Patents

Literature

42 results about "Random surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surgical implant for promotion of osseo-integration

InactiveUS20050119758A1Enhanced cell attachmentInhibit cell growthDental implantsInternal osteosythesisSurface patternSurgical implant

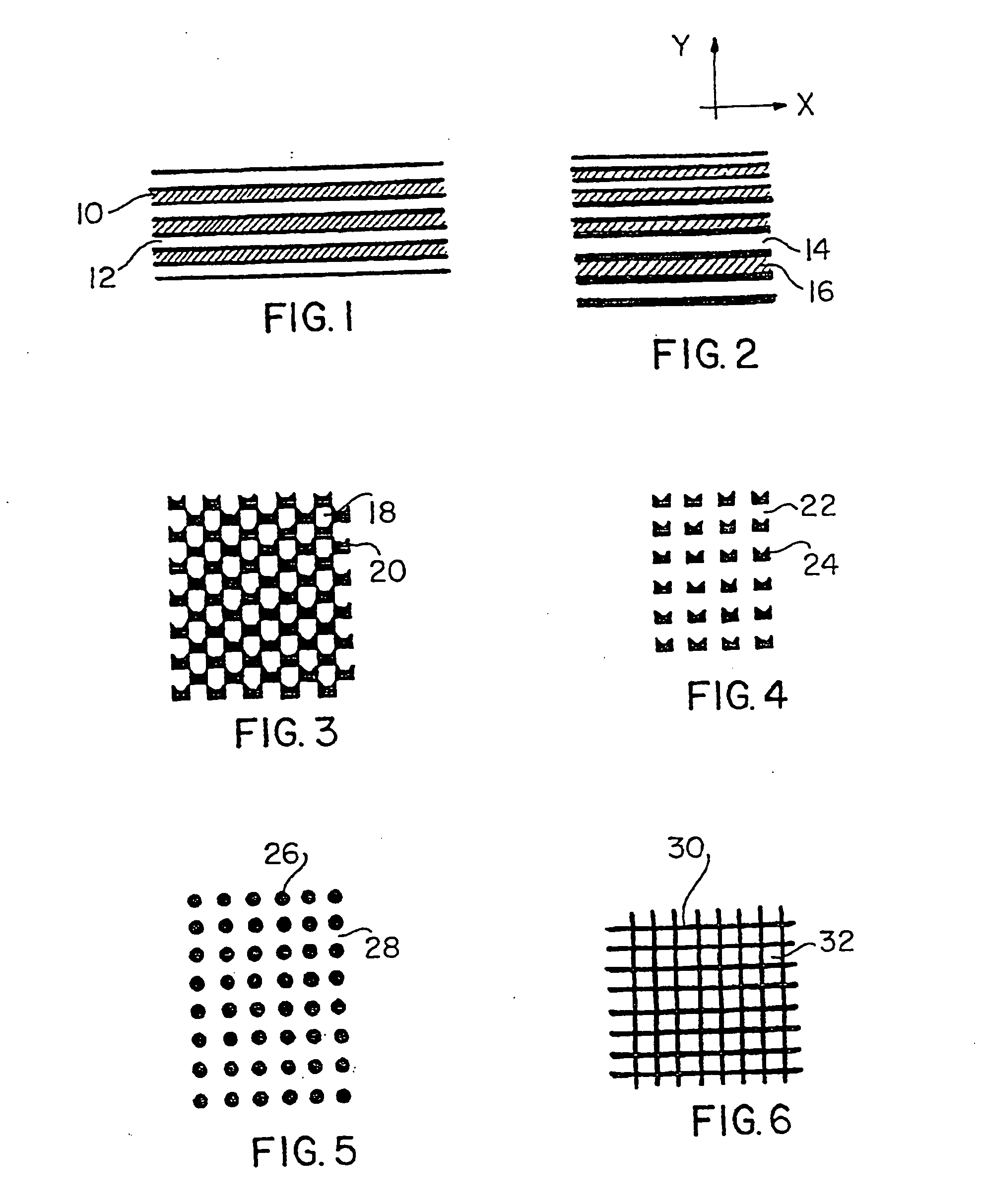

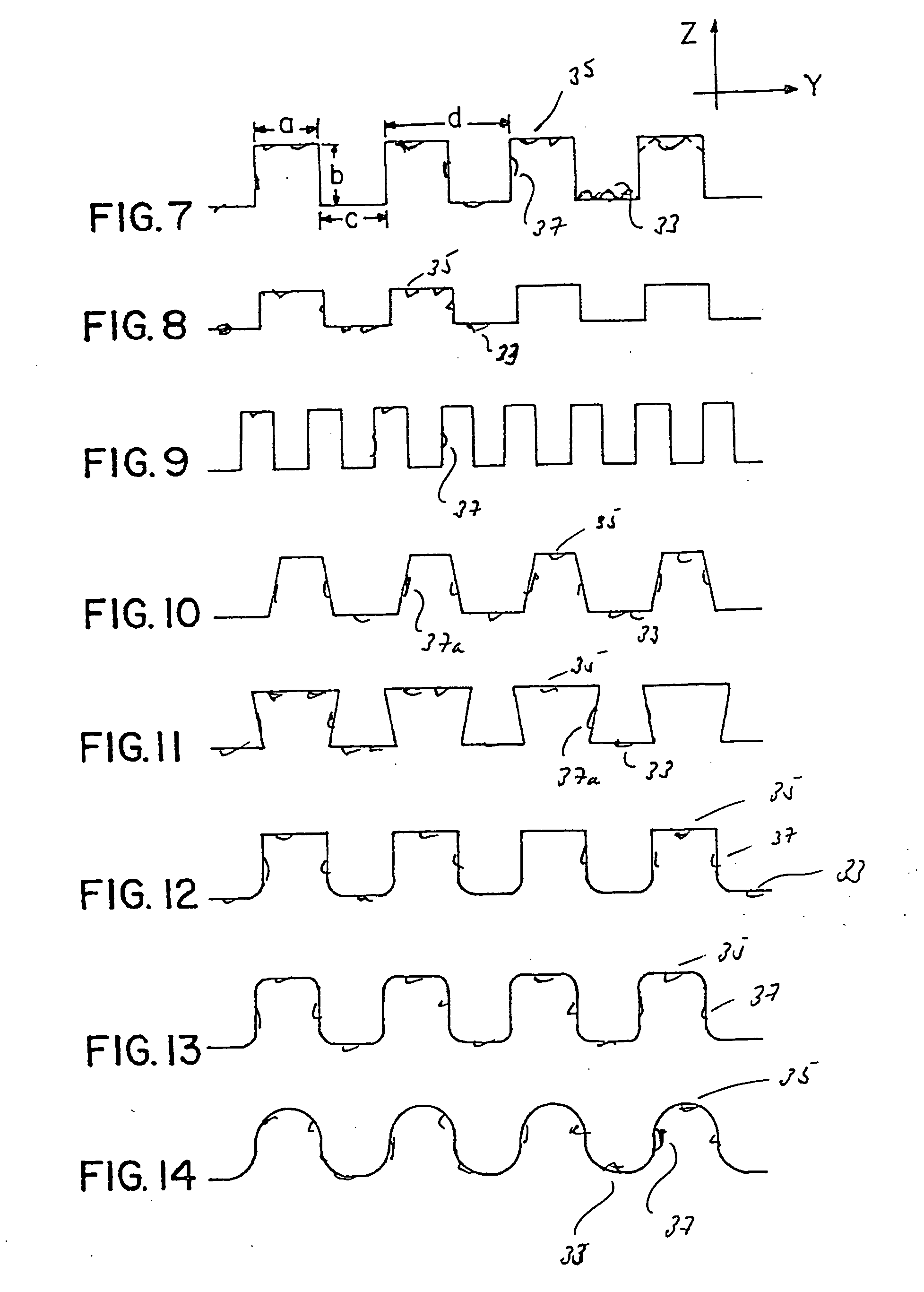

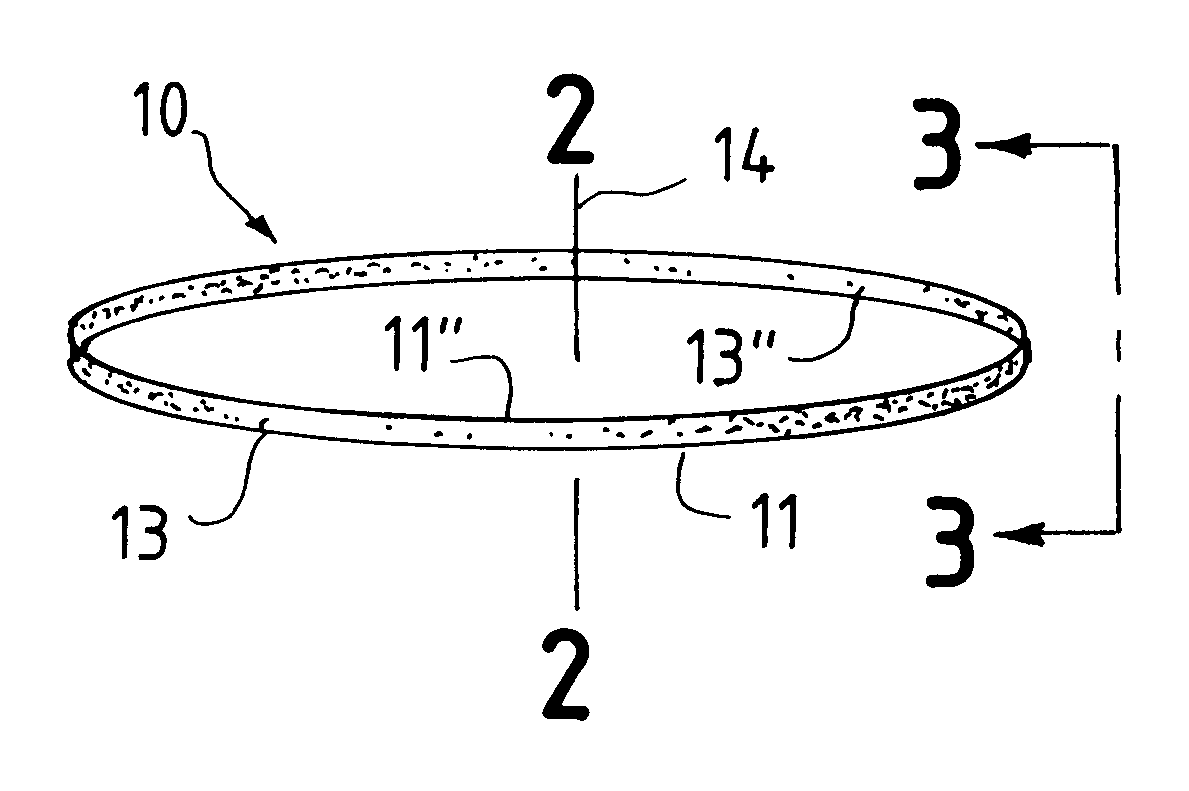

An implant for surgical insertion into tissue of a patient includes a microgeometric, repetitive pattern, in the form of a multiplicity of alternating ridges and grooves, each having an established width in a range of about 2 to about 25 microns, and an established depth in a range of about 2 to about 25 microns, each groove having a base and a wall; and a microgeometric random surface pattern, applied over the repetitive surface pattern, defining a multiplicity of micro-pits having dimensions in a range of about 0.1 to about 4 microns.

Owner:BIO LOK INT INC

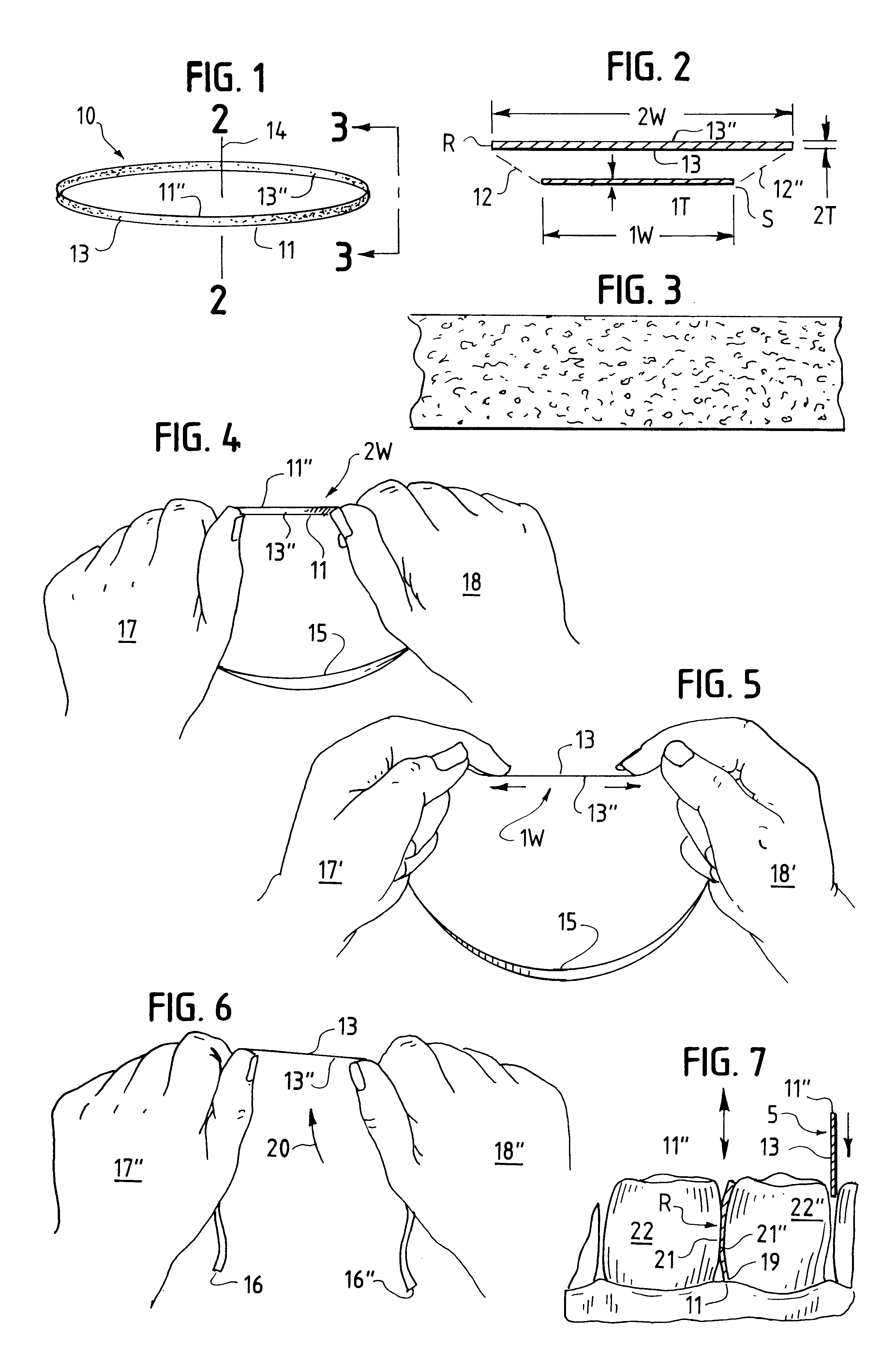

Variable-guage tooth-flossing loops

Embodied in the flexile forms of both an endless-loop and as a linear-tape, a unique tooth flossing device for cleaning away bacteria between the teeth is set forth. Comprised of a nontoxic extrusion-molded thermo-plastic polyurethane having particular properties of excellent elasticity, almost film-like guage of thickness, and a natural random surface-texture serving to aid the flossing procedure. In use, a FLOSS-LOOP(TM) is simply held in the user's thumb-&-forefinger of both hands, so as to pre-stretch "thin" that portion to be slid vertically between the teeth. The exceptionally high stretched tensile-strength of this device enables it to endure the duress of insertion between the teeth, yet once interposed interstitially adjacent the gum-line, the release of excess tension upon the tensioned segment of the loop enables it to resume it's natural thickness-guage of approximately 0.325 mm(0.0128-inch). This novel variable-guage capability of the device, making it able to more effectively burnish away substances from the tooth and sulcus of the gum-tissue during it's thicker guage modality; then again be retensioned to approximately only 0.200 mm-guage for easy interstitial removal. Either version of the device may be coated with various agents effective in combating diseases of the teeth and gums.

