Patents

Literature

41 results about "Micro geometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

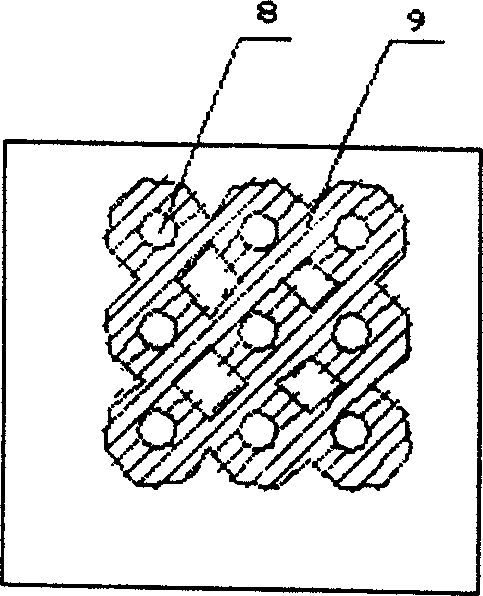

Surgical implant for promotion of osseo-integration

InactiveUS20050119758A1Enhanced cell attachmentInhibit cell growthDental implantsInternal osteosythesisSurface patternSurgical implant

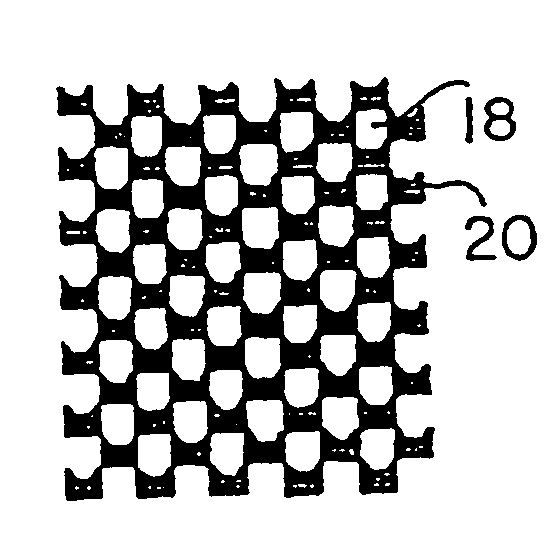

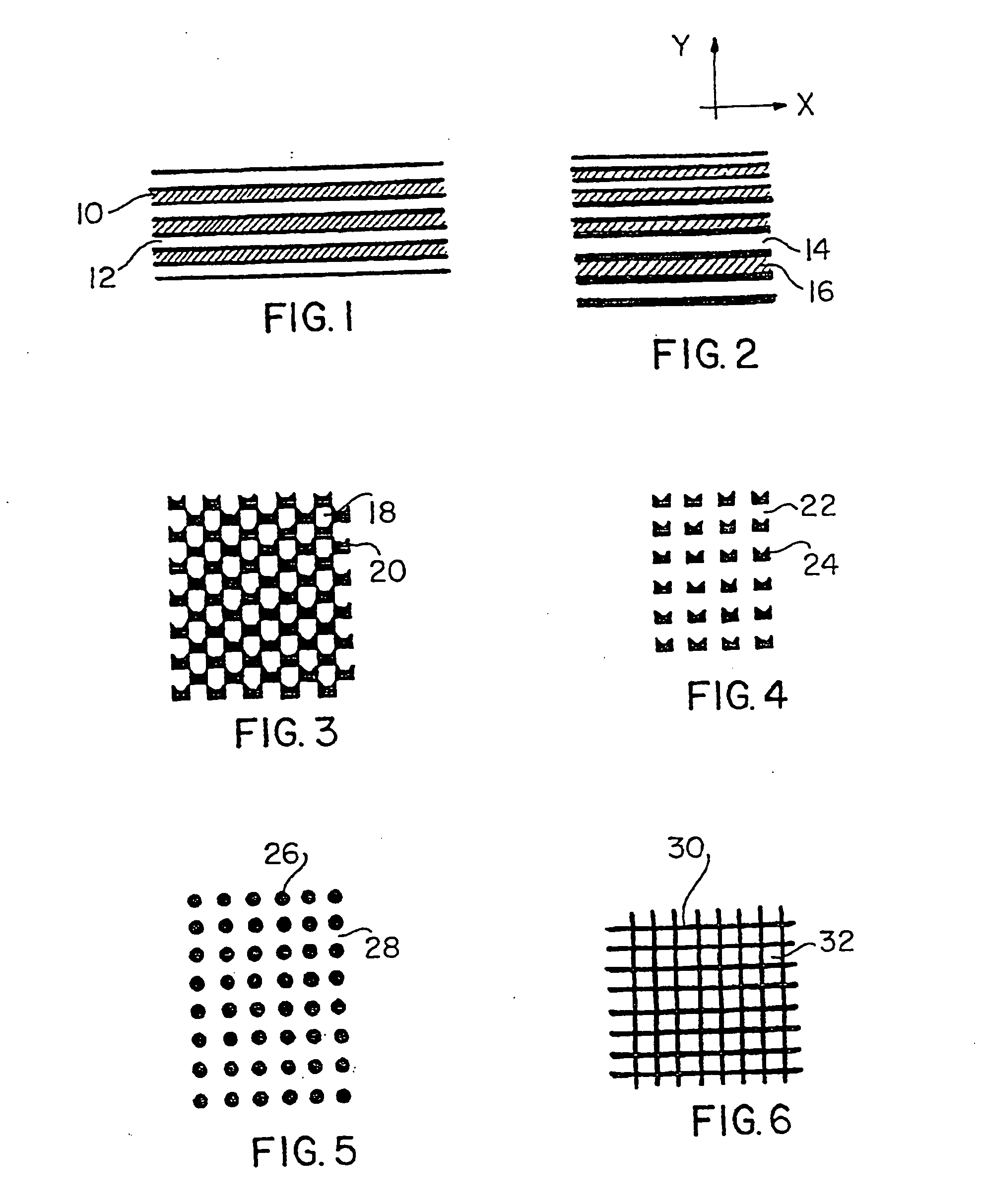

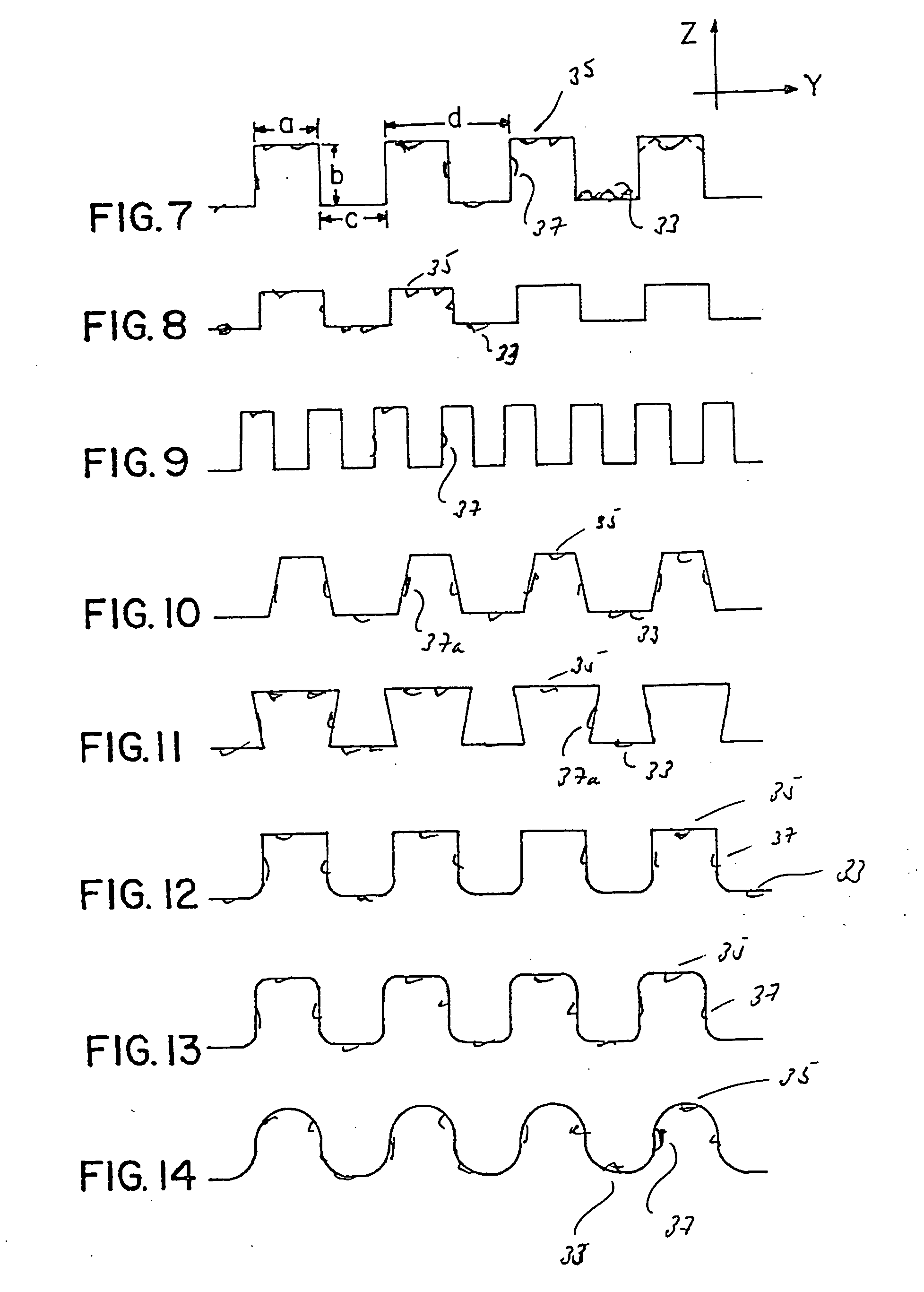

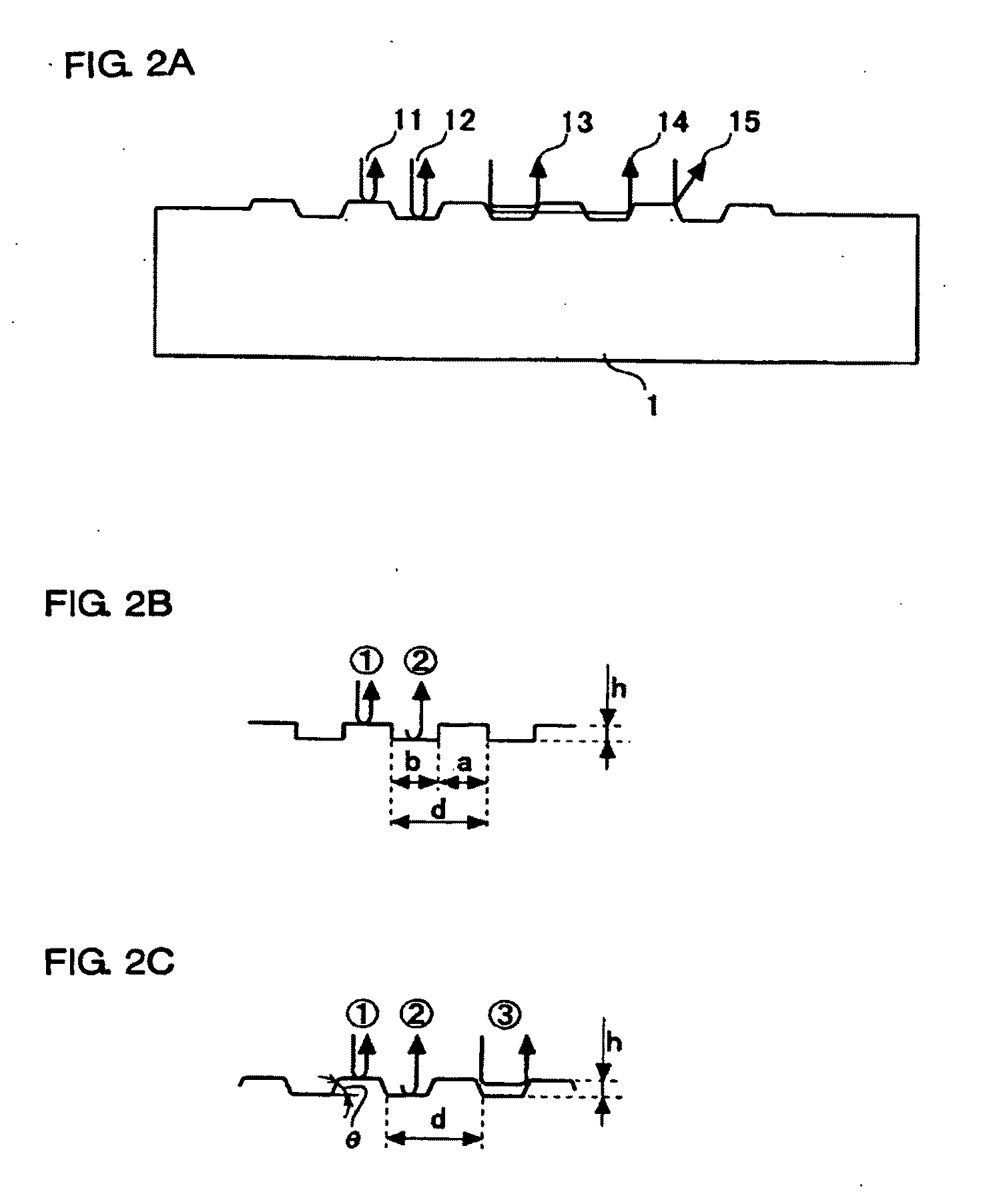

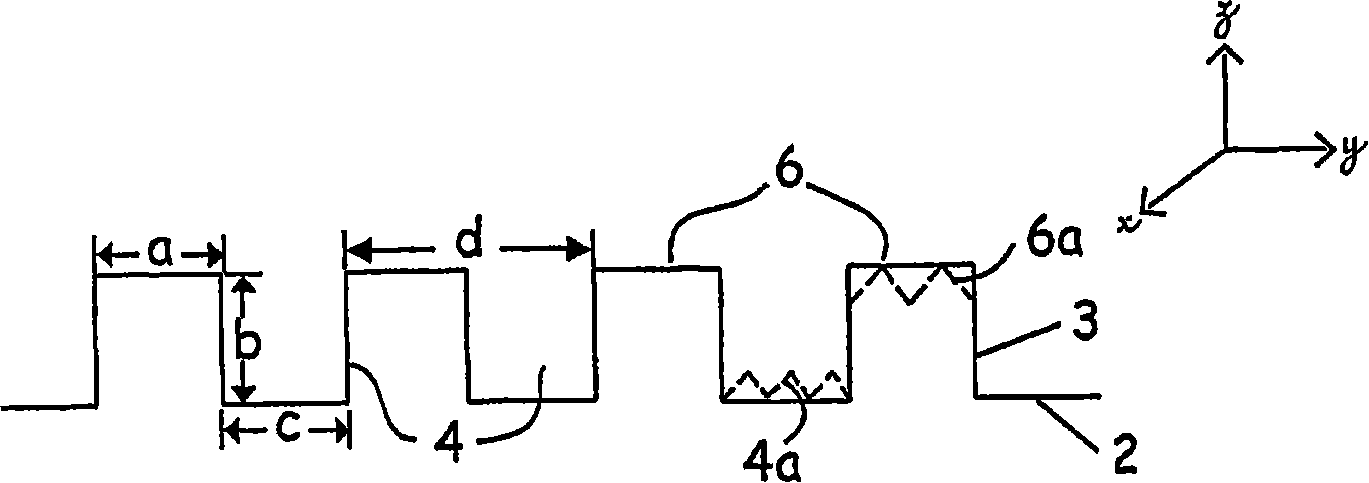

An implant for surgical insertion into tissue of a patient includes a microgeometric, repetitive pattern, in the form of a multiplicity of alternating ridges and grooves, each having an established width in a range of about 2 to about 25 microns, and an established depth in a range of about 2 to about 25 microns, each groove having a base and a wall; and a microgeometric random surface pattern, applied over the repetitive surface pattern, defining a multiplicity of micro-pits having dimensions in a range of about 0.1 to about 4 microns.

Owner:BIO LOK INT INC

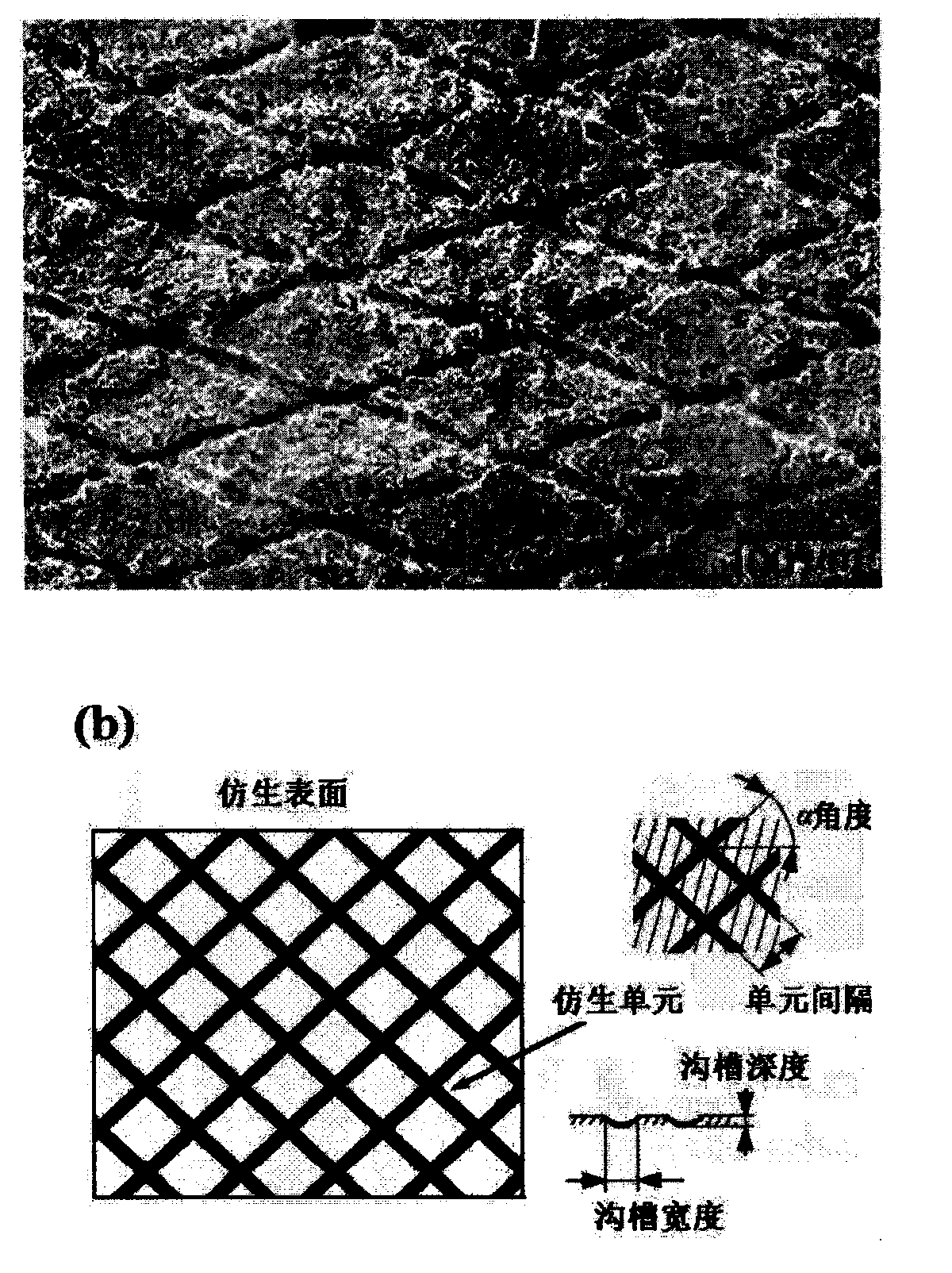

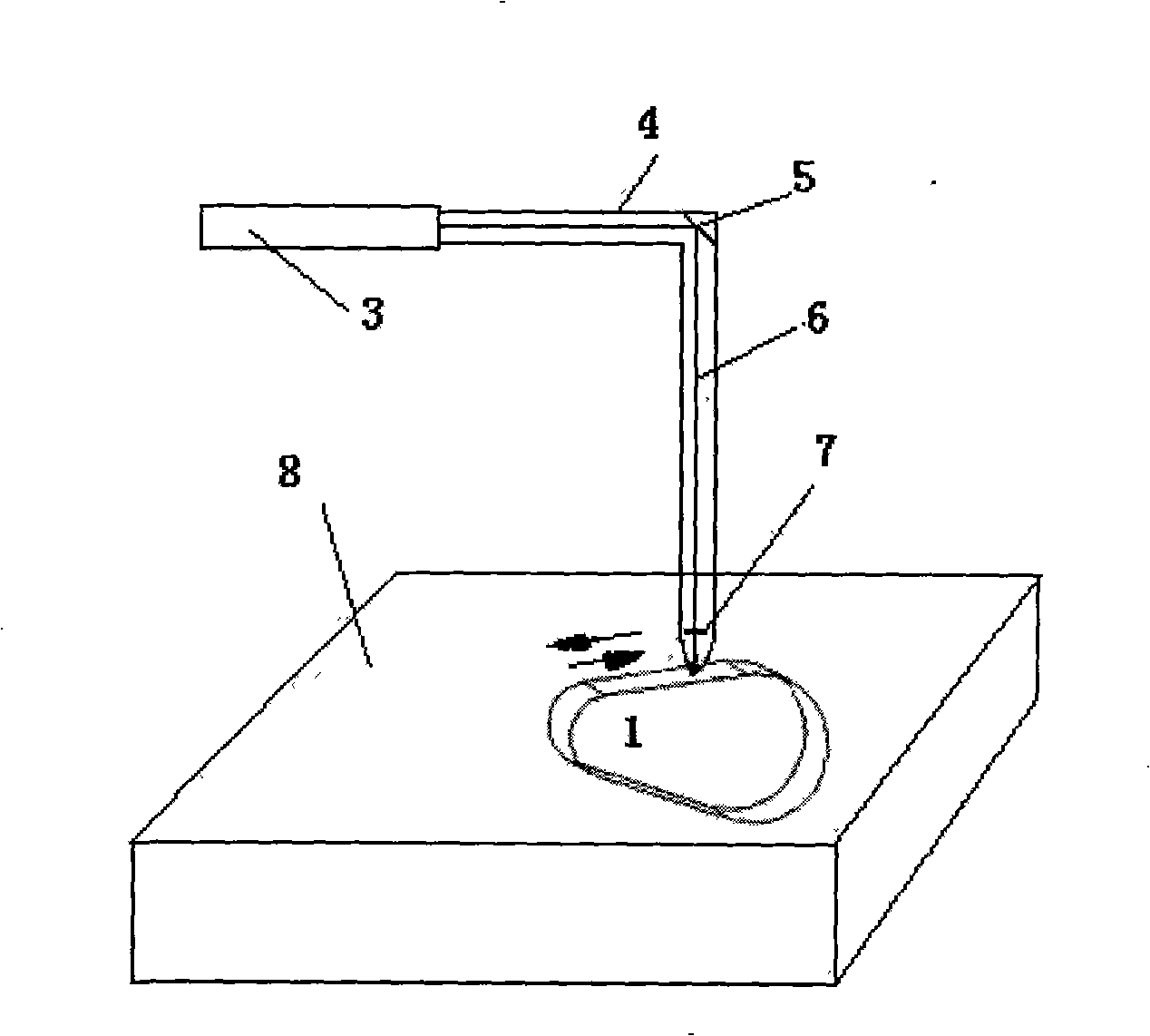

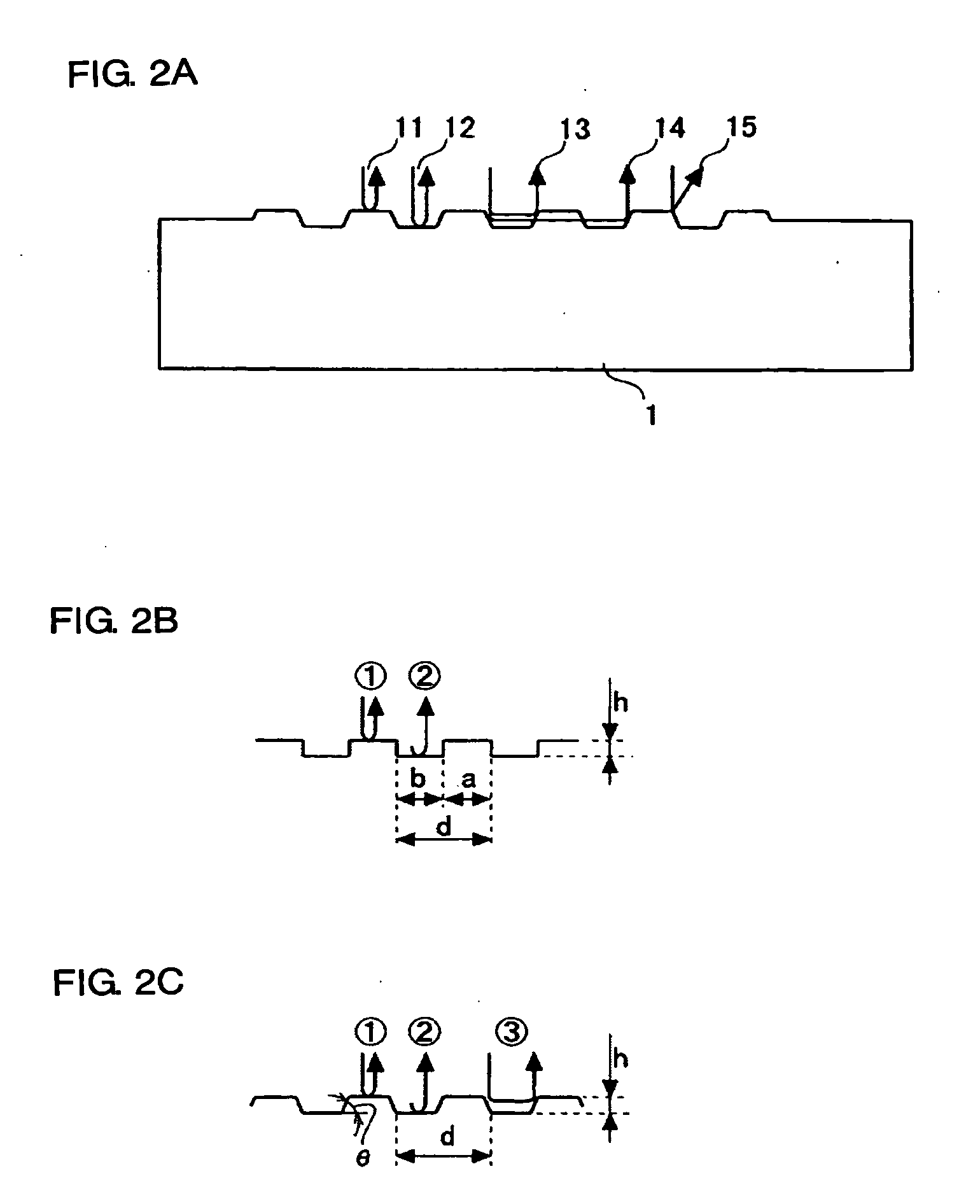

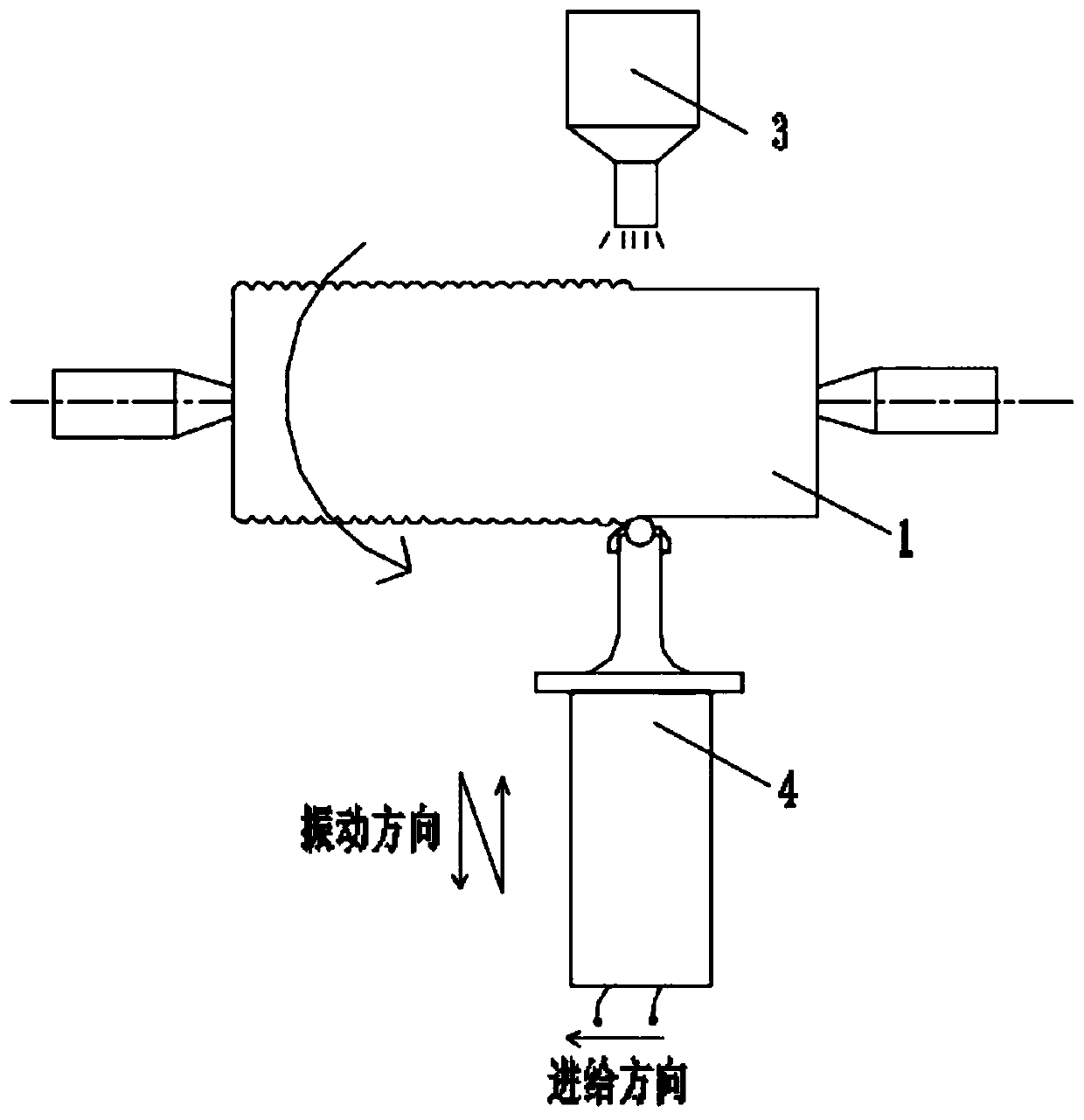

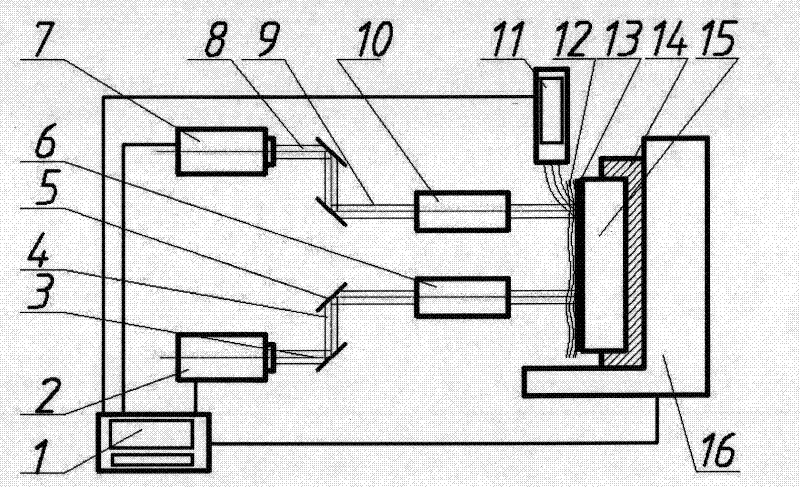

Method and device for compositely preparing surface-layer biomimetic structure by laser

InactiveCN101590569ANo wearNo consumptionLaser beam welding apparatusLight spotVolumetric Mass Density

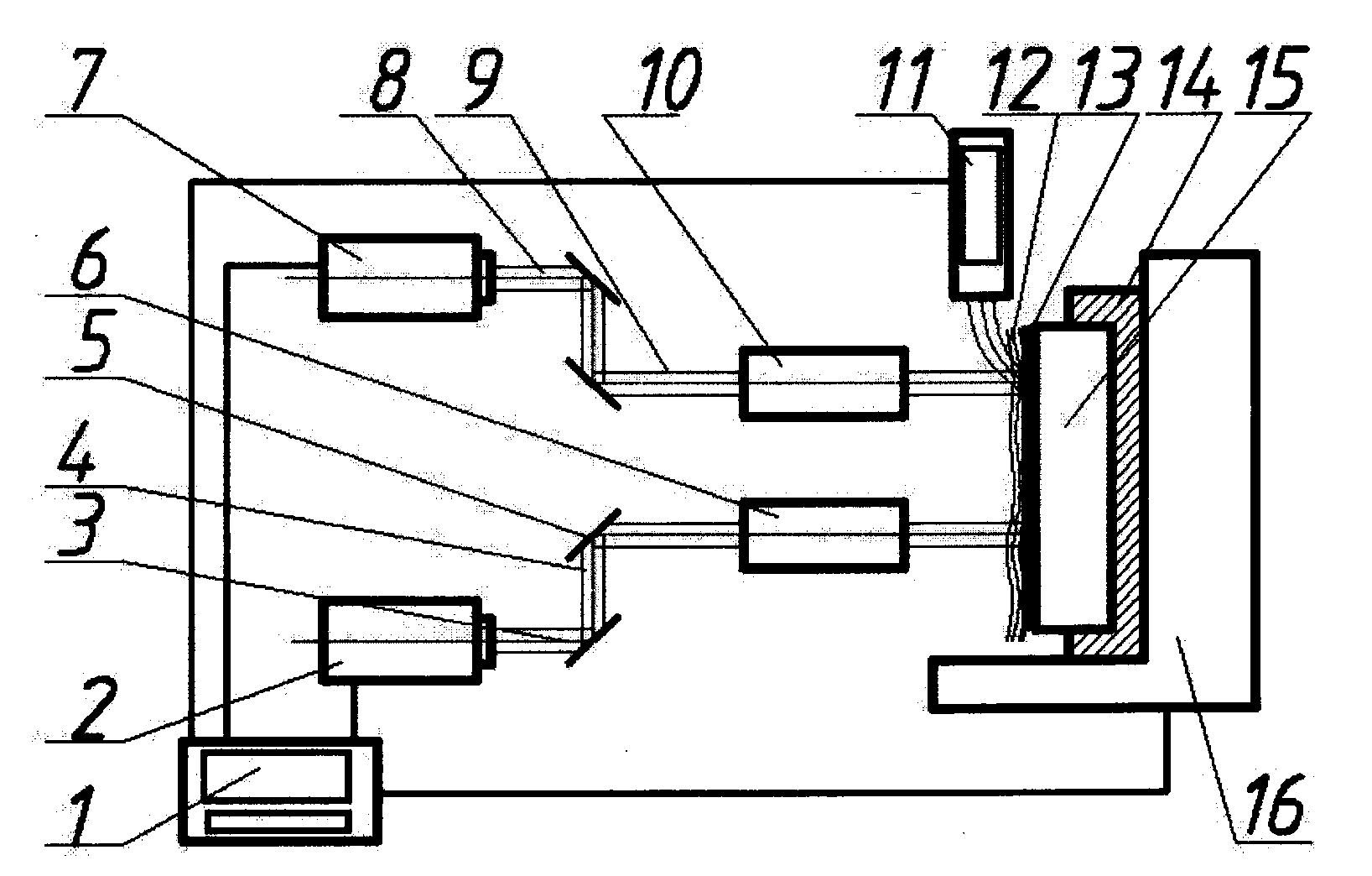

The invention relates to the field of laser processing, in particular to a method and a device for compositely preparing a surface-layer biomimetic structure by mechanical effects based on laser carving and laser shock, which are particularly suitable for processing a biomimetic surface and a friction pair surface. The method is characterized by comprising the following steps: firstly preparing a regular micro geometrical appearance with certain density (space), width, depth, angle and shape on the surface of a workpiece by the laser carving technology; and then forcedly processing the micro geometrical appearance area by laser shock to process a microstructure which has the required shape and management mode and is optimally matched with the requirement of lubricating property on the surface of the workpiece. The device for the implementation method comprises a control device, a nanosecond laser generator, a laser beam I, a light guide tube I, a totally reflecting mirror I, a light spot adjusting device I, a fiber laser, a laser beam II, a light guide tube II, a totally reflecting mirror II, a light spot adjusting device II, an automatic spraying device, a restrain layer, an absorption layer, the workpiece, a workpiece fixture system and a five-axis working platform.

