Laser micro-modelling method for cam surface profile

A cam surface and micro-modeling technology, which is applied to laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems that laser micro-modeling technology has never been applied, heating temperature is not suitable for control, and heating temperature is uneven, so as to improve wear resistance Anti-wear, improve lubrication and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

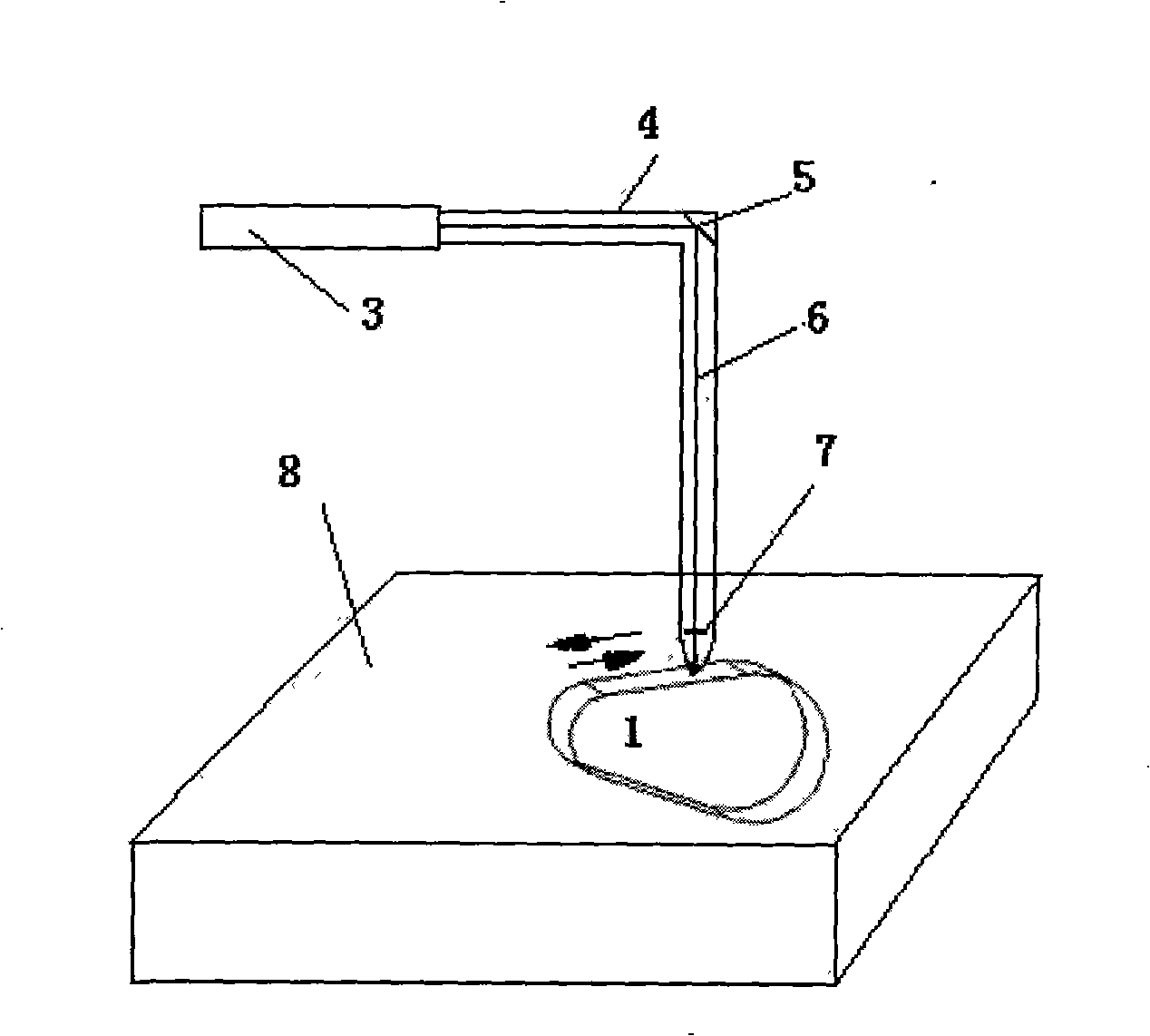

[0015] The laser processing equipment adopts diode-pumped Nd:YAG laser. It is mainly composed of laser part, refrigerator part, workbench part and control cabinet part.

