High-performance surface composite strengthening method for shaft parts

A technology of shaft parts and surface compounding, applied in the field of surface processing of metal materials, can solve the problems of weak film/base bonding force, short service life, high surface roughness, and solve the problem of bonding strength, environmental friendliness, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

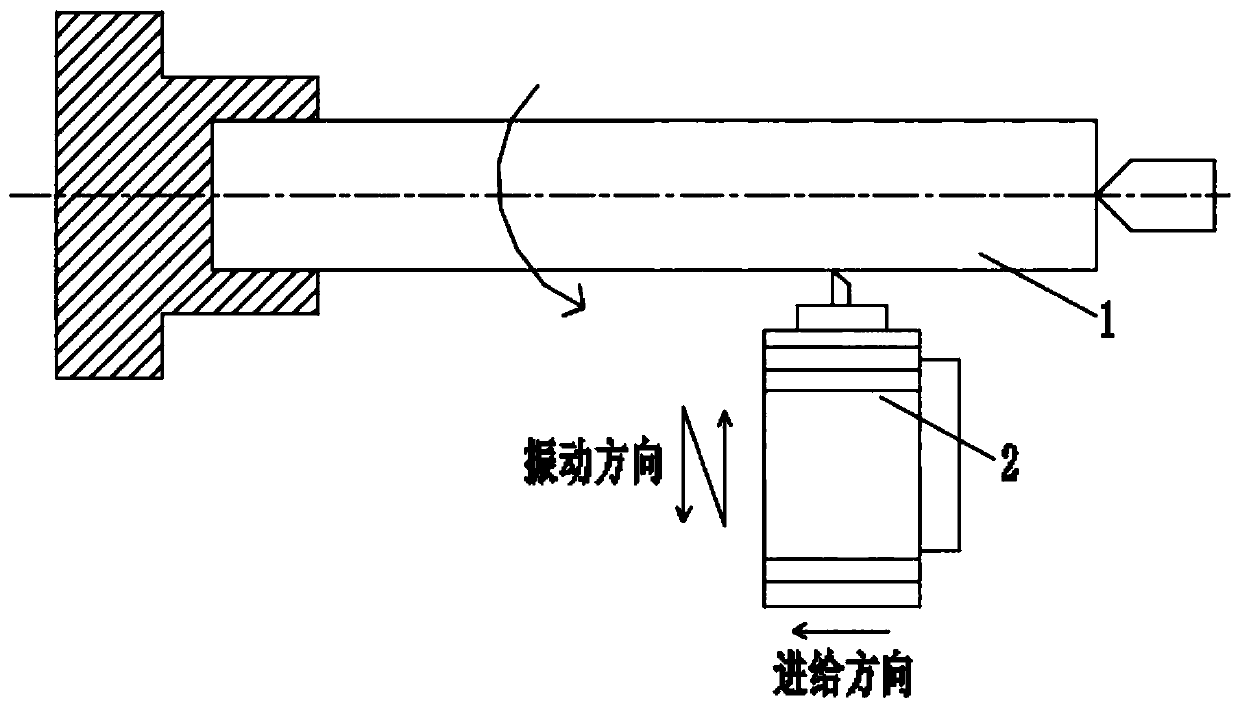

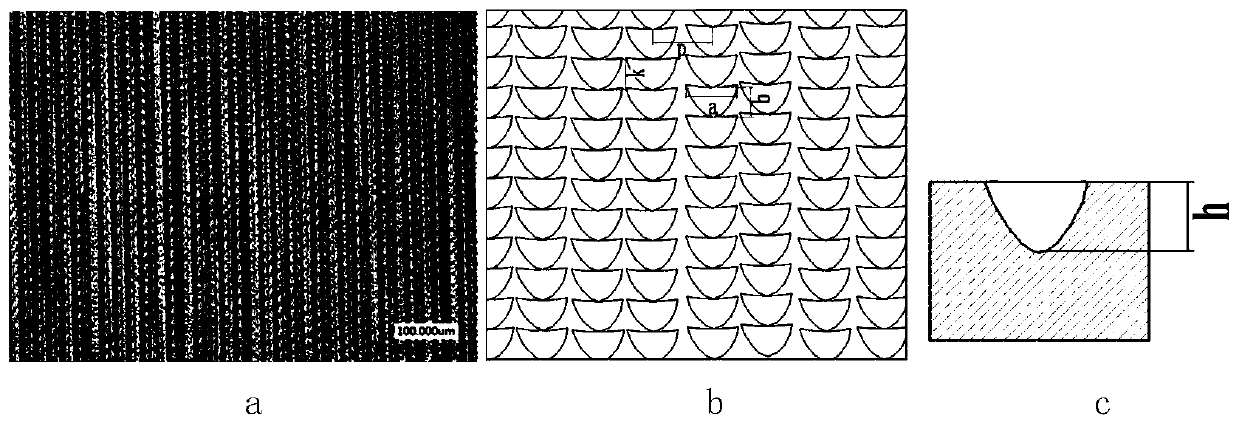

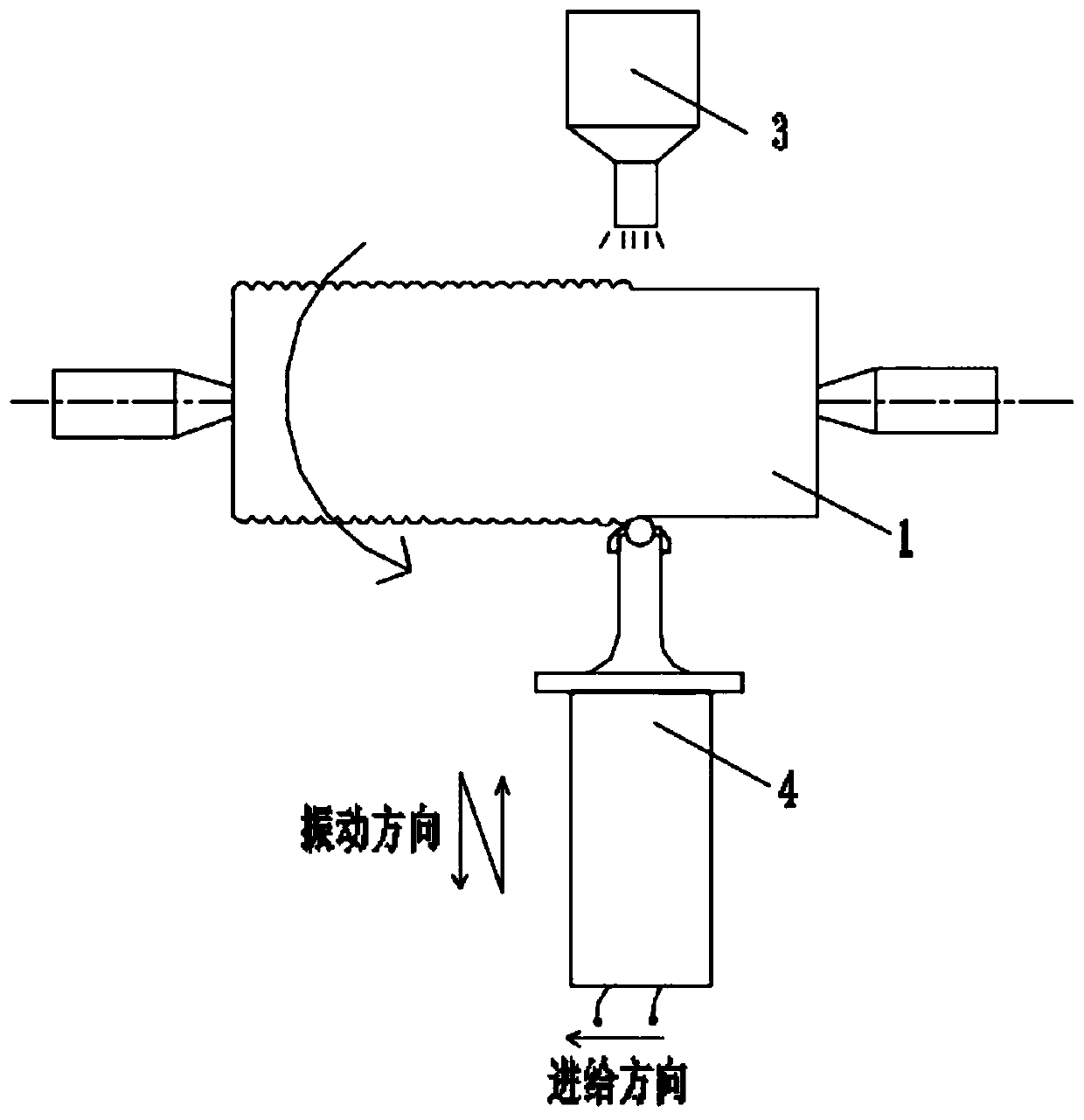

Method used

Image

Examples

experiment example

[0075] Through the scratch test, the interface bonding strength is measured for the shaft parts finished products obtained in Example, Comparative Example 1, Comparative Example 2, Comparative Example 3, and Comparative Example 4, and a comparison diagram of interface bonding strength can be obtained (see Figure 4 ). It can be seen that the interfacial bonding strength of the composite surface shaft parts obtained by the strengthening method of the embodiment is obviously better than that of the comparative examples, and has a good value for popularization and application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com