A calculation method for quantitatively evaluating the sealing performance of a non-API oil casing joint

A technology for quantitative evaluation and sealing performance, applied in calculation, computer-aided design, geometric CAD, etc., can solve the problems that the quantitative relationship of sealing performance cannot be revealed, and has not been considered, so as to improve reliability and versatility, and solve the problems of accuracy and operation Effects of error, enhanced flexibility and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

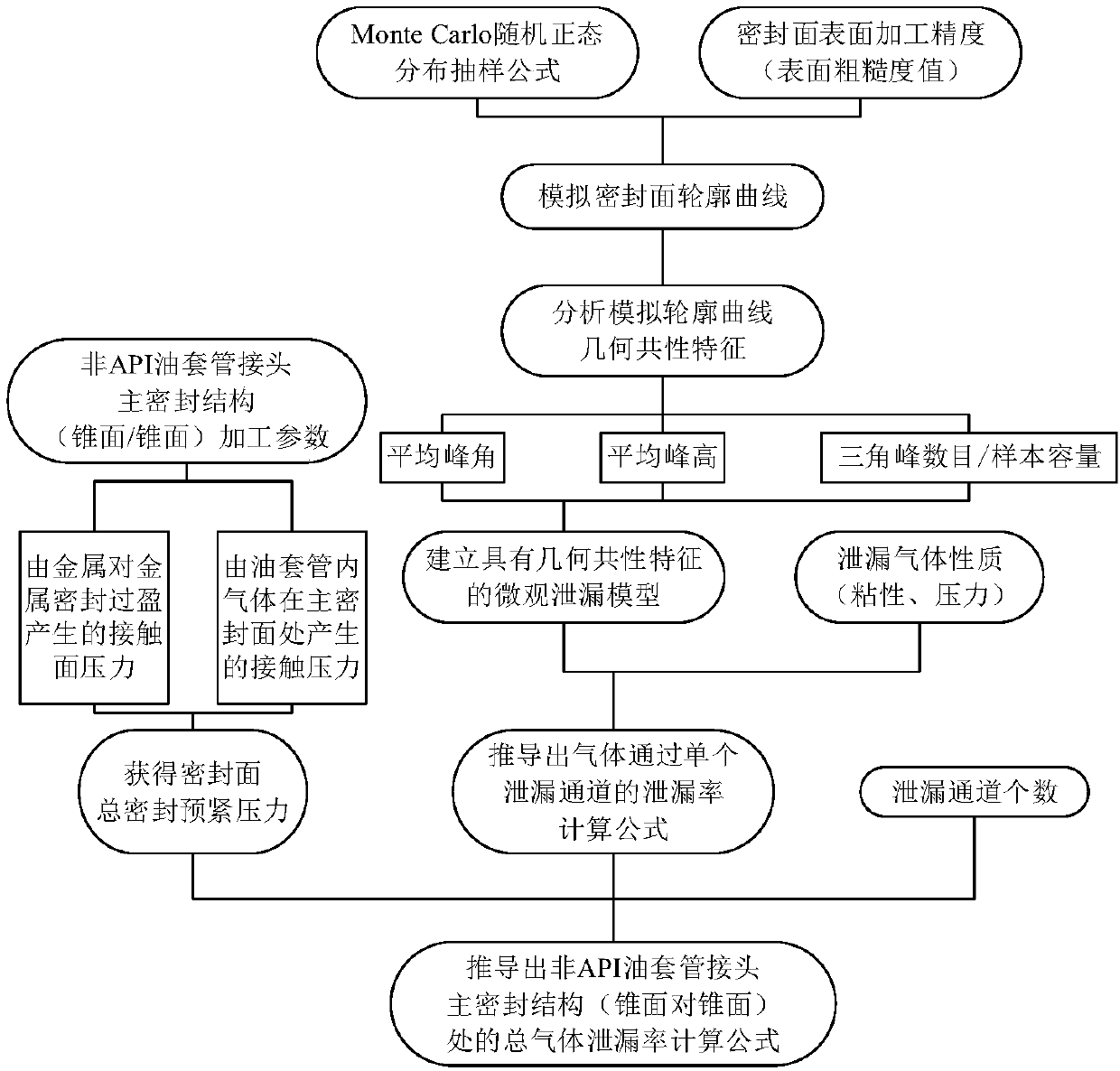

[0038] A calculation method for quantitatively evaluating the sealing performance of non-API oil-casing joints according to the present invention, and its preferred specific implementation method can be found in figure 1 ,include:

