Patents

Literature

33results about How to "Increase cylinder pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

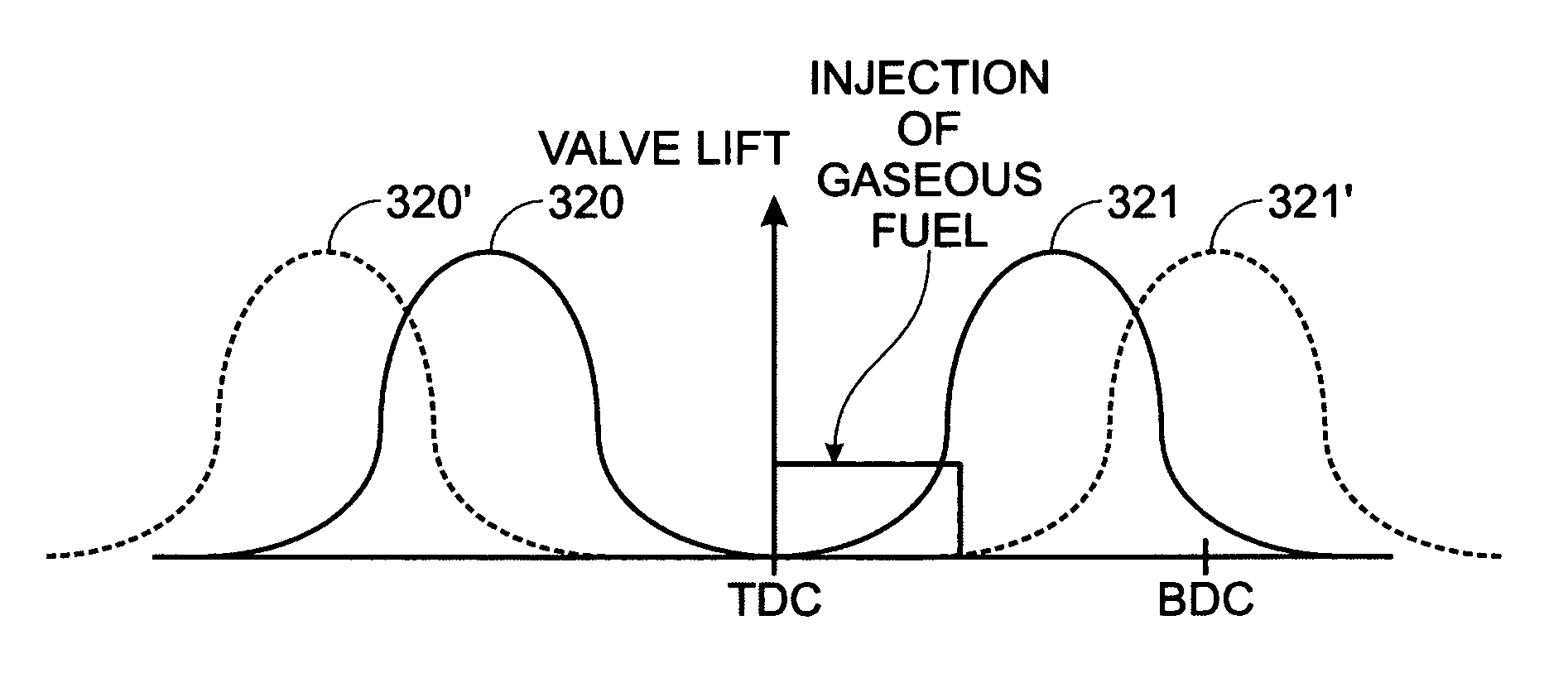

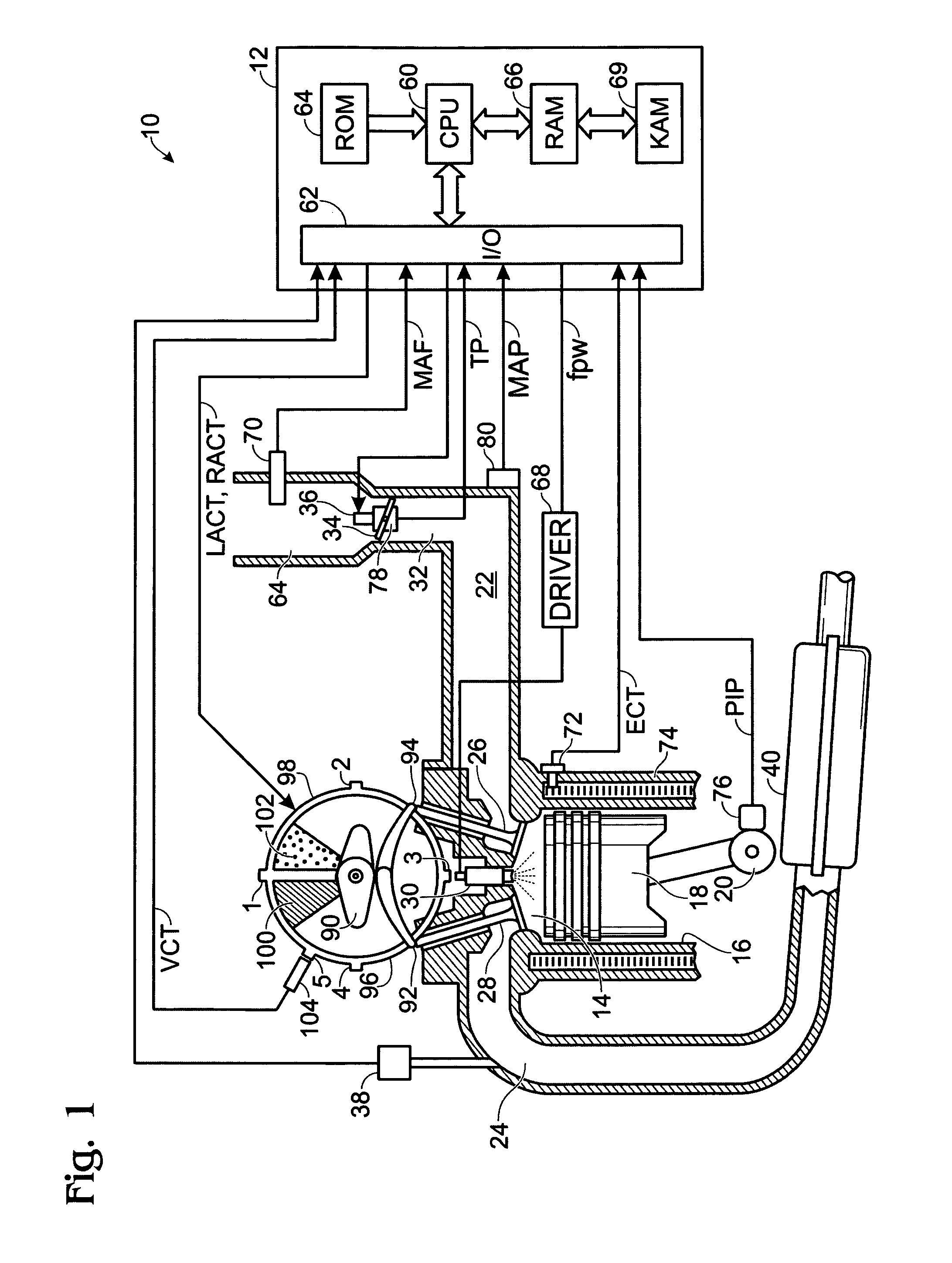

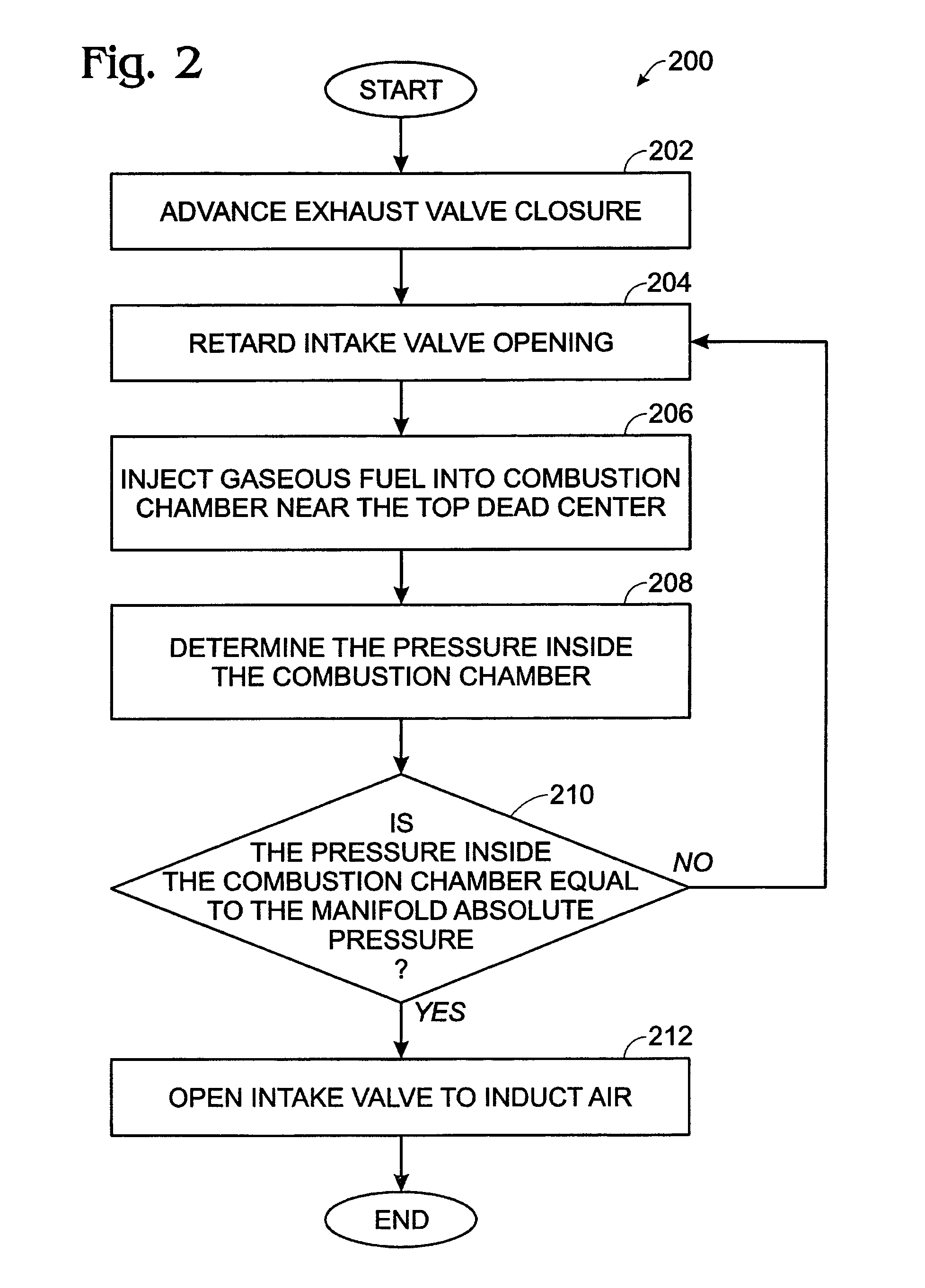

System and method for direct injection of gaseous fuel into internal combustion engine

InactiveUS7117830B1Reduce exhaustReduce volumeValve arrangementsElectrical controlExhaust valveTop dead center

A method for an engine capable of burning gaseous fuel, the engine also including a combustion chamber, at least one intake valve, and at least one exhaust valve, an injector to directly inject pressurized gaseous fuel into the combustion chamber, and a variable valve timing system coupled to the intake valves and exhaust valves, the method comprising closing the exhaust valve before top dead center of piston position to increase combustion chamber pressure achieved at top dead center and to trap exhaust gas in the cylinder; and starting injection of a gaseous fuel directly into the combustion chamber after the exhaust valve is closed and before the intake valve is opened.

