Preparation method and application of stretchable polymer composite material

A composite material and polymer technology, applied in the direction of conjugated synthetic polymer artificial filament, conductive/antistatic filament manufacturing, filament/wire forming, etc., can solve high equipment requirements, limited applications, high fiber brittleness, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

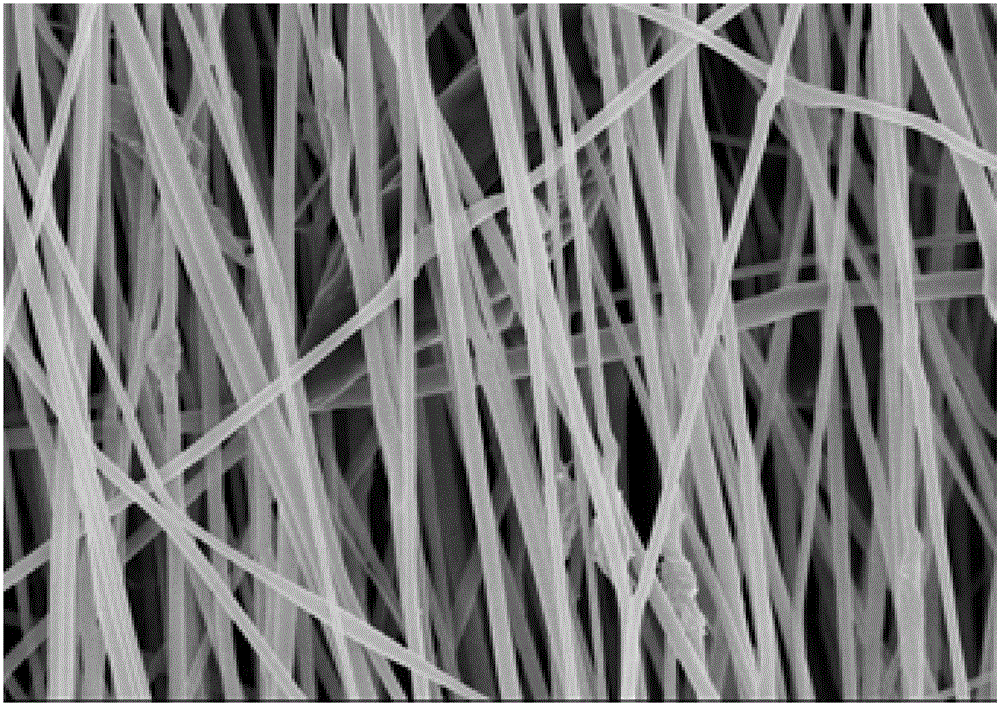

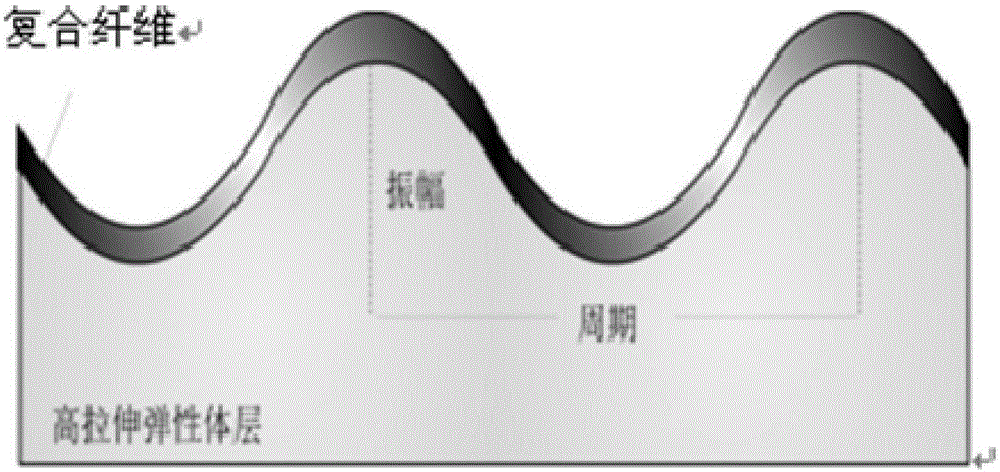

[0027] Example 1 Stretchable polyacrylonitrile / polyaniline composite nanofibers

[0028] (1) Preparation of polyacrylonitrile / aniline precursor solution

[0029] Pour 10 mL of N,N-dimethylformamide (DMF) into a conical flask, and slowly add 1.35 g of polyacrylonitrile (PAN, molecular weight 1.0×10 6 ), at room temperature, continuously stirred with a magnetic stirrer for 12 h to obtain an electrospinning stock solution; under the condition of magnetic stirring, slowly drop 12.5 mL of aniline (ANI) into the PAN solution. Magnetic stirring was carried out for 10 min, and when all was dripped in, the stirring was continued for 3 h to obtain the precursor solution of PAN / ANI.

[0030] (2) Preparation of polyacrylonitrile / aniline ordered precursor fibers

[0031] After pre-stretching the rubber substrate by 300%, it is fixed on a metal receiving roll. The electrospinning device was used for spinning, the receiving distance was 10cm, the working voltage was positive pressure of 1...

Embodiment 2

[0037] Example 2 Stretchable polyacrylonitrile / polyaniline / carbon nanotube composite nanofibers

[0038] (1) Preparation of polyacrylonitrile / aniline / carbon nanotube precursor solution

[0039] Pour 10 mL of N,N-dimethylformamide (DMF) into a conical flask, and slowly add 1.35 g of polyacrylonitrile (PAN, molecular weight 1.0×10 6 ), and continuously stirred with a magnetic stirrer for 12 h at room temperature to obtain an electrospinning dope; under magnetic stirring, 10 mL of carbon nanotube (CNTs) dispersion with a mass fraction of 70-80‰ was added to the PAN solution Then, 12.5 mL of aniline (ANI) was slowly dropped into the above mixed solution. After each addition of 1 mL of LANI solution, magnetic stirring was required for 10 min. .

[0040] (2) Preparation of polyacrylonitrile / aniline / carbon nanotube ordered precursor fibers

[0041]After pre-stretching the rubber substrate by 300%, it is fixed on a metal receiving roll. The electrospinning device was used for spin...

Embodiment 3

[0046] Example 3 Stretchable polyacrylonitrile / polyaniline / silver nanowire composite nanofibers

[0047] (1) Configuration of polyacrylonitrile / aniline / silver nanowire precursor solution

[0048] Pour 10 mL of N,N-dimethylformamide (DMF) into a conical flask, and slowly add 1.35 g of polyacrylonitrile (PAN, molecular weight 1.0×10 6 ), at room temperature, continuously stirred with a magnetic stirrer for 12 h to obtain an electrospinning stock solution; under magnetic stirring, 5 mL of silver nanowires (AgNWs) was added to the PAN solution, and then 12.5 mL of aniline (ANI) was added. Slowly drop into the above mixed solution. After each addition of 1 mL of ANI solution, magnetic stirring is required for 10 min. When all of the ANI solution is added, continue stirring for 3 h to obtain the PAN / ANI / AgNWs precursor solution.

[0049] (2) Preparation of polyacrylonitrile / aniline / silver nanowire ordered precursor fibers

[0050] After pre-stretching the rubber substrate by 300%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com