Patents

Literature

34results about How to "Reduce direct wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

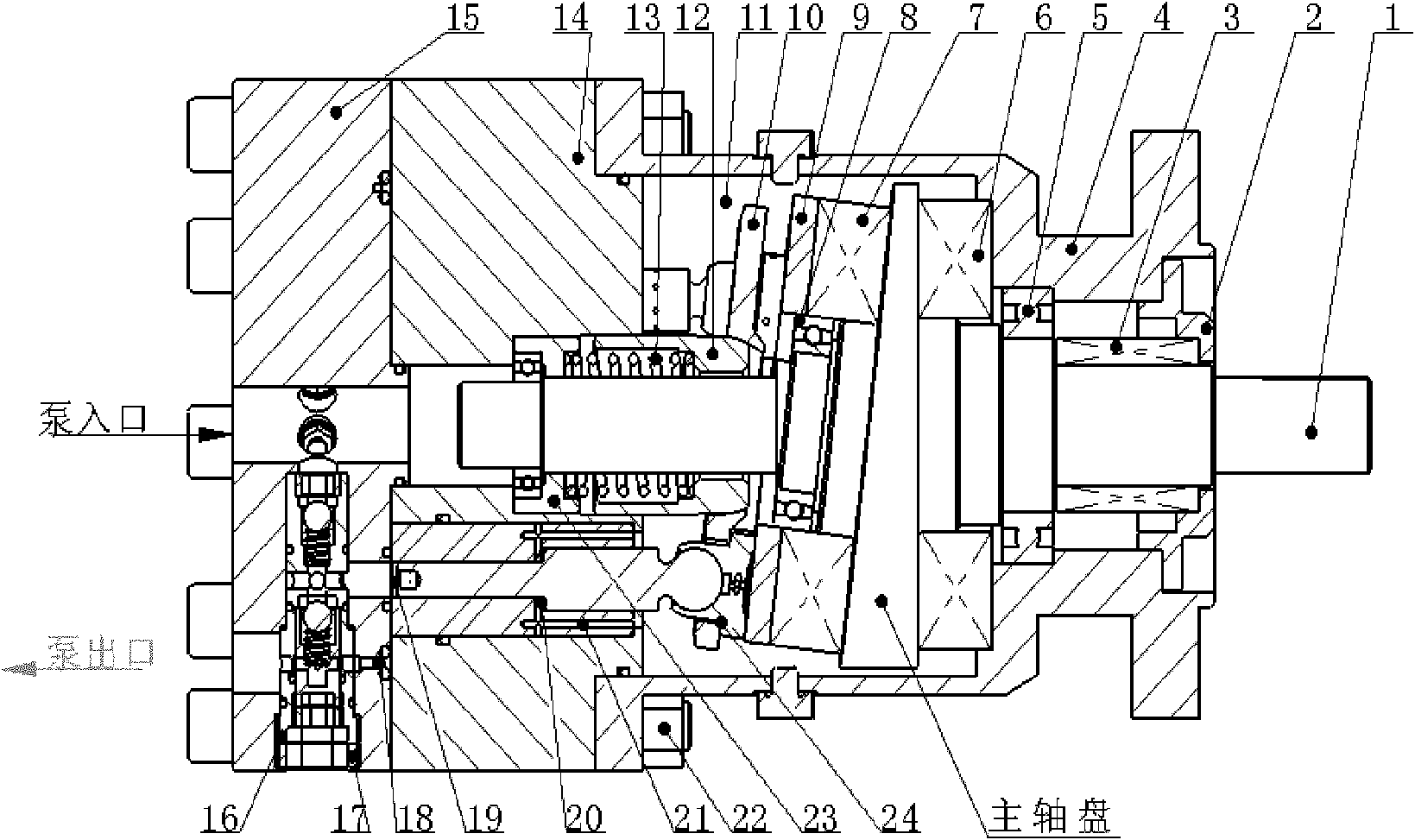

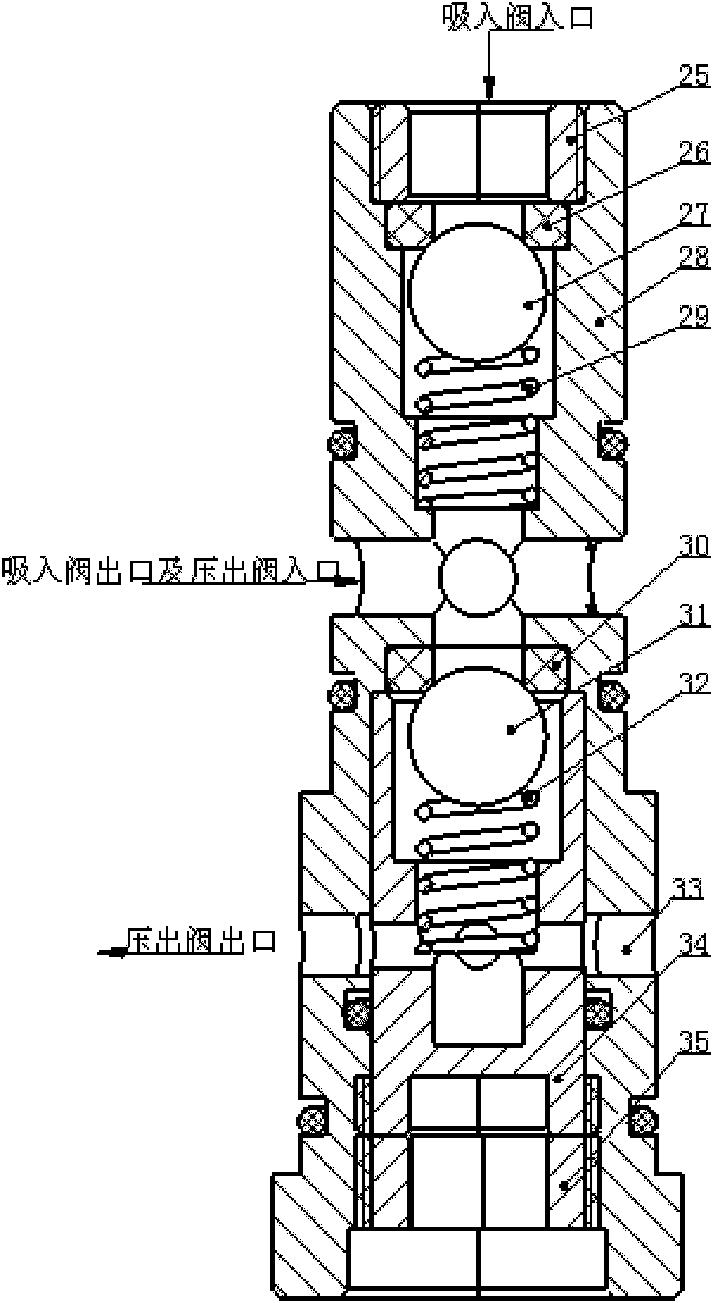

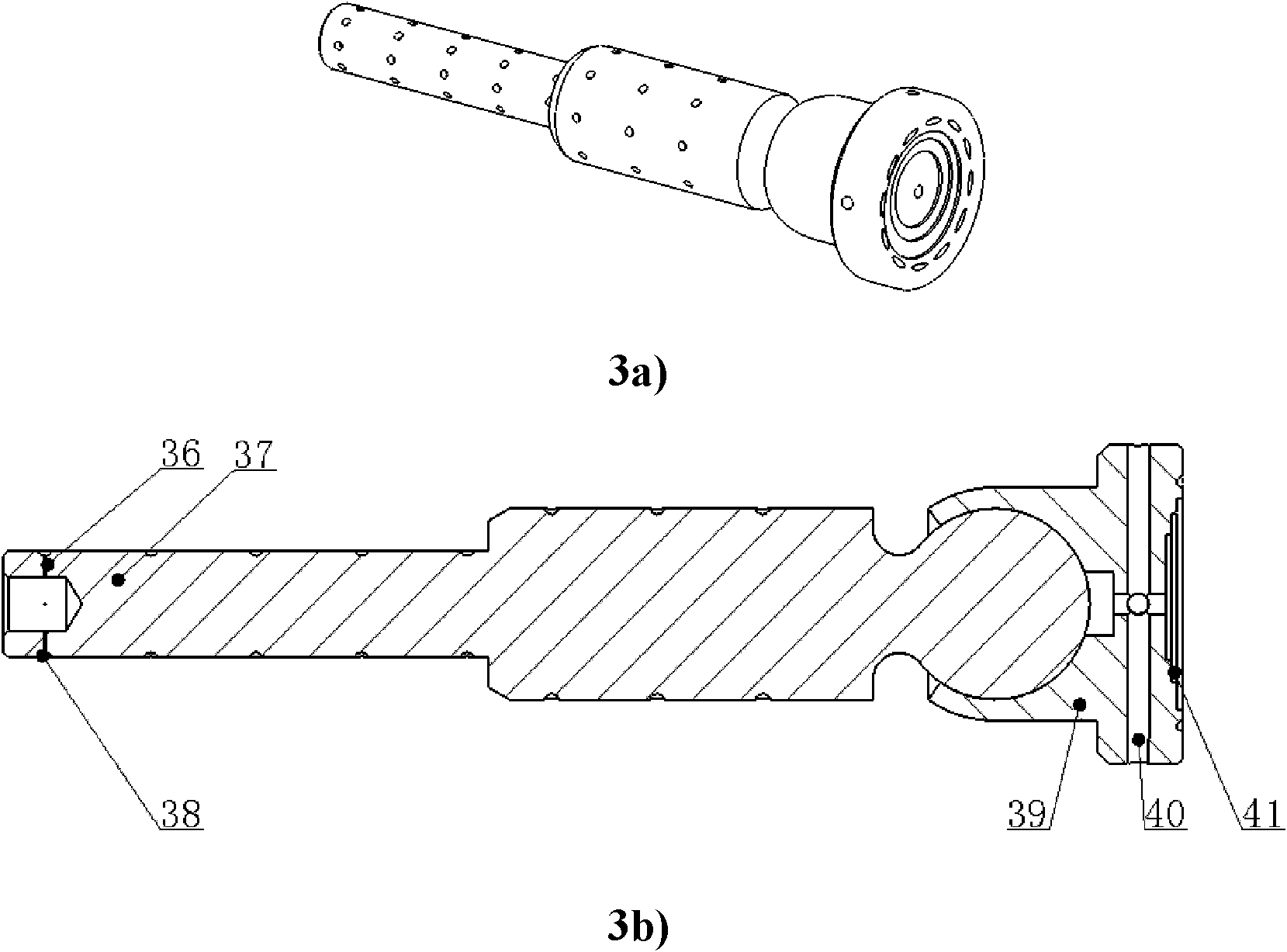

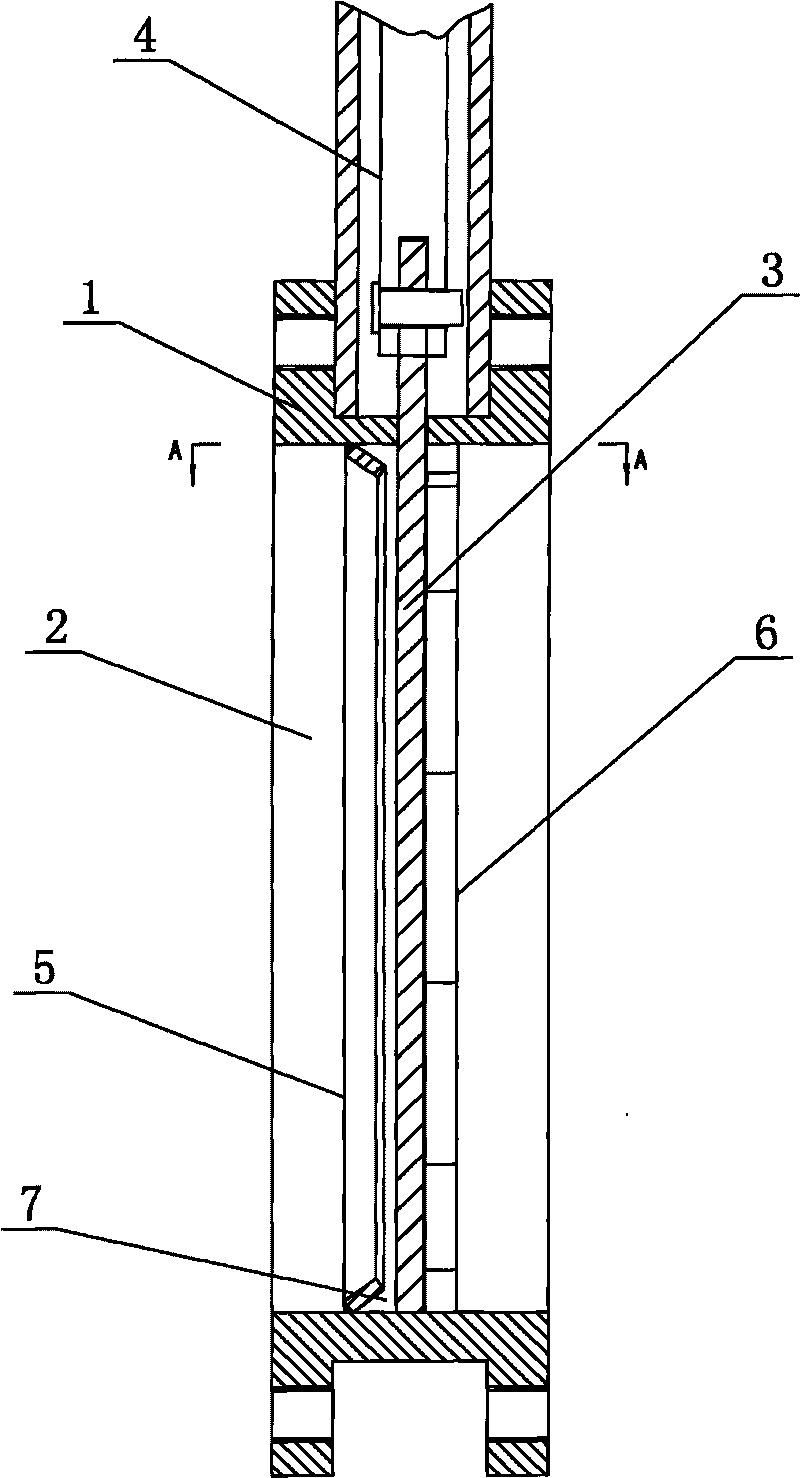

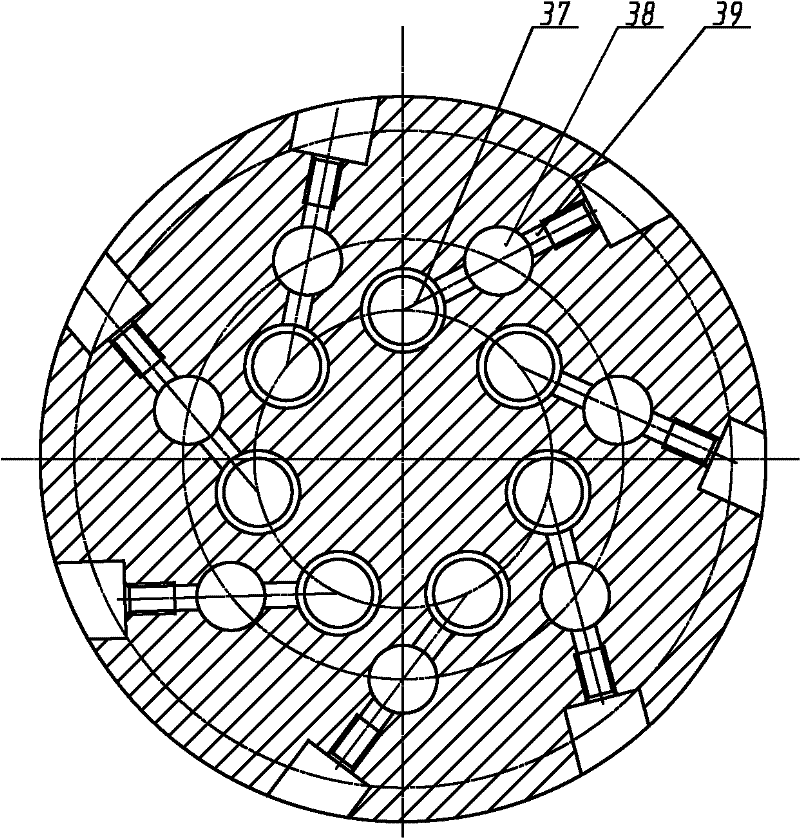

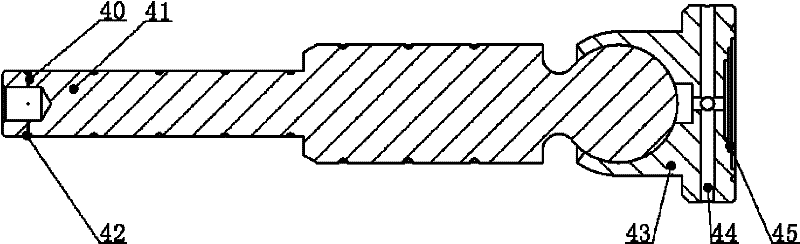

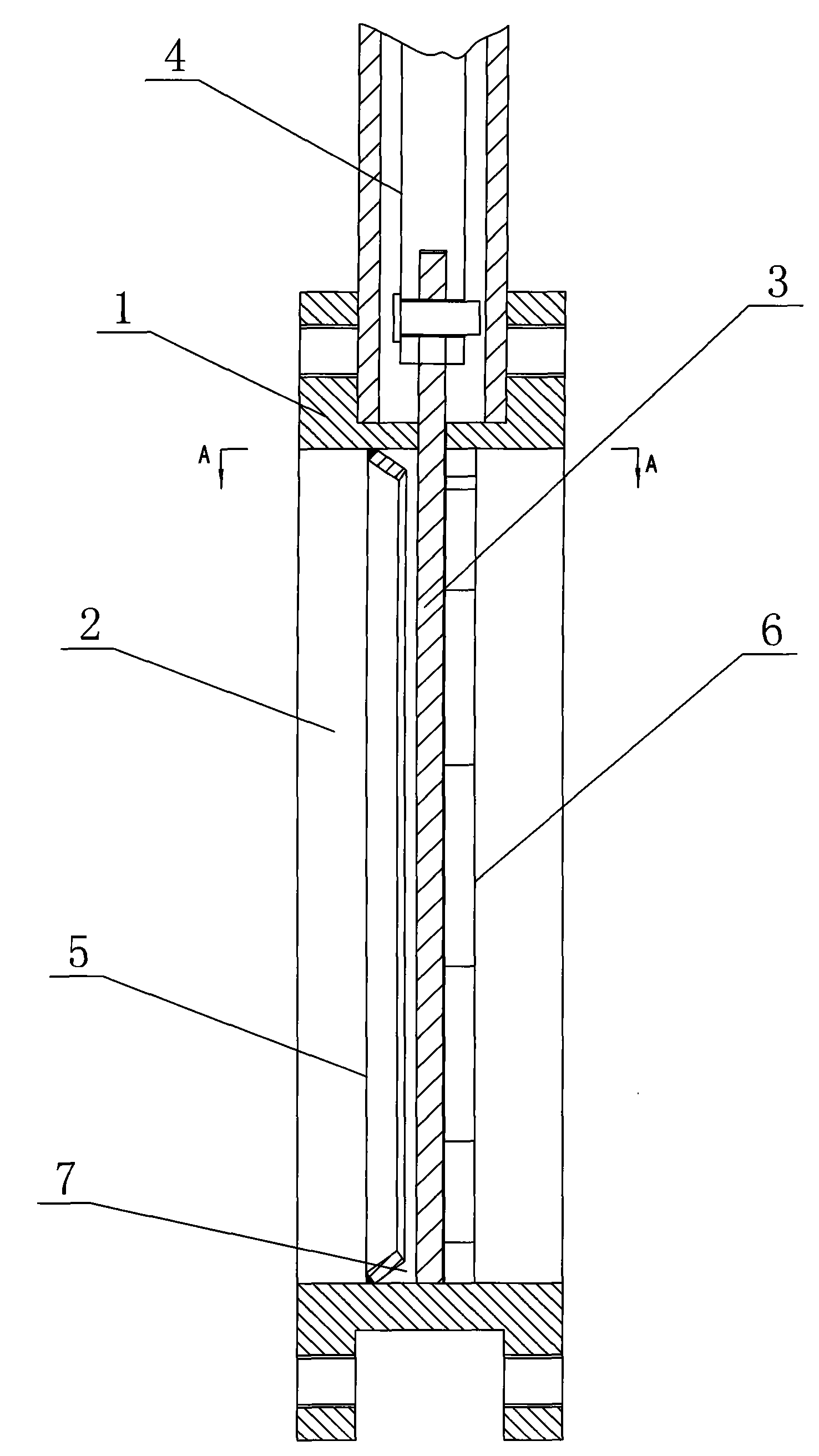

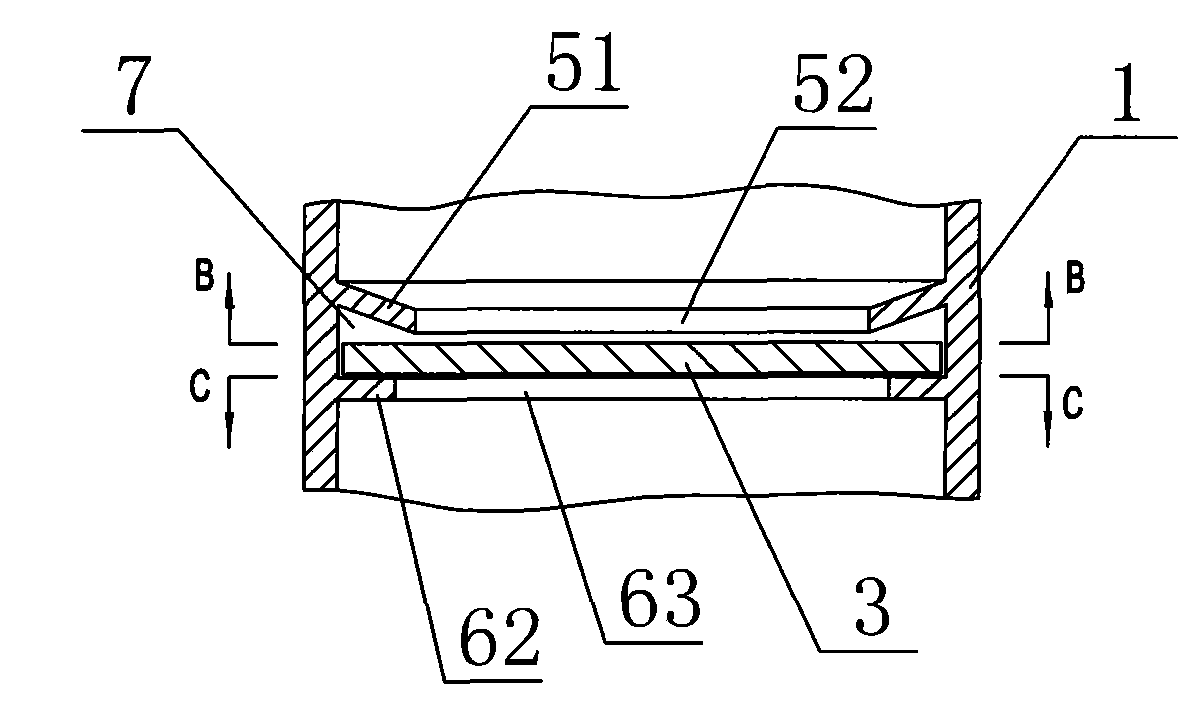

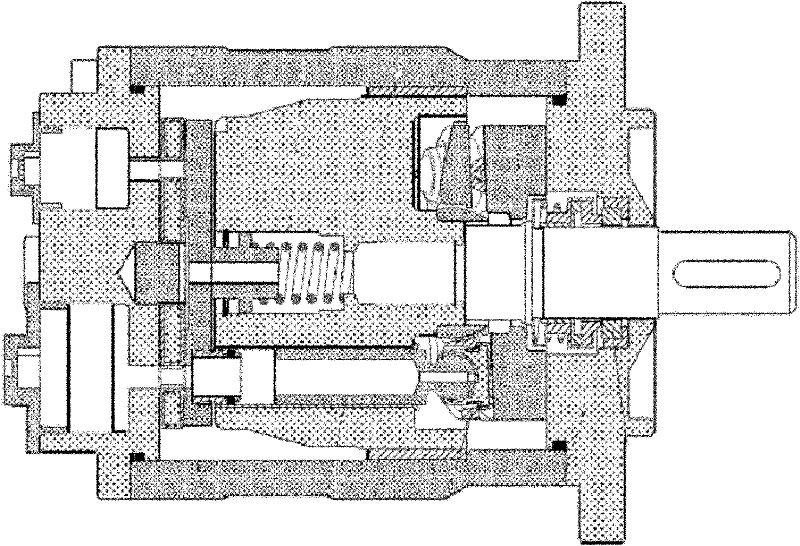

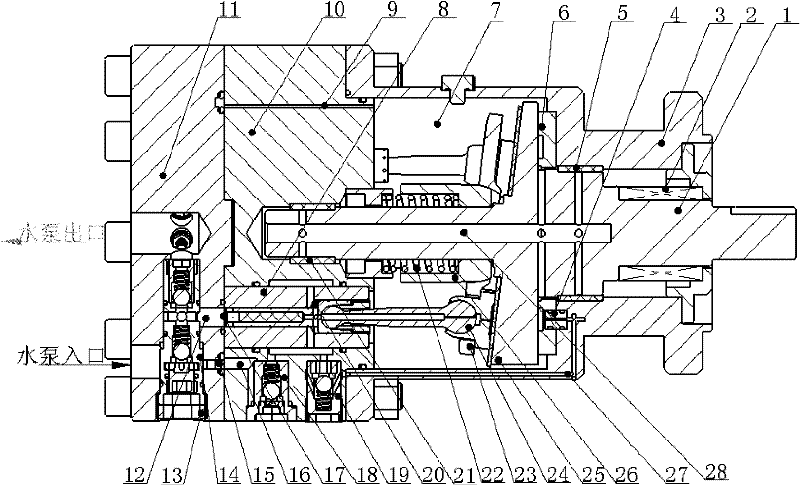

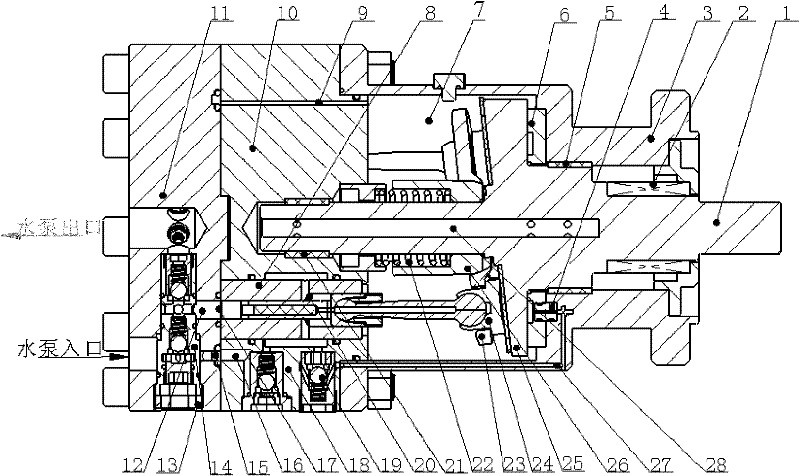

Fully water-lubricated super-pressure plunger water pump

InactiveCN101956685AReduce contact stressSolve friction and wear problemsPositive displacement pump componentsPositive-displacement liquid enginesReciprocating motionEngineering

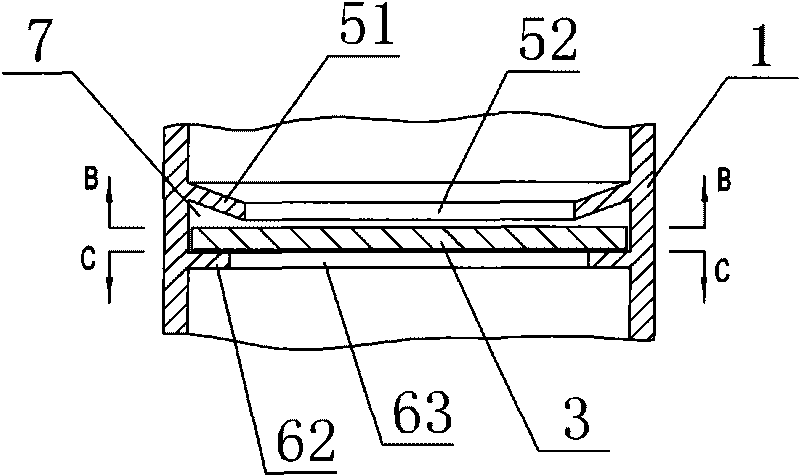

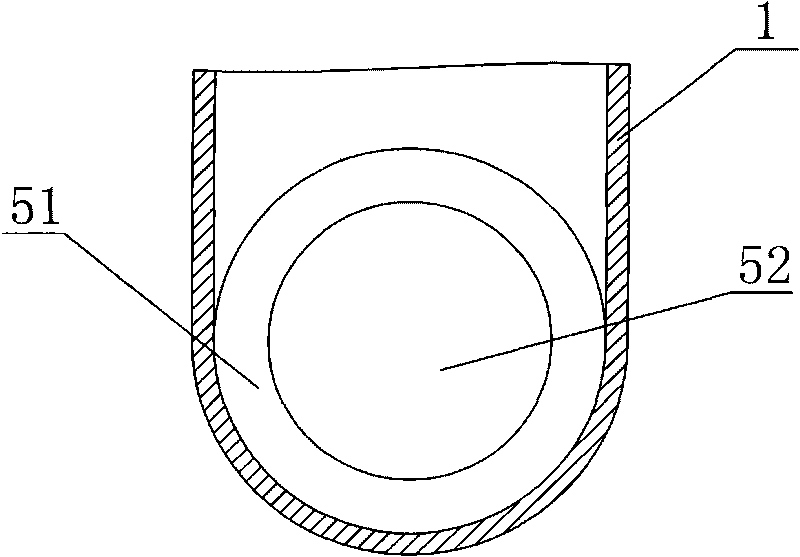

The invention provides a fully water-lubricated super-pressure plunger water pump, mainly comprising a cavity, a live spindle and a plunger flow-distribution unit; the plunger flow-distribution unit comprises a flat valve assembly and a plunger slipper assembly; the plunger slipper assembly is used for dividing the cavity into a pressure cavity and a lubricating cavity which are independent from each other; the plunger slipper assembly carries out reciprocating motion by the driving of the live spindle so that the flat valve assembly sucks in water and discharges water through a water pump inlet and a water pump outlet, and water is simultaneously conveyed to the lubricating cavity through the water pump inlet so as to provide fluid to the rotating unit for lubricating and realizing full water lubrication. The flat valve assembly is designed integrally, and the assembly can be replaced quickly when maintenance so as to shorten maintenance time; the plunger is a stepped structure, the cylindrical surface thereof is provided with recesses, and the bottom of the slipper is provided with a stepped support cavity, thereby solving the wearing and friction problem of the plunger / plunger sleeve pair and slipper / sloping cam plate pair under high-speed heavy-duty condition, and prolonging the service life of the water pump.

