Carbon/carbon composite and metallic material compound cooker and production method

A carbon composite material and metal material technology, which can be used in special materials for cooking utensils, household utensils, kitchen utensils, etc., and can solve the problems of dendrites, twin crystal defects, low mechanical properties of connectors, and difficult to control the thickness of metal layers. , to achieve the effect of high strength, improved strength and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

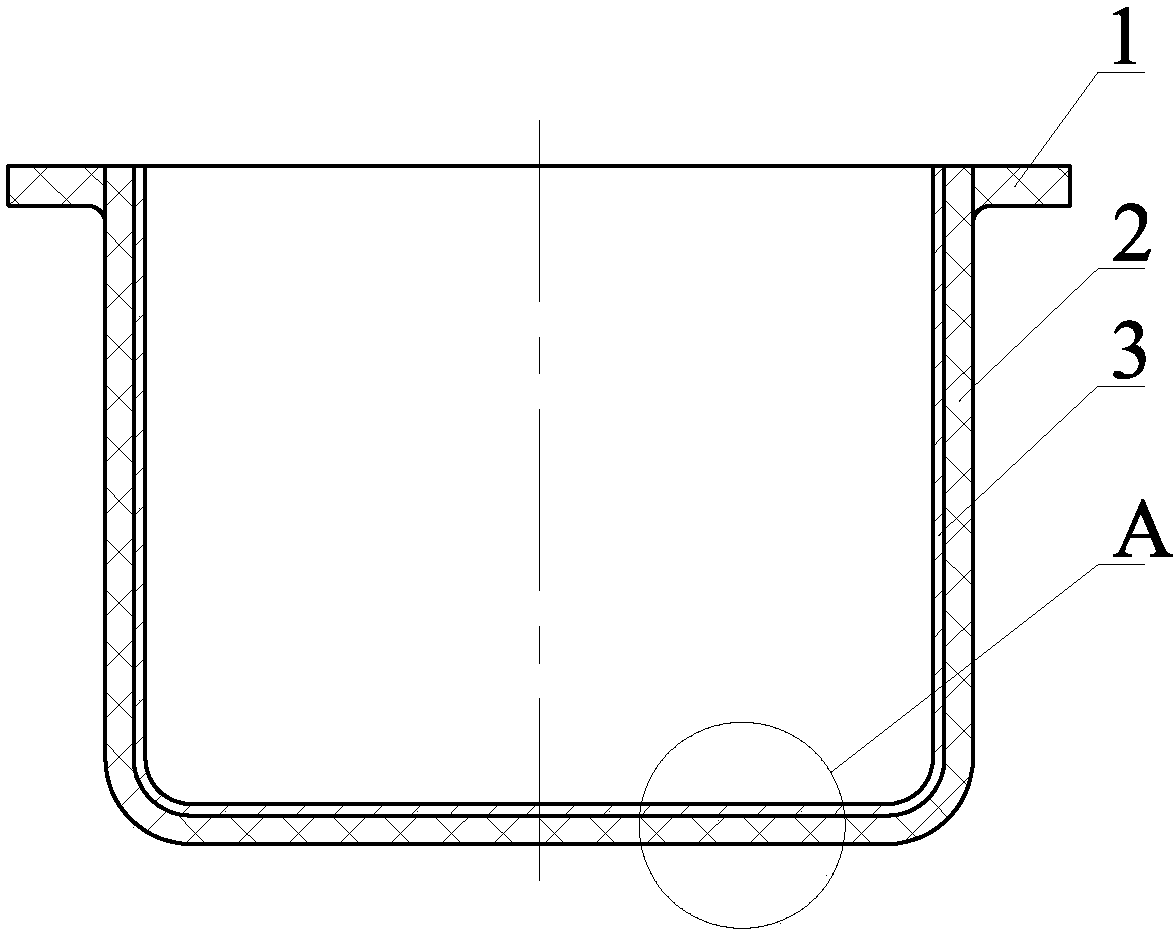

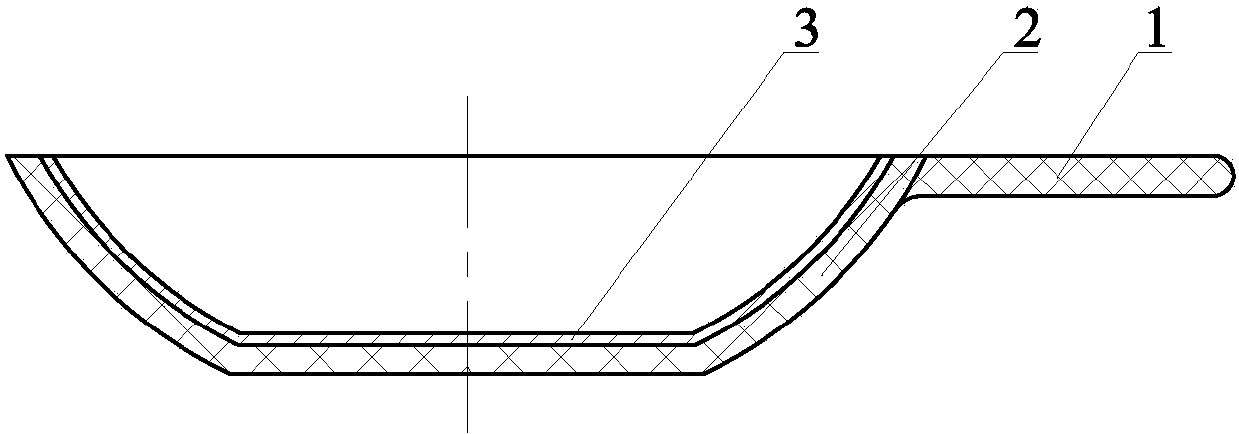

[0032] A carbon / carbon composite material and metal material composite cooking utensil production method, it comprises the following steps:

[0033] (1) Carbon / carbon composite material outer layer green body preparation: the carbon / carbon composite material green body is machined into the carbon / carbon composite material outer layer green body 2 of the desired shape, washed and dried for later use;

[0034] The carbon / carbon composite body in the present invention can be prepared by one or a combination of molding, chemical vapor deposition or liquid phase impregnation methods. In this embodiment, the carbon fiber is made into a prefabricated carbon fiber base layer according to the required structure and shape, and then densified by chemical vapor deposition.

[0035] In order to remove impurities in the outer body 2 of the carbon / carbon composite material, the present invention puts the prepared outer body 2 of the carbon / carbon composite material into a high-temperature fu...