Owner:LOOPS L L C

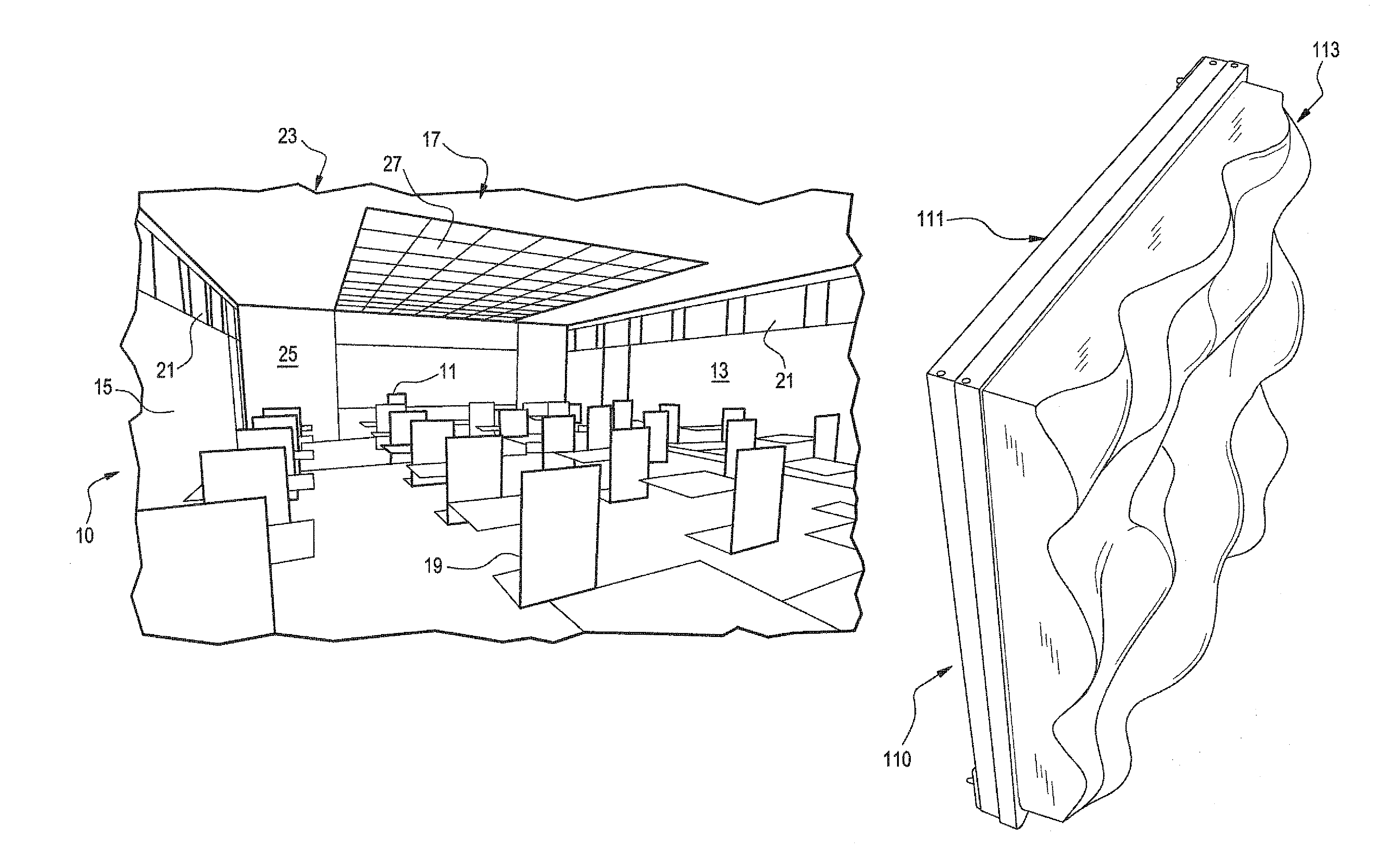

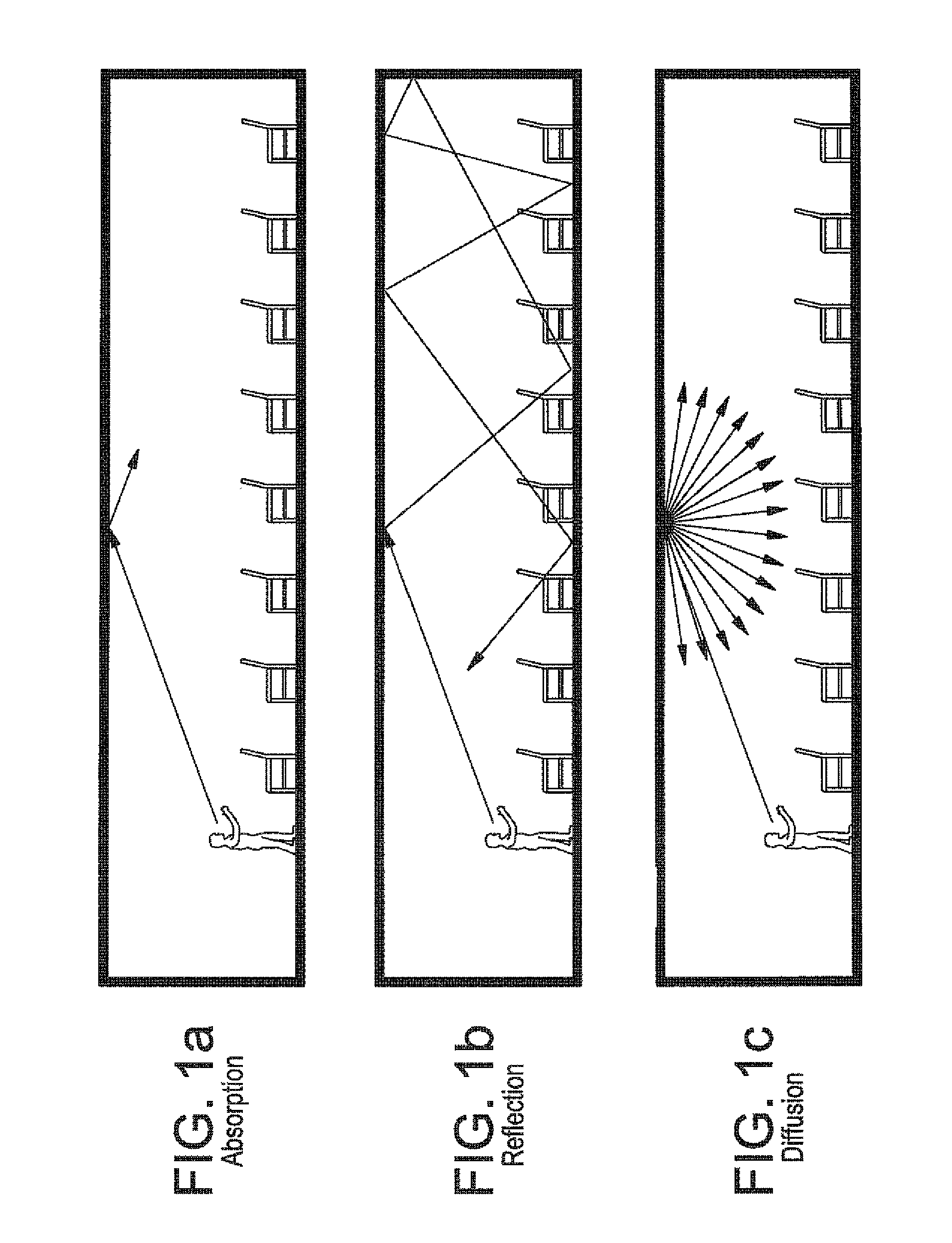

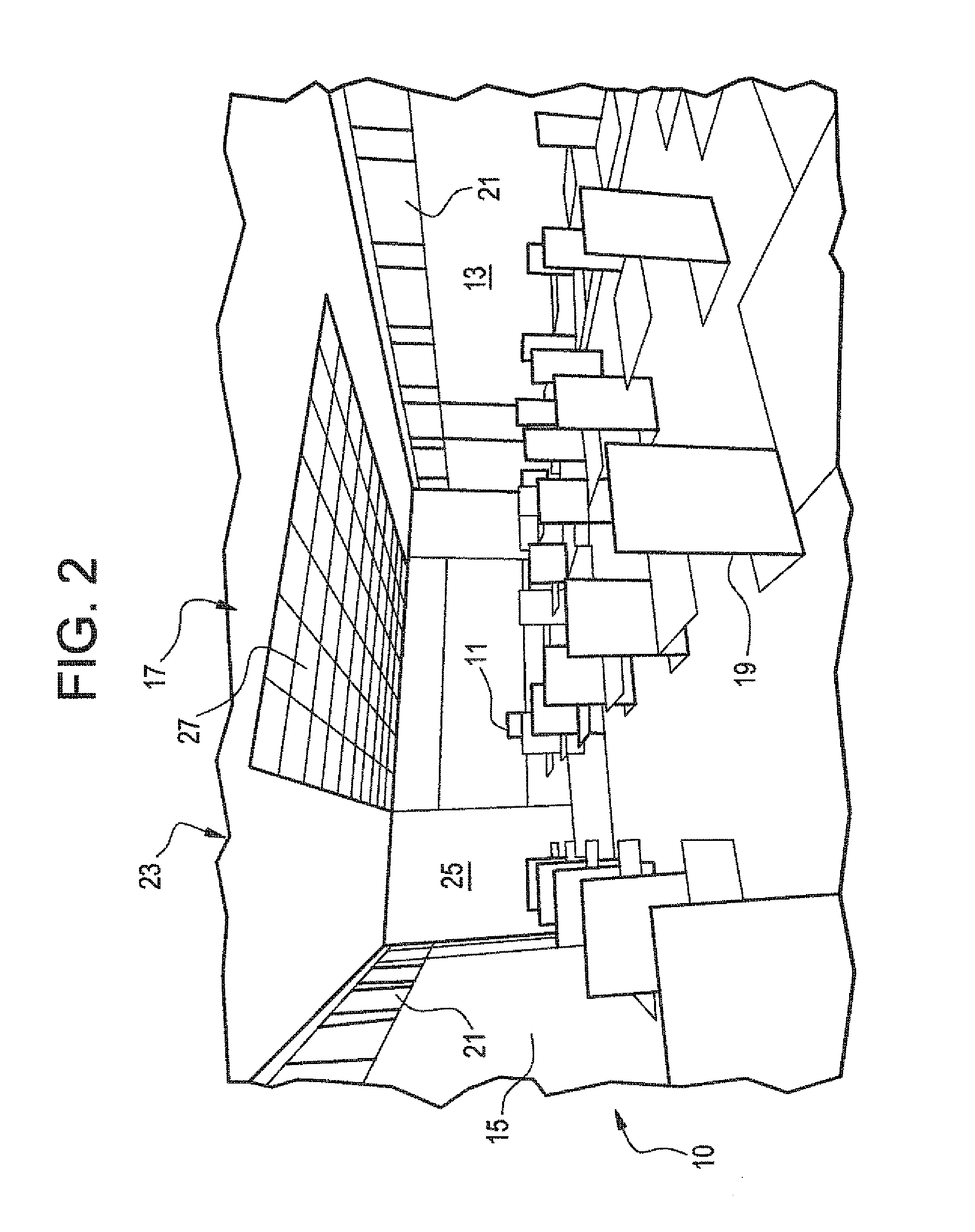

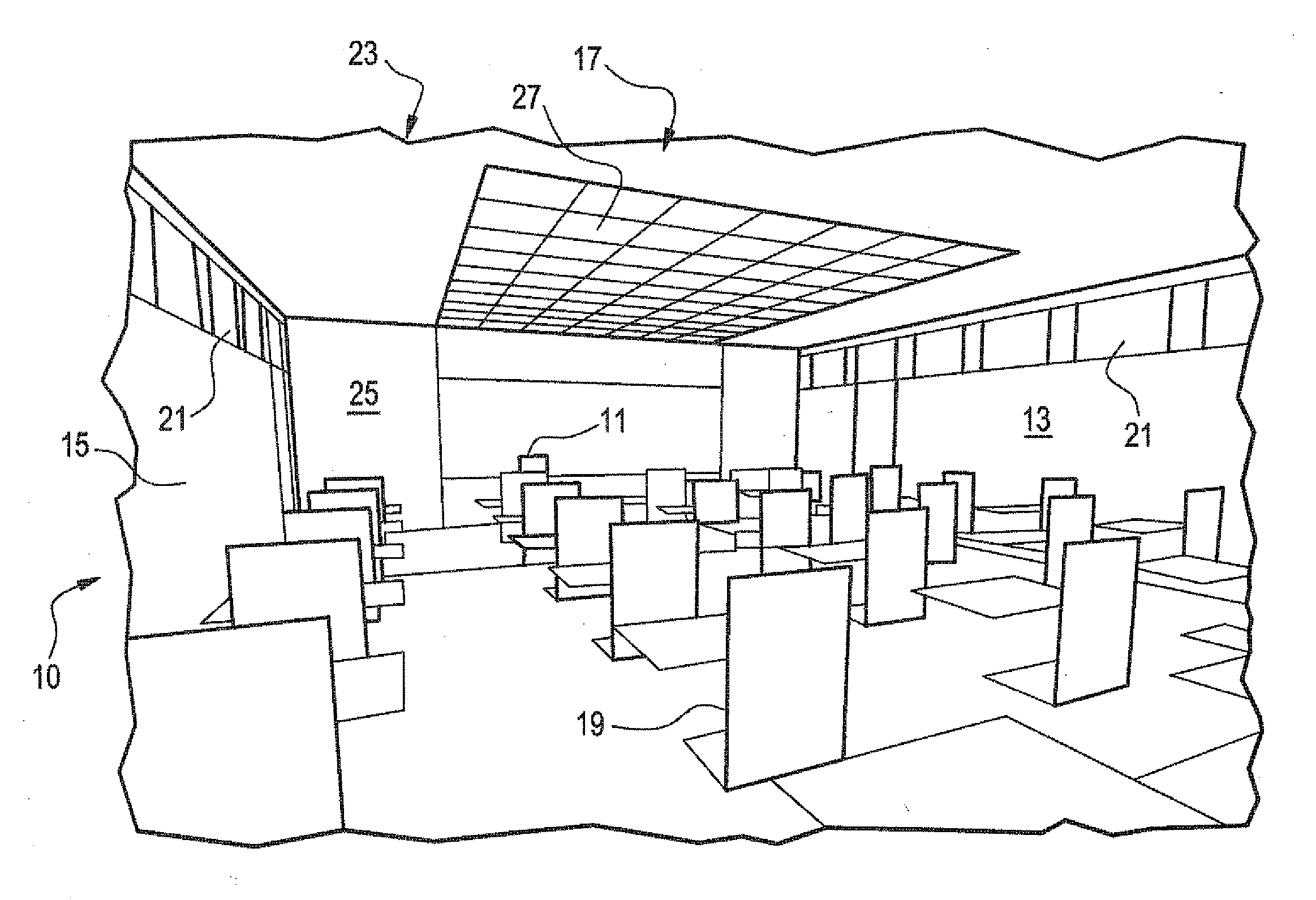

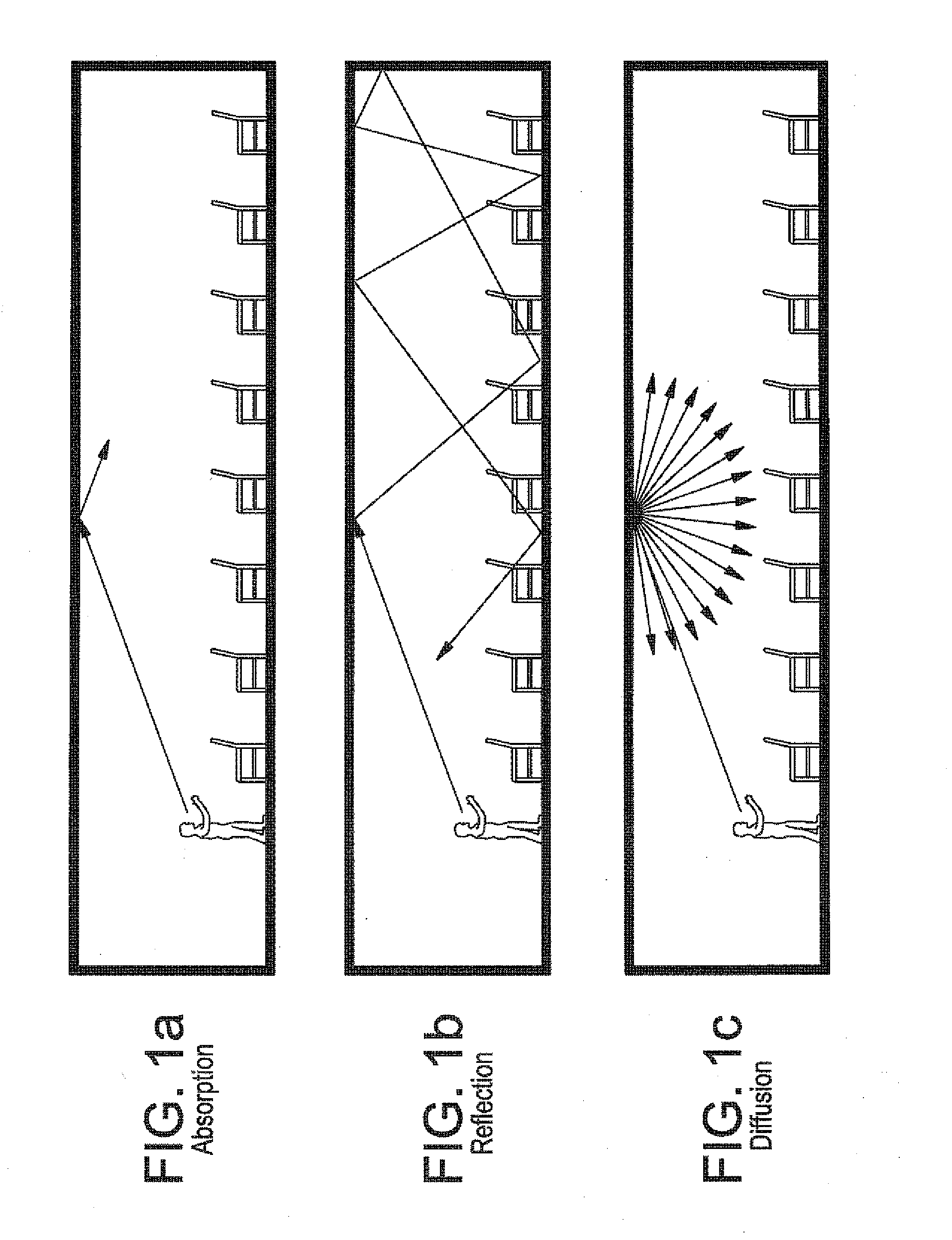

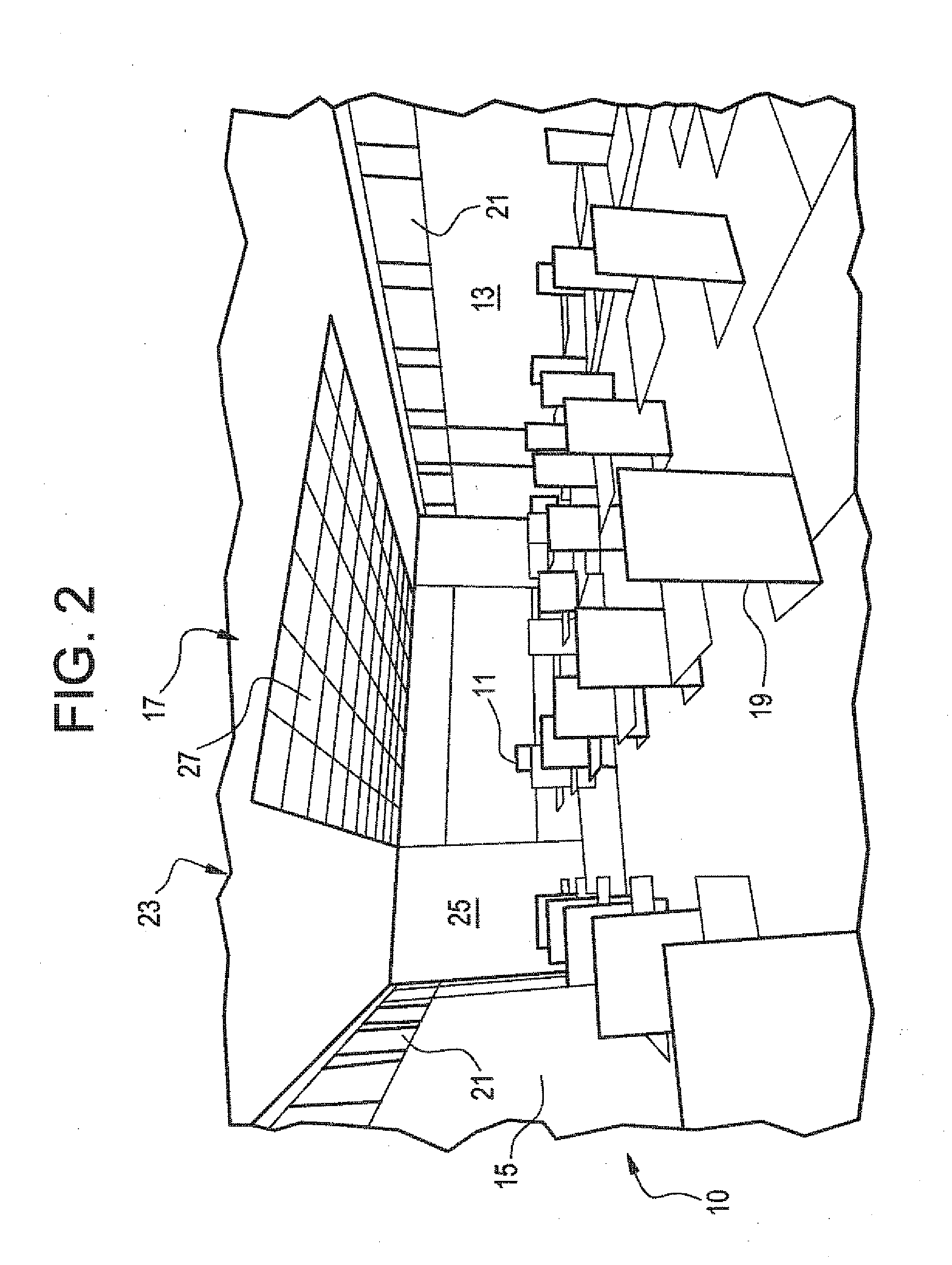

Combination light diffuser and acoustical treatment and listening room including such fixtures

Combination light diffusion with either sound diffusion or absorption is provided in a single lighting fixture, to provide uniform luminosity and sound control. The traditional flat light diffuser is replaced with a translucent acoustical element which either diffuses sound or absorbs the sound. The sound diffuser topology includes random surfaces, geometrical shapes, number theoretic diffusers or optimized rectilinear or curvilinear surfaces. The translucent sound absorber includes microperforated or microslit panels, as well as translucent fabrics and microperforated, translucent wood veneers.

Owner:DANTONIO PETER

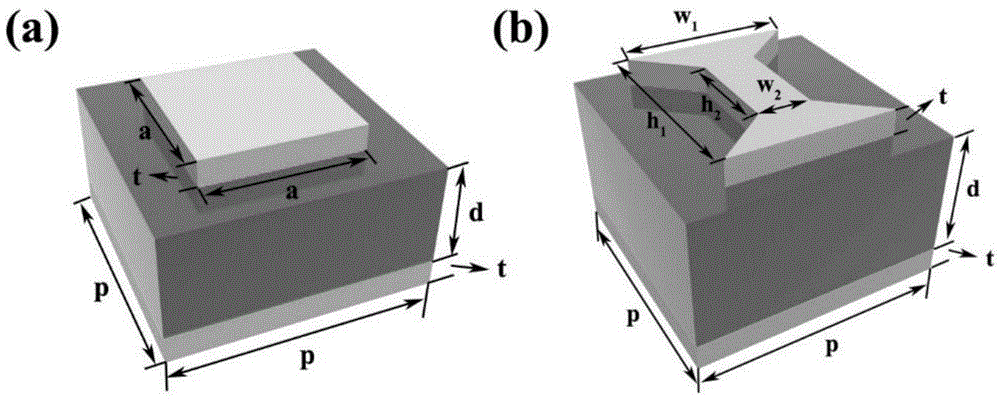

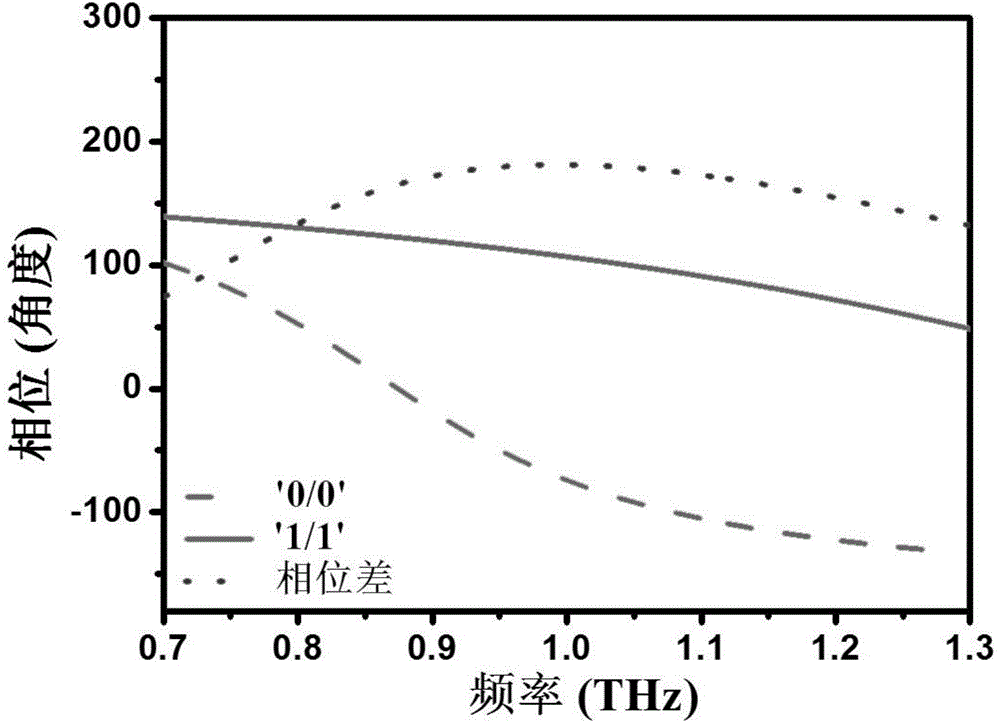

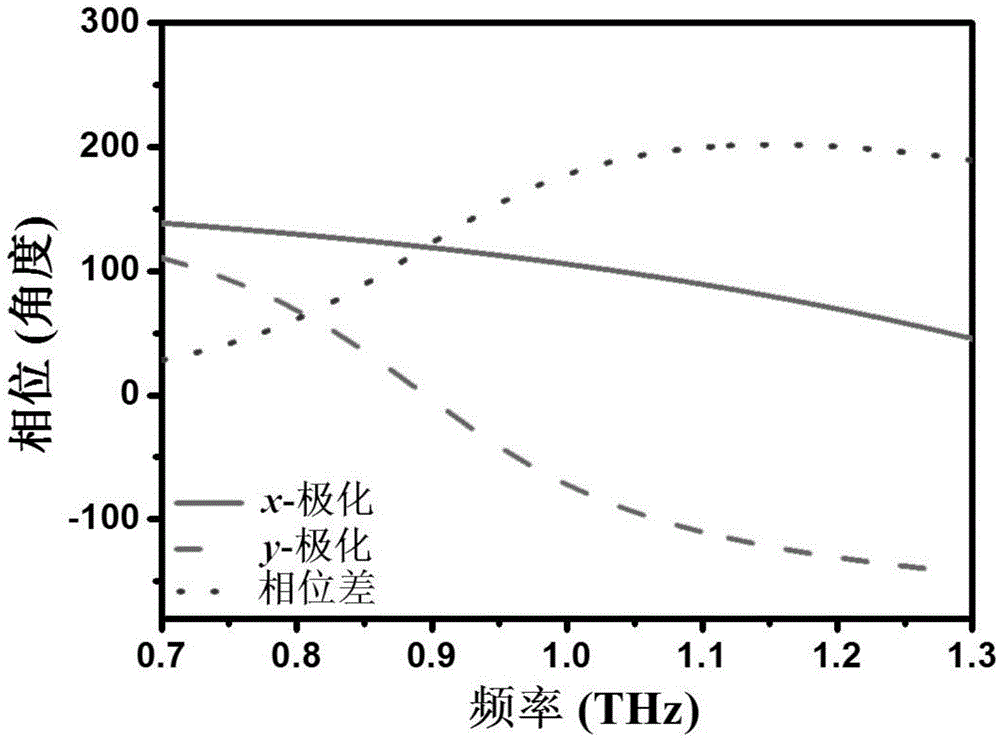

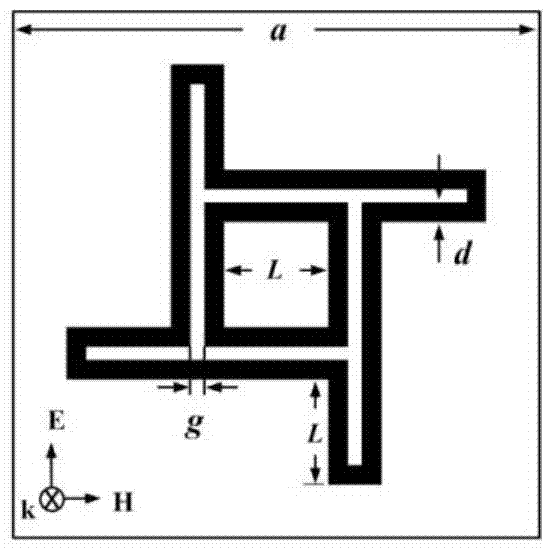

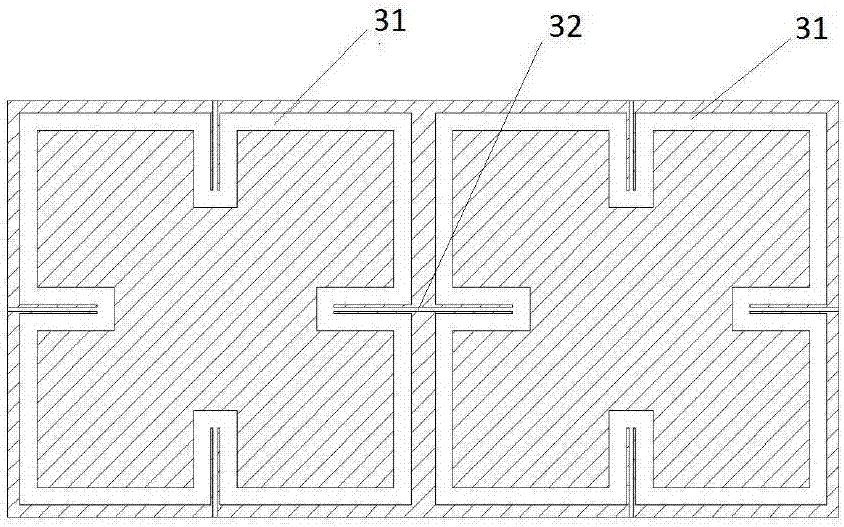

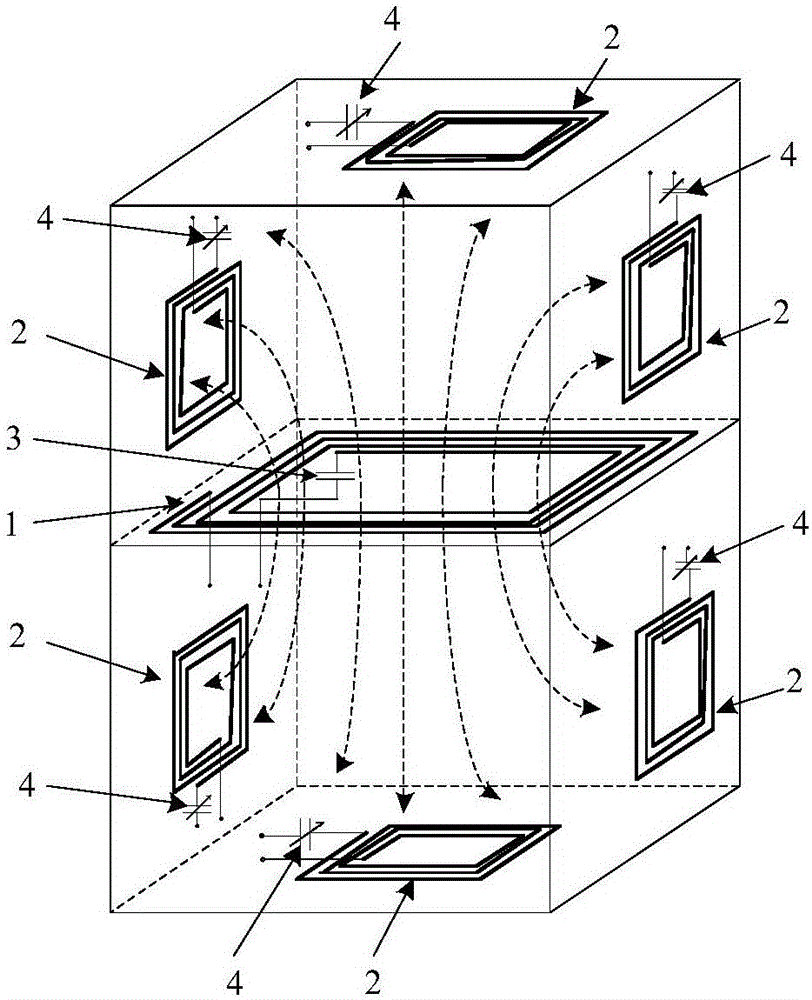

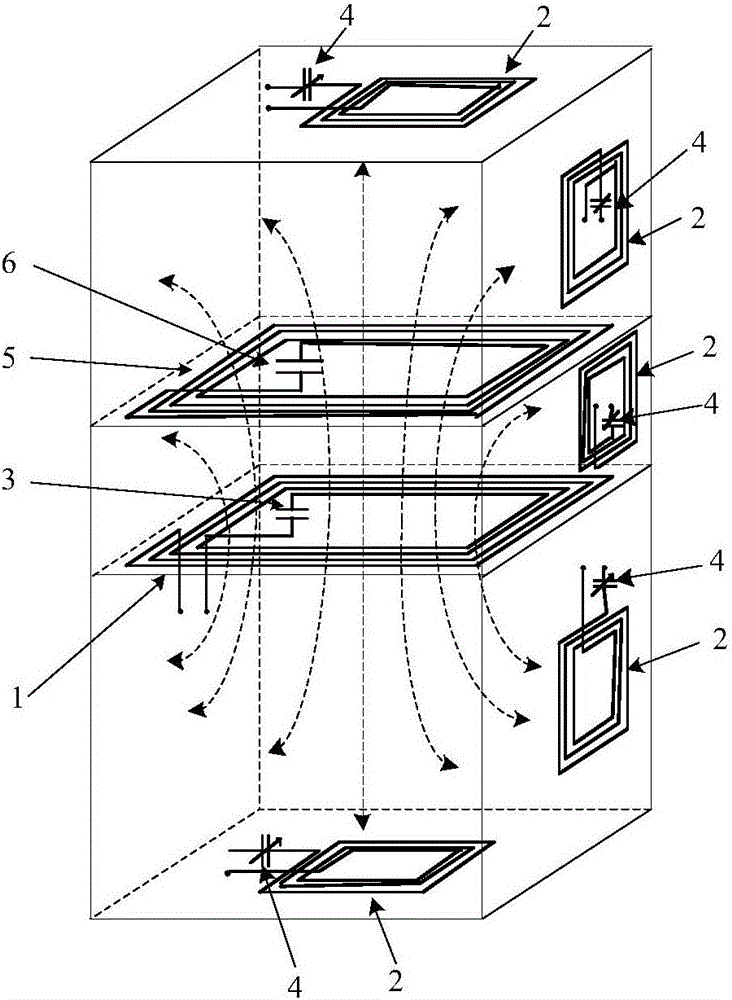

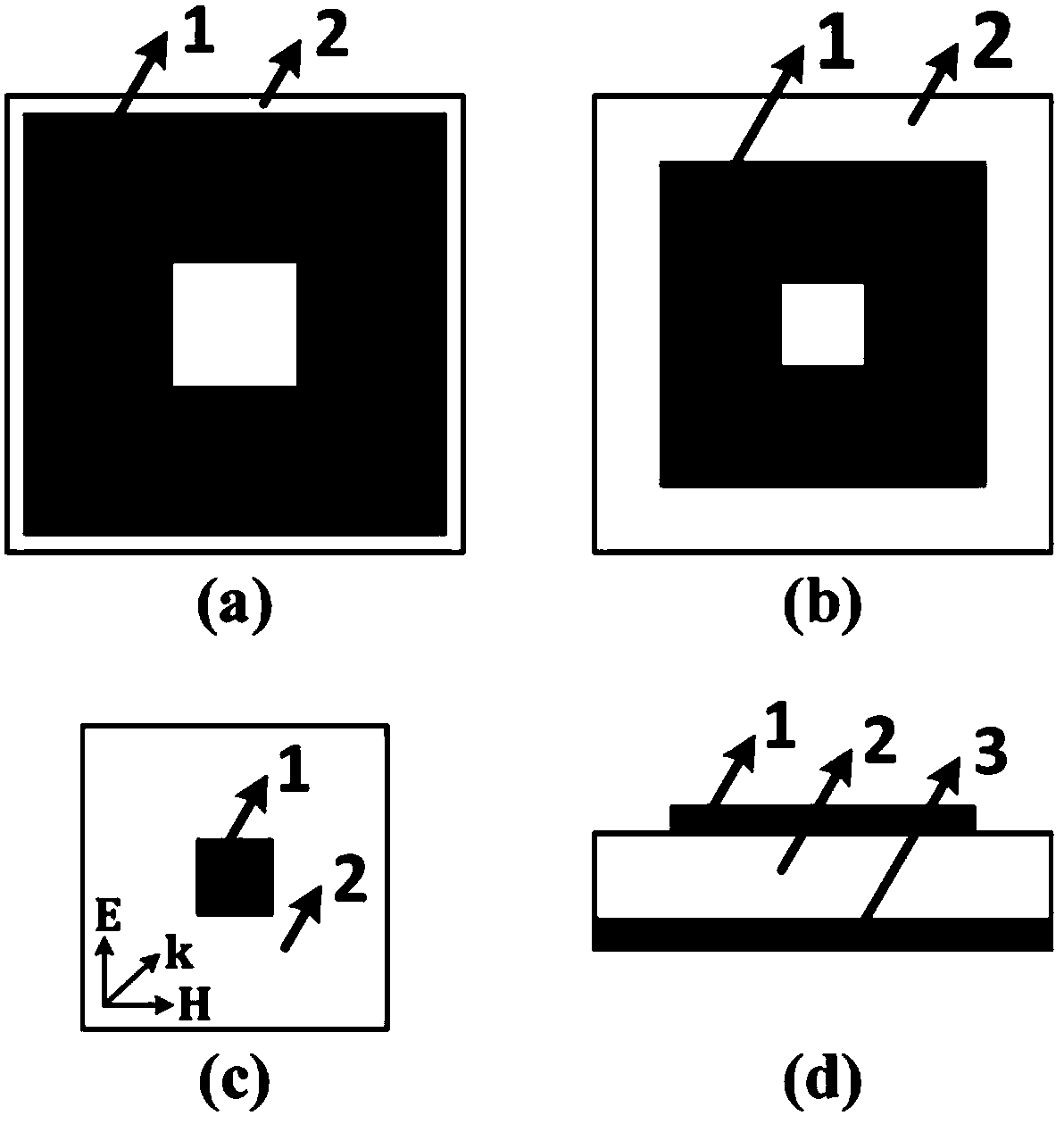

1-bit microwave anisotropic electromagnetic coding meta-material

The invention provides a 1-bit microwave anisotropic electromagnetic coding meta-material. A unit structure of the meta-material consists of an isotropic structure and an anisotropic structure. The design and optimization of geometric parameters of the unit structure can enable each unit to represent independent reflection phase 0 degree and 180 degrees during the irradiation of x-polarization and y-polarization vertically-incident electromagnetic waves, wherein the independent reflection phase 0 degree and 180 degrees are respectively corresponding to a digital state '0' and a digital state '1'. The digital units are arranged on a two-dimensional plane according to digital coding designed in advance, thereby forming the anisotropic electromagnetic coding meta-material. Because each unit is independent in response during x-polarization and y-polarization, the coded meta-material can make independent response during the irradiation of x-polarization and y-polarization vertically-incident electromagnetic waves, including abnormal beam separation and random surface scattering. The meta-material is simple in structure, is easy to machine, is wide in frequency band, can be used for the design of beam separation to generate a plurality of beams, or can be used for the design of an invisible surface, and effectively reduces the radar scattering section of a target.