Owner:JIANGSU UNIV

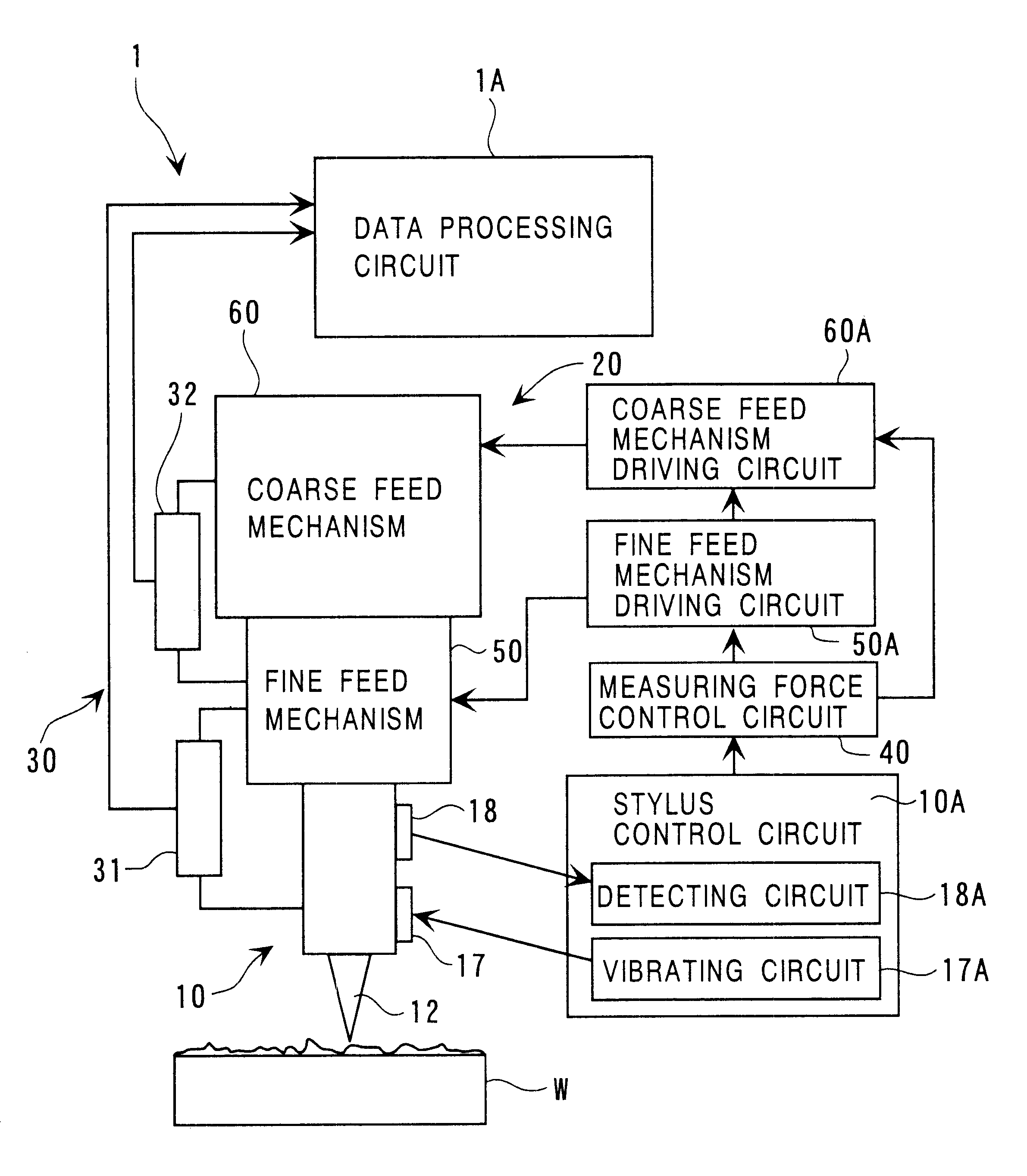

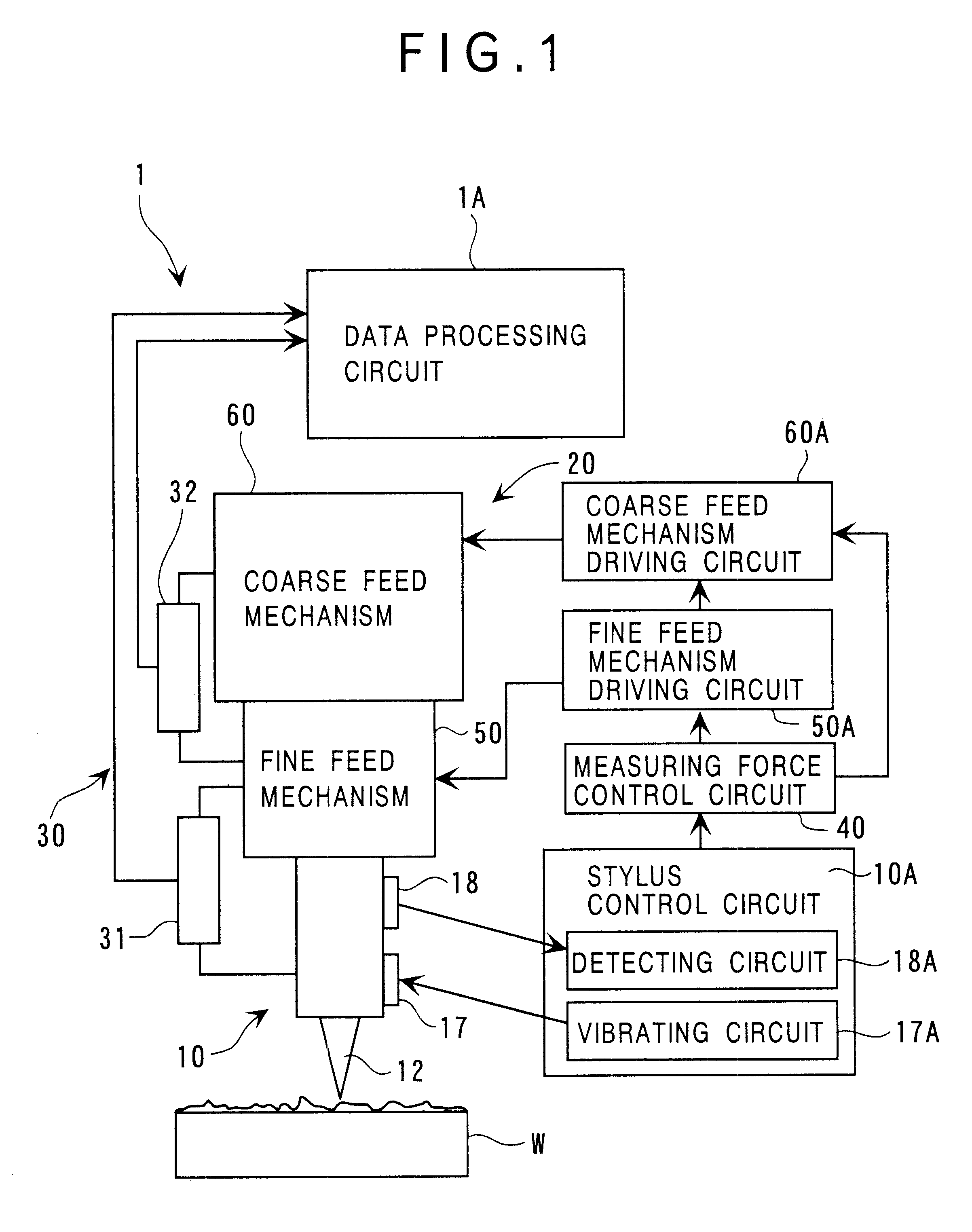

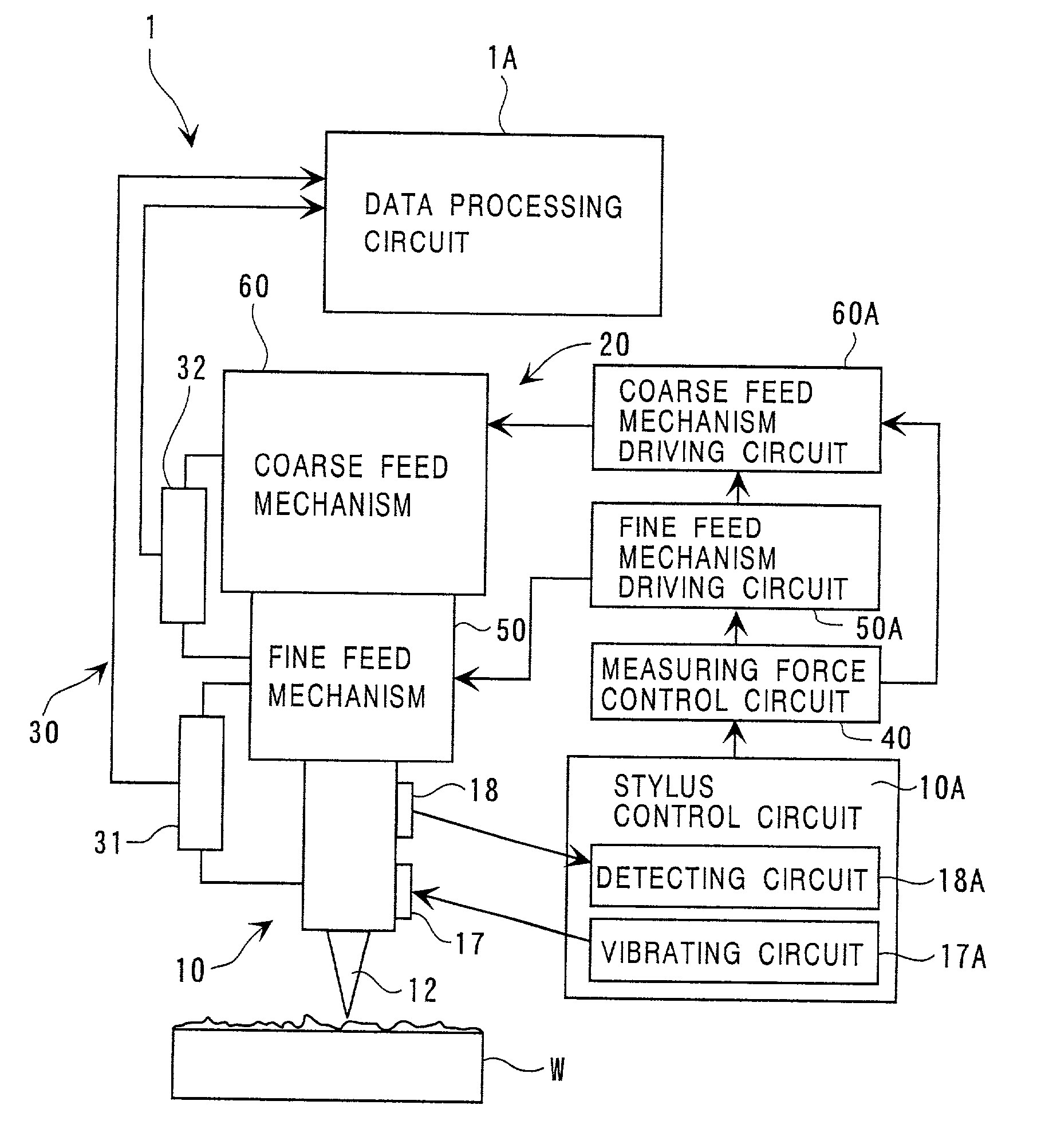

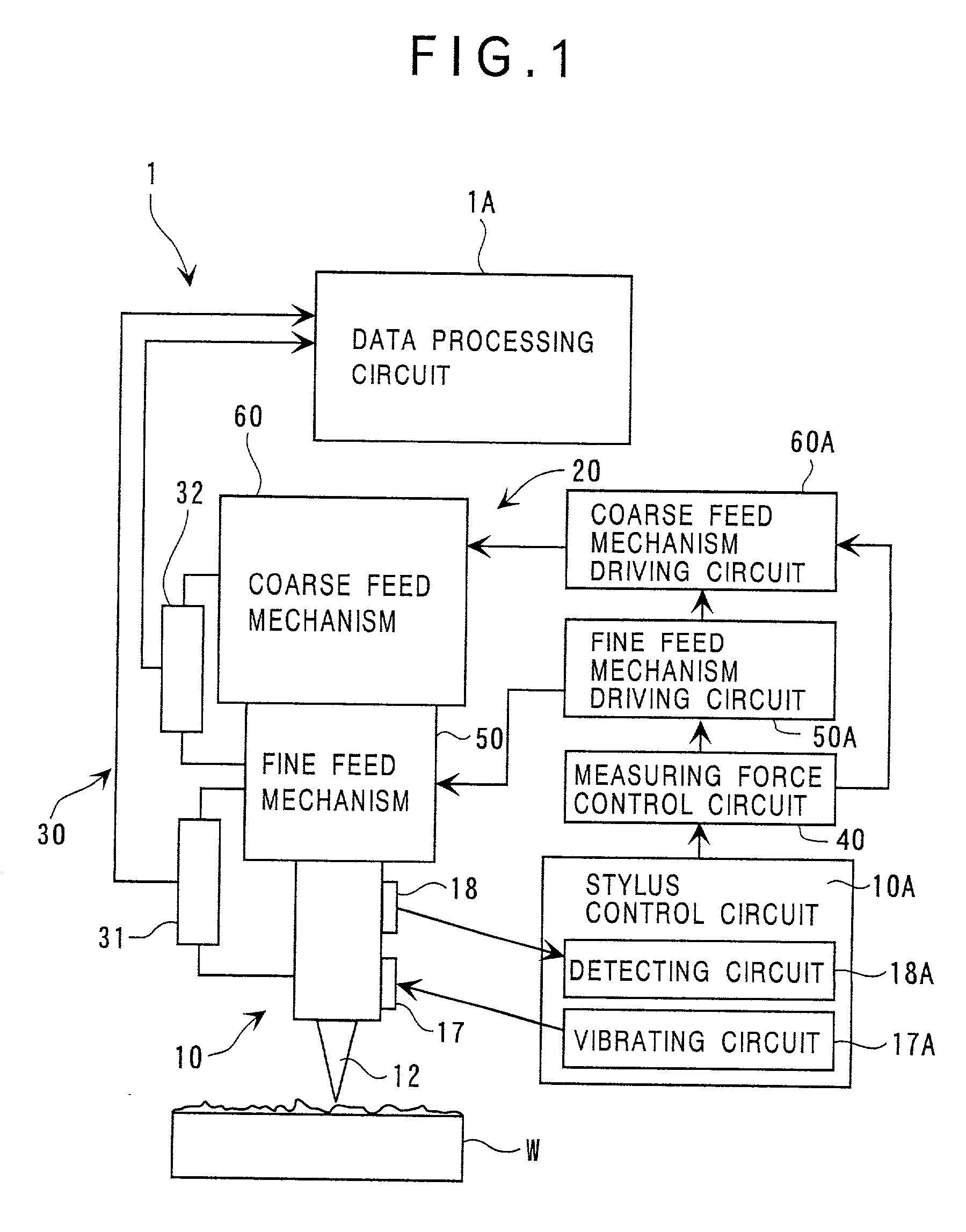

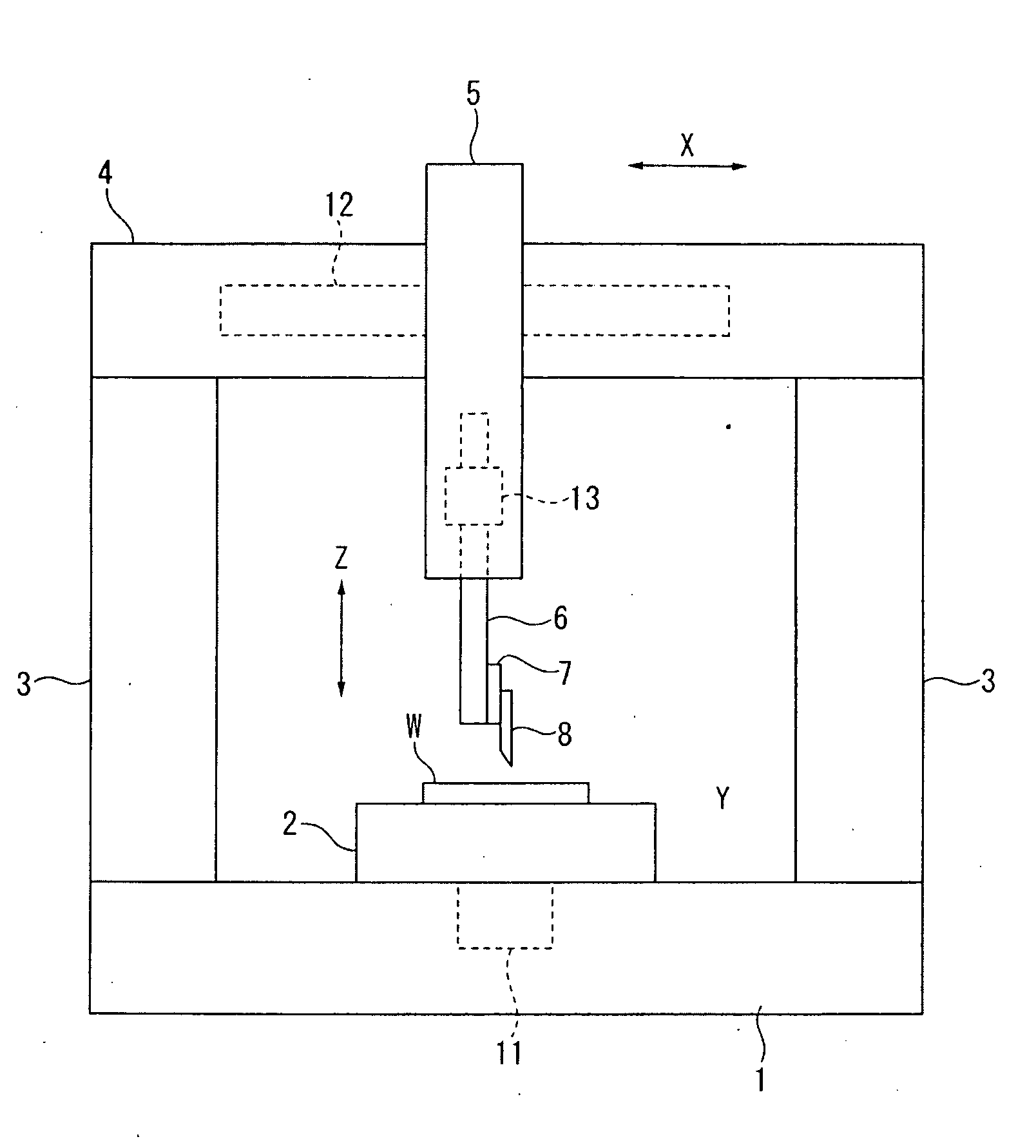

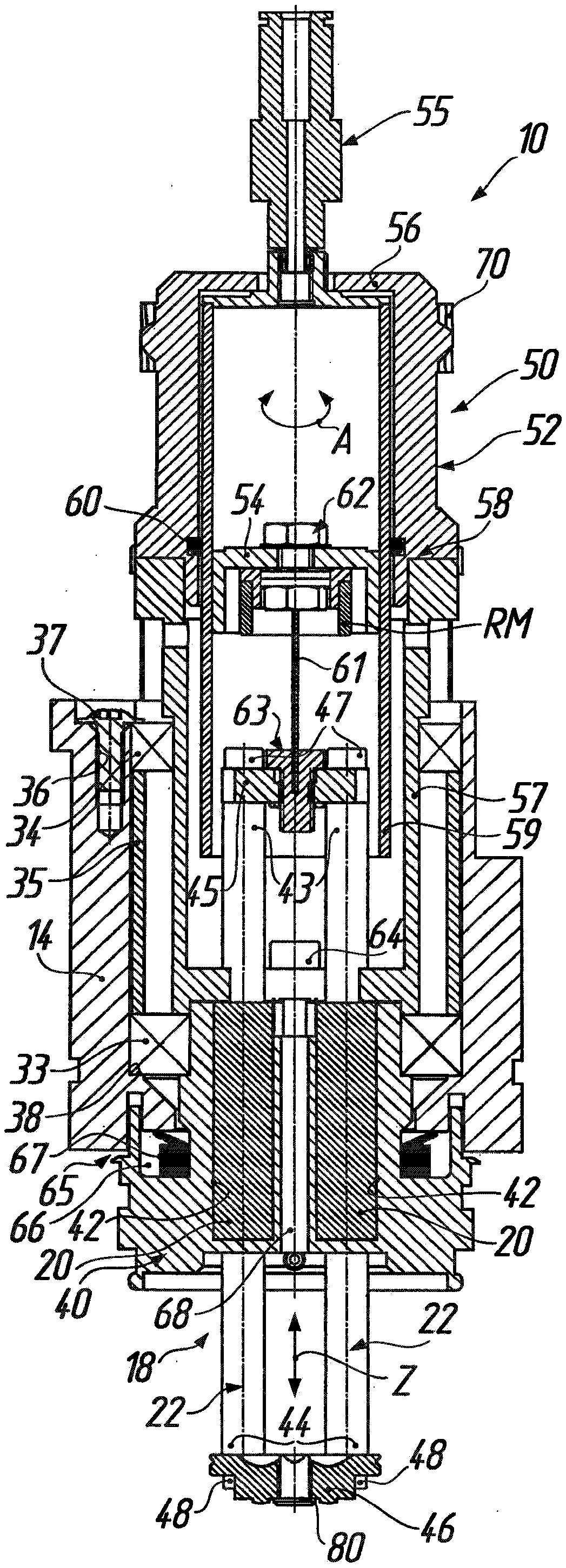

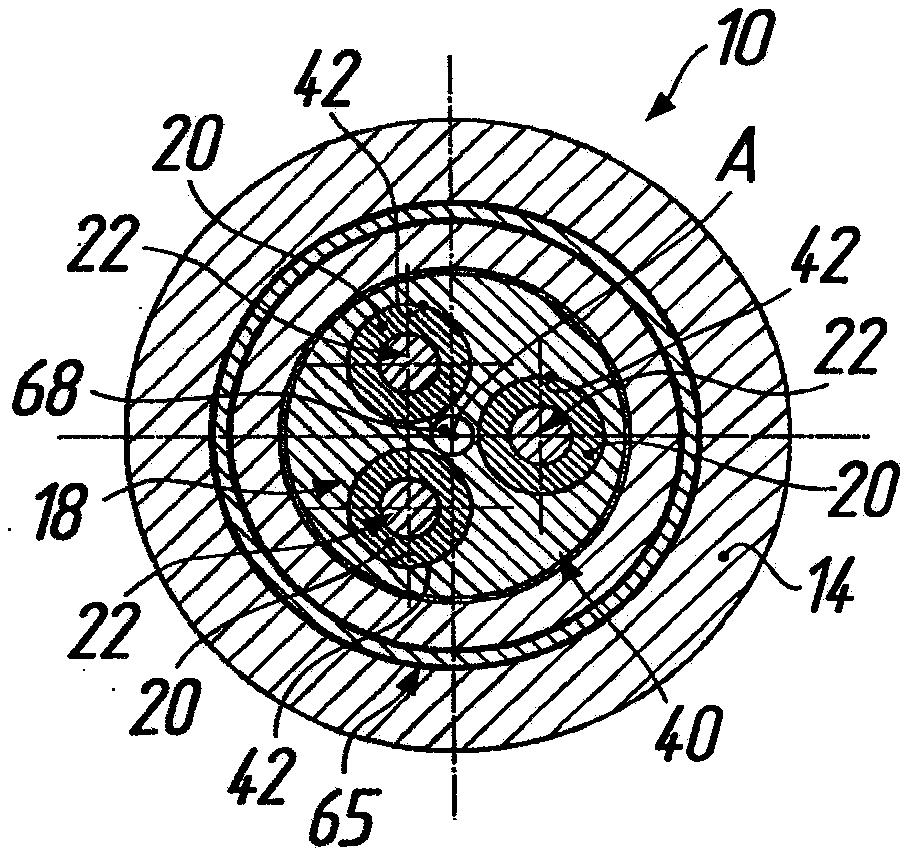

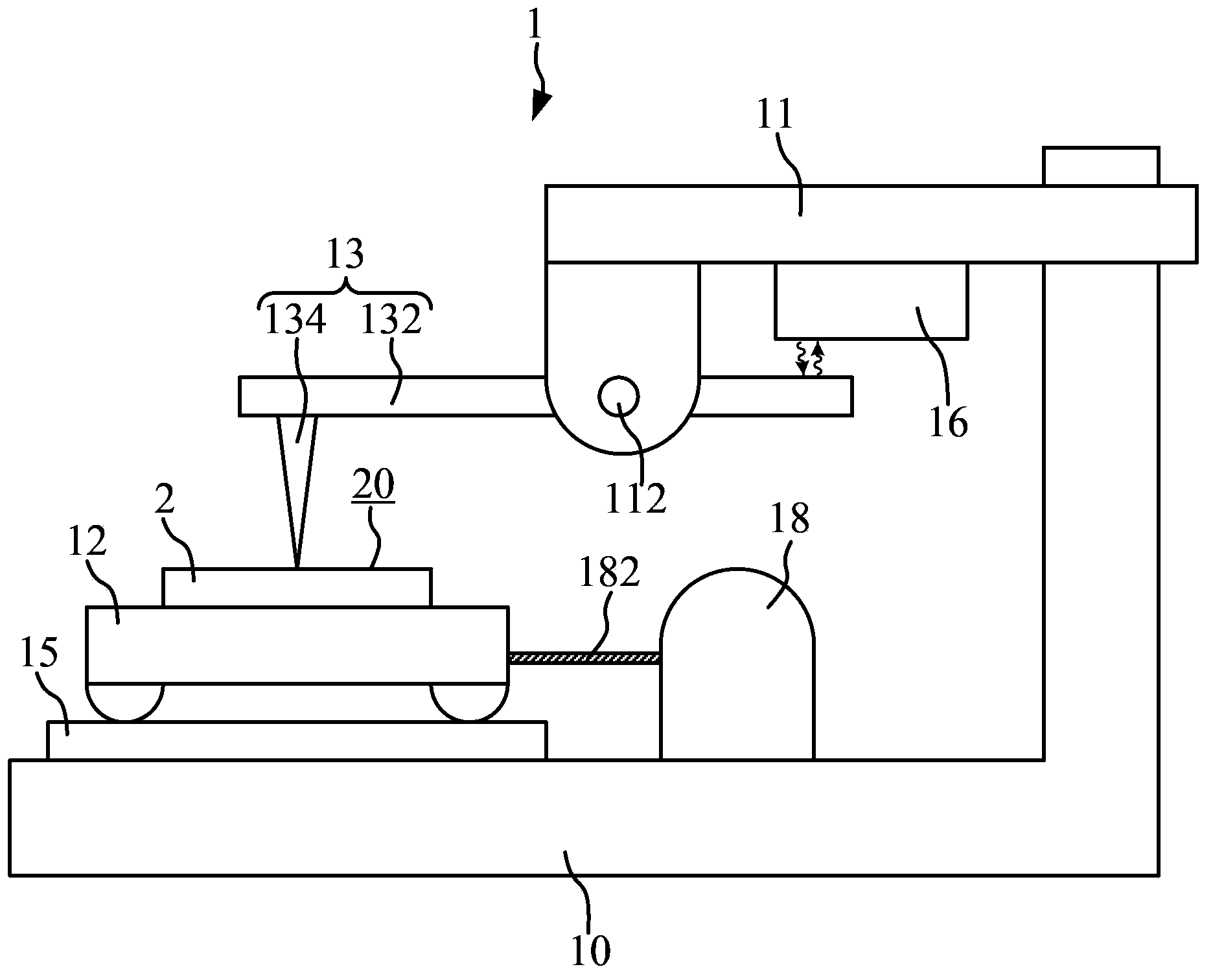

Microscopic geometry measuring device

InactiveUS6604295B2Eliminate mechanical interferenceDegradation in responsivityMechanical counters/curvatures measurementsNanotechnologyMeasurement deviceEngineering

A fine feed mechanism (50) and a coarse feed mechanism (60) respectively for minutely and greatly displacing a stylus (12) is provided to a microscopic geometry measuring device (1), so that the respective mechanisms (50, 60) are combinedly actuated for easily controlling the movement of the stylus (12) in a wide range at a short time. Further, a movable balancing portion (53) moving in a direction opposite to a movable driving portion (52) is provided to the fine feed mechanism (50). Since a reaction force caused by the movement of the movable driving portion (52) is cancelled by another reaction force caused by the movement of the movable balancing portion (53) at a fixed portion (51), no mechanical interference is caused between the respective mechanisms (50, 60), thus accurately controlling the movement of the stylus (12).