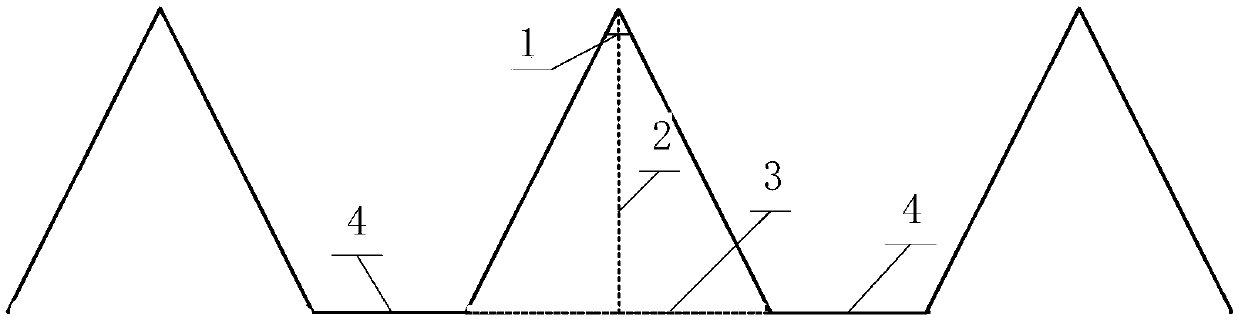

[0039] Step 1: Build a metal-to-metal seal microscopic leak model with preset surface roughness

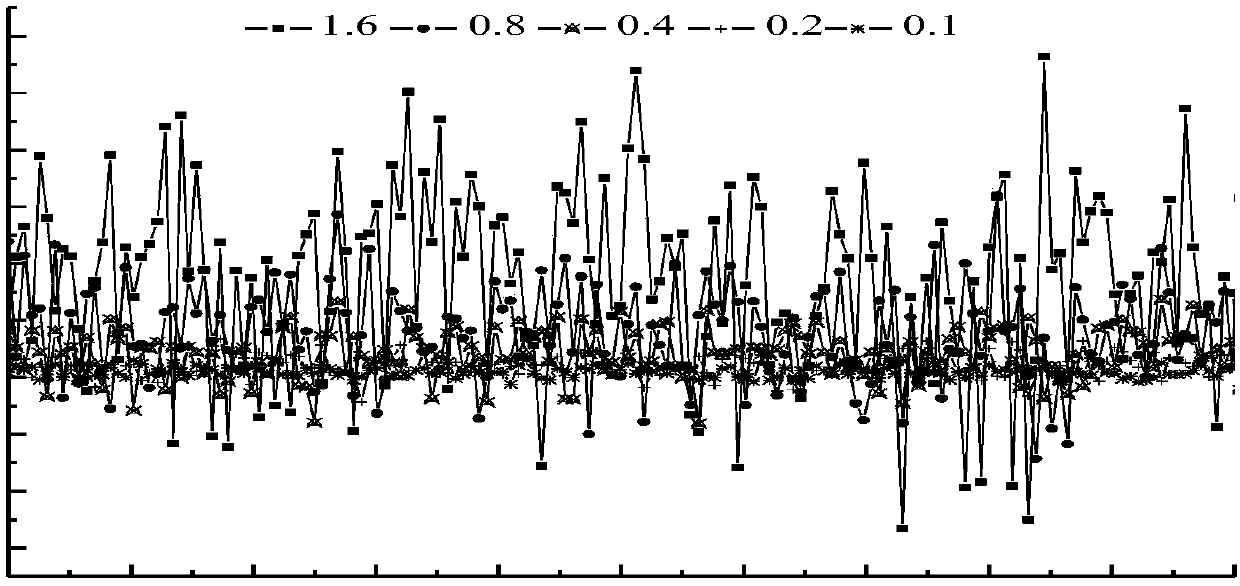

[0040]Using the Monte Carlo random normal distribution sampling formula combined with the sealing surface roughness processing parameters, the sealing surface contour curve that obeys the normal distribution and the preset surface roughness value is simulated.

[0041] Monte Carlo random normal distribution sampling formula:

[0042]

[0043] In the formula, μ is the sample mean; σ is the sample standard deviation; r 1 , r 2 It is a random number sequence uniformly distributed between [0,1].

[0044] The surface roughness value of the sealing surface is taken as the sample mean value μ, and one-sixth of the maximum height value of the sealing su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com