Owner:SOUTHEAST UNIV

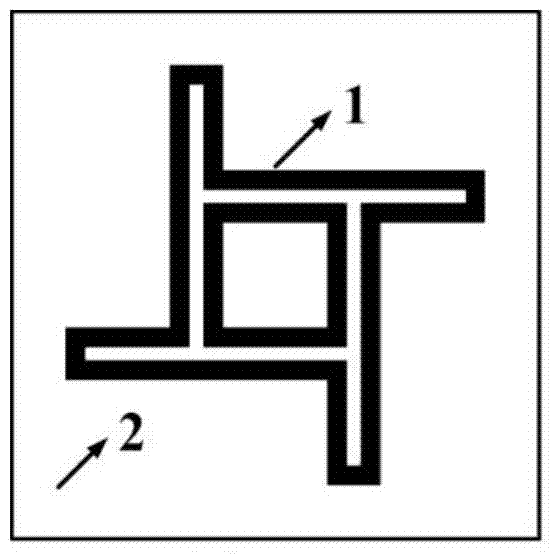

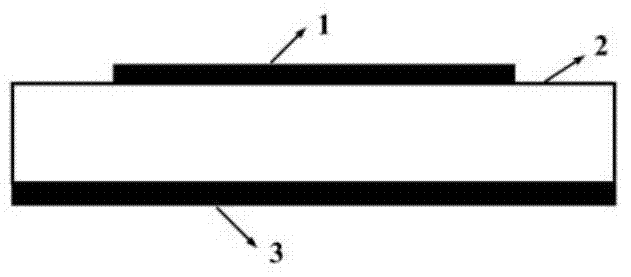

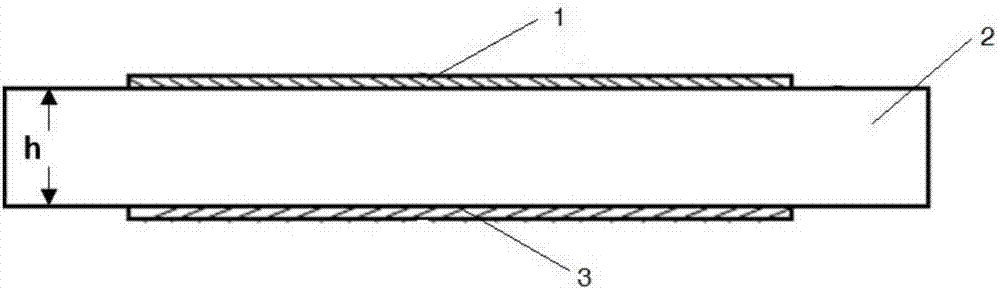

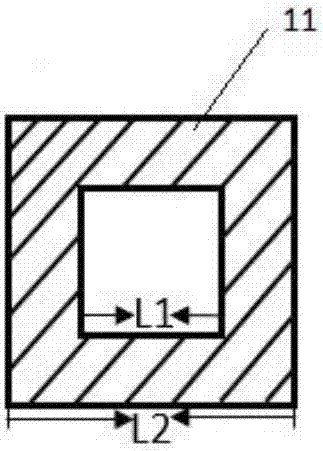

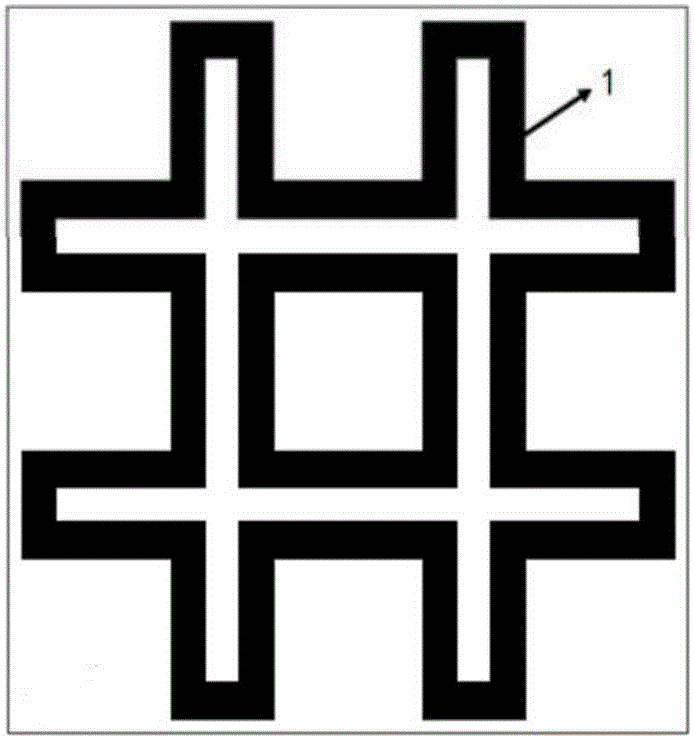

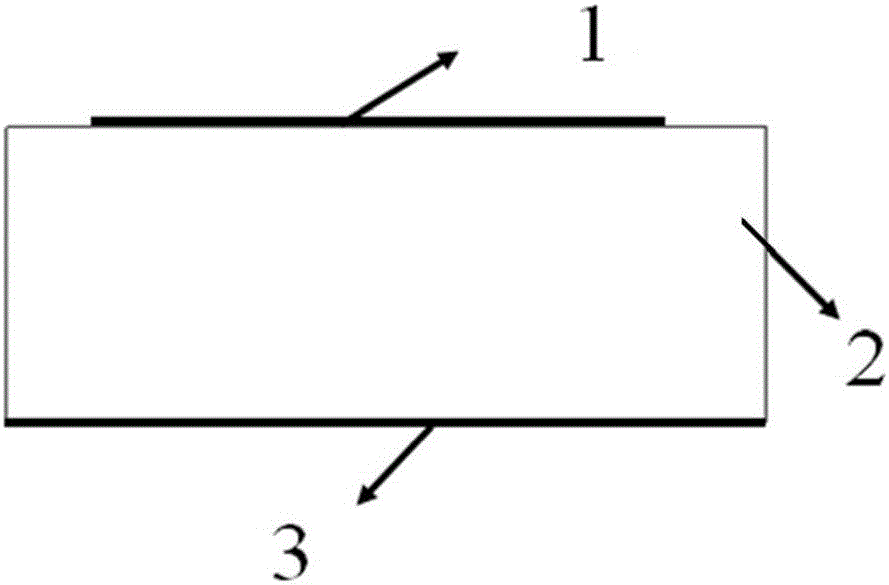

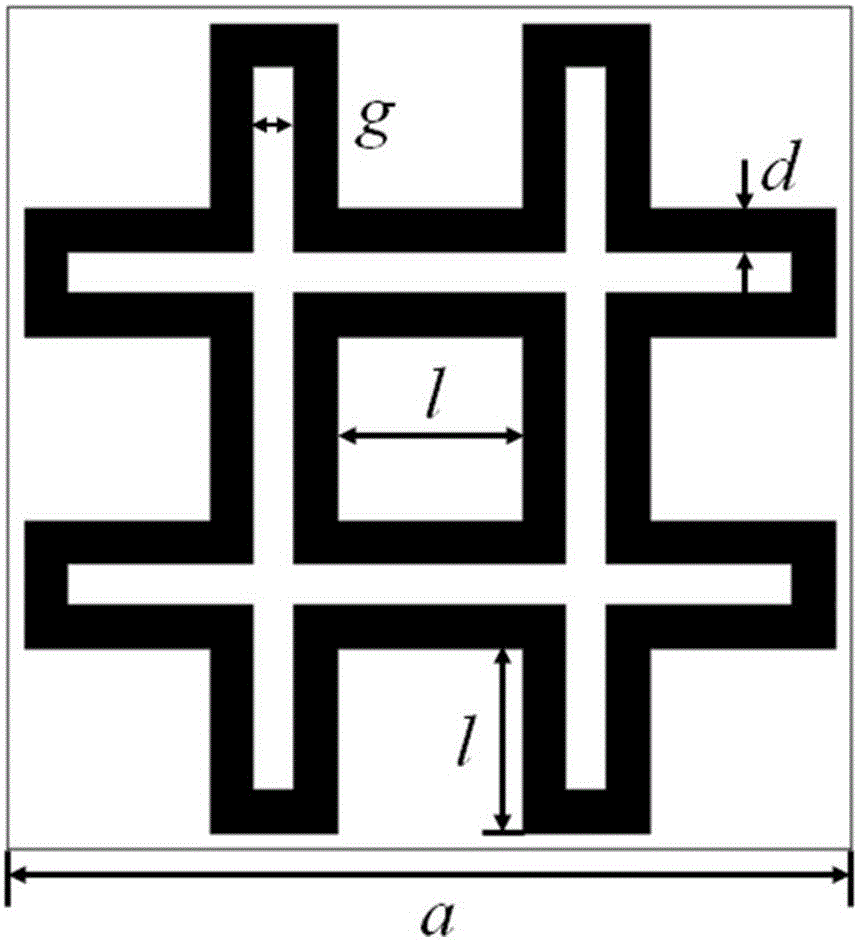

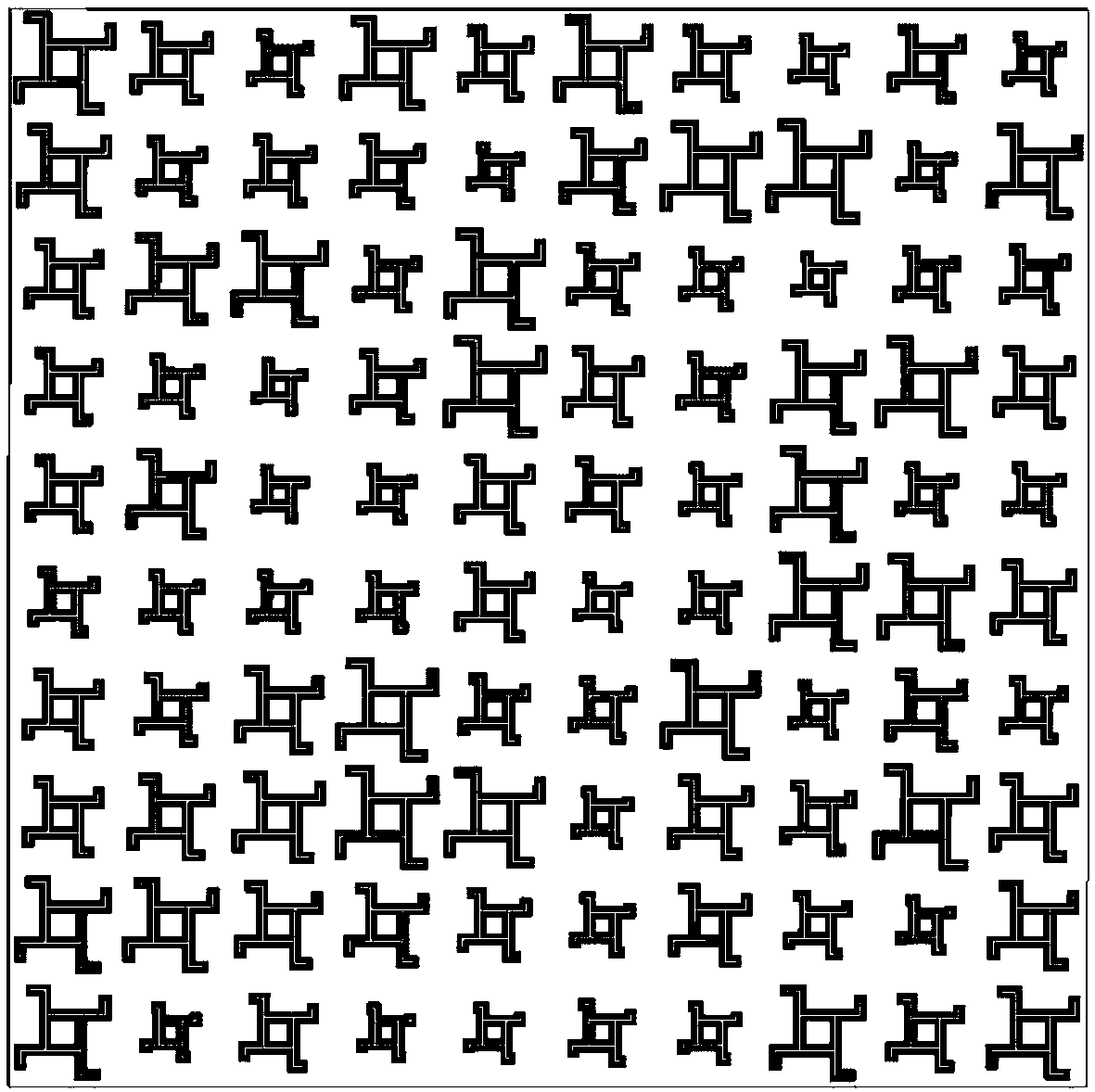

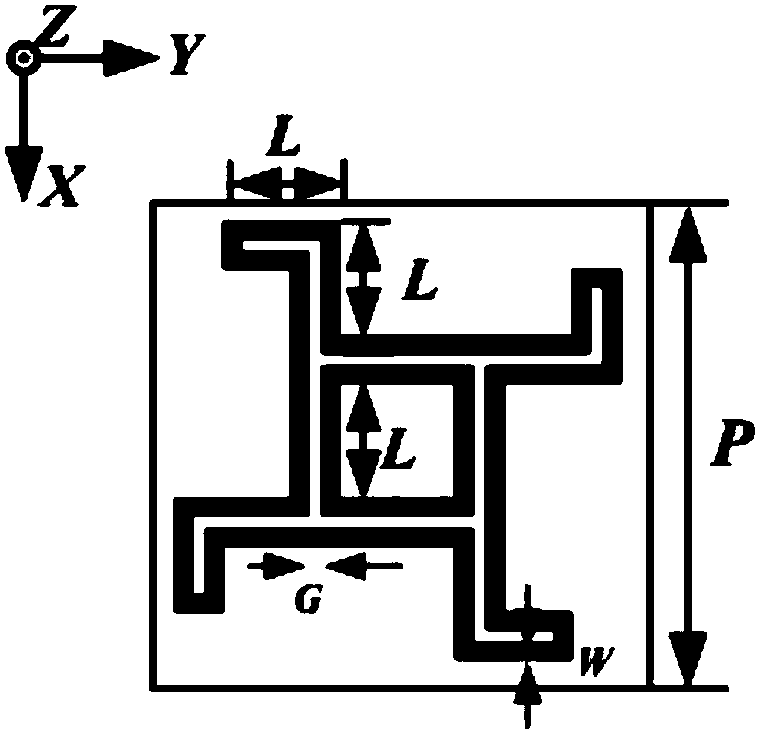

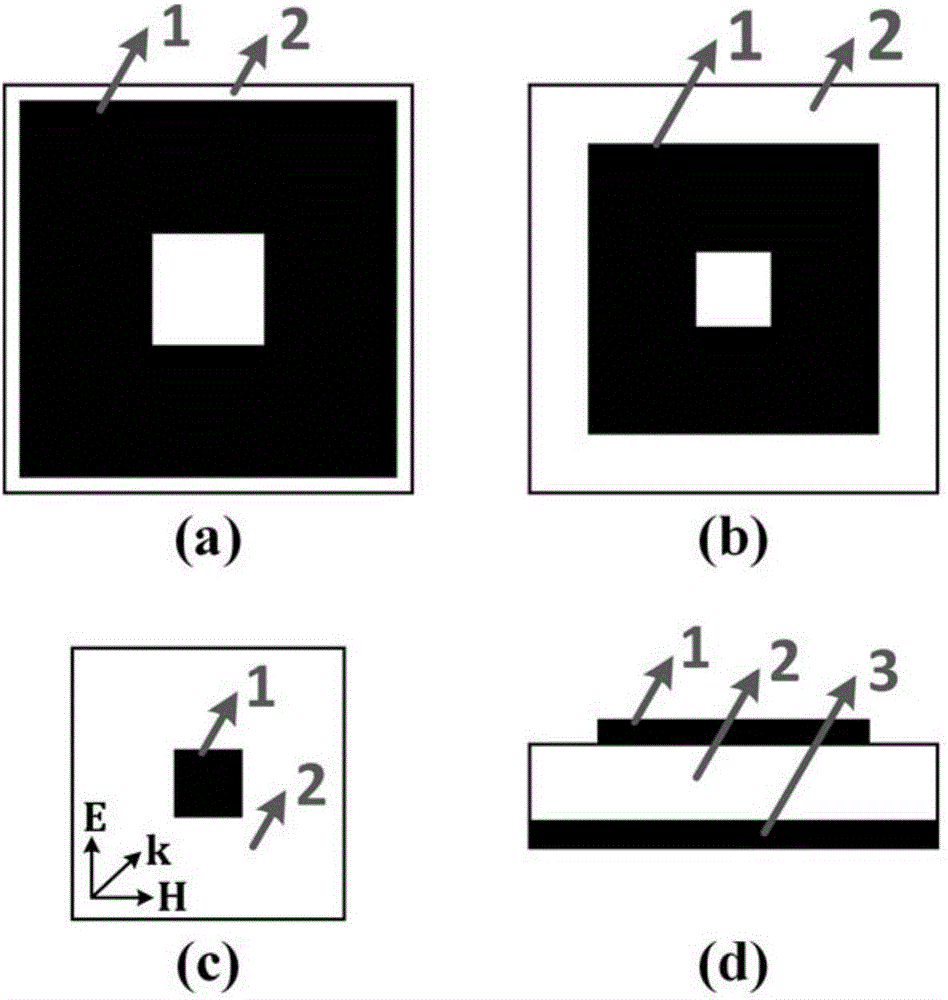

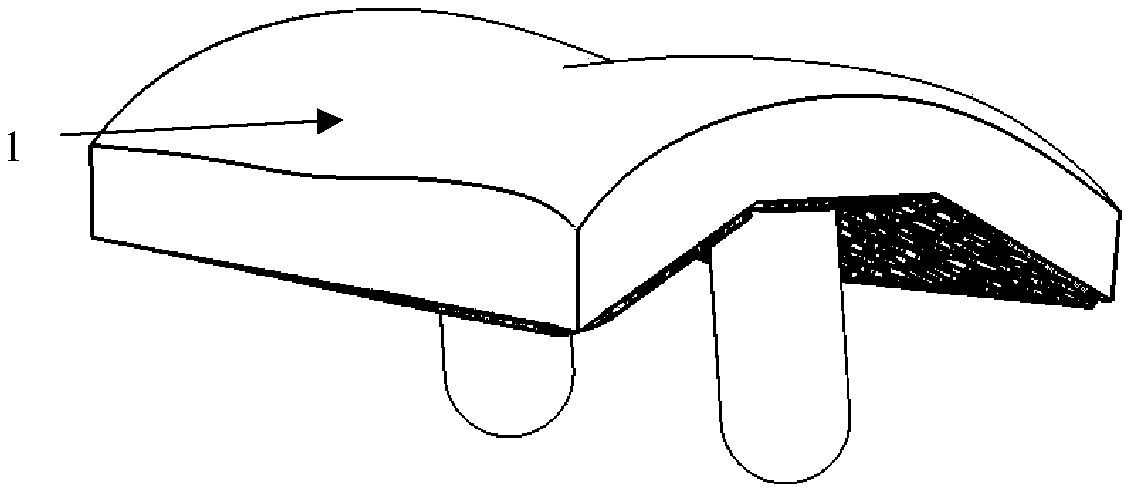

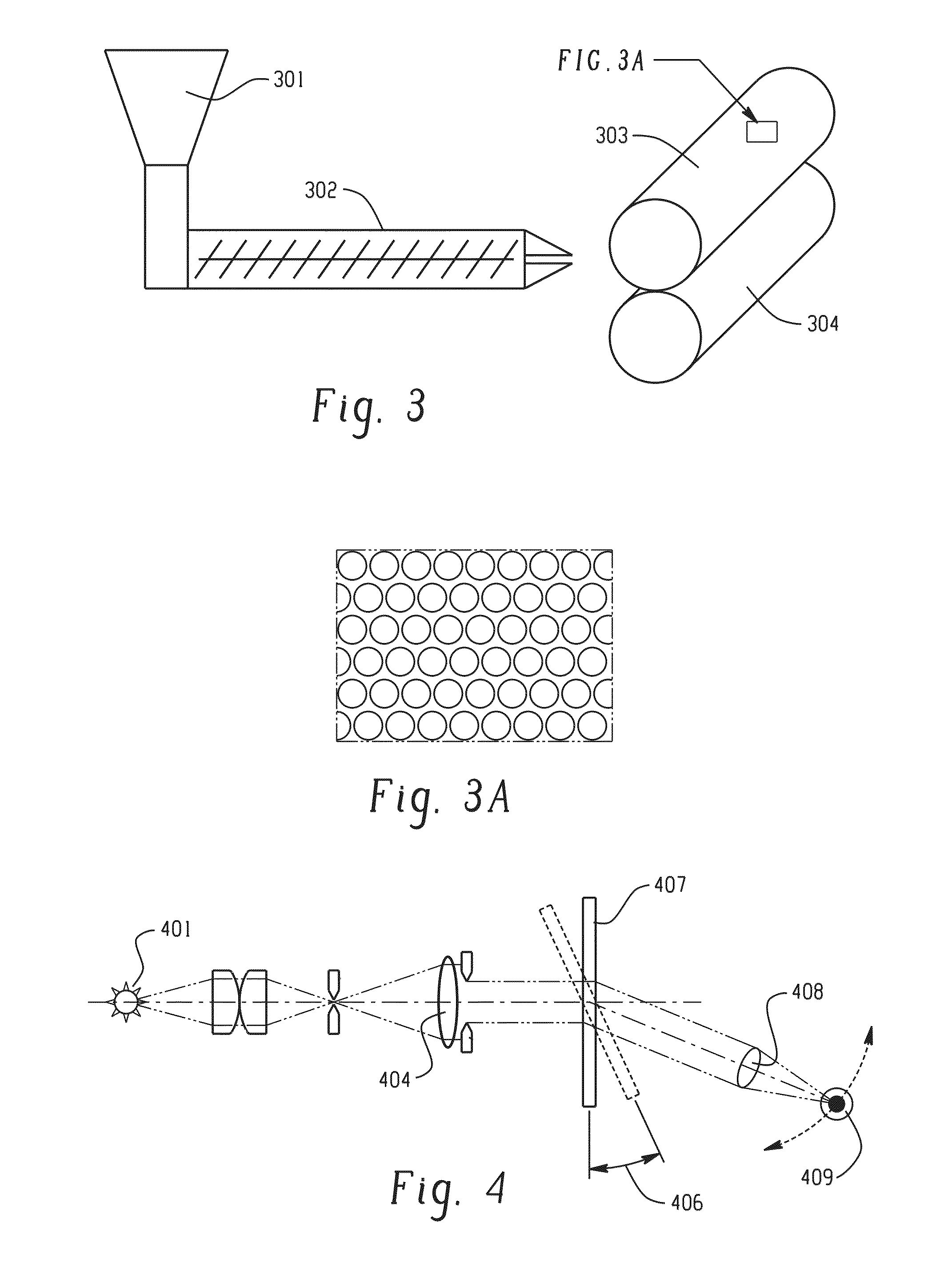

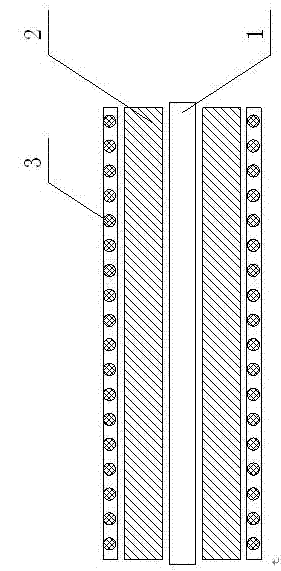

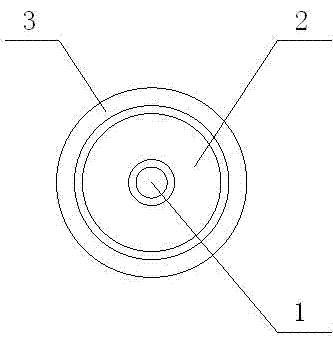

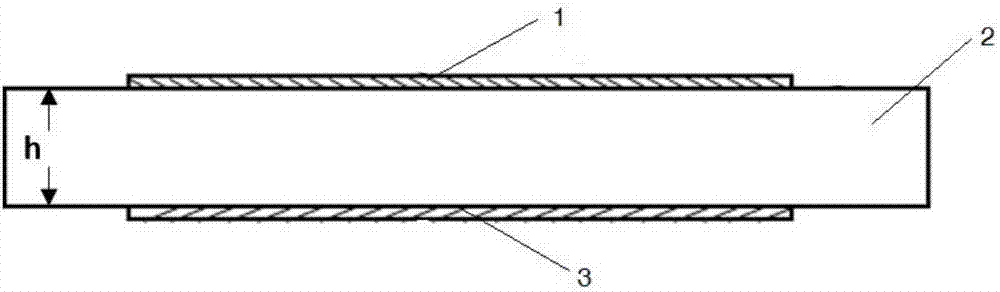

Single-layered broadband random surface

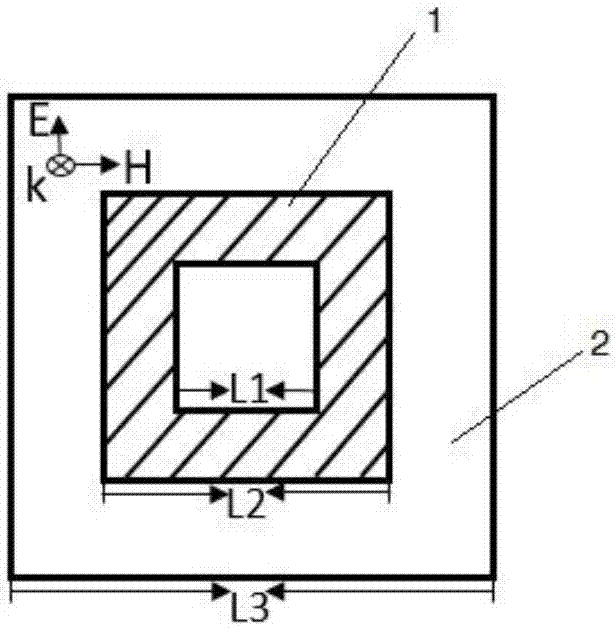

ActiveCN103490169AThe production process is simpleSimple structureAntennasResonanceElectromagnetic wave transmission

The invention discloses a single-layered broadband random surface. The random surface comprises a dielectric substrate (2), a windmill metal patch 1 basic unit (1) and a metal floor (3), wherein the windmill metal patch 1 basic unit (1) and the metal floor (3) are respectively coated on the upper surface and lower surface of the dielectric substrate (2); the metal floor (3) is used for preventing electromagnetic wave transmission; the basic unit (1) is formed by using a single-layered double-resonance unit with a randomly distributed size, and composed of a regular square ring located in the center of the unit and a branch-containing square ring located at the periphery of the regular square ring. The random surface disclosed by the invention can be used for effectively reducing the RCS (radar cross-section) of a two-dimensional metal target body in an X waveband; the random surface is simple in manufacturing and easy to operate; the random surface has absolute advantages in comparison with previous multilayer modes, so that the random surface has extremely high application prospect in practice.

Owner:SOUTHEAST UNIV

Combination light diffuser and acoustical treatment and listening room including such fixtures

InactiveUS20140071662A1Minimize light streakingMaximize sound absorptionNon-electric lightingCeilingsWood veneerLuminosity

Combination light diffusion with either sound diffusion or absorption is provided in a single lighting fixture, to provide uniform luminosity and sound control. The traditional flat light diffuser is replaced with a translucent acoustical element which either diffuses sound or absorbs the sound. The sound diffuser topology includes random surfaces, geometrical shapes, number theoretic diffusers or optimized rectilinear or curvilinear surfaces. The translucent sound absorber includes microperforated or microslit panels, as well as translucent fabrics and microperforated, translucent wood veneers.

Owner:DANTONIO PETER

Transmission type artificial electromagnetic surface and design method thereof

InactiveCN107093800AThe overall thickness is thinLight in massAntennasEngineeringElectromagnetic simulation

The invention discloses a transmission type artificial electromagnetic surface and a design method thereof. The transmission type artificial electromagnetic surface comprises a medium substrate, a random surface covering an upper surface of the medium substrate, and a frequency selection surface covering a lower surface of the medium substrate, wherein the random surface is an unit array composed of three-different-dimension basic units which are uniformly arranged in a random mode, and the frequency selection surface is a structural array formed by same square ring units having branch knots. The transmission type artificial electromagnetic surface is advantaged in that composite high frequency stealth and low frequency wave permeability functions are realized, and small thickness, light weight and easy processing are realized; the method comprises steps that (1), a traditional random surface design method is employed to design structural dimensions and spatial arrangement of each basic unit forming the random surface; (2), the square ring units having the branch knots are selected to form the frequency selection surface; and (3), basic composite units are constructed, and the structural dimensions of each unit are adjusted through electromagnetic simulation till high wave permeability and X wave band stealth requirements of the low frequency are satisfied.

Owner:SOUTHEAST UNIV

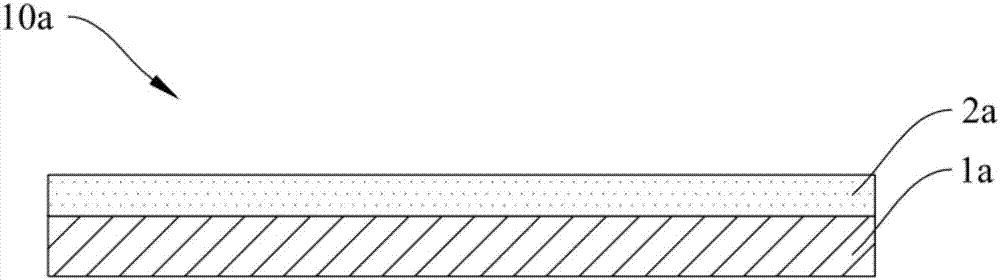

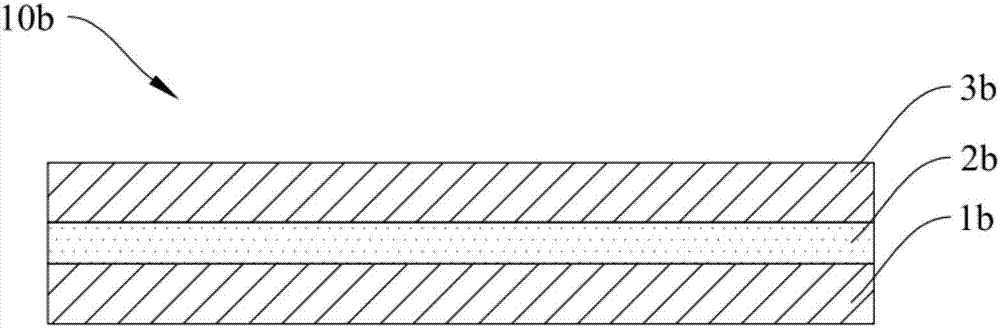

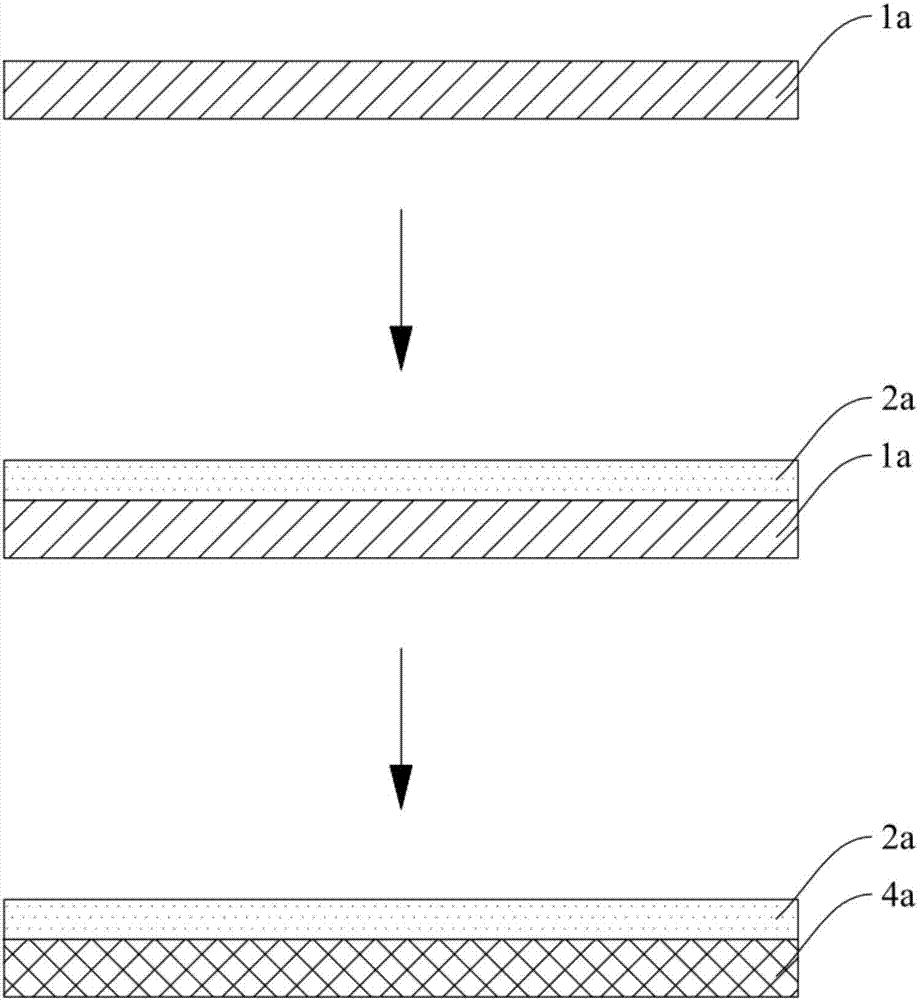

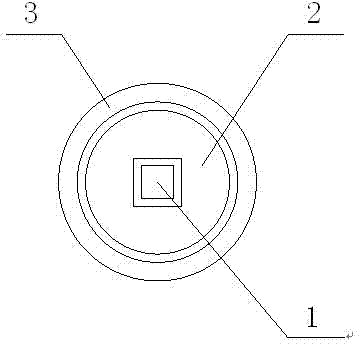

Transparent broadband random surface

InactiveCN106356636AThe production process is simpleRaw materials are simpleAntennasX-waveUnit structure

The invention discloses a transparent broadband random surface, comprising multiple unit structures. The unit structure comprises the upper transparent conductive film layer, transparent substrate and lower transparent conductive film layer. The upper transparent conductive film layer is located at the upper surface of transparent substrate and the lower transparent conductive film layer is fully covered at the lower surface of transparent substrate; the upper transparent conductive film layer is the double resonance unit structure with random sizes; and the double resonance unit structure is the symmetrical structure, comprising the ring located at the center of unit structure and stub ring located at the periphery of ring. The transparent broadband random surface can realize the light transmittance >=85% within the scope of visible light, effectively shorten the RCS of target object in the X wave band with simple technology, uniform structure and transparent visible light, has excellent electromagnetic scattering properties and play an important role in such fields as invisibility of aircraft cockpit.

