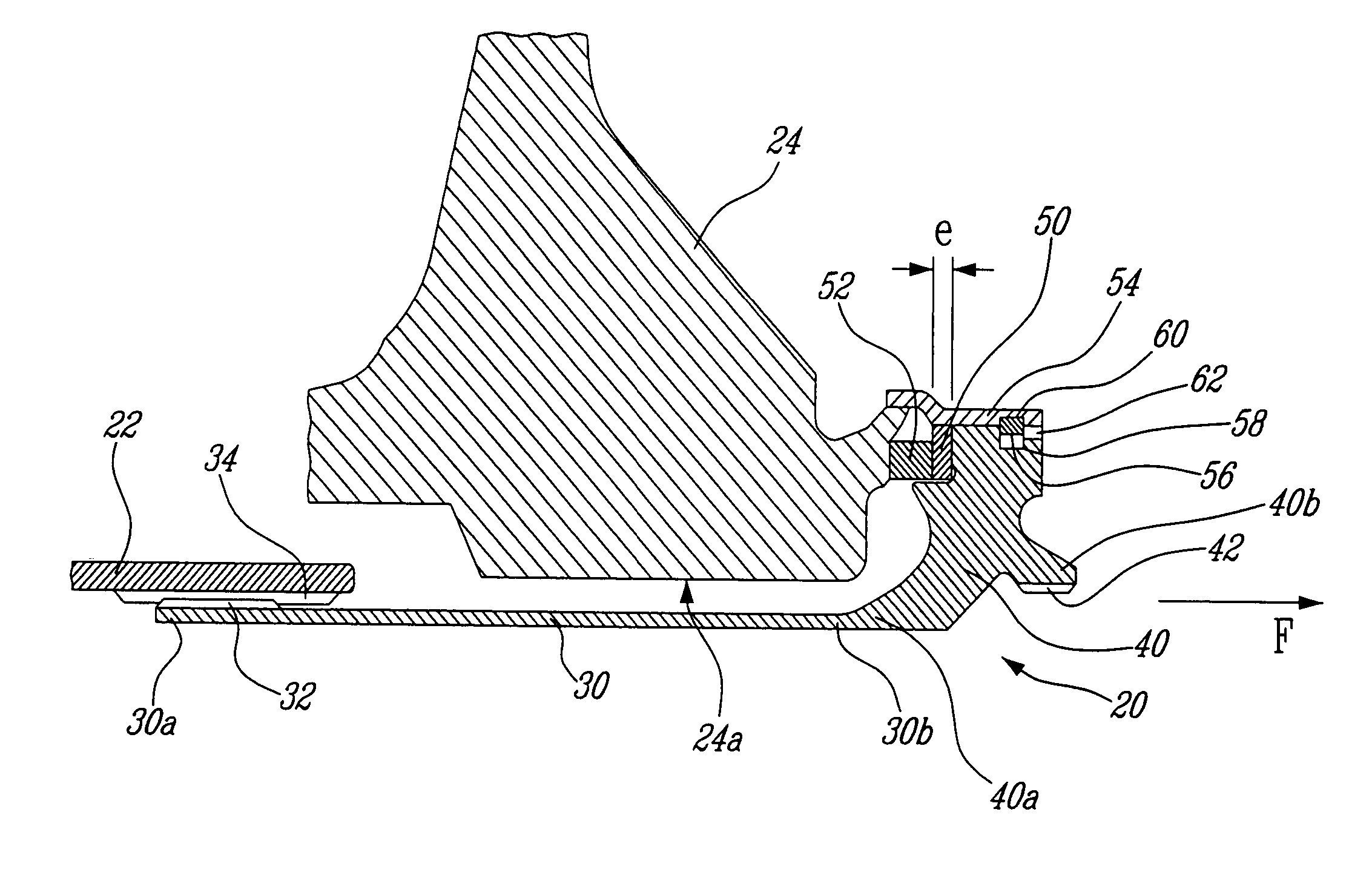

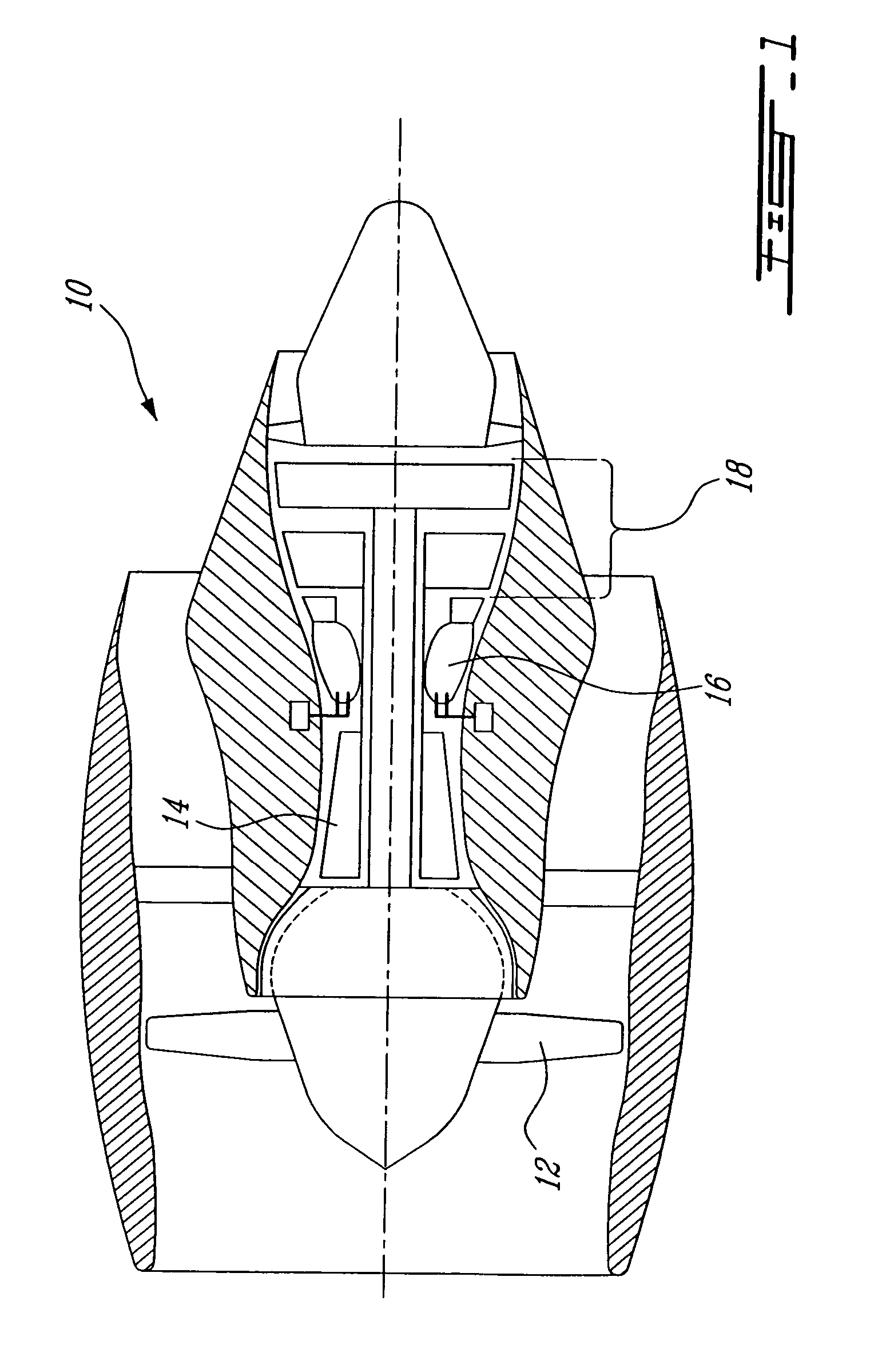

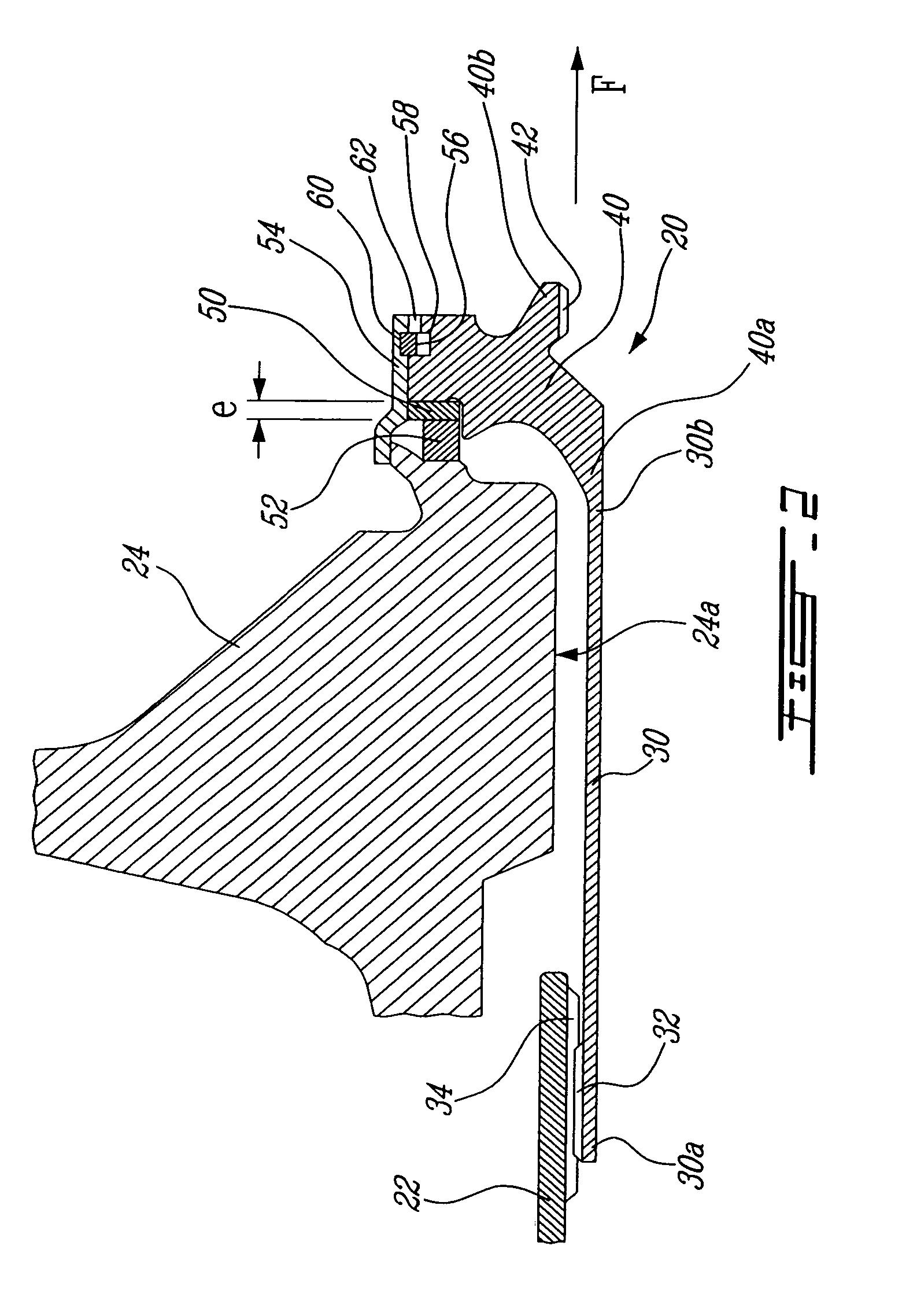

Pre-stretched tie-bolt for use in a gas turbine engine and method

The tie-bolt comprises an elongated tubular portion and a retaining portion coaxially and rigidly attached to the tubular portion. The retaining portion has an outer diameter larger than that of the tubular portion. An annular spacer is removably provided between the retaining portion and the component to be secured by the tie-bolt.

Owner:PRATT & WHITNEY CANADA CORP

Preparation method and application of high-strength oriented polyvinyl alcohol hydrogel

ActiveCN110229374AGuaranteed biocompatibilityReduce usageTissue regenerationProsthesisFreeze thawingPolymer science

Owner:BEIFANG UNIV OF NATITIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com