Embodiment 2

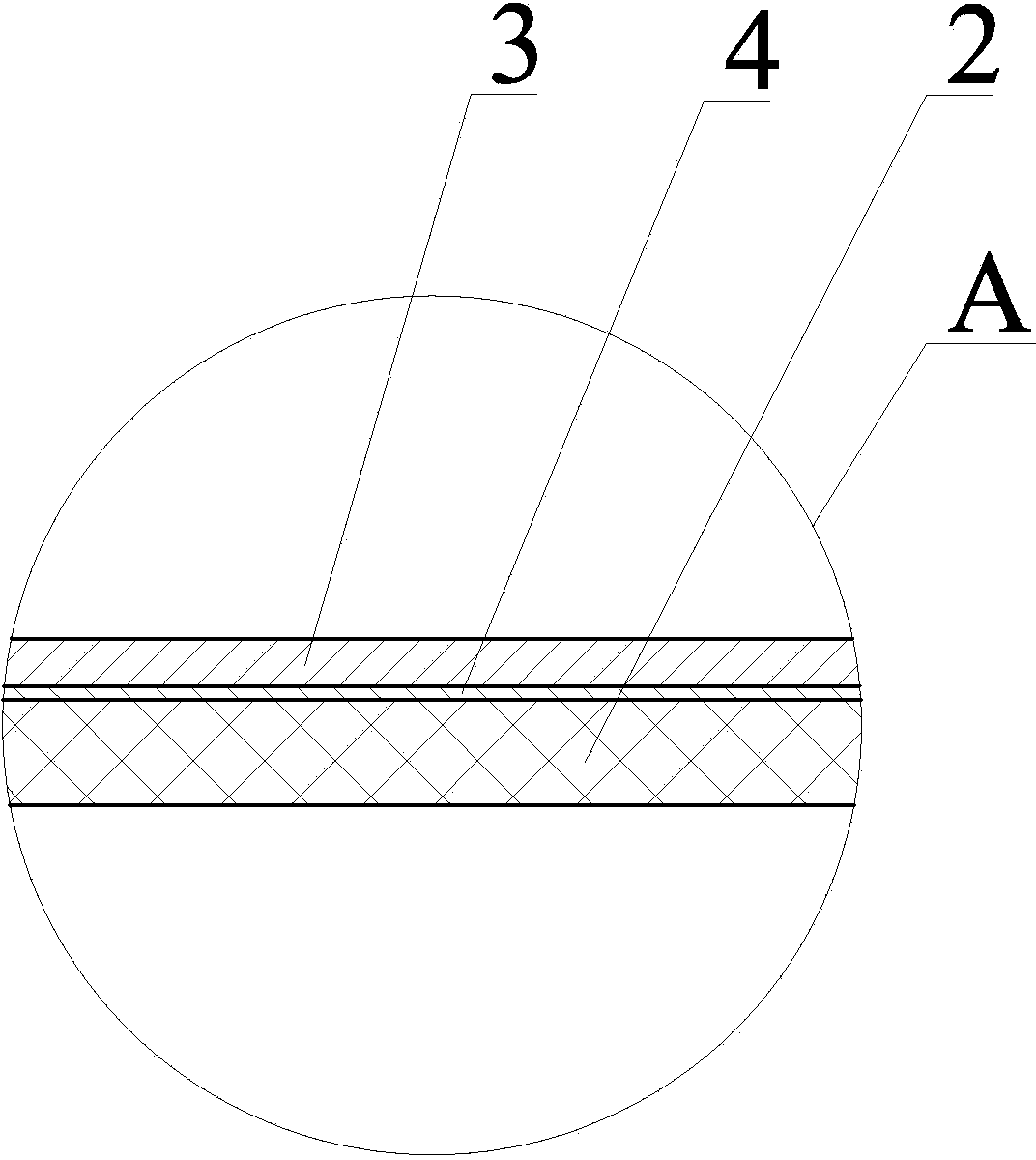

[0057] In step (2) of the present invention, the metal salts are aluminum nitrate and chromium nitrate, the atomic number ratio of aluminum ions to chromium ions in the aqueous alcohol solution is 15:4, and aluminum nitrate and nitric acid are prepared on the surface of the outer body 2 of the carbon / carbon composite material Chrome coating. In step (3), a carbon / carbon composite outer layer green body 2 with a metal particle layer of aluminum particles and chromium particles on the surface is prepared, and the thickness of the metal particle layer is 28 μm. In step (4), the metal material inner layer green body 3 is made of metal aluminum material.

[0058] After testing, the shear strength of the interface between the base body 2 of the carbon / carbon composite material and the base body of the metal aluminum material in this embodiment is 30 MPa.

[0059] The rest are the same as embodiment 1.

Embodiment 3

[0061] In step (2) of the present invention, the metal salts are nickel nitrate and copper sulfate, the atomic number ratio of nickel ions to copper ions in the aqueous alcohol solution is 15:2, and nickel nitrate and sulfuric acid are prepared on the surface of the outer body 2 of the carbon / carbon composite material copper coating. In step (3), put the carbon / carbon composite outer layer body 2 prepared in step (2) into a reduction furnace, and pass through hydrogen at 1100°C for calcination and reduction. The reduction time is 3 hours, and then cooled to room temperature to produce A carbon / carbon composite material outer layer green body 2 having a metal particle layer with nickel particles and copper particles on the surface is obtained; the thickness of the metal particle layer is 50 μm. In step (4), the metal material inner layer green body 3 is made of metal iron material. In step (5), the carbon / carbon composite material outer layer body 2 obtained in step (3) and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com