Owner:FORD GLOBAL TECH LLC

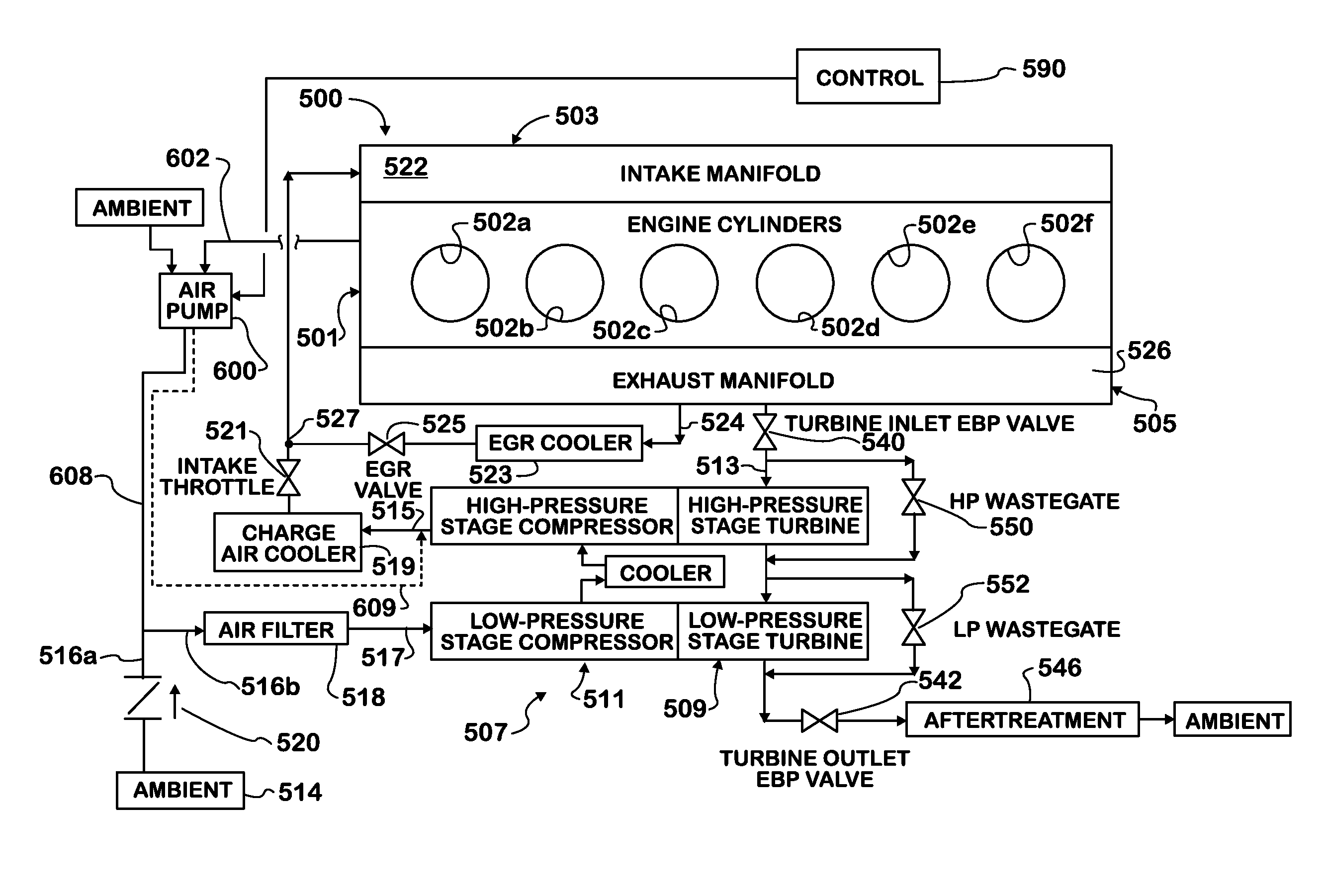

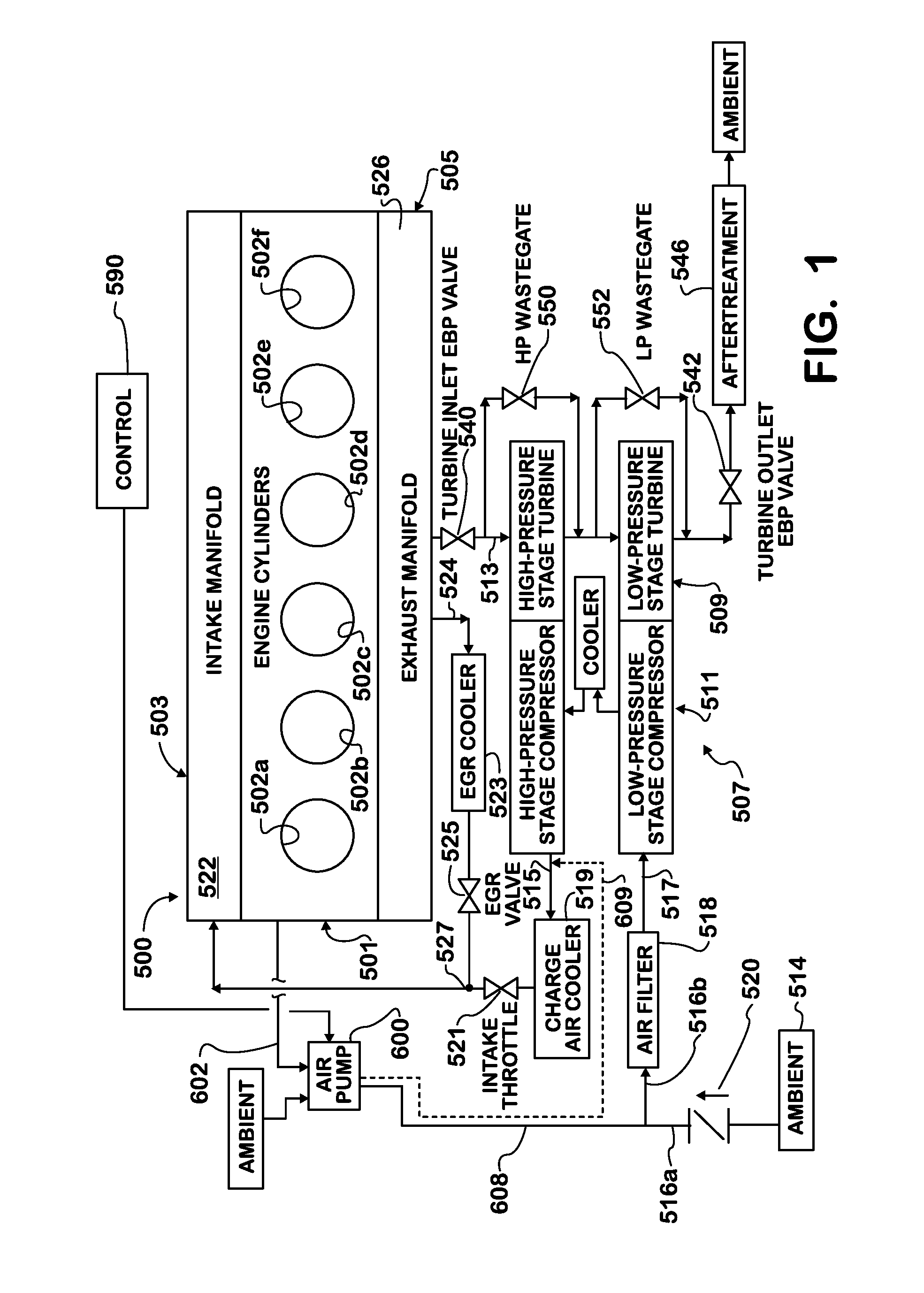

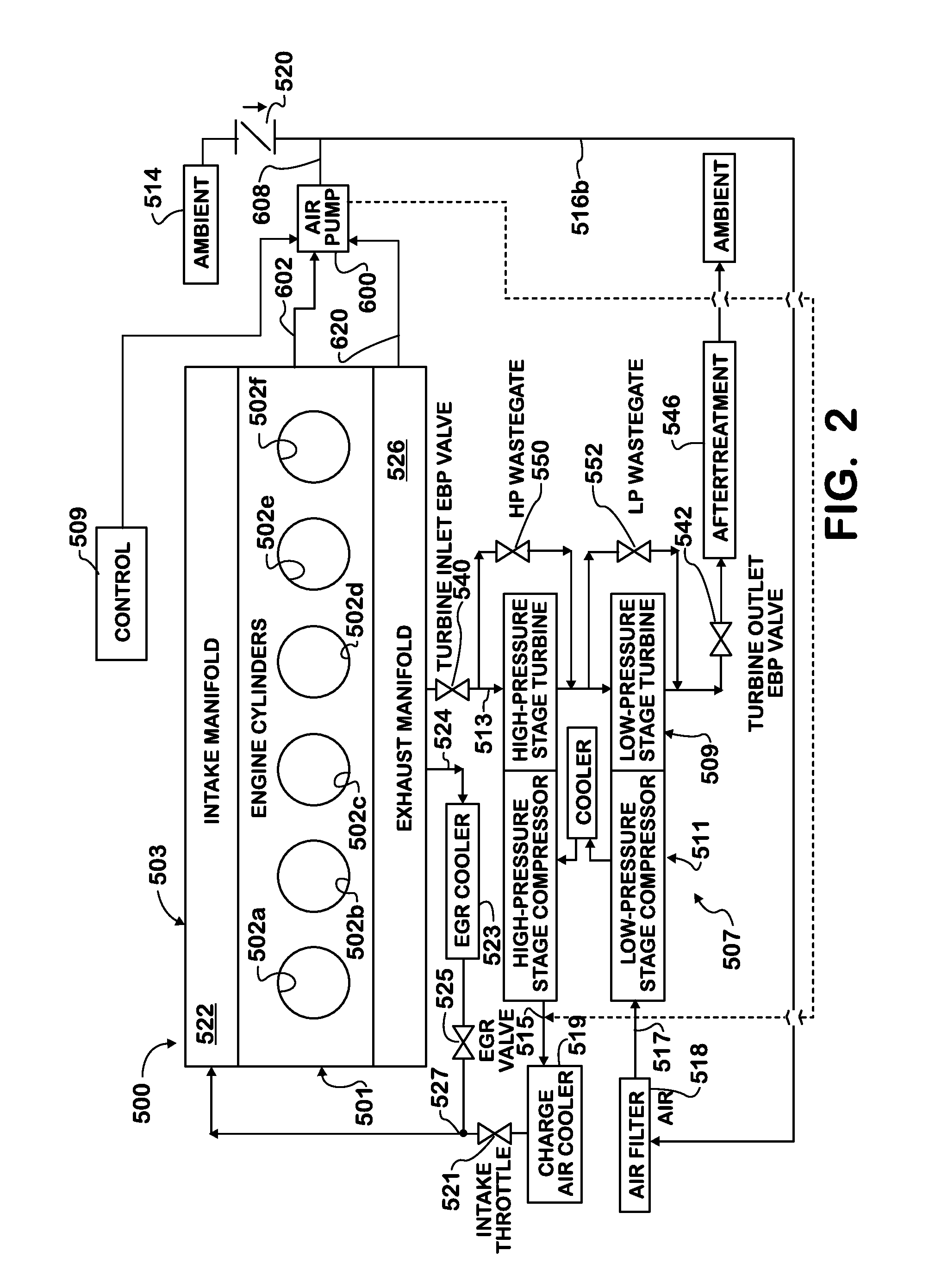

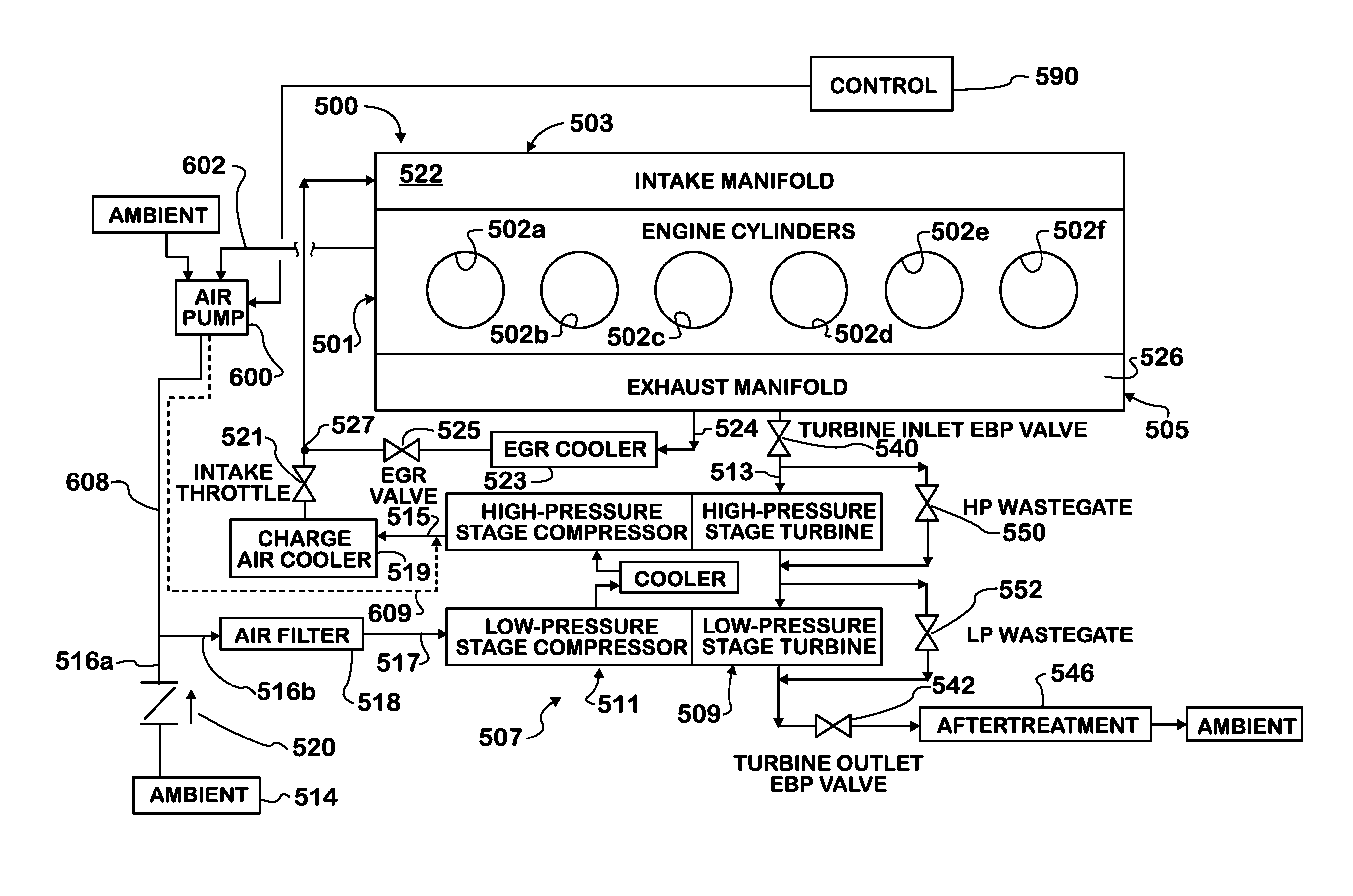

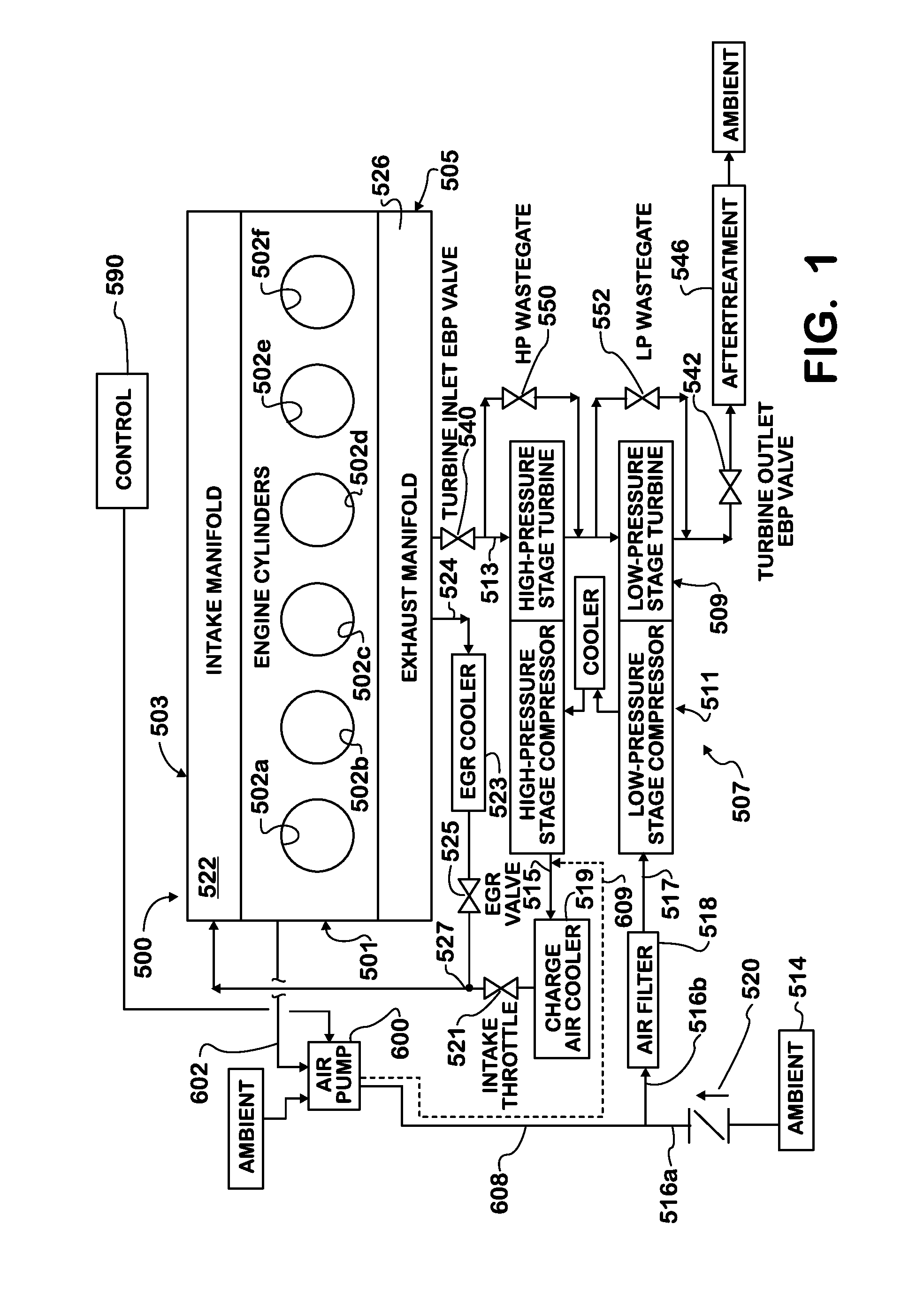

Supercharged boost-assist engine brake

ActiveUS20110036088A1Increase air circulationHigh trafficValve arrangementsElectrical controlExhaust valveControl system

A control system for engine braking for a vehicle powered by a turbocharged engine uses a supercharger to assist a turbocharger compressor to boost turbocharger air flow into the engine cylinders. An engine driven air pumping device draws ambient air, or alternately exhaust gas through the pump inlet, compresses the air, and delivers the compressed air through the pump outlet to the turbocharger compressor inlet or alternately the turbocharger compressor outlet. The increased air flow into the cylinders and out of the cylinder exhaust valves increases retarding power of the vehicle.