Owner:JIANGSU SAIBO DEFENSE TECH CO LTD

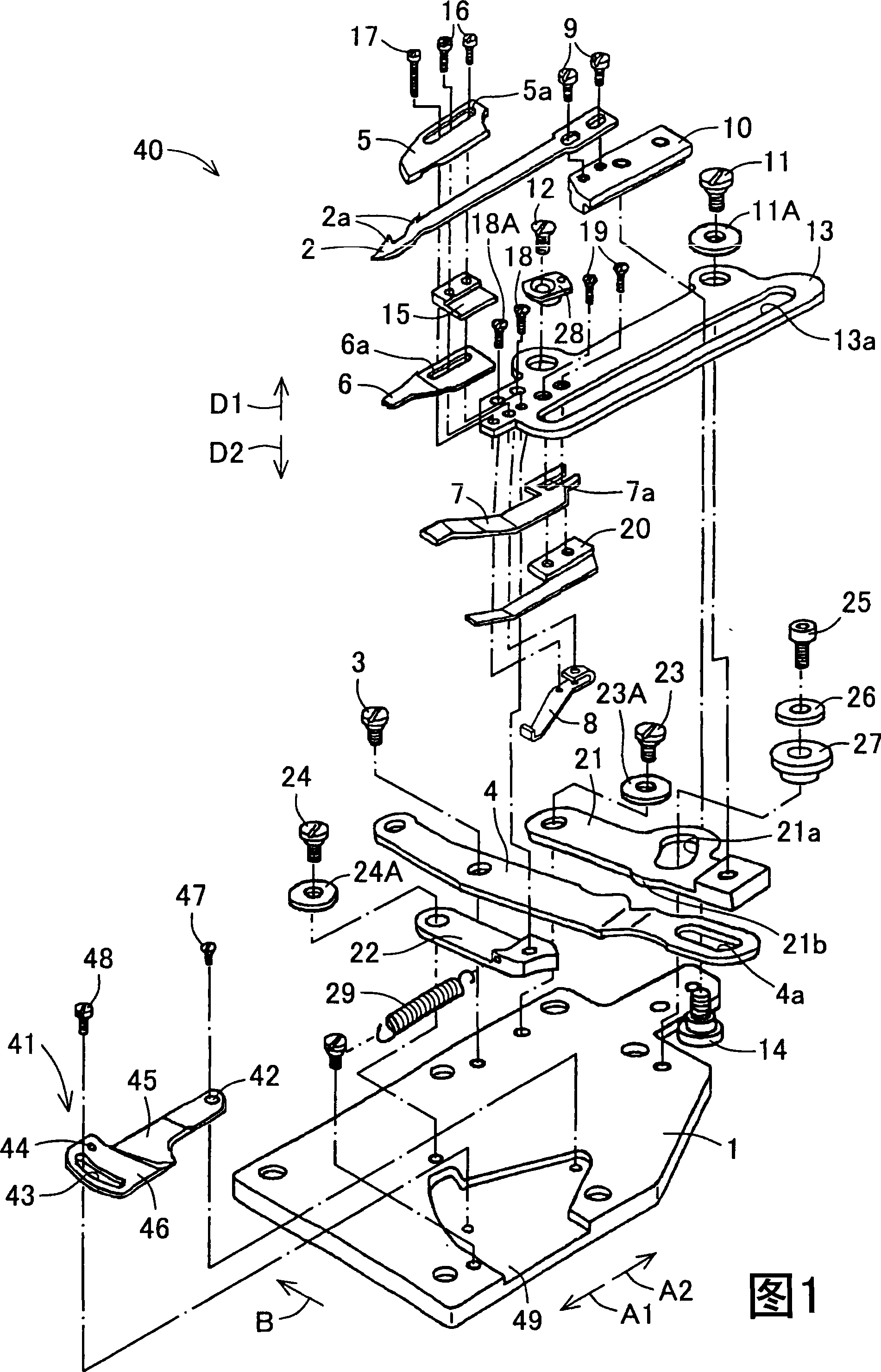

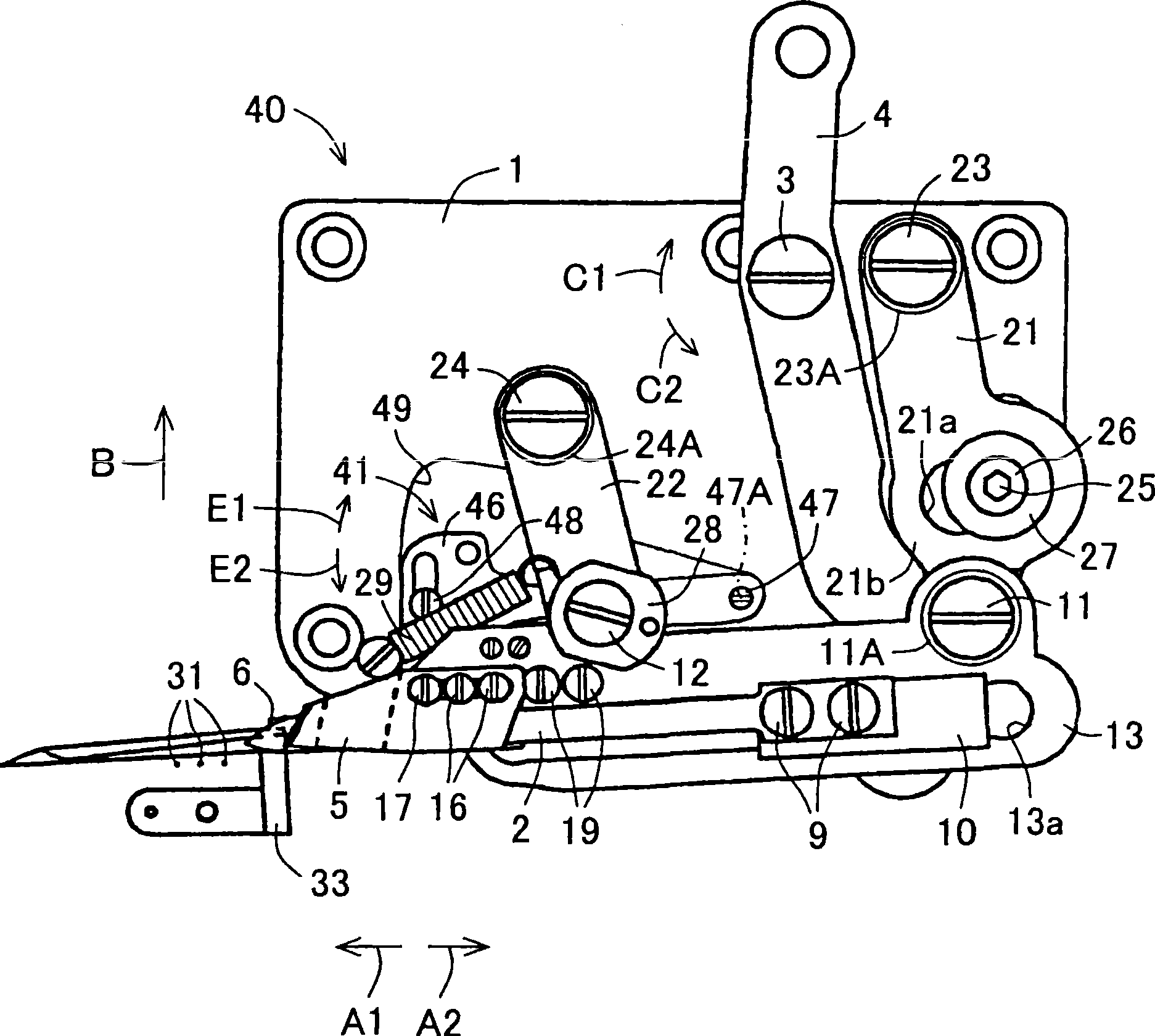

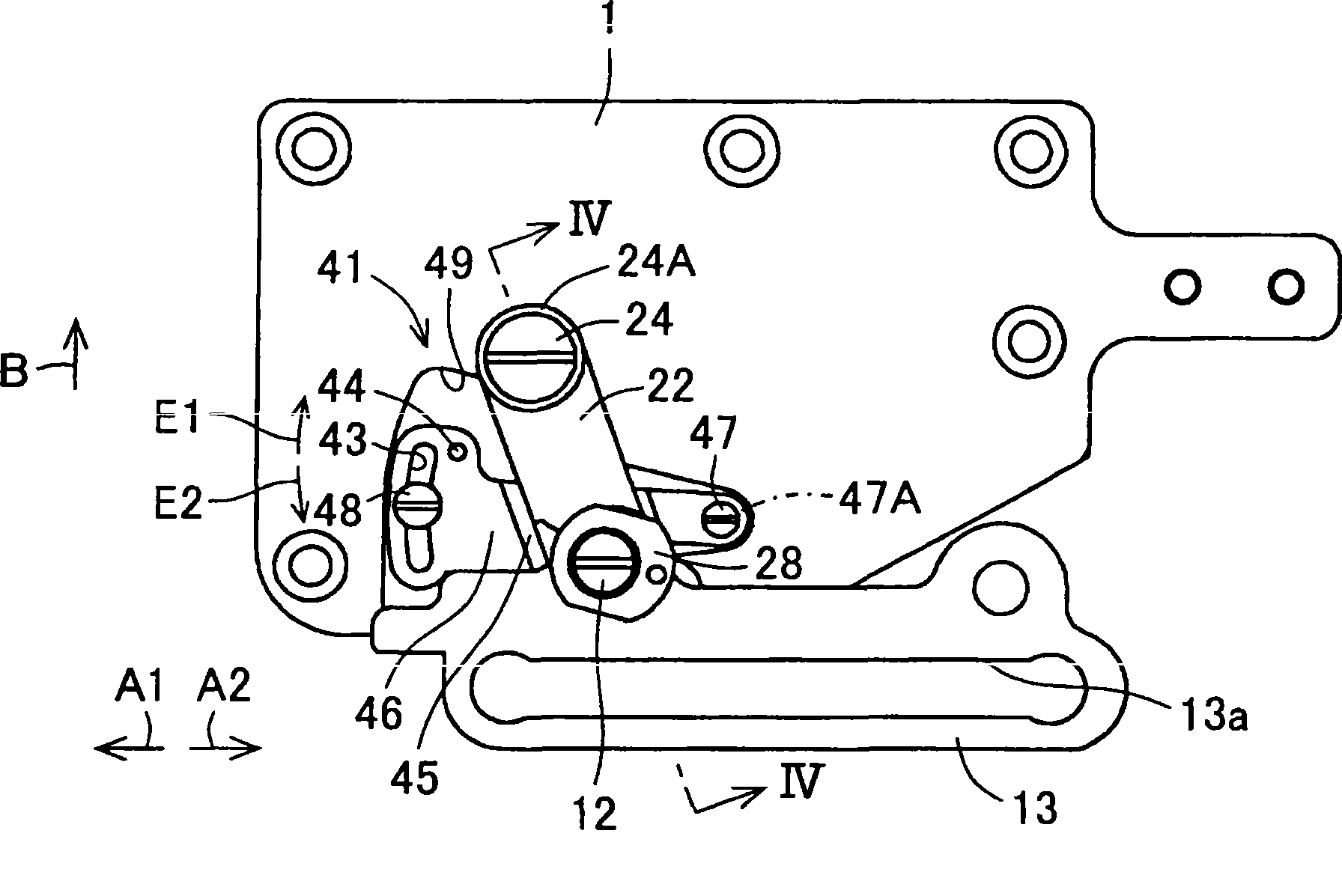

Wire-cutting device for sewing machine

InactiveCN101424015ADoes catchEasy to adjust and accurateNeedle severing devicesThread-break detectorsYarnWire cutting

The present invention provides a yarn cutting device of sewing machine, which can authentically capture an upper thread coil with a movable blade for cutting off. The height position of a blade holding base (13) which holds a movable blade (2), a fixed blade (5) and a yarn clamping plate (7) in the up-and-down direction can be adjusted with a height adjusting part (41). The height of the blade holding base (13) is adjusted with the height adjusting part (41) so that the movable blade which is adjacent with the entering positions of needle supporting plate and curved needle and enters from a narrow space between the lower surface of needle supporting plate and upper surface of curved needle is configured to a position that does not contact a random surface selected from the lower surface of needle supporting plate and upper surface of curved needle. The upper thread coil is caught authentically by a yarn hooking part of movable blade (2) for being cut off.

Owner:YAMATO SEWING MASCH MFG CO LTD

Ultra-wide-band fully-polarized stealth random surface and design method thereof

The invention discloses an ultra-wide-band fully-polarized stealth random surface and a design method thereof. Each unit structure comprises an upper-layer metal patch layer, a medium substrate and alower-layer continuous metal backboard, which are combined together in sequence. The designed random surface realizes non-directional scattering of electromagnetic waves through the microstrip reflection array antenna theory. The unit structures of the random surface are same in structure, but different in size. An HFSS automatic parametric modeling method is suitable for continuous establishing of such model. In order to realize automatic generation of different sizes of unit structures and get the ordered arrangement, programming design can be carried out through MATLAB software to finish automatic modeling of the random surface. The random surface is small in difficulty of the design principle, has an ultra-wideband low RCS characteristic, and meanwhile, has a polarization insensitive property; and the random surface has the advantages of very low profile, thinner thickness, light weight and easy processing, and can be widely applied to the field of electromagnetic stealth of each device platform and weapon platform and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

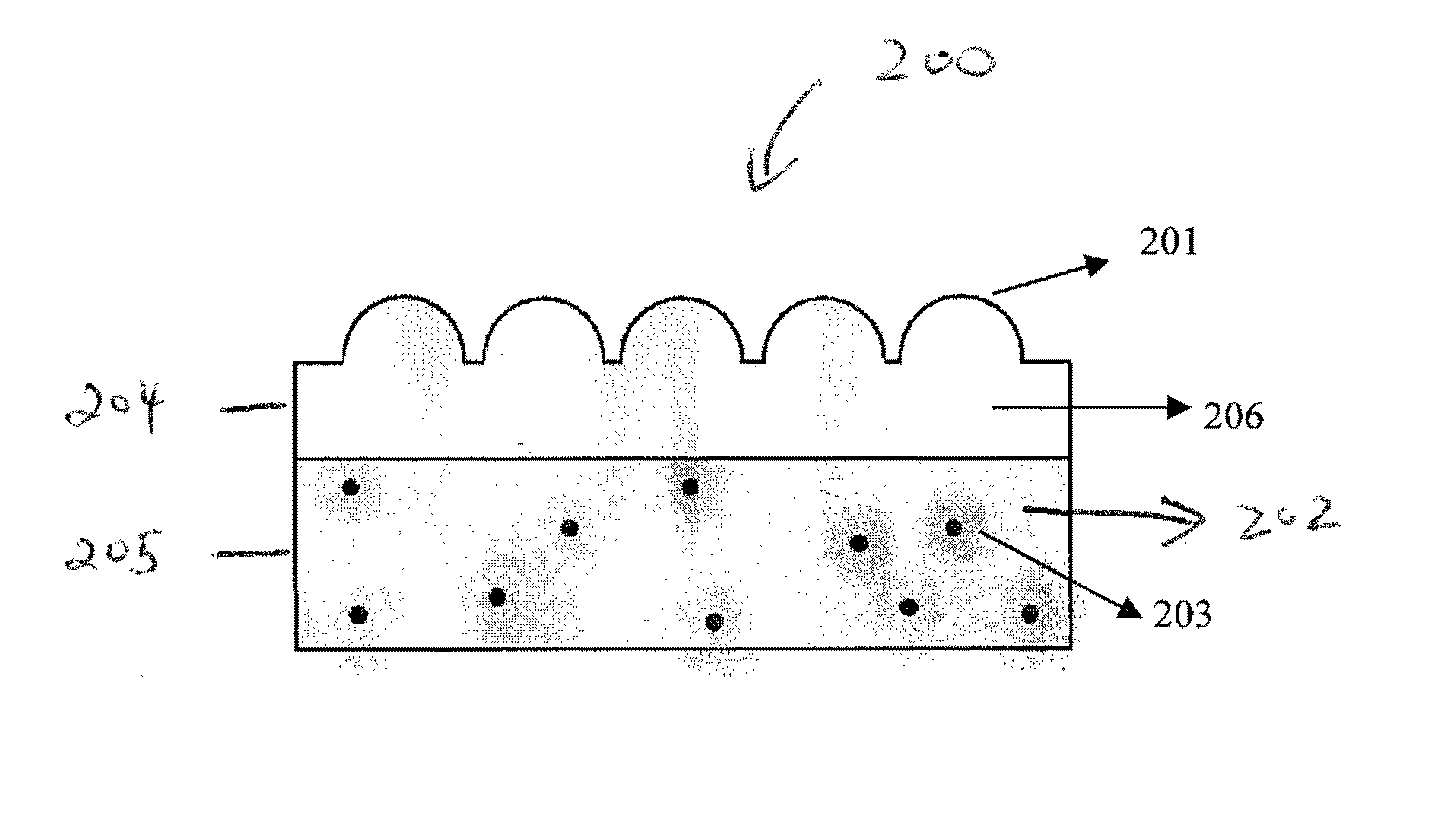

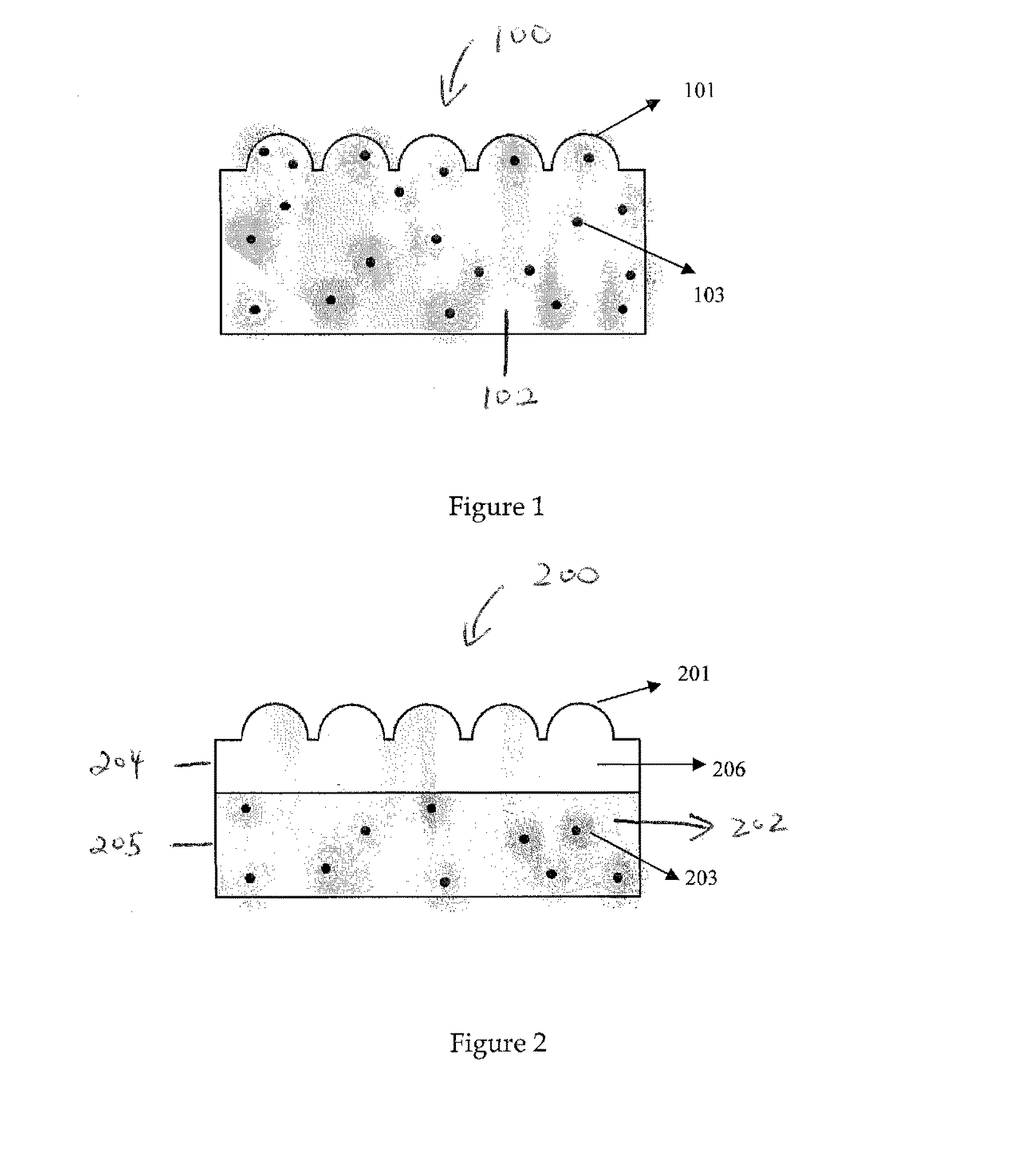

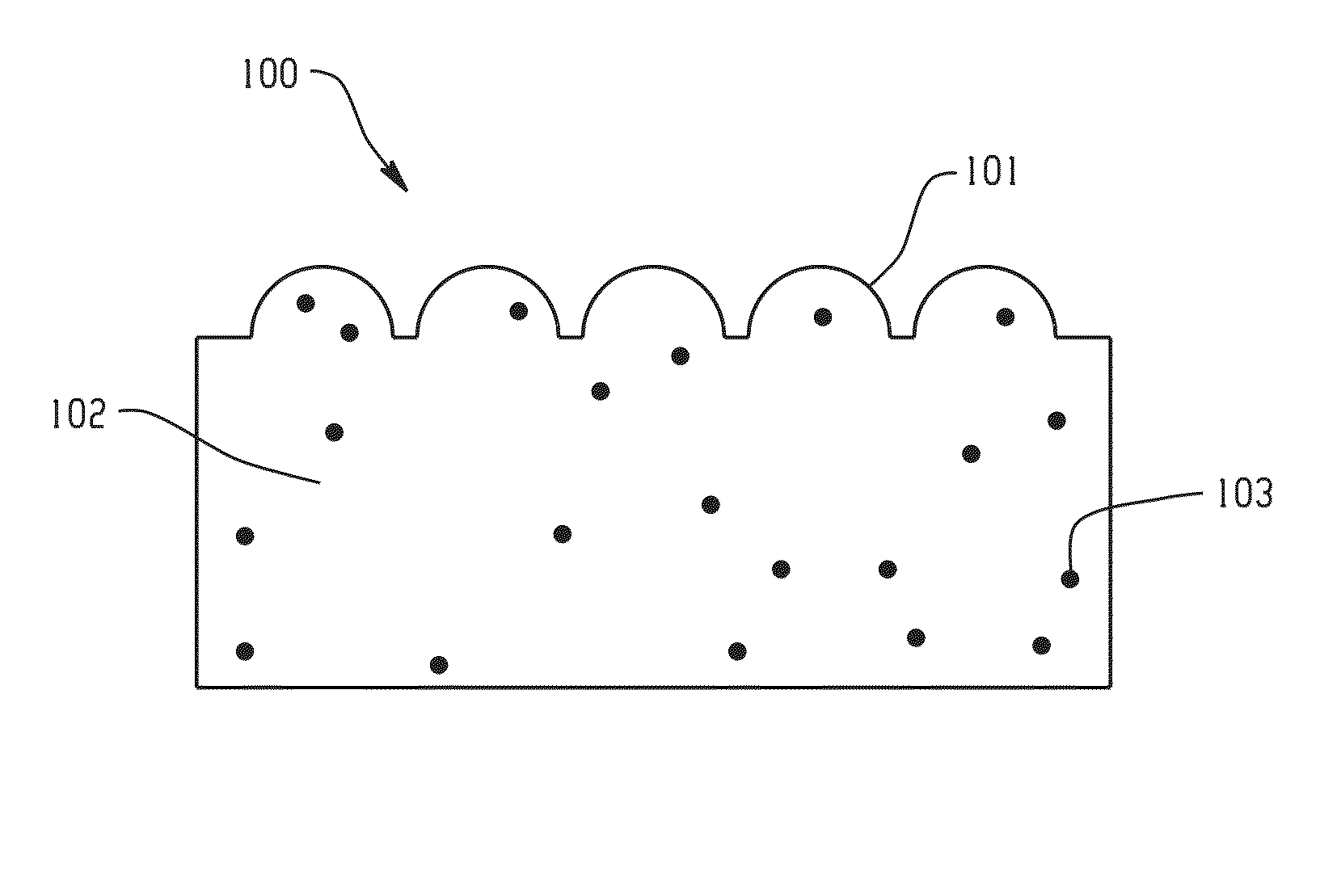

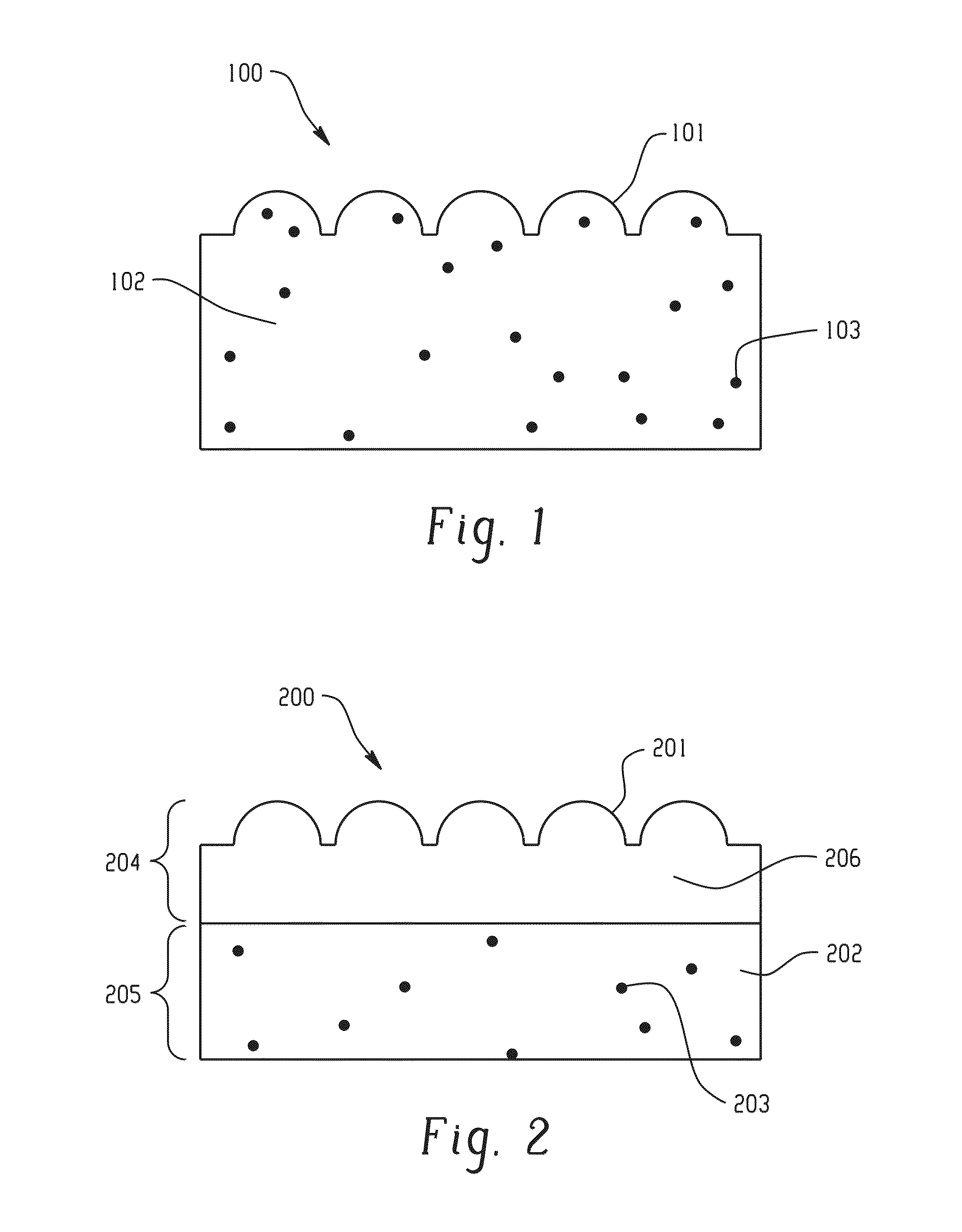

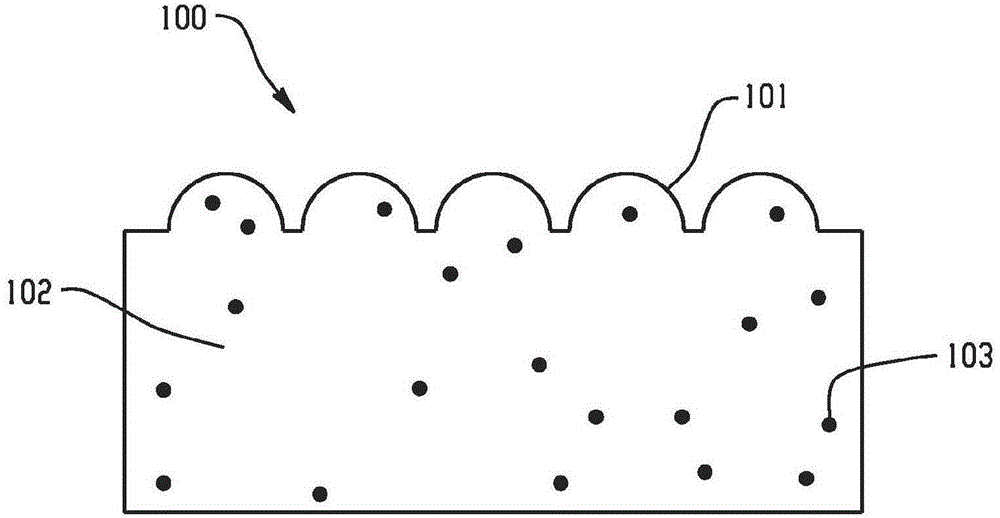

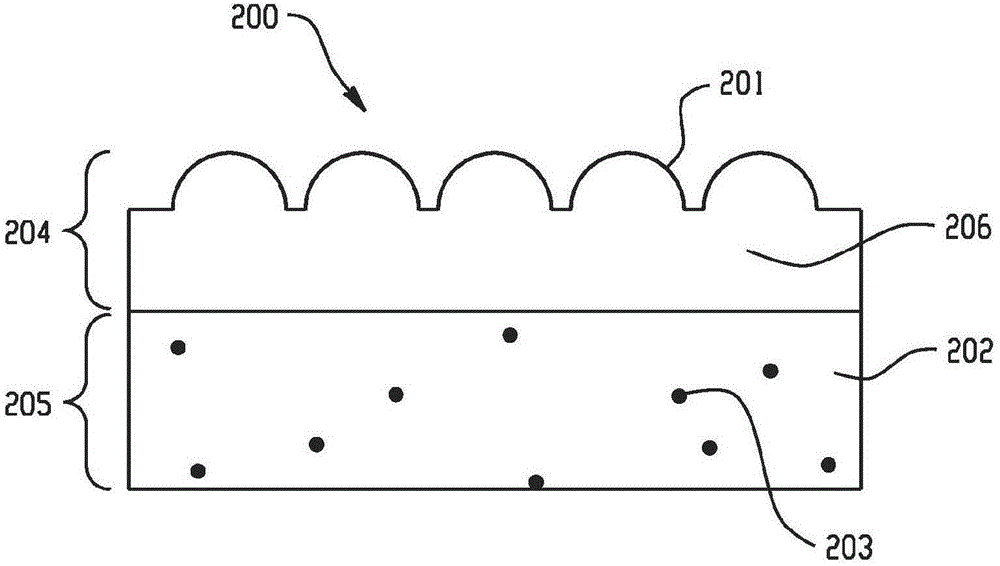

Sheet for LED light cover application

Disclosed herein is a sheet comprising a polymeric material; light diffusing particles disposed in the polymeric material; and a non-random surface texture on a surface of the sheet; wherein the surface texture comprises hemispherical structures, partial hemispherical structures, ellipsoidal structures, immersed spherical beads, ellipsoidal beads, “bell-shape” bump, complex lens shape structures, pyramidal structures, reversed pyramidal structures, or combinations comprising at least one of the foregoing. The sheet has excellent hiding power and transmission at the same time and is suitable for LED light cover applications. The unit structures have an aspect ratio of 0.15 to 0.5 and a pitch of greater than or equal to 100 μm