[0016] The material selected for the cam is carbon steel which is a representative general material of the cam.

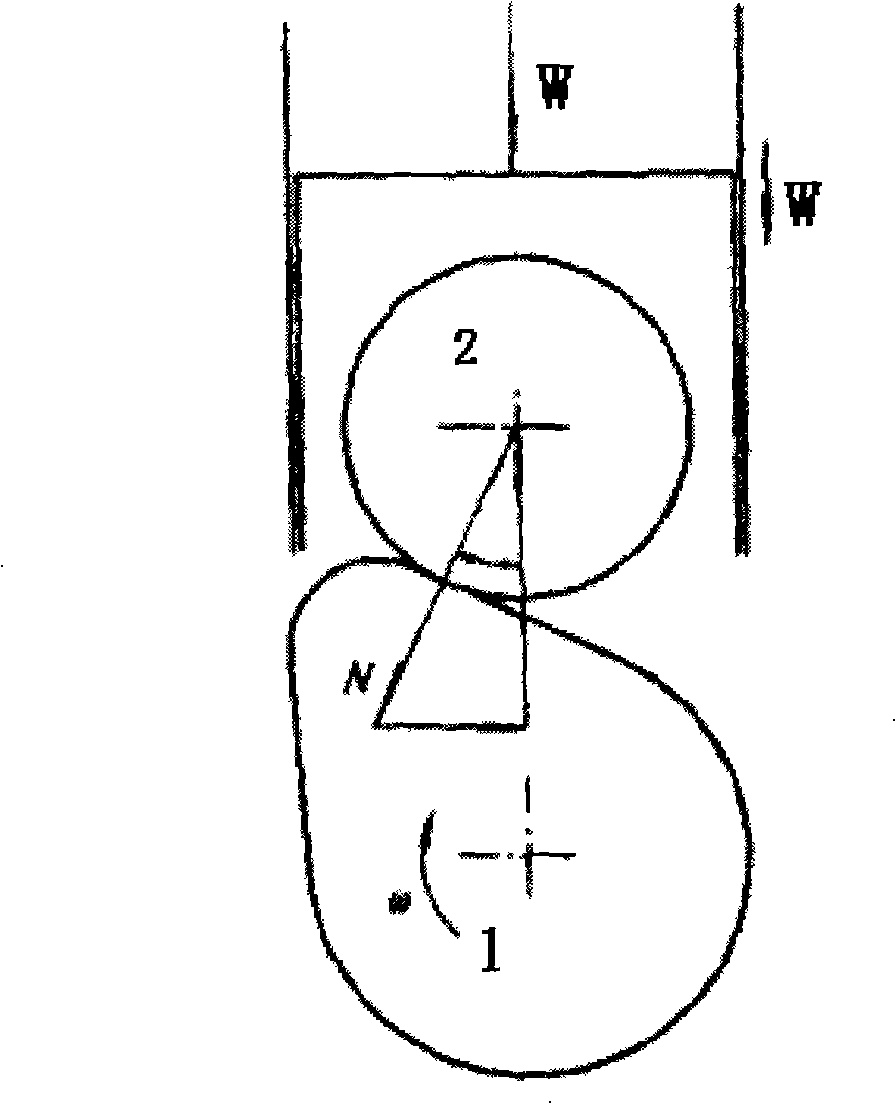

[0017] The specific implementation process of the present invention will be described below by taking the engine fuel injection pump cam as an example.