Owner:INT ENGINE INTPROP CO LLC

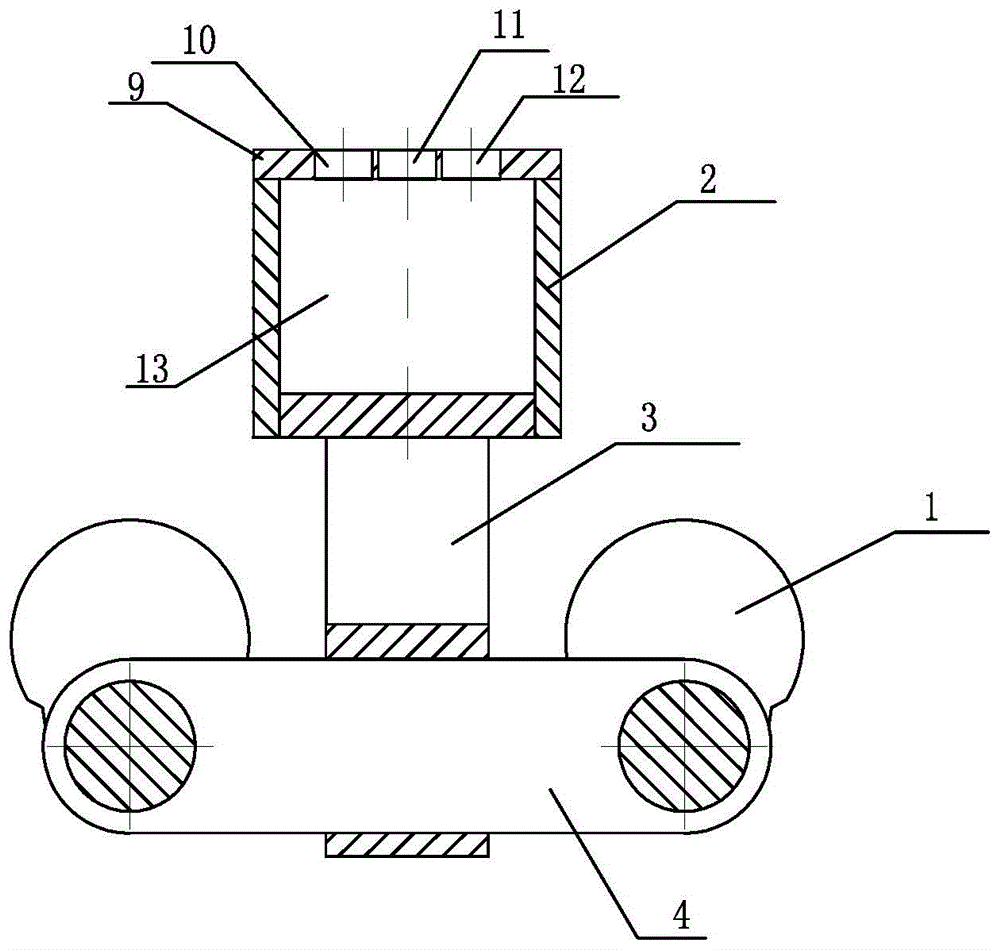

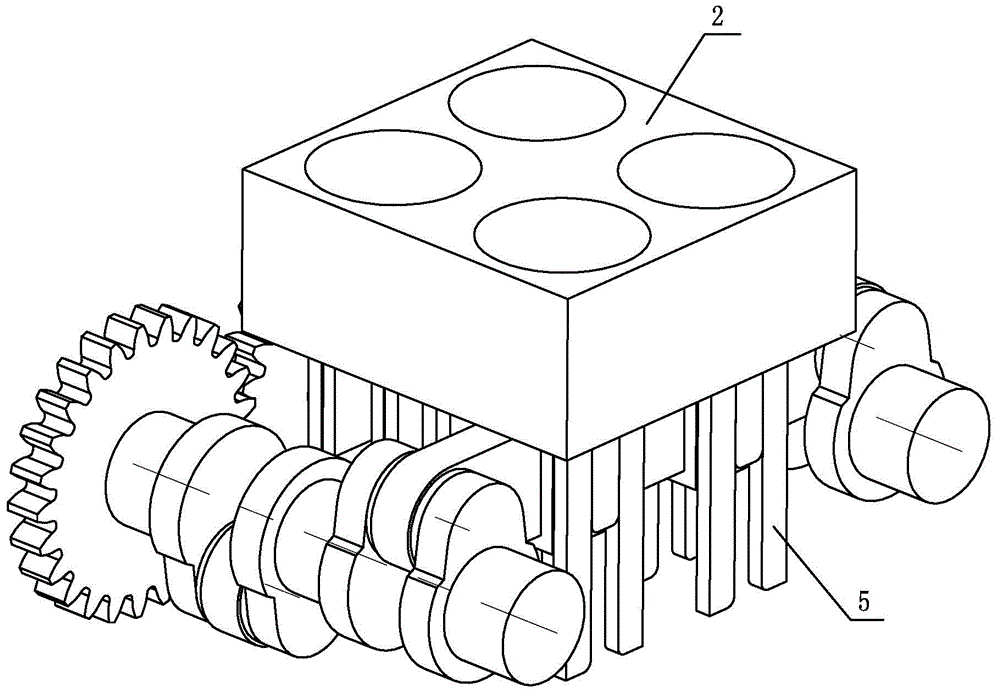

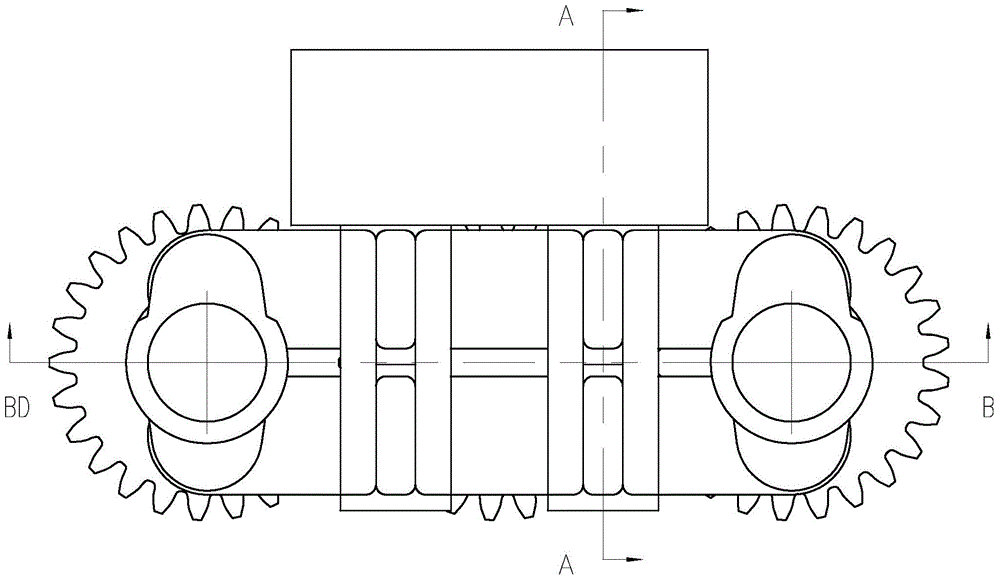

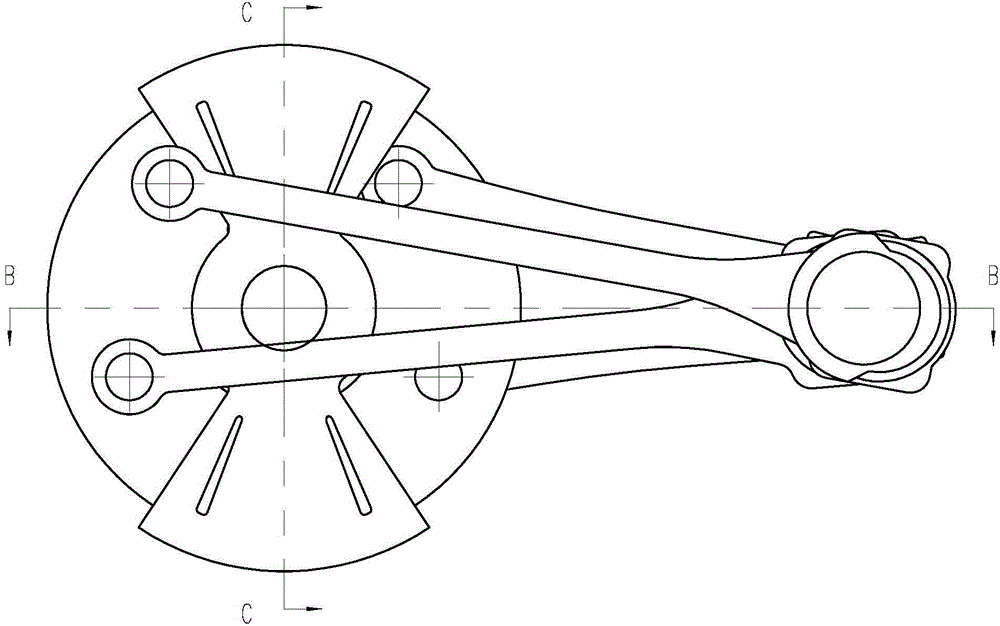

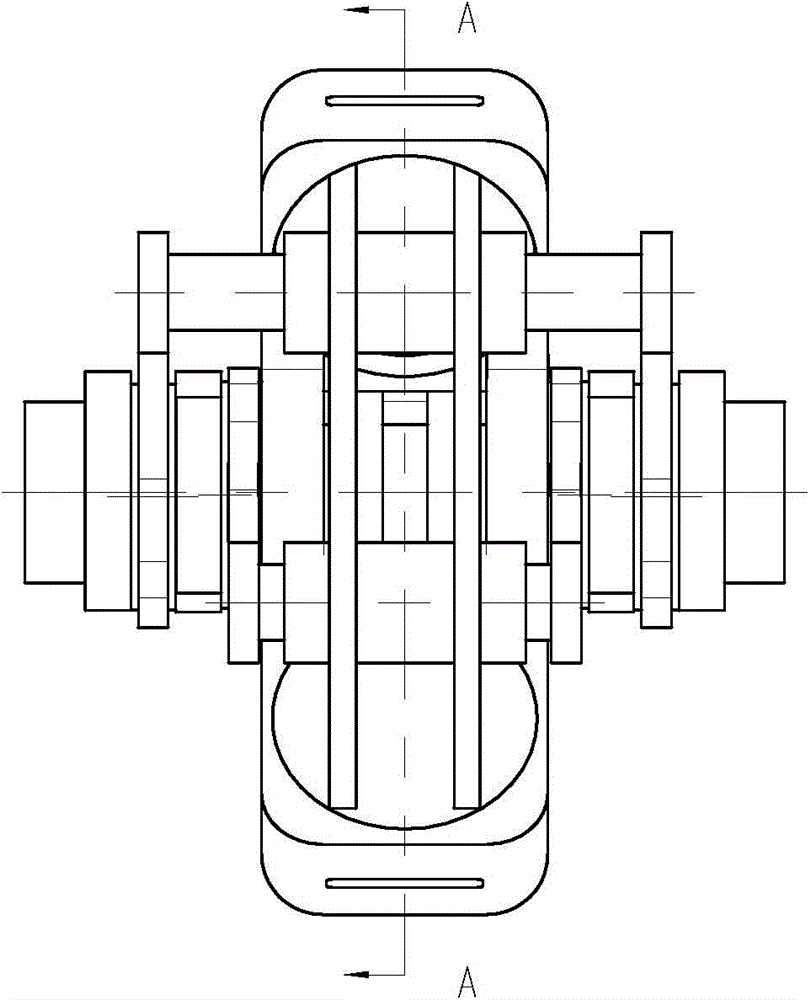

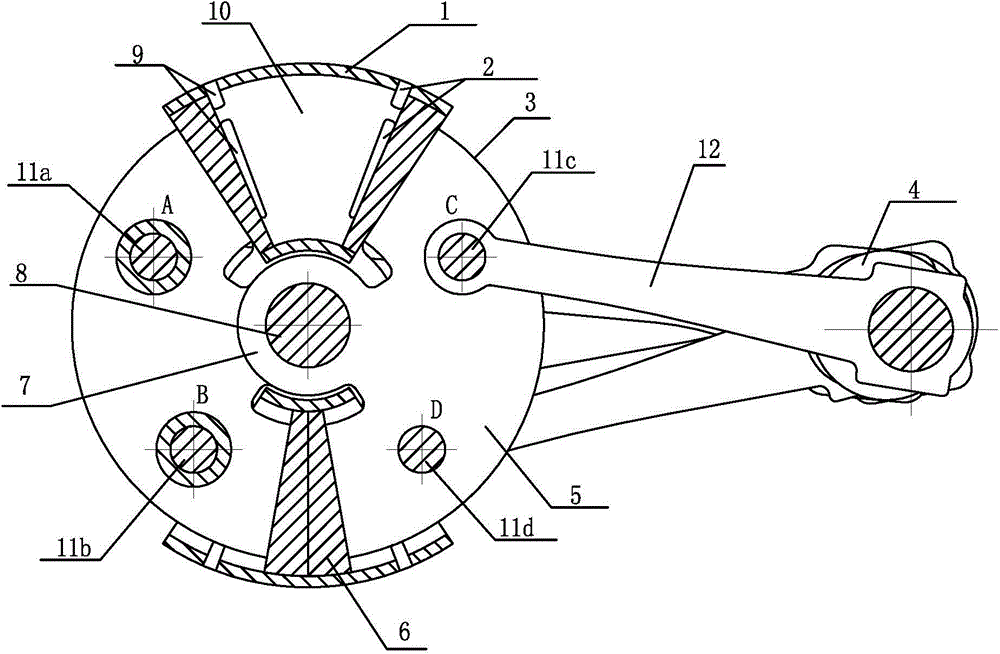

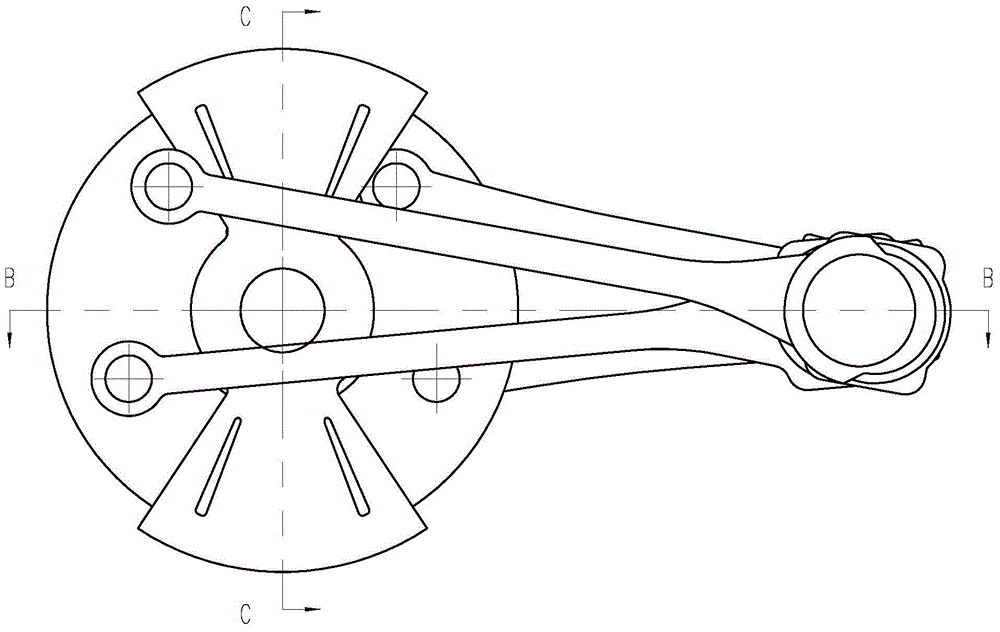

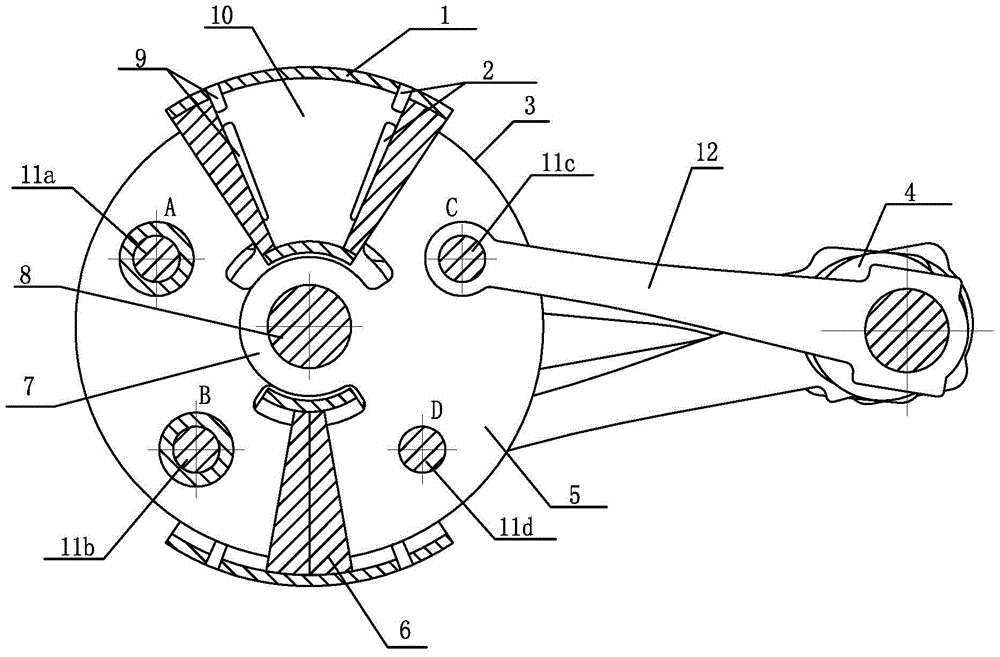

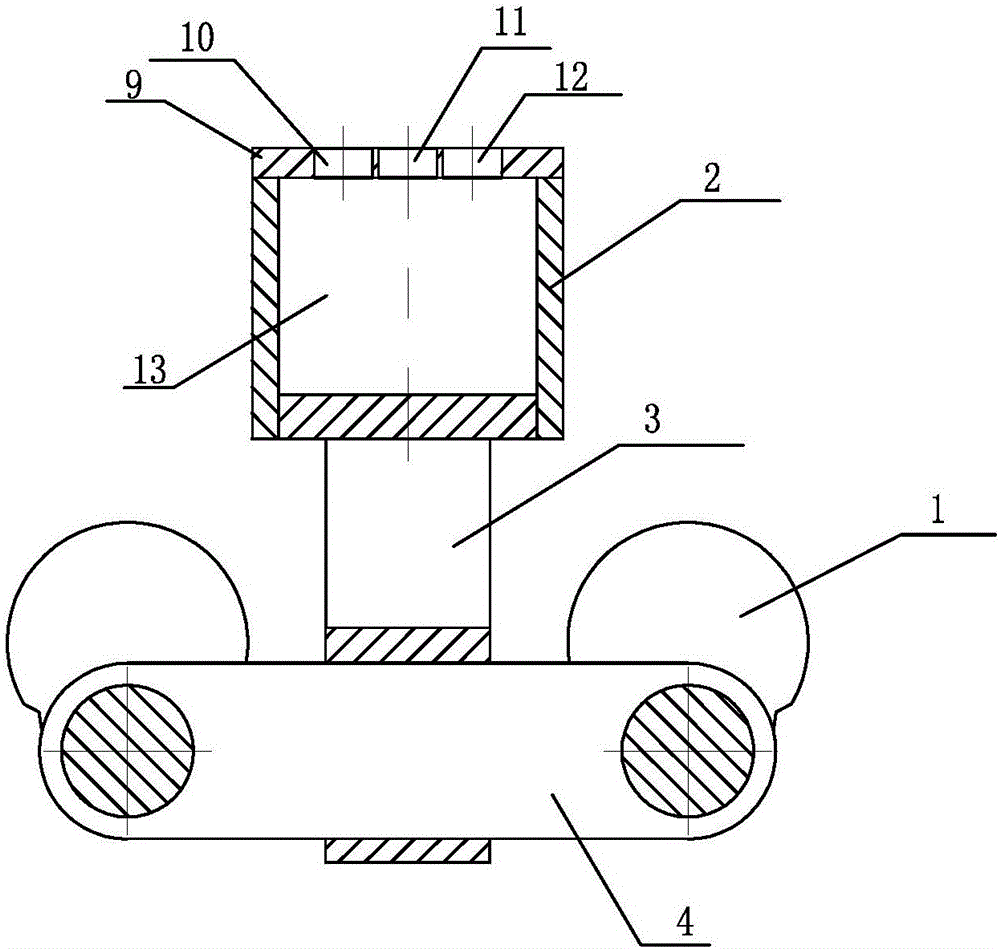

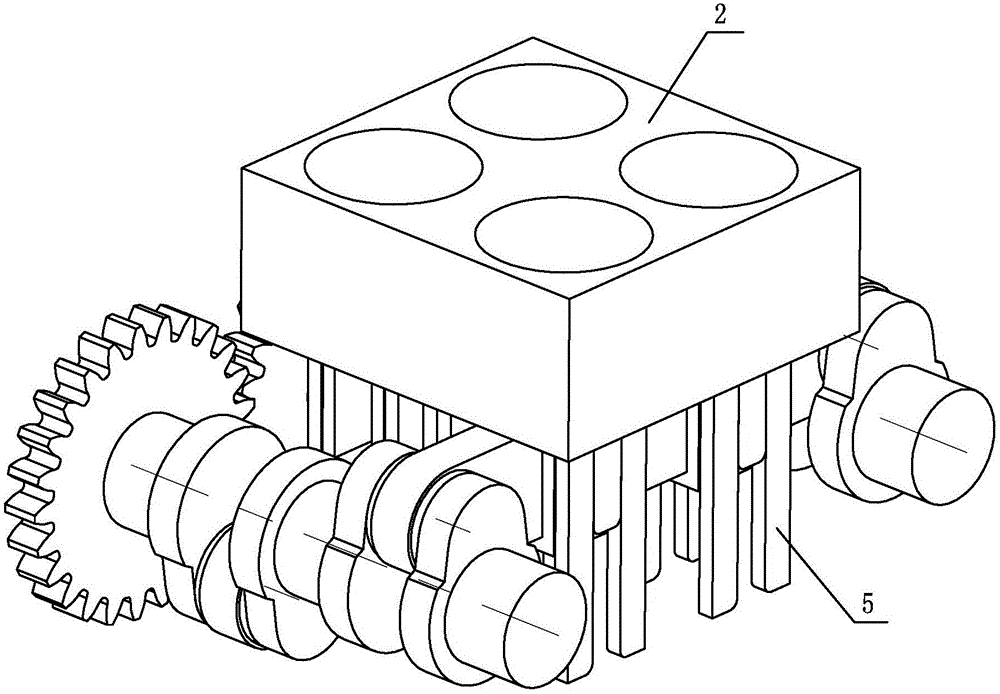

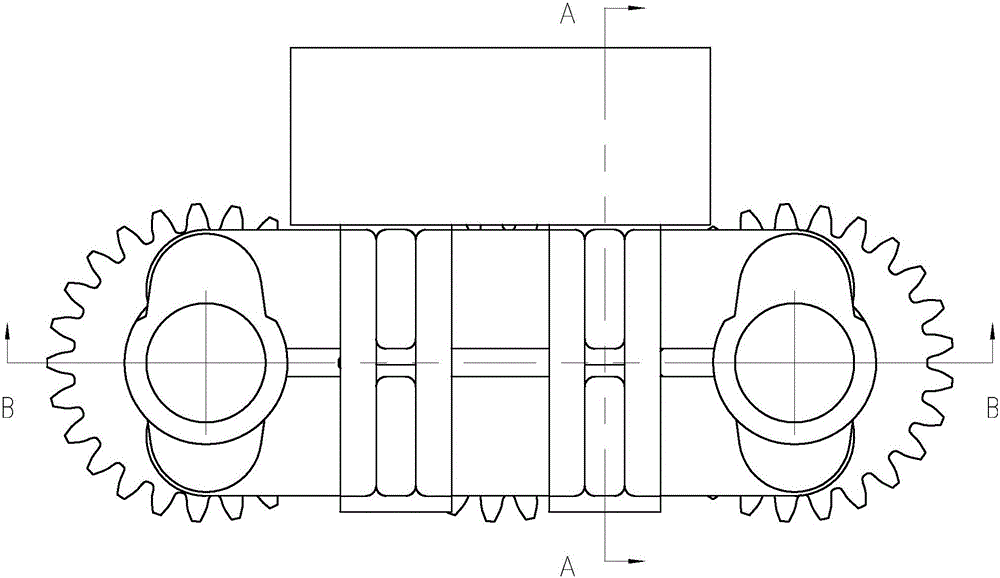

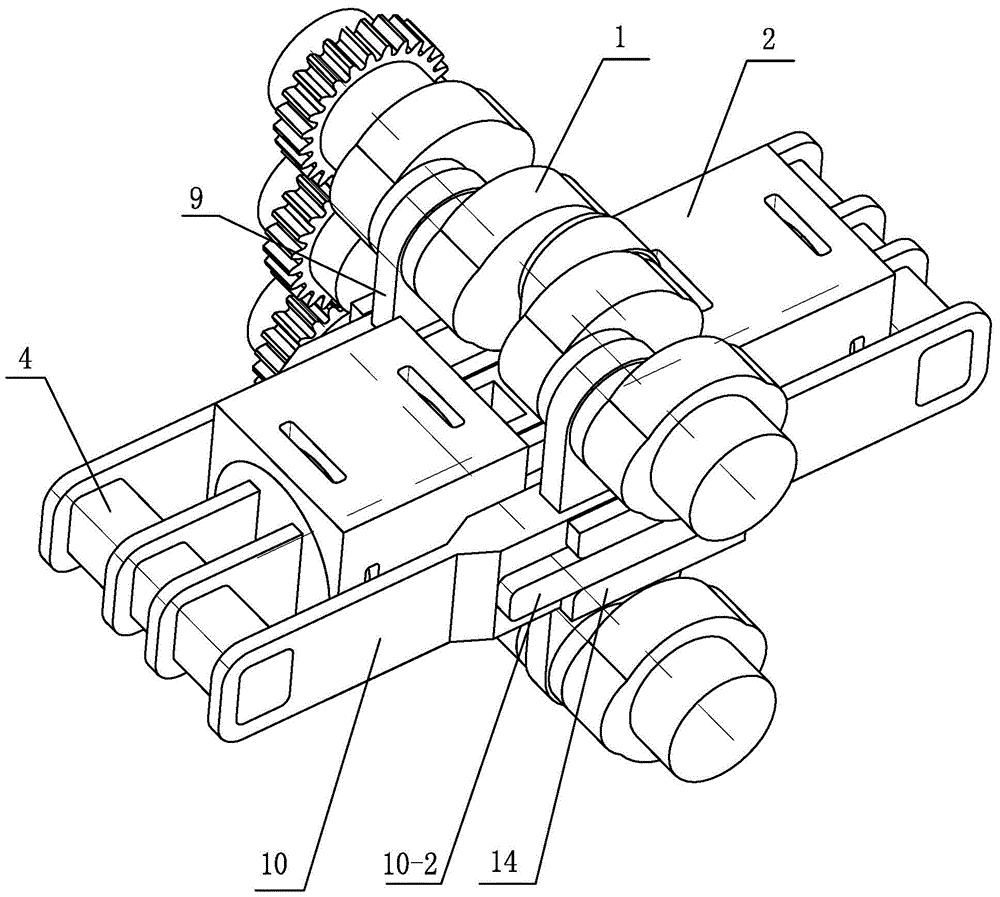

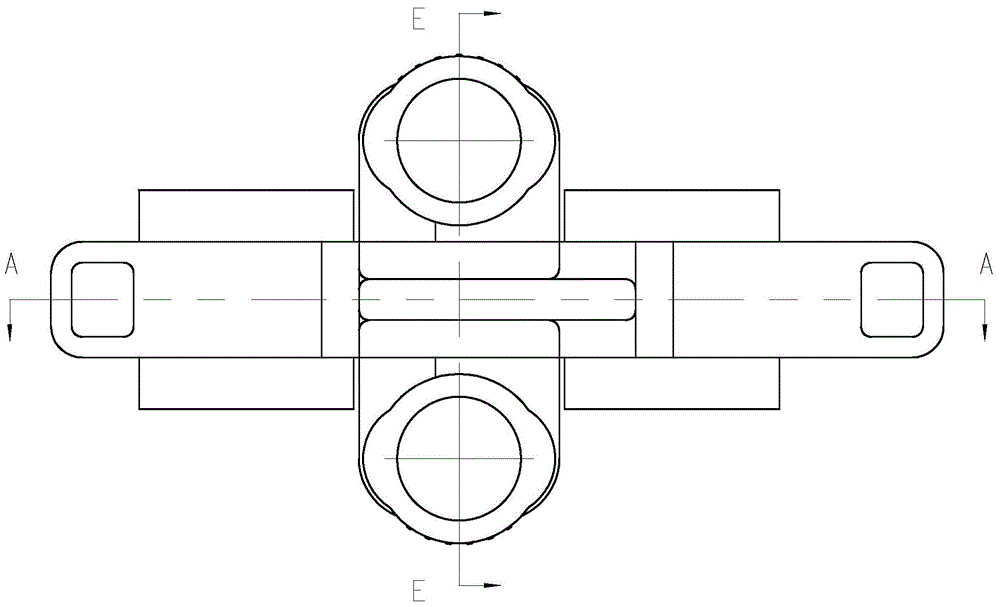

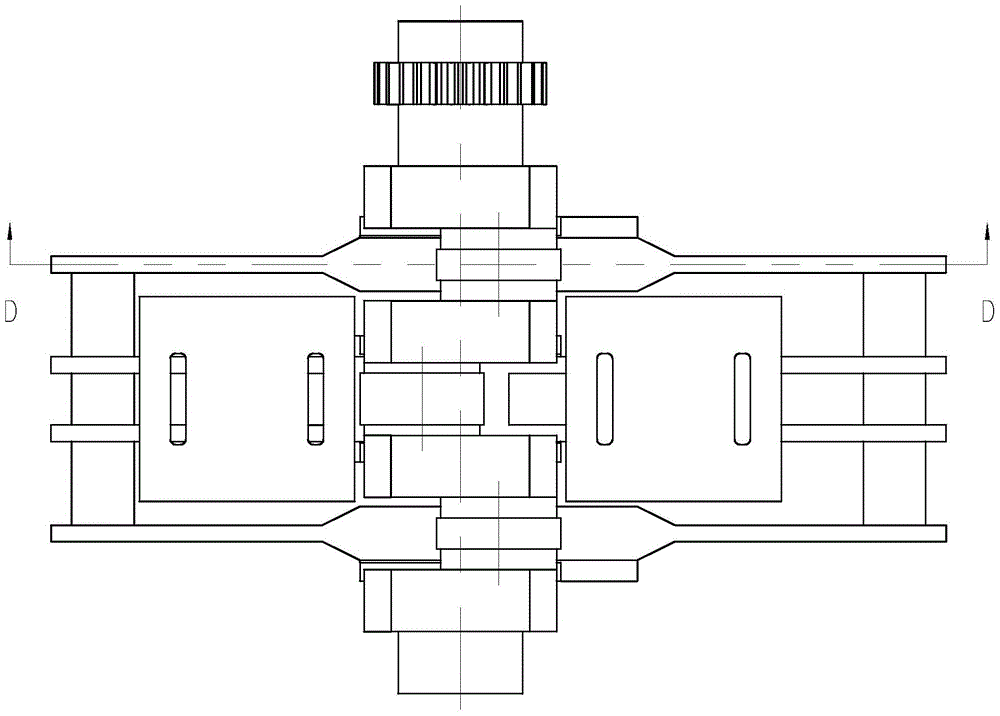

Double-crank mechanism engine

ActiveCN104481689AReduce toughnessReduce manufacturing costCylinder headsCylindersGas cylinderReciprocating motion

The invention discloses a double-crank mechanism engine, belonging to the technical field of engines. The double-crank mechanism engine comprises a gas cylinder and a piston capable of performing straight reciprocating motion in the gas cylinder, wherein two parallel crankshafts are arranged at the two sides of the gas cylinder; a connecting rod is hinged between corresponding crankshaft pins of the two crankshafts to form a double-crank mechanism; a connecting rod insertion slot and a slide block are arranged on a piston rod on the rear end of the piston, the connecting rod is inserted to the connecting rod insertion slot in a sliding manner, a guide block is fixed in the engine; a guide rail for sliding the slide block is formed on the guide block; the slide block is inserted to the guide rail; transmission gears are arranged on the end parts of the crankshafts; an output gear is engaged between the two transmission gears; and an output shaft is arranged on the output gear. The double-crank mechanism engine can be used for effectively lowering the abrasion and the impact of the piston and a cylinder sleeve, improving the reliability of the ceramic material applied to the engine and improving the practical heating efficiency.