Owner:SABIC GLOBAL TECH BV

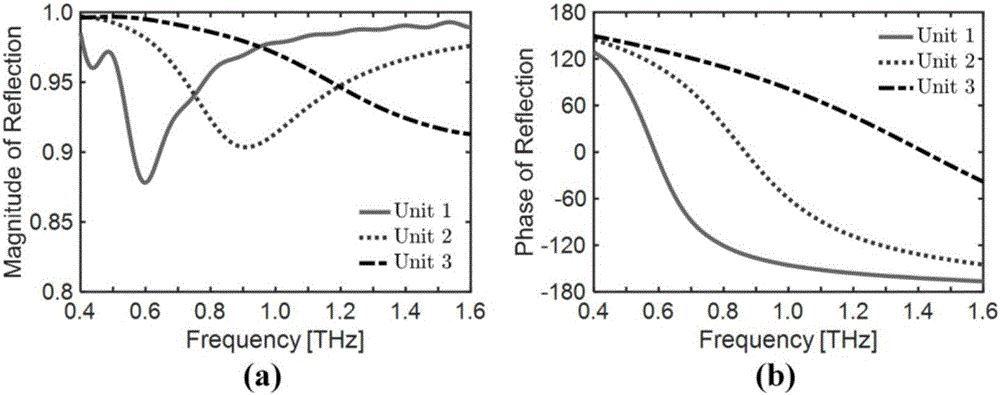

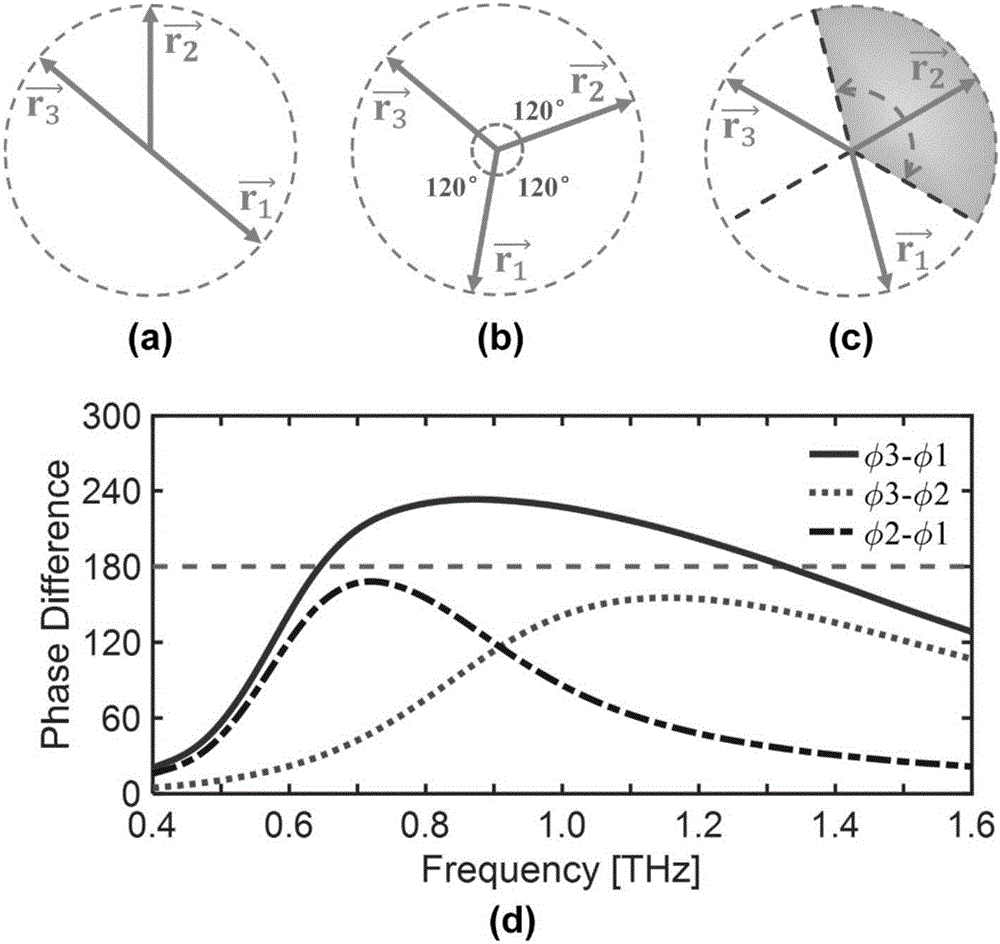

Random surface with accurately designed bandwidth

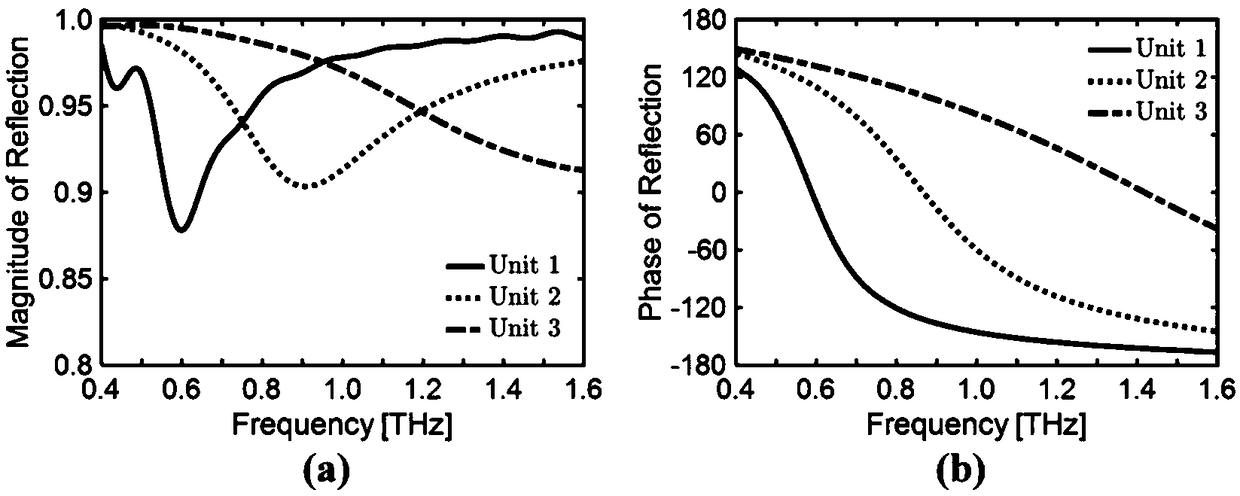

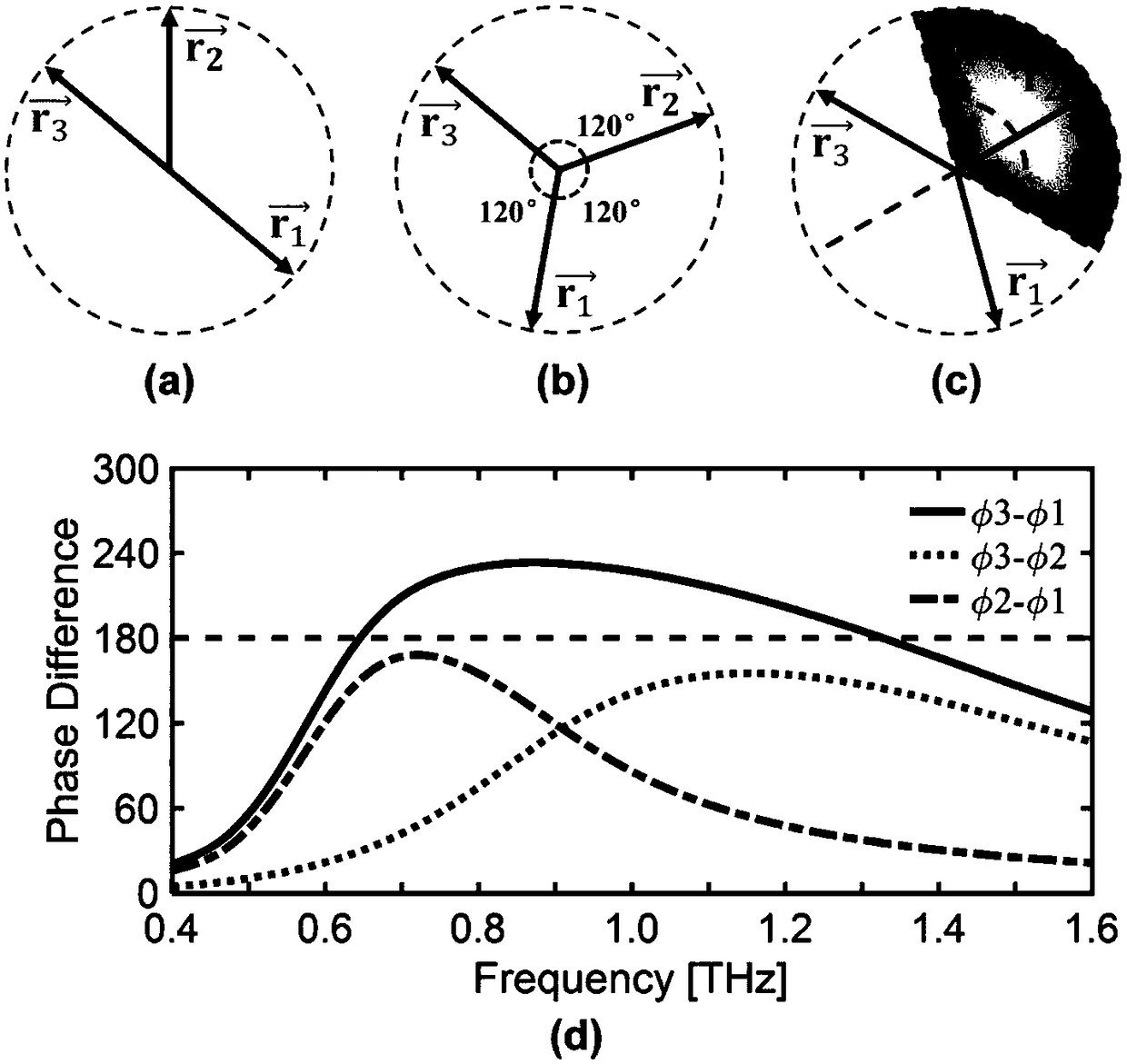

ActiveCN106129632AThe principle is simpleElectromagnetic simulation calculation is smallAntennasPhase differenceDielectric substrate

The invention discloses a random surface with an accurately designed bandwidth. The random surface is formed by arranging three fundamental submatrixes, wherein the submatrixes are the same in size and are basically the same in number; and different submatrixes are formed by periodically arranging the same fundamental units, so that three kinds of fundamental units are arranged in all. Each fundamental unit comprises a dielectric substrate, a metal patch and a metal backboard, wherein each metal patch and each metal backboard cover the upper surface and the lower surface of the corresponding dielectric substrate respectively. The fundamental units have low loss characteristics; and the phase relationship meets the condition that the phase difference between every two fundamental units does not exceed 180 degrees. The condition that the reflectivity does not exceed 1 / 9 of that of a same size of metal plate can be achieved under the condition. The operation bandwidth of the random surface can be accurately estimated under the premise of not needing large-scale simulation; and the random surface has important engineering application value. The random surface can be applied to large-angle incidence through optimizing arrangement of the submatrixes; obvious scattering is avoided in all back scattering directions; and the random surface has a potential application prospect in the field of stealth.

Owner:SOUTHEAST UNIV

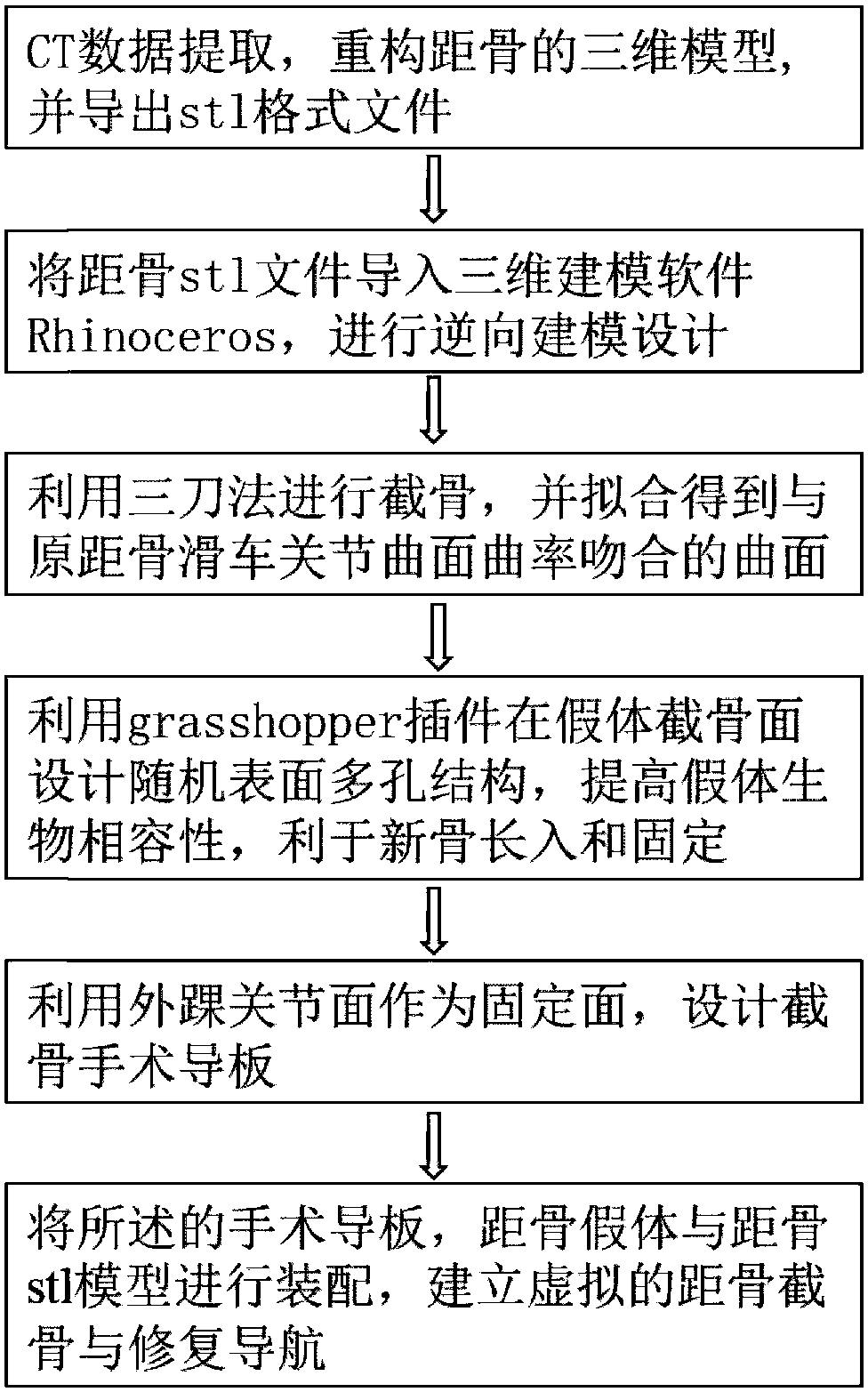

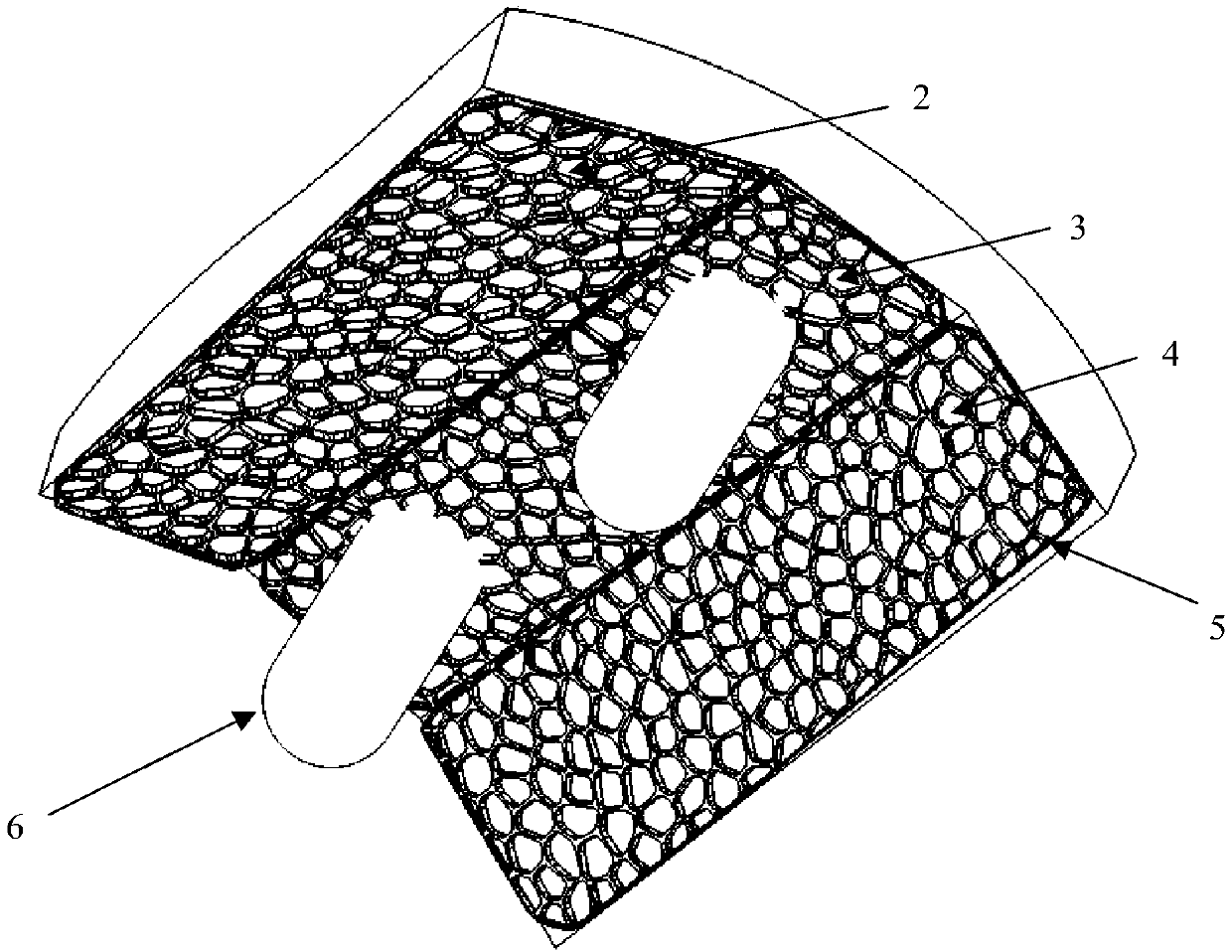

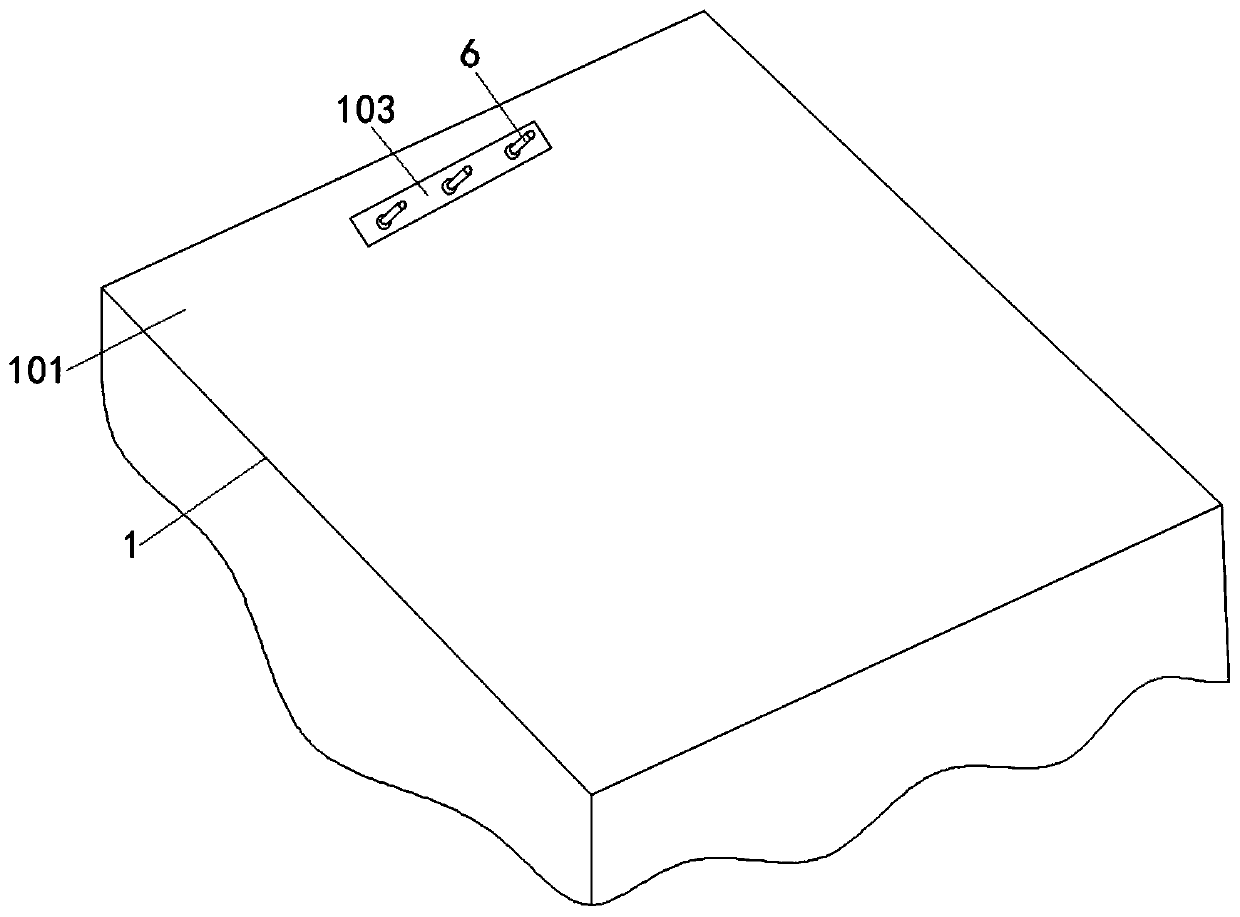

Personalized porous structure astragalus restoration, osteotomy surgical guide plate and design method thereof

PendingCN108030532AHigh degree of reductionImprove adaptabilityBone drill guidesArticular surfacesArticular surface

The invention discloses a personalized porous structure astragalus restoration, an osteotomy surgical guide plate and a design method thereof. The design method comprises the following steps of extracting CT data, reconstructing a three-dimensional model of astragalus, and exporting a stl format file; importing the stl file into a three-dimensional modelling software Rhinoceros for an inverse modeling design; using a three-knife method to perform osteotomy, and obtaining a curved surface fitted with curvature of a curved surface of an original astragalus hinge joint through matching; using a grasshopper plug-in to design a random surface porous structure on a prosthesis osteotomy surface, improving the biocompatibility of a prosthesis, facilitating new bone ingrowth, fixedly using a lateral malleolus articular surface as a fixing surface, and designing the osteotomy surgical guide plate; assembling the surgical guide plate, the astragalus prosthesis and a astragalus styl model, and establishing a virtual astragalus osteotomy and repair navigation. The method is based on the CT data of the astragalus of a patient, and combined with the reverse modeling design and an forward modelingdesign to design the astragalus restoration and the osteotomy navigation.

Owner:SOUTH CHINA UNIV OF TECH

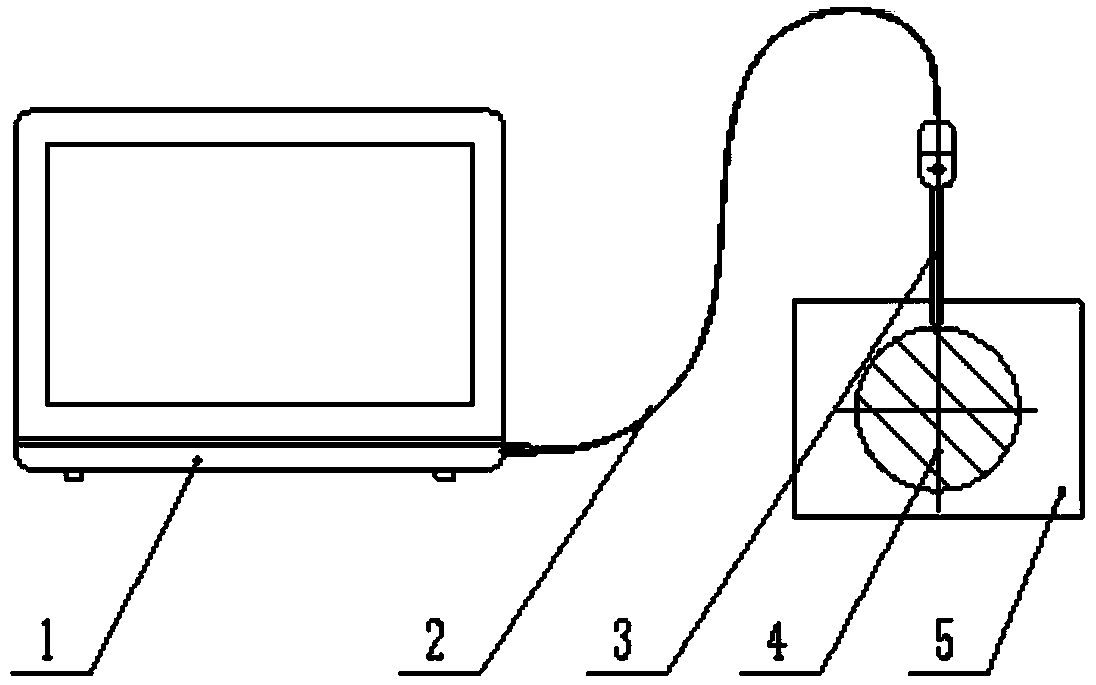

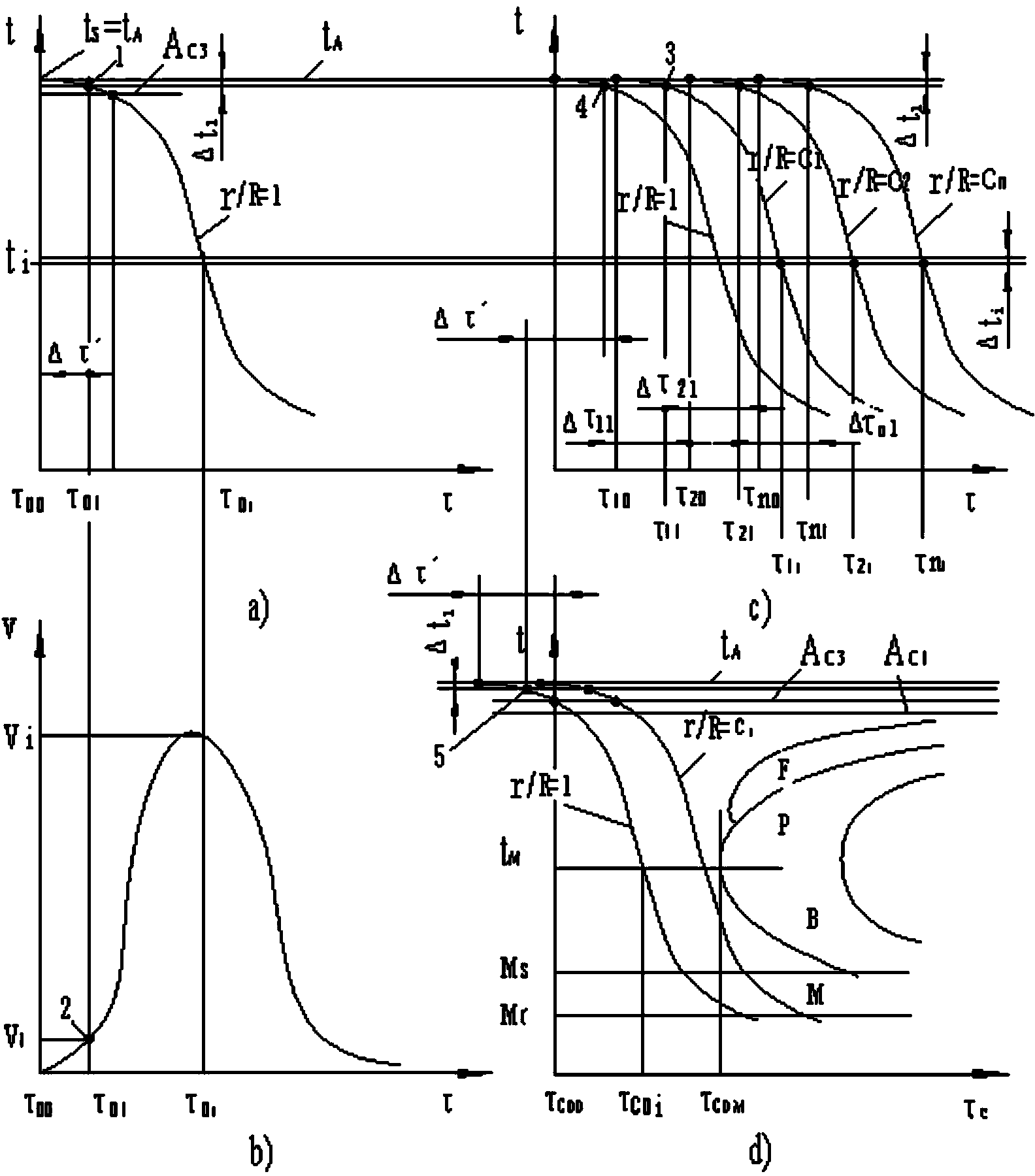

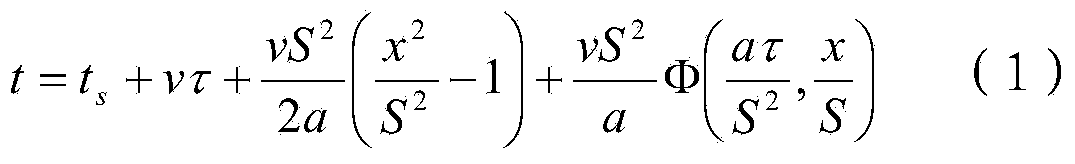

Solid section temperature change measurement system

InactiveCN103413059ASimple calculationNo loss of calculation accuracySpecial data processing applicationsCooling curveEngineering

The invention discloses a solid section temperature change measurement system. The solid section temperature change measurement system is characterized by comprising a module for intercepting solid surface temperature and time relations, a data fitting module, a fitting data differential module, a parameter input and calculation module and a CCT (continuous cooling transformation) and TTT (time temperature transformation) curve superposition module. Influences of internal heat sources, quality, physical properties and ingredients of solids on heat transfer are embodied on temperature time curves of the solid surfaces classified according to shape, and different temperature moments form a cooling curve from the measured section center parts of the solids to the random surface positions by measuring surface temperature time curves of to-be-measured objects, obtaining temperature change speeds of the object surfaces and calculating moments with the same temperature as the surfaces from the center parts of the measured solids to the random surface positions. The complex calculation process is simplified while calculation accuracy is not reduced, and the goal of practicality is achieved simultaneously.