Owner:MITUTOYO CORP

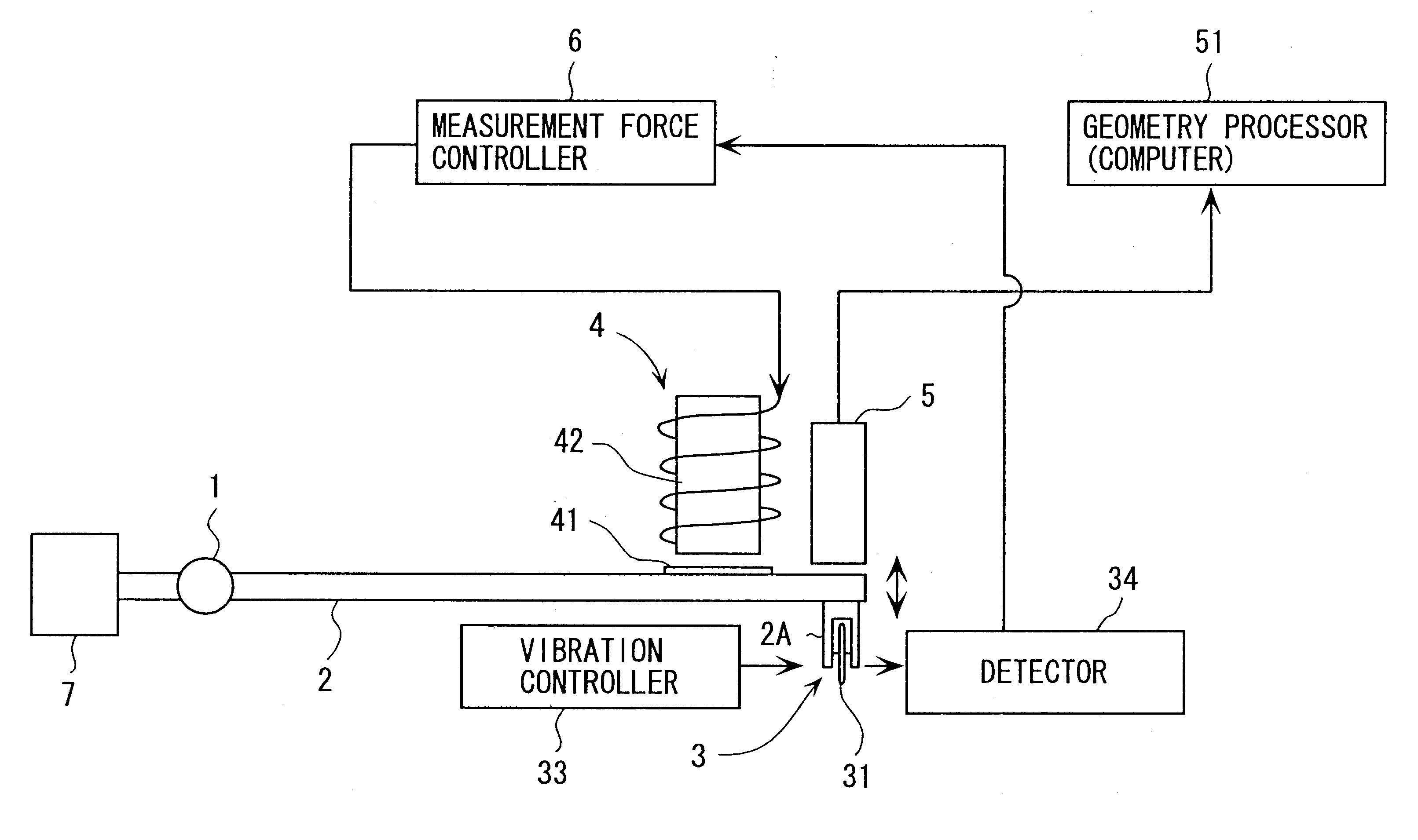

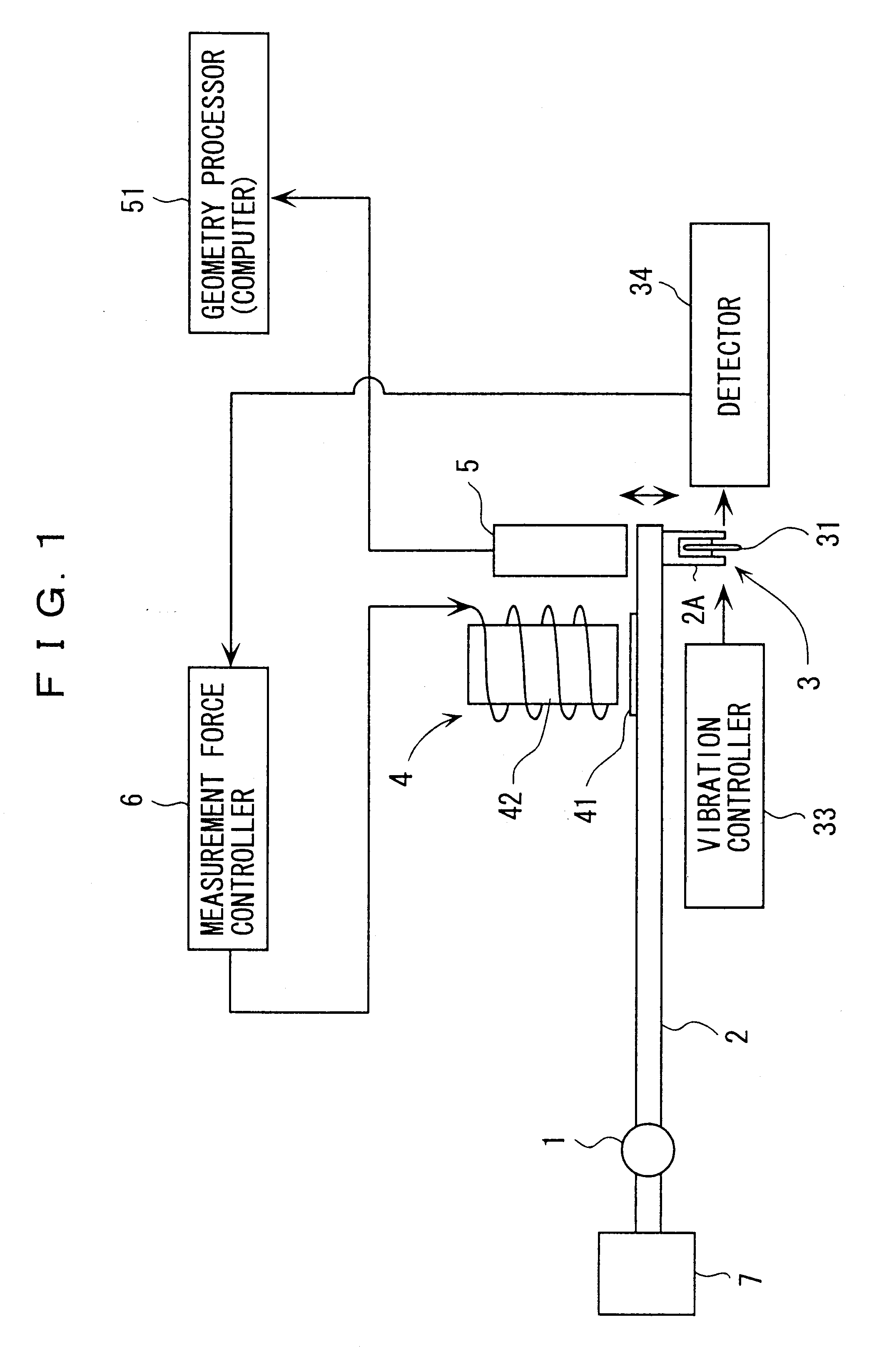

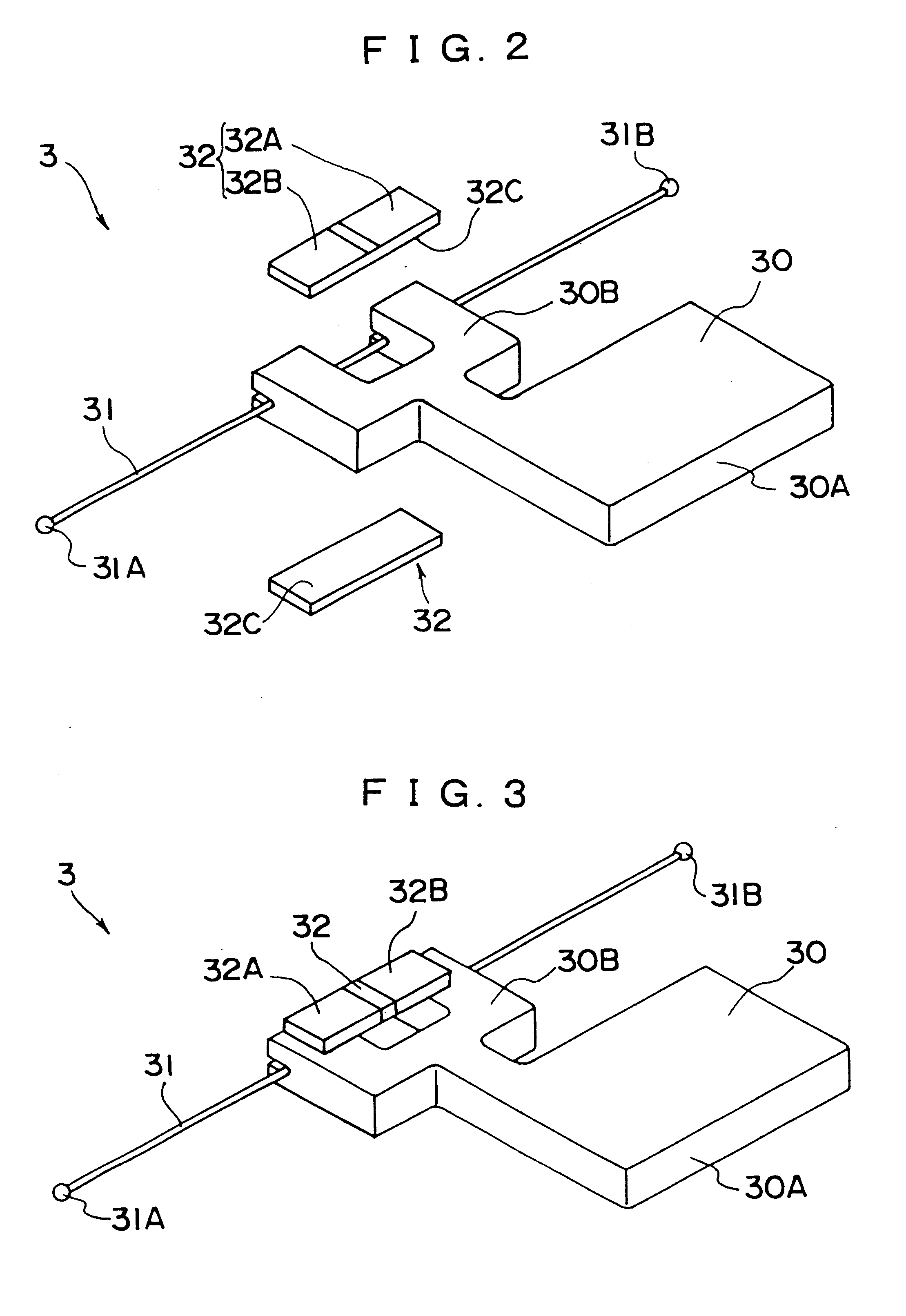

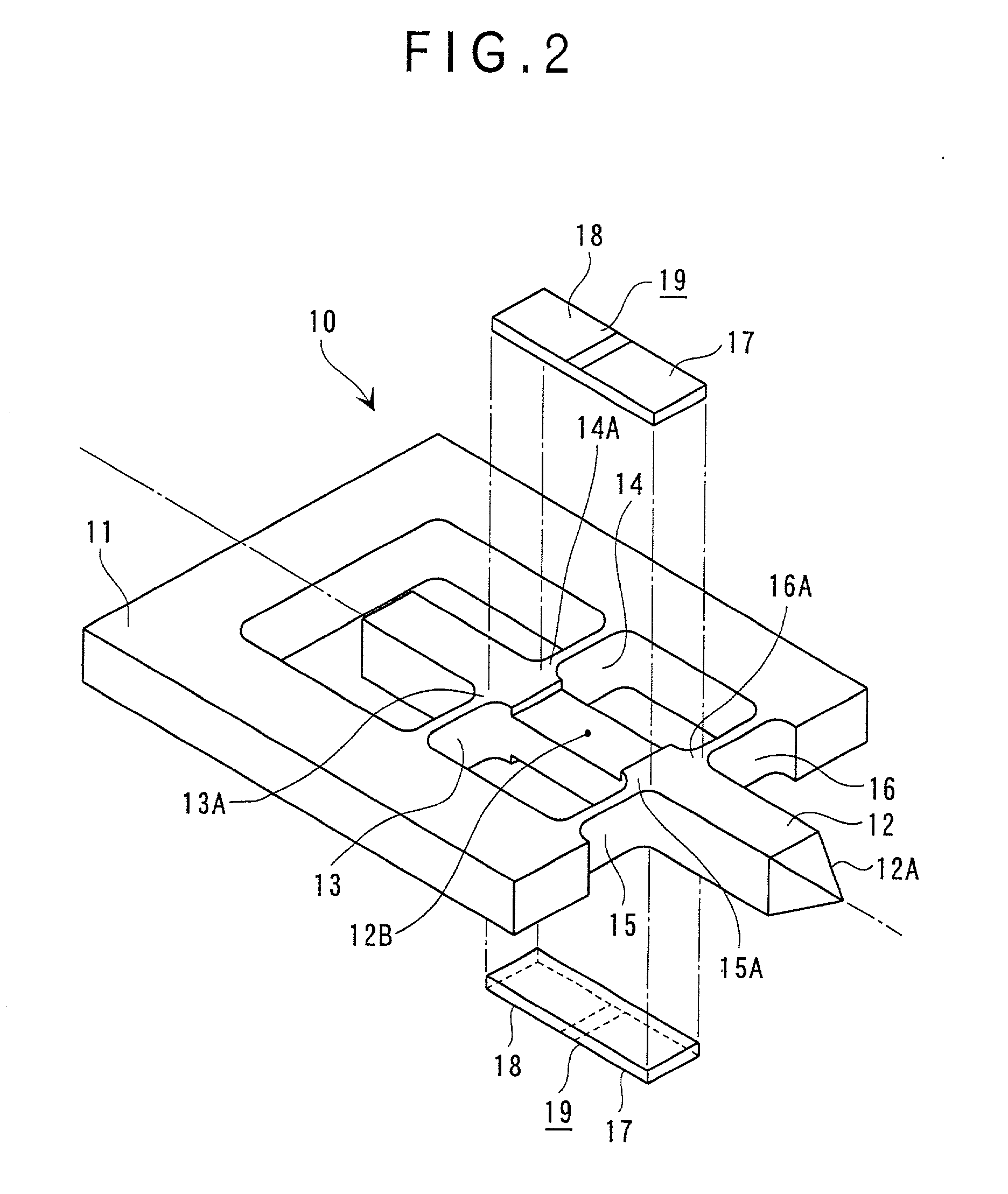

Micro-geometry measuring device

InactiveUS6314800B1Compasses with pivoted armsMechanical counters/curvatures measurementsMeasurement deviceState variation

A micro-geometry measuring device capable of reducing measuring force thereof for avoiding damage on micro-geometry of workpiece surface and measuring at a high-speed is provided. The micro-geometry measuring device has a stylus mechanism having a stylus mechanism provided to an arm and having a stylus body, a measuring force adjusting mechanism for adjusting a measuring force working between the stylus body and the workpiece, a displacement sensor for detecting a position of the arm, and a measuring force controller for controlling the measuring force adjusting mechanism. The stylus mechanism includes a vibrator for resonantly vibrating the stylus body, and a detector for detecting vibration status changing when the stylus body touches the workpiece. The change in vibration of the stylus body vibrated by the vibrator is directly detected by the detector and a signal therefrom is fed back to the measuring force controller to keep constant measuring force working between the stylus body and the workpiece.

Owner:MITUTOYO CORP

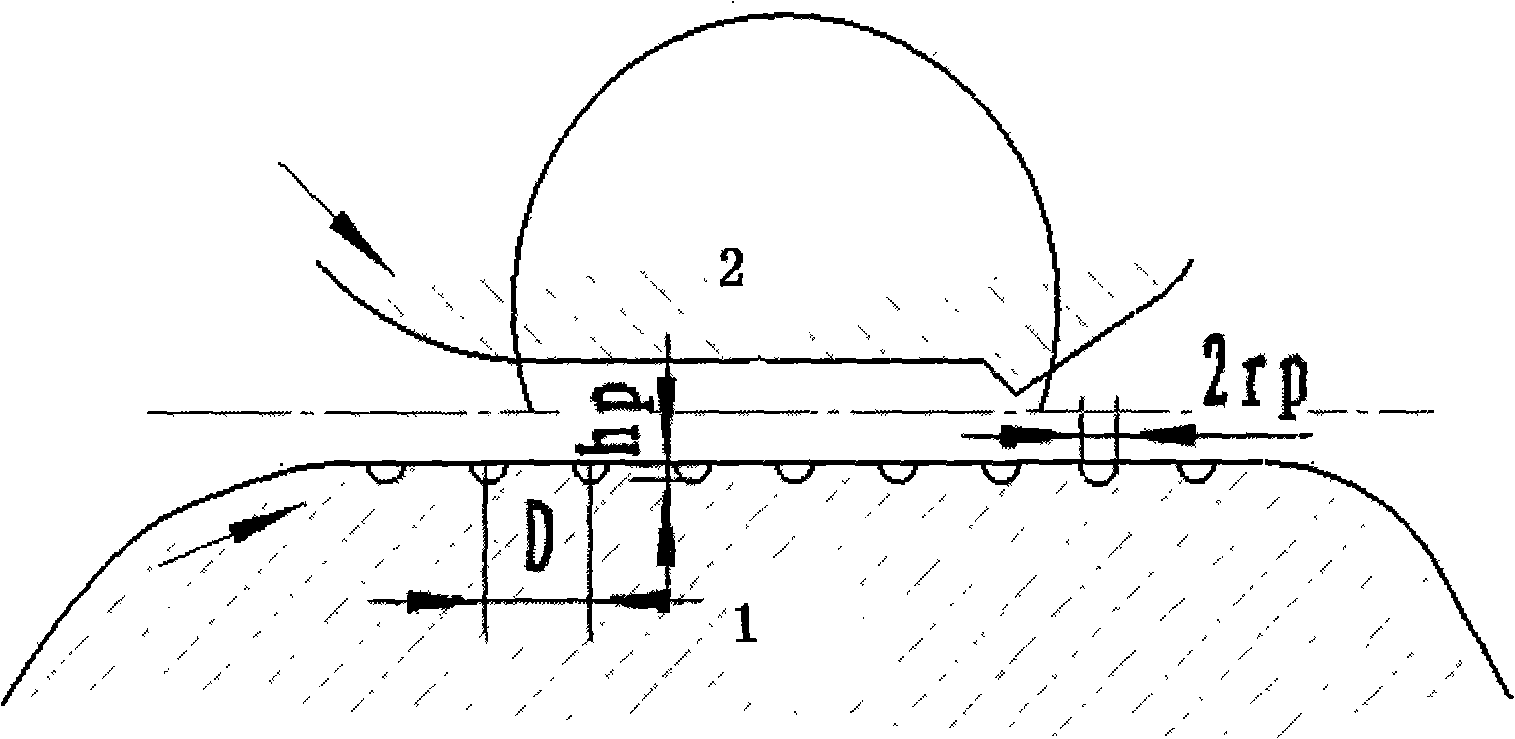

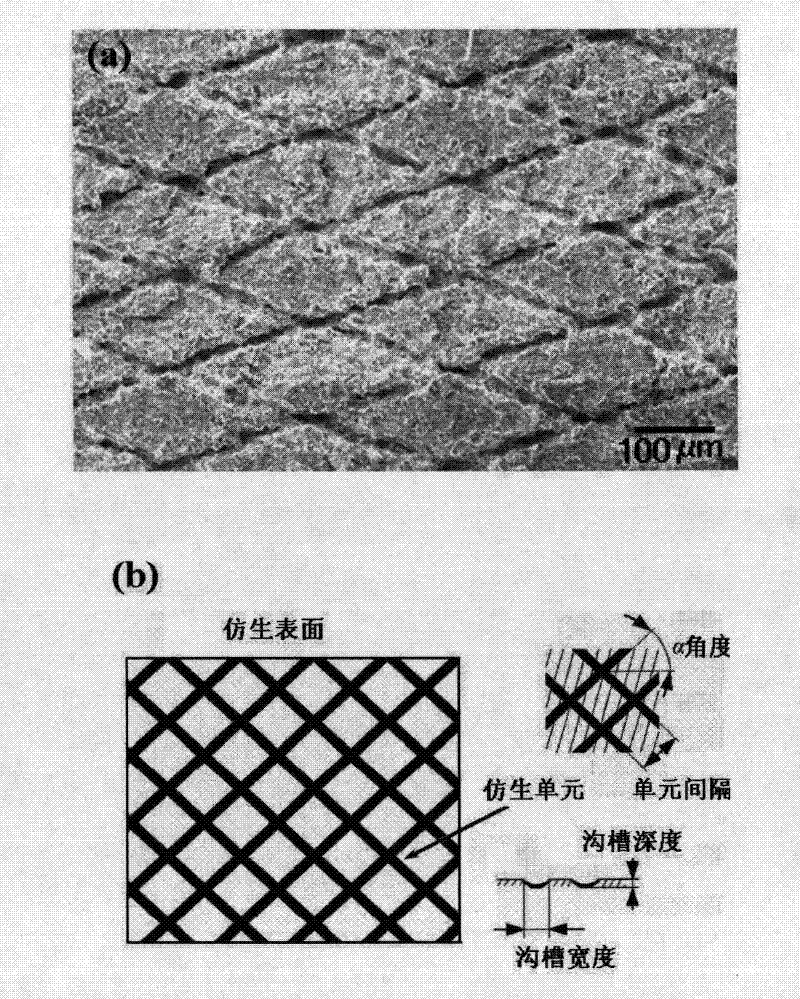

Laser micro-modelling method for cam surface profile

InactiveCN101318262AImprove wear resistance and anti-wear performanceImprove the lubrication effectLaser beam welding apparatusEngineeringOxygen

The invention relates to a laser composite processing technology for friction pair surfaces of cam rollers, in particular to a laser microscopic reshaping and modifying processing method carried out on cam surfaces of fuel injection pumps of engines. At first, the micro-geometrical morphology design scheme of the cam surface is determined; the laser micro-model processing of different morphology schemes are implemented by controlling laser processing technique parameters, namely the power density is 10<5> to 10<7>W / cm, the pulse width is 25ns to 200ns, the repetition frequency is 5KHz to 15 KHz, the scanning speed is 0r / min to 300r / min and the assistant gases of nitrogen or oxygen, and combining spatial tracks of work piece movements; and the micro-geometrical morphology with high hardness is formed by a micro-concave cavity and a micro-concave groove on the specific local working surface of the cam; the laser composite processing technology for the friction pair surfaces of the cam rollers not only can significantly improve the lubrication property of the cam surface, improve the wear resistance of the cams but also can prolong the service life of the cams and improve the whole property of the engines.

Owner:JIANGSU UNIV

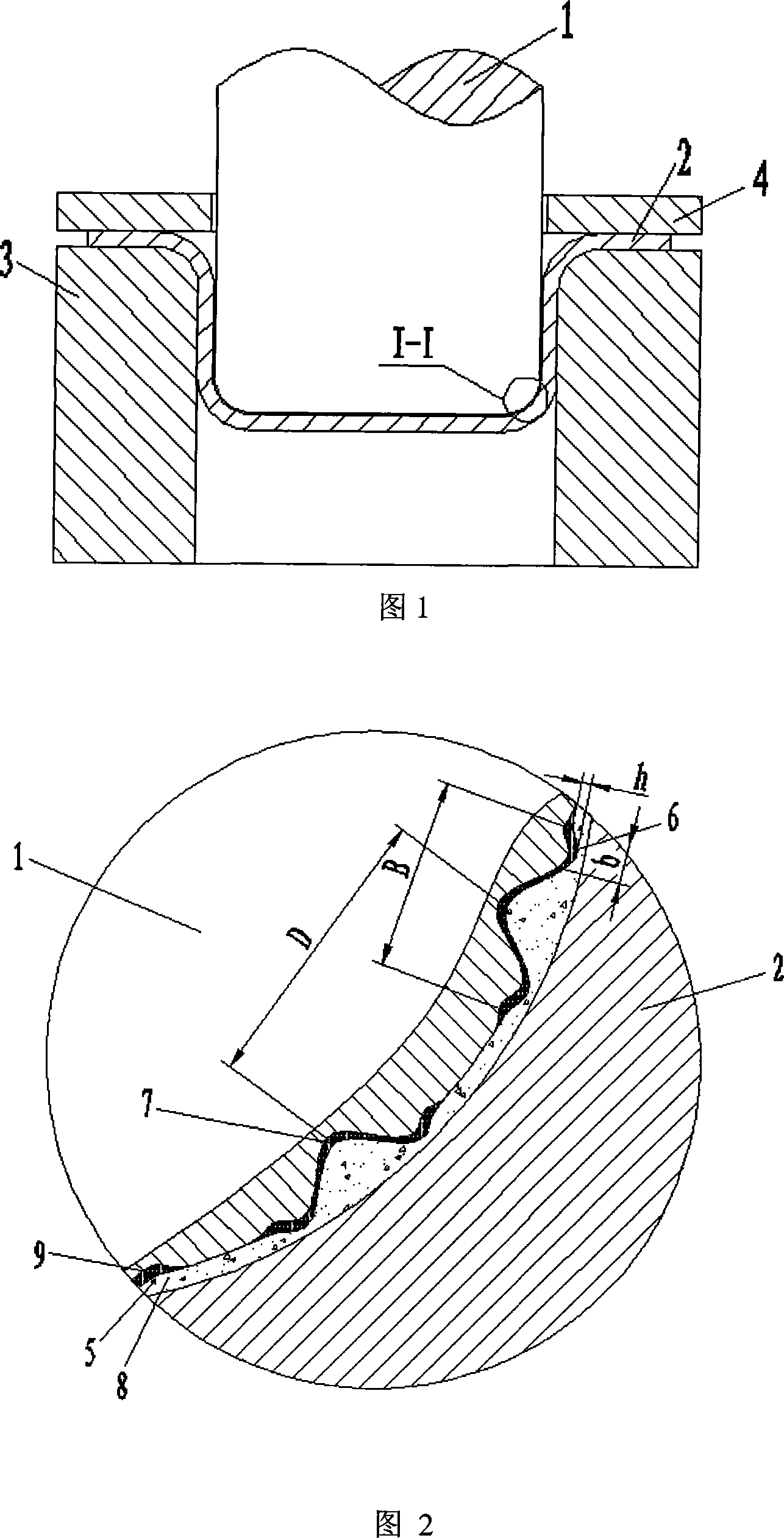

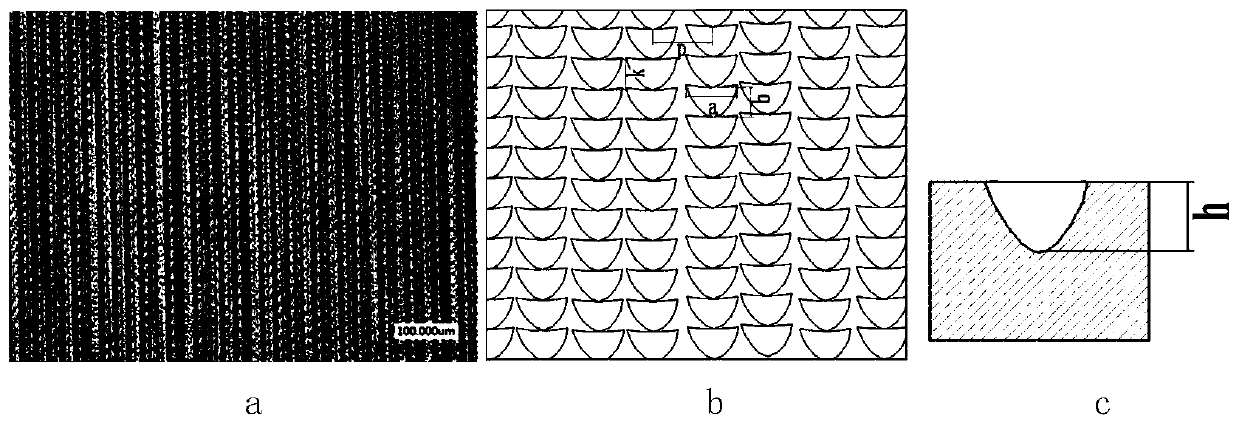

Laser roughening metal plastic forming mould and its preparation method

InactiveCN101143377AImprove wear resistance and anti-wear performanceExtended service lifeShaping toolsLaser beam welding apparatusWear particleHardness

The invention is a forming mould and a manufacturing method of a laser texturing metal plastic. After being processed by the laser, the hardness of a surface of the forming mould of laser texturing metal plastic is HV800 to 10000, which has the microstructure of crater-shaped micro-geometrical structure consisting of spacing and unevenly distributed micro pits and bosses around the micro pits. Wherein, the geometric parameters of the crater-shaped micro-geometrical structure are: the pit diameter (B) of the pit is 20 to 500 Mu m; the height (h) of the boss is 1 to 8 Mu m; the width (b) of the boss is 3 to 20 Mu m; and distance D between two adjacent pits is 50 to 500 Mu m. The invention has an advantage that surface material is microscopically hardened and pinning is macroscopically strengthened when plastic forming is practiced by the mould, thereby greatly improving properties of wear resistance of the mould. In addition, the micro pits on the surface of the mould can be used fro storing lubrication oil and gathering wear particles, thereby improving lubrication state of the mould to have an effect of lubrication and friction-reducing. And the special laser texturing structure of the surface optimizes forming the technology of the metal plastic.

Owner:JIANGSU UNIV

Microscopic geometry measuring device

InactiveUS20020124427A1Eliminate mechanical interferenceDegradation in responsivityMechanical counters/curvatures measurementsNanotechnologyMeasurement deviceEngineering

A fine feed mechanism (50) and a coarse feed mechanism (60) respectively for minutely and greatly displacing a stylus (12) is provided to a microscopic geometry measuring device (1), so that the respective mechanisms (50, 60) are combinedly actuated for easily controlling the movement of the stylus (12) in a wide range at a short time. Further, a movable balancing portion (53) moving in a direction opposite to a movable driving portion (52) is provided to the fine feed mechanism (50). Since a reaction force caused by the movement of the movable driving portion (52) is cancelled by another reaction force caused by the movement of the movable balancing portion (53) at a fixed portion (51), no mechanical interference is caused between the respective mechanisms (50, 60), thus accurately controlling the movement of the stylus (12).