Owner:王蓬波

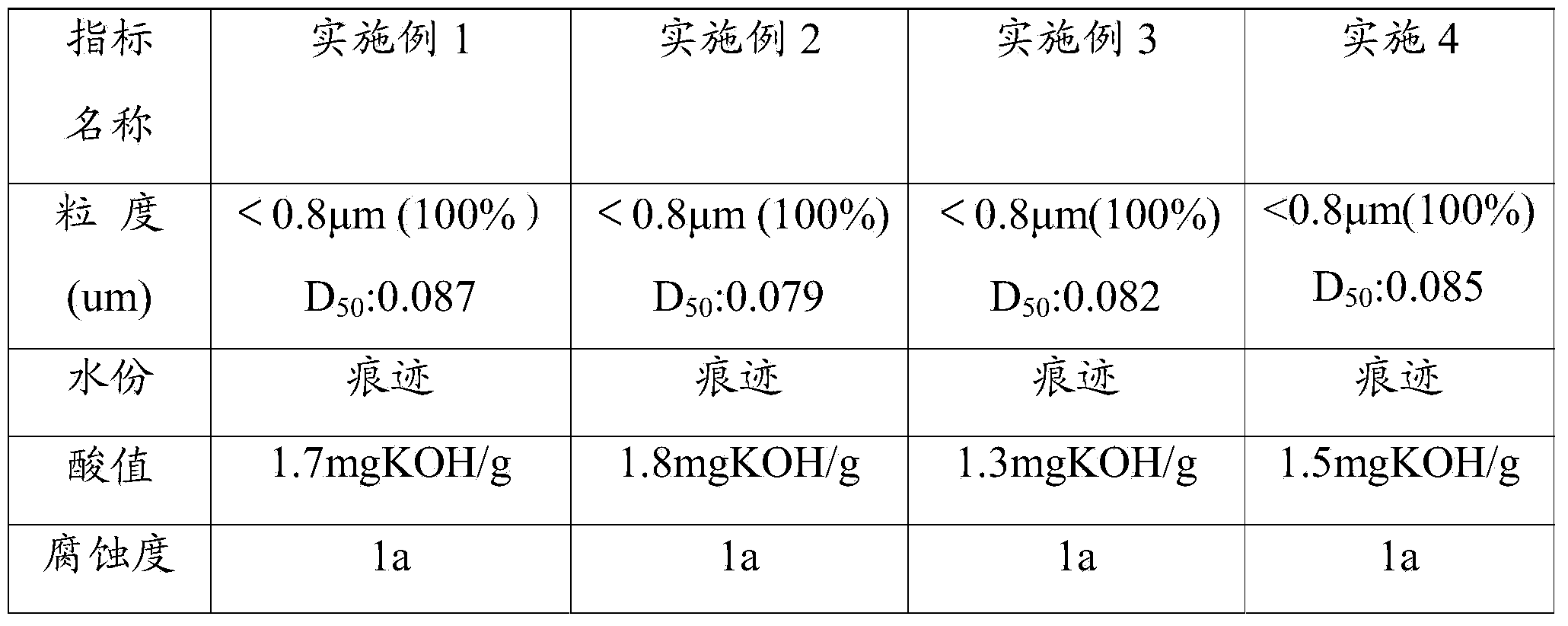

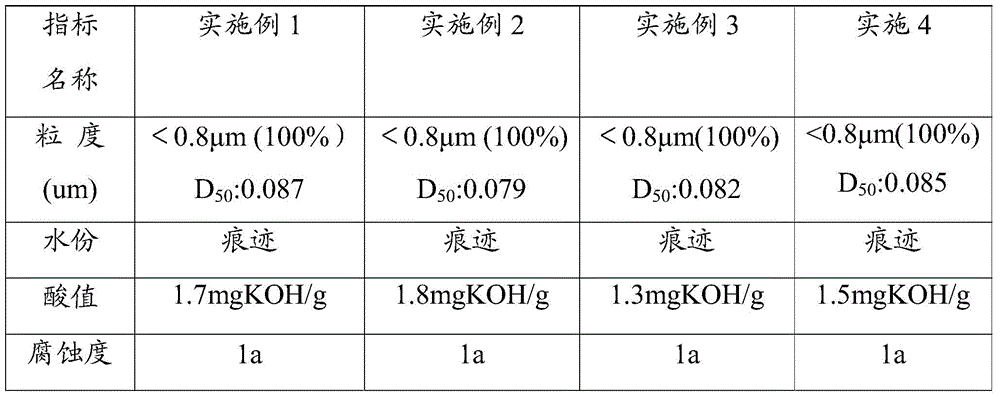

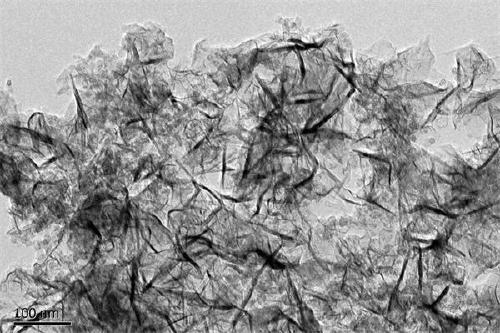

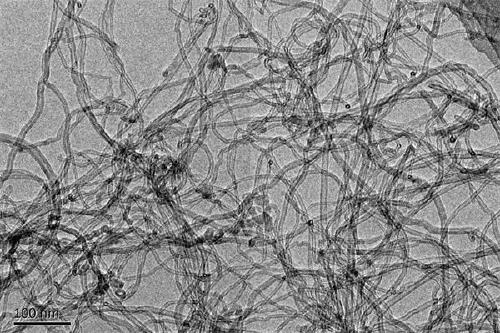

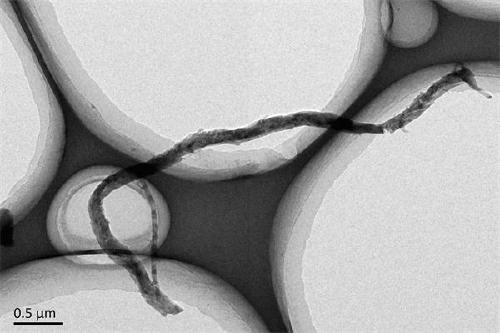

Lubricating oil containing surface modified carbon nanomaterials and preparation method thereof

The invention relates to lubricating oil containing surface modified carbon nanomaterials and a preparation method thereof, in particular to lubricating oil containing graphene, carbon nanotubes and nanocarbon fibers and a preparation method thereof. Graphene, carbon nanotubes and carbon nanofibers are coated with polydopamine and grafted with long-carbon-chain paraffins correspondingly on surfaceto obtain corresponding modified carbon nanomaterials. The modified carbon nanomaterials, base oil, and other lubricant functional additives are mixed in proportion to obtain the lubricating oil containing the surface modified carbon nanomaterials. The lubricating oil containing the surface modified carbon nanomaterials and the preparation method thereof solve problems of stability and dispersibility, produces ball effects and supporting effects, and further produce a solid-liquid dual-function lubrication mechanism and a stable porous structure, and remarkably improve performance of the lubricating oil.

Owner:HEILONGJIANG HUASHENG GRAPHITE CO LTD

Graphene-containing frictional regulator and preparation method thereof

ActiveCN104342236AImprove thermal conductivityImprove the lubrication effectAdditivesColloidOil phase

The invention discloses a graphene-containing frictional regulator and a preparation method thereof. The graphene-containing frictional regulator comprises the following components in percentage by mass: 0.3-1.2% of nano graphene, 3-8% of nano graphite particles, 1-6% of polymer protective colloid, 0.5-5% of dispersing agent, and the balance of base oil. Through the frictional regulator, the lubrication between metal pieces on the surface of a friction pair can be greatly promoted, and the wear is reduced; the anti-wear, lubrication, remediation and sealing properties can be increased to form synergistic effect, antiwear and lubrication effects of an engine on the severe wear when the engine is in cold starting can be enhanced, and the service life of the engine can be prolonged. The system has excellent dispersion and suspension properties as well as has no precipitation through an oil phase dispersion technology, and the frictional regulator is stable in the performances of the colloid.

Owner:GUANGDONG DONGGUAN TEAMRUN ELECTRONICS MATERIAL

Supercharged boost-assist engine brake

ActiveUS8281587B2Increase powerIncrease cylinder pressureValve arrangementsElectrical controlExhaust valveControl system

A control system for engine braking for a vehicle powered by a turbocharged engine uses a supercharger to assist a turbocharger compressor to boost turbocharger air flow into the engine cylinders. An engine driven air pumping device draws ambient air, or alternately exhaust gas through the pump inlet, compresses the air, and delivers the compressed air through the pump outlet to the turbocharger compressor inlet or alternately the turbocharger compressor outlet. The increased air flow into the cylinders and out of the cylinder exhaust valves increases retarding power of the vehicle.

Owner:INT ENGINE INTPROP CO LLC

Wear-resisting energy-saving agent for lubricating oil, its preparation method and application

The present invention provides an antiwear energy-saving agent containing refined mineral oil, zinc dialkyl dithiophosphate and deactivator for lubricating oil, it possesses excellent functions of reducing friction, reducing wear, resisting rust, resisting corrosion and resisting oxidation, and has strong cleaning dispersing power and good extreme pressure resistance and long-acting lubricating property and excellent compatibility with lubricant. This invention also provides its preparation method and application to lubricating oil and soaking field.

Owner:臧玉蓉 +1

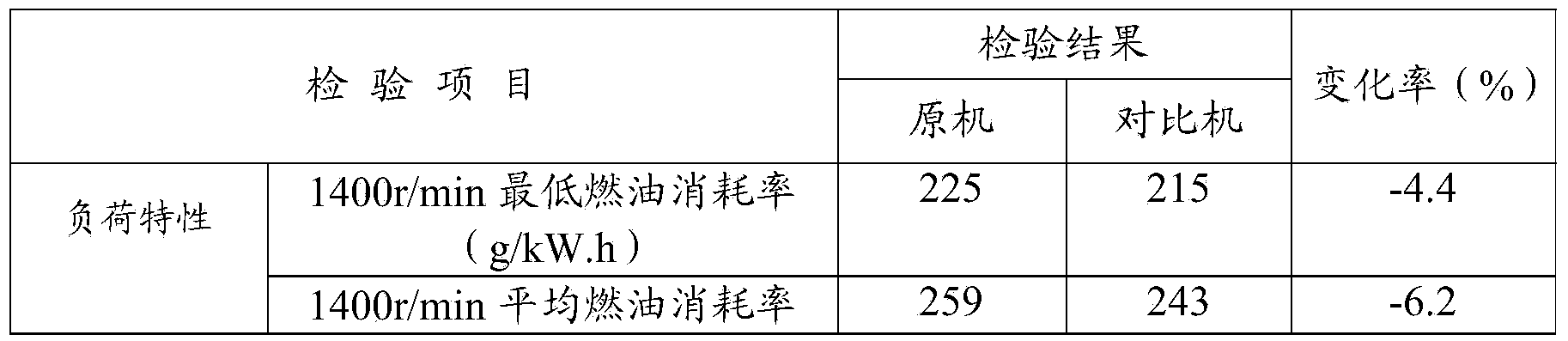

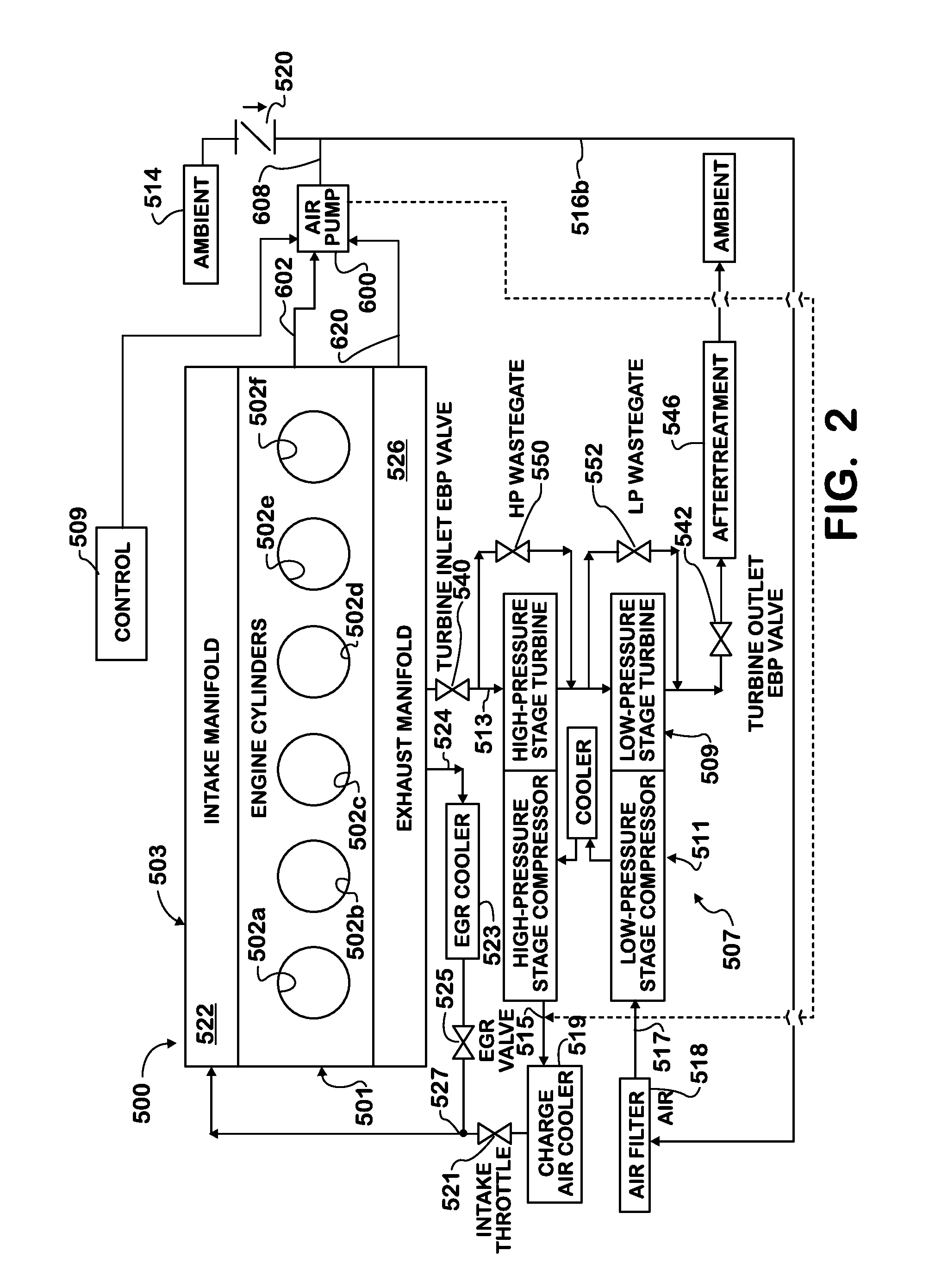

Energy-saving and synergistic nano graphite lubricant additive and preparation method thereof

The invention provides an energy-saving and synergistic nano graphite lubricant additive and a preparation method thereof. The preparation method is characterized by comprising the following steps of: ball-milling graphite powder, deironing, separating and drying, and processing to obtain nano graphite powder; and mixing the nano graphite powder, gear oil, a dispersion stabilizer, basic oil and a solid lubricant to obtain the finished energy-saving and synergistic nano graphite lubricant additive. By the preparation method, the engine can save fuel oil by over 7 percent, reduce the lubricant oil consumption by 50 percent, prolong the oil change period by one time, reduce abrasion of machine parts and prolong the engine overhaul mileage by 50 percent; moreover, the abrasion is reduced, the abrasion rate of an engine cylinder is reduced by 25 to 36 percent, the engine air tightness is increased, the discharge of harmful gases in the tail gas is reduced, and dual benefit of saving the energy and protecting the environment can be gained.