Owner:HUAZHONG UNIV OF SCI & TECH

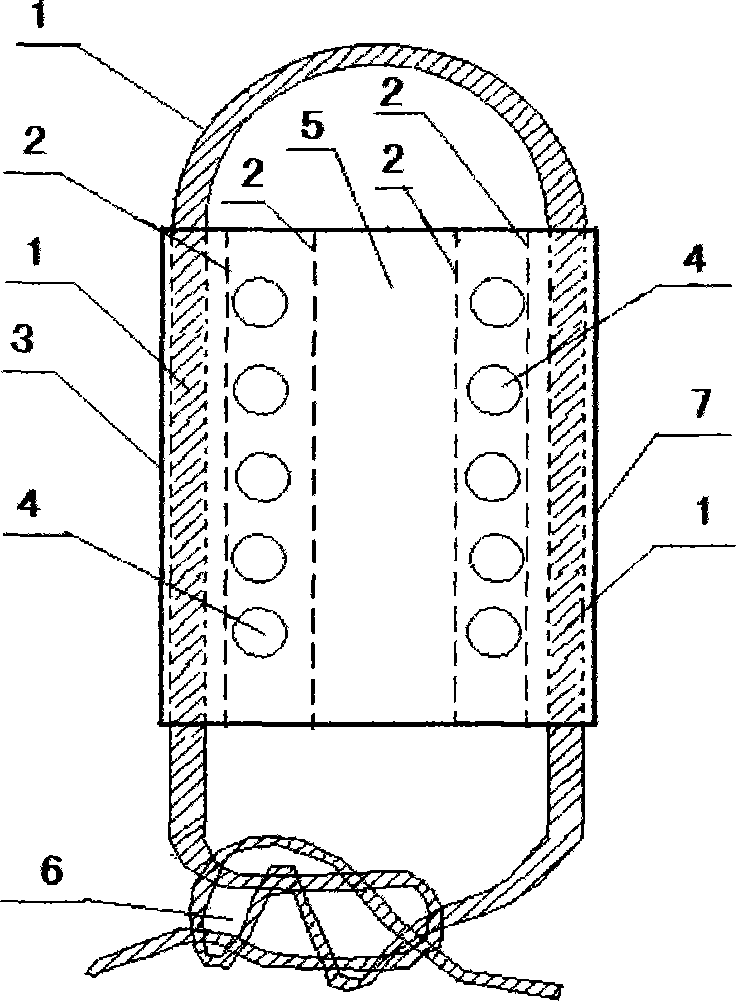

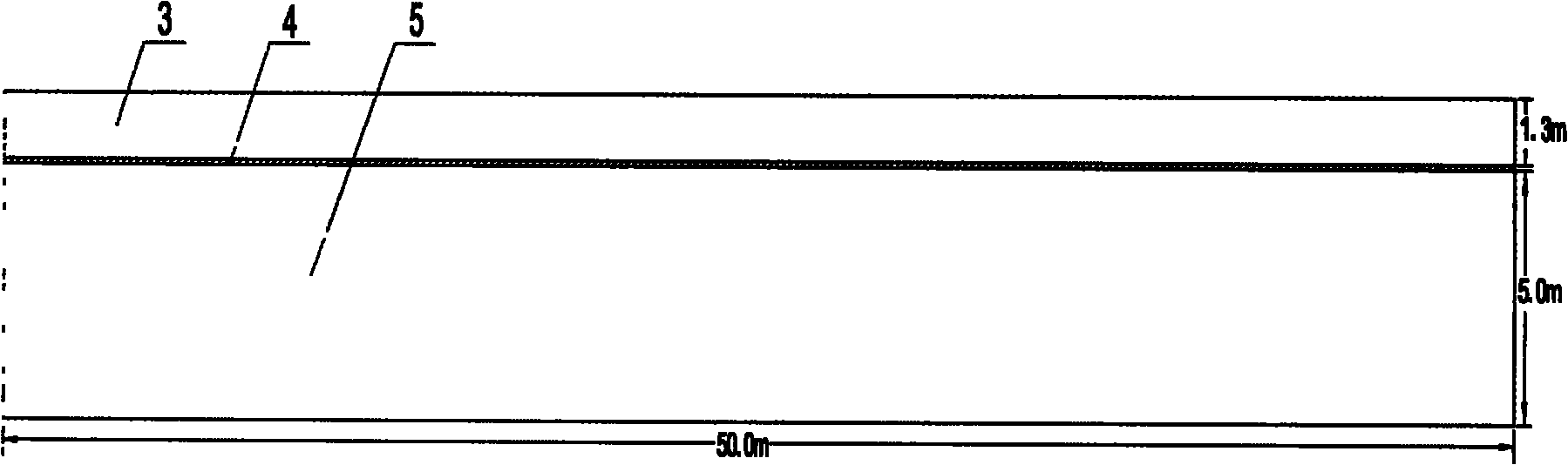

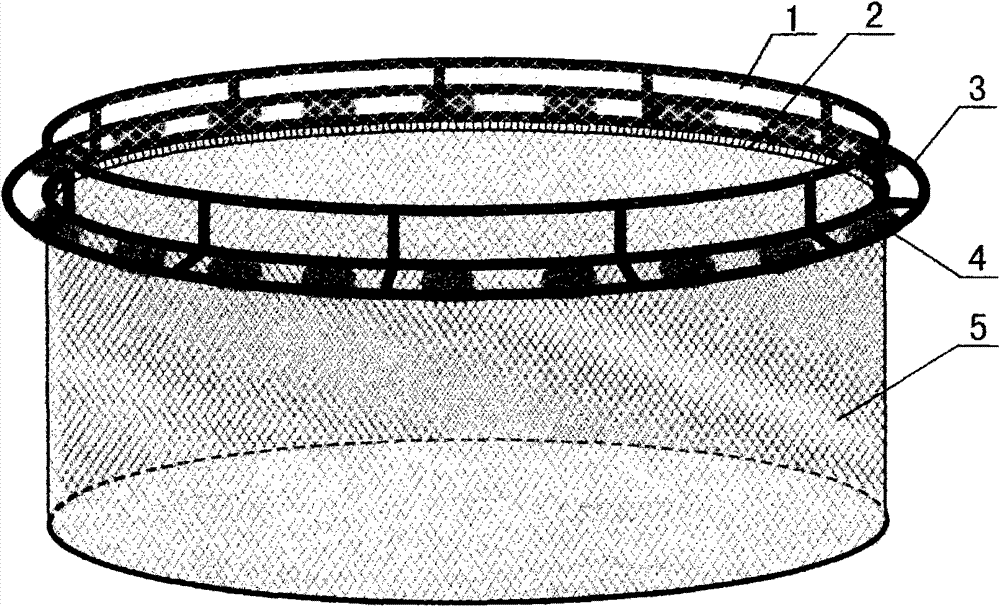

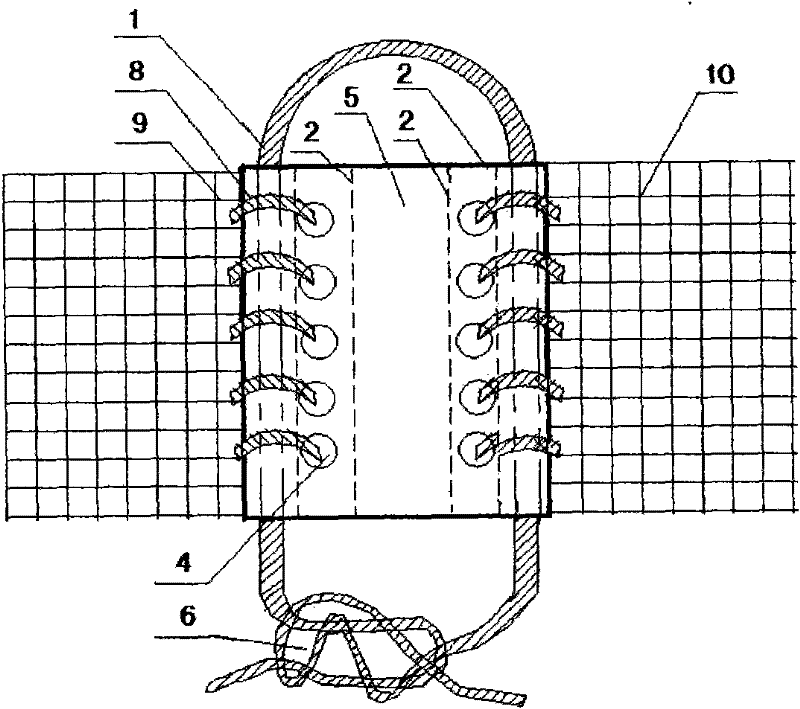

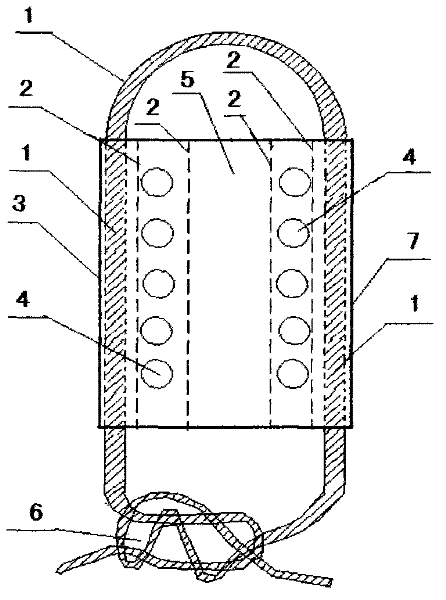

Method for manufacturing antifouling and antibiosis type yellow croaker net cage

InactiveCN102763610AReduce harmImprove survival rateClimate change adaptationPisciculture and aquariaAntibiosisEngineering

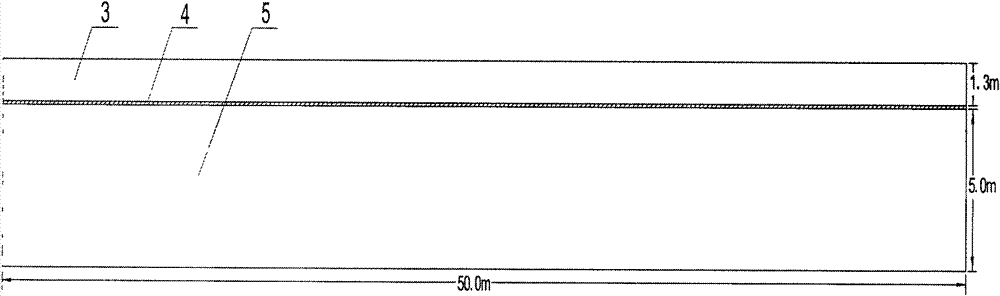

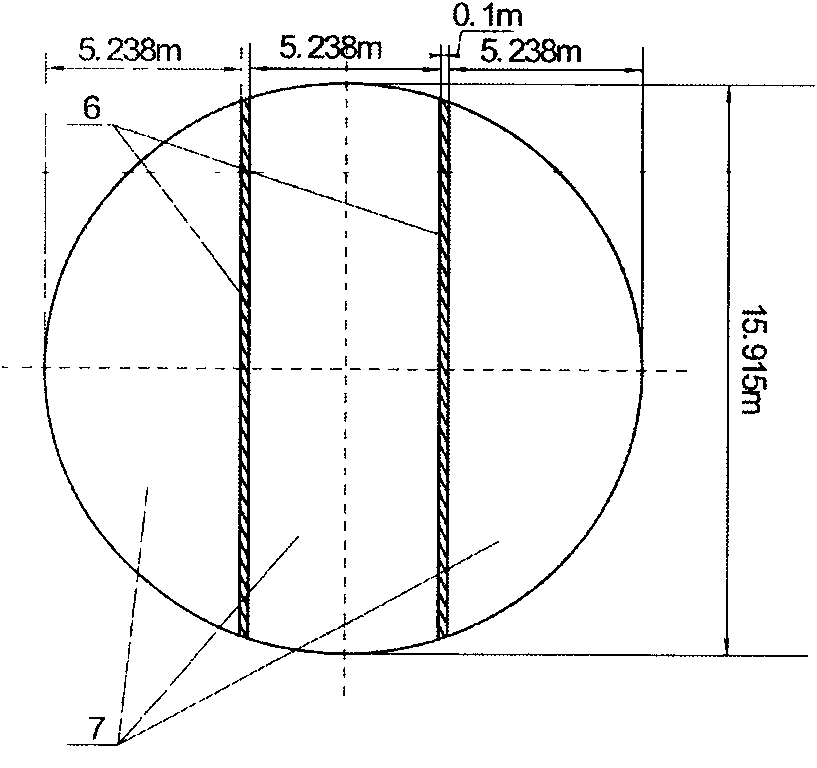

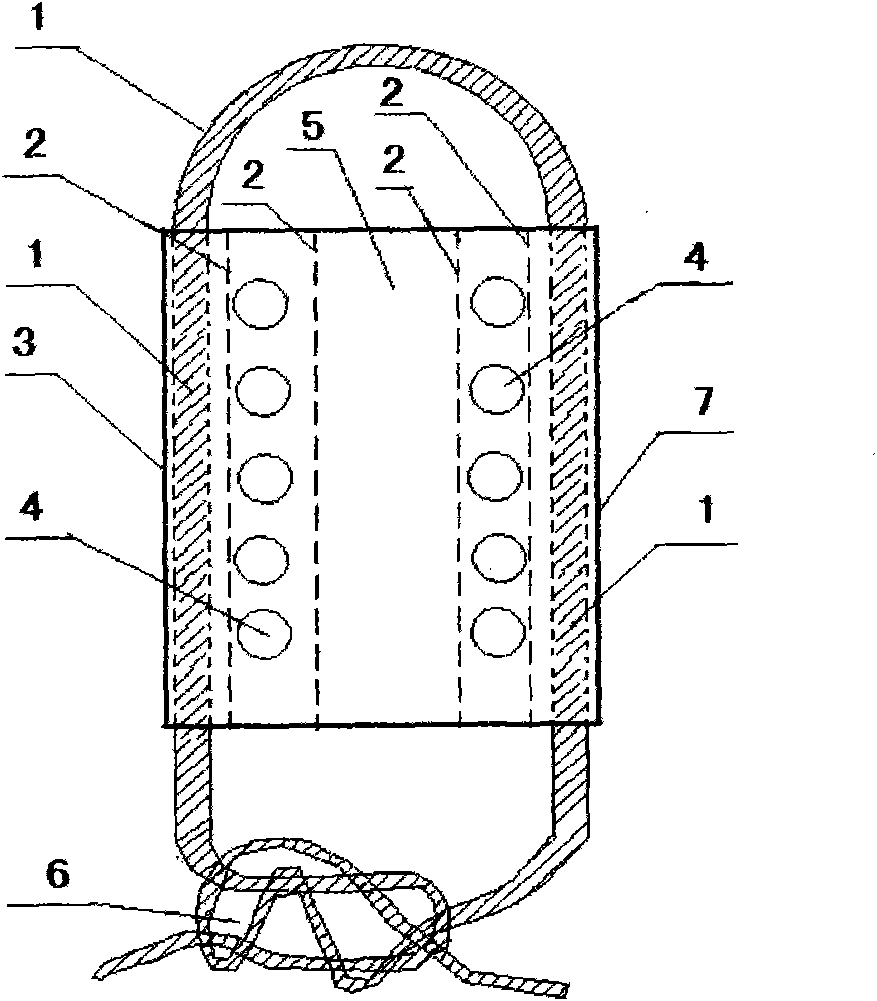

The invention discloses a method for manufacturing an antifouling and antibiosis type yellow croaker net cage, which relates to a method for manufacturing a mariculture net cage. According to the invention, the method for manufacturing the antifouling and antibiosis type yellow croaker net cage adopts a buoyancy force system and a netting system, and is characterized in that the buoyancy force system adopts a combination buoyancy force form of 'an anti-aging high-density polyethylene double-floating-pipe cylindrical frame structure + 18 cube cystosepiments with each edge length of 60cm; the netting system adopts a combination structure netting form of 'a first box longitudinal netting + a second box longitudinal netting + a net cage bottom netting; the net cage bottom netting is assembledon a circular high-density polyethylene pipe support which is wrapped with a layer of polyamide multifilament wrap knitting net; and three cross lacing lines are installed at the bottom of the net cage, a polypropylene rope is tied at the cross point of the cross lacing lines, and two foam float bowls which are externally wrapped by double-layer seawater corrosion protection canva and nylon nets are tied at the other end of the polypropylene rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