Owner:MITUTOYO CORP

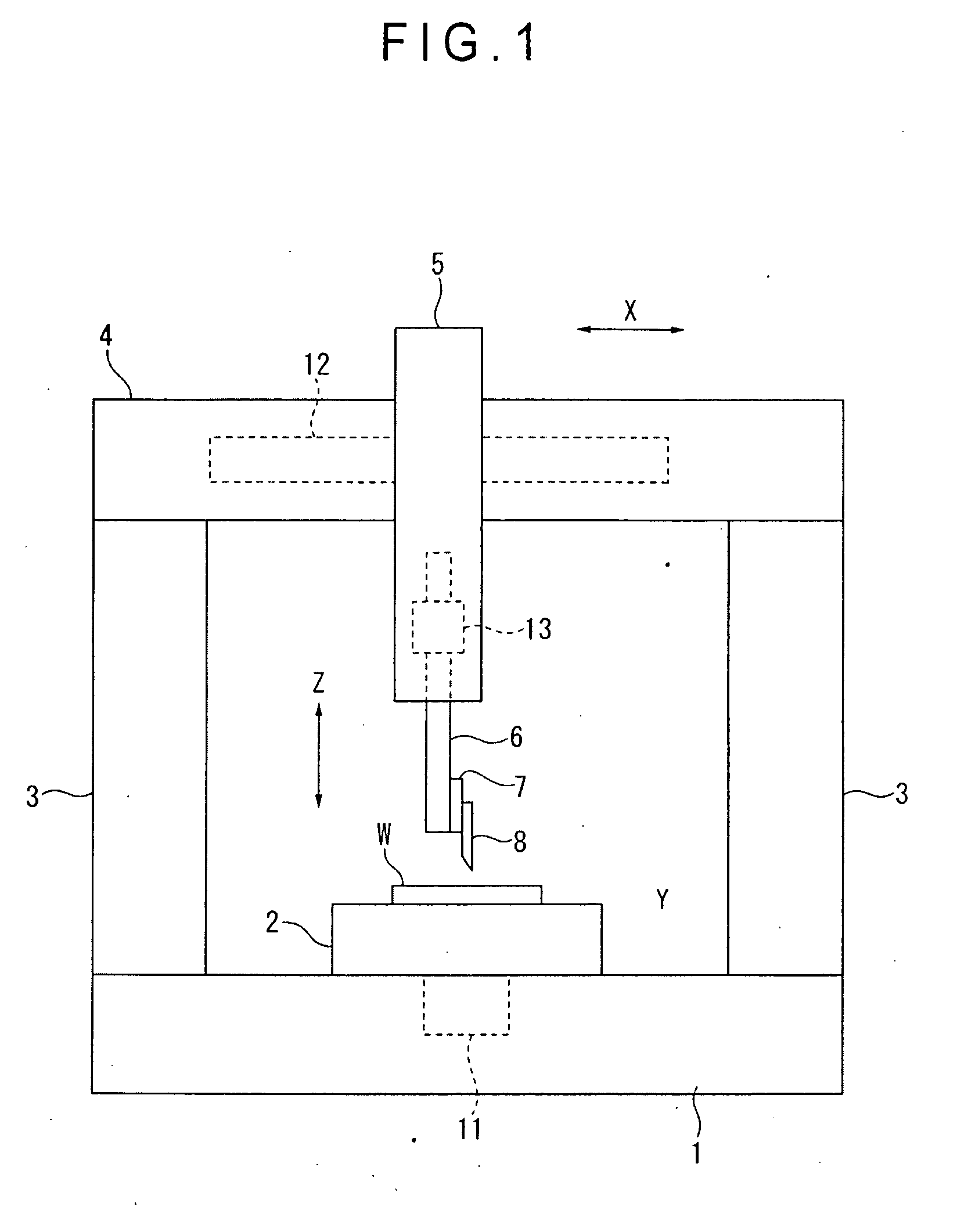

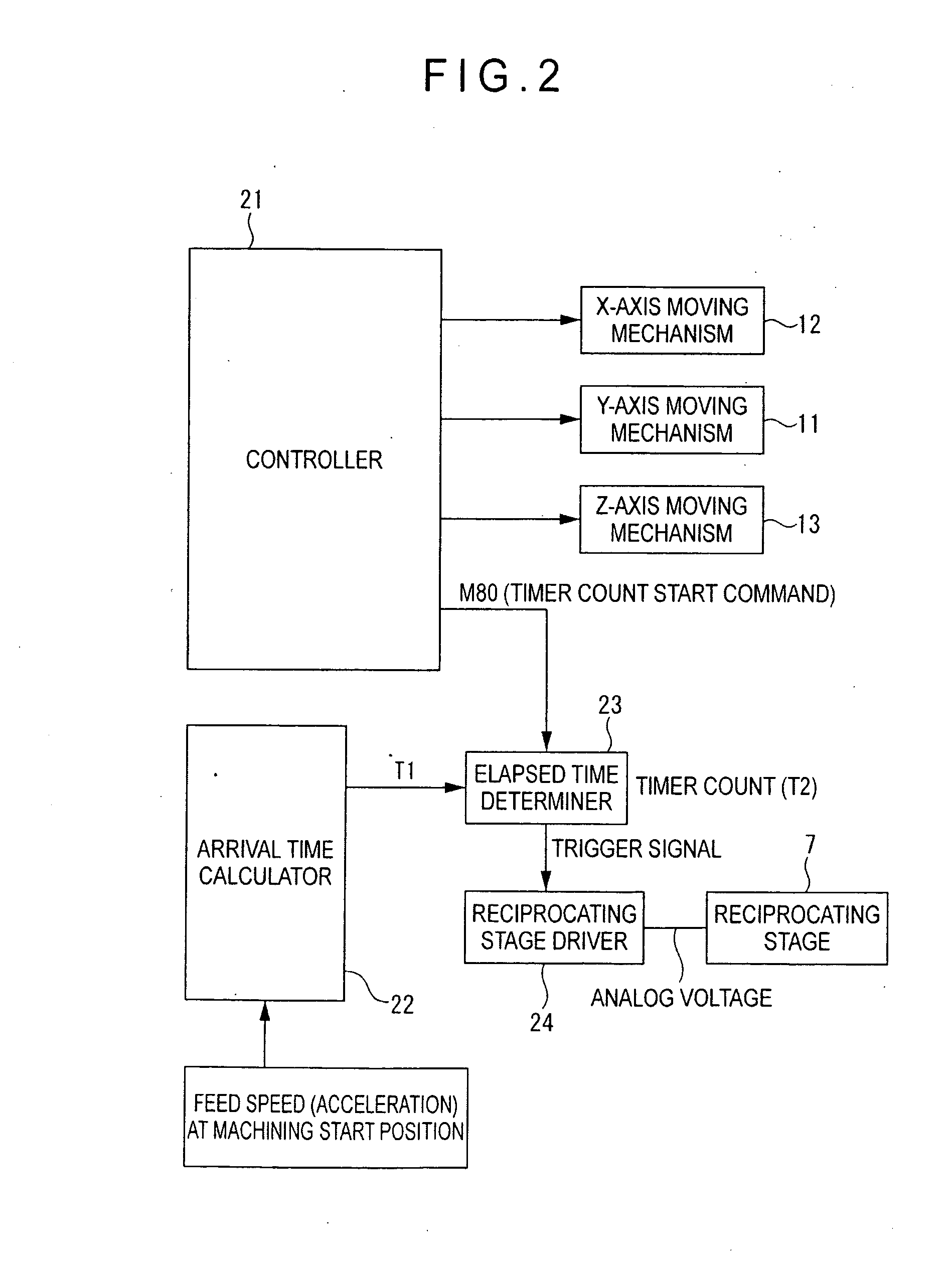

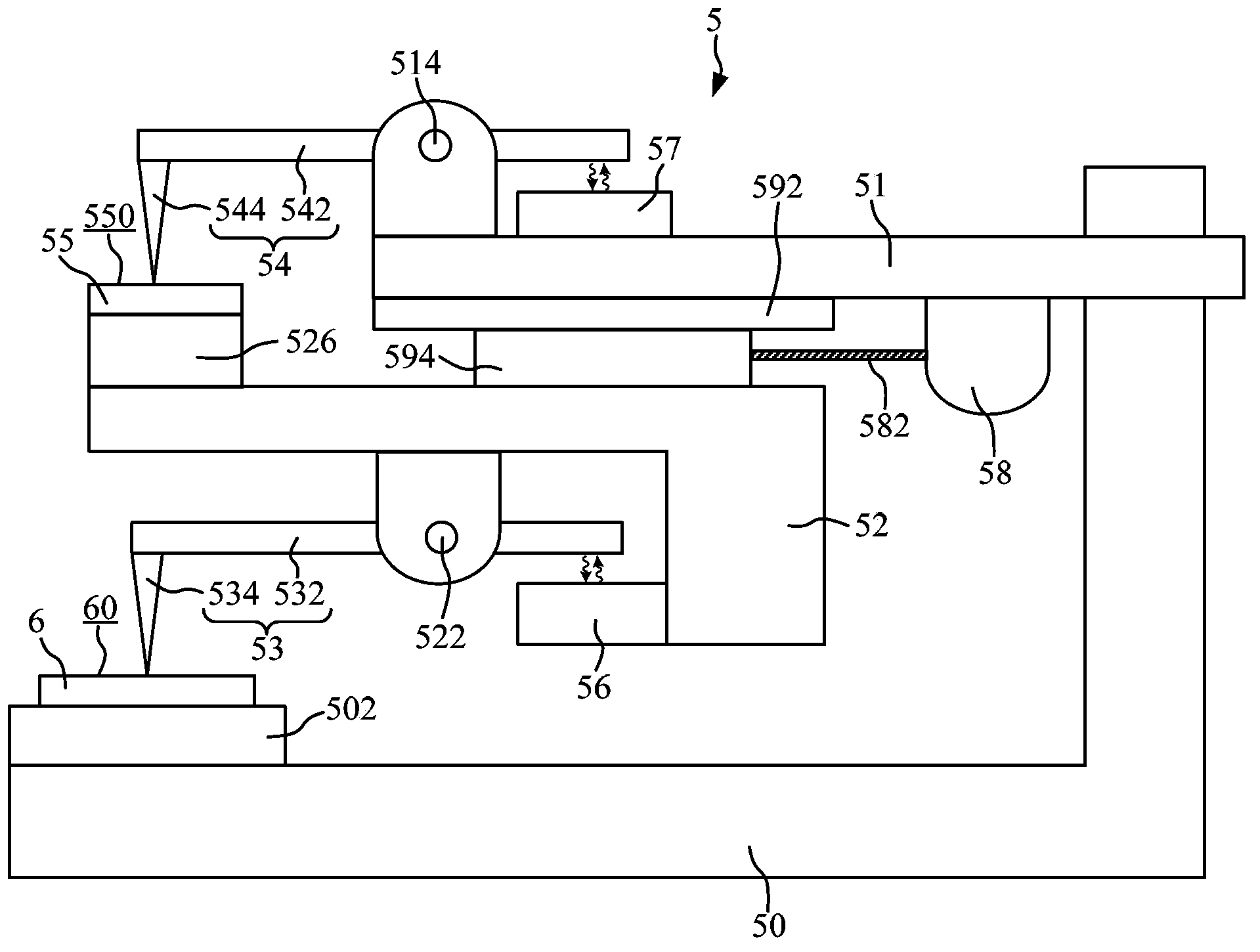

Microscopic geometry cutting device and microscopic geometry cutting method

ActiveUS20090019979A1Their depth of cut be limitedReduce depthProgramme controlAutomatic control devicesArrival timeEngineering

A microscopic geometry cutting device includes: a controller that outputs a timer count start command in starting a driving program which controls a drive of an X-axis or a Y-axis moving mechanism; an arrival time calculator that calculates an arrival time from when the timer count start command is output till when the cutter arrives at a machining start position in accordance with relative moving speed information of the moving mechanisms and machining start position information of a workpiece W; an elapsed time determiner that determines whether an elapsed time from when the timer count start command is output is coincident with the arrival time and outputs a trigger signal when the elapsed time is coincident with the arrival time; and a reciprocating stage driver that drives the reciprocating stage in a manner that the cutter advances and retracts in a predetermined cutting depth in response to the trigger signal.

Owner:TOSHIBA MASCH CO LTD

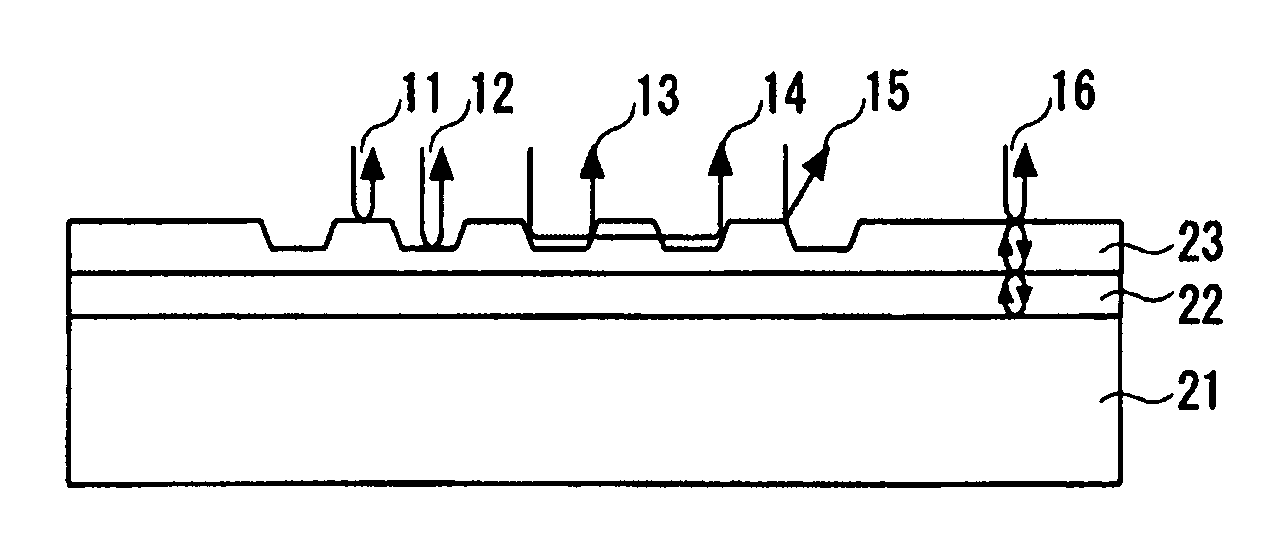

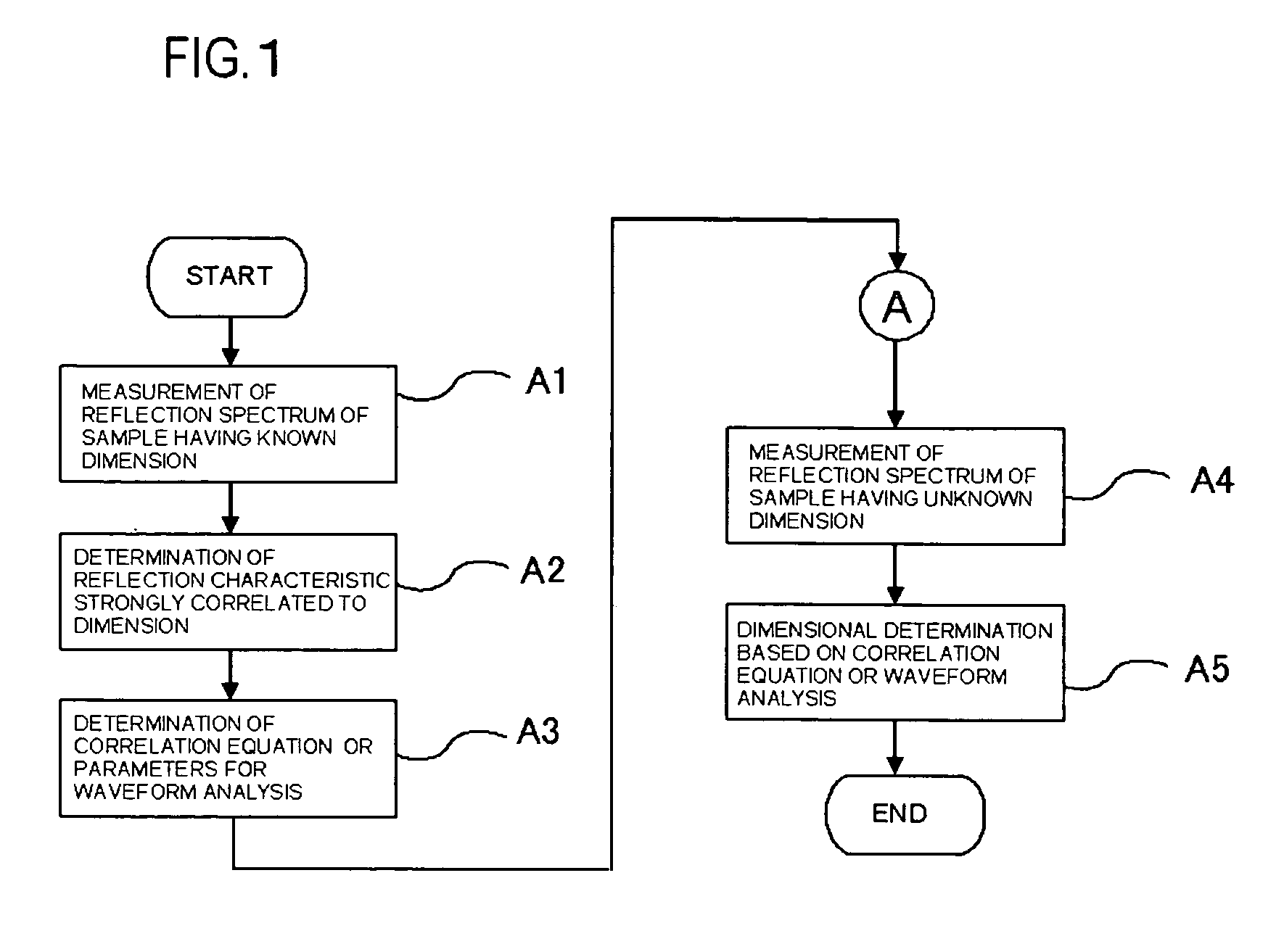

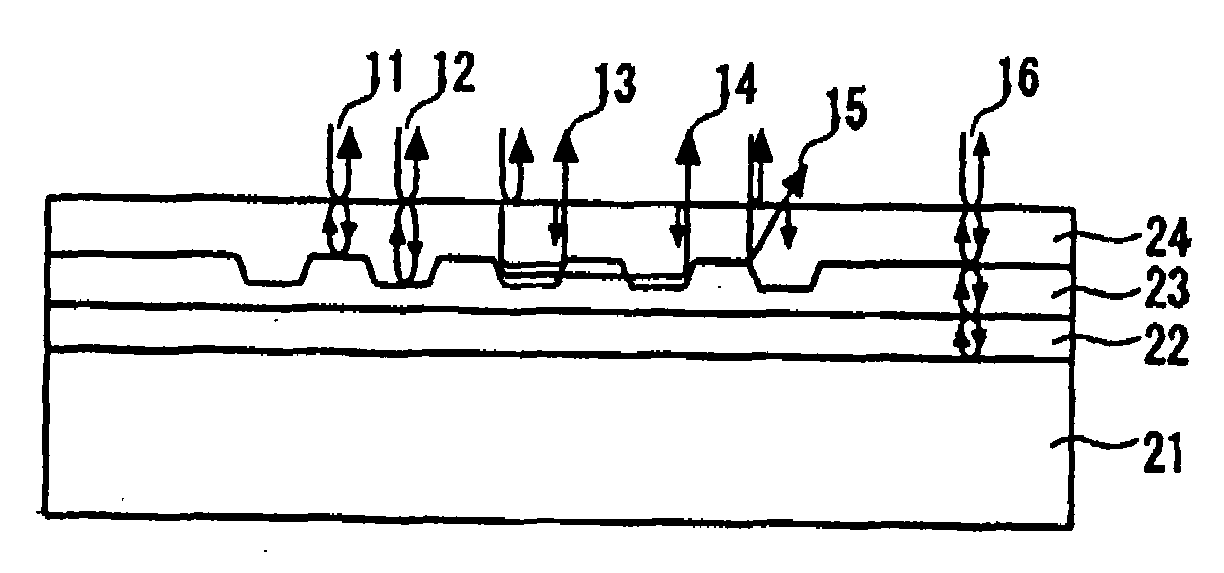

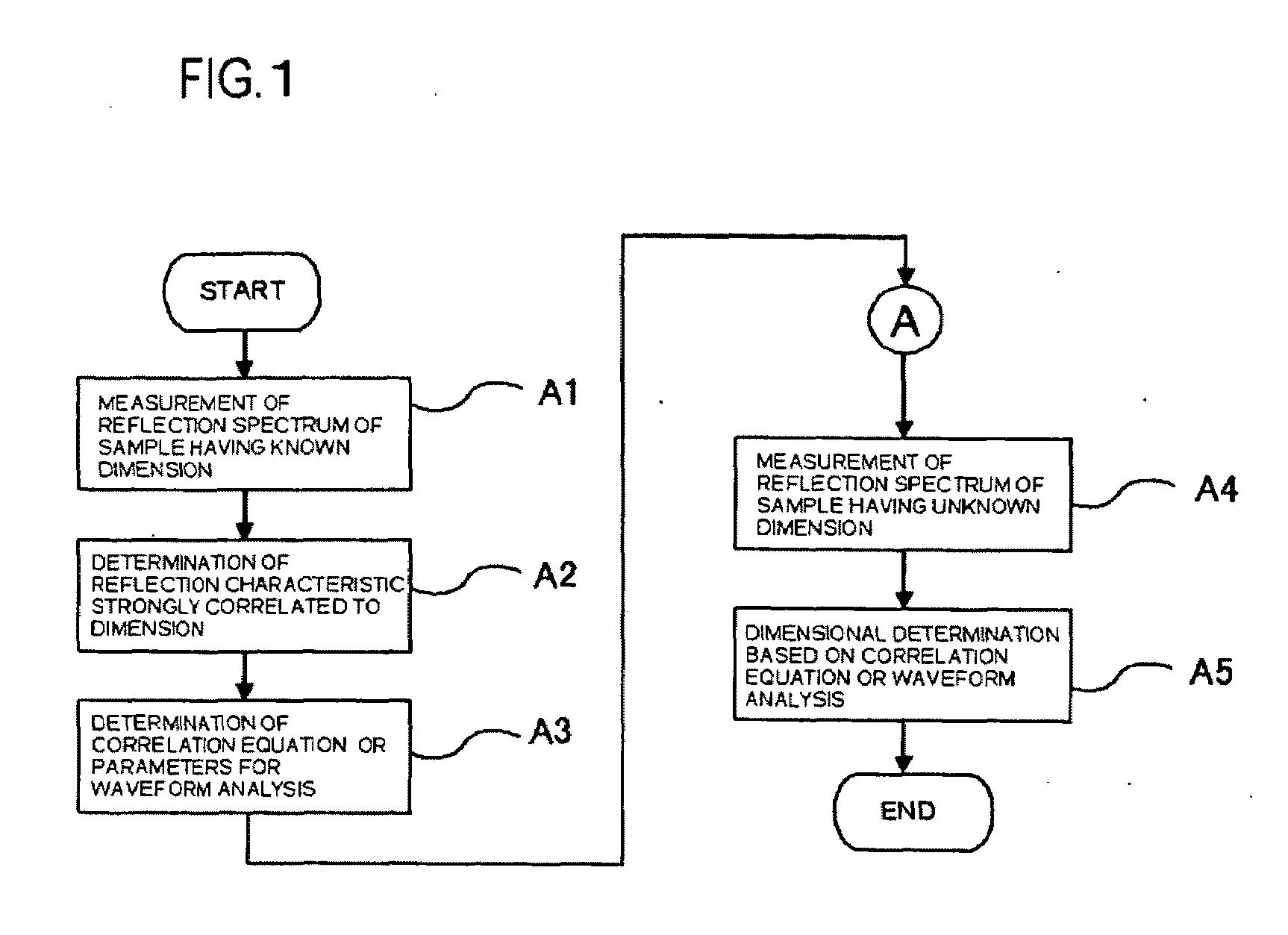

Method of measuring micro-structure, micro-structure measurement apparatus, and micro-structure analytical system

InactiveUS20050219548A1Readily and accurately measureSemiconductor/solid-state device testing/measurementUsing optical meansNon destructiveMicro structure

This invention provides a method and an apparatus of measuring a micro-structure, capable of evaluating a geometry of a micro-structure formed typically on the surface of a semiconductor substrate, in a non-destructive, easy, precise and quantitative manner. A reflection spectrum of a sample having a known dimension of a target micro-geometry is measured (A1), features (waveform parameters) which strongly correlate to a dimension of the measured micro-geometry are determined (A2), a relation between the dimension of the micro-geometry and the waveform parameters is found (A3), and a dimension of the micro-structure having an unknown dimension is finally determined using this relation and based on the reflection spectrum obtained therefrom (A4, A5).

Owner:NEC ELECTRONICS CORP

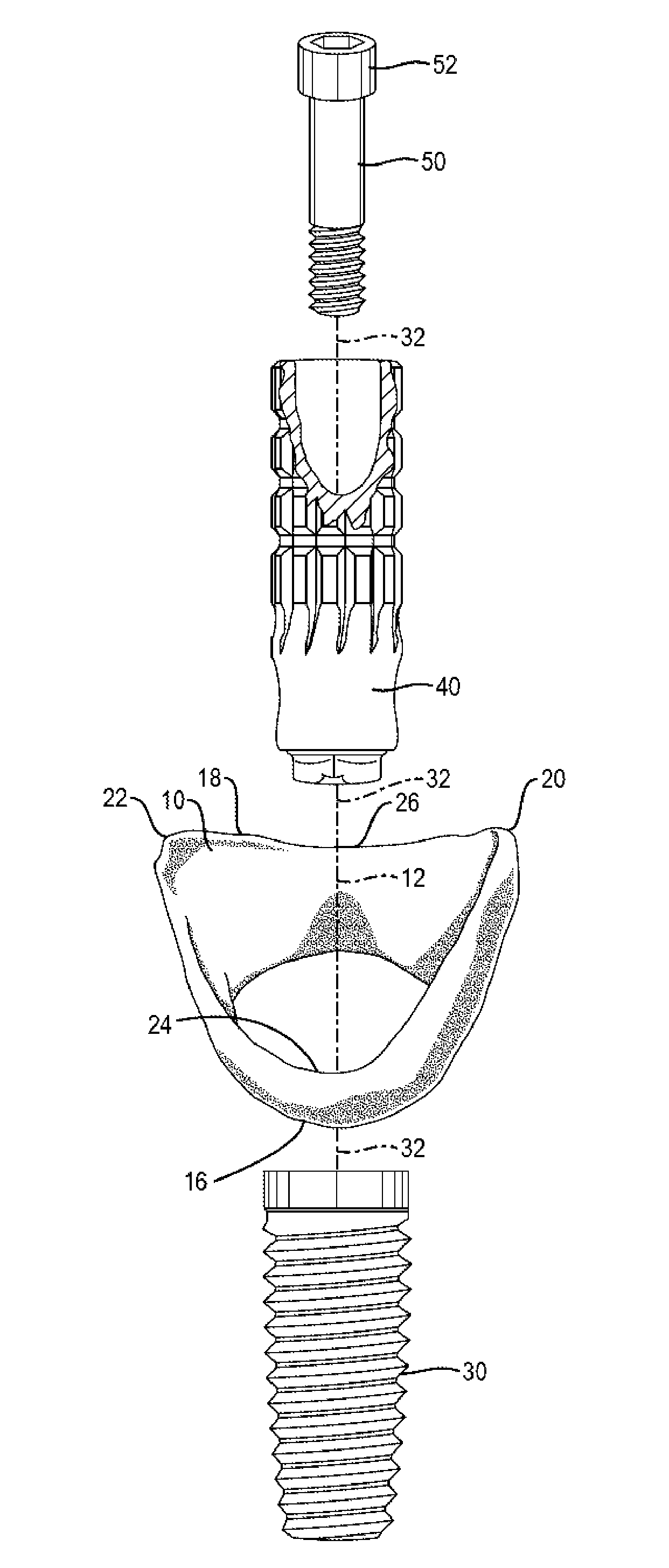

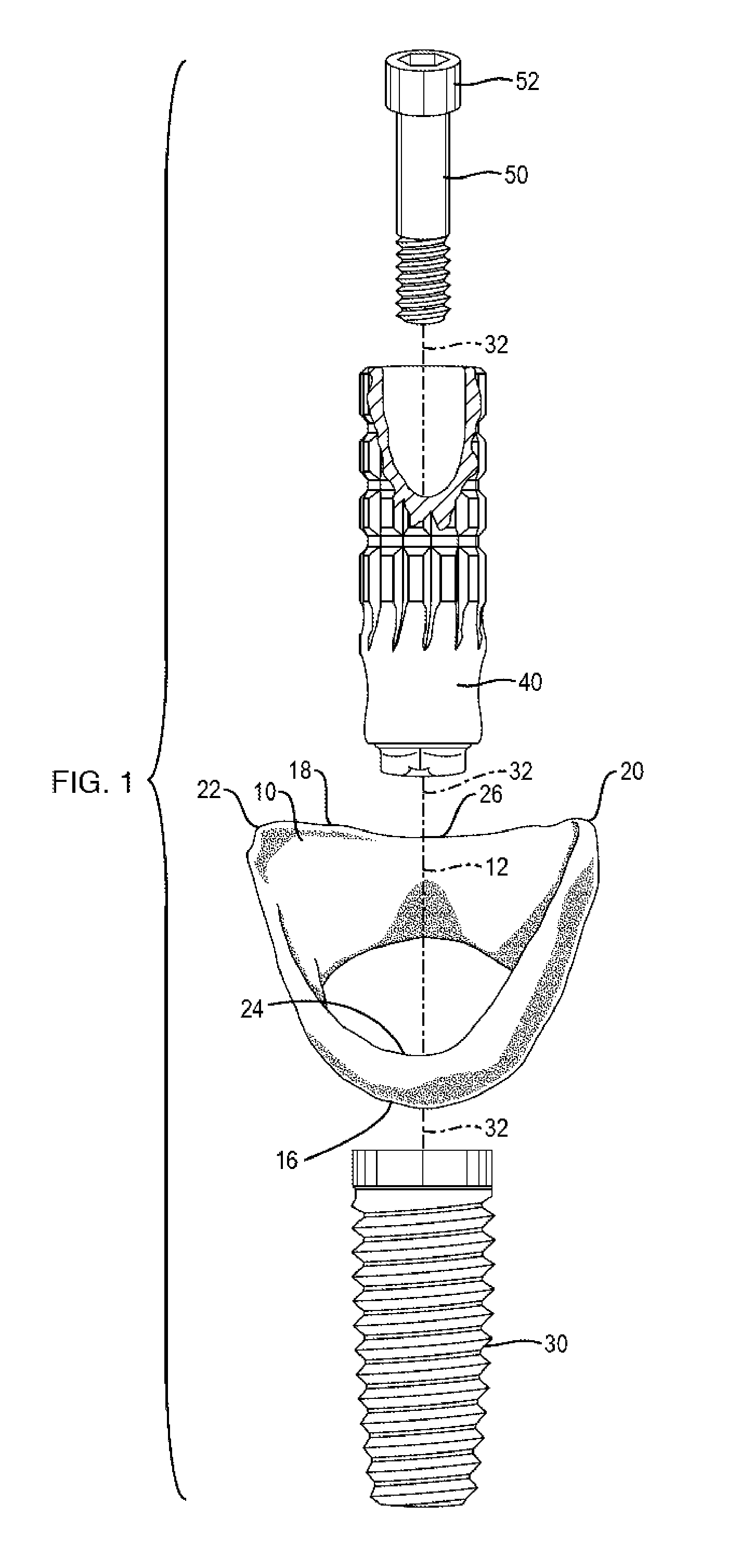

Soft tissue preservation temporary (shell) immediate-implant abutment with biological active surface

An immediate dental implant shell has outer, multiple zones for engaging a soft tissue socket left immediately after tooth extraction from a bone socket. The zones have combinations of different biologic agents, macro- or micro-geometric, or micro- or macro-morphology irregularities to better engage gingival sulcus, junctional epithelium and dento-gingival fiber zones of the soft tissue socket. The shell may also have various guide markings and projections to aide drilling of the implant hole in the bone socket. A dental implant is placed in the drilled implant hole before or after the shell has been placed in the soft tissue socket, and has an axis that is independent of the shell axis so the shell and implant both sit in optimum positions in their respective soft and bone sockets.