Owner:司银奎

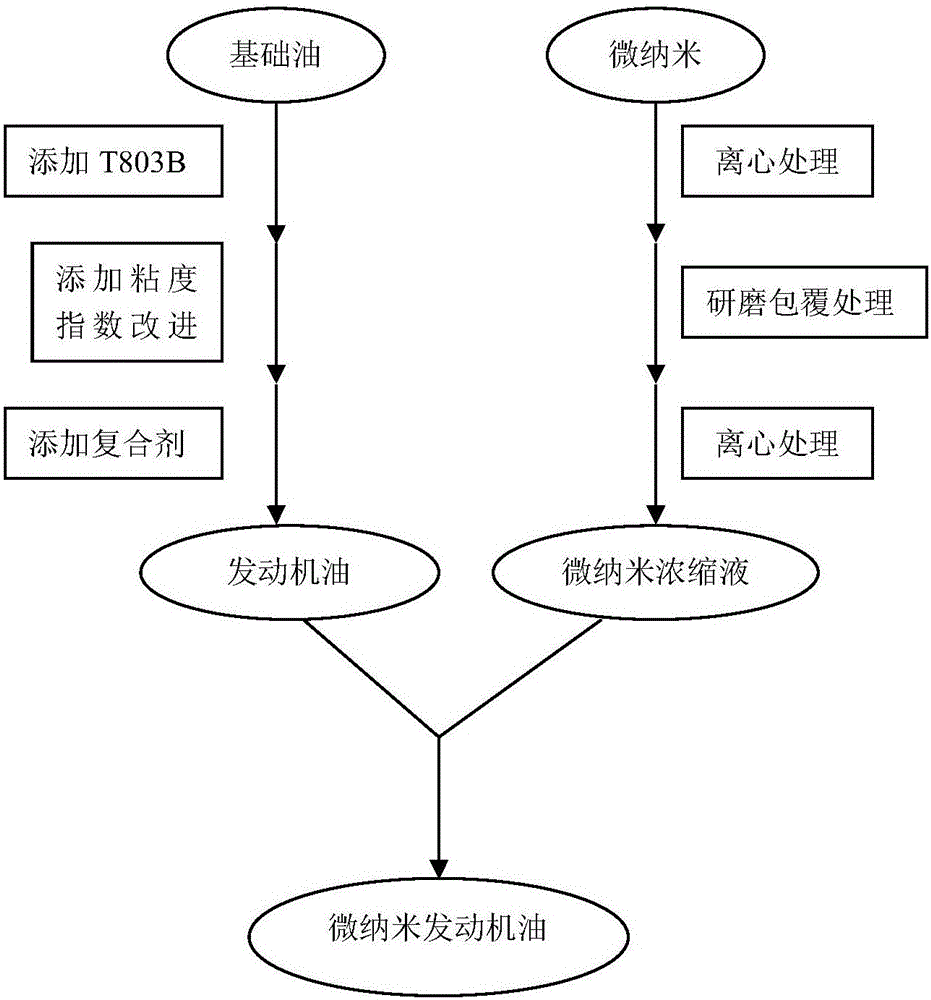

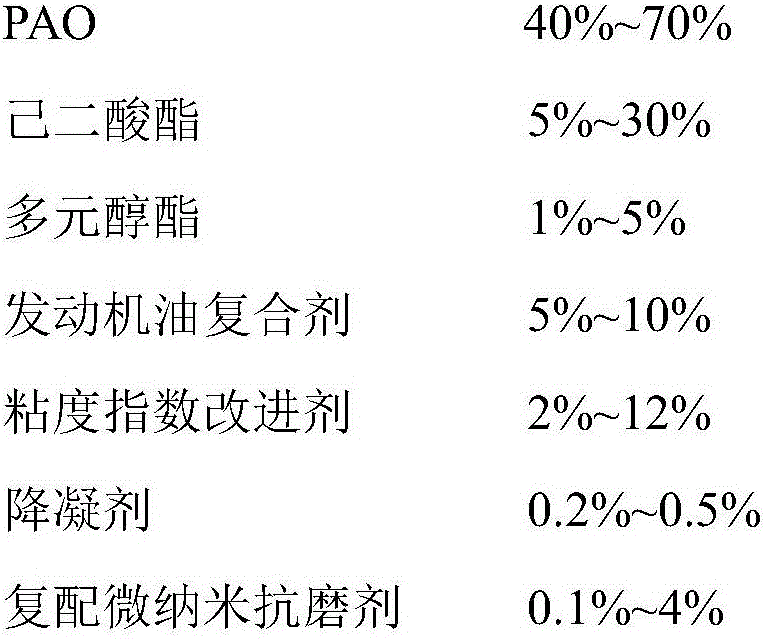

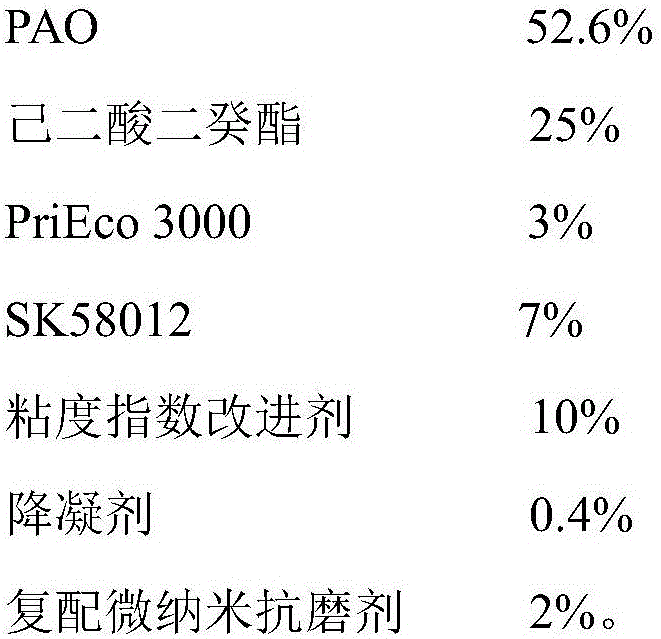

Micro-nano engine oil and preparation method thereof

ActiveCN106701277AEvenly dispersedIncrease productivityLubricant compositionMicro nanoMetal particle

The invention relates to micro-nano engine oil and a preparation method thereof. The micro-nano engine oil is prepared from, by mass, 40%-70% of PAO, 5%-30% of adipate, 1%-5% of polyol ester, 5%-10% of an engine oil complexing agent, 2%-12% of a viscosity index improver, 0.2%-0.5% of a pour point reducer and 0.1%-4% of a compound micro-nano antiwear agent. The micro-nano antiwear agent is micro-nano metal particles, the micro-nano metal particles are treated through the processes of centrifugal separation, grinding dispersion, centrifugal treatment and the like and finally uniformly suspend in PAO to prepare micro-nano concentrated liquid, the micro-nano concentrated liquid is mixed with engine oil mixed liquid taking the PAO as base oil, uniform dispersion of the nano particles is guaranteed, after mixing is conducted, the finished product can be obtained only by conducting constant-temperature stirring for 1 h, and therefore the production efficiency is improved.

Owner:广东恒昌科技润滑油有限公司

Energy-saving and anti-friction graphite lubricating oil and preparation method therefor

The invention relates to an energy-saving and anti-friction graphite lubricating oil and methods for making the same. The energy-saving and anti-friction graphite lubricating oil includes 1-3 parts by weight of graphite lubricating oil additive, and 97-99 parts by weight of national standard lubricating oil; the graphite lubricating oil additive includes 10-20 parts by weight of graphite powder, 30-35 parts by weight of dispersant, and 45-60 parts by weight of base oil. Graphite lubricating oil of the present invention is added in automobile engine and transmission case, and in automobile, fuel oil is saved 7-12% in the car that takes gasoline as fuel, and fuel gas is saved 15-20% in the car that takes gas as fuel, and diesel fuel is used as fuel. Save 3-5% of fuel in large and medium-sized vehicles, save 5-8% of gas in large and medium-sized vehicles fueled by gas, reduce the wear and tear of parts by more than double, extend the oil change period of lubricating oil by more than 30%, and reduce carbon monoxide in engine exhaust , carbon dioxide and carbohydrates and other harmful gases more than 30% of the emissions.