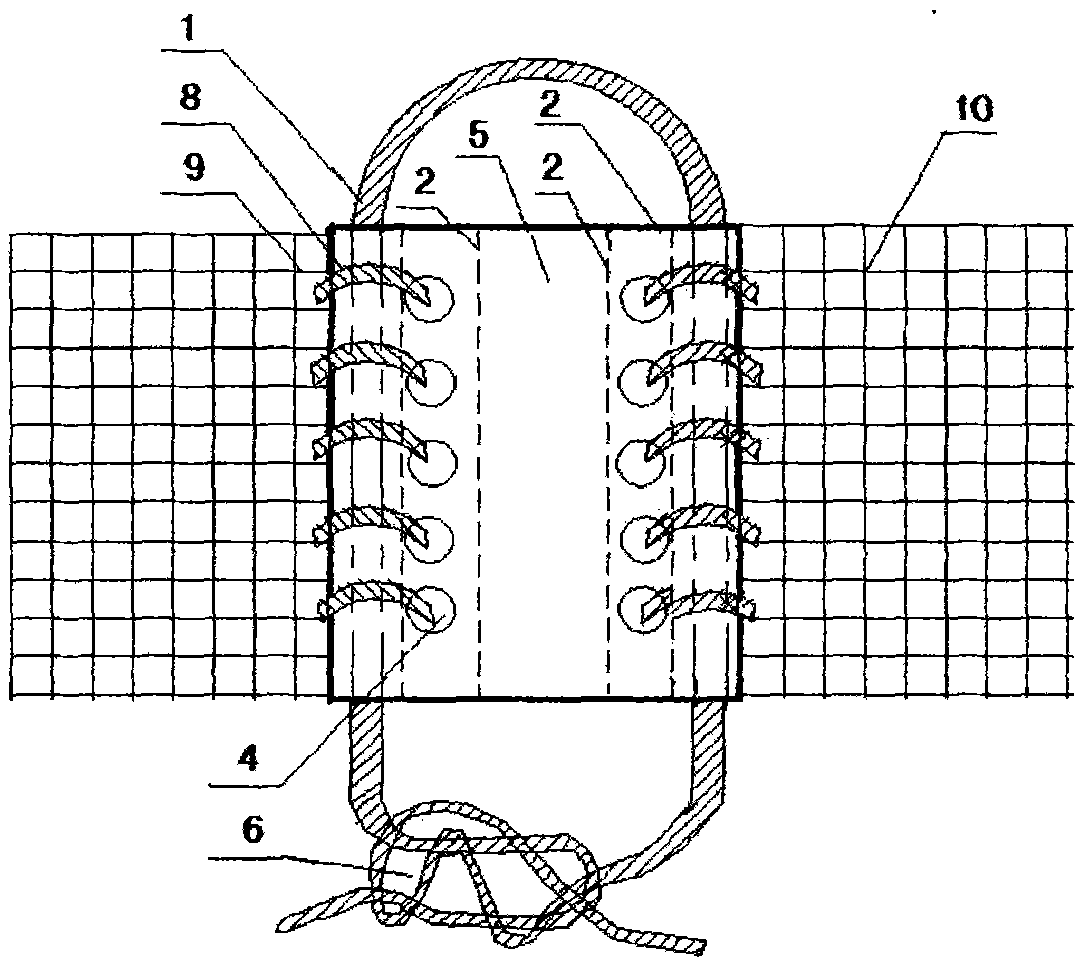

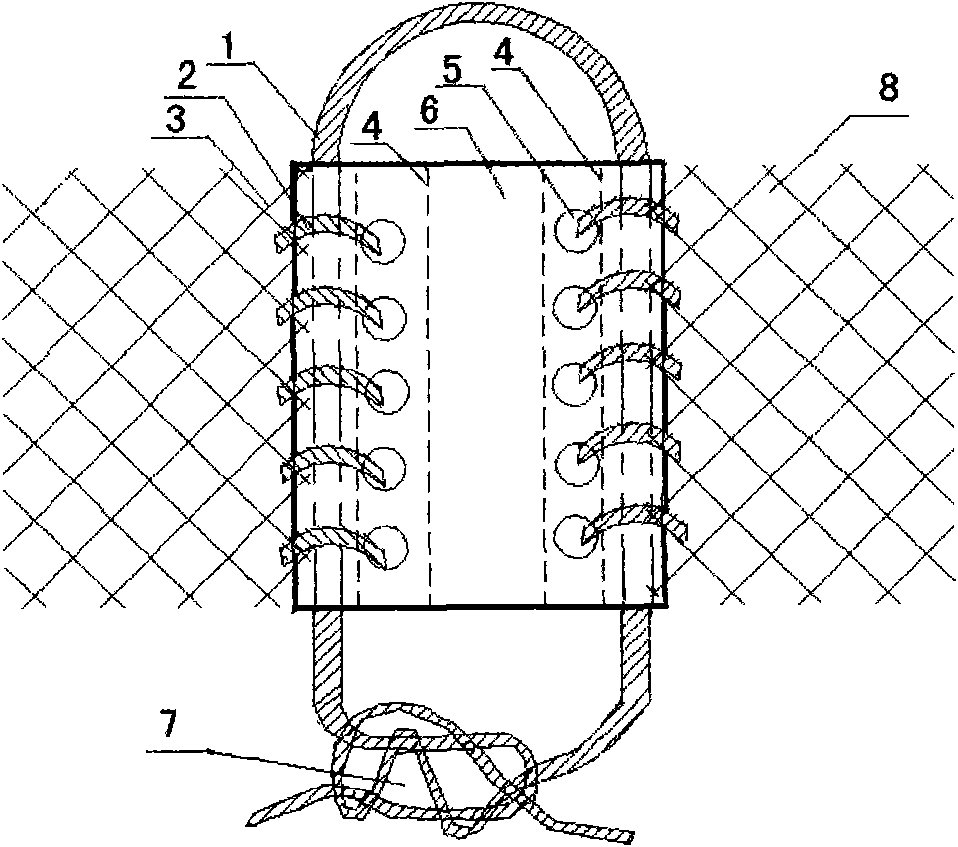

Half-soft state connecting method between copper alloy woven meshes for cage

InactiveCN102084830AQuality improvementImprove mechanical propertiesClimate change adaptationPisciculture and aquariaMetallurgyCopper alloy

The invention discloses a half-soft state connecting method between copper alloy woven meshes for a cage, relates to connection of copper alloy woven meshes for the cage, and provides a method for splicing the copper alloy woven meshes for the cage. In the method, sea anchoring cloth, ropes, suture lines and tarpaulin rings are adopted, and the method is characterized in that: the sea anchoring cloth, the ropes, the suture lines and the tarpaulin rings are assembled into half-soft state connecting pieces; the half-soft state connecting pieces are arranged between two copper alloy woven meshes; one end of a high-strength polyethylene rope is fixed at a net joint which is 3 meshes away from the splicing edge of the copper alloy woven meshes; the other end of the high-strength polyethylene rope passes through ring plates of the half-soft state connecting pieces and meshes of the woven meshes in turn; the other end of the high-strength polyethylene rope is fixed at a net joint which is 4 meshes away from the splicing edge of the copper alloy woven meshes; and the half-soft state connecting pieces are spliced with the other copper alloy woven mesh in the adjacent two copper alloy woven meshes together. The method is used for splicing the adjacent two copper alloy woven meshes in the cage.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

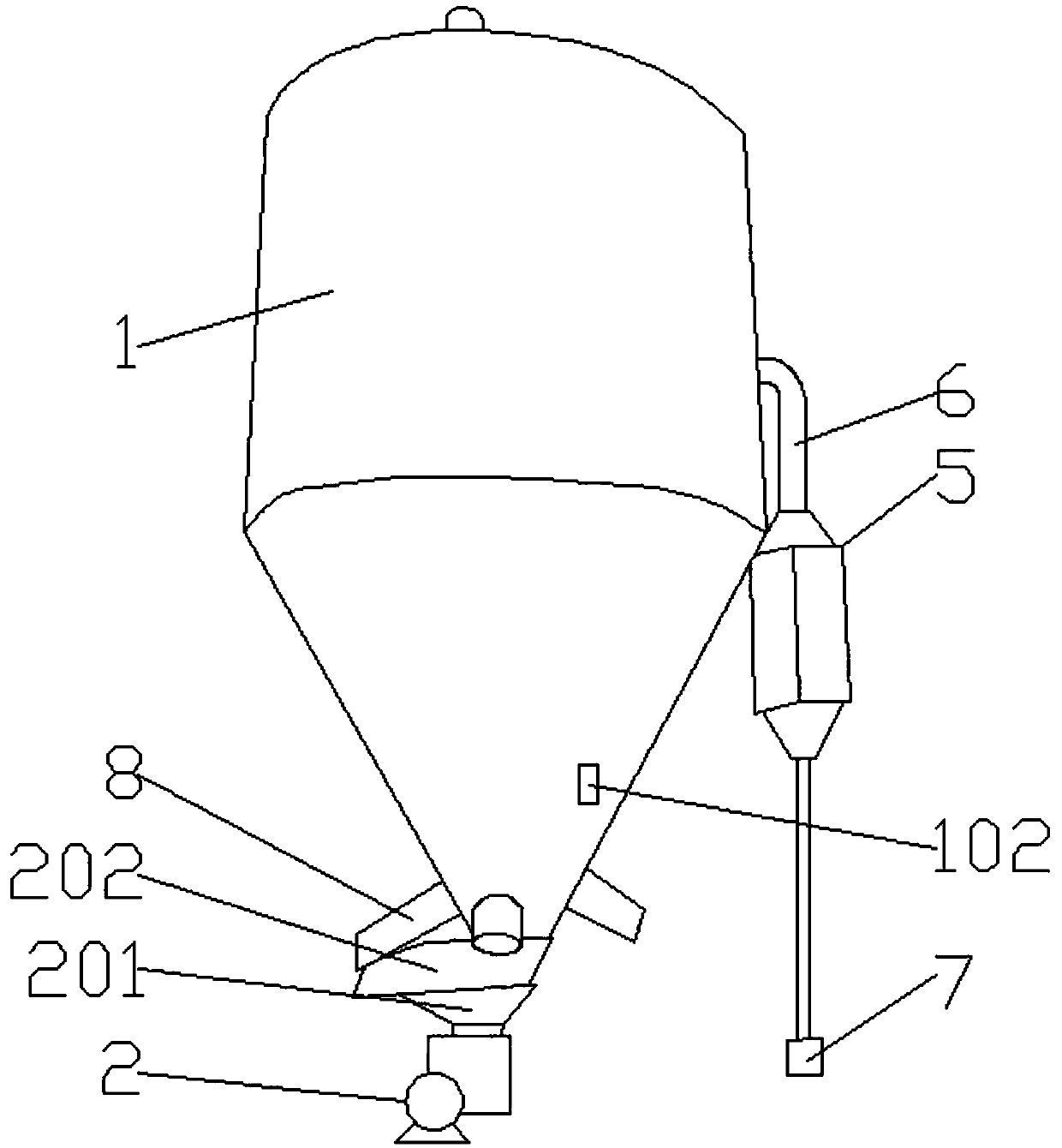

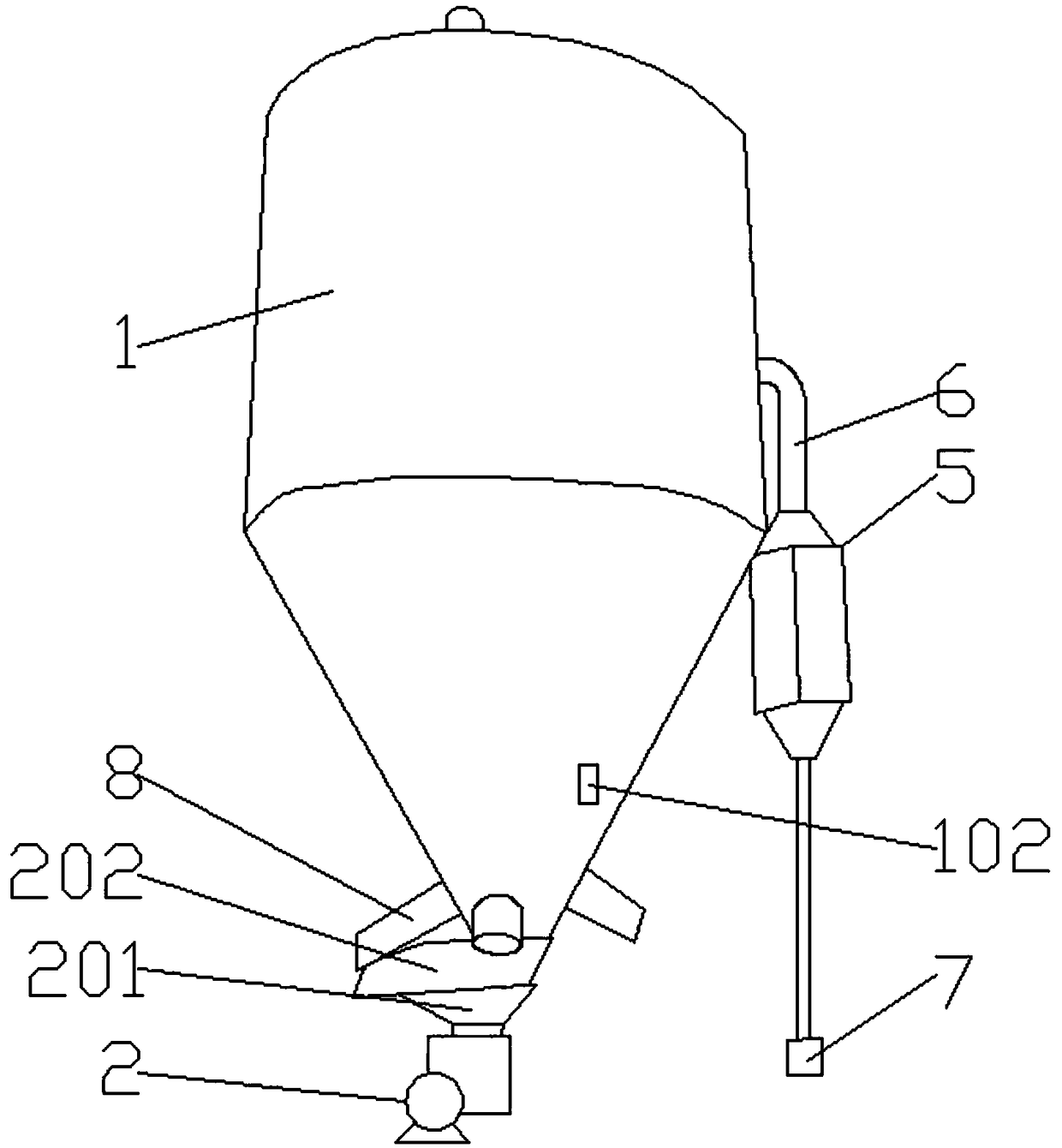

Broken plastic stirring device

The invention relates to the technical field of waste plastic reprocessing equipment and particularly discloses a broken plastic stirring device. The broken plastic stirring device comprises a material cylinder, a feeding device, a stirring device body, an air uniformizing device and a temperature increasing device. The feeding device comprises a feeding bin, feeding hoppers, a first screw rod, asecond screw rod, a first spiral blade and a second spiral blade, and the spiral direction of the second spiral blade is opposite to the spiral direction of the first spiral blade. The stirring devicebody comprises a stirring motor, a stirring shaft, a spiral stirring blade and a spreading disk, and the spiral stirring blade is of a structure gradually becoming larger from bottom to top on the stirring shaft. The air uniformizing device comprises a main air pipe, annular air uniformizing pipes and gourd-shaped air uniformizing nozzles. The temperature increasing device comprises a shell, twosupporting plates, insulating rings and heating pipes. The broken plastic stirring device has the characteristics that stirring is uniform, the manpower cost and the material resource cost are both low, and dust and moisture are easy to discharge.