Owner:EVOLLUTION IP HLDG

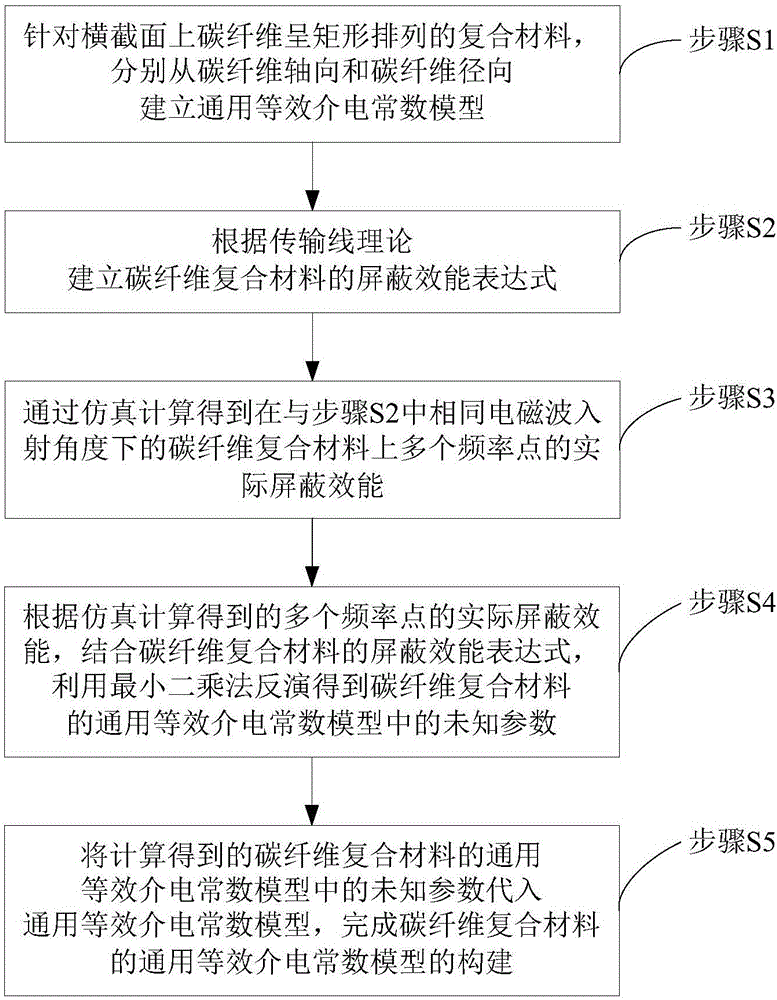

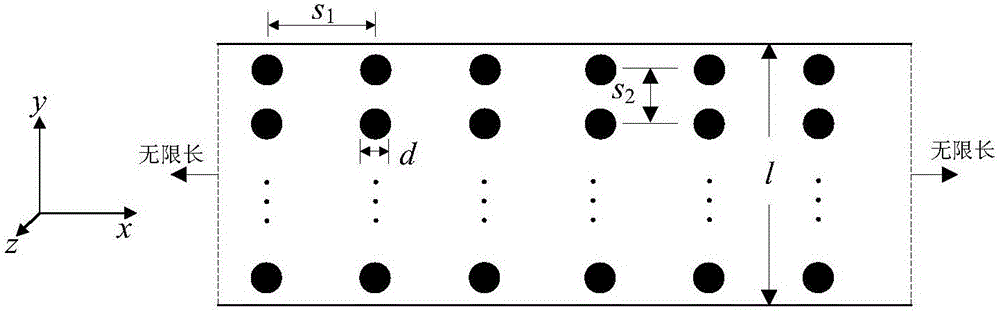

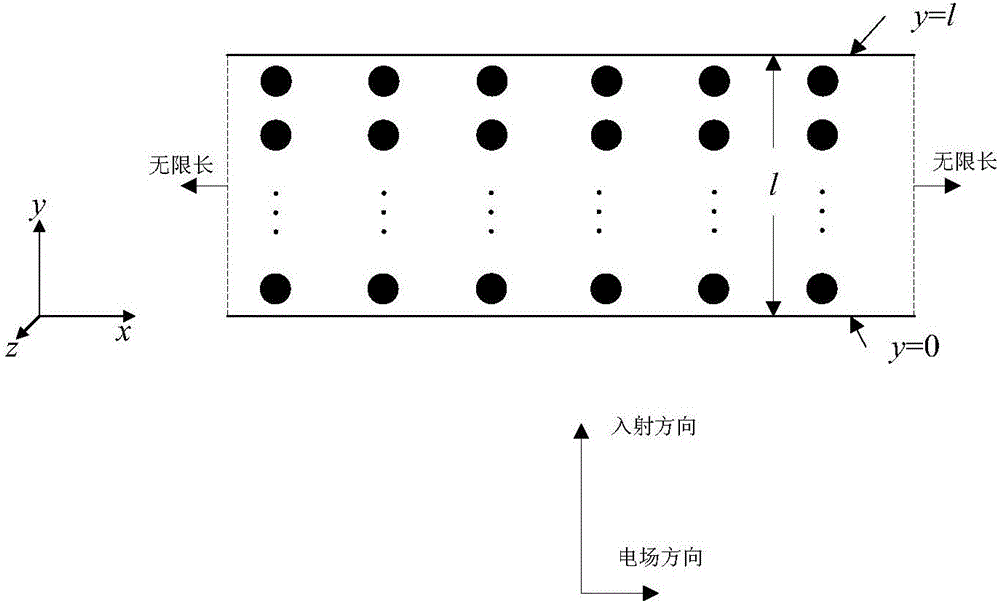

Construction method of carbon fiber composite material equivalent dielectric constant model

ActiveCN106503377ASolve the problem of too many partitionsSimple calculationDesign optimisation/simulationSpecial data processing applicationsDielectricFibrous composites

Owner:上海神添实业有限公司

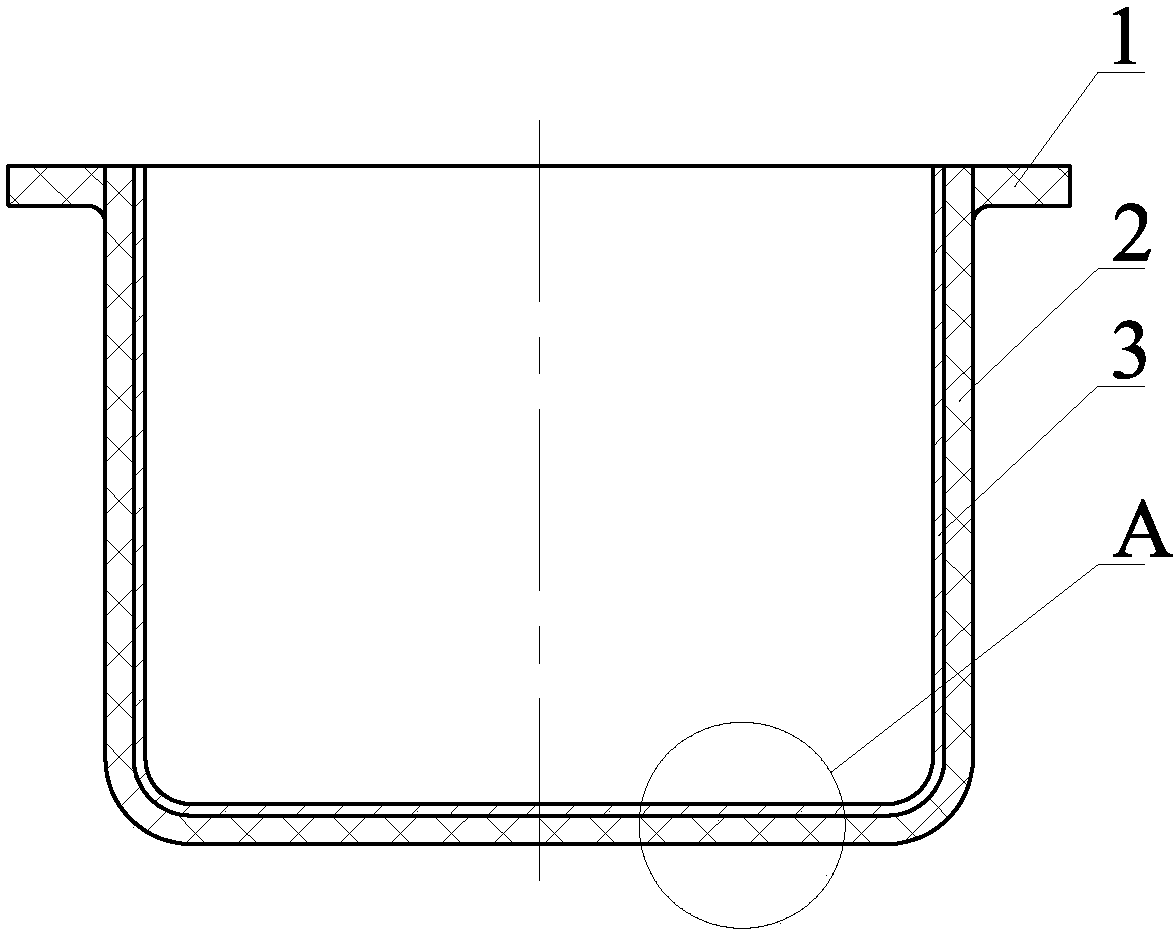

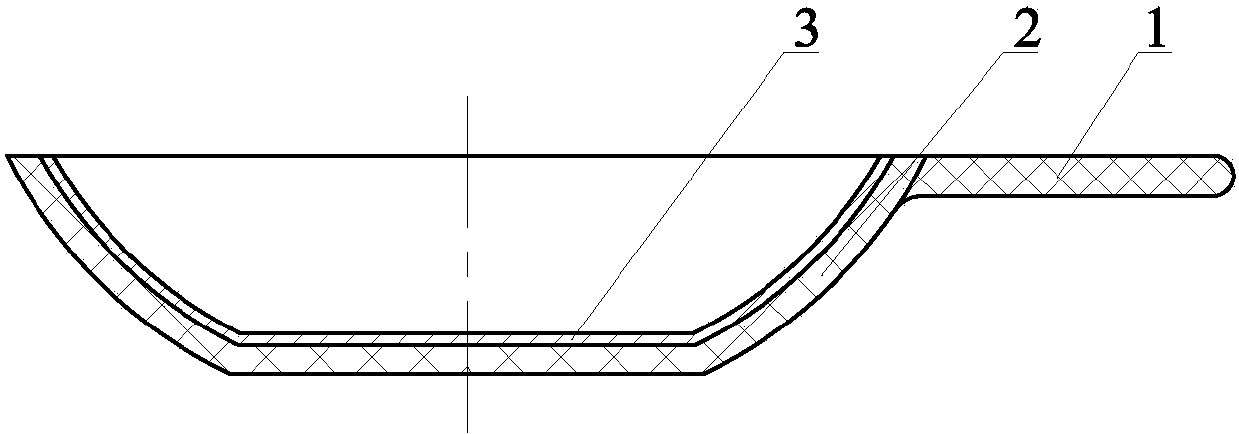

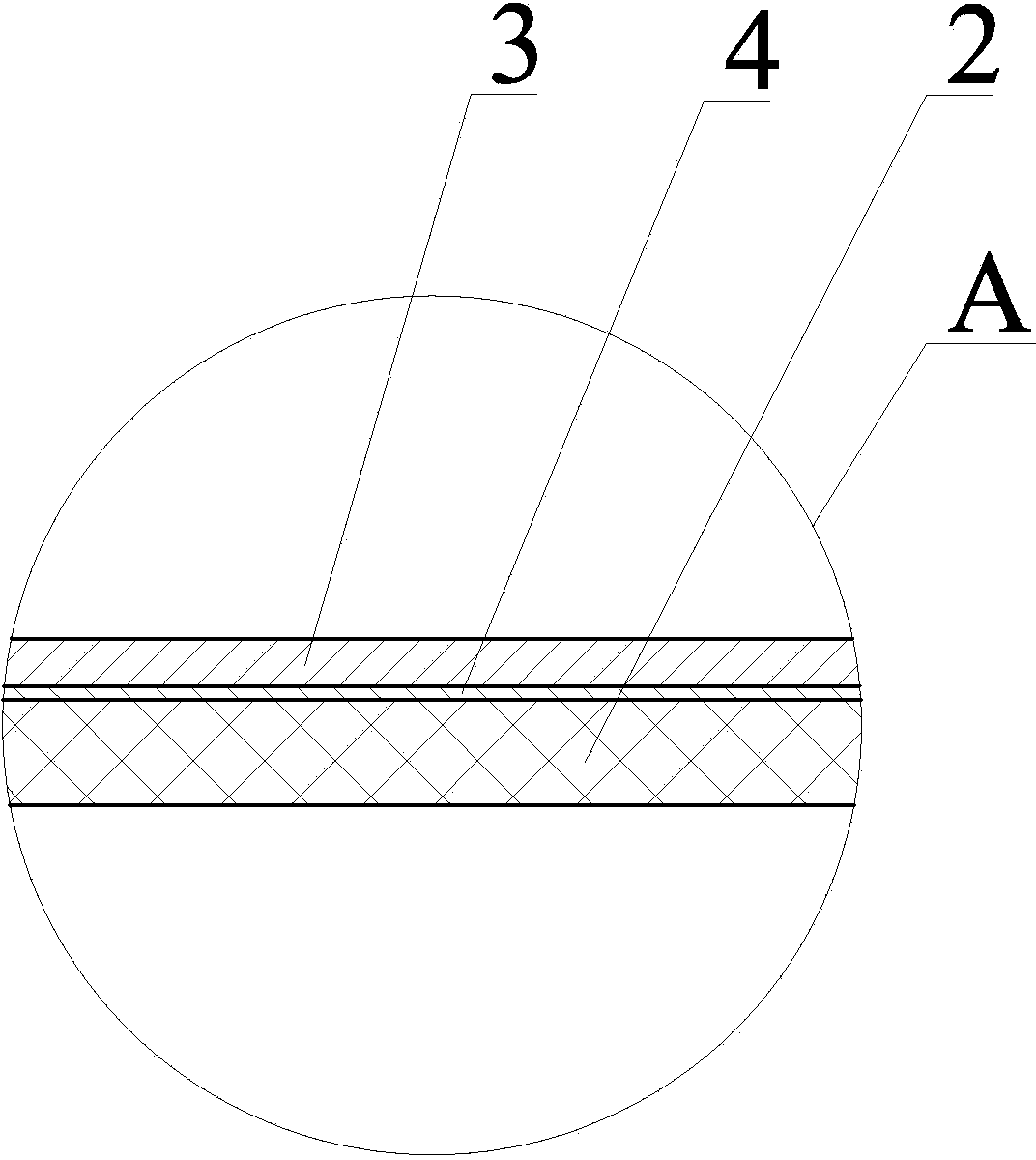

Carbon/carbon composite and metallic material compound cooker and production method

ActiveCN103431746AImprove wettabilityHigh strengthCooking-vessel materialsCarbon compositesMetallic materials

The invention discloses a carbon / carbon composite and metallic material compound cooker and a production method. The method is characterized by comprising the steps of carbon / carbon composite material outer layer green body manufacture, liquid phase impregnation, calcination reduction, metal material inner layer green body manufacture and composite treatment. The manufactured compound cooker comprises a carbon / carbon composite material outer layer green body, a metal material inner layer green body, and a connecting layer connecting the carbon / carbon composite material outer layer green body and the metal material inner layer green body. The method is simple in technology. The metal connecting layer is prepared on the surface of the carbon / carbon composite through the liquid phase impregnation and the calcination reduction, and the chemical component and the micro-geometry structure of the surface of the carbon / carbon composite are changed. Moreover, the attached metal connecting layer and the metal materials have good compatibility, so that the produced carbon / carbon composite and metallic material compound cooker has the advantages of being quick in heating, high in heat efficiency, light, corrosion resistant, high in strength and the like compared with an existing single-iron electromagnetic heating cooker or other existing multi-metal electromagnetic heating cookers.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

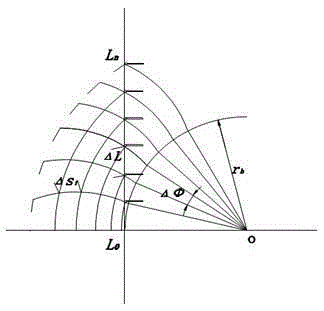

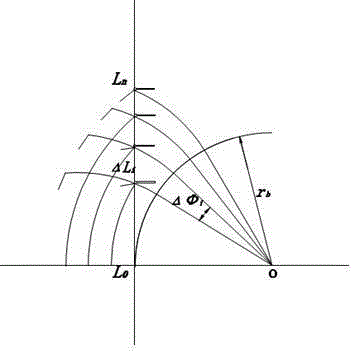

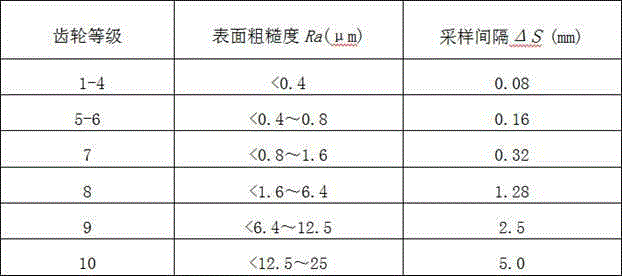

Tooth surface equal interval sampling method used for improving gear measuring precision

ActiveCN105277165ASolve the problem caused by uneven samplingHigh measurement accuracyMeasurement devicesGear grindingMeasuring instrument

The invention provides a tooth surface equal interval sampling method used for improving the gear measuring precision. In a gear measuring process, the problem that the tooth profile measuring precision of a gear measuring instrument is affected by the shortcomings of the existing data acquisition technology is solved, and the problem that corresponding error curve reference of tool and gear grinding is inaccurate is solved. The problems that addendum sampling points are sparser than dedendum sampling points and the tooth surface microscopic geometry cannot be integrally and truly reflected are solved. The gear measuring precision is improved. Error curves and actual tooth profile points are one-to-one corresponding for visual analysis, which is conducive to the gear error analysis and provides reference for gear tool grinding.

Owner:FIRST TRACTOR

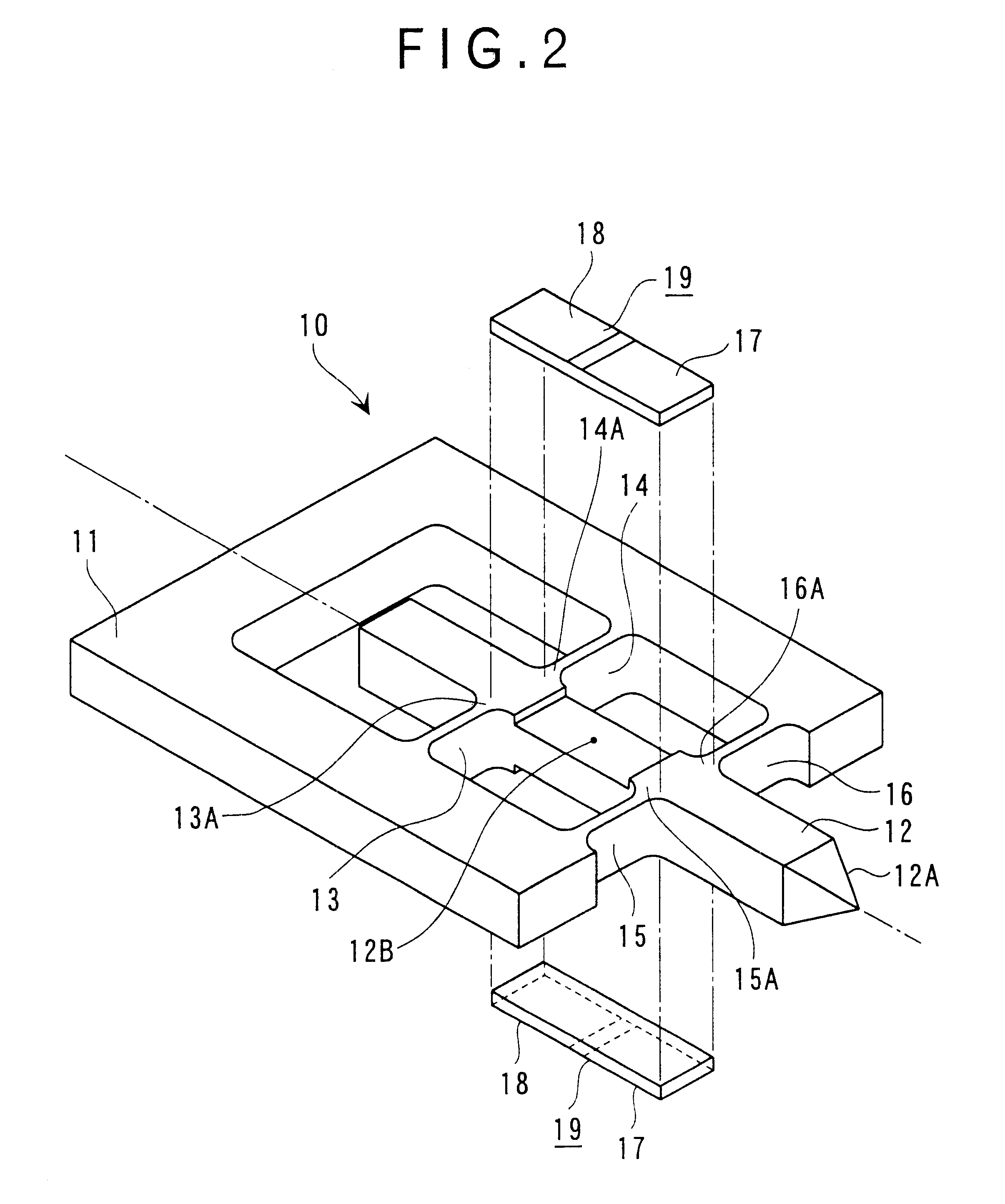

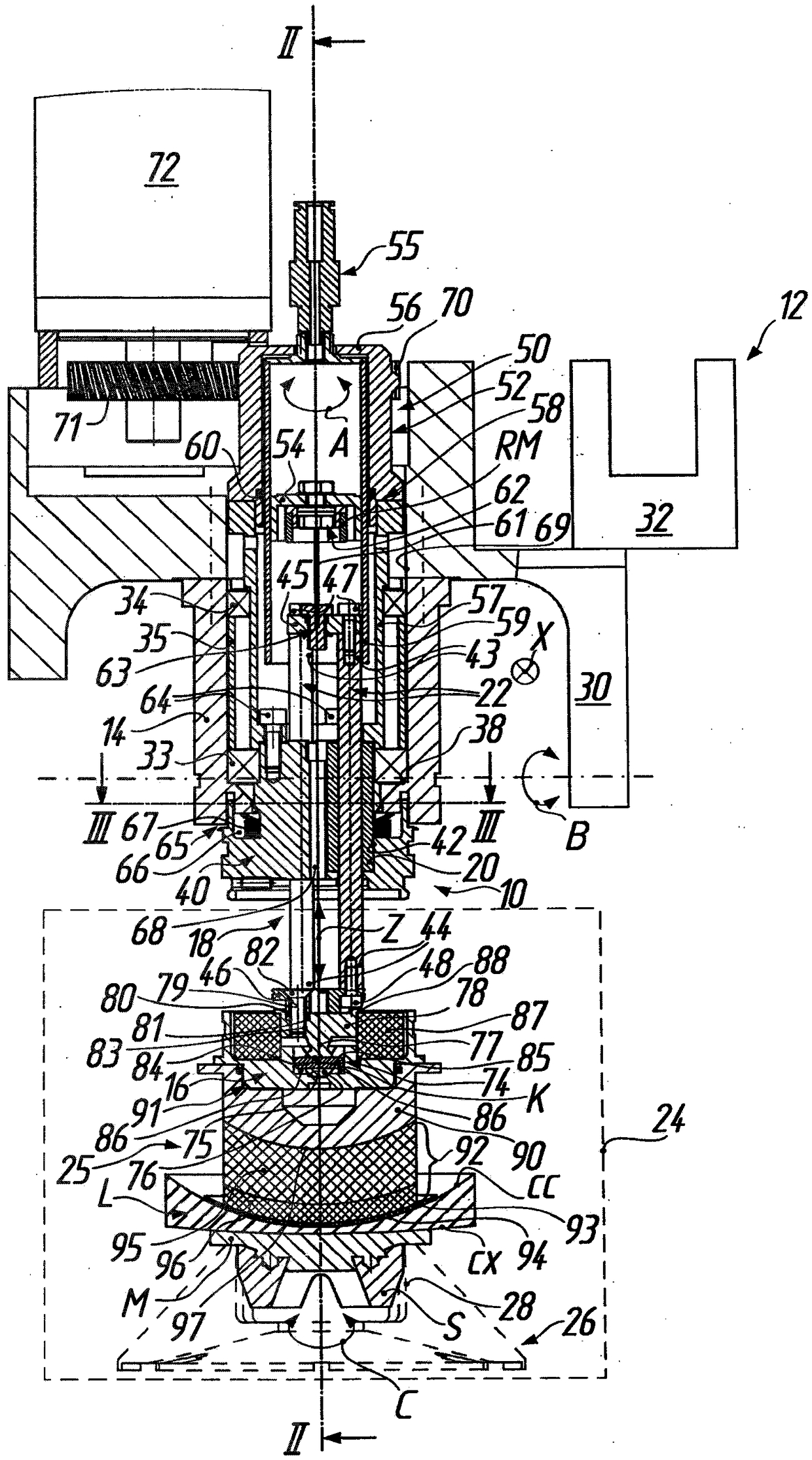

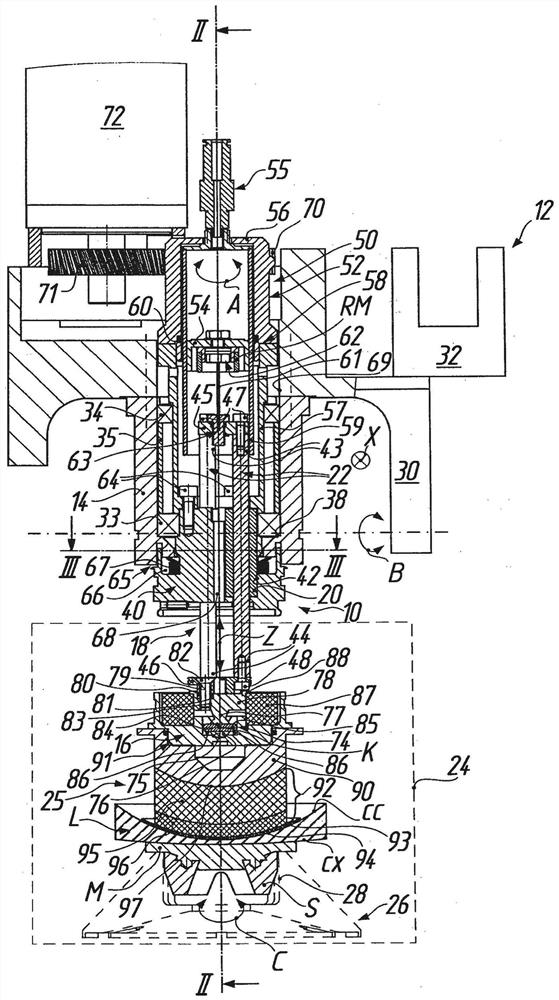

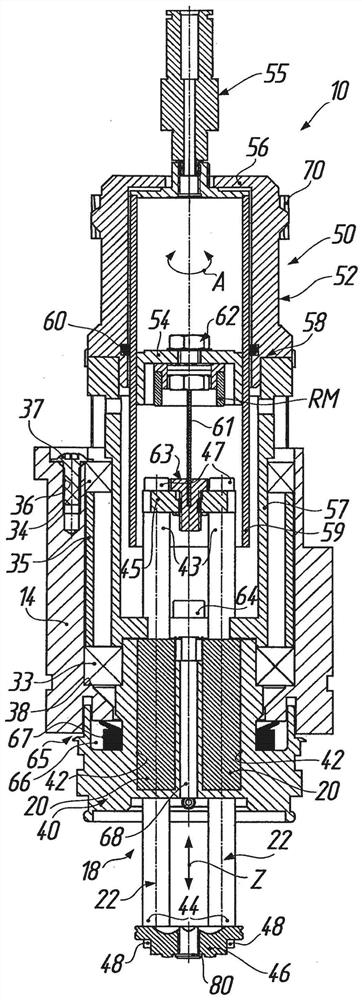

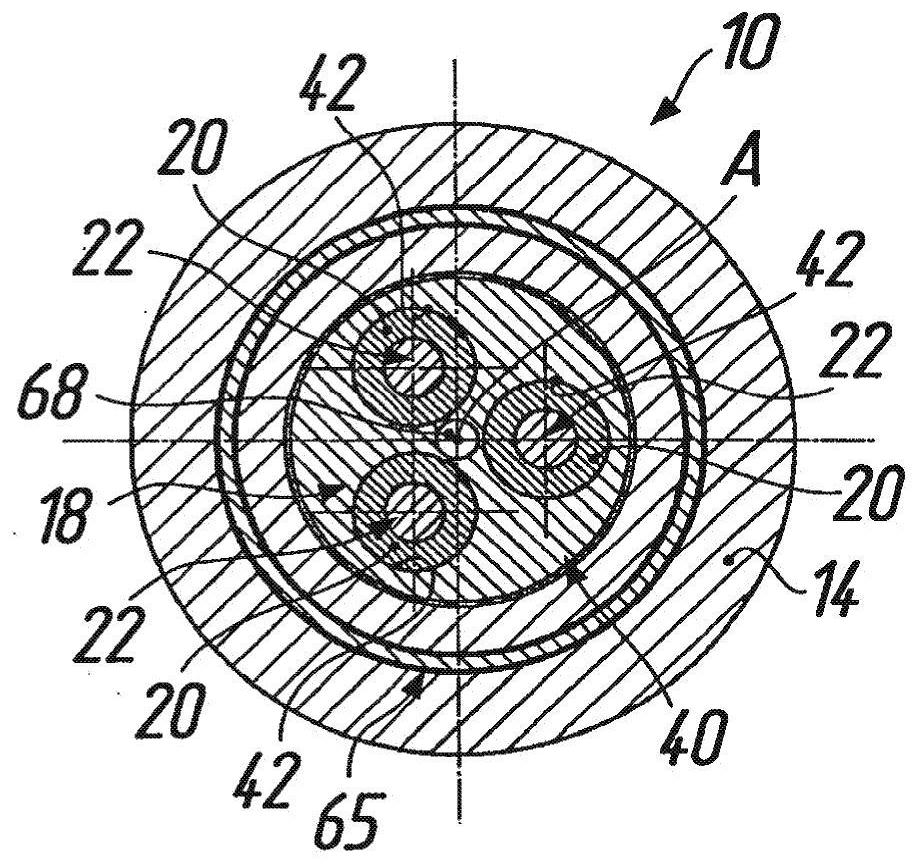

Tool spindle for a device for fine machining optically active surfaces on workpieces

ActiveCN109153102AAvoid errorsOptical surface grinding machinesFeeding apparatusRotational axisEngineering

The invention relates to a tool spindle (10) for a device (12) for fine machining optically active surfaces (cc, cx) on workpieces (L), having a spindle housing (14) and a tool holding portion (16) which protrudes beyond the housing. The tool holding portion can be axially advanced (advancing axis Z) towards the workpiece along the tool rotational axis via a guiding assembly (18), which can be rotated about a tool rotational axis (A) in the spindle housing, and if necessary can be tilted about a tilting point (K) on the tool rotational axis. In order to axially advance the tool holding portion, the guide assembly has a plurality of linear mounting elements (20), which are distributed about the tool rotational axis in a uniform manner, and respective paired guide rods (22), which are connected to the tool holding portion in a traction- and pressure-resistant manner. In this manner, the tool holding portion is capable of following the macro geometry of the workpiece in a smooth and delicate manner when machining the micro geometry of the workpiece.