Owner:SHANDONG JIANZHU UNIV

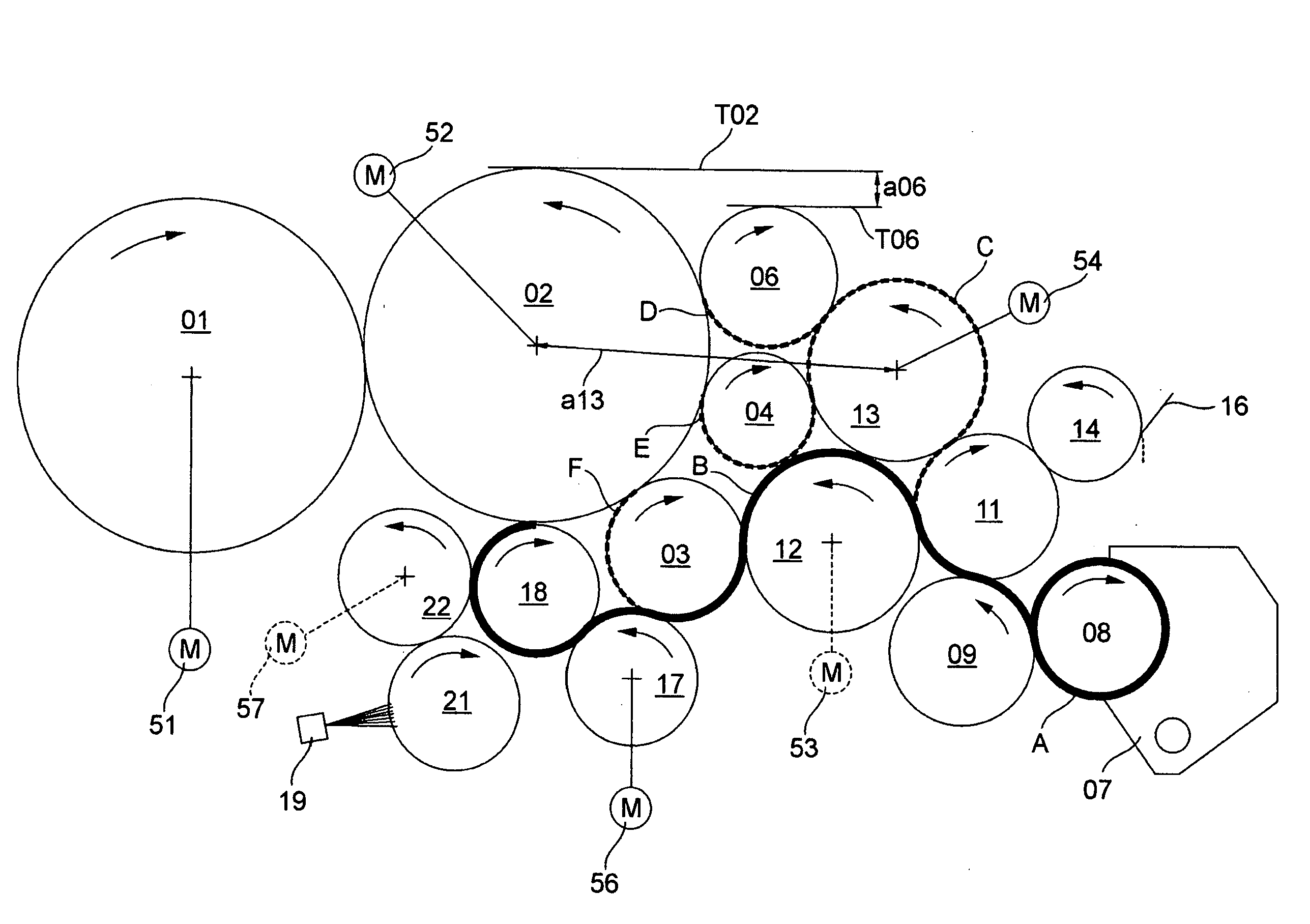

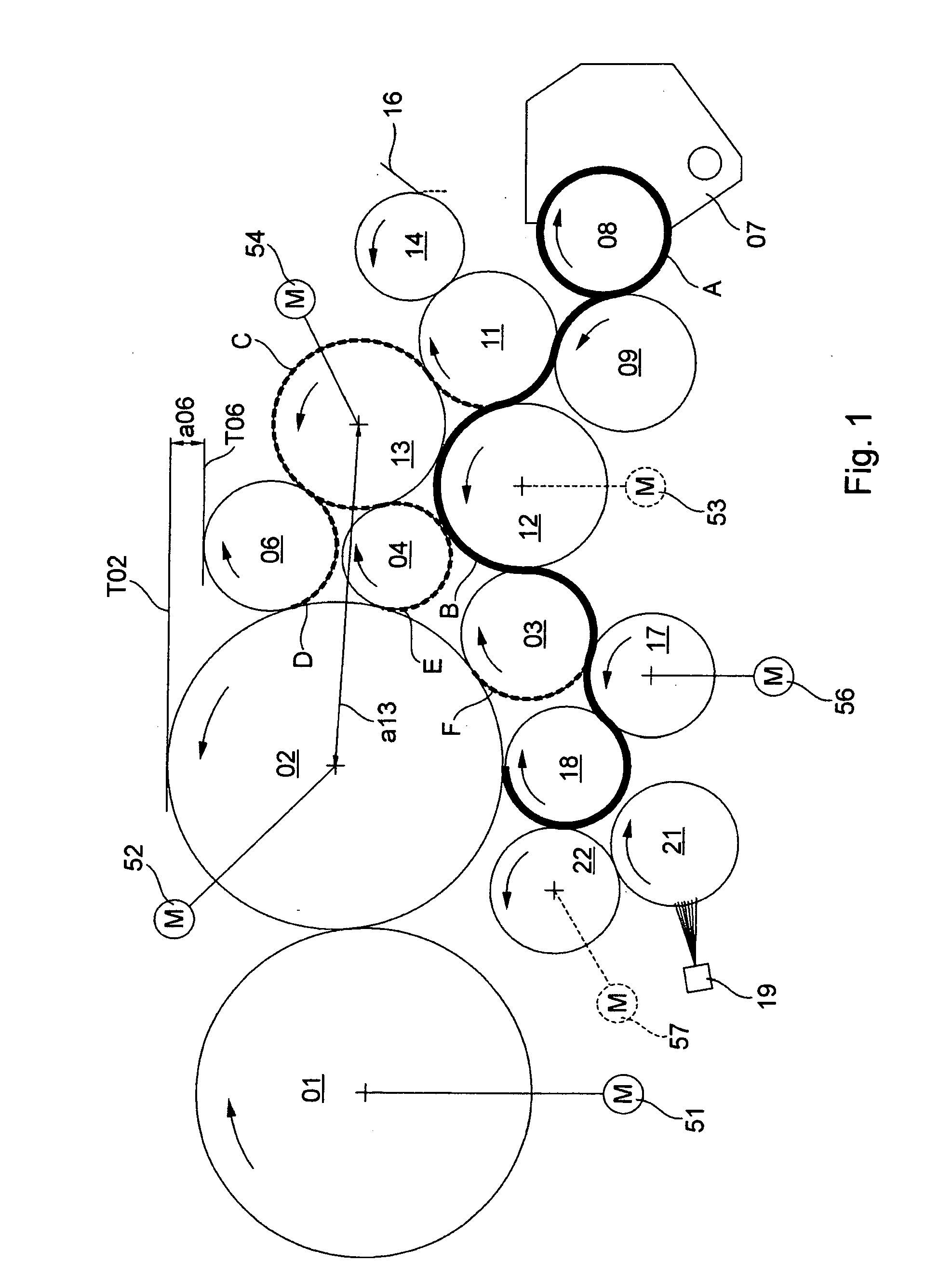

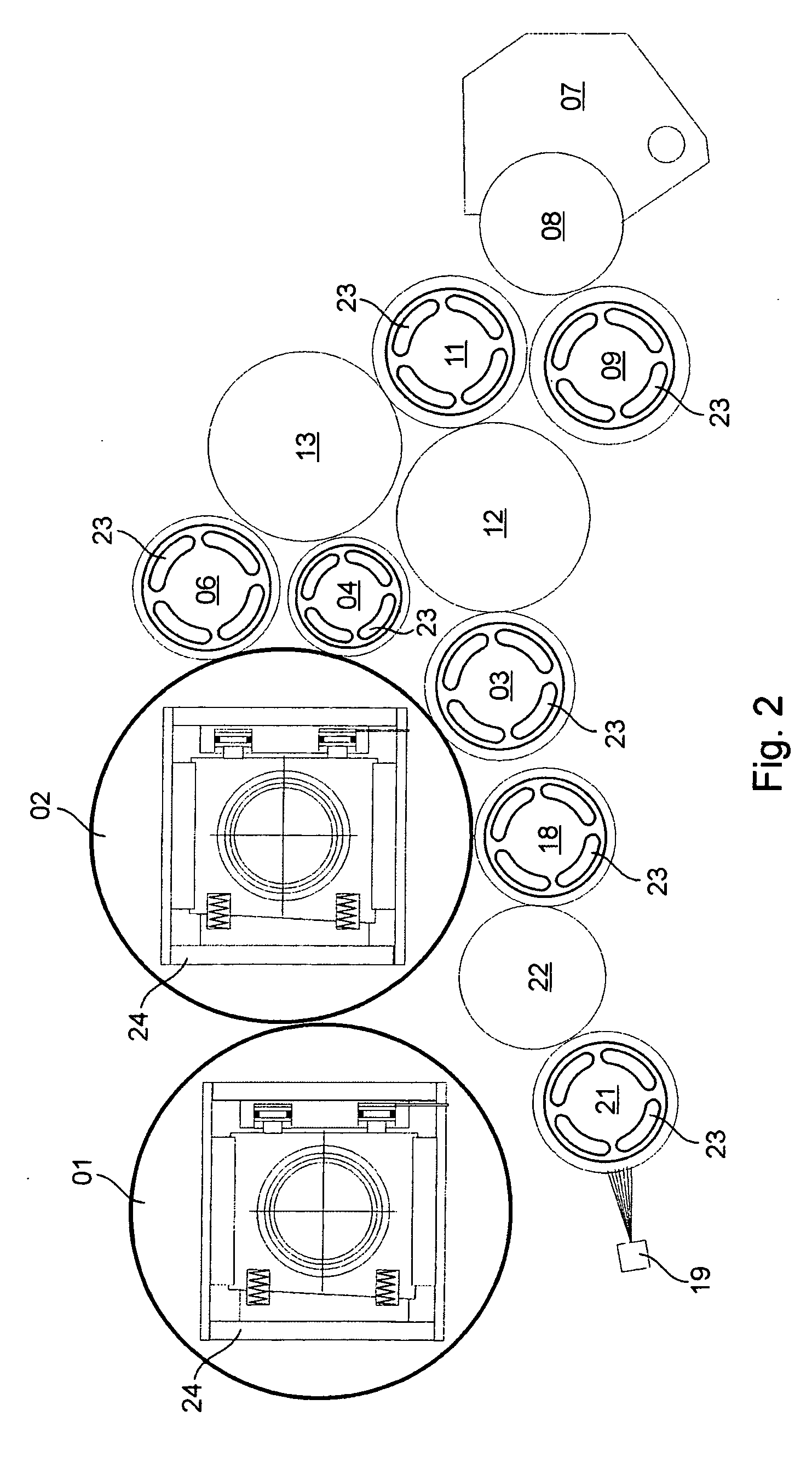

Inking unit of a rotary press, comprising a film roller

InactiveUS20090090261A1Quality improvementLimit transportAgricultural rollersPrinting roller shellsEngineeringHardness

An inking unit of a rotary printing press includes a film roller. The film roller has a structured outer surface that has a Shore D hardness ranging between 80 and 90 and a stochastic surface. The stochastic surface is incorporated into the outer surface of the film roller by peening.

Owner:KOENIG & BAUER AG

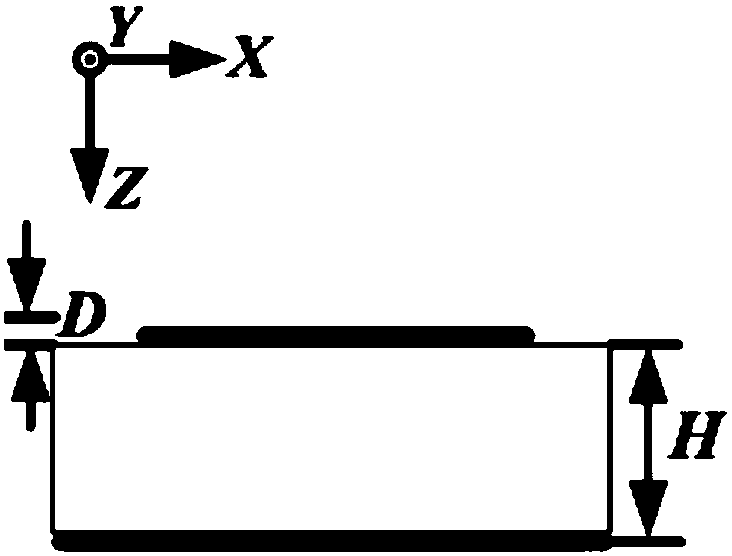

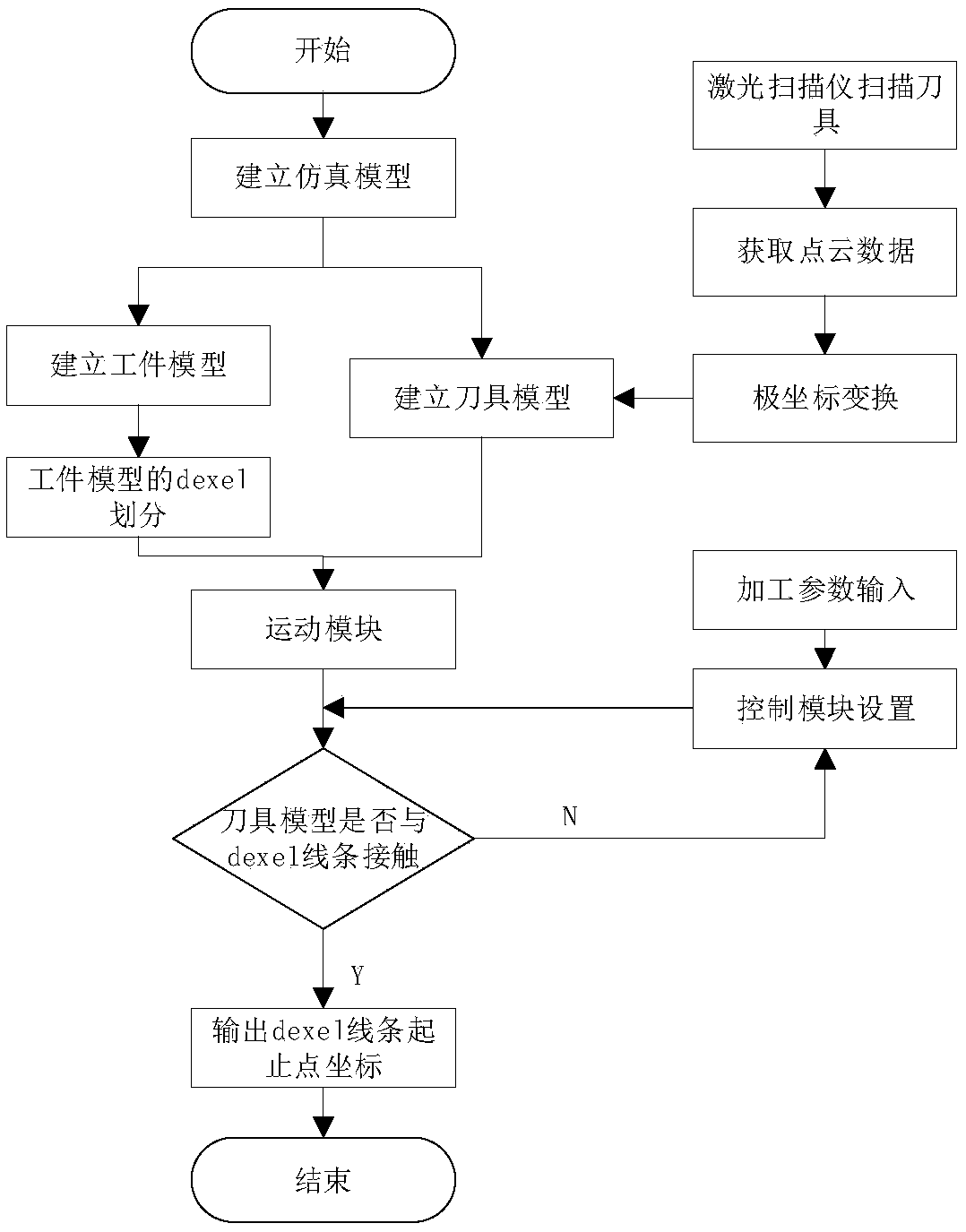

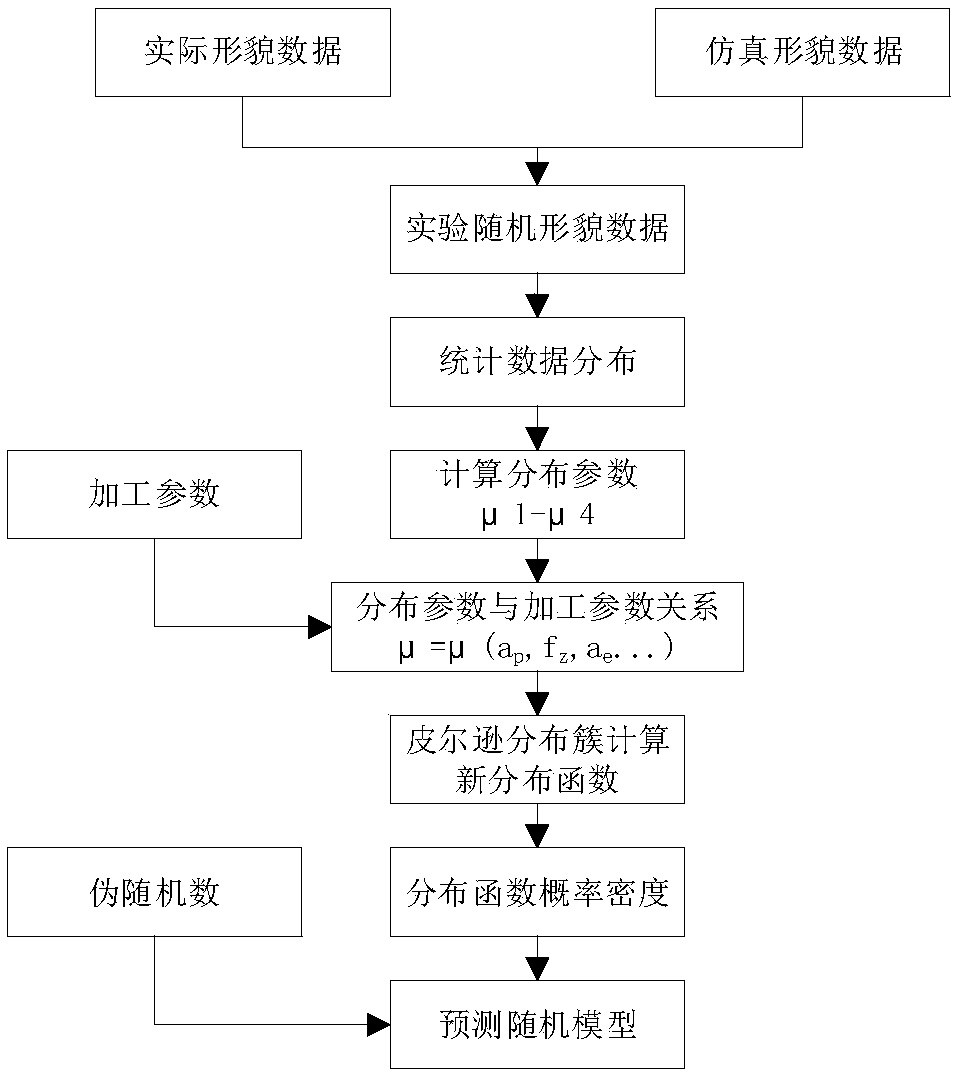

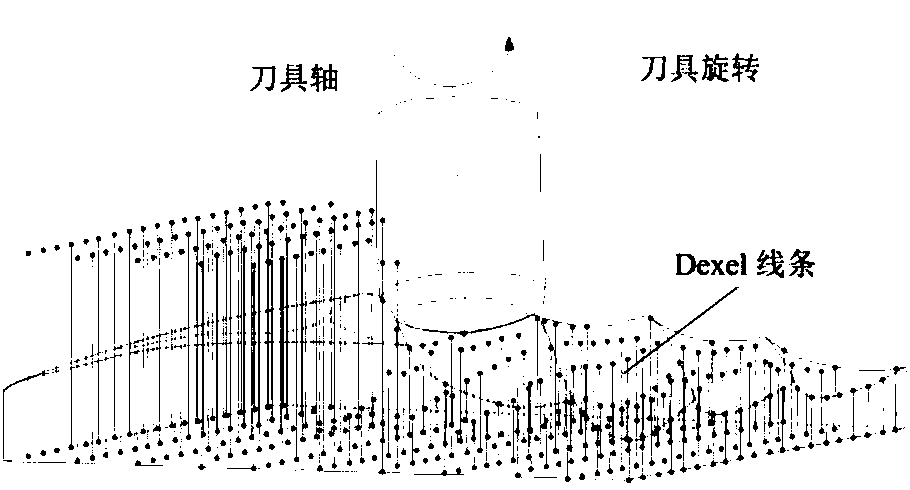

Prediction method of workpiece surface form based on side milling machining

ActiveCN108127481AHigh precisionImprove accuracyMeasurement/indication equipmentsMilling equipment detailsEngineeringMachining process

The invention discloses a prediction method of a workpiece surface form based on side milling machining, and belongs to the technical field of machine manufacturing simulation. The prediction method comprises the steps of comparing measured surface form data of a workpiece in the real-time machining processwith surface form data of a workpiece model and obtaining difference value data of the surface formdata of the workpiece and the surface form data of theworkpiece model as experimental random surface form data; according to a probability statistics method, a Pearson distributing cluster anda random number, processing the experimental randomsurface form data to obtain a surface form prediction random model; according to the surface form prediction random model of the workpiece model, changing machining parameters in a simulation model to obtain surface form data, corresponding to the machining parameters, of the workpiece in actual side milling machining, so that the surface form data of the workpiece is predicted. By means of the method, the advantages of experiment and a statistics method are integrated, the limit on the experiment is gotten rid of, operation is also simplified, and compared with an existing prediction method, the efficiency and the prediction precision are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

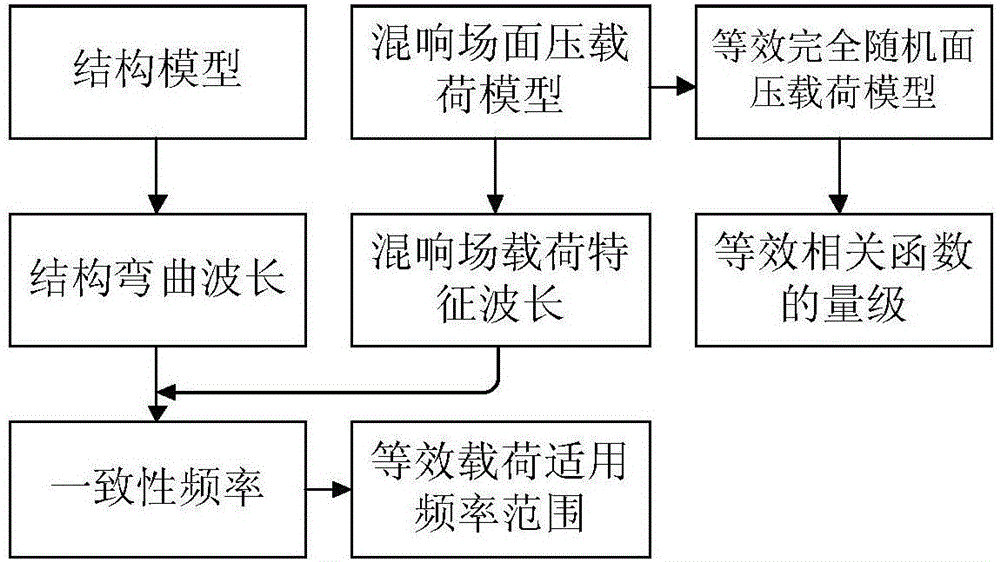

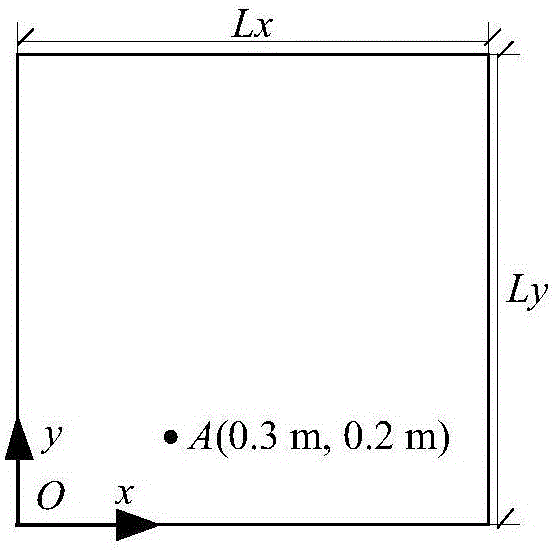

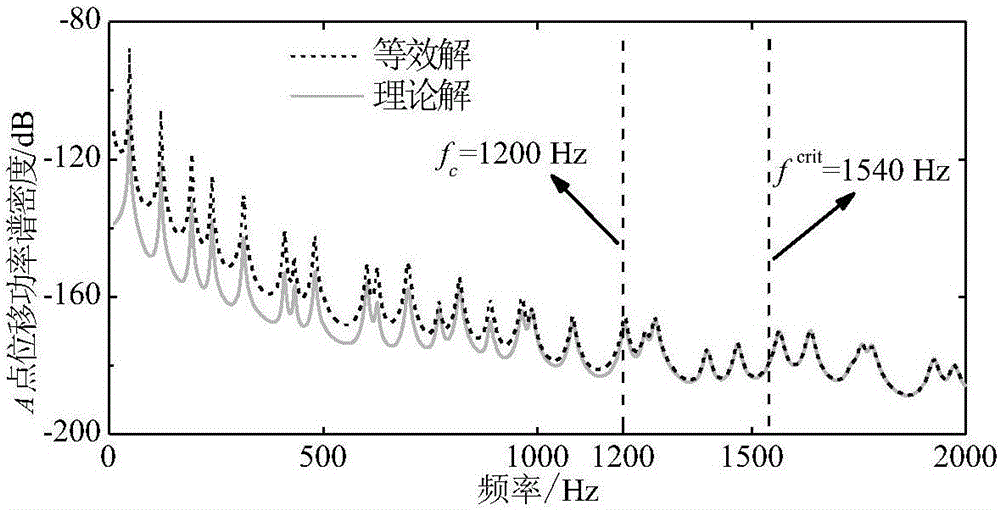

Equivalence technology for reverberation field random surface pressure load model

ActiveCN106484952ASmall amount of calculationShorten the design cycleGeometric CADSpecial data processing applicationsLoad modelDesign cycle

The invention discloses an equivalence technology for a reverberation field random surface pressure load model. The technology comprises the following steps of (1) performing equivalence on the reverberation field random surface pressure load model to form an equivalent complete random surface pressure load model; (2) determining an order of magnitude of an equivalent correlation function of the equivalent complete random surface pressure load model; and (3) determining a structure bending wavelength and a reverberation field load feature wavelength, then calculating a consistency frequency, and based on this, determining a suitable frequency range of the equivalent complete random surface pressure load model. The equivalence technology for the reverberation field random surface pressure load model, provided by the invention, is a technology for making a reverberation field load model equivalent to the complete random surface pressure load model; and by the technology, the calculation amount of structure dynamic response analysis under the effect of a reverberation field surface pressure load can be effectively reduced, the design cycle can be shortened, and the design cost can be reduced.

Owner:SOUTHEAST UNIV

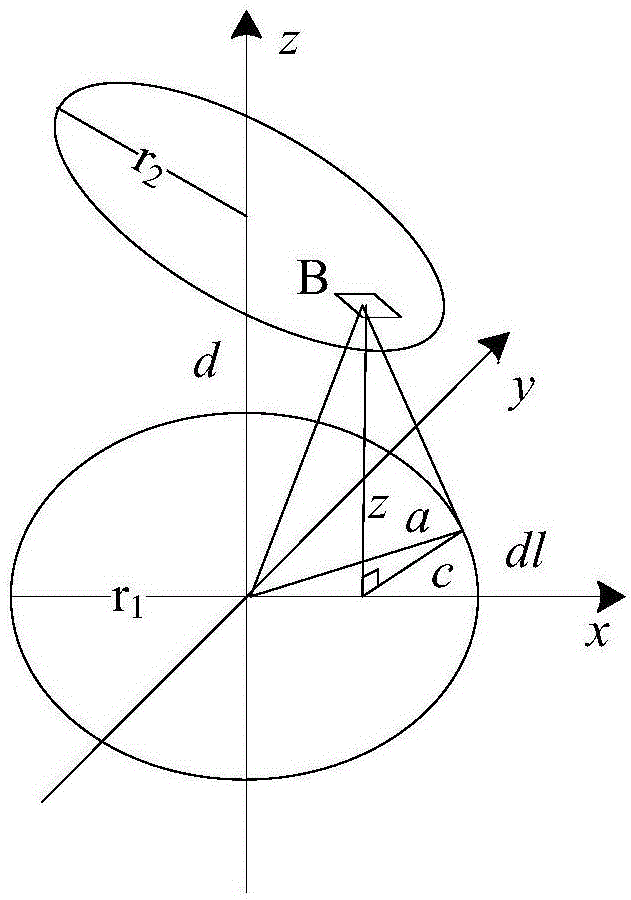

Wireless electric energy transmission resonator for refrigerator sensor and energy distribution method

ActiveCN106230129AFlexible and diverse power supply structureSolve the disadvantages of frequent battery replacementCircuit arrangementsCapacitanceWireless transmission

The invention discloses a wireless electric energy transmission resonator for a refrigerator sensor and an energy distribution method. The wireless electric energy transmission resonator comprises a resonator transmission coil, a resonator receiving coil, a resonator transmission coil compensation capacitor, a resonator receiving coil compensation capacitor, a resonator relay coil and a resonator relay coil compensation capacitor. The resonator receiving coil can be arranged on a random surface of a front surface, a back surface, a left surface, a right surface, an upper surface and a lower surface of a refrigerator along with the sensor. The relay coil is introduced for improving energy efficiency characteristic in middle-distance and long-distance wireless transmission. In consideration of factors such as sensor power requirement in the refrigerator and spatial position, through adjusting the value of a receiving-end resonant matching capacitor, according-to-requirement distribution and effective distribution of energy can be realized. The wireless electric energy transmission resonator for the refrigerator sensor and the energy distribution method have advantages of performing direct electric energy supply to many sensor elements in the refrigerator or charging the battery, improving power supply stability to the sensor, preventing restriction of a power supply and a lead to the sensor, and realizing freer spatial layout.

Owner:SOUTHEAST UNIV

Slice, preparing method thereof, circuit substrate with slice, and preparing method of circuit substrate

The invention discloses a slice for forming a cutting substrate protecting film. The slice comprises a first release sheet and a protecting film forming layer. The protecting film forming layer is formed on a release surface of the first release sheet, wherein the protecting film forming layer comprises the components of silicon dioxide which is modified by an amino silane coupling agent or an epoxy siloxane coupling agent, and epoxy resin. The invention further discloses a preparing method of the slice, and a circuit cutting substrate with the protecting film on a random surface.