Owner:德清意欣塑料制品有限公司

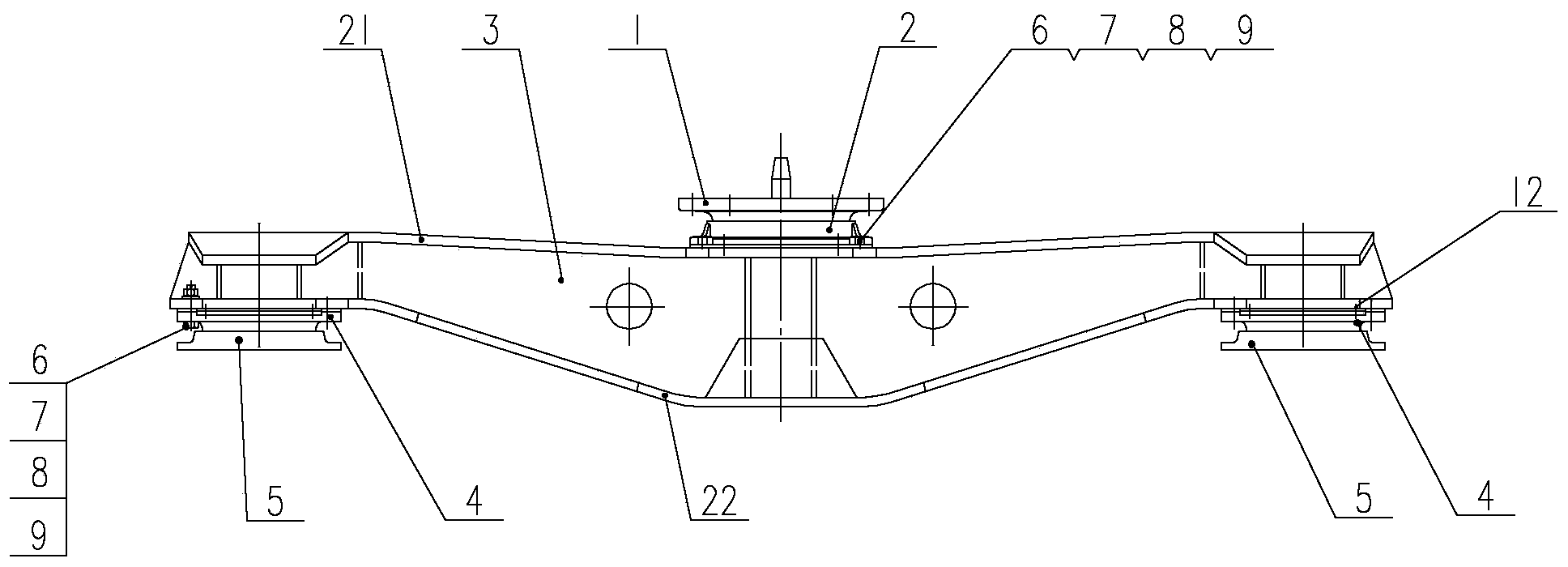

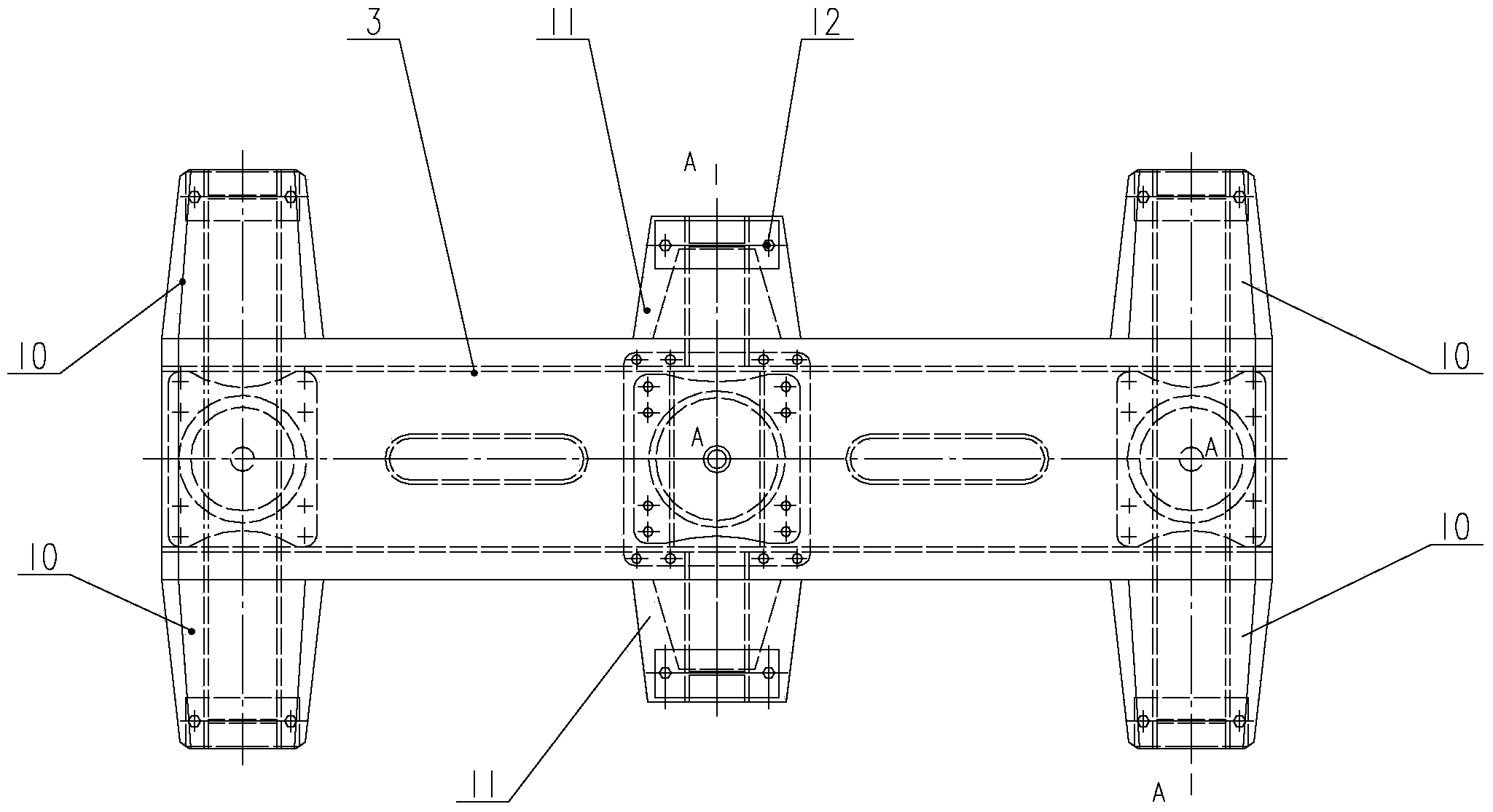

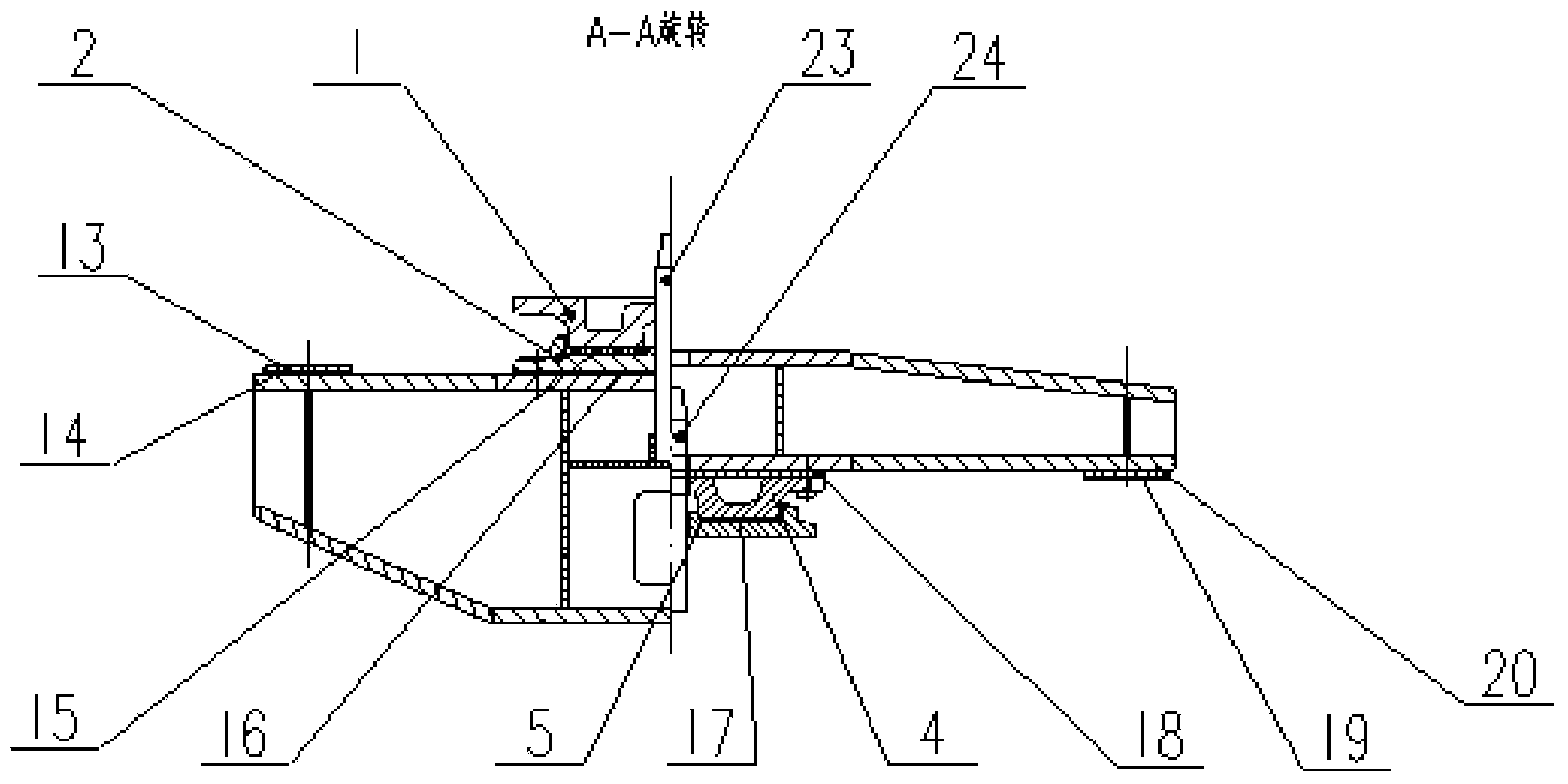

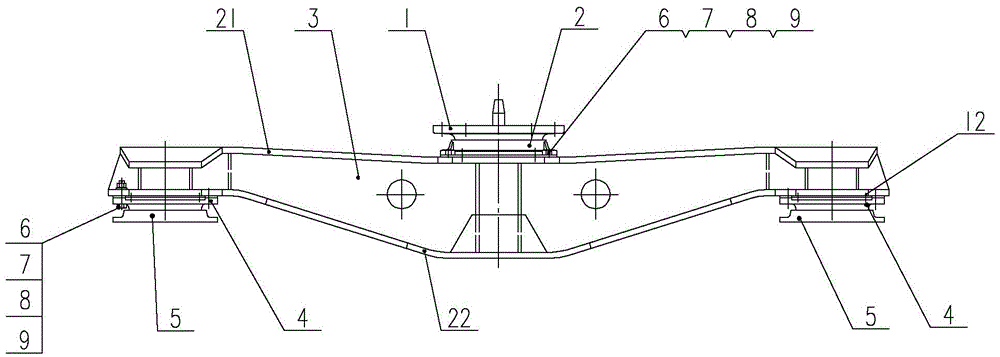

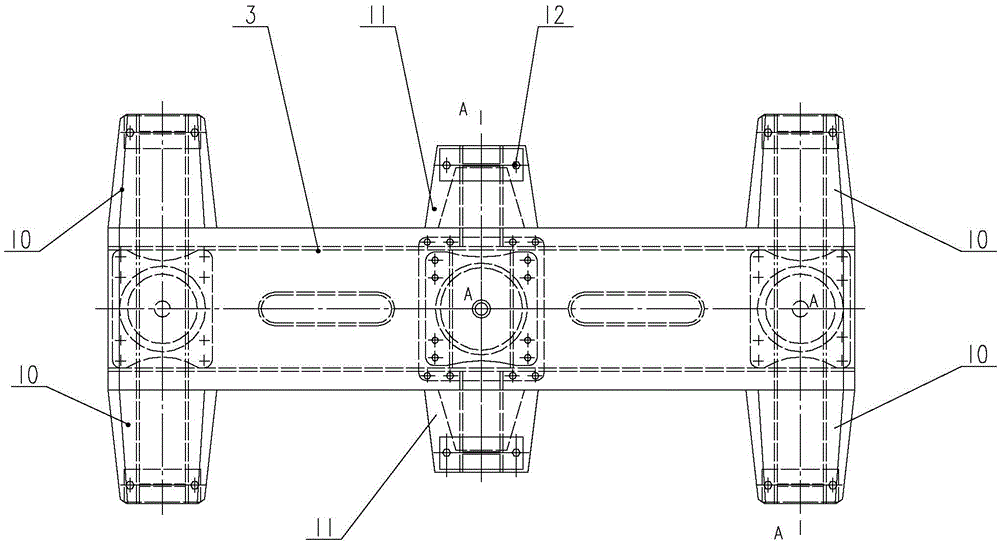

Cross-mounting bottom frame device

ActiveCN103661465AShorten the design cycleIncrease loading capacityBogiesBogie-underframe connectionsBogieEngineering

The invention relates to a cross-mounting bottom frame device. The cross-mounting bottom frame device comprises a transversely arranged middle beam assembly, four end sleeper beam assemblies connected with the front and back sides of the two ends of the middle beam assembly respectively, two middle sleeper beam assemblies connected with the front and back sides of the middle of the middle beam assembly respectively, a bottom frame center disc assembly arranged on the upper surface of the middle beam assembly between the two middle sleeper beam assemblies, two steering frame center disc assemblies arranged at the lower surfaces of the two ends of the middle sleeper beam assembly between the two end sleeper beam assemblies respectively, two lower side bearings arranged on the upper surfaces of the free ends of the two middle sleeper beam assembly respectively, and four upper side bearings installed on the lower surfaces of the free ends of the four end sleeper beam assemblies respectively, wherein the middle beam assembly is of a fish-belly-shaped box type structure, the end sleeper beam assemblies and the middle sleeper beam assemblies are respectively of a box structure with the fixed end being gradually thinned to the free end, the length of each end sleeper beam assembly in the horizontal direction is larger than that of each middle sleeper beam assembly, and the height of each end sleeper beam assembly in the vertical direction is smaller than that of each middle sleeper beam assembly. The cross-mounting bottom frame device can combine two double-shaft steering frames into a four-shaft steering frame.

Owner:CRRC QIQIHAR ROLLING CO LTD

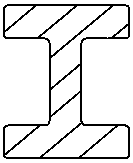

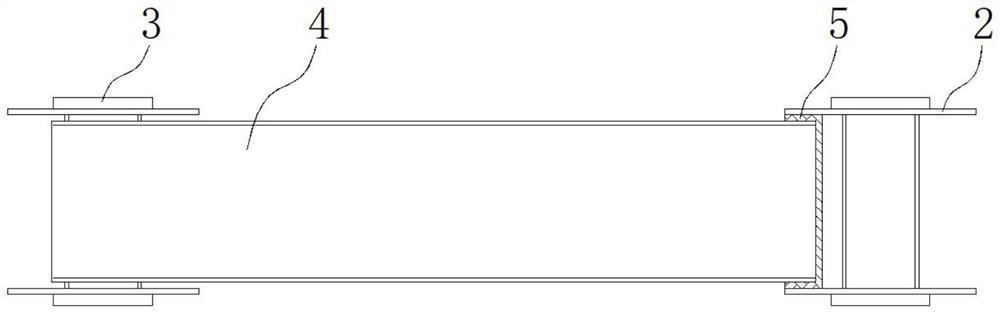

Protective valve seat structure of gate valve

The invention discloses a protective valve seat structure of a gate valve, comprising a valve body, wherein through holes are arranged in the valve body, a flashboard mutually matched with the through holes is arranged in the valve body, the upper end of the flashboard is connected with a valve rod arranged on the valve body, a diagonal upper guard plate is fixedly arranged in the through hole above the flashboard, and a separate lower guide plate is fixedly arranged in the through hole below the flashboard. The invention has the advantages that simple structure and convenient operation are realized; the arranged diagonal upper guard plate can prevent materials from entering a guide rail region of the flashboard during the material falling down process so as to reduce the material stacking phenomenon of the guide rail region of the flashboard, keep the flashboard to flexibly open and close, reduce the direct abrasion of the flashboard from the materials and prolong the service life of the flashboard; the arranged separate guide plate can support the flashboard when the flashboard is closed so as to prevent the deformation of the flashboard due to the material load; simultaneously, the residual materials in the guide rail region of the flashboard can be cleared during the flashboard opening and closing processes, thus the blocking phenomenon of the flashboard can be avoided.

