Micro geometrical morphology measurement system

A geometry and measurement technology, applied in the field of differential microscopic geometry measurement systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

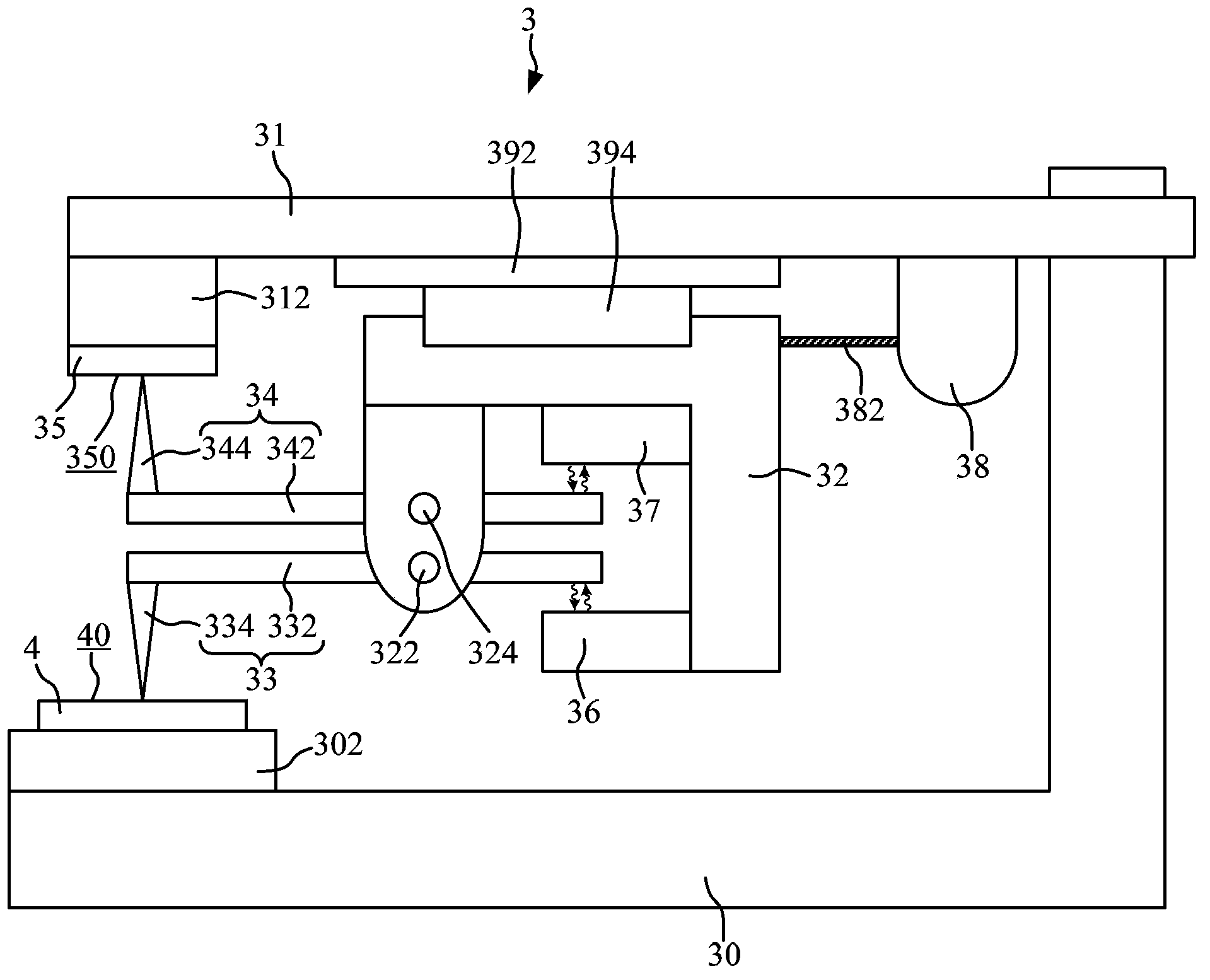

[0082] see figure 2 , the architecture of the micro-geometric topography measurement system 3 of the first preferred embodiment of the present invention is schematically shown in figure 2 middle. The microscopic geometry measurement system 3 of the present invention is used to measure the microscopic geometry of the test piece 4 .

[0083] The microscopic geometry measurement system 3 of the first preferred embodiment of the present invention includes a first scanning device 33, a second scanning device 34, a flat substrate 35, a first displacement sensing device 36, and a second displacement sensing device 37 and processing unit (not shown figure 2 middle). Likewise, the condition of the flat substrate 35 is that its surface roughness must be below sub-millimeters.

[0084] The first scanning device 33 includes a first pivotable arm 332 and a first probe 334 . The first probe 334 is connected to the first pivotable arm 332 and contacts the measuring surface 40 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com