Owner:WUHAN CHOICE TECH CO LTD

Sheet for LED light cover application

Disclosed herein is a sheet comprising a polymeric material; light diffusing particles disposed in the polymeric material; and a non-random surface texture on a surface of the sheet; wherein the surface texture comprises hemispherical structures, partial hemispherical structures, ellipsoidal structures, immersed spherical beads, ellipsoidal beads, “bell-shape” bump, complex lens shape structures, pyramidal structures, reversed pyramidal structures, or combinations comprising at least one of the foregoing. The sheet has excellent hiding power and transmission at the same time and is suitable for LED light cover applications. The unit structures have an aspect ratio of 0.15 to 0.5 and a pitch of greater than or equal to 100 μm.

Owner:SABIC GLOBAL TECH BV

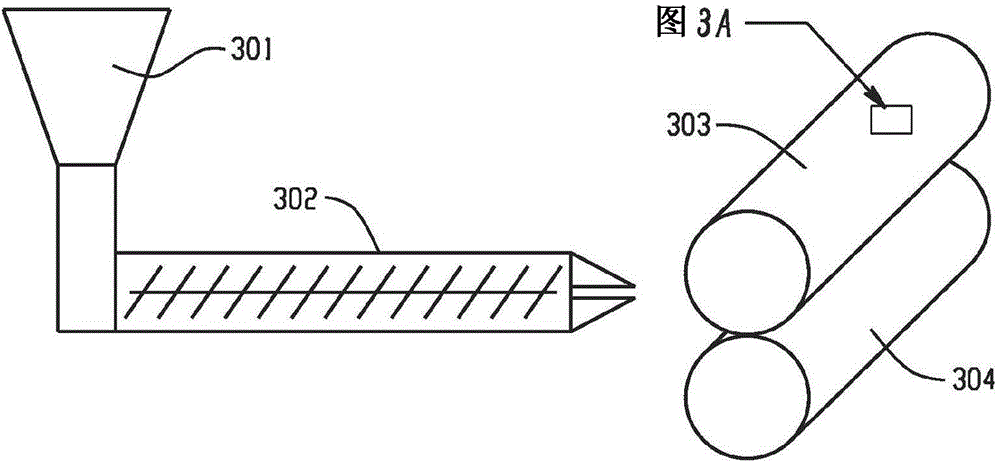

Processing mold used for carbon fiber complex core pressing moulding

InactiveCN102394149AHigh extrusion speedReduce mistakesCable/conductor manufactureFiberCarbon fibers

The invention relates to a processing mold used for carbon fiber complex core pressing moulding. The processing mold comprises a horizontally arranged mold. A cylindrical surface of the mold is provided with an infrared generator which is formed by winding resistance wire around the cylindrical surface of the mold. A carbon fiber complex core runs through a through hole of the mold. A shape of the through hole of the mold can be set as a round shape, a square shape, an abnormal shape, a plate shape or other shapes. At six surfaces of the carbon fiber complex core or one surface combined with other random surface, a mold through which an infrared spectrum (1 micron to 4 microns) can penetrates is provided. The processing mold of the present invention has the advantages of simple structure, high precision, energy saving and high efficiency.

Owner:王兆进

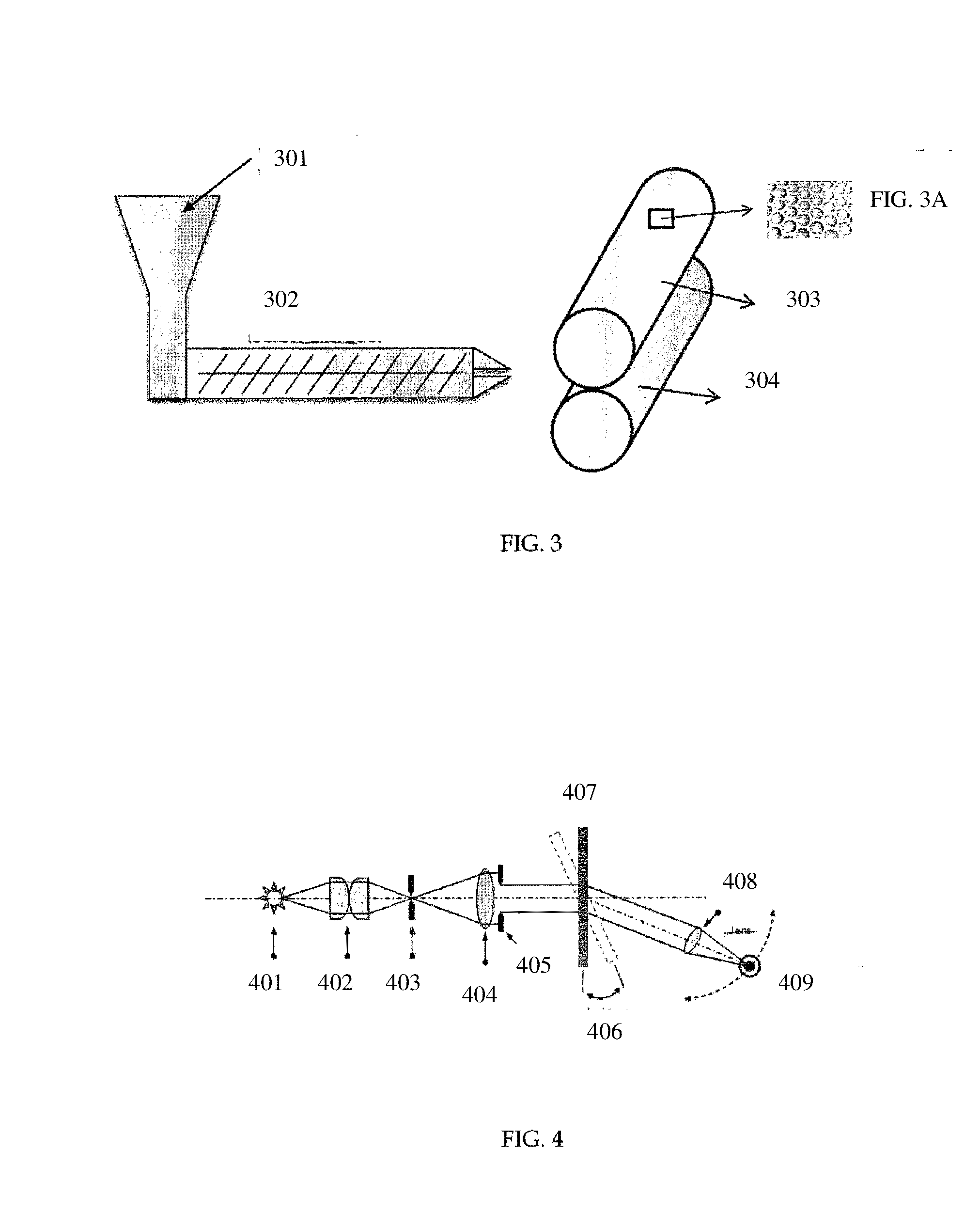

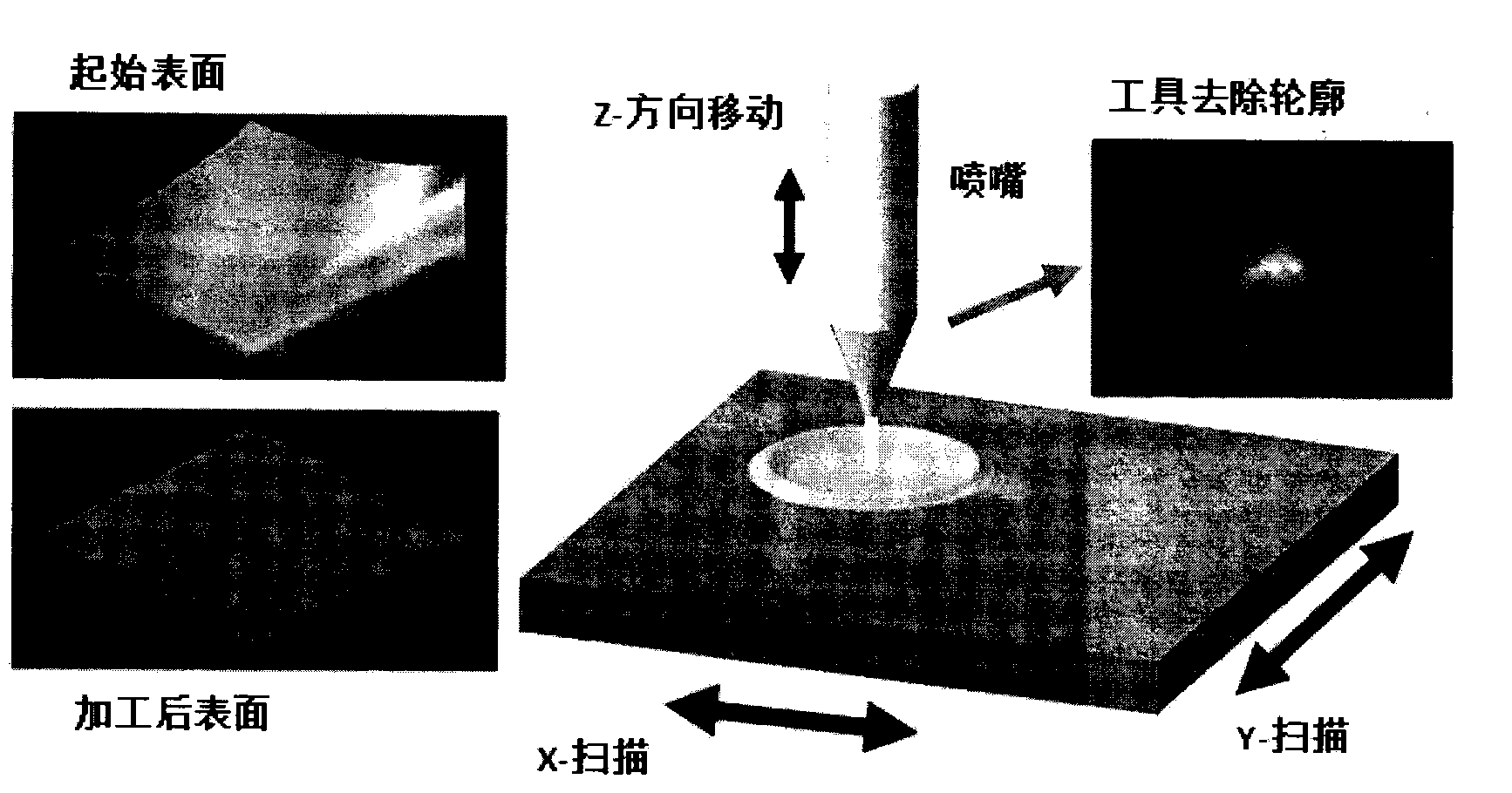

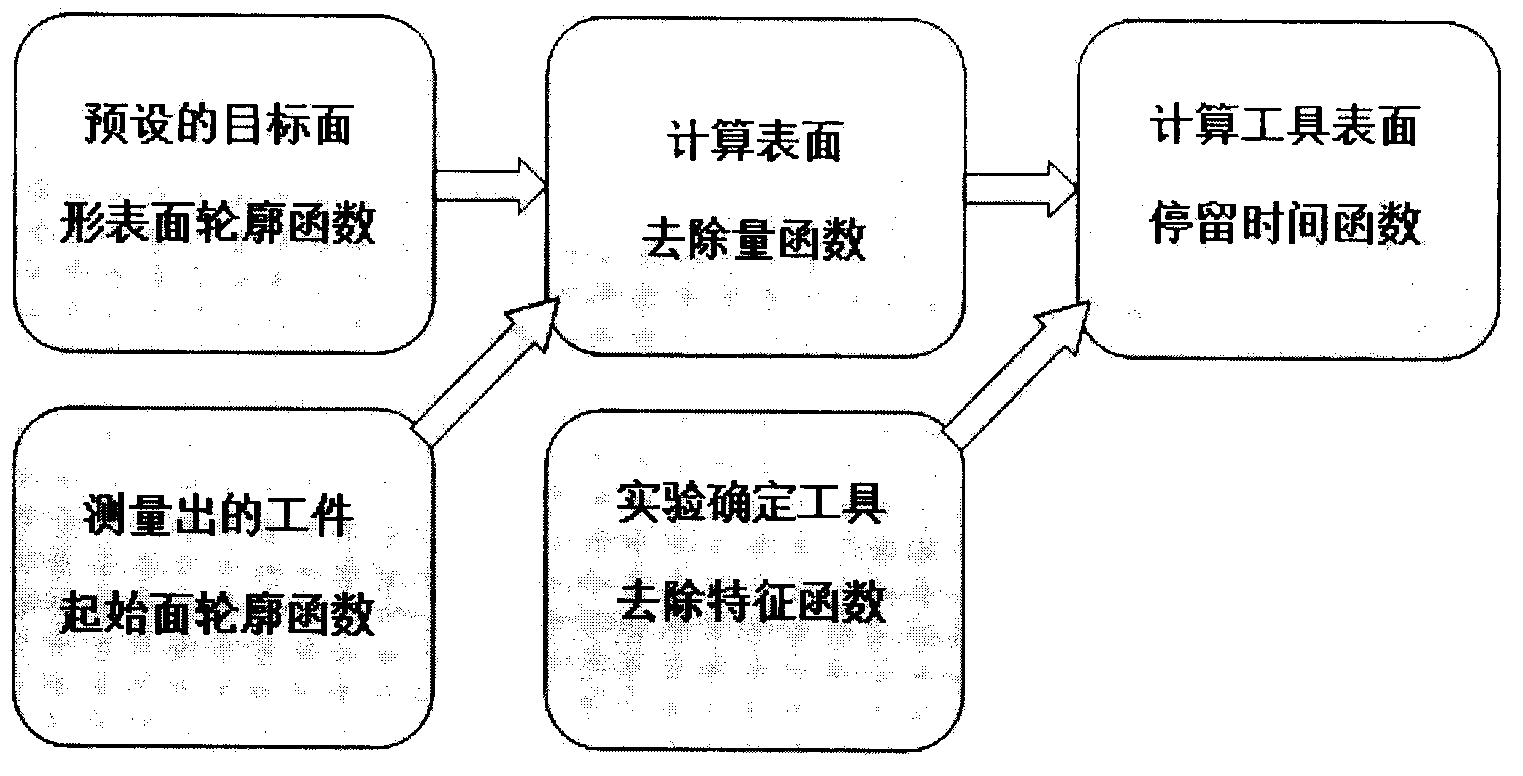

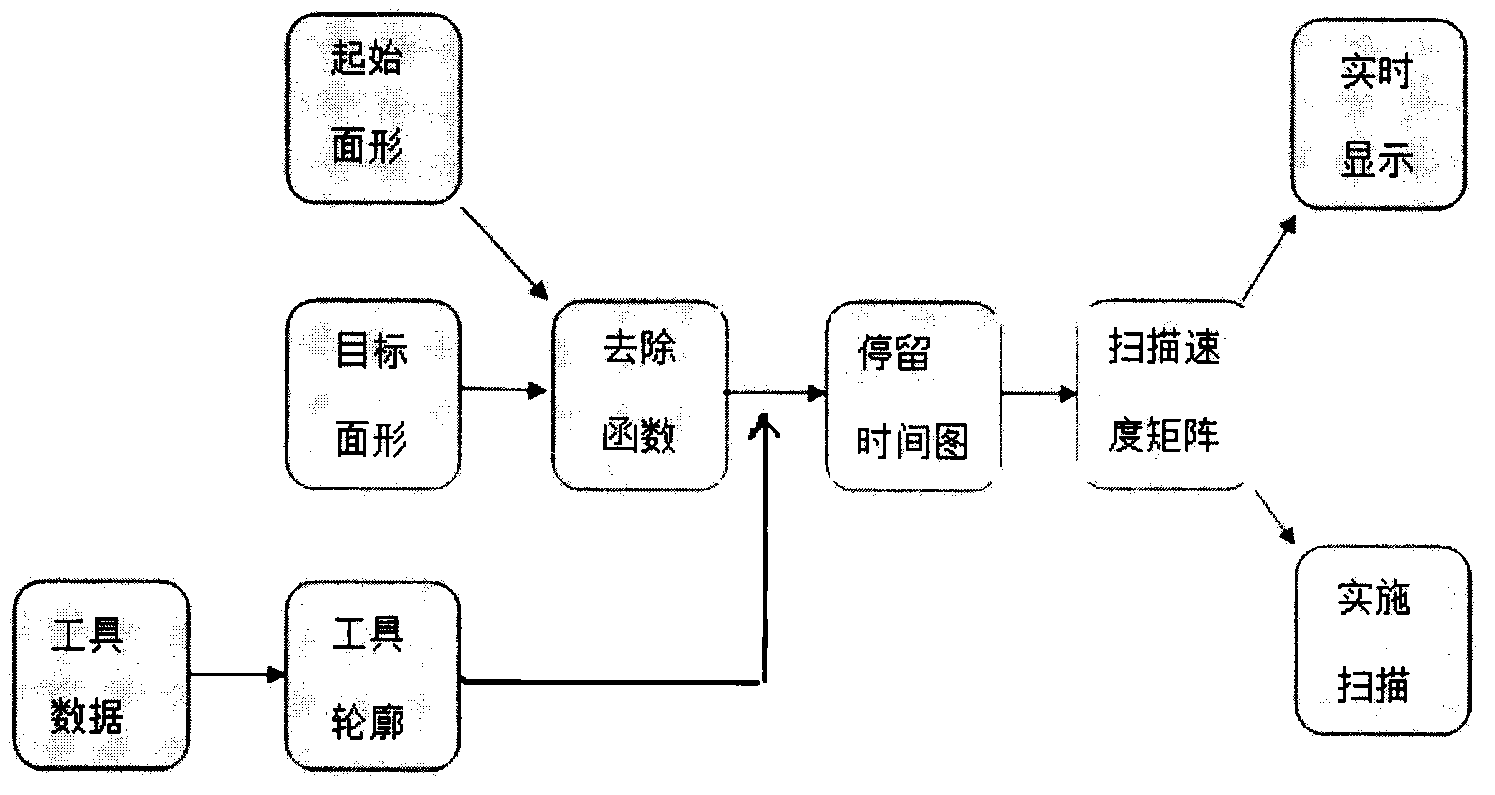

Deterministic processing system for high-precision optical surface with random surface shape

InactiveCN103802031AEasy to operateNo pollution in the processBlast gunsManufacturing technologySemiconductor materials

The invention relates to the field of high-precision optical processing, and discloses a three-dimensional processing system for a high-precision optical surface with a random surface shape. The mobility of a work-piece in the vertical direction is enhanced by software control on the basis of a computer-controlled deterministic polishing technology, so that the work-piece keeps the invariable height difference in the processing process and can ensure the constant removal rate when a large-fluctuation non-planer component is processed. Thus, the high-precision processing of a non-planer optical curve surface with the random surface shape is achieved. By adopting the processing system, the ultra-high precision, with the error is 1 / 100 wavelength, of the surface shape of an optical component with 10cm*10cm size can be achieved, the processing capability of a root-mean-square (RMS) error at about 1 / 1,000 wavelength can be achieved, and the processing capability of the random surface shape of the curve surface is achieved. The deterministic processing system can be applicable to a plurality of different application materials such as an optical surface and a semiconductor material film surface, and can become a manufacturing technology which is convenient, flexible and universal and can be applied to a plurality of industries.

Owner:黄智 +1

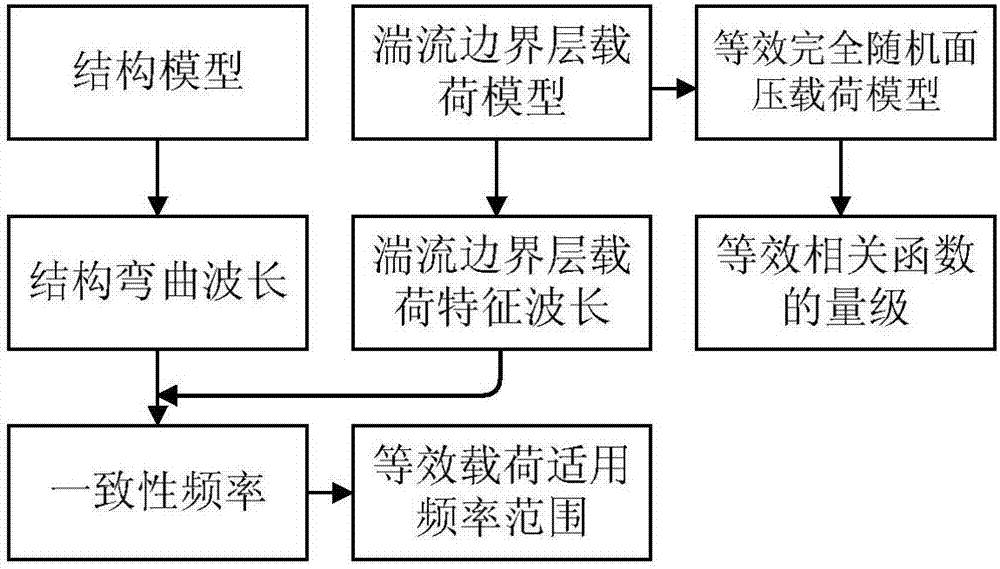

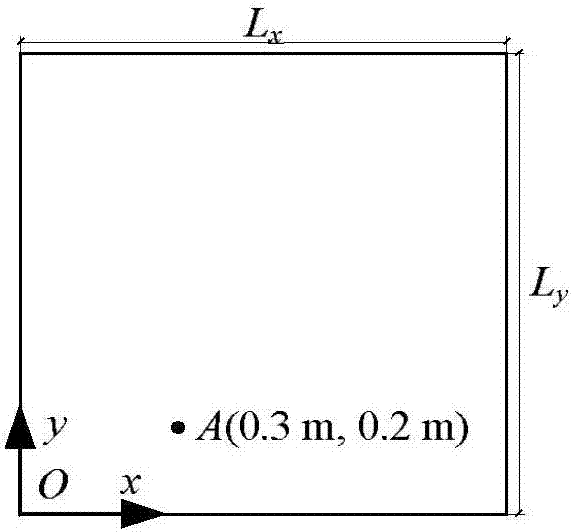

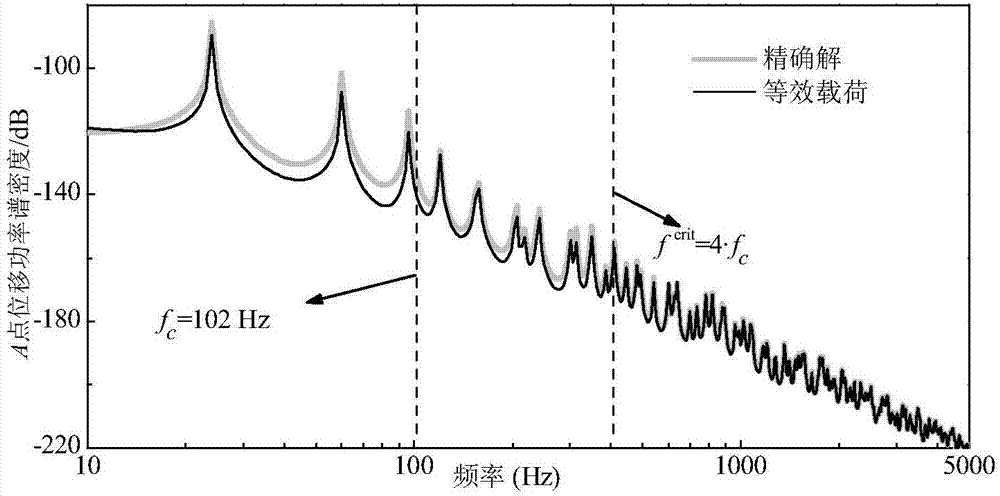

Equivalent method for turbulent boundary layer loading model

ActiveCN107169217ASmall amount of calculationShorten the design cycleDesign optimisation/simulationSpecial data processing applicationsStructural dynamicsDesign cycle

The invention discloses an equivalent method for a turbulent boundary layer loading model. The method comprises the following steps: (1) after equivalence of a turbulent boundary layer loading model, forming an equivalent completely random surface pressure loading model; (2) determining order of an equivalent correlation function of the equivalent completely random surface pressure loading model; (3) determining structure curved wavelength and turbulent boundary layer loading characteristic wavelength, so as to calculate consistency frequency, and determining appropriate frequency range of the equivalent random surface pressure loading model on the basis. The equivalent method for a turbulent boundary layer loading model is a technology which makes the turbulent boundary layer loading model equivalent to the completely random surface pressure loading model, and the technology can effectively reduce calculated amount of structural dynamic response analysis under action of the turbulent boundary layer loading, and design cycle is shortened, and design cost is saved.