Owner:江苏鑫通环保科技有限公司

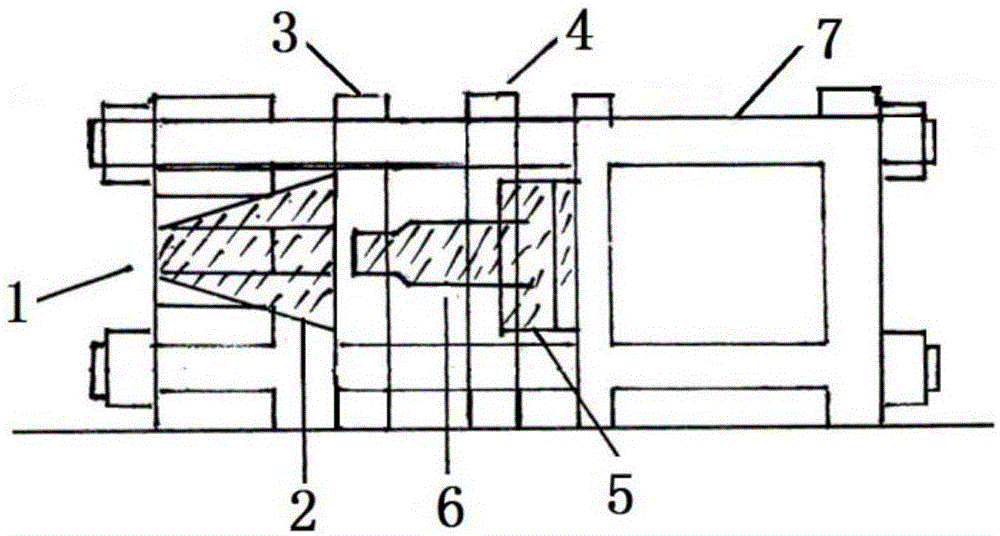

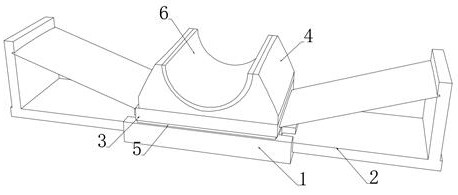

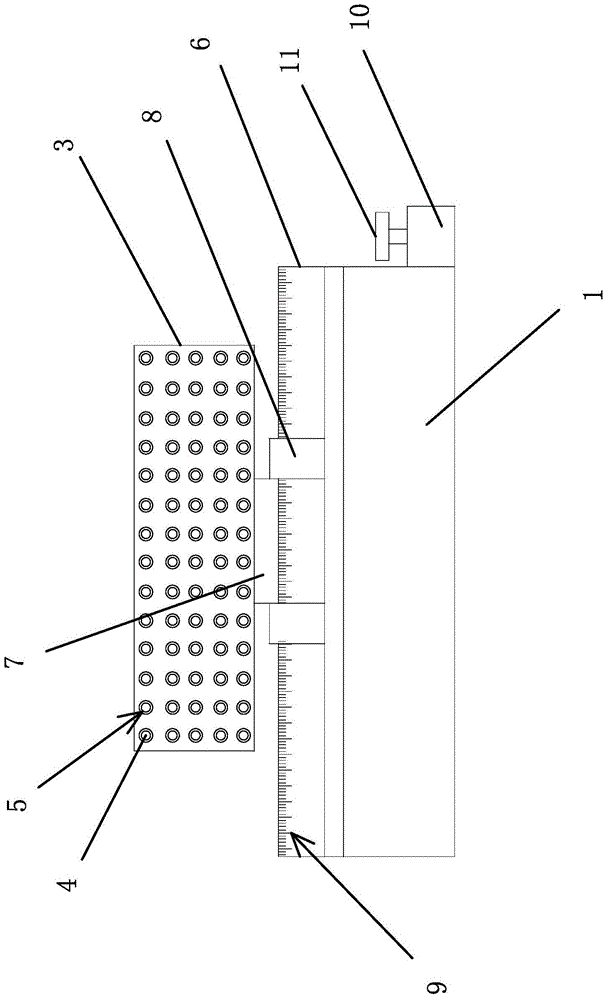

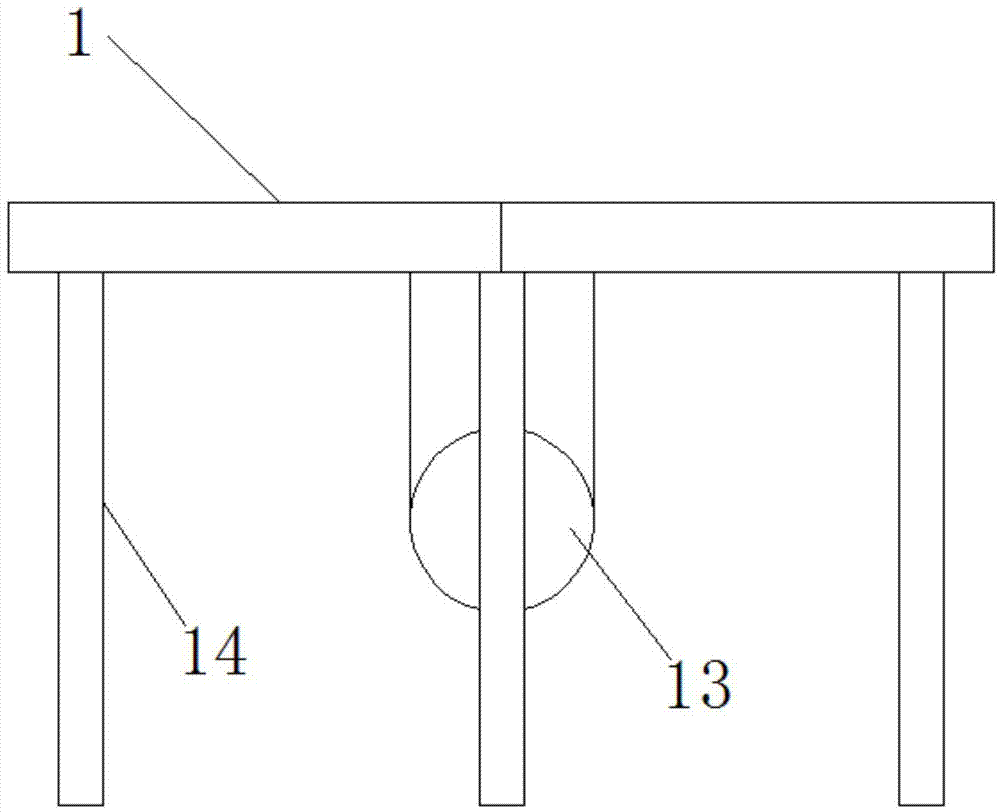

Rebar head portion upsetting machine and use method thereof

The invention discloses a rebar head portion upsetting machine and a use method thereof and belongs to the field of cold headers. An upsetting die and an upsetting device are installed on a machine frame. The rebar head portion upsetting machine comprises guide rods; the guide rods penetrate through the upsetting die and the upsetting device sequentially be arranged on the machine frame from left to right; the upsetting die comprises a clamping die and a die cavity; the die cavity is located in the clamping die; the upsetting device comprises an upset head cap and an upsetting head; the upsetting head is arranged at the left end of the upset head cap; the right end of the upset head cap is arranged on a hydraulic control system. The upsetting machine further comprises a front movable board and a rear movable board, wherein the front movable board is arranged on the right side of the upsetting die; the upsetting head on the upsetting device sequentially penetrates through the rear movable board and the front movable board; the left end of the rear movable board is arranged on the upset head cap; the guide rods penetrate through the front movable board and the rear movable board and the front movable board and the rear movable board are connected through a lead screw; the guide rods are cylindrical; the rear movable board can move on the guide rods left and right. The rebar head portion upsetting machine is large in upsetting force, high in upsetting quality and stable in complete-machine performance.

Owner:MAANSHAN CITY ZHIFENG MACHINERY

Large diameter gas measuring meter

InactiveCN103542896AHigh precisionImprove stabilityVolume/mass flow by differential pressureLower limitThermal acceleration

The invention discloses a large diameter gas measuring meter. The end portion of a flow meter is provided with a Venturi tube outer tube, the inside of the Venturi tube outer tube is provided with a Venturi tube inner tube to form a throttle body, a positive pressure guide tube and a negative pressure guide tube are arranged inside a protective pipe, the upper ends of the positive pressure guide tube and the negative pressure guide tube are fixed onto a connecting plate through a flange, the portion of the connecting plate, which is located at the rear of the protective pipe, is provided with a temperature measuring tube, pressure sensors arranged inside the negative pressure guide tube and the positive pressure guide tube and a temperature sensor arranged inside the temperature measuring tube are jointly connected with a signal processing display, and a thermal accelerometer is arranged inside the protective tube and is connected with the signal processing display. The double Venturi structure of the large diameter gas measuring meter improves the accuracy and stability of the measurement of flow-velocity fluid; when a flow is below the lower limit of a flow sensor, the gated thermal accelerometer works, the advantages of accurately measuring micro flows of a thermal acceleration sensor is fully taken advantages of, and the measuring range of an original flow meter is widened.

Owner:JIANGSU HUAERWEI TECH GRP

Connection method for adjacent meshes of copper alloy trapezius net

InactiveCN102085547AThe method of operation is reasonable and reliableReduce chafingBinding endsClimate change adaptationBraidCopper alloy

The invention discloses a connection method for adjacent meshes of a copper alloy trapezius net, relating to a connection method for a mesh of an aquaculture net cage. In the connection method for the adjacent meshes of the copper alloy trapezius net, a cylindrical braid, a rope, a suture line and a tarpaulin ring are adopted. The connection method is characterized in that a soft connecting piece is arranged between two copper alloy trapezius nets, and ring plates manufactured by the tarpaulin ring on the soft connecting piece correspond to screens on the copper alloy trapezius net one by one; one end of a polyethylene rope is fixed on one net knot at one side of the trapezius net, and the other end of the polyethylene rope successively passes through the tarpaulin ring on the soft connecting piece and screens on the copper alloy trapezius net until the other end of the polyethylene rope passes through all the ring plates on the same side of the soft connecting piece and all the screens on the trapezius net; the other end of the polyethylene rope is fixed on one net knot of the copper alloy trapezius net; and the soft connecting piece is connected with the other copper alloy trapezius net with the same method. The connection method is used for connecting the adjacent meshes of the copper alloy trapezius net.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Fixing device for high-protection fan component transportation

ActiveCN114194631ARelieve pressureReduce bumpsNon-rotating vibration suppressionLarge containersMagnetic dampingEngineering

The invention discloses a high-protection fixing device for fan component transportation, and belongs to the technical field of transportation fixing. According to the scheme, overhanging supports are matched with stress belts to reduce pressure of fan components on a transportation vehicle, bumping to the fan components caused by jolting in the transportation process is effectively reduced, and the safety of the transportation vehicle is improved. Meanwhile, buffer supports are matched with magnetic damping petals to fix the fan assembly, magnetic suction cups on the magnetic damping petals are used for being attracted to the fan assembly, the stability of the fan assembly is improved, and electromagnetic petals are matched with magnetic layers of the magnetic suction cups, so that part of diffusion damping balls are evenly distributed in a bag; the other part of the diffusion damping balls gather below the magnetic suction cup to support the fan assembly, the bearing capacity of the fan assembly is improved through cooperation with hydraulic oil, meanwhile, when the fan assembly is vibrated, the diffusion damping balls are squeezed to be scattered and then can reset in time, and dynamic supporting force is provided for the fan assembly.

