Tooth surface equal interval sampling method used for improving gear measuring precision

A technology of equal interval sampling and gear measurement, applied in measurement devices, instruments, etc., to improve measurement accuracy and facilitate error analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

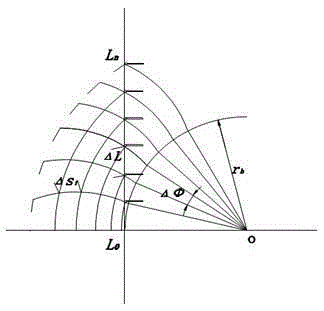

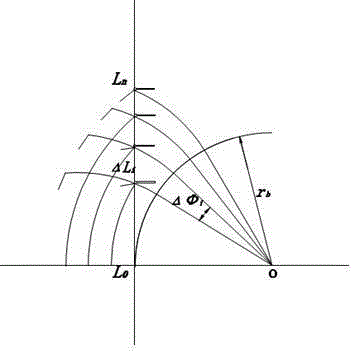

[0021] The present invention will be further described below in conjunction with accompanying drawing. The operating principle of the present invention is: tooth surface equidistant sampling description, such as figure 2 shown. Sampling at equal intervals on the tooth surface is to pre-determine a series of uniform sampling points on the involute section of the tooth surface. When these points are reversed to the development length (or development angle), it can be seen that the angle) on the interval ΔL (or spread angle interval Δφ ) are not equal, the distance between the developed lengths at the root of the tooth is the largest, the closer to the top of the tooth, the smaller the interval, and the interval at the top of the tooth is the smallest, but the sampling interval on the tooth surface ΔS are equal.

[0022] The specific method to improve the accuracy of gear measurement by sampling at equal intervals from the tooth surface is as follows:

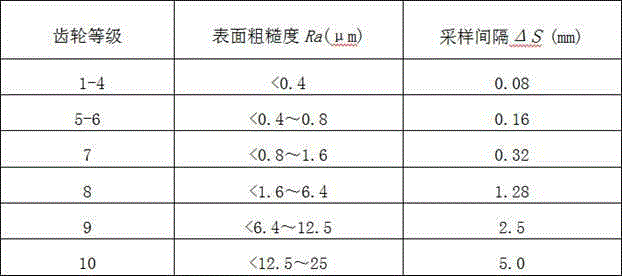

[0023] (1) Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com