Method for laser compound treating surface of friction pair

A compound treatment and friction pair technology, applied in heat treatment furnaces, heat treatment equipment, laser welding equipment, etc., can solve problems such as cylinder bore and piston ring frustration, surface hardness does not increase, cylinder bore deformation, etc., to achieve smooth and smooth oil passage , Improve the lubrication condition and reduce flash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

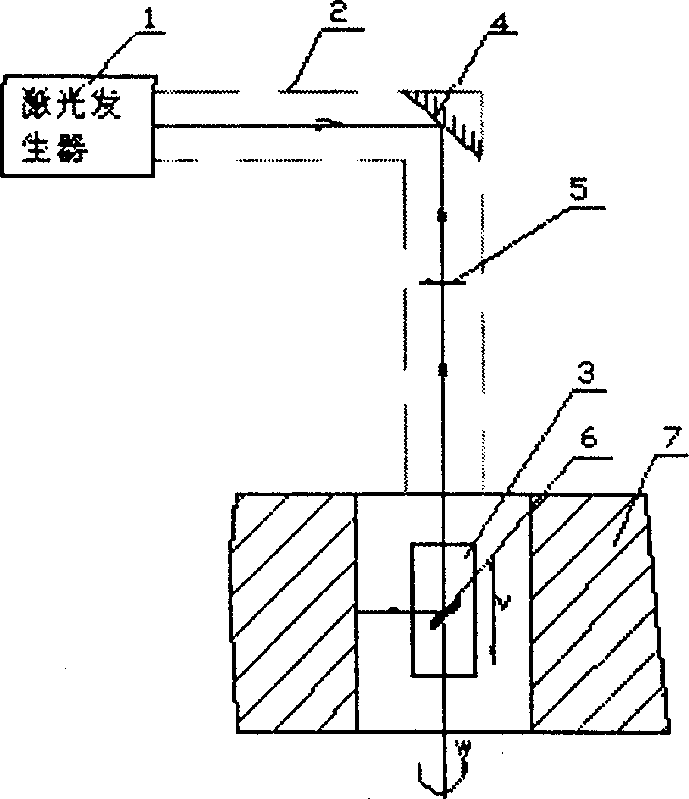

[0021] Such as figure 1 As shown, the device includes three main parts: a laser generator (1), a laser output head (3) and an external optical path system (2) composed of a mirror (4), a lens (5) and a mirror (6). The laser light generated by the laser generator (1) is collected by the mirror (4) to the lens (5), and then irradiated onto the surface of the workpiece (7) by the mirror (6). Through the reciprocating movement of the laser output head (3) up and down and the rotation of the workpiece (7), or the rotation of the laser output head (3) itself, or the rotation of the reflector (6) in the laser output head (3), the Synthesize laser scanning trajectories of various shapes to achieve surface laser composite processing on the required area of the workpiece.

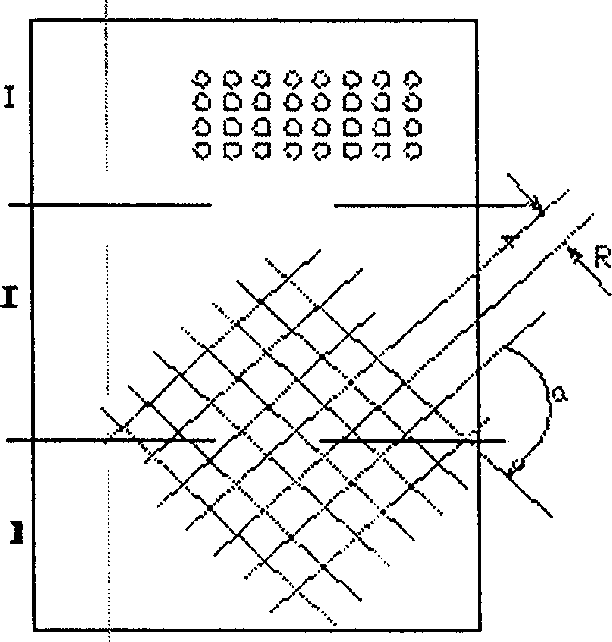

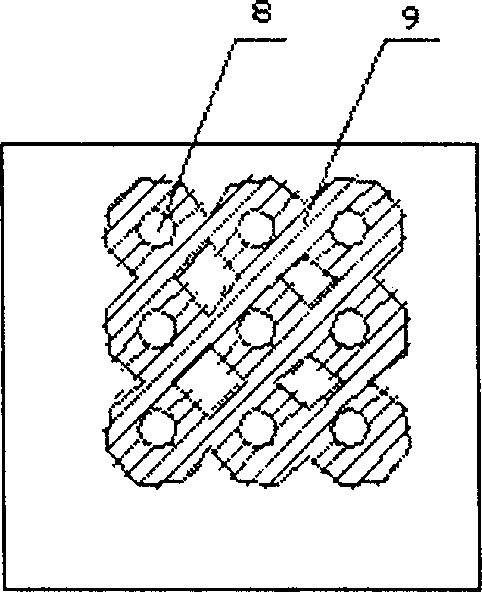

[0022] Such as figure 2 , 3 As shown, an embodiment of the present invention treats cylinder bore surfaces. After the cylinder bore is precision machined by final mechanical honing, the original surface for la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com