Owner:JIANGSU LONGYUAN ZHENHUA MARINE ENG

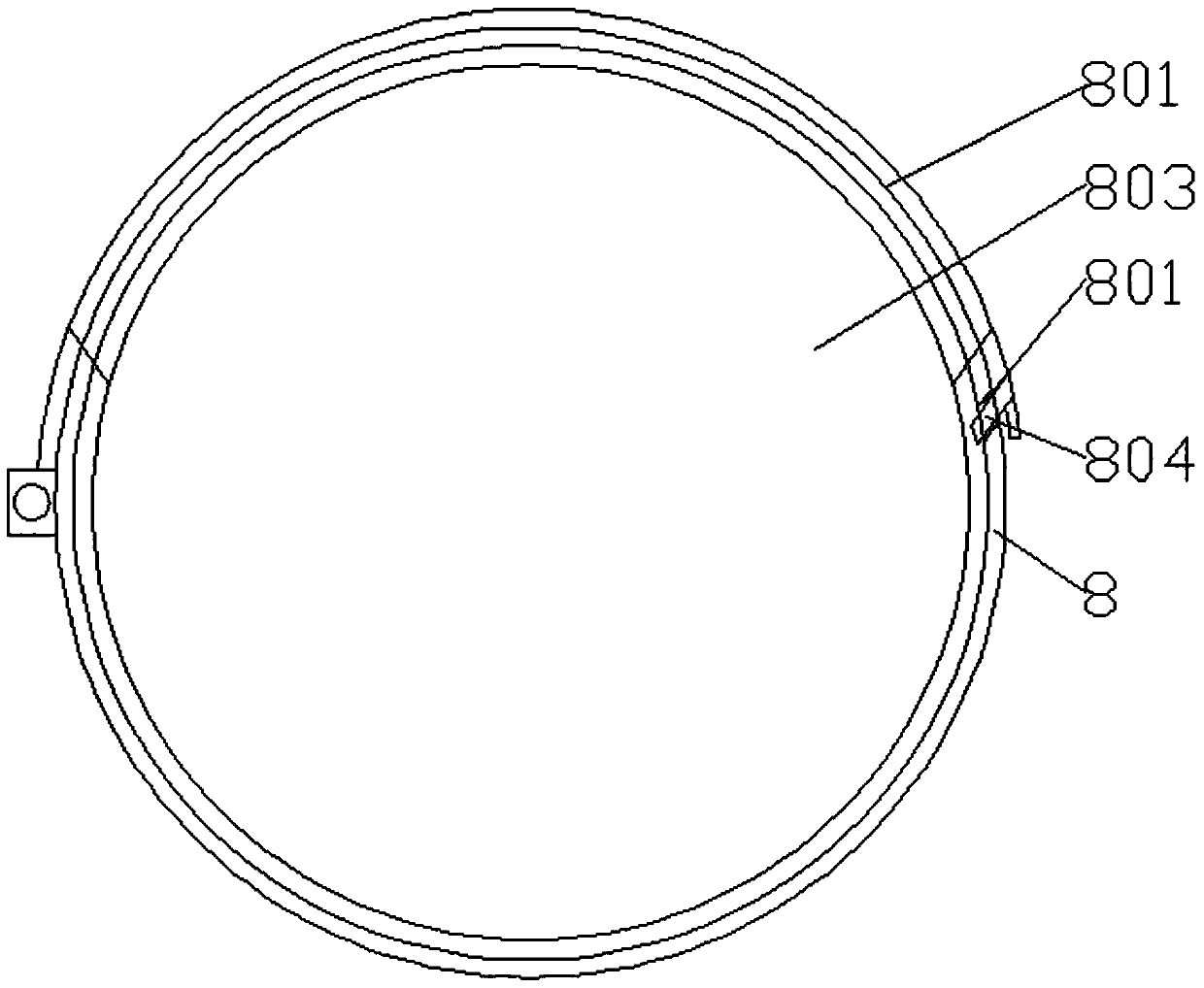

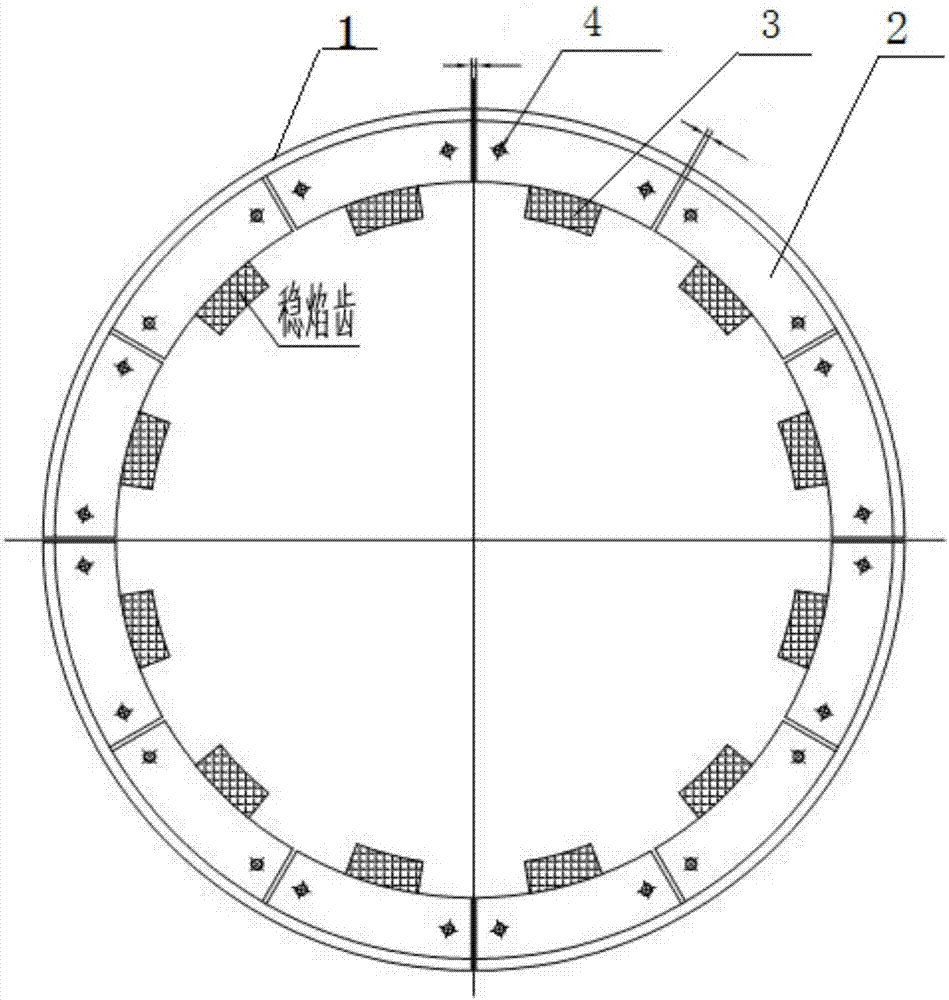

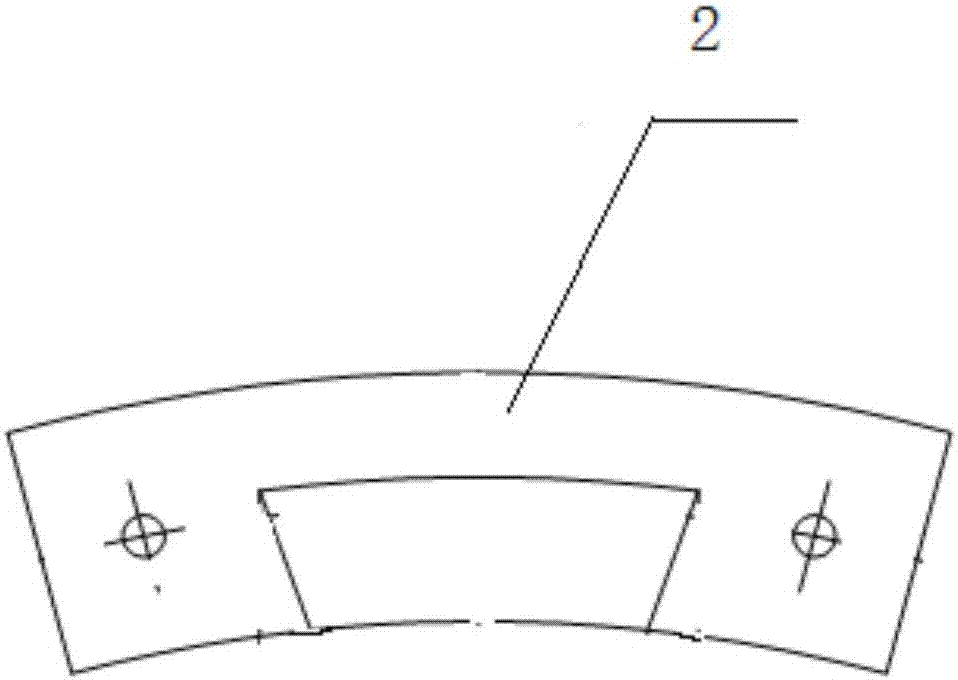

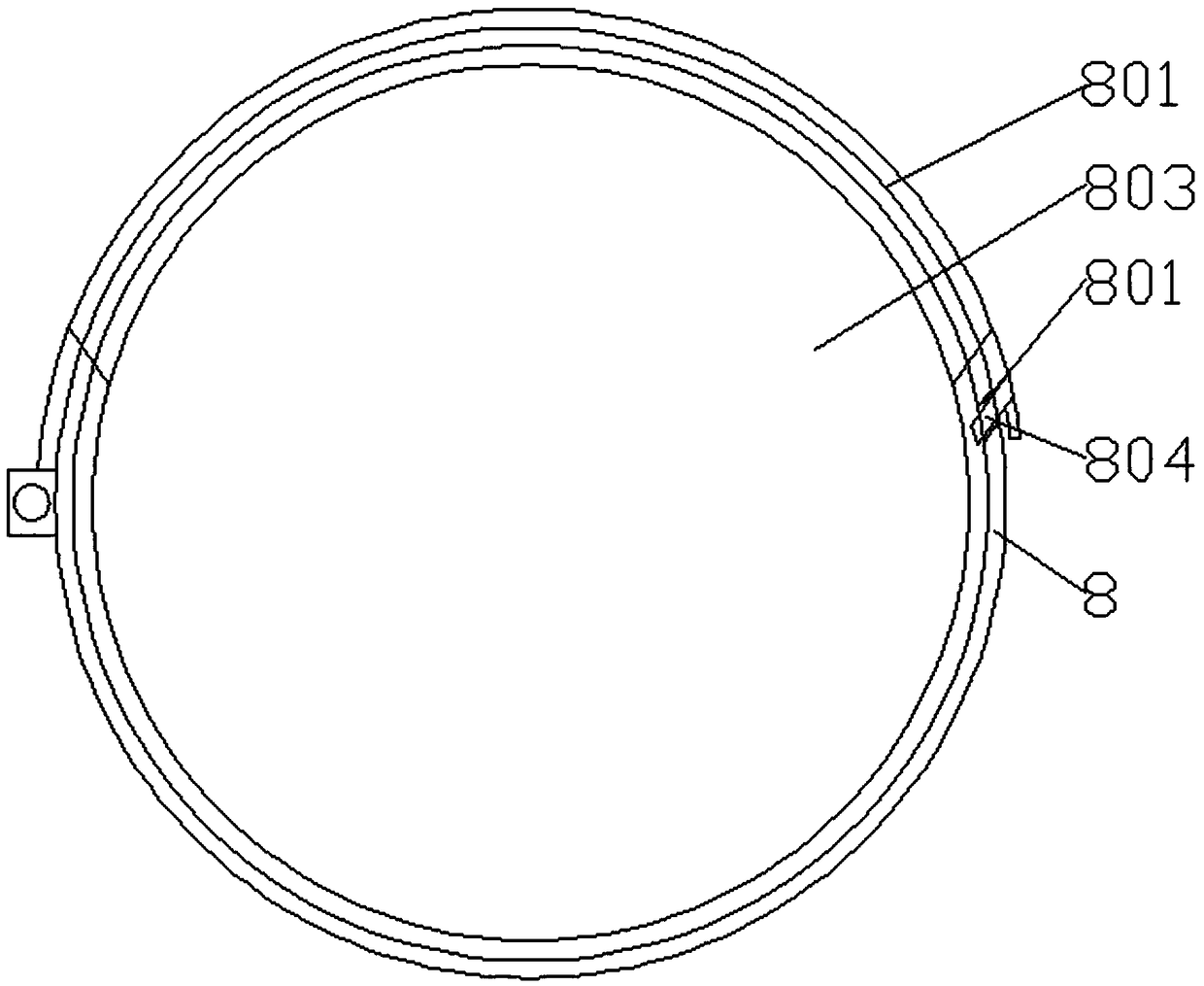

Burning stabilizing ring structure of vortex burner

InactiveCN107166380APrevent burning lossExtended service lifePulverulent fuel combustion burnersCombustorEngineering

The invention discloses a burning stabilizing ring structure of a vortex burner. The burning stabilizing ring structure comprises a burning stabilizing ring body and further comprises a plurality of flame stabilizing teeth, a pressing plate and a bolt assembly. The flame stabilizing teeth are pressed to the burning stabilizing ring body through the pressing plate. The pressing plate is arranged on the burning stabilizing ring body. The bolt assembly penetrates through the burning stabilizing ring body, the pressing plate and the flame stabilizing teeth, so that the flame stabilizing teeth are fixed to the burning stabilizing ring body at equal intervals, and the windward faces of the flame stabilizing teeth are made from silicon carbide. The silicon burning stabilizing ring can resist high temperature and abrasion, the burning stabilizing teeth can be effectively prevented from falling off, the service life of the burner is prolonged, and safety and economy of a power plant are improved.