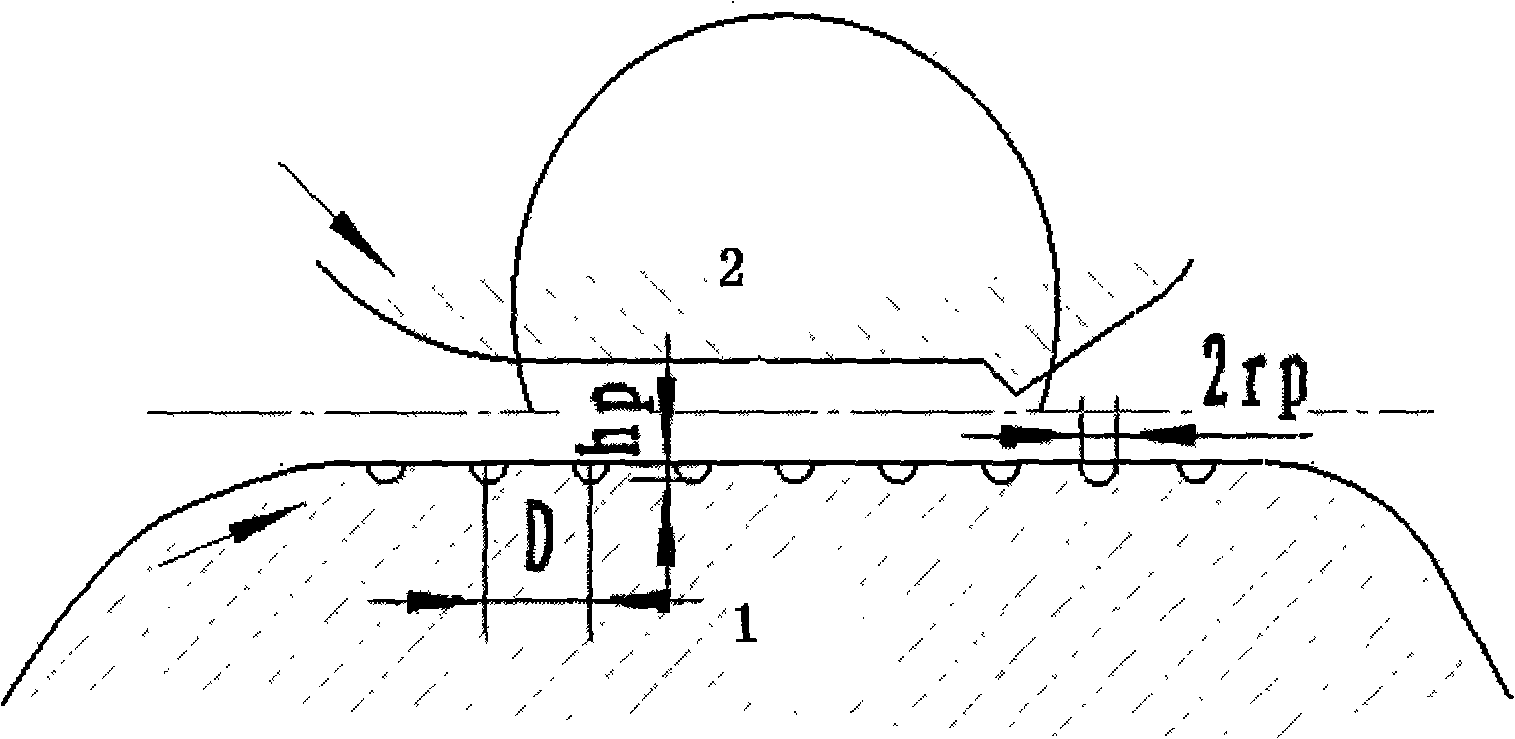

[0018] 1. Diode-pumped Nd:YAG laser, the laser mode is TEM00, with a telescope beam expander in the cavity, which outputs high-quality beams, and uses acousto-optic Q-switching technology to generate pulsed lasers. The main parameters during the test are: the output wavelength is 532nm and 1064nm, the laser output power is P=1~10W, the laser power instability is -3%~+3%; the pump current is 8~22A, the Q-switching repetition frequency 1064nm adopts 7~40KHz, 532nm adopts 5~15KHz, beam quality coefficient M2<2, divergence angle<3mrad. The blown a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com