Owner:青岛路比特科技有限公司

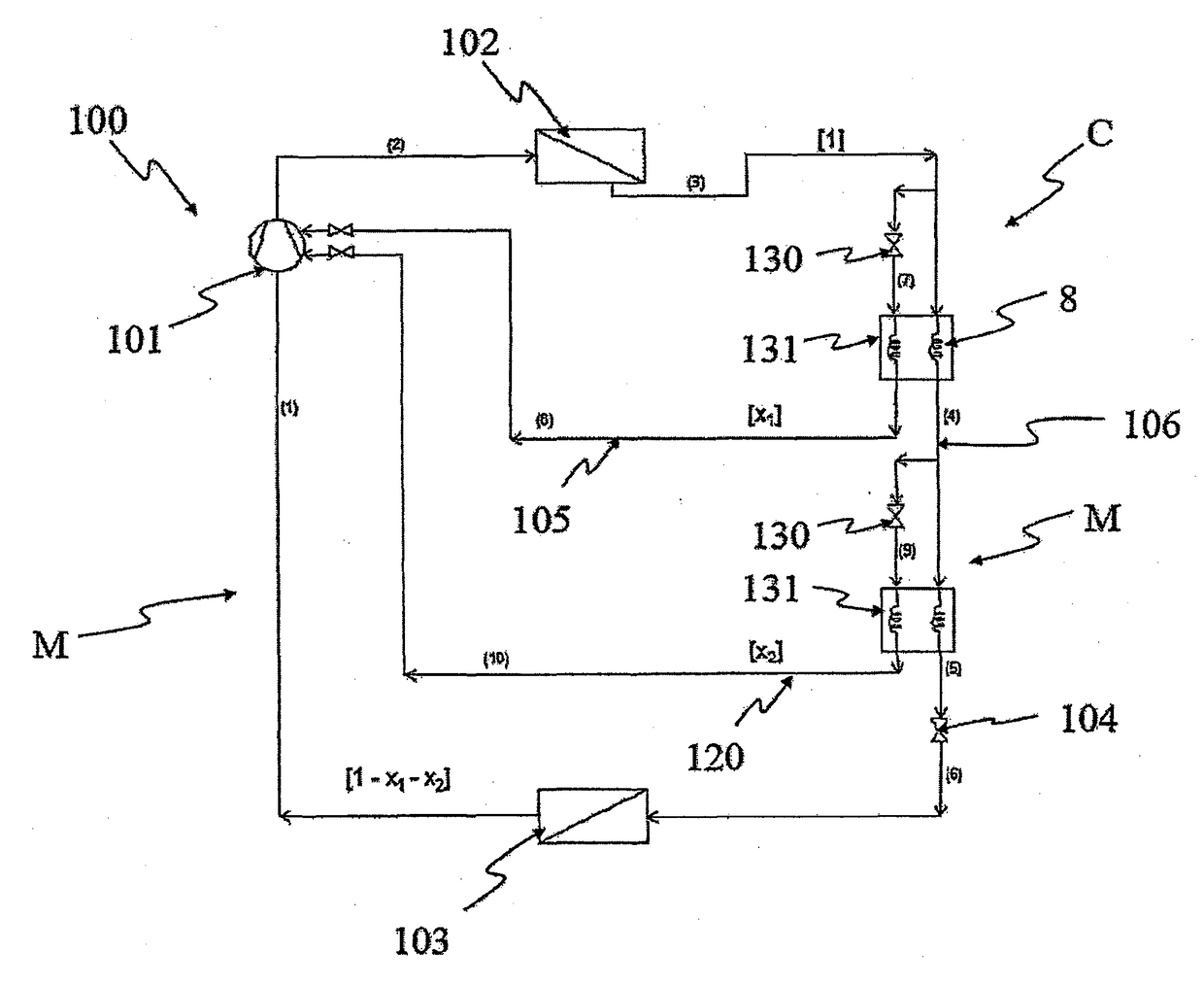

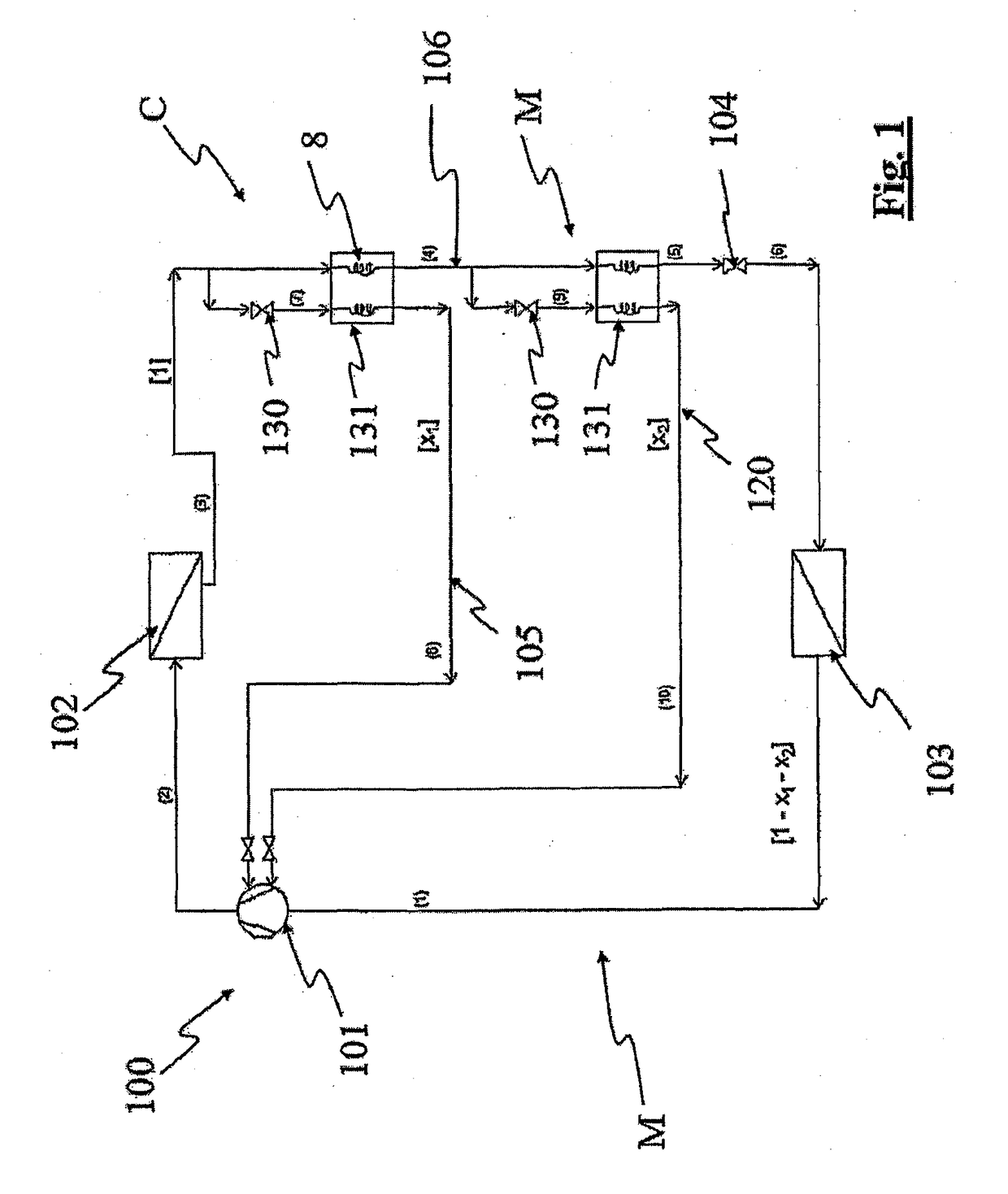

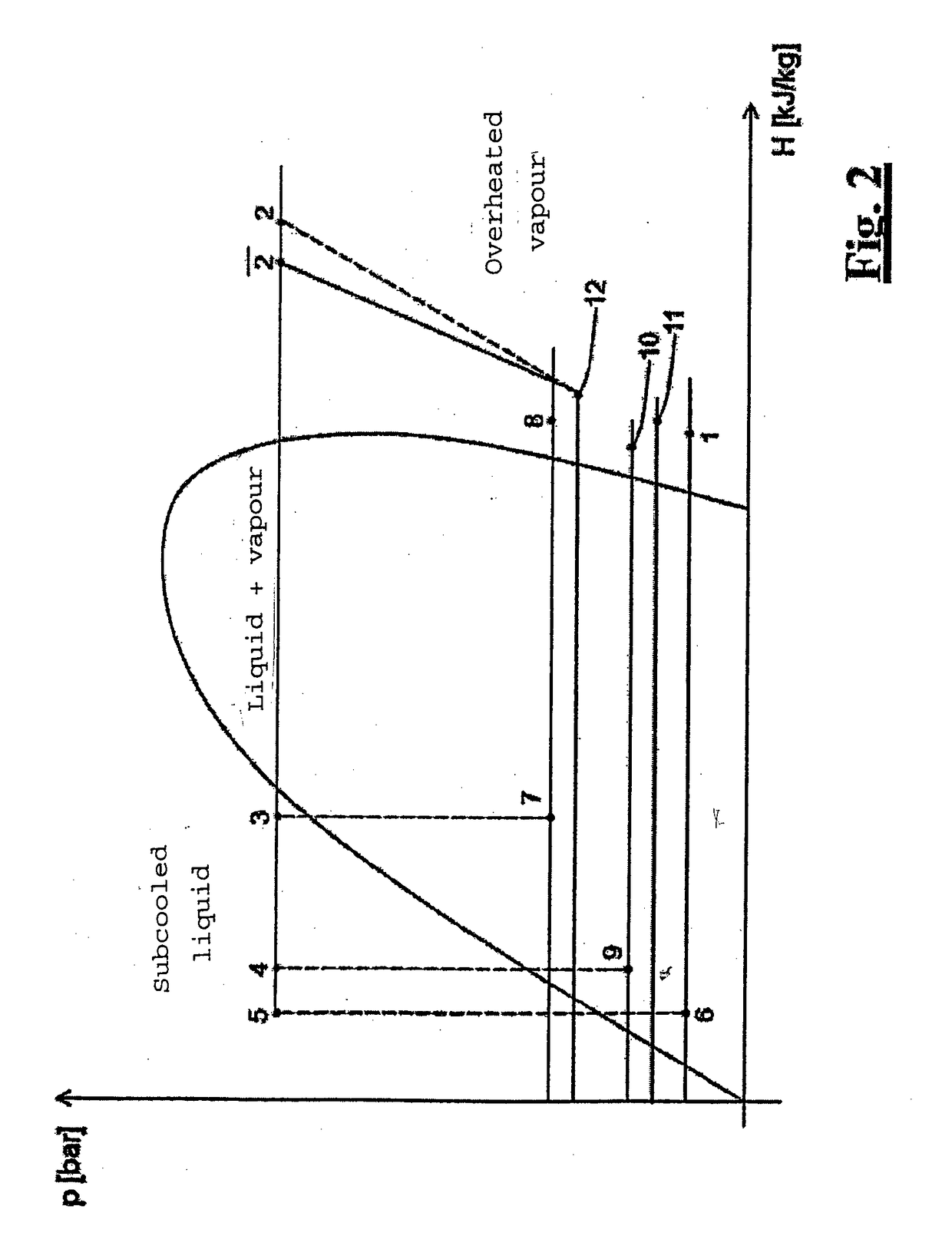

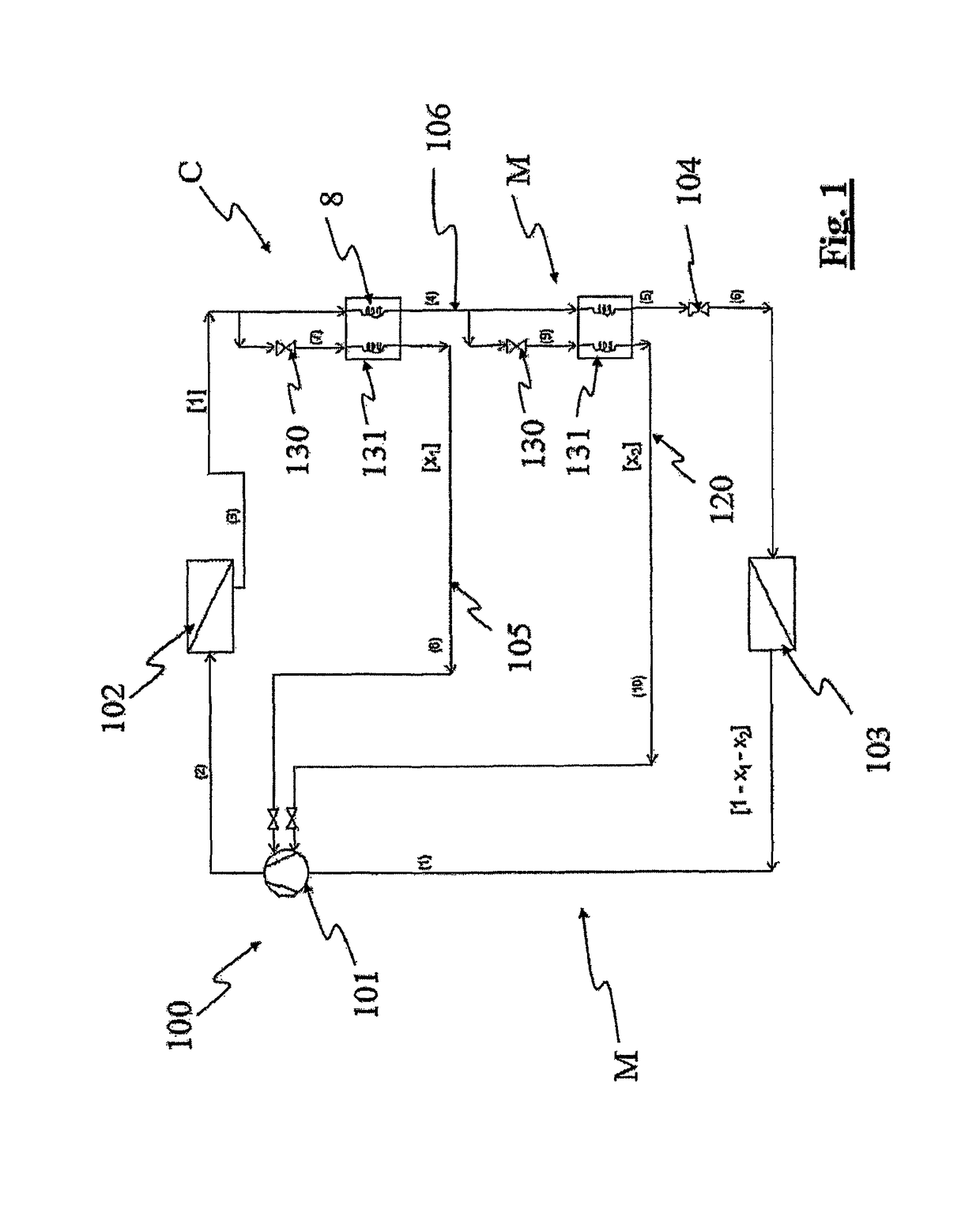

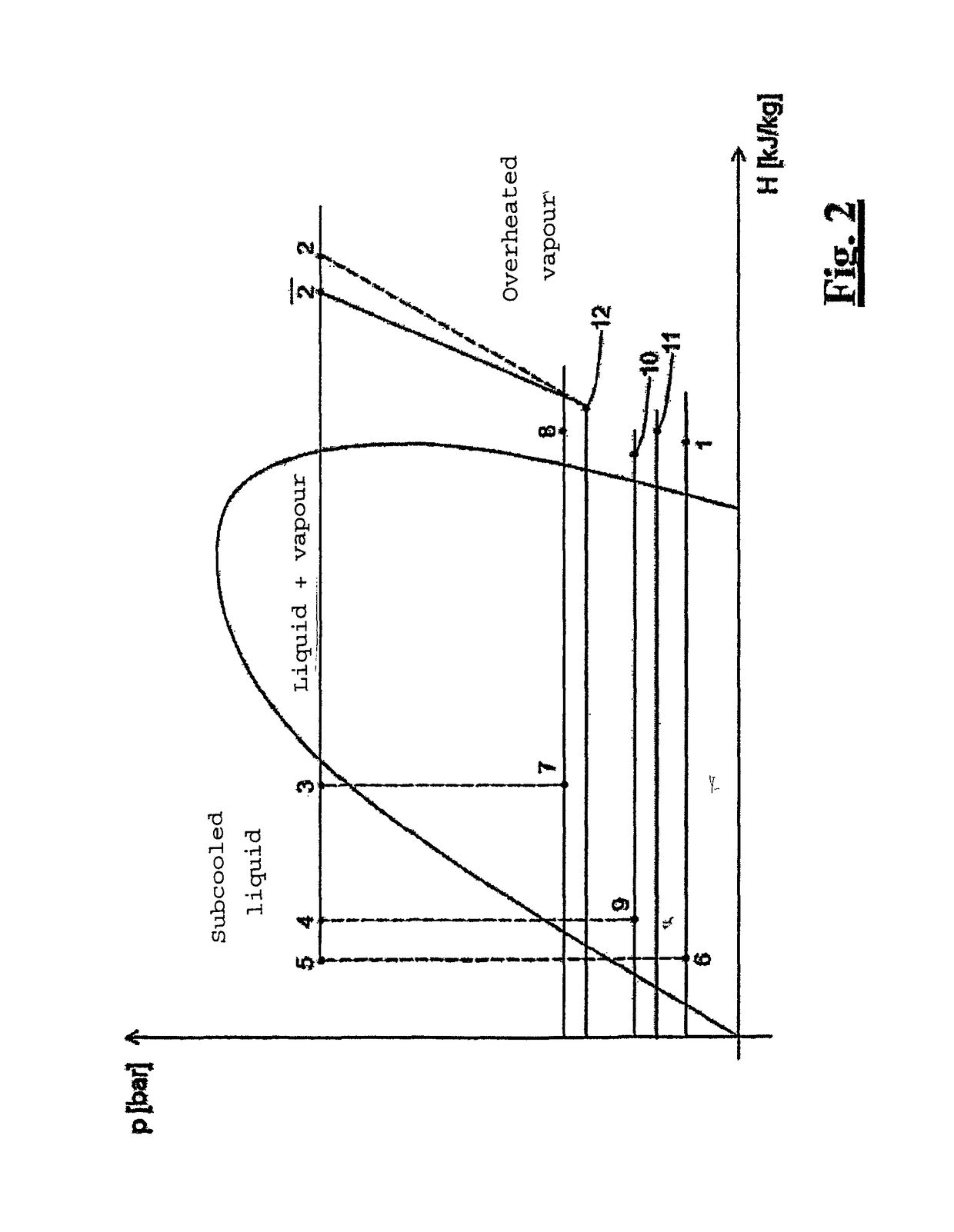

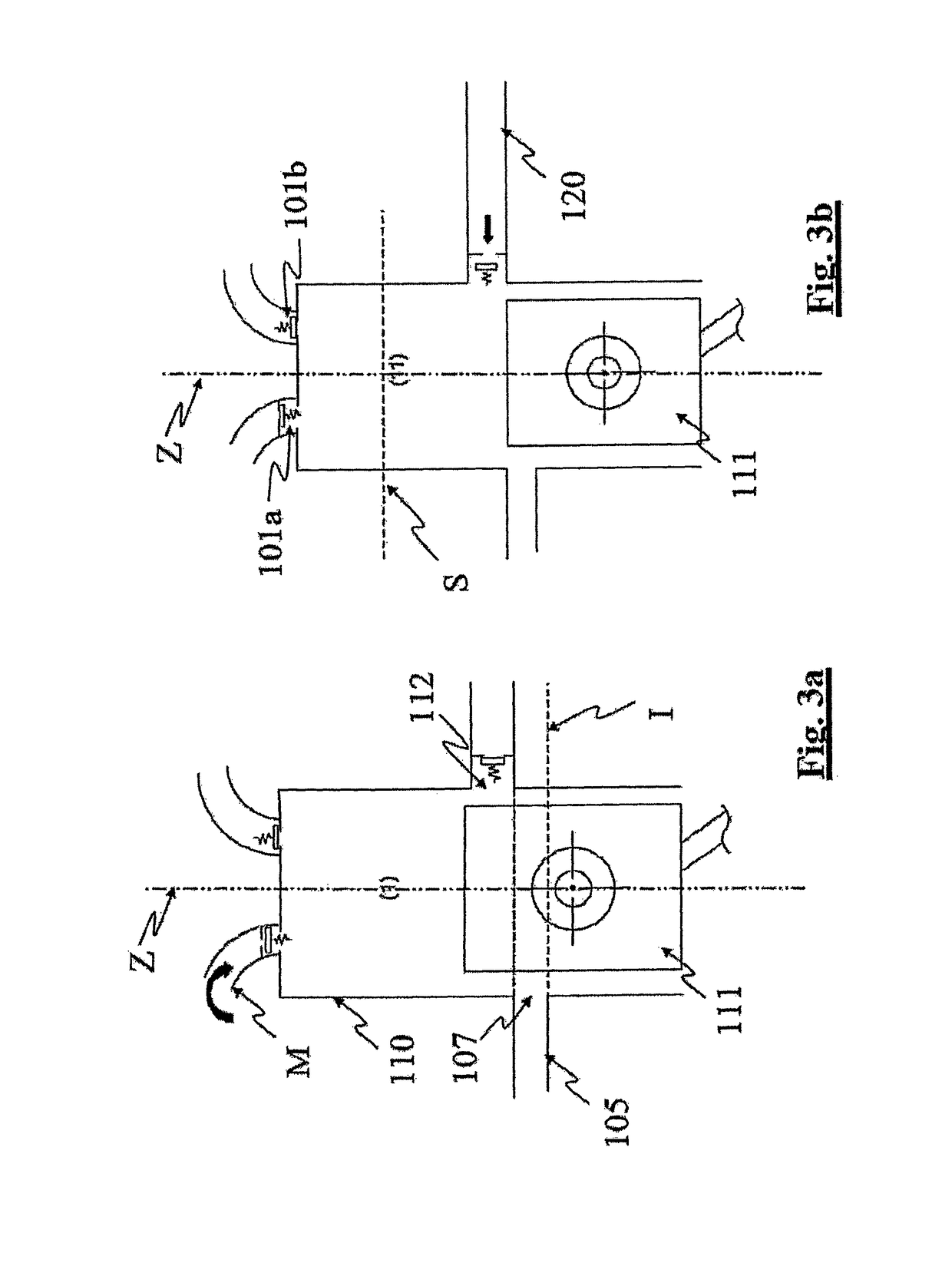

Refrigeration device

ActiveUS20170343244A1Improve efficiencyIncreased complexityMechanical apparatusCompression machines with non-reversible cycleMain branchEngineering

A refrigeration device having a closed circuit in which a flow rate of coolant is circulating is provided. The closed circuit has a condenser and a main branch provided with a reciprocating compressor inside which a defined flow rate of the coolant enters, from the main branch, at a defined suction pressure, of an evaporator and a first expansion valve that is arranged between the condenser and the evaporator. The closed circuit further has a first secondary economizer branch for a first fraction of flow rate of the coolant, the first secondary economizer branch fluidically connecting the compressor to a section of the closed circuit between the condenser and the first expansion valve, wherein the compressor has a first side inlet port for the entrance of the first fraction of coolant flow rate.

Owner:ANGELANTONI TEST TECH

Cleaning agent for engine lubrication system without disassembly

ActiveCN108546583AEasy to cleanImprove adsorption capacityLubricant compositionOil sludgeCarbon deposit

Owner:杭州维客泰美品牌管理有限公司

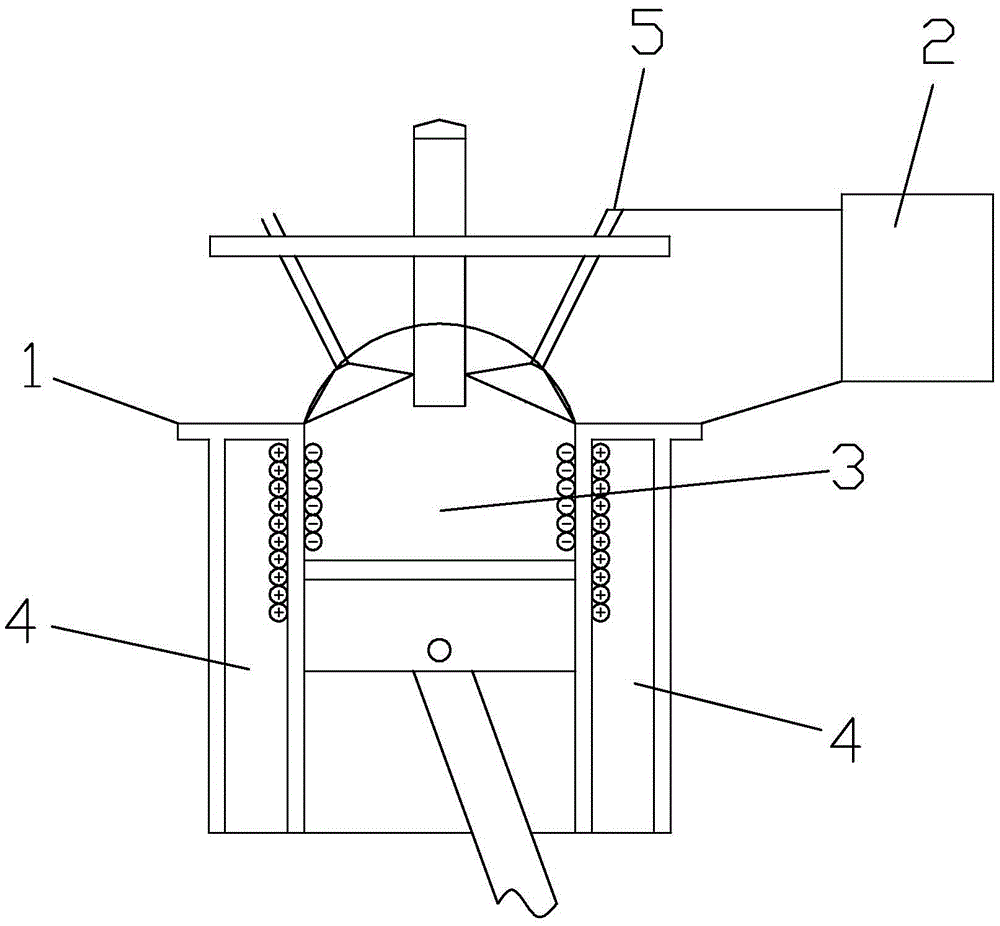

Engine energy increasing system

InactiveCN105484902AIncrease motivationImprove combustion efficiencyInternal combustion piston enginesCombustion-air/fuel-air treatmentCombustion chamberElectrical polarity

The invention discloses an engine energy increasing system which comprises an engine and an ion generator, wherein the engine comprises a combustion chamber, an air line communicating with the combustion chamber, and a cooling chamber surrounding the periphery of the combustion chamber; the ion generator comprises an A-type ionic charge output module and a B-type ionic charge output module; the output terminal of the A-type ionic charge output module is connected with the air line; the output terminal of the B-type ionic charge output module is connected with the cooling chamber; and the polarity of ionic charge output by the A-type ionic charge output module is opposite to the polarity of ionic charge output by the B-type ionic charge output module. According to the invention, a strong special ionic field can be formed outside the whole combustion chamber, the air line brings A-type ionic charge into the combustion chamber, and molecules of combustible mixture of the A-type ionic charge and B-type ionic charge attached to the cylinder wall of the combustion chamber of the engine merge with each other violently and quickly in extremely short time, so as to increase combustion vitality, thus improving the combustion efficiency of fuel oil.

Owner:吴国东

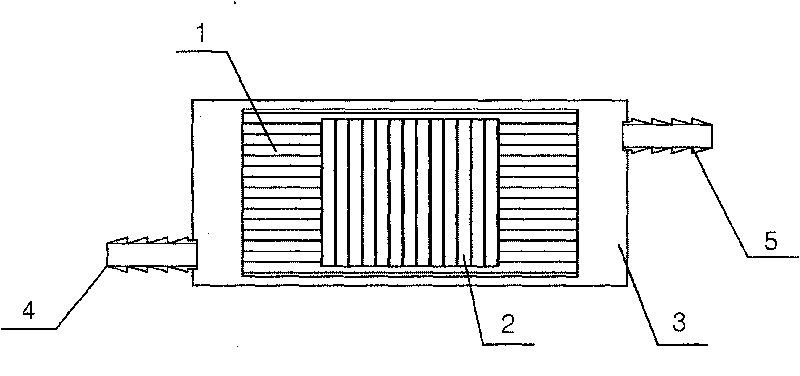

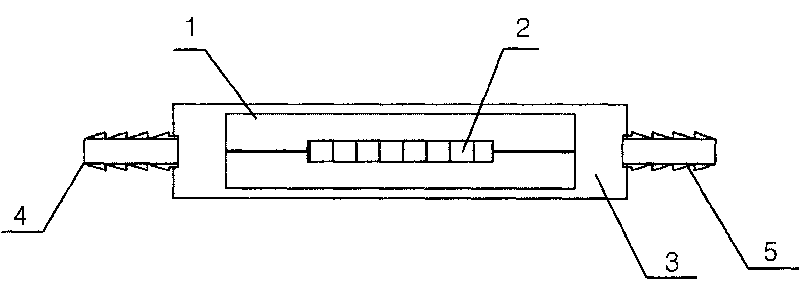

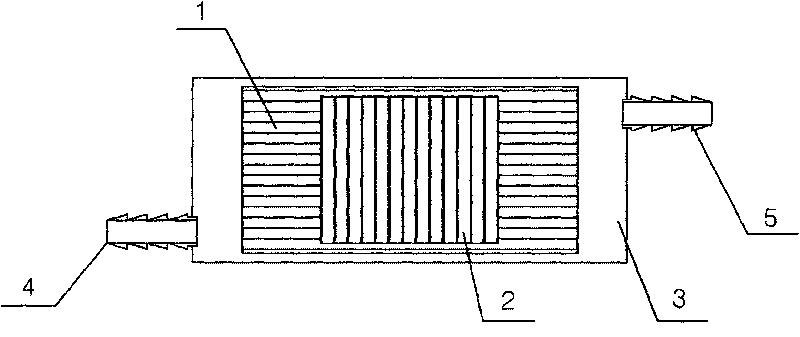

Spectrum function honeycomb ceramic fuel oil internal energy increasing device and manufacturing method thereof

InactiveCN101761426AIncrease disturbanceImprove internal energyInternal combustion piston enginesCombustion-air/fuel-air treatmentPolyvinyl alcoholAdhesive

The invention relates to fuel oil saving technology, in particular to a spectrum function honeycomb ceramic fuel oil internal energy increasing device and a manufacturing method thereof. The device comprises an oil inlet and an oil outlet arranged on a shell, a honeycomb ceramic body is arranged in the shell, and a rare earth permanent magnet energy block is arranged in the middle of the honeycomb ceramic body, wherein the honeycomb ceramic body is formed from 15-20% of chloritoid phyllite, 25-30% of alumina, 5-10% of calcite, 25-30% of tourmaline, 10-15% of iron oxide and 2% of polyvinyl alcohol adhesive by smashing, milling, hot mixing, vacuum refining, extrusion molding into a honeycomb micropore shape and firing at a high temperature of 1300 DEG C. The device can increase the utilization rate of the fuel oil, reduces the emission of hydrocarbon and particles in automobile exhaust, maintains an internal combustion engine and protects the atmospheric environment.

Owner:李永军

Anti-attrition oil saving agent for structural porcelain

InactiveCN101665739AReduce coefficient of frictionReduce wearAdditivesMachine partsMechanical equipment

The invention relates to an anti-attrition oil saving agent for structural porcelain, comprising lubricating oil or lubricating grease used as a carrier. Natural ore powder with fineness specificationof 500 nanometers-2 micrometer is uniformly added in the lubricating oil or the lubricating grease, the content of the natural ore powder in the lubricating oil or the lubricating grease is 0.01-1%,the natural ore powder comprises the following elements in percentage by weight: 5-20% of silicon, 5-20% of aluminum, 5-20% of calcium, 5-20% magnesium, 1-10% of ferrum and 1-10% of natrium, and the natural ore powder is selected and added in the lubricating oil or the lubricating grease according to a certain proportion, and after emulsification and diffusion treatment, the anti-attrition oil saving agent is prepared. A appropriate amount of the anti-attrition oil saving agent is added in engine oil so as to synthesize a smooth and hard structural porcelain protection layer with machine bodyelements on a negative friction surface in virtue of heat energy generated by high-temperature fuel gas of the engine and friction during the operation of mechanical equipment, thereby reducing the friction coefficients of machine parts and the abrasion and achieving the purpose of saving oil.