Owner:SATISLOH AG

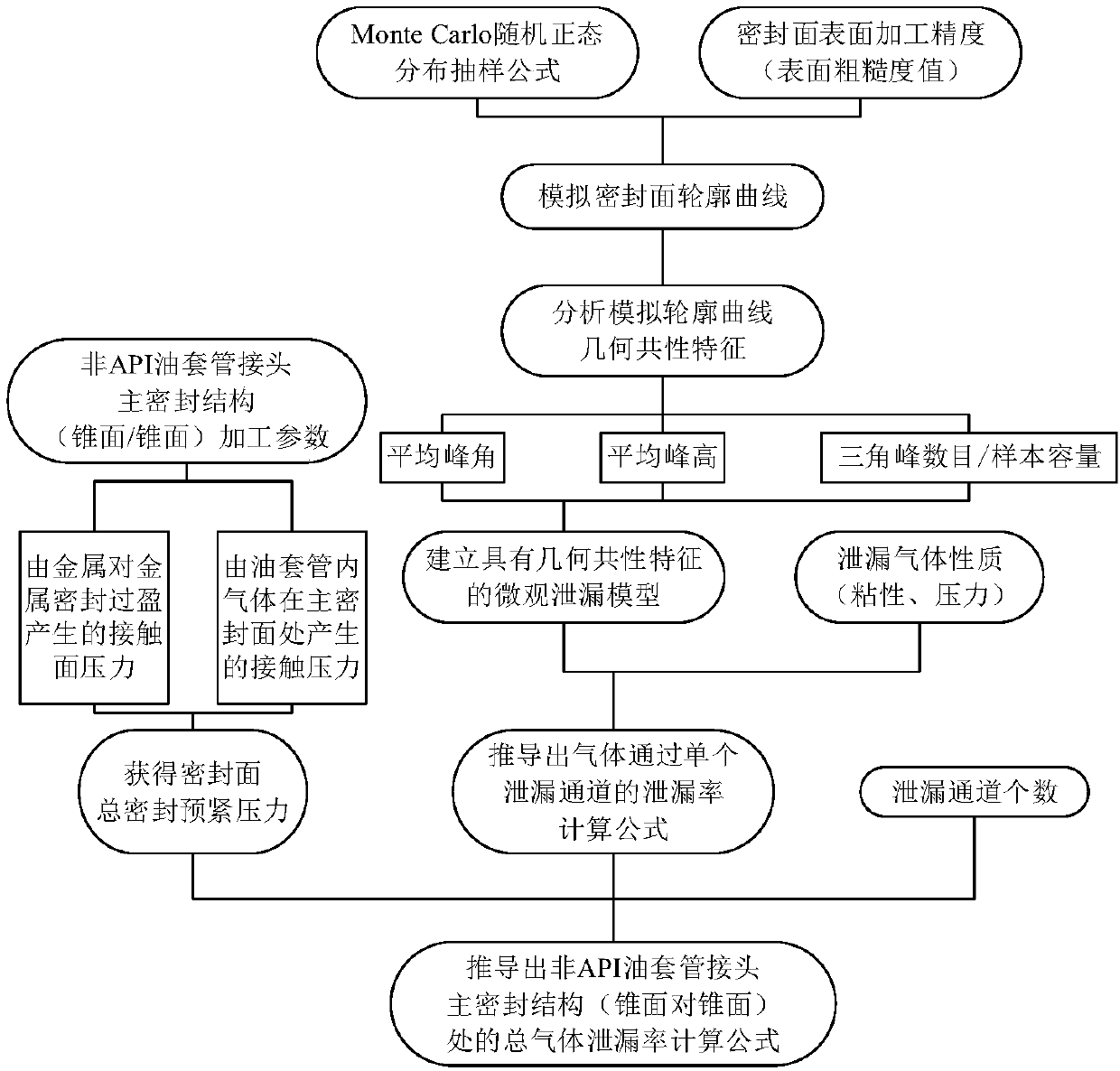

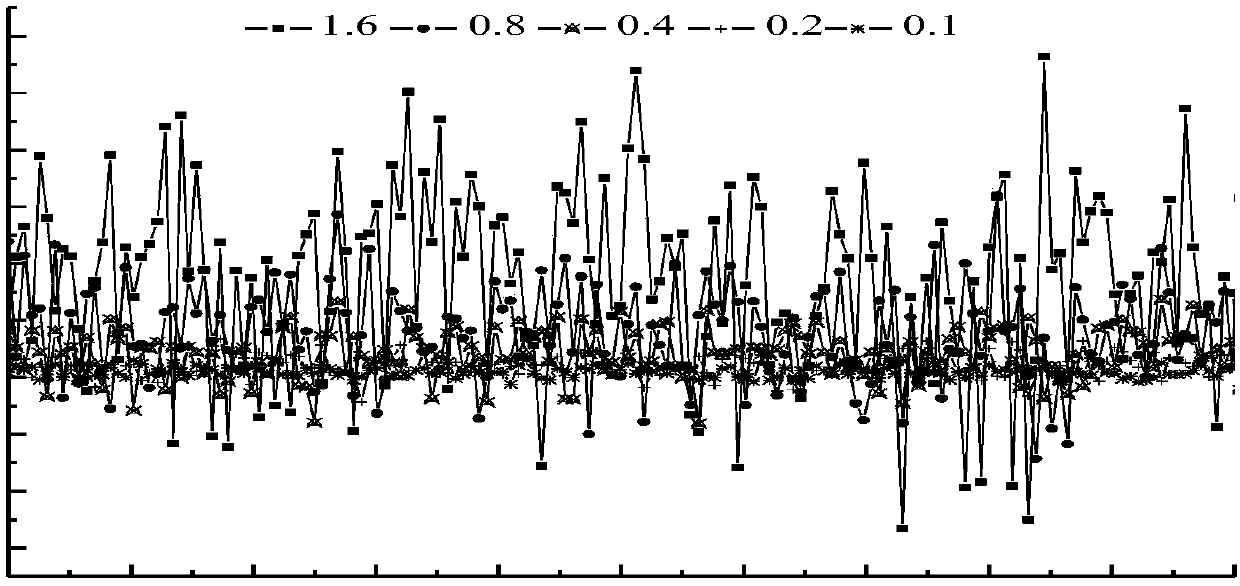

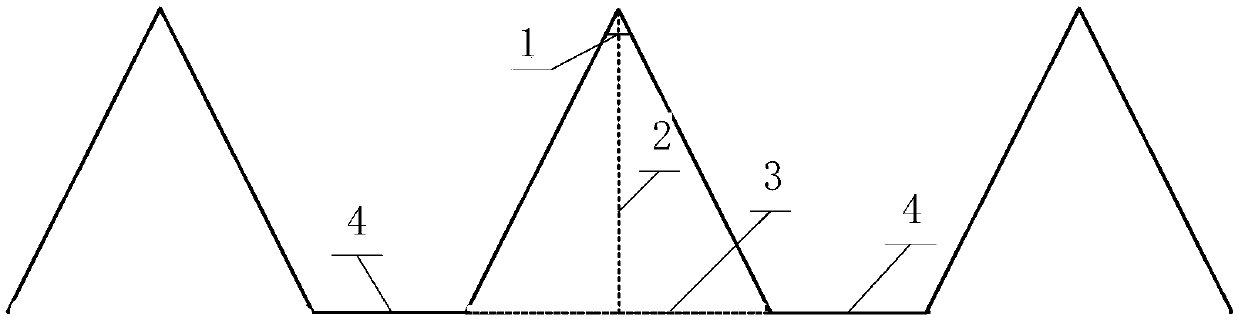

A calculation method for quantitatively evaluating the sealing performance of a non-API oil casing joint

InactiveCN109657255AIncrease credibilityImprove versatilityGeometric CADDesign optimisation/simulationSurface roughnessQuantitative assessment

The invention relates to a calculation method for quantitatively evaluating the sealing performance of a non-API oil sleeve joint. The method comprises the following steps: firstly, combining a MonteCarlo random normal distribution sampling formula with sealing surface roughness; and carrying out simulation to obtain a contour curve of the sealing surface, obtaining simulation curve geometric common characteristics according to contour curve geometric morphology characteristic statistical data under different sample capacities and surface roughness, and establishing a metal-to-metal sealing microscopic leakage model; then deducing a gas leakage rate calculation formula containing the microscopic geometrical morphology characteristics of the sealing surface by combining the characteristicsof the leaked gas, and finally, according to the processing parameters of the main sealing structure of the non-API oil casing pipe joint, obtaining the total sealing pre-tightening pressure of the main sealing surface, and performing calculating to obtain the total gas leakage rate of the main sealing structure, thereby obtaining the non-API oil casing pipe joint sealing performance quantitativeevaluation and prediction method. The influence of sealing machining parameters of multiple oil casing pipe joints and the characteristic of leaked gas on the leakage rate is considered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

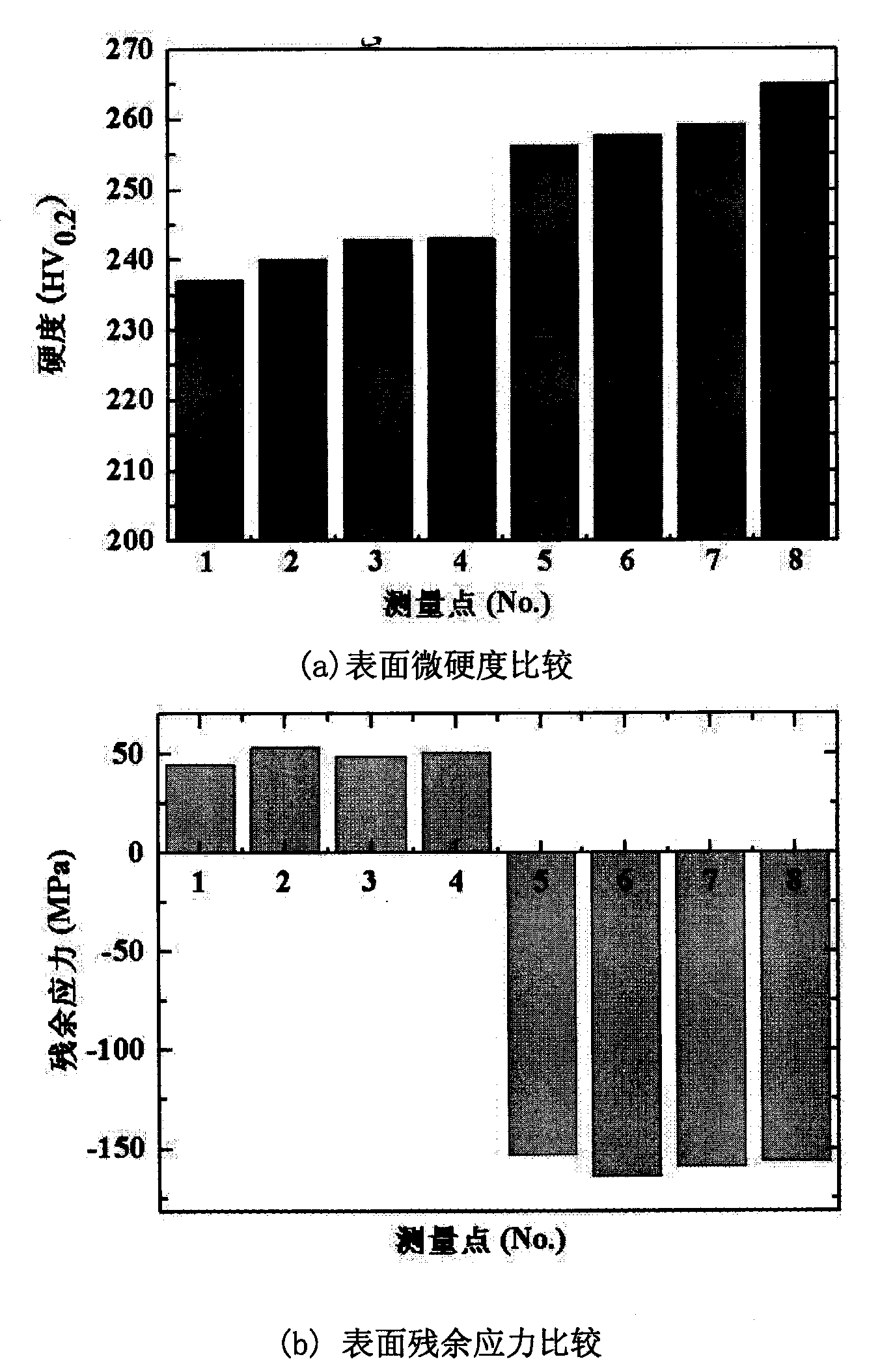

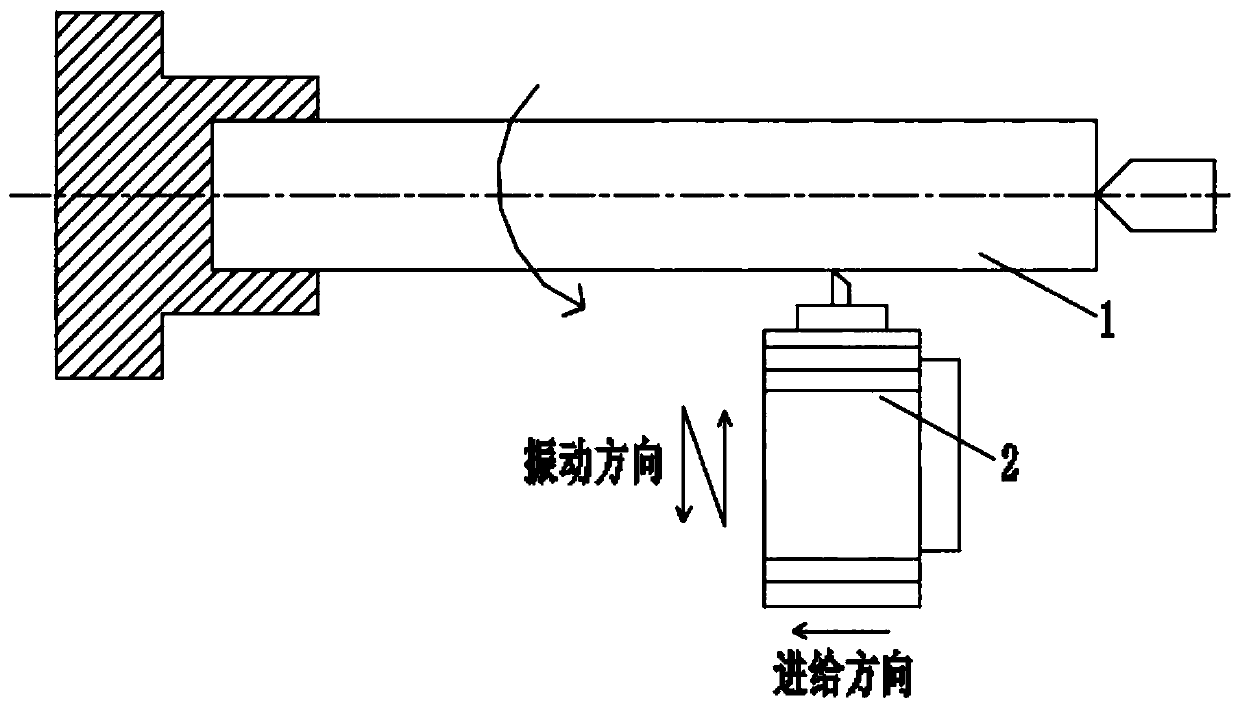

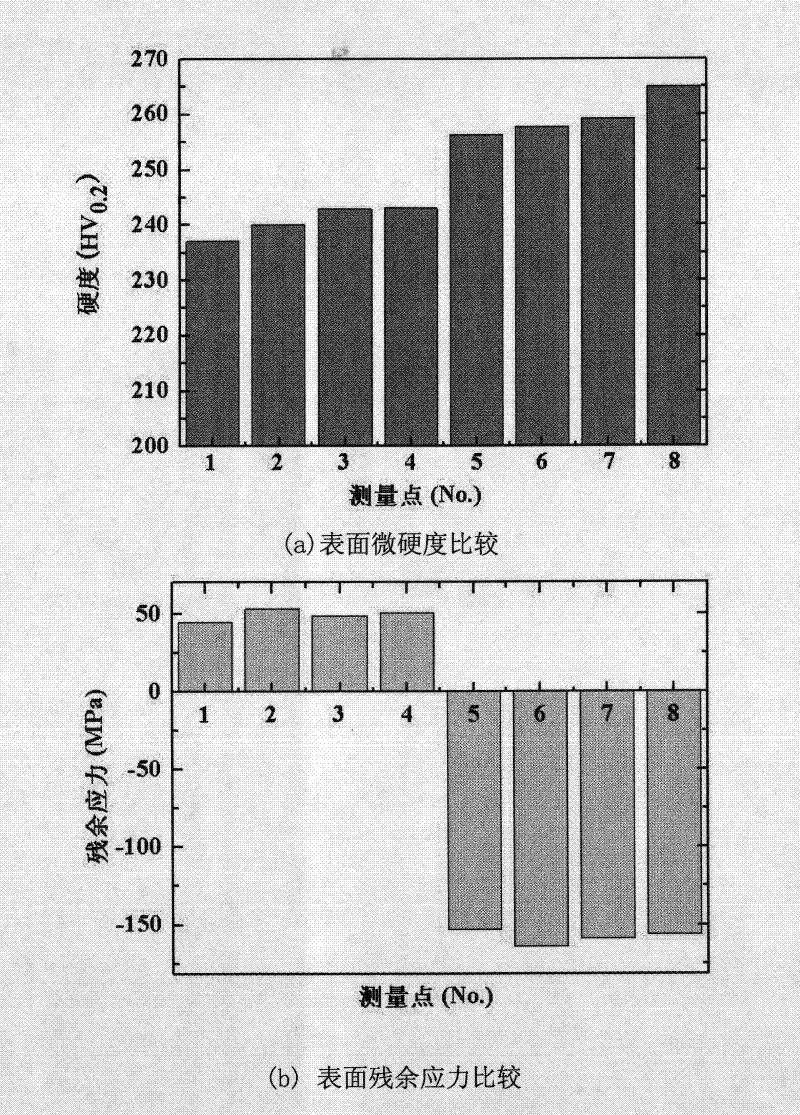

High-performance surface composite strengthening method for shaft parts

The invention discloses a high-performance surface composite strengthening method for shaft parts, and belongs to the field of surface machining of metal materials. The surface composite strengtheningmethod comprises the following steps that S1, carrying out radial vibration turning on the shaft parts, and forming a specific regular distributed micron scale / nano scale microcosmic geometrical morphology on the surfaces of the shaft parts; S2, coating the surfaces; and S3, carrying out mechanical reinforcement treatment on the coating surfaces by adopting an ultrasonic rolling processing technology. Compared with the prior art, the high-performance surface composite strengthening method for the shaft parts can greatly improve the bonding strength of a bonding interface of a base material and a coating layer, meanwhile, the hardness, the fatigue strength and the wear-resistant and corrosion-resistant shaft parts of the final forming surfaces are improved, and the method has good popularization and application values.

Owner:QILU UNIV OF TECH

Method of measuring micro-structure, micro-structure measurement apparatus, and micro-structure analytical system

ActiveUS20090066967A1Readily and accurately measureSemiconductor/solid-state device testing/measurementUsing optical meansMicro structureNon destructive

This invention provides a method and an apparatus of measuring a micro-structure, capable of evaluating a geometry of a micro-structure formed typically on the surface of a semiconductor substrate, in a non-destructive, easy, precise and quantitative manner. A reflection spectrum of a sample having a known dimension of a target micro-geometry is measured (A1), features (waveform parameters) which strongly correlate to a dimension of the measured micro-geometry are determined (A2), a relation between the dimension of the micro-geometry and the waveform parameters is found (A3), and a dimension of the micro-structure having an unknown dimension is finally determined using this relation and based on the reflection spectrum obtained therefrom (A4, A5).

Owner:RENESAS ELECTRONICS CORP

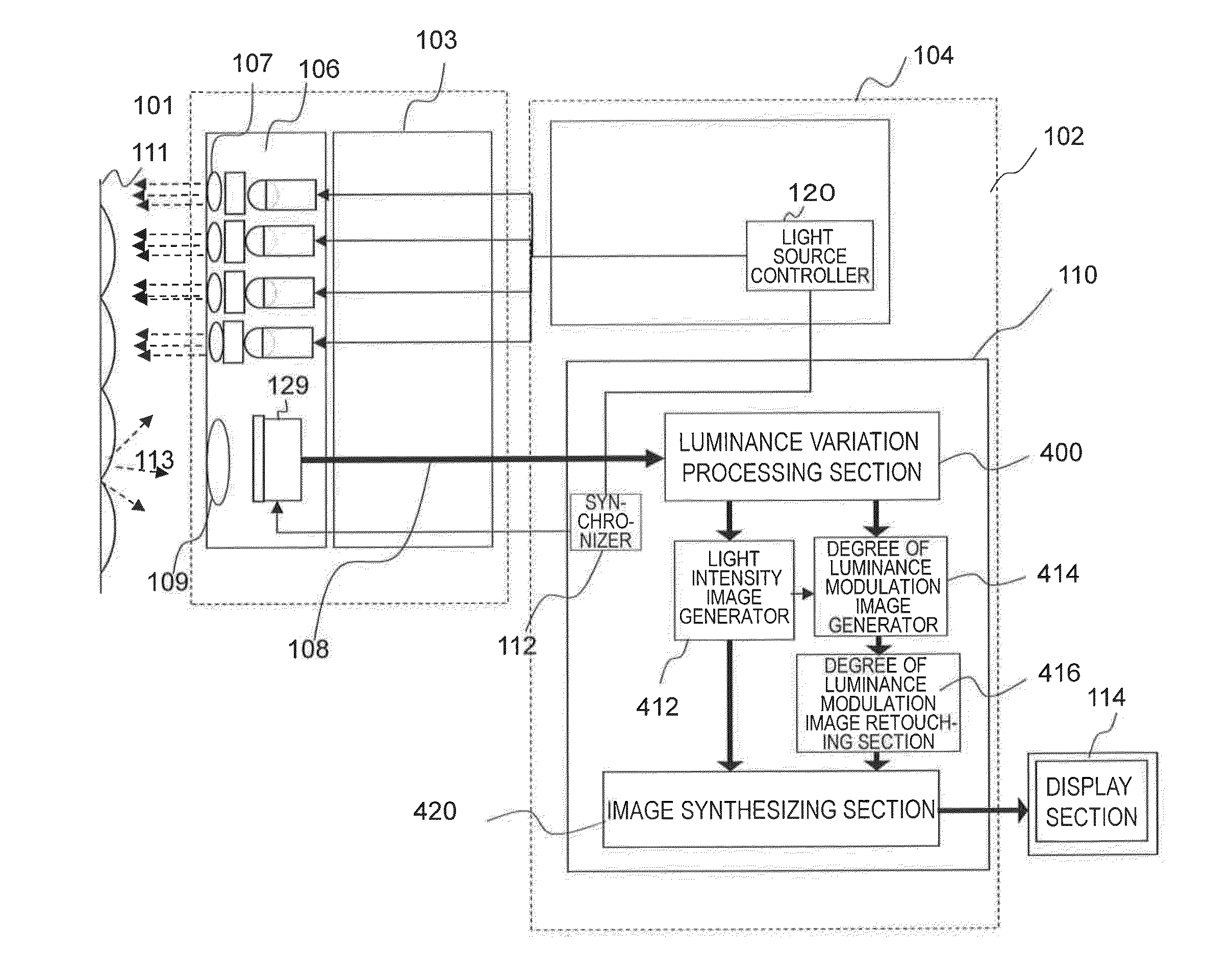

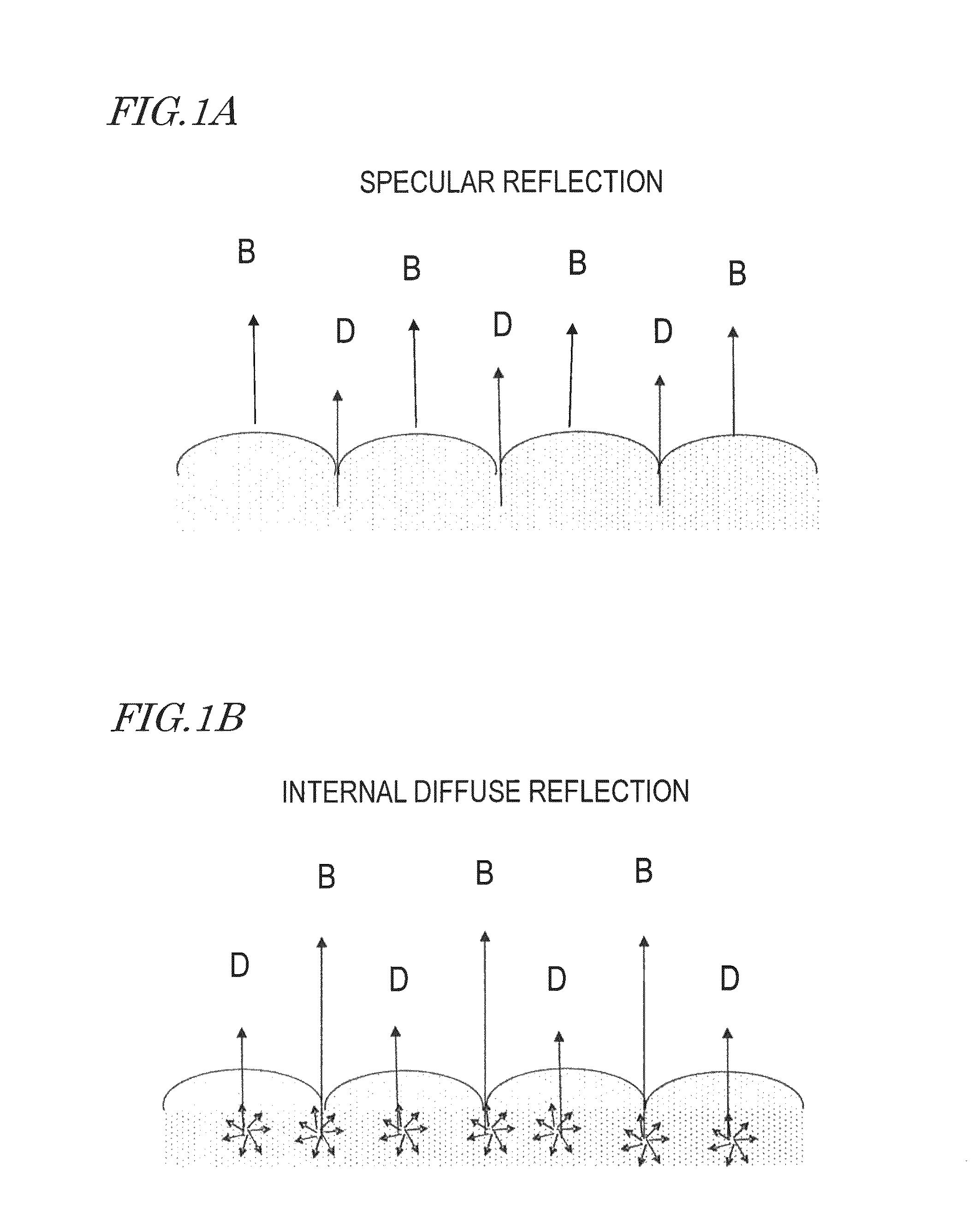

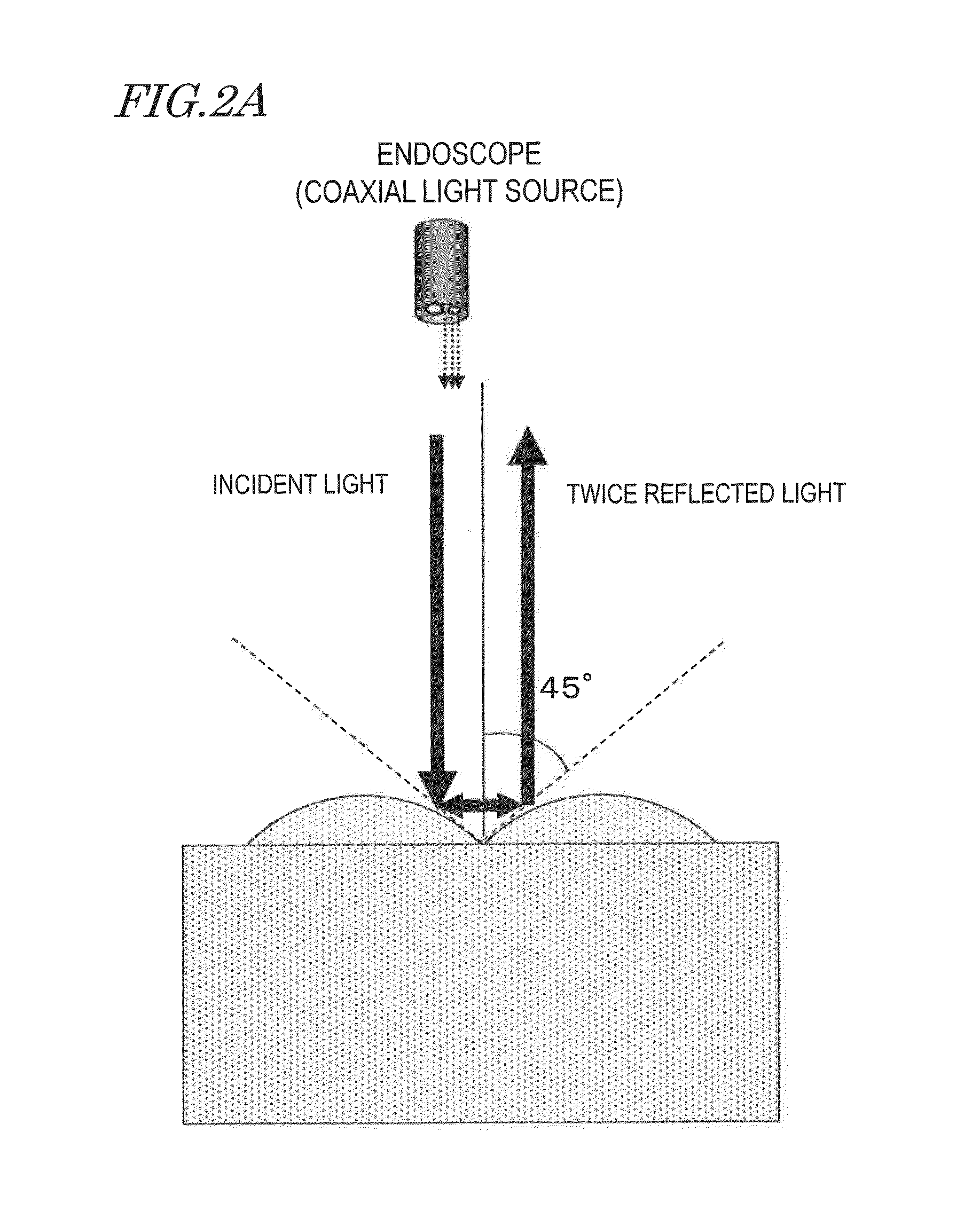

Imaging device and endoscope for detecting and displaying the shape of the micro-geometric texture of a transparent structure

ActiveUS9392231B2Degree of improvementEasily depressedTelevision system detailsSurgeryImaging processingLight beam

In image capturing processor in one embodiment comprises: an image capturing section including an image sensor that captures a polarization image of an object being illuminated with an illuminating light beam; and an image processing section. The image processing section has: a light intensity image generator which generates a light intensity image based on the output of the image sensor; a polarization degree image generator which generates a polarization degree image by calculating the degree of polarization on a pixel-by-pixel basis; a retouching section which generates a retouched polarization image by enhancing the degree of polarization of the polarization degree image at depressions on a micro-geometric surface of the object and by correcting at least one of its hue, saturation and value; and an image synthesizing section which synthesizes the retouched polarization image and the light intensity image together.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

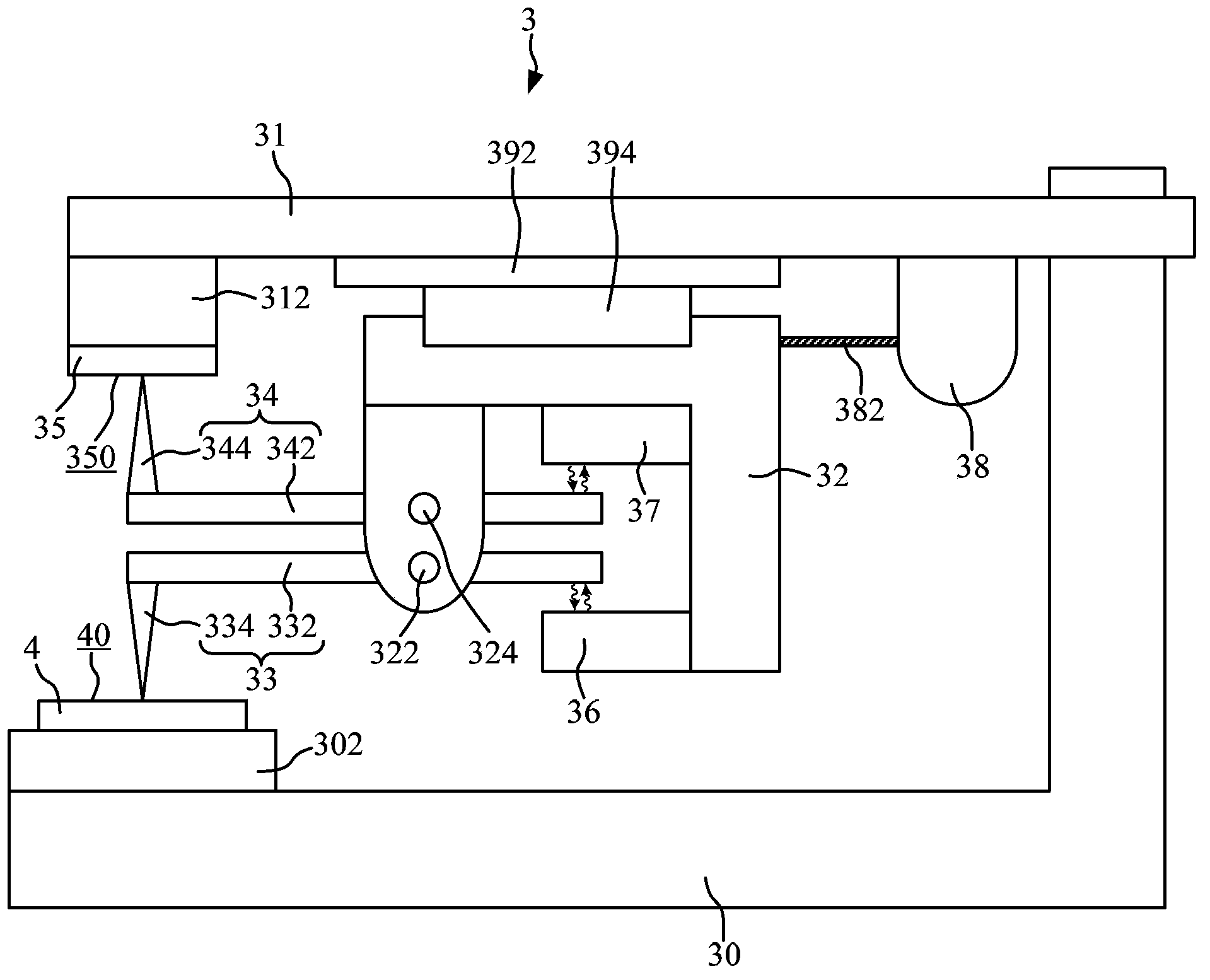

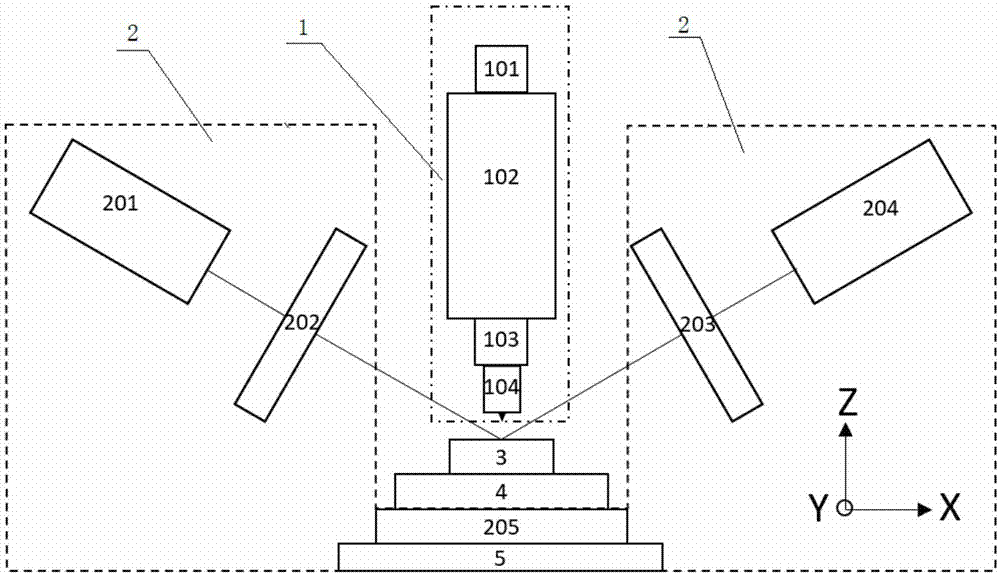

Micro geometrical morphology measurement system

InactiveCN104344791AElectric/magnetic contours/curvatures measurementsUsing optical meansPhysicsMicro geometry

The invention provides a micro geometrical morphology measurement system which is used for measuring the micro geometrical morphology of a test piece. The micro geometrical morphology measurement system comprises a first scanning device, a second scanning device and a flat substrate. The first probe of the first scanning device is contacted with the test piece. The second probe of the second scanning device is contacted with the flat substrate. The second scanning device or the flat substrate and the first scanning device are synchronously actuated so that the first probe is enabled to move on the test piece and the second probe is enabled to move on the flat substrate. The micro geometrical morphology of the test piece is obtained via calculation of first displacement of the first pivotally rotatable arm of the first scanning device and second displacement of the second pivotally rotatable arm of the second scanning device.