Owner:SOUTHEAST UNIV

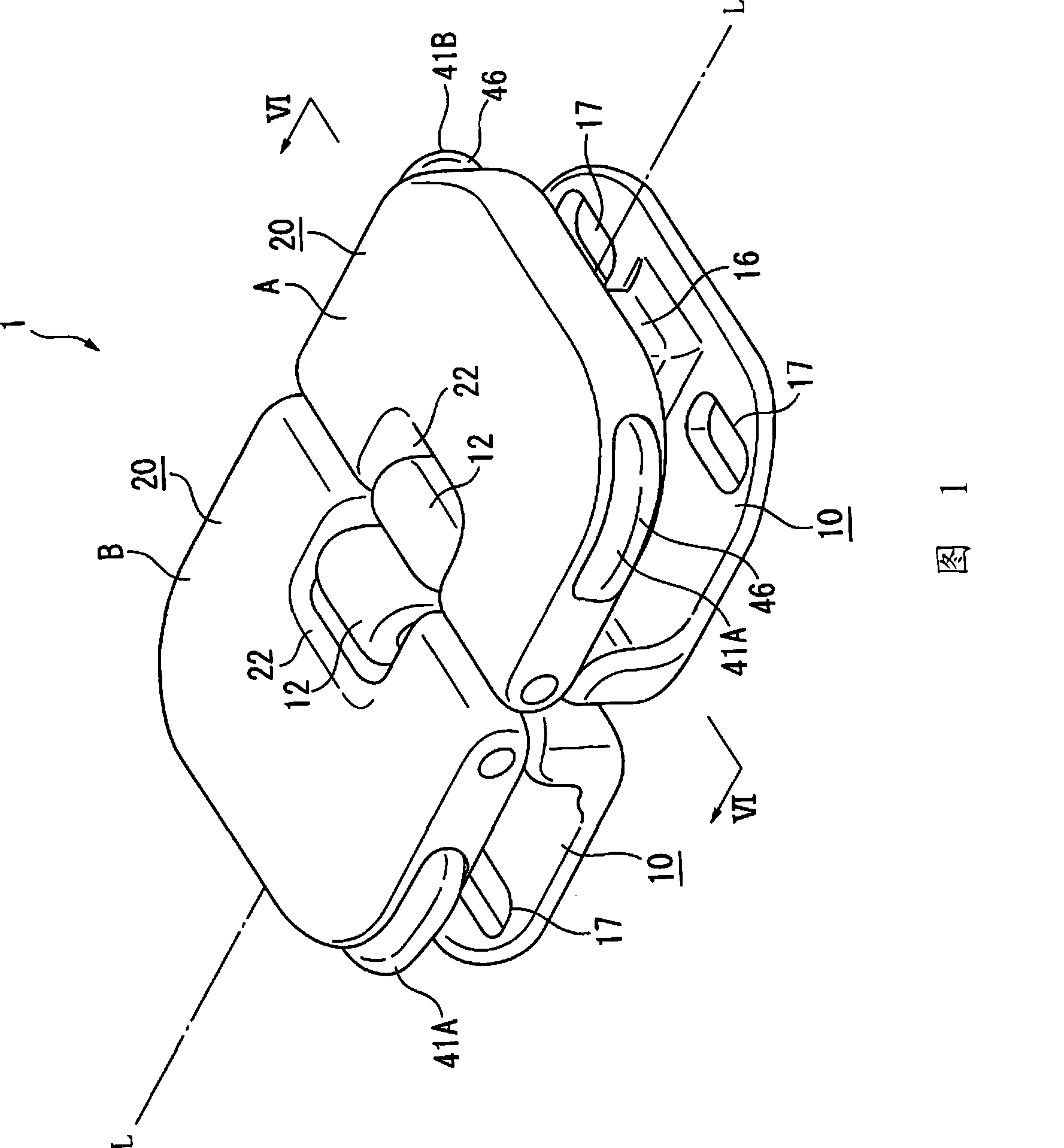

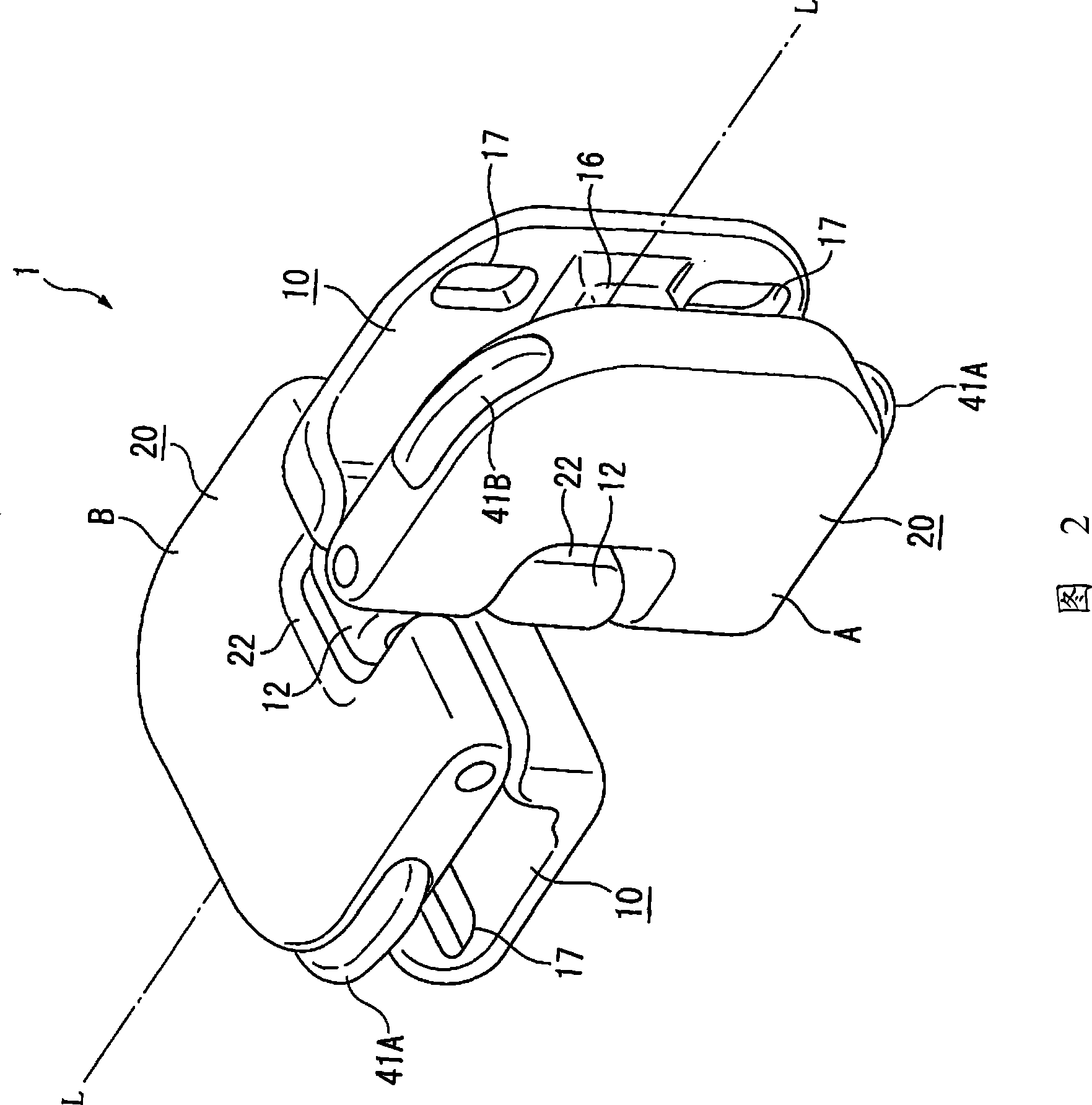

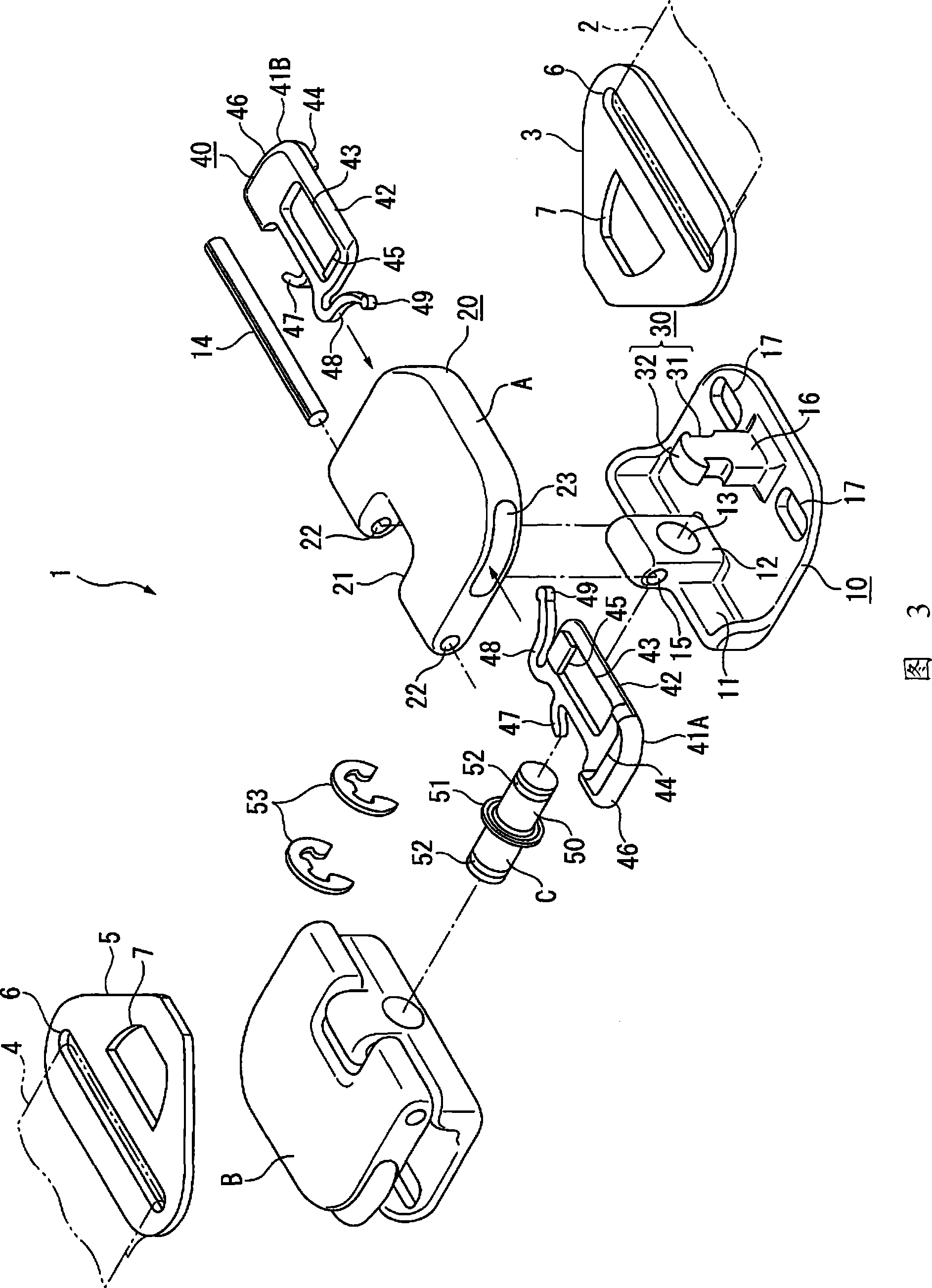

Connection device

The present invention provides a connecting device which is provided with a pair of holding devices (A, B) that are rotatablely connected with each other. Each holding device (A, B) comprises a first clamping plate (10), a second clamping plate (20), a clamping part (30) and a clamped part (40). The second clamping plate (20) can be supported on the upper part relatively to the first clamping plate (10) with a fluctuation mode. The clamping part (30) has a projection shape and is installed on a random surface (the first clamping plate (10)) selected from the face-to-face surfaces of the firstclamping plate (10) and the second clamping plate (20). The clamped part (40) is installed on the other surface (the second clamping plate (20)) selected from the face-to-face surfaces of the first clamping plate (10) and the second clamping plate (20), and is clamped with the clamping part. The connecting structure can be minimized wholly, and can prevent the movement of strip, rope or connecting piece.

Owner:YKK CORP

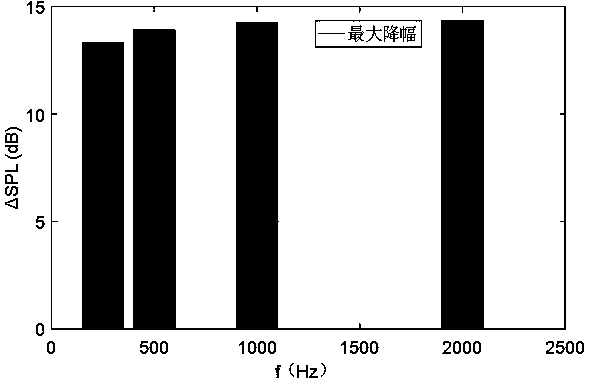

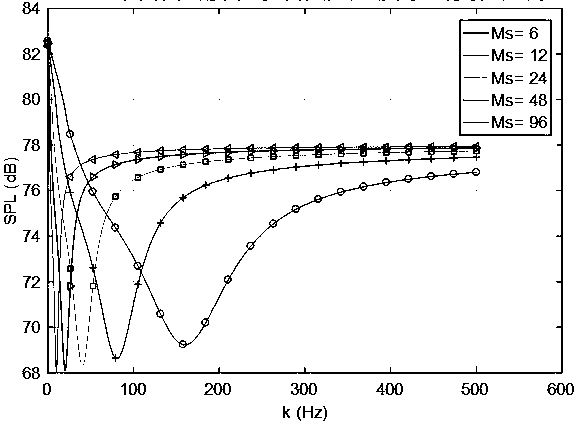

Apical-dominance sound barrier design method based on flow resistance and surface density coupling grading

The invention discloses an apical-dominance sound barrier design method based on flow resistance and surface density coupling grading. The flow resistance and surface density coupling of the sound barrier from the top to bottom changes gradually; and the appearance of the sound barrier has a random surface structure on the premise of the flow resistance and surface density coupling grading the sound barrier from the top to bottom. According to the invention, On the basis of the sound barrier theory and calculation model, the apical-dominance sound barrier has the substantially improved noise reduction performance when being compared with the conventional sound barrier; and a reasonable surface density and flow resistance coupling design is provided for the noise frequency needing to be processed, so that the optimal noise reduction effect is realized; and compared with the traditional sound barrier, the apical-dominance sound barrier enables the target frequency noises to be reduced substantially, wherein the theoretical maximum noise reduction amplitude can reach 25dB. The provided apical-dominance sound barrier has advantages of simple structure and great convenience in maintenance; and the great noise reduction effect is realized without heightening.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

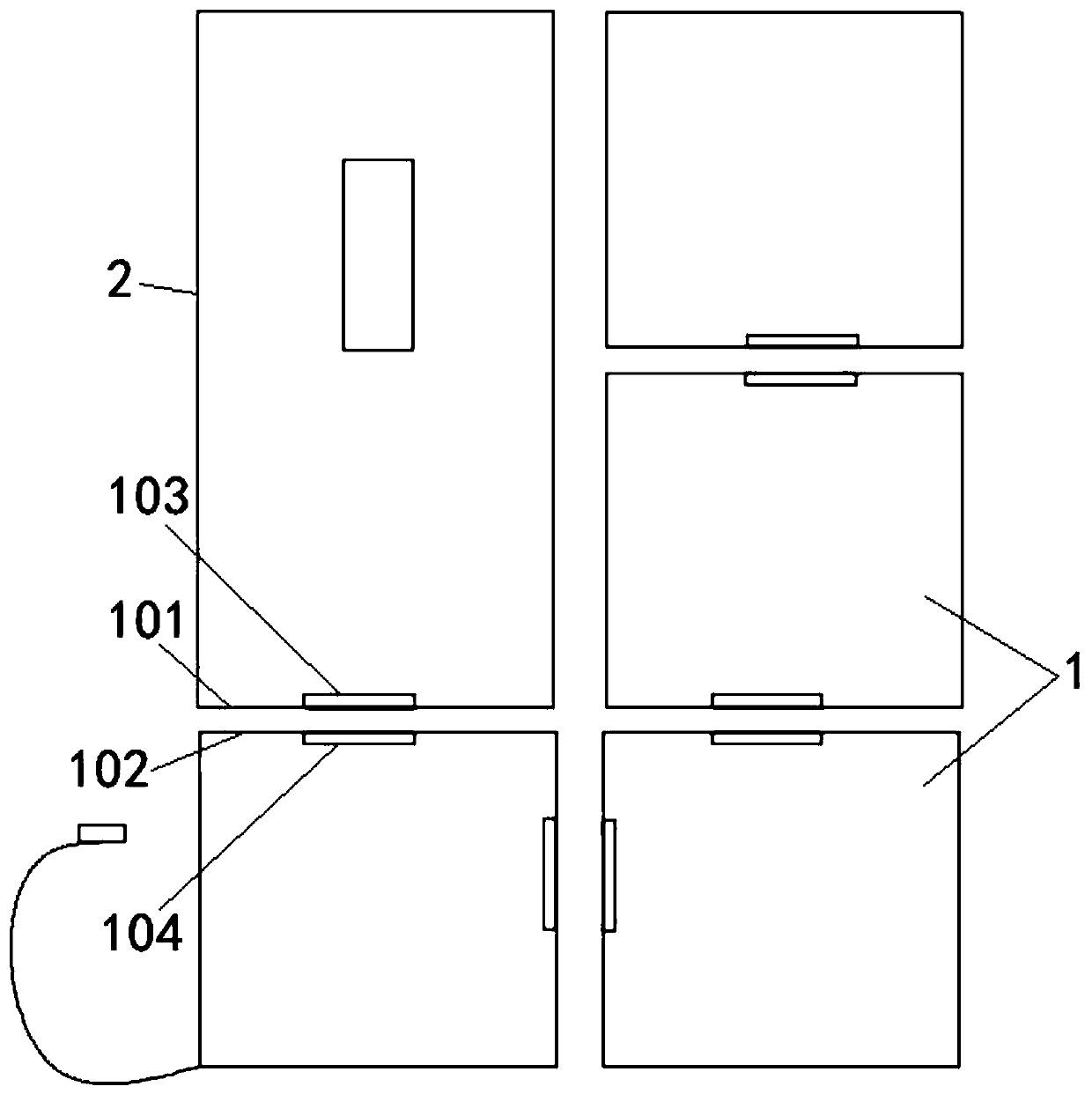

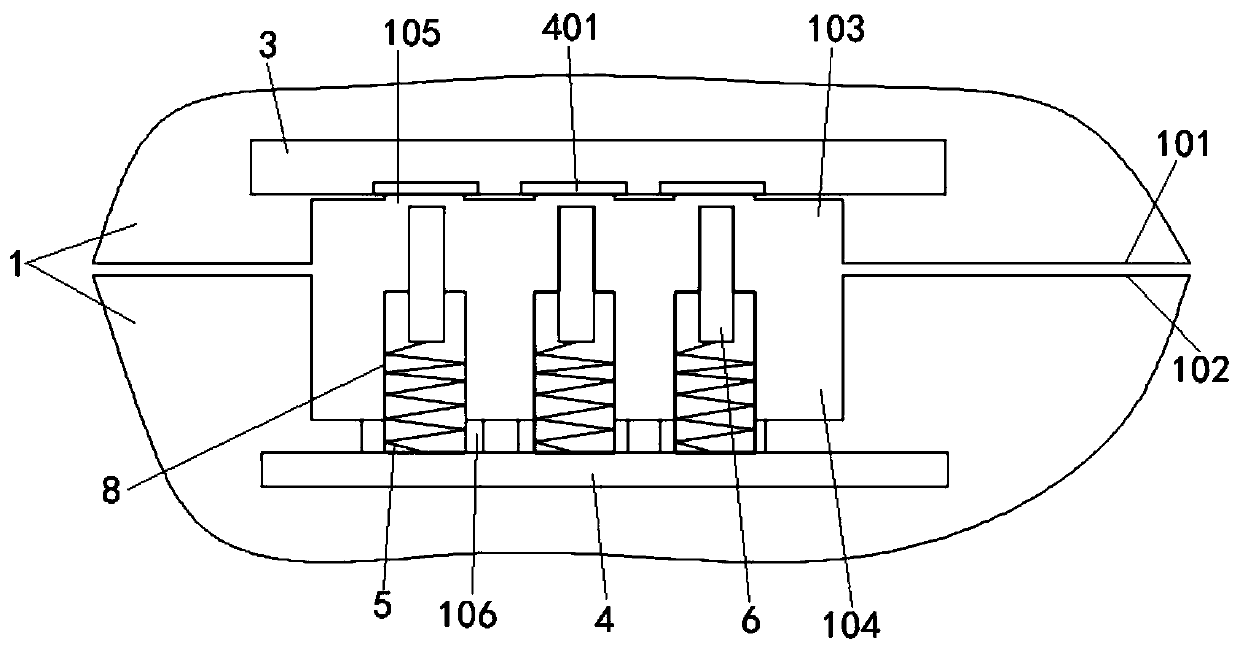

Power supply connection device for combined refrigerator

PendingCN110307687ASimple installation combinationSafe and reliable electrical connectionLighting and heating apparatusCoupling contact membersElectrical connectionEngineering

The invention discloses a power supply connection device for a combined refrigerator, and relates to the technical field of refrigerators. The combined refrigerator comprises independent box bodies, wherein the plurality of the independent box bodies are combined to form a combined refrigerator, the contact surfaces of every two adjacent independent box bodies are respectively a first connecting surface and a second connecting surface; and a plurality of first grooves are formed in the first connecting surfaces, a plurality of second grooves are formed in the second connecting surfaces, a plurality of first PCBs and a plurality of second PCBs are fixedly installed in every two adjacent independent boxes respectively, and the first PCBs are electrically connected with plugs through a plurality of springs to form a male connector. According to the power supply connection device, random two independent boxes in the combined refrigerator are electrically connected and matched through the plugs and copper contacts, and are suitable for random surfaces of the independent box bodies, only one power line is used, so that power supply can be realized for the combined refrigerator, the installation and combination of the combined refrigerator in the process are simple, the electrical connection mode is safe and reliable, the later maintenance operation of people is facilitated, and the aesthetic feeling of the combined refrigerator is improved.

Owner:CHANGHONG MEILING CO LTD

Sheet for led light cover application

Disclosed herein is a sheet comprising a polymeric material; light diffusing particles disposed in the polymeric material; and a non-random surface texture on a surface of the sheet; wherein the surface texture comprises hemispherical structures, partial hemispherical structures, ellipsoidal structures, immersed spherical beads, ellipsoidal beads, "bell-shape" bump, complex lens shape structures, pyramidal structures, reversed pyramidal structures, or combinations comprising at least one of the foregoing. The sheet has excellent hiding power and transmission at the same time and is suitable for LED light cover applications. The unit structures have an aspect ratio of 0.15 to 0.5 and a pitch of greater than or equal to 100 mum

Owner:SABIC GLOBAL TECH BV

Optical sensor and method for forming same

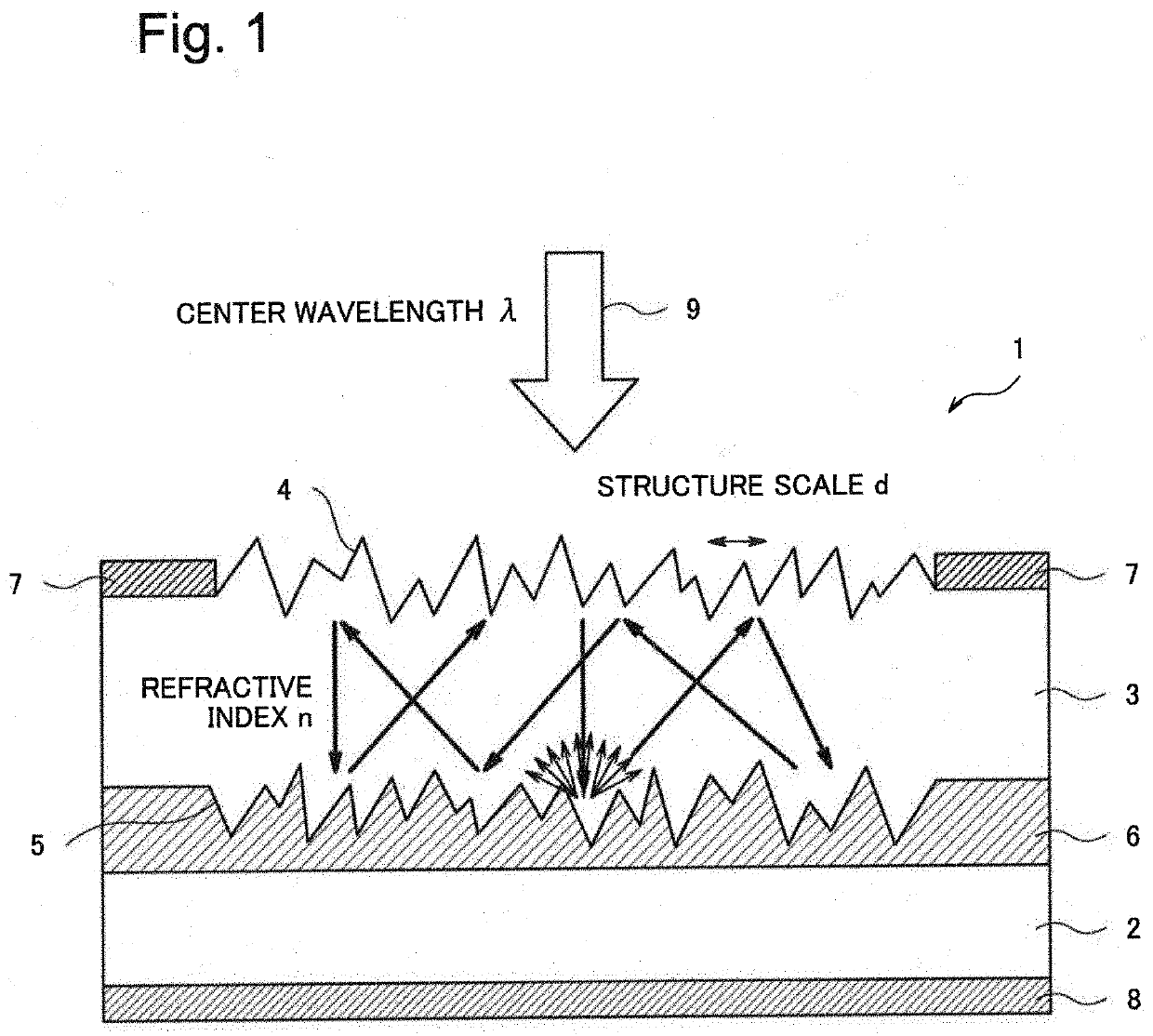

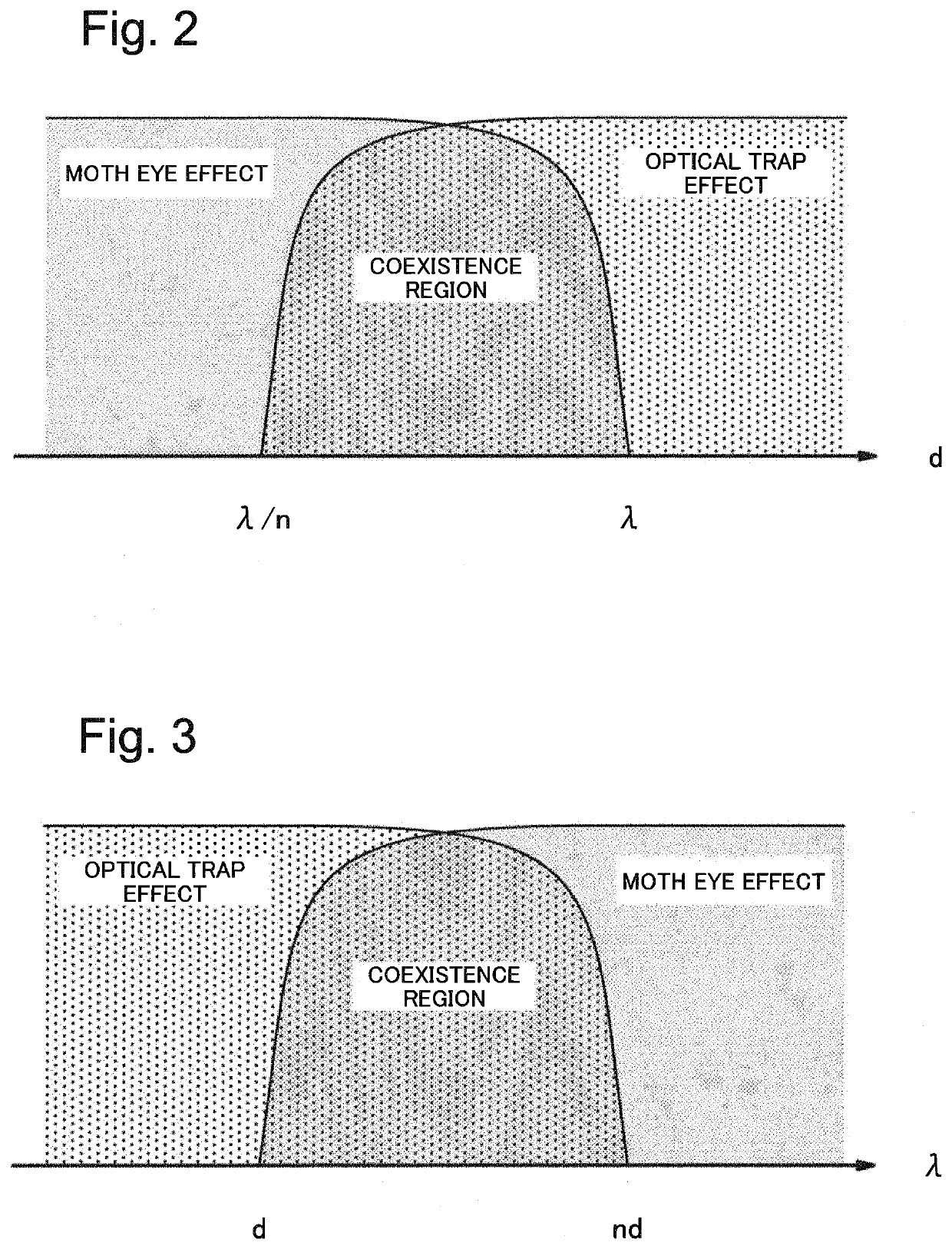

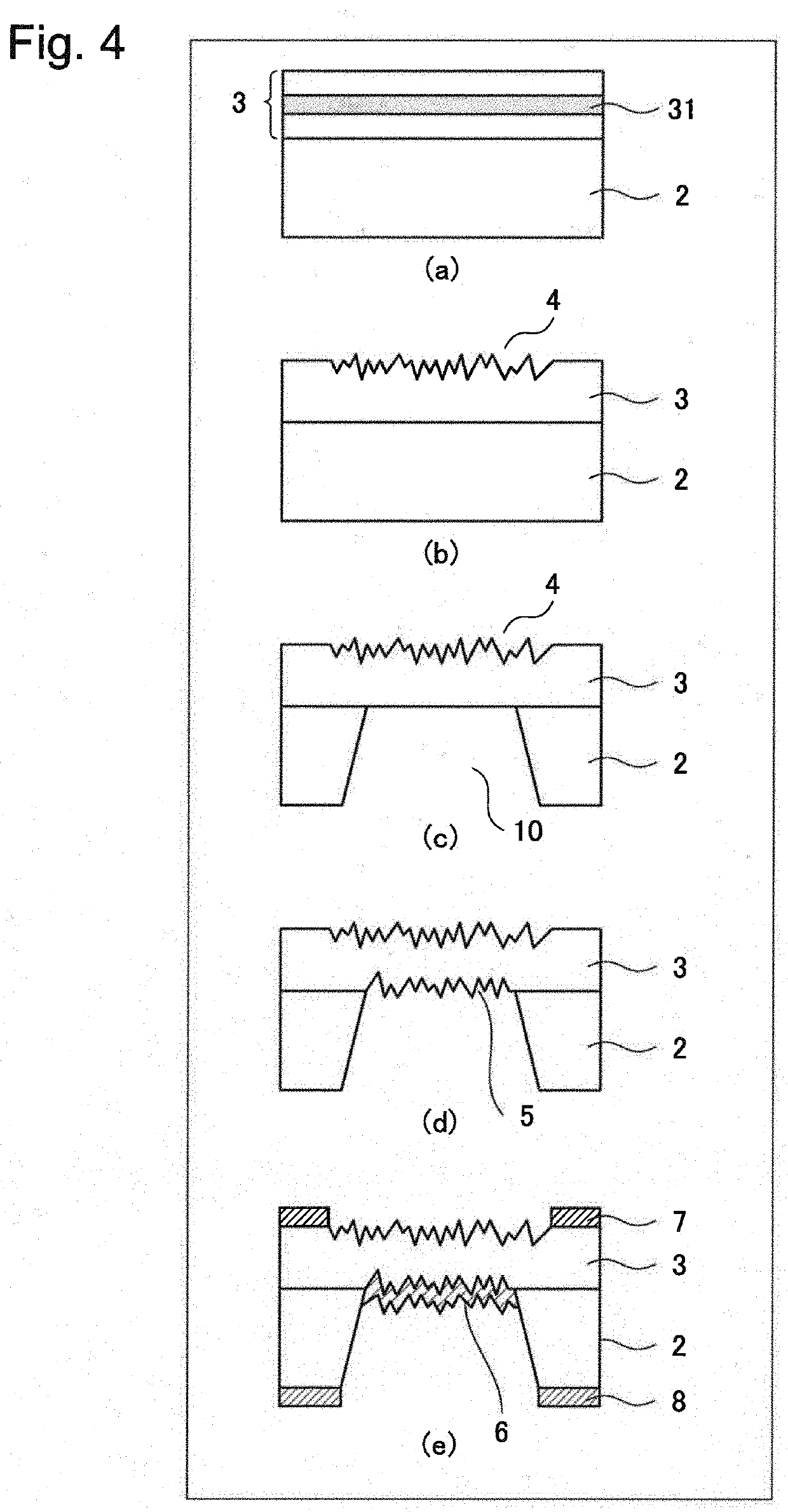

ActiveUS10879407B2Improve photoelectric conversion efficiencySimple structureSemiconductor devicesRefractive indexOptical transducers

In order to provide an optical sensor that is capable of obtaining both an optical trap effect and a moth eye effect with a single texture structure, a semiconductor optical sensor according to the present invention includes a light absorption medium that has a refractive index n and a thickness sufficiently less than a light transmission length, wherein the center wavelength to be observed is defined as λ. The semiconductor optical sensor is characterized by: having, in a light incident surface, a texture structure having a random surface direction and a typical structure scale d defined as in (λ / n).

Owner:NEC CORP

Random Surfaces with Precisely Designed Bandwidths

ActiveCN106129632BReduce Design WorkloadThe principle is simpleAntennasPhase differenceDielectric substrate

Owner:SOUTHEAST UNIV

Iterative Fourier algorithm-based method for designing broadband random surface

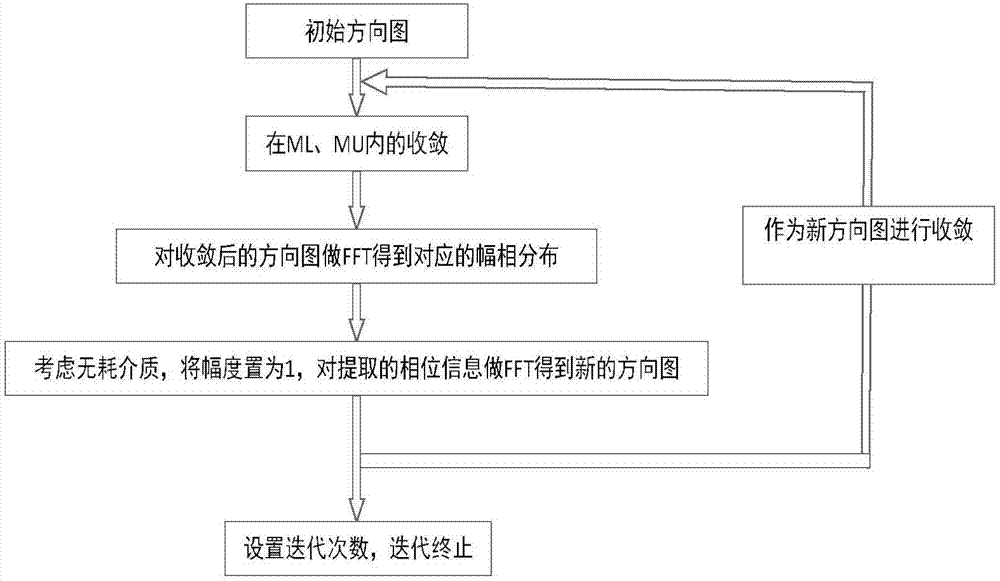

ActiveCN106934102AReduce RCSGuaranteed Stealth PerformanceDesign optimisation/simulationSpecial data processing applicationsBroadbandWide band

The invention discloses an iterative Fourier algorithm-based method for designing a broadband random surface. The method comprises the steps of firstly performing reduction on an initial array factor directional diagram by adopting an iterative Fourier algorithm to obtain an ideal array factor directional diagram meeting the design requirement; and secondly based on the condition that units and the directional diagram have Fourier relationships, performing inverse Fourier transform on the ideal array factor directional diagram to obtain unit array phase information of the broadband random surface, determining the size of each basic unit in a unit array according to the phase information, and obtaining unit array layout of the broadband random surface meeting the design requirement. According to the method, the required random surface is forwards designed based on the iterative Fourier algorithm, so that long-time optimization is avoided, the finally obtained array layout can be ensured to effectively reduce the RCS (Radar Cross Section) of the random surface indeed, and the stealth performance can be greatly ensured; and the stealth frequency band of the random surface is relatively wide.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com