Owner:关景瀛

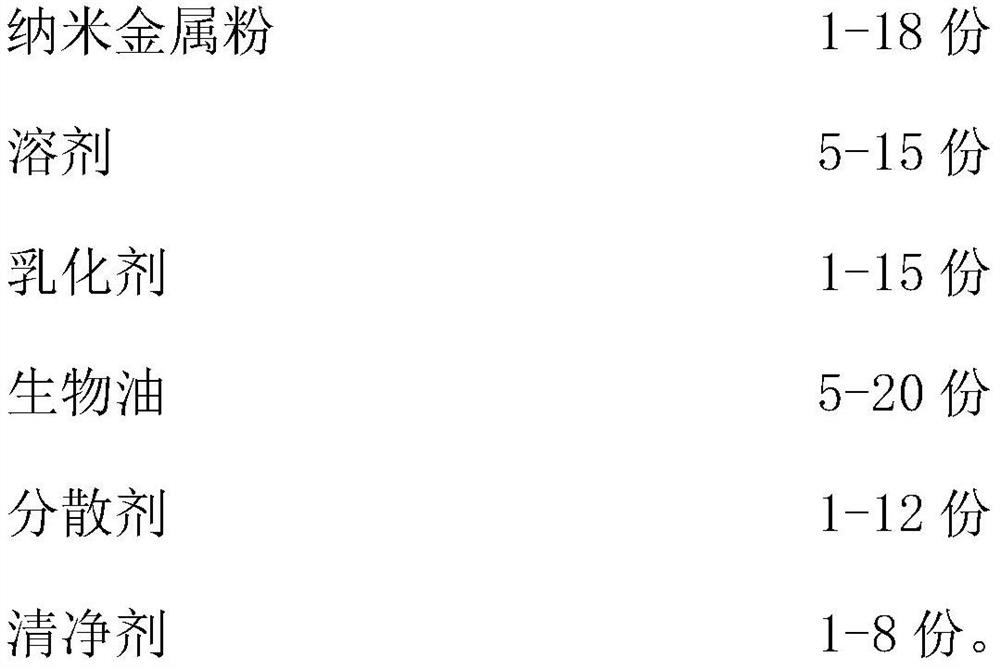

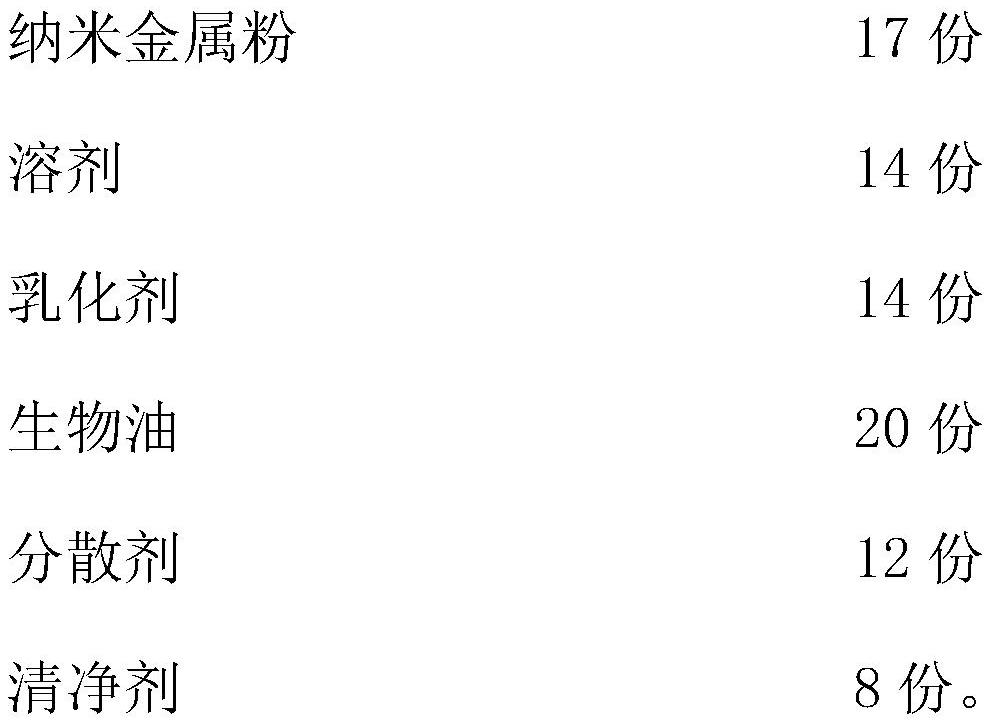

Nano engine oil additive and preparation method thereof

The invention discloses a nano engine oil additive and a preparation method thereof. The nano engine oil additive is prepared from 1-18 parts of nano metal powder, 5-15 parts of solvent, 1-15 parts ofemulsifier, 5-20 parts of bio-oil, 1-12 parts of dispersing agent and 1-8 parts of clearing agent. The nano engine oil additive is prepared from the components, and the nano engine oil additive is added into base oil mixed liquid of engine oil, thus the friction coefficient of an engine can be greatly reduced, and engine abrasion is reduced.

Owner:速马力(广州)环保研究院有限责任公司

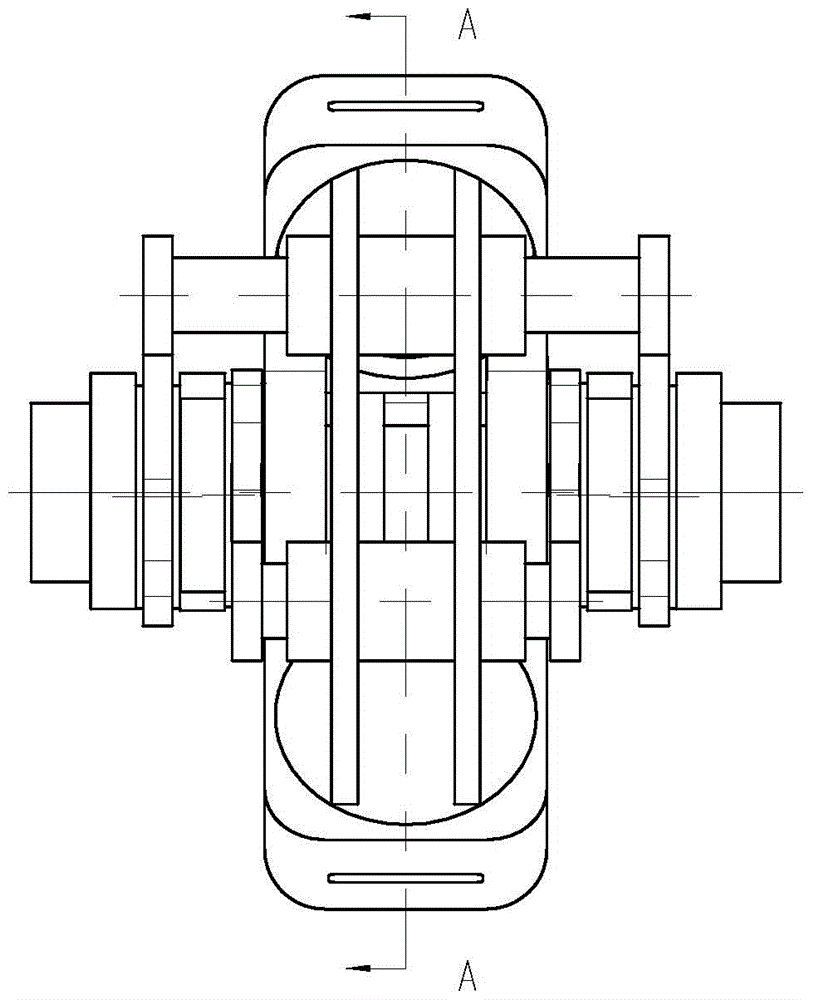

Double-cylinder two-stroke cylinder engine

ActiveCN104481680AReduce toughnessReduce manufacturing costInternal combustion piston enginesCombustion chamberGas cylinder

The invention discloses a double-cylinder two-stroke cylinder engine, belonging to the technical field of engines. The double-cylinder two-stroke cylinder engine comprises two gas cylinders which are oppositely arranged, two double-ended pistons, and a crankshaft, wherein inner cavities of the gas cylinders are manufactured into circular-ring-shaped curved surfaces; piston inlets are formed in the two ends of each gas cylinder; a central shaft is arranged between the two gas cylinders; each double-ended piston comprises a piston arm, wherein piston heads are fixed at the two ends of the piston arm; the piston arm is hinged on the central shaft; a sealed combustion chamber is formed between the two opposite piston heads of the gas cylinder; a connecting rod is hinged between the piston arm and the crank of the crankshaft; the crankshaft, the connecting rod, the piston arm and the central shaft form a crankshaft rocker rod mechanism capable of synchronously swinging the double-ended pistons, and enabling the piston heads to rotate back and forth around the central shaft between inner and outer stop points. The double-cylinder two-stroke cylinder engine can be used for effectively lowering the abrasion and impact of the piston and the cylinder sleeve, greatly improving the reliability of the ceramic material applied to the engine and improving the practical heating efficiency.

Owner:王蓬波

Graphite lubricating oil friction-reducing additive and preparation method thereof

InactiveCN105985838AFriction reduction achievedAchieve anti-wearLubricant compositionGasolineFuel oil

The invention relates to a graphite lubricating oil friction-reducing additive and a preparation method thereof. The graphite lubricating oil friction-reducing additive comprises the following components: 10 to 20 parts of graphite powder, 30 to 35 parts of a dispersant and 45 to 60 parts of base oil. The graphite lubricating oil friction-reducing additive provided by the invention is added into engine lubricating oil in a proportion of 1.2% to 1.5% and into automobile transmission gear oil in a proportion of 2% to 3%, and has the following advantages: fuel oil is saved by 7% to 12% in a car with gasoline as a fuel; fuel gas is saved by 15% to 20% in the car with the fuel gas as the fuel; the fuel oil is saved by 3% to 5% in large-sized and medium-sized automobile with diesel as the fuel; the fuel gas is saved by 5% to 8% in large-sized and medium-sized automobile with the fuel gas as the fuel; wear of mechanical parts is reduced by one time or more; and the change period of the lubricating oil is prolonged by 30%.

Owner:青岛路比特科技有限公司

A kind of friction modifier containing graphene and preparation method thereof

ActiveCN104342236BImprove thermal conductivityImprove the lubrication effectAdditivesOil phaseColloid

The invention discloses a graphene-containing frictional regulator and a preparation method thereof. The graphene-containing frictional regulator comprises the following components in percentage by mass: 0.3-1.2% of nano graphene, 3-8% of nano graphite particles, 1-6% of polymer protective colloid, 0.5-5% of dispersing agent, and the balance of base oil. Through the frictional regulator, the lubrication between metal pieces on the surface of a friction pair can be greatly promoted, and the wear is reduced; the anti-wear, lubrication, remediation and sealing properties can be increased to form synergistic effect, antiwear and lubrication effects of an engine on the severe wear when the engine is in cold starting can be enhanced, and the service life of the engine can be prolonged. The system has excellent dispersion and suspension properties as well as has no precipitation through an oil phase dispersion technology, and the frictional regulator is stable in the performances of the colloid.

Owner:GUANGDONG DONGGUAN TEAMRUN ELECTRONICS MATERIAL

Lubricating oil containing surface-modified carbon nanomaterials and preparation method thereof

The invention relates to lubricating oil containing surface modified carbon nanomaterials and a preparation method thereof, in particular to lubricating oil containing graphene, carbon nanotubes and nanocarbon fibers and a preparation method thereof. Graphene, carbon nanotubes and carbon nanofibers are coated with polydopamine and grafted with long-carbon-chain paraffins correspondingly on surfaceto obtain corresponding modified carbon nanomaterials. The modified carbon nanomaterials, base oil, and other lubricant functional additives are mixed in proportion to obtain the lubricating oil containing the surface modified carbon nanomaterials. The lubricating oil containing the surface modified carbon nanomaterials and the preparation method thereof solve problems of stability and dispersibility, produces ball effects and supporting effects, and further produce a solid-liquid dual-function lubrication mechanism and a stable porous structure, and remarkably improve performance of the lubricating oil.

Owner:HEILONGJIANG HUASHENG GRAPHITE CO LTD

Structure ceramic metal abrasion reduction material

The invention relates to a structure ceramic metal abrasion reduction material which comprises lubricating oil or lubricating grease used as a carrier; natural ore powder with the fineness specification of 100 to 500 nanometers is uniformly added into the lubricating oil or the lubricating grease; the content of the ore powder in the lubricating oil or the lubricating grease is 0.1% to 1%; the core powder comprises elementary components: 5% to 20% of silicon, 5% to 20% of aluminium, 5% to 10% of calcium, 5% to 20% of magnesium, 5% to 10% of carbon, 1% to 10% of iron, 1 to 10% of sodium and 0.01% to 1% of scandium; the structure ceramic metal abrasion is prepared by the steps of: selecting the ore powder, adding the ore powder into the lubricating oil or the lubricating grease according toa certain proportion and carrying out emulsification and diffusion treatment; a right amount of reduction material is added into machine oil of an engine; in the running process of mechanical equipment, the reduction material is combined with engine body elements on the frictional negative surface by virtue of the heat energy generated by the high temperature gas and the friction of the engine toform a smooth and hard structure ceramic protective layer, thereby achieving the purpose that frictional factors of the machine elements are decreased, the abrasion is reduced, the service life of the machine elements is prolonged and the oil is saved.

Owner:中科宝鹿新材料(辽宁)有限公司

Two-cylinder two-stroke ring cylinder engine

ActiveCN104481680BReduce toughnessReduce manufacturing costInternal combustion piston enginesCombustion chamberGas cylinder

Owner:王蓬波

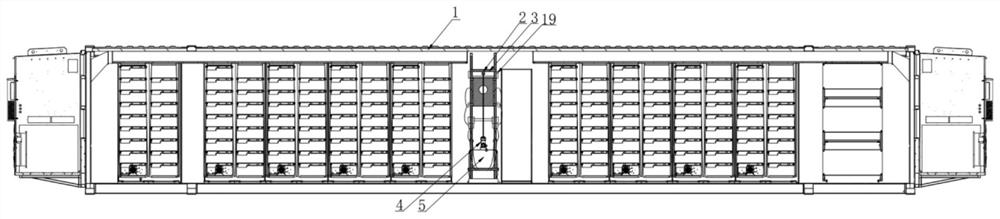

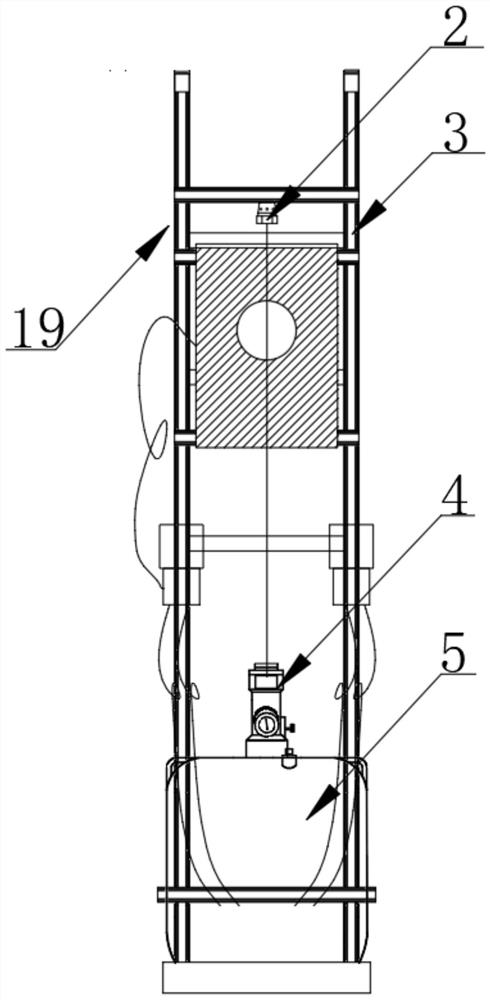

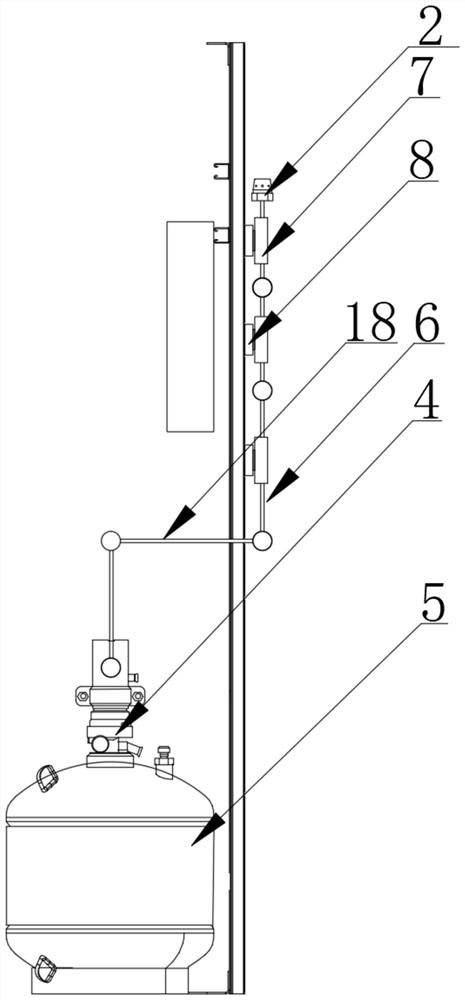

Container gas spraying fire extinguishing device

The container gas spraying fire extinguishing device comprises a container, a fire fighting cabinet is installed at the center of the bottom end in the container, a gas steel cylinder is installed on the bottom end face in the fire fighting cabinet, an electromagnetic valve is connected to the top end face of the gas steel cylinder through a bolt, a spraying head is arranged on the side, away from the gas steel cylinder, of the fire fighting cabinet, and the spraying head can rotate by 360 degrees; the container has the beneficial effects that the structure and layout of the fire-fighting gas spraying pipeline can be redesigned according to the space size of the container and the fire-fighting requirements of objects installed in the container, the situation that only one gas spraying head is installed in the middle of a fire-fighting pipeline in the container is reduced, and the fire-fighting efficiency is improved. Meanwhile, the steel cylinder pressure of fire extinguishing gas is increased, and the gas pressure in the pipeline is improved by changing the pipe diameter of the pipeline, so that the quick and safe fire extinguishing function is realized, and personnel can conveniently inspect, maintain and replace the spraying pipeline.

Owner:靖江市亚泰新能源科技有限公司

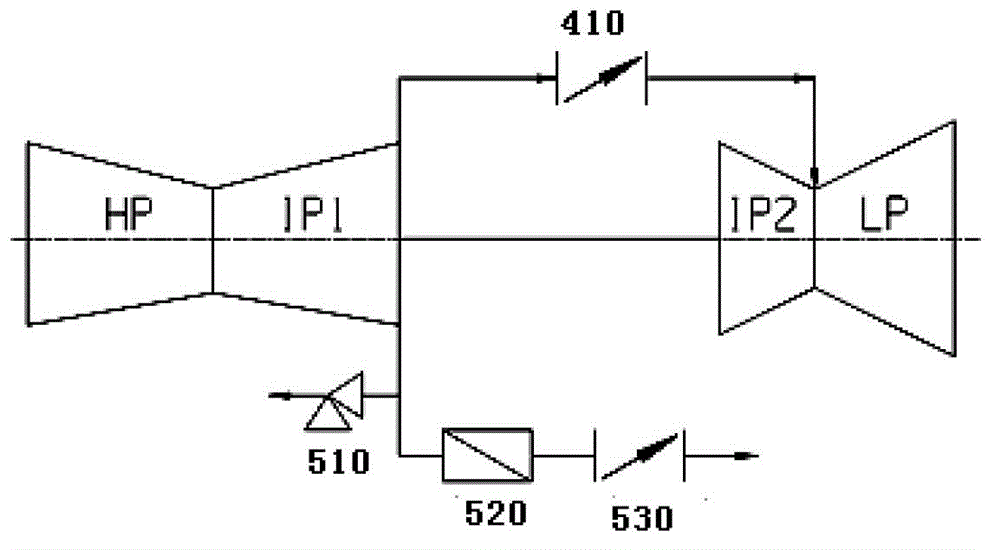

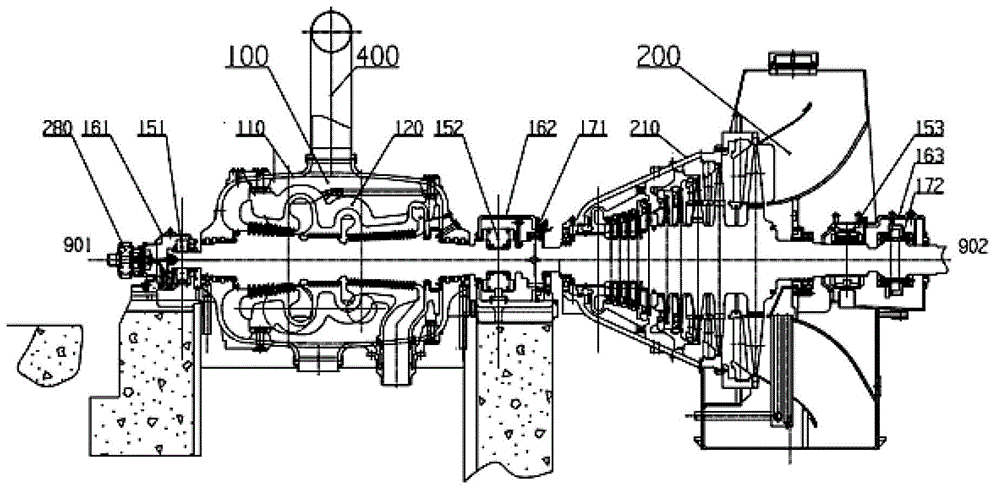

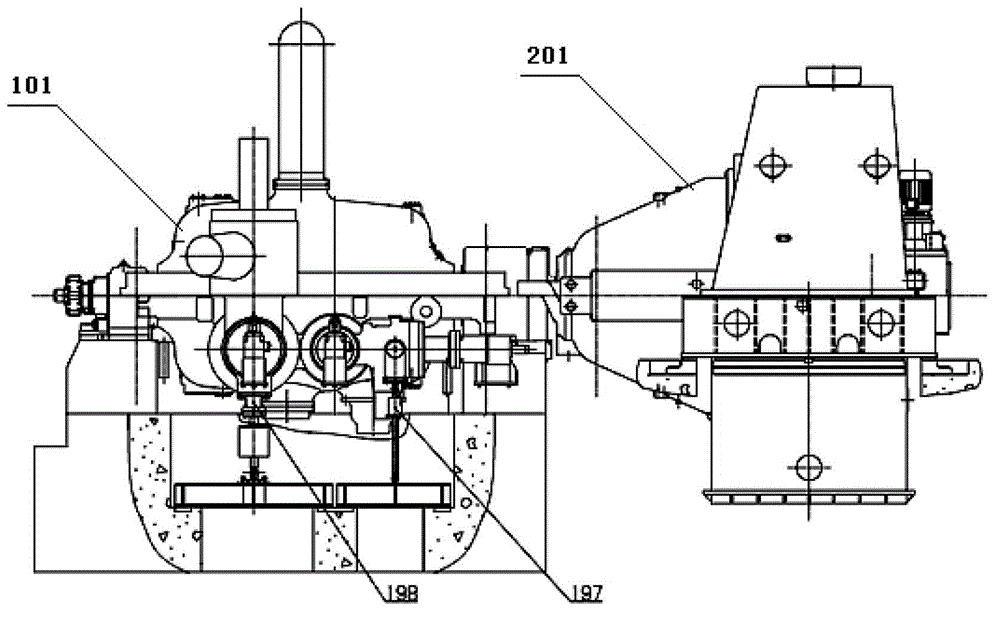

Cogeneration condensing steam turbine

ActiveCN103032115BReduce design difficultyImprove internal efficiencyEnergy industryEngine componentsCogenerationEngineering