Owner:FORCE PRECISION INSTR

Surface polishing process for metal part

The invention discloses a surface polishing process for a metal part. The surface polishing process is specifically carried out according to the following steps that firstly, the surface of the metalpart is subjected to high pressure washing, is placed in cleaning liquid for degreasing treatment, is dried and is then ultrasonically cleaned; the metal part is then placed into a polishing solutionfor polishing, and pickling, neutralization, rinsing and drying are carried out; and finally, metal anti-rust wax is applied to the surface of the metal part. According to the surface polishing process, an environment-friendly polishing process is adopted, the operation is simple, running cost is low, safety and environmental protection are achieved, the micro-geometry shape of the metal surface can be can improved after polishing, the micro-roughness of the metal surface is reduced, and the gloss of the metal surface is improved.

Owner:宗江伟

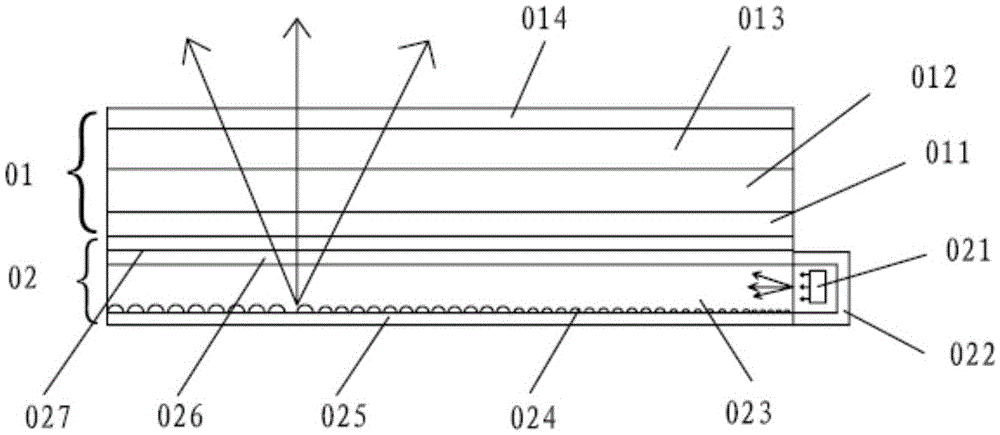

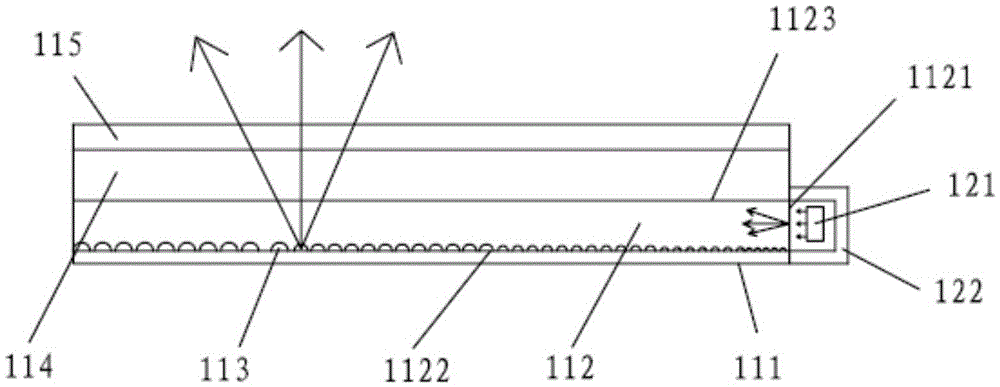

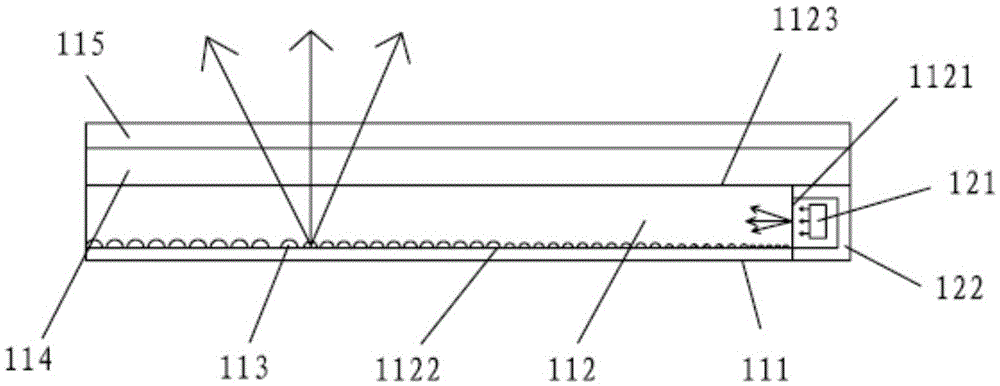

Lighting liquid crystal display panel and liquid crystal display device and display terminal

ActiveCN106292059AEvenly distributedReduce transmission mediumNon-linear opticsLiquid-crystal displayLight guide

The invention discloses a lighting liquid crystal display panel. The lighting liquid crystal display panel comprises an upper glass plate, a lower glass plate, a liquid crystal, a circuit and the like. The lower glass plate is used for achieving the light guiding function, and comprises a light inlet face, a light outlet face and a light guiding body, wherein the light inlet face is arranged on the side face of the lower glass plate and rightly opposite to light beams emitted by a light source of the light inlet face, the part of light beams directly enter the lower glass plate through the light inlet face, the other part of light beams are reflected by a reflecting cover to enter the lower glass plate through the light inlet face; the light outlet face is arranged on the upper bottom face of the lower glass plate and used for guiding out the light beams in the lower glass plate; the light guiding body is arranged on the lower bottom face of the lower glass plate or arranged inside the lower glass plate and parallel to the light outlet face; a plurality of micro geometries for reflecting or refracting the light beams are sequentially arranged on the light guiding body. By means of the lighting liquid crystal display panel, the light guiding effect of an original backlighting source can be developed through the lower glass plate, propagation media and paths of light are greatly reduced, and the using ratio of light and the light outlet efficiency of the liquid crystal display panel are improved.

Owner:宋义

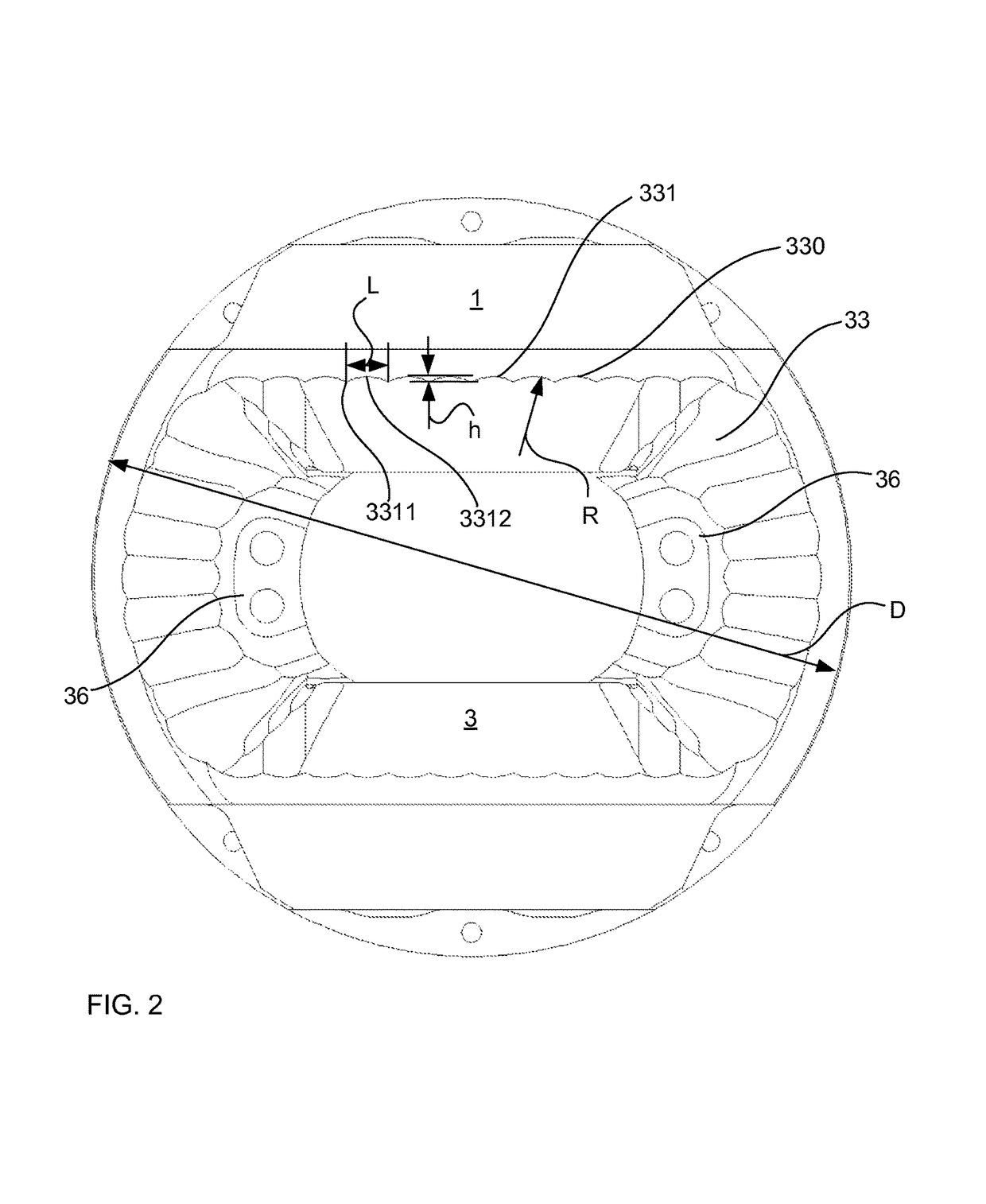

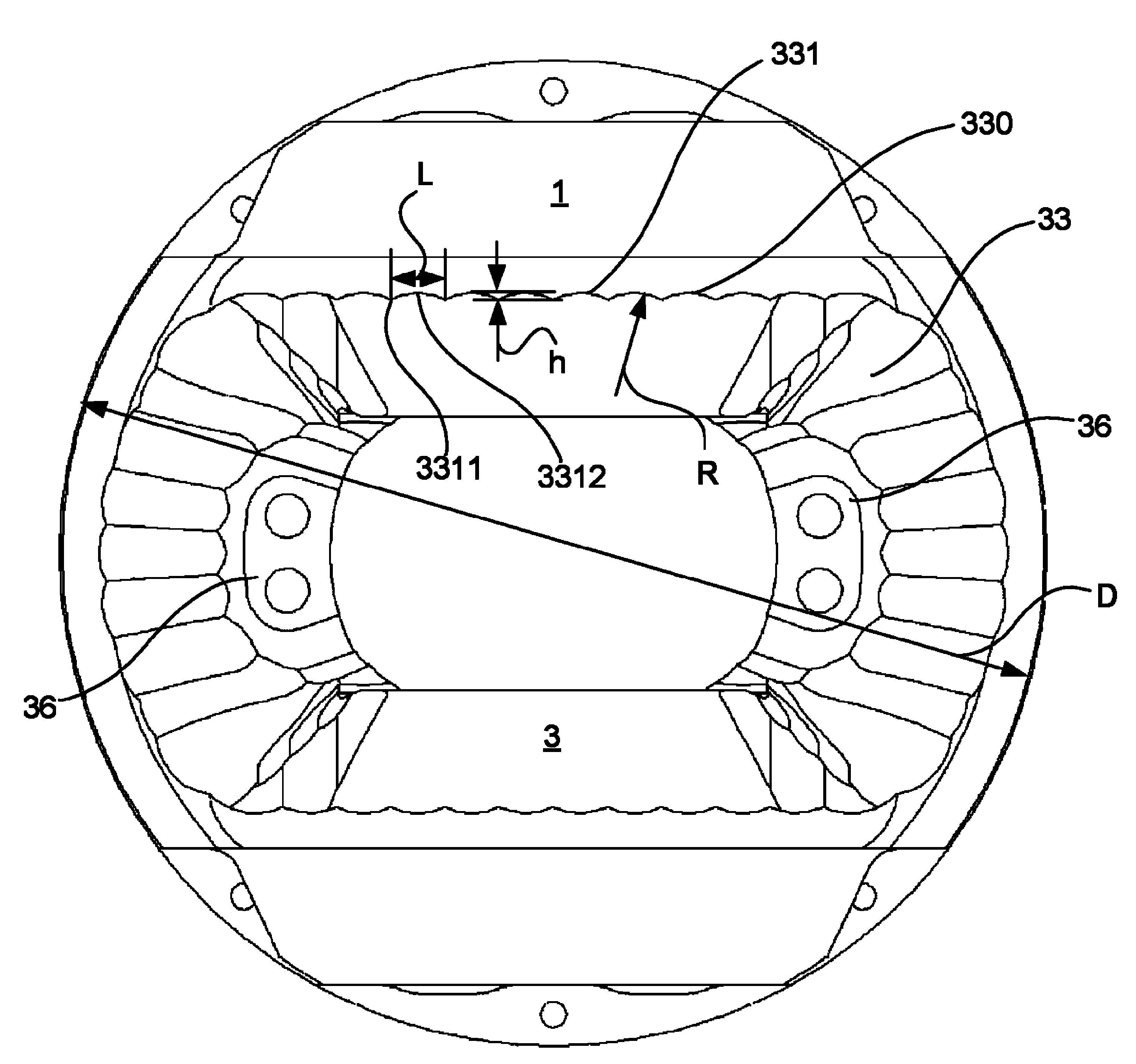

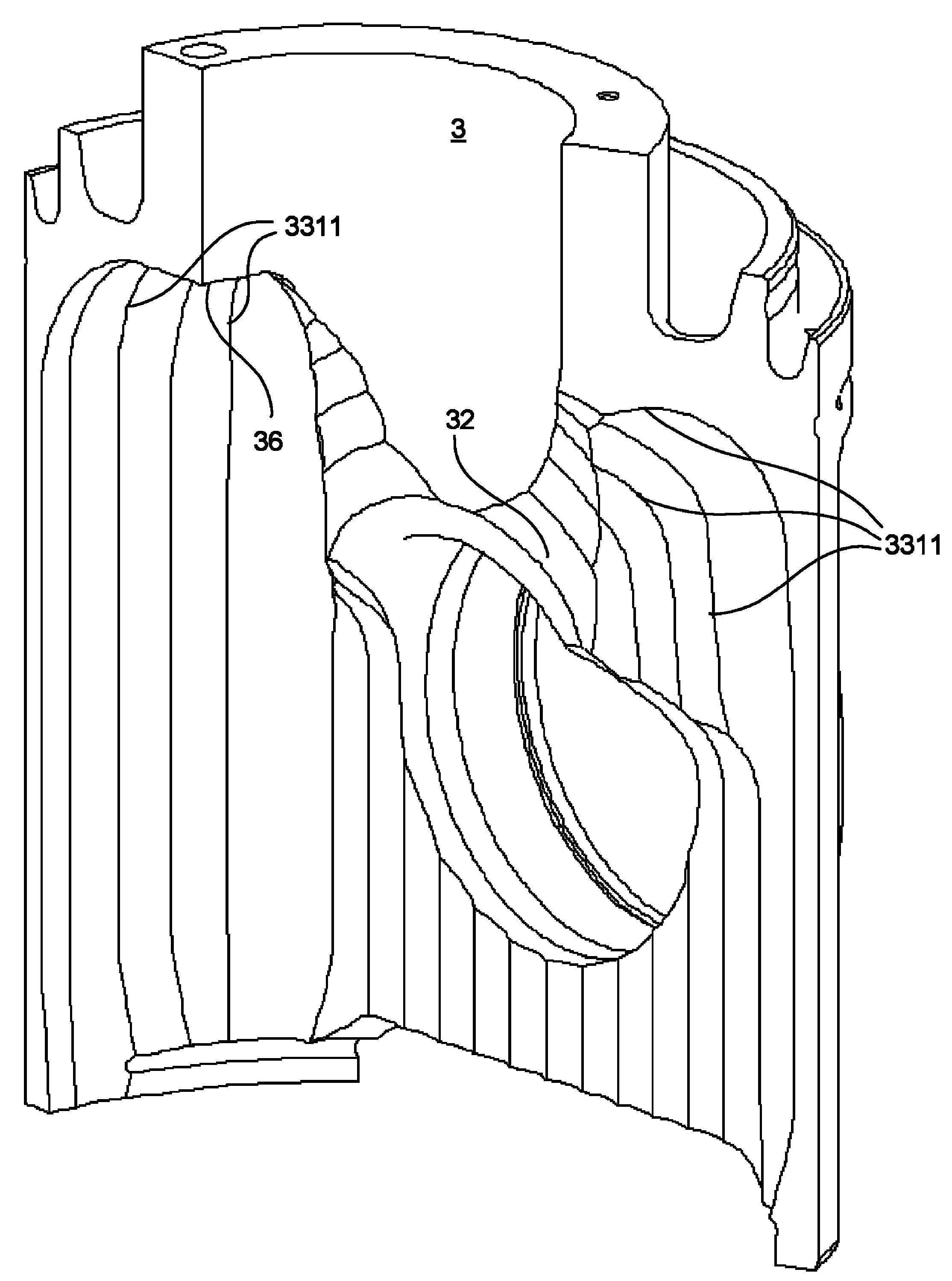

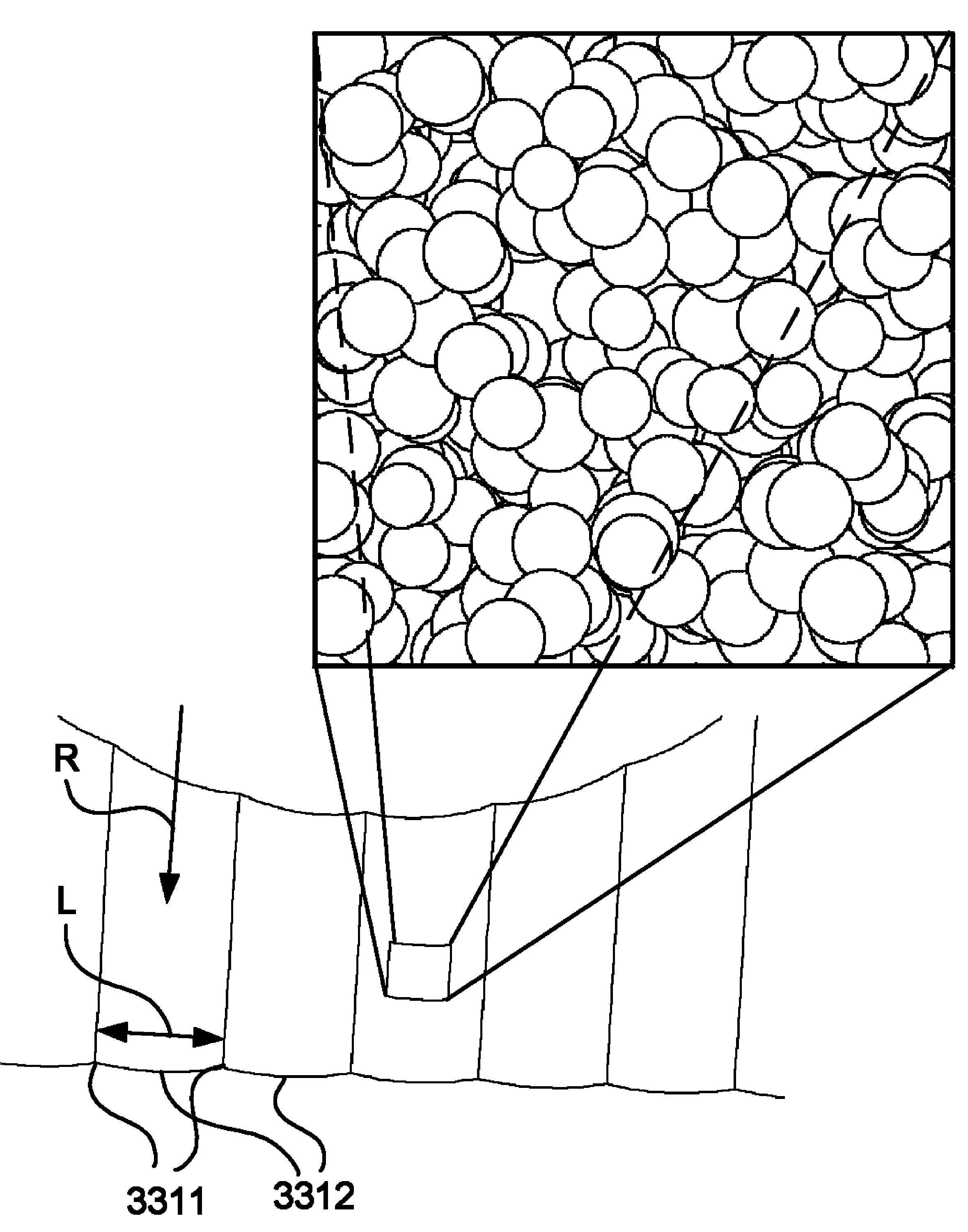

Piston for large sized internal combustion engine

ActiveUS9777668B2Increase cylinder pressureEconomical side of the piston productionBoltsMachines/enginesCombustion chamberSurface roughness

A piston for internal combustion diesel engine having a piston diameter of 180 to 650 mm, includes a top part and a body part connectable to each other, the top part defining, when installed in a cylinder of the engine, the piston side of a combustion chamber, and the body part having an aperture for a gudgeon pin, bosses for distributing forces, when in use, between the piston and the gudgeon pin, the body part having an interior, an outer surface and operable connecting surfaces. The interior of the body part includes an interior wall having a macro geometry of wavy surface, where a wave has a length of 3 to 25 mm and a height of 0.3 to 3 mm, the wavy surface having a micro geometry measurable as a surface roughness of 5 to 9 μm.

Owner:COMPONENTA FINLAND

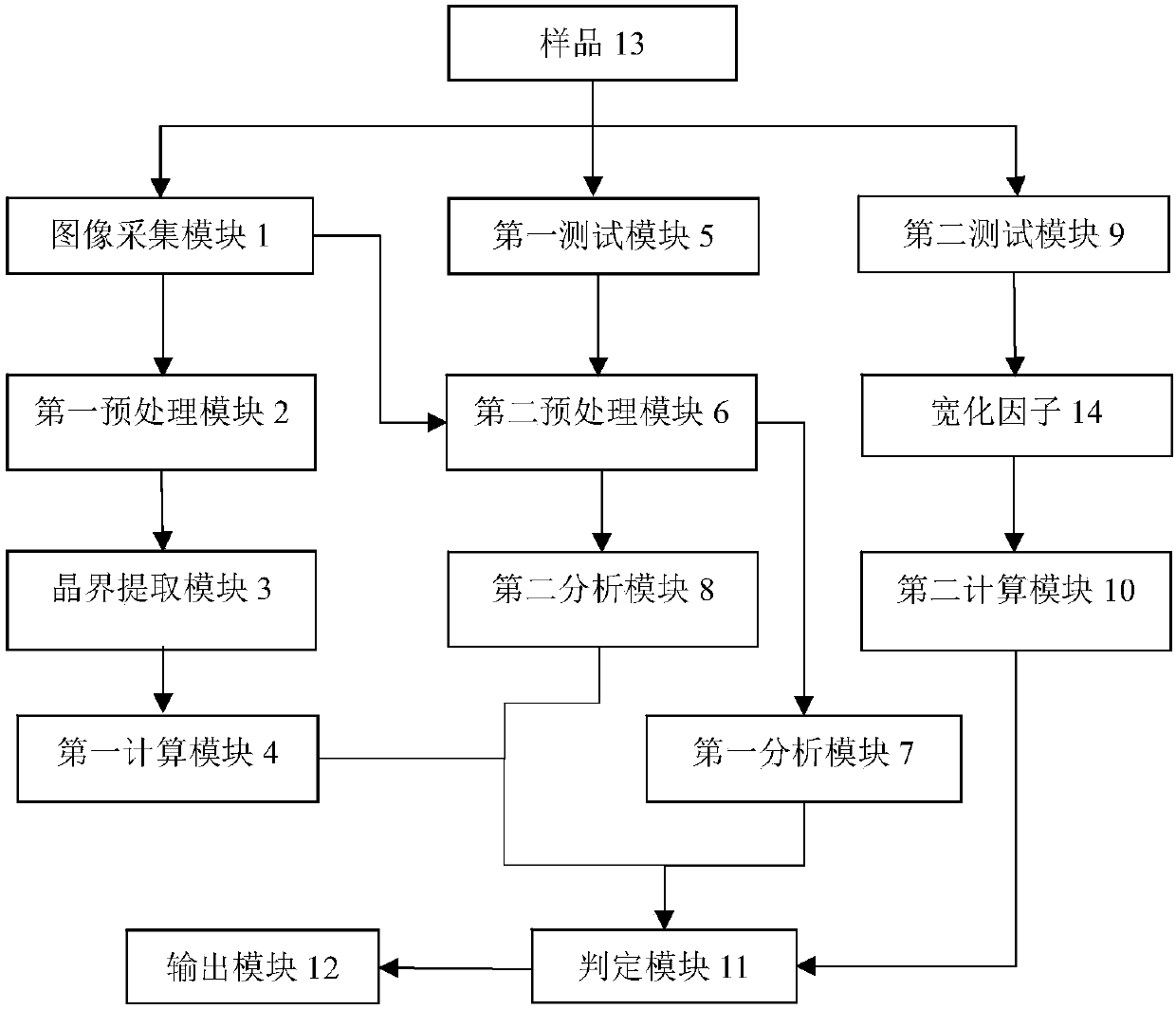

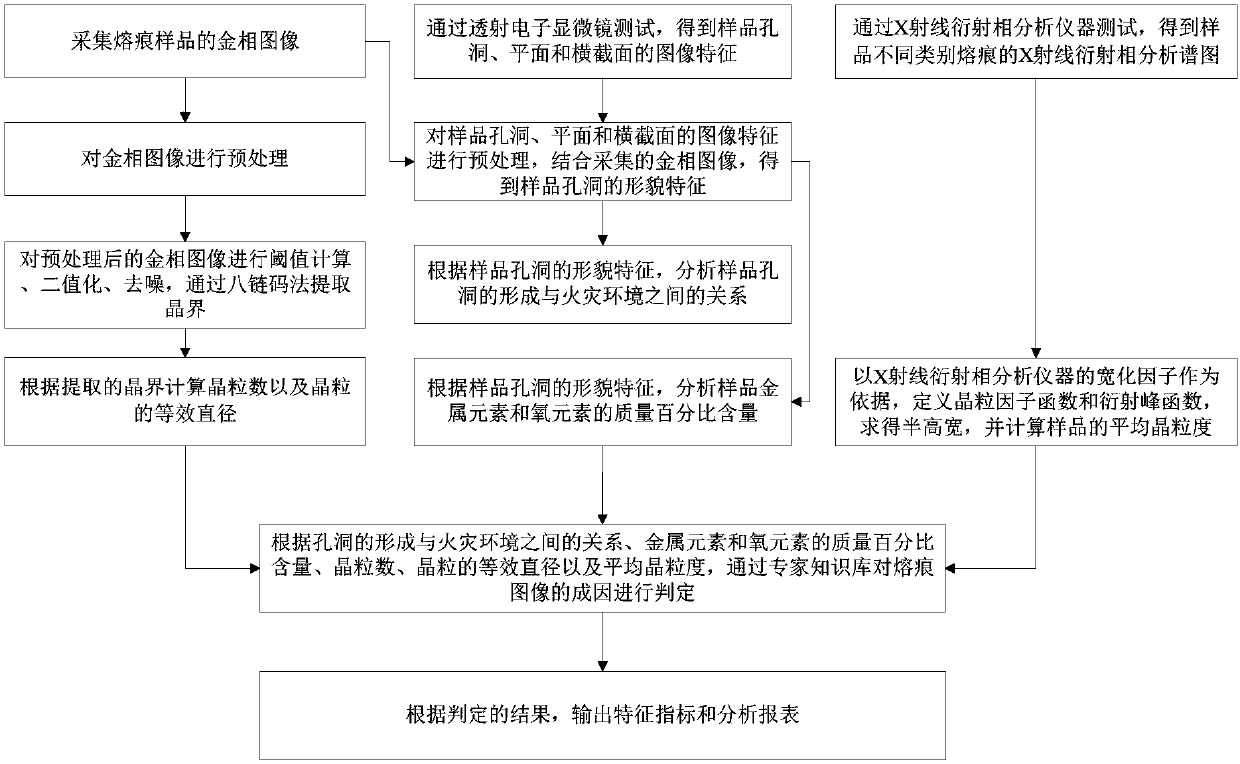

Metal fire melted mark quantitative metallography and phase analysis system and method

InactiveCN107807074AImprove identification efficiencyImprove accuracyImage analysisParticle size analysisAdditive ingredientX-ray

The invention discloses a metal fire melted mark quantitative metallography and phase analysis system and method. The system comprises an image collecting module, a first preprocessing module, a crystal boundary extracting module, a first test module, a second preprocessing module, a first analysis module, a second analysis module, a second test module, a second test module, a judgement module andan output module. The quantitative assessment analysis can be performed on the morphology, the element ingredient, the phase ingredient, the crystal particle number and the crystal particle size of metal fire melted marks, so that the fire evidence identification efficiency and accuracy are improved; according to regional melted mark transmission electron microscopy test and X-ray diffractive phase analytical instrument test, data mining and image processing machines can be used for recognition; the microscopic geometry size, the morphological characteristics, the regional element ingredientand structure, the phase ingredient and the phase ingredient distribution rule of the metal fire melted marks in different firing modes are uncovered; the serialized, systematized and standardized study on the fire marks is realized.

Owner:黄靖淳

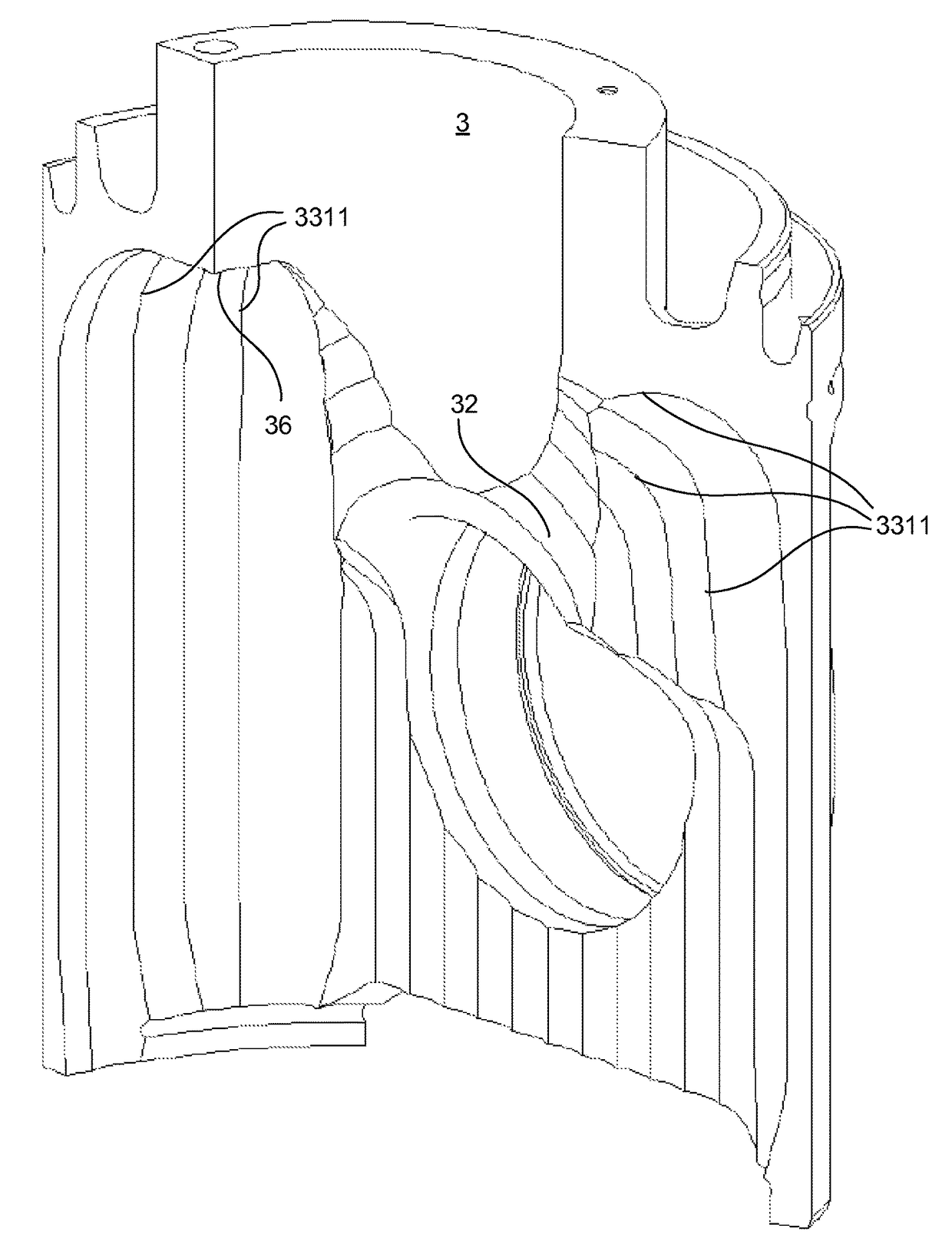

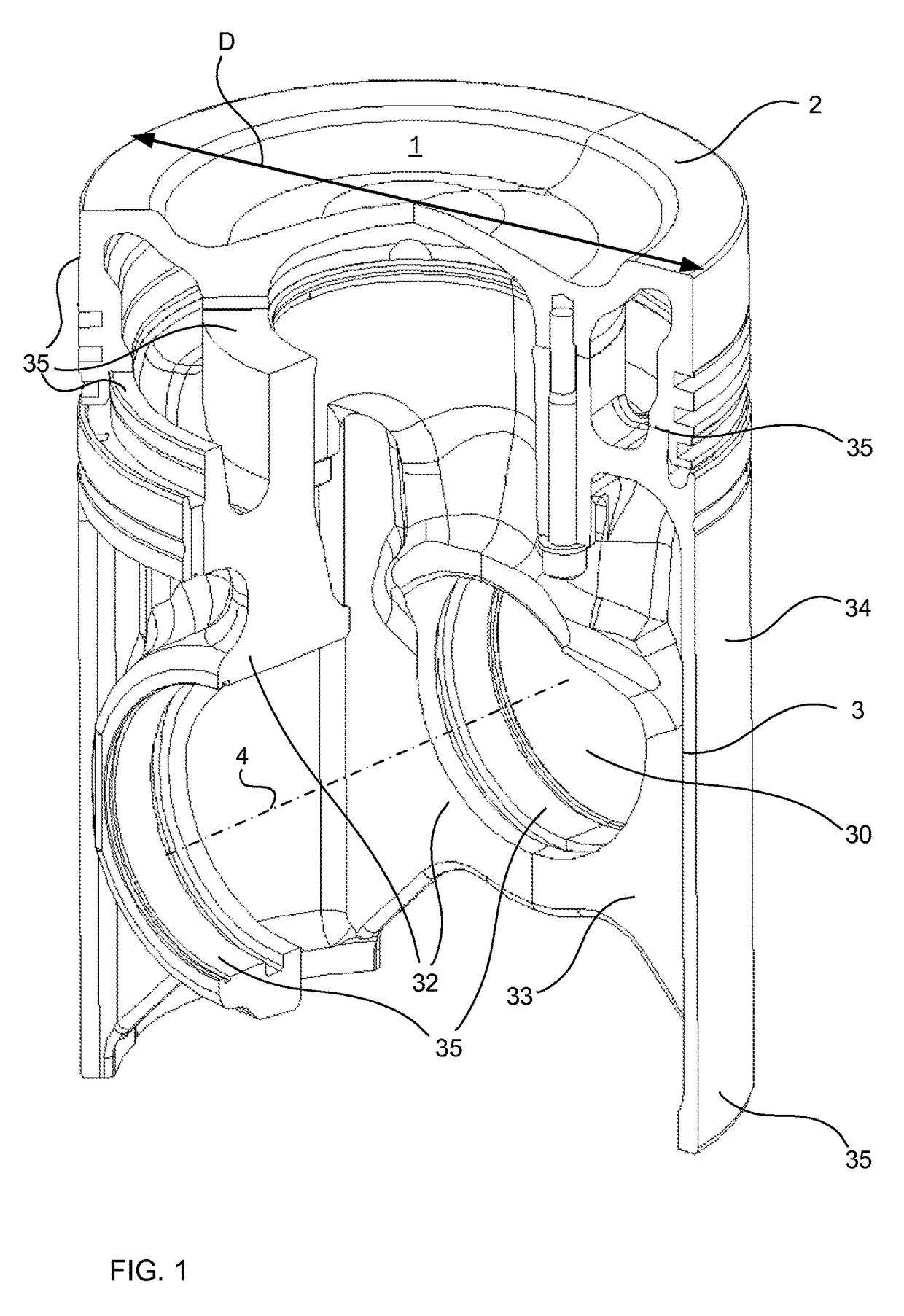

Piston for large sized internal combustion engine

ActiveCN104204485AImprove fatigue resistanceGuaranteed manufacturing costMachines/enginesPistonsCombustion chamberSurface roughness

A piston (1) for internal combustion diesel engine having a piston diameter (D) of 180 to 650 mm, the piston (1) comprising a top part (2) and a body part (3) connectable to each others, - the top part (2) defining, when installed in a cylinder of the engine, the piston (1) side of a combustion chamber, and - the body part (3) having an aperture (30) for a gudgeon pin (4), bosses (32) for distributing forces, when in use, between the piston (1) and the gudgeon pin (4), the body part (3) having an interior (33), an outer surface (34) and operable connecting surfaces (35). The interior (33) of the body part (3) comprises an interior wall (or surface) (330) having a macro geometry of wavy (331) surface, where a length (L) of a wave (331) is 3 to 25 mm and a height (h) of a wave (331) is 0,3 to 3 mm, the wavy surface having a micro geometry measurable as a surface roughness of 5 to 9 mum.

Owner:COMPONENTA FINLAND

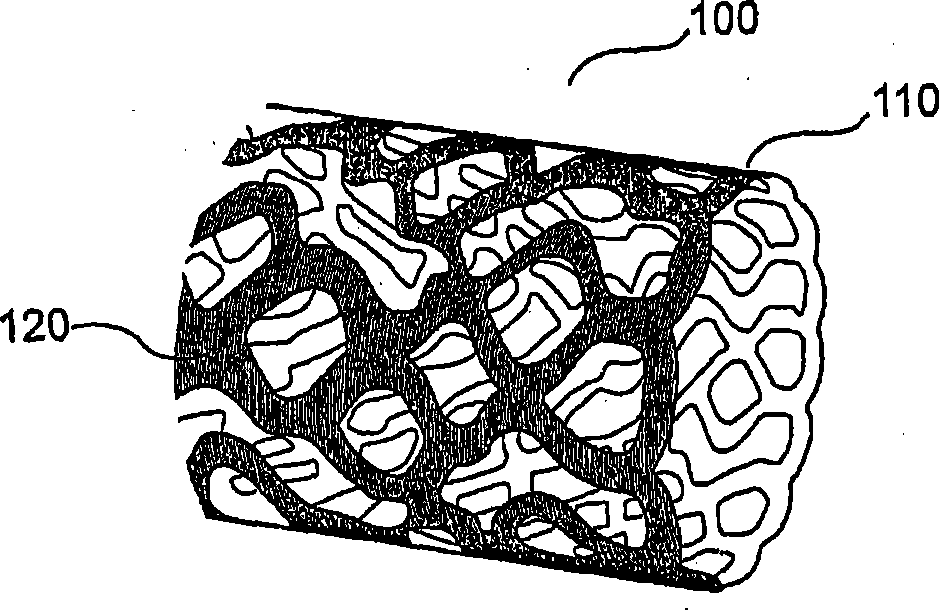

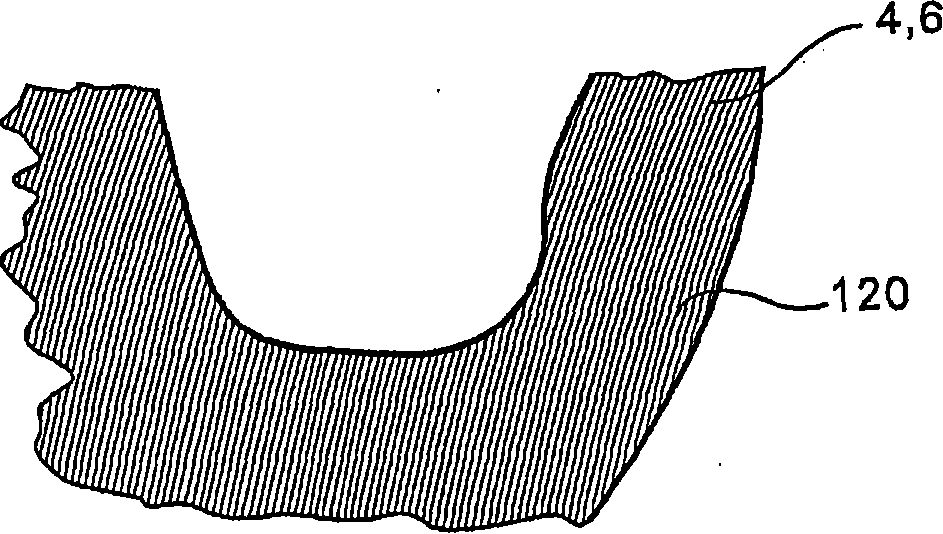

Surgical stent having micro-geometric patterned surface

A surgical stent having thereon micro-geometric patterned surface and the method of use for inhibiting smooth muscle cell growth into stent lumen are disclosed. The surgical stent has a generally cylindrical stent frame configured to be implanted into a body lumen, and the stent frame has thereon a micro-geometric patterned surface with includes a multiplicity of microgrooves distributed in a pre-determined pattern. Each of the microgrooves has a width in a range of from about 4 to about 40 microns and a depth in a range of from about 4 to 40 microns. The surgical stent can further include drug wells, and the surgical stent can have a biocompatible chemical compound, such as thrombosis inhibitor or cell growth inhibitor, embedded in the microgrooves or drug wells.

Owner:BIOLOK INT

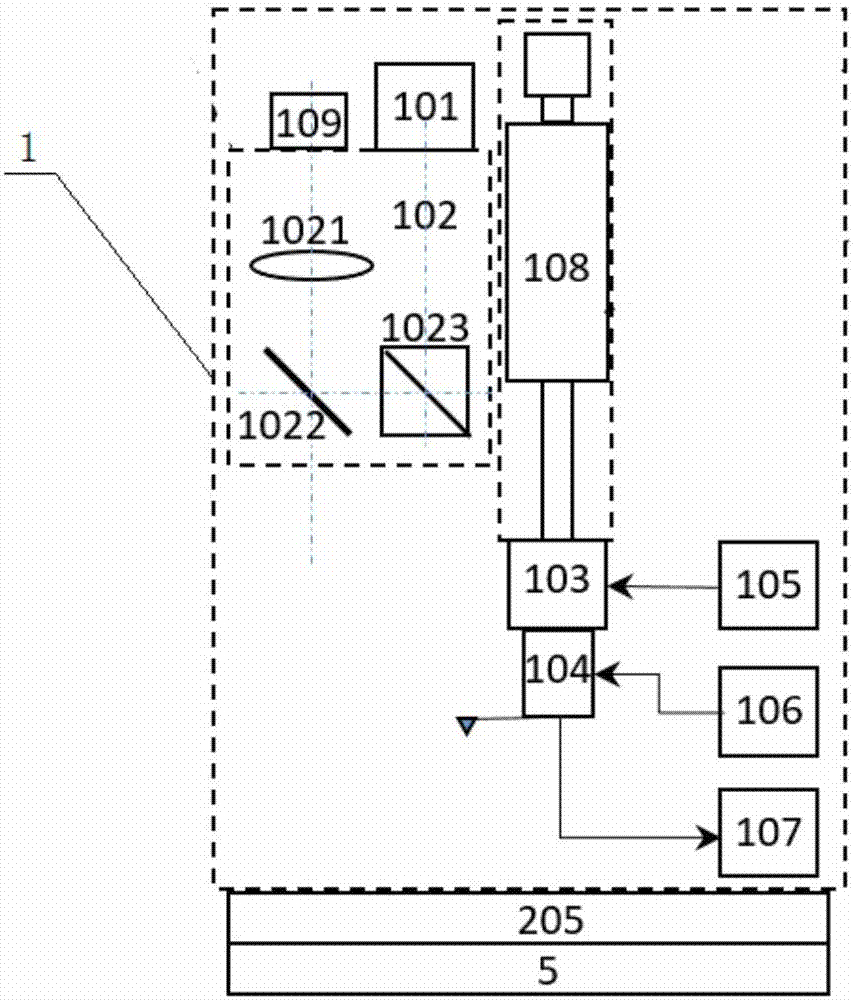

Method and device for compositely preparing surface-layer biomimetic structure by laser

InactiveCN101590569BNo wearSimple processLaser beam welding apparatusNanosecond laserLaser processing

The invention relates to the field of laser processing, in particular to a method and a device for compositely preparing a surface-layer biomimetic structure by mechanical effects based on laser carving and laser shock, which are particularly suitable for processing a biomimetic surface and a friction pair surface. The method is characterized by comprising the following steps: firstly preparing aregular micro geometrical appearance with certain density (space), width, depth, angle and shape on the surface of a workpiece by the laser carving technology; and then forcedly processing the micro geometrical appearance area by laser shock to process a microstructure which has the required shape and management mode and is optimally matched with the requirement of lubricating property on the surface of the workpiece. The device for the implementation method comprises a control device, a nanosecond laser generator, a laser beam I, a light guide tube I, a totally reflecting mirror I, a light spot adjusting device I, a fiber laser, a laser beam II, a light guide tube II, a totally reflecting mirror II, a light spot adjusting device II, an automatic spraying device, a restrain layer, an absorption layer, the workpiece, a workpiece fixture system and a five-axis working platform.

Owner:JIANGSU UNIV

Scanning probe-elliptical polarization multifunctional coupling in-situ measurement device

ActiveCN107884599AEasy to operateAccurate image of test resultsScanning probe techniquesMeasurement deviceInteraction point

The invention discloses a scanning probe-elliptical polarization multifunctional coupling in-situ measurement device comprising an XY micro-motion scanner, a scanning probe microscopic measurement mechanism and an elliptical polarization light measurement mechanism. An under measurement sample support, a Z-axis piezoelectric micro-motion scanner and the XY micro-motion scanner and an XYZ coarse motion scanner are connected in series along an Z axis and rigidly connected with the scanning probe measurement mechanism on a pedestal. The tip of the scanning probe is on the interaction point of theincident light and the reflected light of the elliptical polarization light measurement mechanism, and the YZ plane formed by the scanning probe and the Z-axis is perpendicular to the XZ plane on which the incident light and the reflected light of the elliptical polarization light measurement mechanism are located. The beneficial effects of the device are that macro optical thickness and micro geometric information of the work sample can be measured in an in-situ, synchronous and real-time way, and operation is convenient, test is accurate and vivid and the measurement characterization efficiency is high.

Owner:TIANJIN UNIV

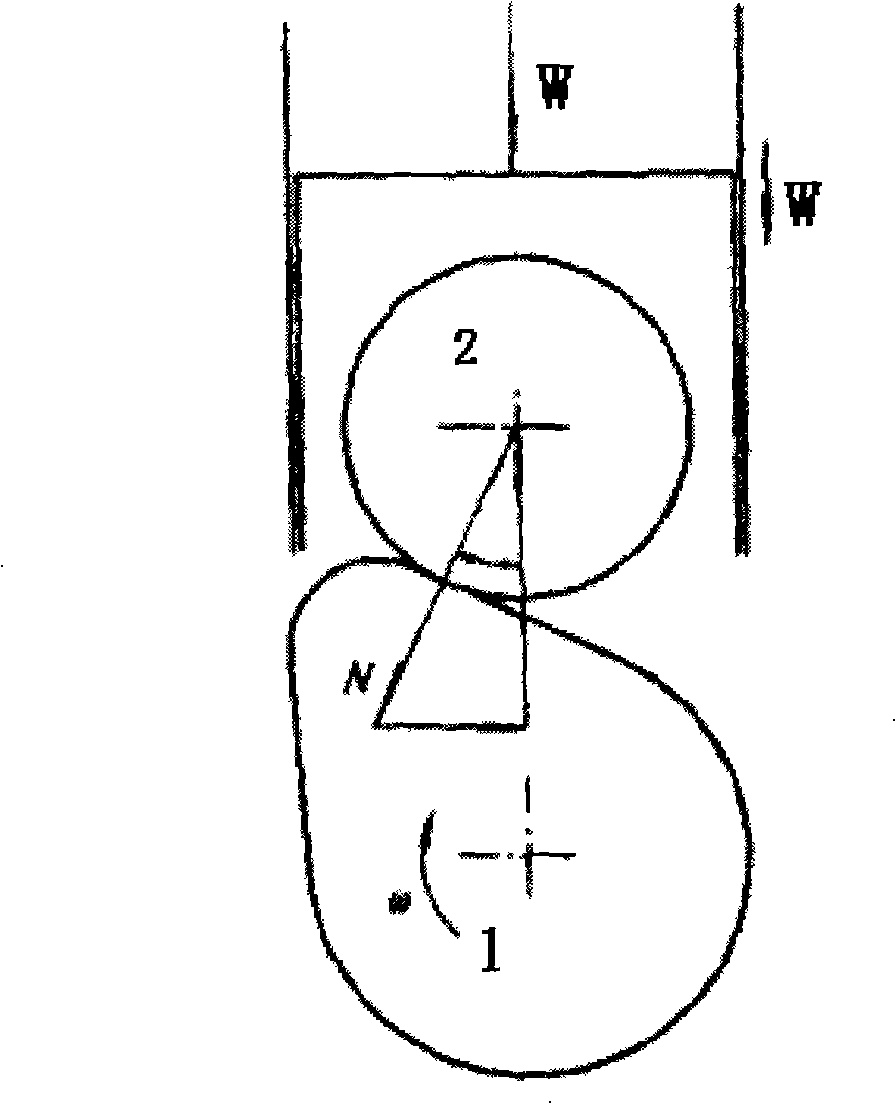

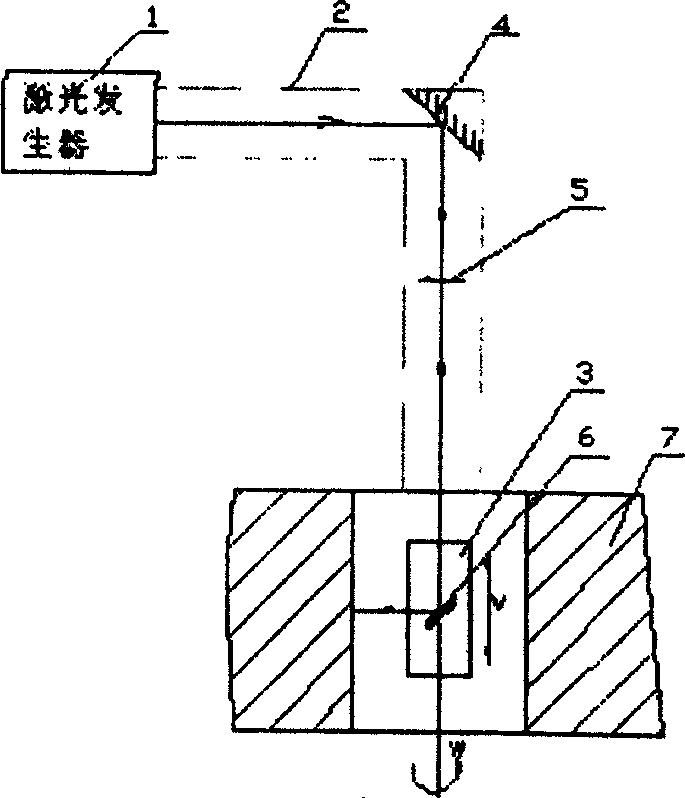

Method for laser compound treating surface of friction pair

InactiveCN1171700CImprove the lubrication effectImprove wear resistance and anti-wear performanceFurnace typesLaser beam welding apparatusLaser technologyMicroscopic scale

A laser technology for processing the surface of friction set, especially the inner surface of cylinder for IC engine, to generate an antiwear hardened layer and a microscopic geometry for lubricating is disclosed. Two laser device with different parameters are used to respectively generate the microscopic pits and hardened layer in the region to be seriously abrased and the microscopic geometry for higher lubricating performance in other regions.

Owner:JIANGSU UNIV

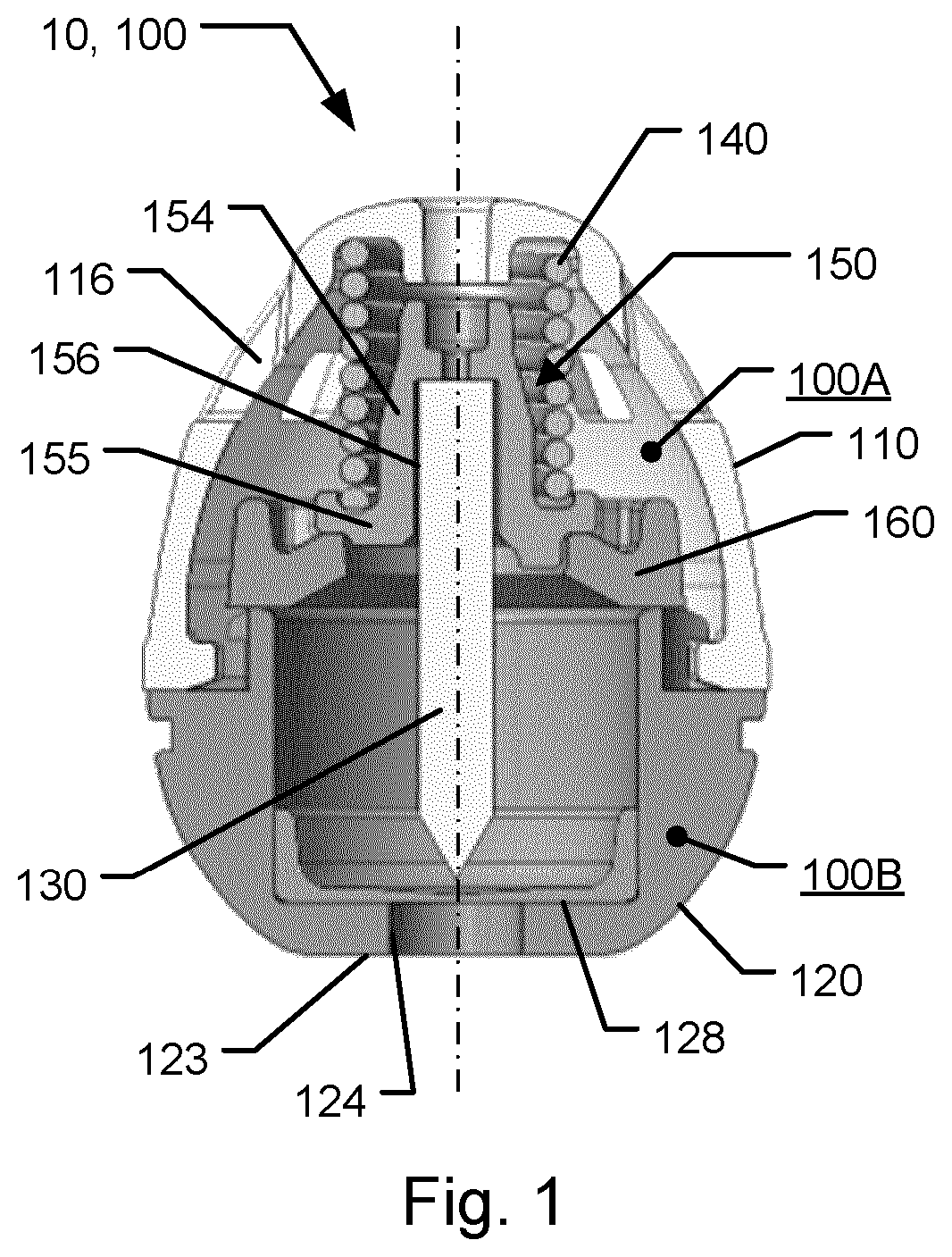

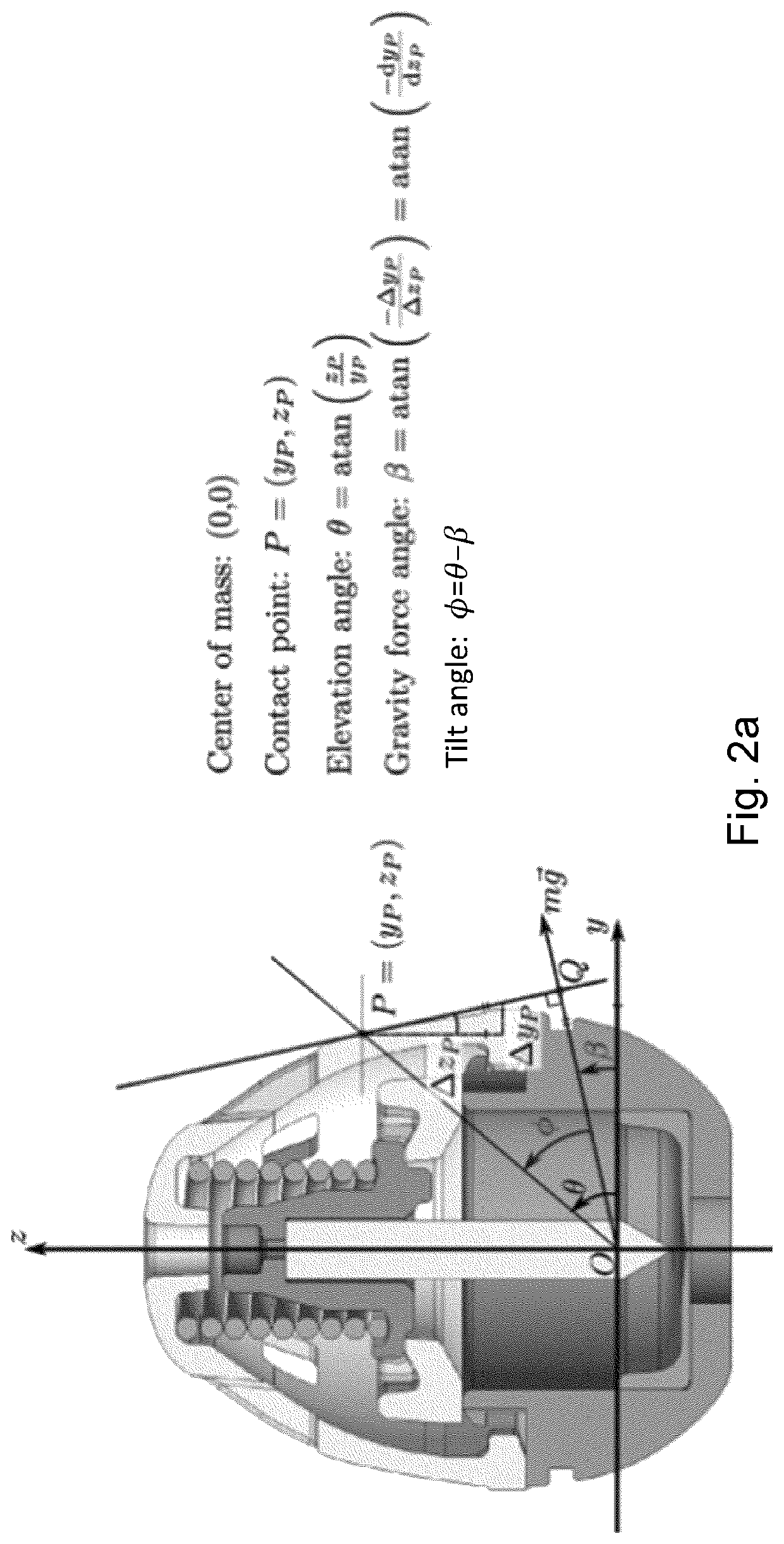

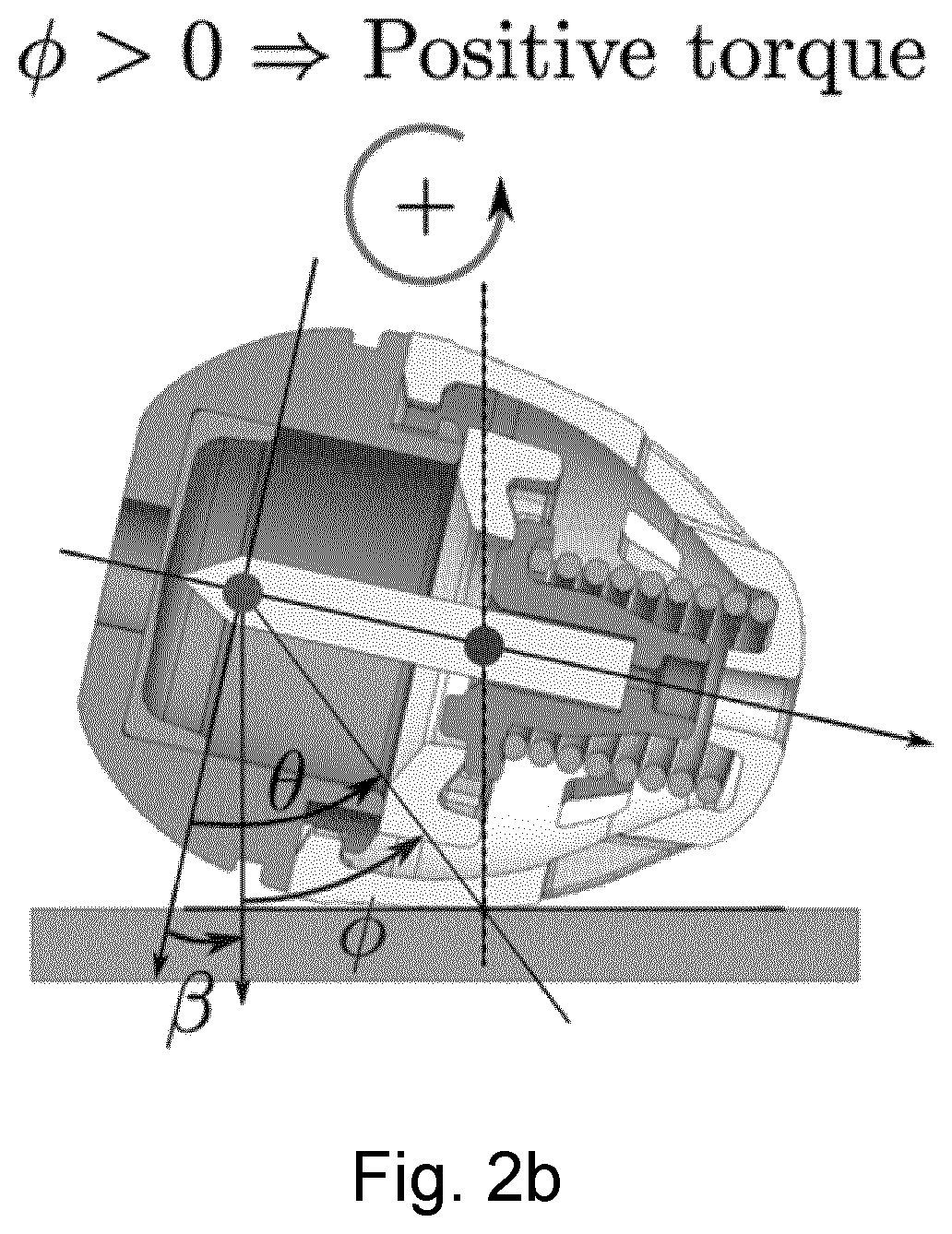

Capsule device having improved self-righting ability

PendingUS20220265560A1Reduce frictionReduce static frictionAutomatic syringesMedical devicesAnatomySurface roughness

A capsule device suitable for insertion into a lumen of a patient, the lumen having a lumen wall, wherein the capsule device (100, 200, 300, 400, 500) comprises a) a capsule housing (110, 120, 210, 220) having an outside shape formed as a rounded object and defining an exterior surface, and b) a tissue interfacing component (130, 230) disposed relative to the capsule housing (110, 120, 210, 220), the tissue interfacing component (130, 230) configured to interact with the lumen wall at a target location, wherein the capsule device is configured as a self-righting capsule having a geometric center and a center of mass offset from the geometric center along a first axis, wherein when the capsule device (100, 200, 300, 400, 500) is supported by the tissue of the lumen wall while being oriented so that the centre of mass is offset laterally from the geometric center the capsule device experiences an externally applied torque due to gravity acting to orient the capsule device with the first axis oriented along the direction of gravity to enable the tissue interfacing component (130, 230) to interact with the lumen wall at the target location, wherein at least a portion of the exterior surface of the capsule device (100, 200, 300, 400, 500) has a surface property exhibiting one or more surface properties selected from the group consisting of a surface coating, a surface roughness, a surface geometry, and a surface micro-geometry, and wherein said surface property is selected to provide low friction, such as low static friction, ensuring slipping movement of the capsule device relative to the tissue of the lumen wall when said externally applied torque due to gravity acts on the capsule device.

Owner:NOVO NORDISK AS

Tool spindles of devices for the finishing of optically active surfaces on workpieces

ActiveCN109153102BAvoid errorsOptical surface grinding machinesFeeding apparatusEffective surfaceMacroscopic scale

The invention relates to a tool spindle (10) of a device (12) for finishing an optically active surface (cc, cx) on a workpiece (L), with a spindle housing (14) and a tool holding section protruding beyond the housing (16). The tool holding section is axially advanced (advance axis Z) towards the workpiece along the tool axis of rotation via a guide assembly (18) which is housed in the spindle housing Can be rotated about the tool rotation axis (A). For axial advancement of the tool holding section, the guide assembly has: a plurality of linear mounting elements (20) evenly distributed around the tool axis of rotation; and corresponding pairs of guide rods (22), which are connected in a tension- and pressure-resistant manner to the tool holding section. As a result, the tool holding section can follow the macroscopic geometry of the workpiece in a smooth and fine manner when machining the microscopic geometry of the workpiece.

Owner:SATISLOH AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com