The invention provides a cogeneration condensing steam turbine, which comprises two parts, e.g., a high / intermediate-pressure module and an intermediate / low-pressure module. The high / intermediate-pressure module comprises a high / intermediate-pressure cylinder. The intermediate / low-pressure module comprises an intermediate / low-pressure cylinder. A cylinder separation point of the high / intermediate-pressure cylinder and the intermediate / low-pressure cylinder is arranged in intermediate-pressure circulation, and cylinder separation pressure is 1 to 3MPa. The intermediate-pressure end of the high / intermediate-pressure cylinder is communicated with the intermediate-pressure end of the intermediate / low-pressure cylinder through a communicating pipe. A steam extraction pipe is arranged at a steam exhaust port of the high / intermediate-pressure cylinder or on the communicating pipe. According to the steam turbine, the cylinder separation point is arranged in the intermediate-pressure circulation, the steam turbine is divided into the two parts, e.g., the high / intermediate-pressure module and the intermediate / low-pressure cylinder, and compared with the conventional steam turbine adopting a steam extraction regulation mode of arranging a rotary partition plate or a built-in steam extraction regulation valve in a runner of the steam turbine, the steam turbine has the advantages that difficulty in the design of the steam turbine is effectively lowered, and the internal efficiency of a cogeneration turboset is improved; and in addition, the cylinder separation pressure of the high / intermediate-pressure cylinder and the intermediate / low-pressure cylinder is increased, so that the steam extraction pressure of the steam extraction pipe can be increased, and the adaptability of such a steam extraction mode to steam extraction parameters can further be improved effectively.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

double crank engine

ActiveCN104481689BReduce toughnessReduce manufacturing costCylinder headsCylindersGas cylinderReciprocating motion

The invention discloses a double-crank mechanism engine, belonging to the technical field of engines. The double-crank mechanism engine comprises a gas cylinder and a piston capable of performing straight reciprocating motion in the gas cylinder, wherein two parallel crankshafts are arranged at the two sides of the gas cylinder; a connecting rod is hinged between corresponding crankshaft pins of the two crankshafts to form a double-crank mechanism; a connecting rod insertion slot and a slide block are arranged on a piston rod on the rear end of the piston, the connecting rod is inserted to the connecting rod insertion slot in a sliding manner, a guide block is fixed in the engine; a guide rail for sliding the slide block is formed on the guide block; the slide block is inserted to the guide rail; transmission gears are arranged on the end parts of the crankshafts; an output gear is engaged between the two transmission gears; and an output shaft is arranged on the output gear. The double-crank mechanism engine can be used for effectively lowering the abrasion and the impact of the piston and a cylinder sleeve, improving the reliability of the ceramic material applied to the engine and improving the practical heating efficiency.

Owner:王蓬波

Refrigeration device

ActiveUS10145587B2Improve efficiencyIncreased complexityMechanical apparatusCompression machines with non-reversible cycleMain branchEngineering

A refrigeration device having a closed circuit in which a flow rate of coolant is circulating is provided. The closed circuit has a condenser and a main branch provided with a reciprocating compressor inside which a defined flow rate of the coolant enters, from the main branch, at a defined suction pressure, of an evaporator and a first expansion valve that is arranged between the condenser and the evaporator. The closed circuit further has a first secondary economizer branch for a first fraction of flow rate of the coolant, the first secondary economizer branch fluidically connecting the compressor to a section of the closed circuit between the condenser and the first expansion valve, wherein the compressor has a first side inlet port for the entrance of the first fraction of coolant flow rate.

Owner:ANGELANTONI TEST TECH

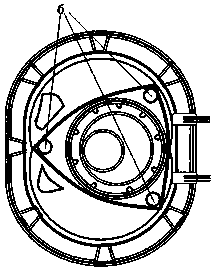

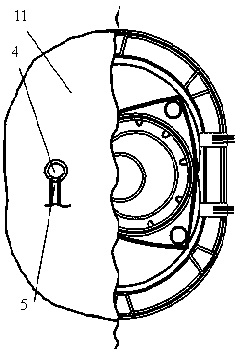

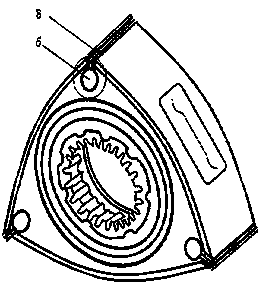

A top sealing and lubricating device for a rotary engine

ActiveCN106224121BReduce air leakageAvoid dry grindingSealing arrangements for enginesLubricant conduit arrangementsRotary engineEngineering

Owner:上海洲跃生物科技有限公司

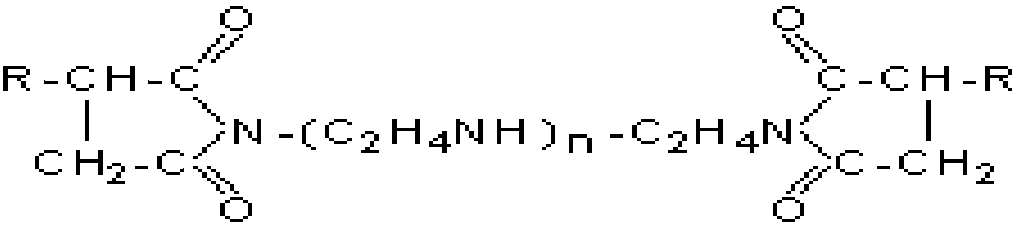

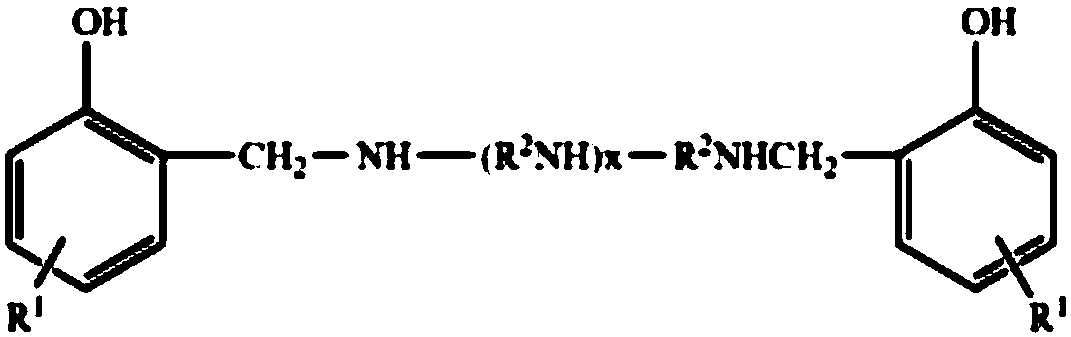

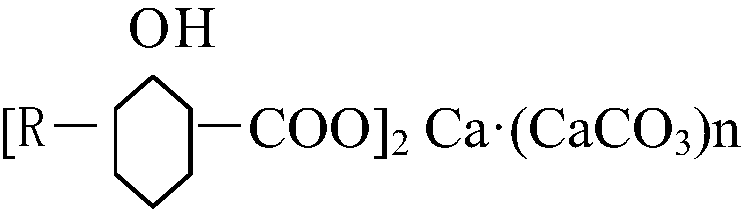

Prompt effect wearproof lubricant additive and preparation thereof

The invention provides an immediately available anti-wear lubricant additive with environmental protection, high efficiency and low cost and a preparation method thereof, and the method comprises the steps as follows according to the parts by weight: 1) putting lead oxide of 15 to 20 parts into base oil 650SN of 80 to 90 parts under room temperature, and giving stirring to produce paste; 2) giving heating and stirring for naphthenic acid of 250 parts until to temperature between 95 and 105 DEG C, slowly adding the naphthenic acid into the pasty mass, and then giving stirring for 3 to 3.5 hours under the constant temperature 95 and 105 DEG C, to acquire mother liquid; 3) adding base oil 650SN of 50 parts, pour point depressants of 2 to 3 parts, high-alkaline synthetic calcium sulphonate as detergent of 10 parts, ashless dispersant with polyisobutylene and multi-succimide of 10 parts, sulphur and phosphorous secondary-alcohol radical zinc salt as antioxidant and corrosion inhibitor of 10 parts, high-alkaline sulfonate as anti-wear additive of 3 to 6 parts, and sulfurized calcium alkyl detergent of 10 to 15 parts; 4) stirring for 1.5 hours under the constant temperature between 70 and 80 DEG C; 5) filtering. The preparation method of the invention has the advantages of simple procedures, no waste water or gas, environmental protection, high efficiency, low cost and high yielding. The anti-wear lubricating oil additive acquired by the preparation method can be used in combination with the lubricating oil, and extend the exchange period two to three times longer and the service life of engines one to two times longer.

Owner:广州市象丰润滑油品有限公司

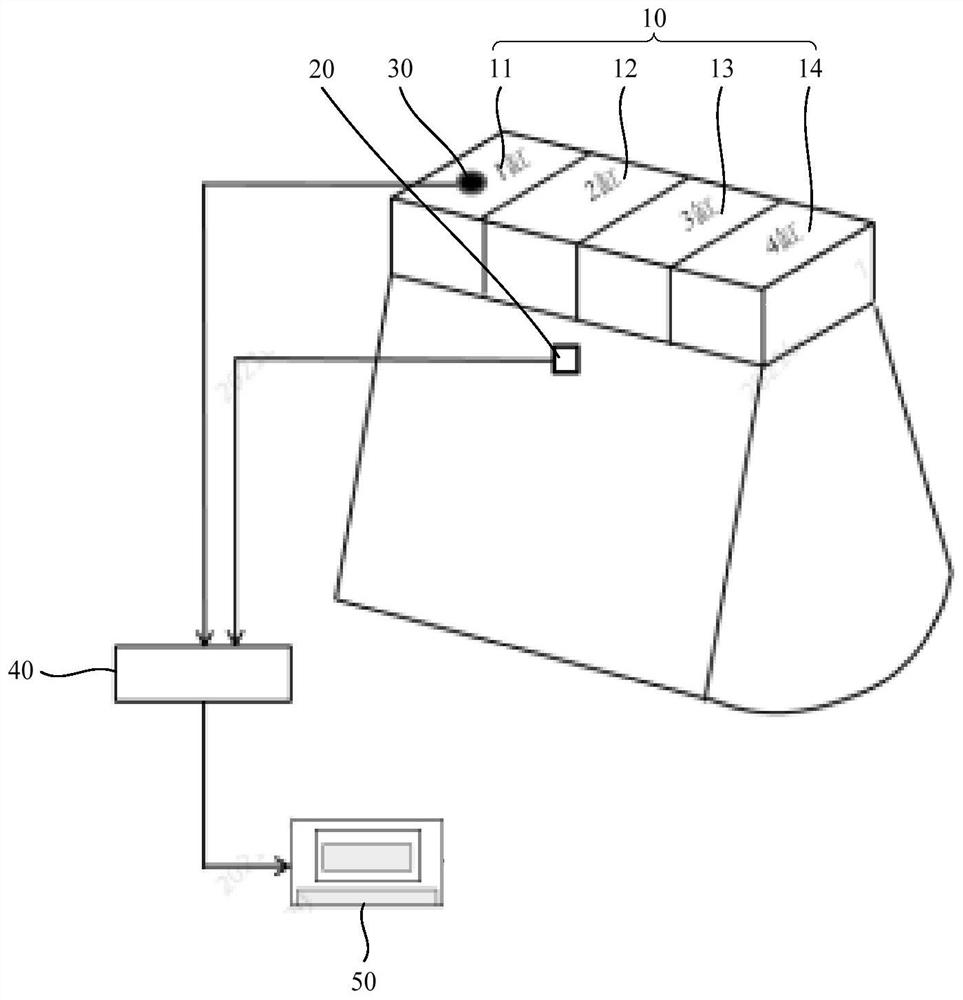

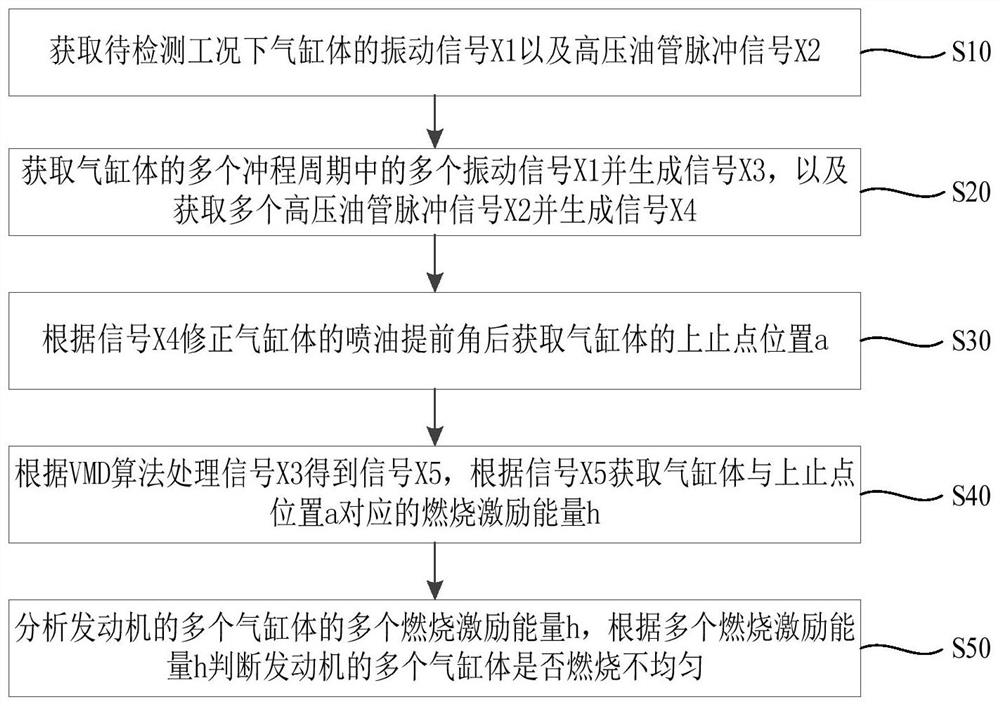

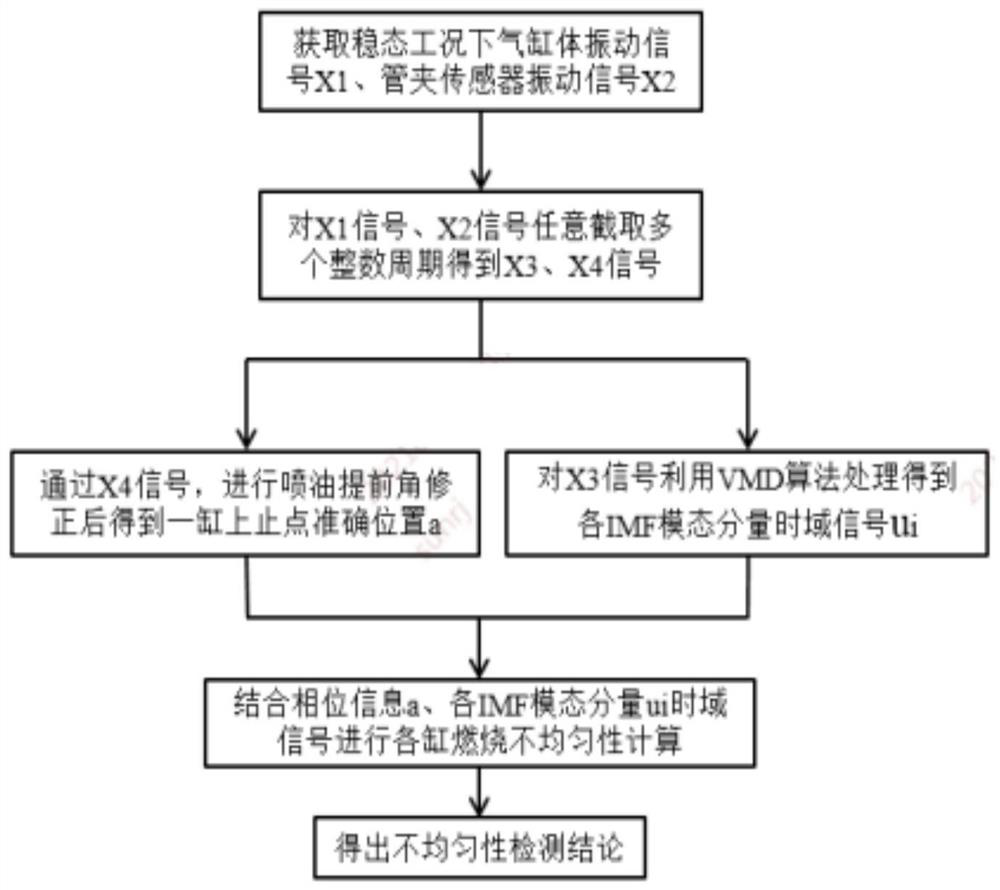

System and method for detecting uneven combustion of engine

PendingCN114441179ASolve the costAddress reliabilityInternal-combustion engine testingInternal combustion piston enginesControl engineeringData acquisition

The invention particularly relates to an engine combustion nonuniformity detection system and method, and the system comprises a vibration sensor which is disposed on a cylinder body of an engine and is used for detecting a vibration signal of the cylinder body; the pipe clamp sensor is arranged on a high-pressure oil pipe of the engine and used for detecting a high-pressure oil pipe pulse signal of the high-pressure oil pipe; the data acquisition card is electrically connected with the vibration sensor and the pipe clamp sensor respectively; and the controller is electrically connected with the data acquisition card, and judges whether the engine burns unevenly or not according to the vibration signals and the high-pressure oil pipe pulse signals acquired by the data acquisition card. According to the engine combustion non-uniformity detection system provided by the invention, fault detection of combustion non-uniformity of each cylinder of the engine is completed by adopting a signal processing means according to signals detected by the vibration sensor and the pipe clamp sensor.

Owner:WEICHAI POWER CO LTD

Double crank two-stroke engine

ActiveCN104533614BReduce toughnessReduce manufacturing costMachines/enginesFour-stroke engineCrankshaft

The invention discloses a two-stroke engine of a double-crank mechanism, and belongs to the technical field of engines. The two-stroke engine of the double-crank mechanism comprises upper and lower two crankshafts opposite to each other, and a gear transmission mechanism. Connecting rods are hinged between crank throws corresponding to the two crankshafts; three connecting rods form the double-crank mechanism; two cylinders are symmetrically arranged at the two sides of the crankshafts; inner pistons and outer pistons are oppositely arranged in the cylinders; combustion chambers are formed between the inner pistons and the outer pistons; the inner pistons at the two edges are fixed on one inner piston arm; the connecting rods penetrate through from the inner piston arms; outer piston arms at the two edges are mounted on one frame structure; the frame structure has two connecting plates; the connecting rods at the two edges of the crankshafts penetrate through the internals of the connecting plates; slide blocks are arranged on the connecting plates; a guide block is fixed in the engine; and a slide block is inserted in a guide rail. The two-stroke engine of the double-crank mechanism effectively reduces the wear and the impact of the pistons and cylinder sleeves, improves the reliability of ceramic materials applied to the engine, and improves actual heat efficiency.

Owner:王蓬波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com