Owner:JIANGSU JINGCHENG MASCH MFG CO LTD

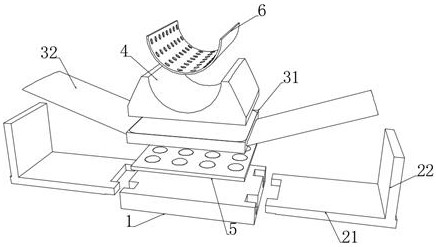

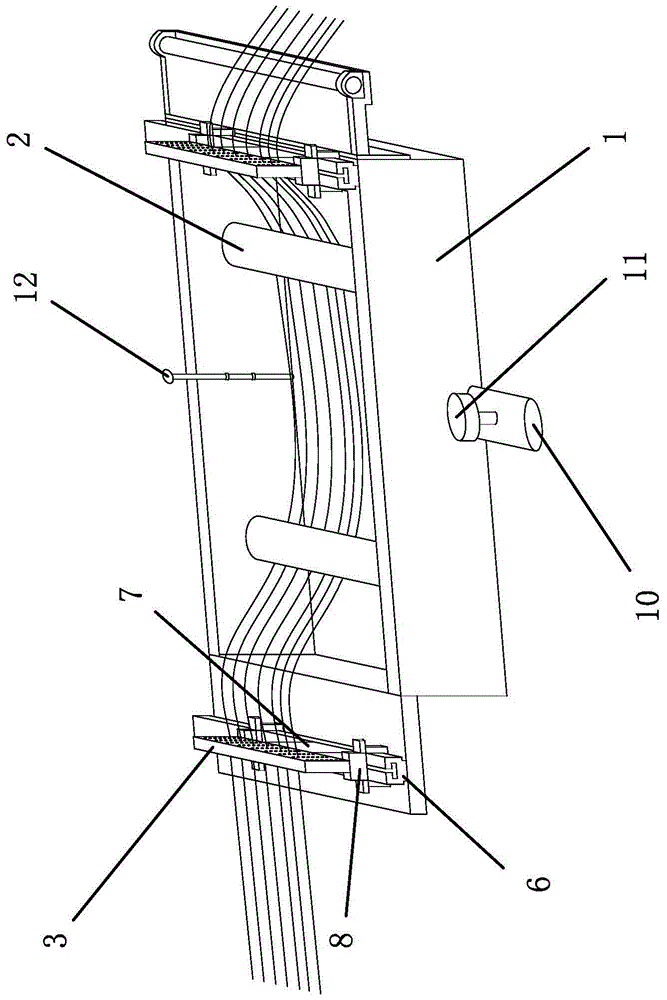

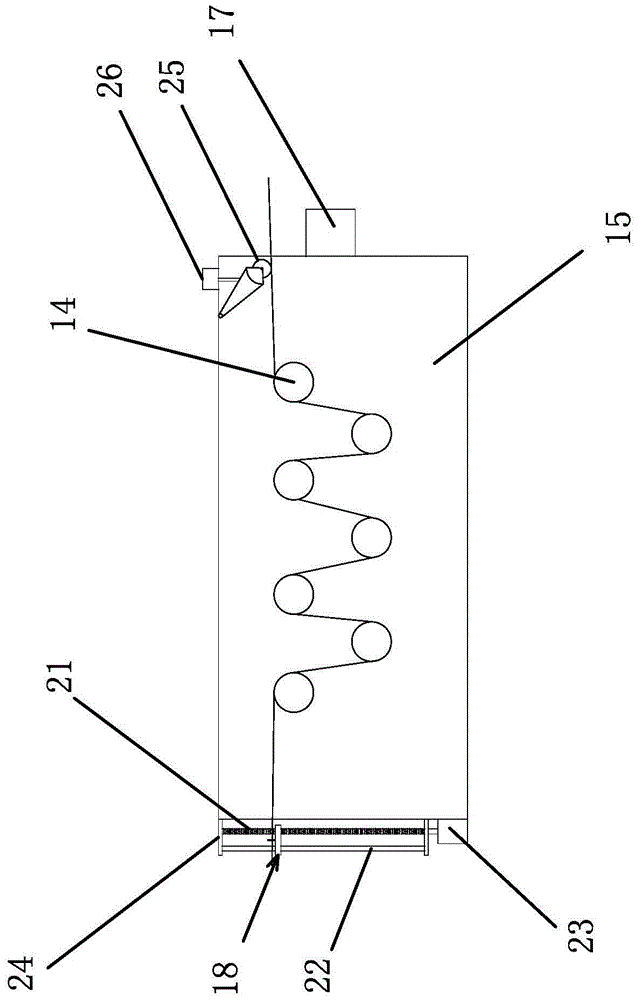

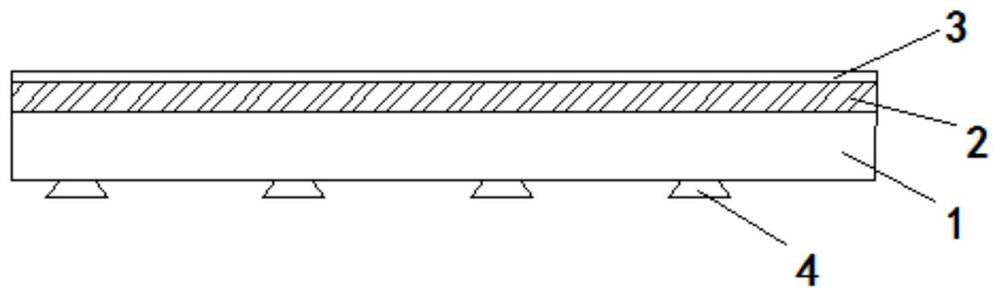

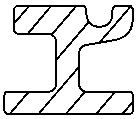

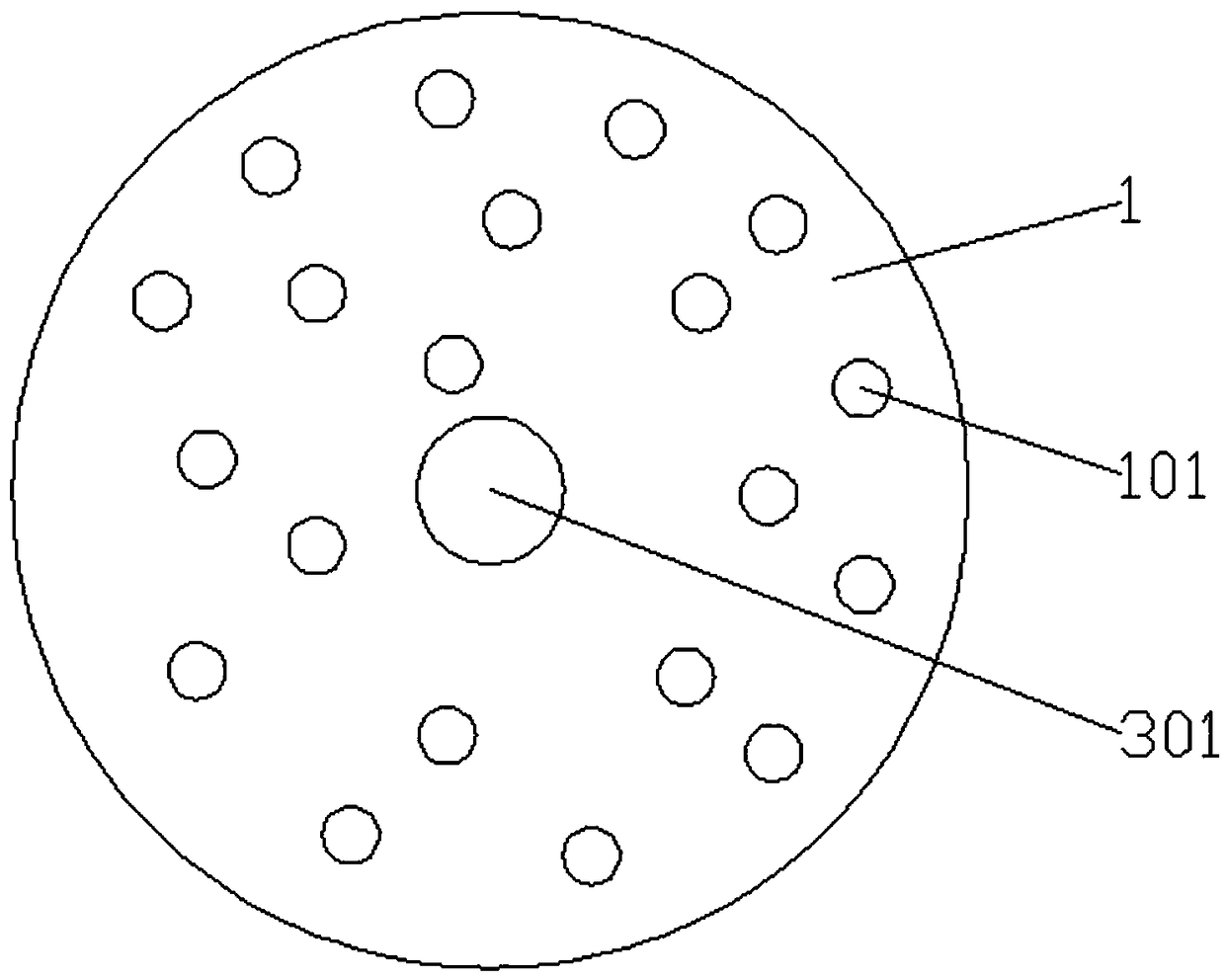

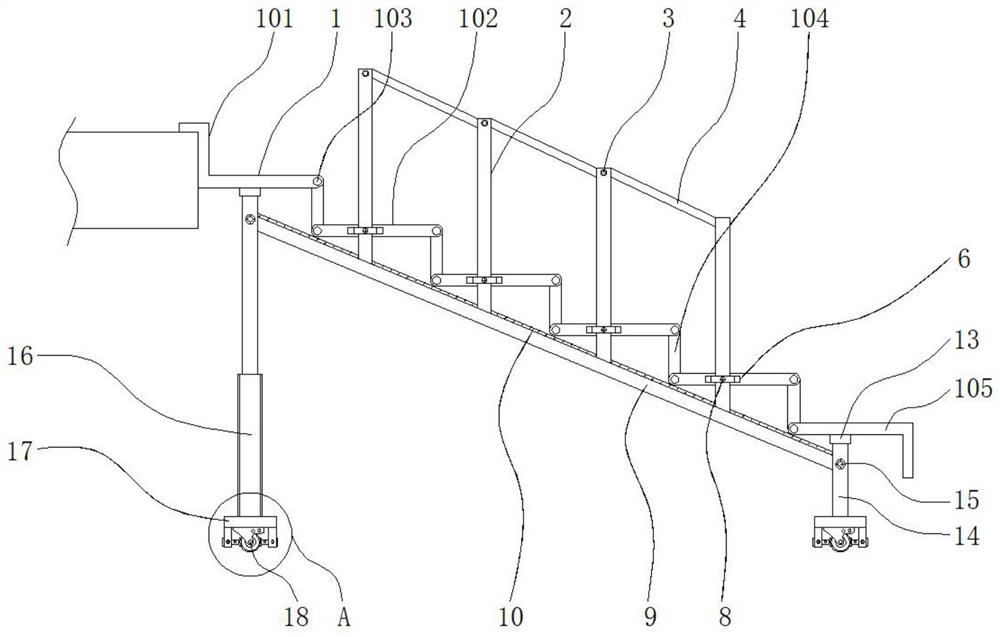

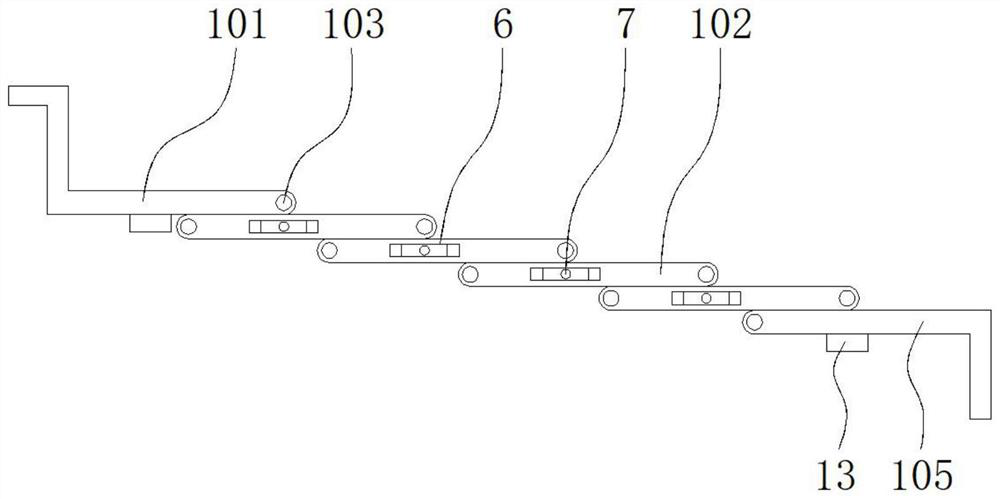

A monofilament automatic production line

The invention provides a monofilament automatic production line, which belongs to the technical field of monofilament production equipment. This fully automatic monofilament production line includes a mixing machine, an extruder, a cooling device, a drafting device, a heat setting device, a winding machine, a cooling device, including a cooling water tank, a cooling roller and a guide sieve plate. The cooling water tank is in the shape of a cuboid Shaped and filled with cooling water, the cooling roller is set in the cooling water tank, and a guide sieve plate is connected to each end of the cooling water tank; the drafting device includes a chassis, seven drafting roller shafts and seven drafting rollers, seven The drafting rollers are sleeved on the outside of the drafting rollers one by one, and one end of the drafting rollers is rotatably connected to the cabinet, and the drafting rollers are linked with each other through gear meshing; the heat setting device includes an oven cover, a pressure roller 1. A square oil tank containing high-temperature oil and a shaping motor fixed on the outer side of the oil tank. An electric heater is installed at the inner bottom of the oil tank, and a setting roller is installed at the upper port of the oil tank. The product quality and production efficiency of monofilament are improved.

Owner:ZHEJIANG JINGCHENG SPECIAL MONOFILAMENT CO LTD

A multifunctional wall switch protection cover

The invention discloses a multi-purpose wall switch protection cover, comprising a wall switch and a wall switch protection cover at the outside of the wall switch, wherein the wall switch is embeddedon a wall, the wall switch protection cover at the outside of the wall switch is hinged to a hinge seat through a hinge shaft, and the hinge seat is fixedly disposed at a lower right end of a mounting block. In the multi-purpose wall switch protection cover disclosed by the invention, when the wall switch protection cover is opened, a neck in the surface can be used for placing a mobile phone orthe like, so that the mobile phone can be charged conveniently, multiple groups of airflow holes on a lower surface of the wall switch protection cover can output air to serve as a hair dryer, the lower end of the wall switch protection cover is sealed in a lower end sealing neck through a rubber sealing block, so that the sealing property of the wall switch protection cover is relatively high.

Owner:山东开亿基因科技有限公司

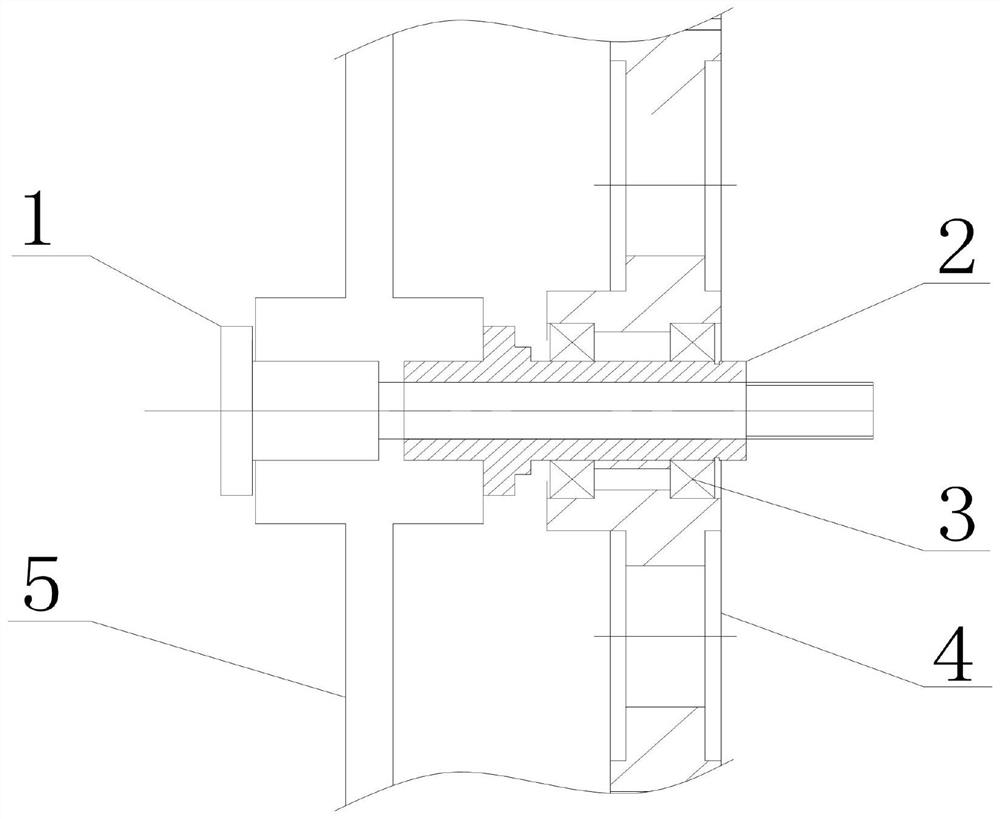

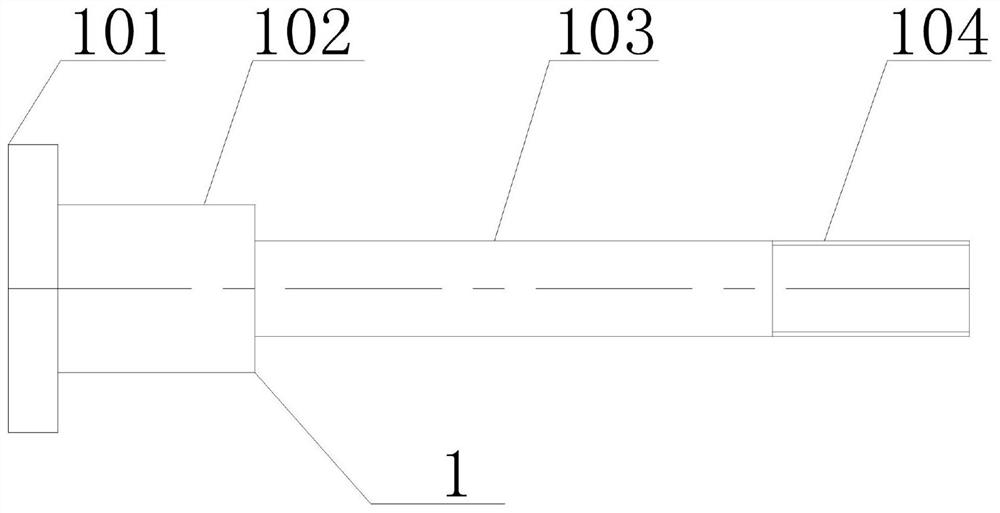

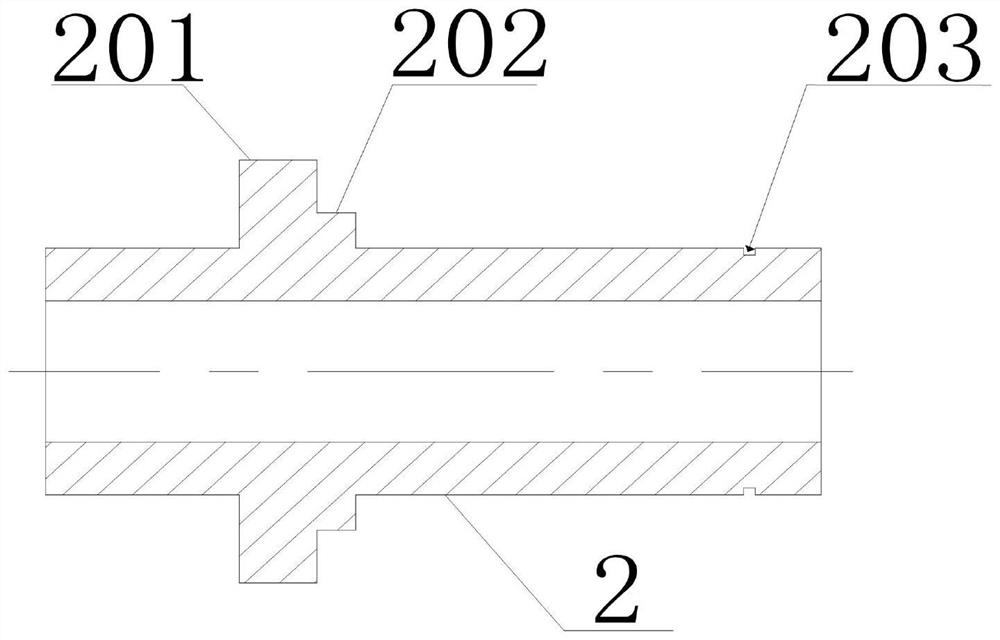

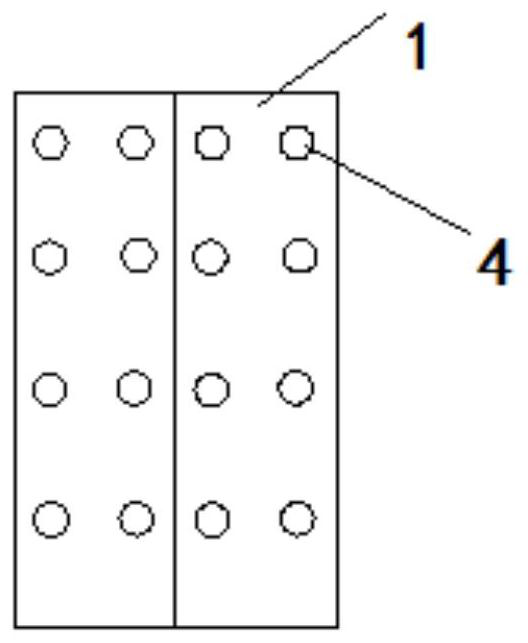

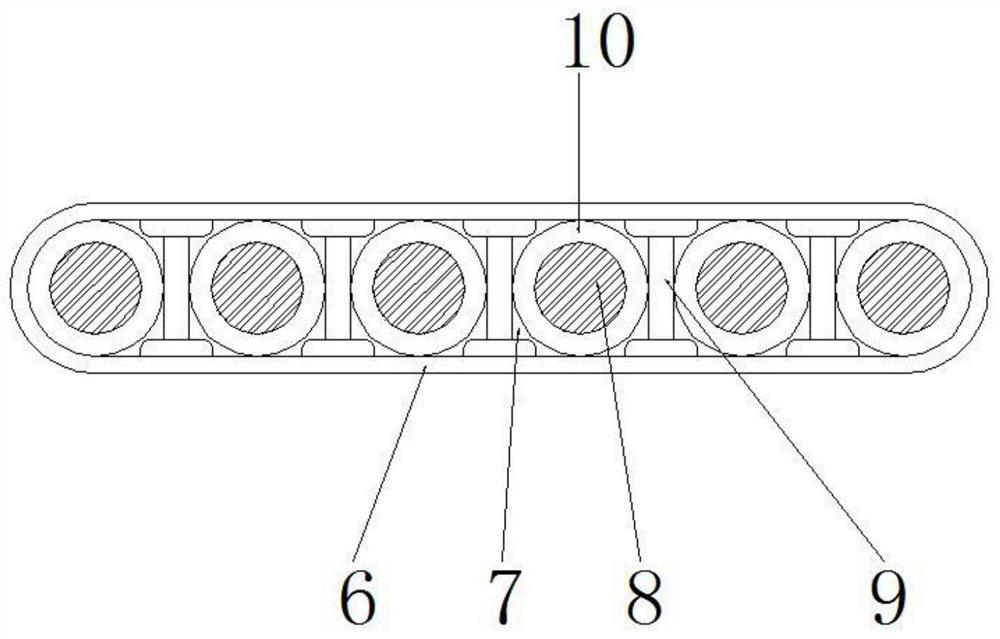

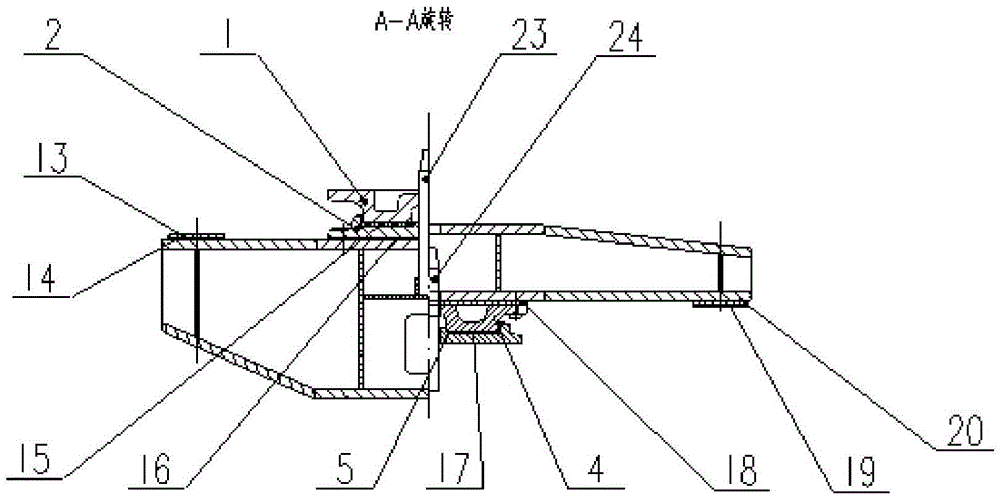

Connecting device for stranding machine

InactiveCN112002491AReduce direct wear and tearExtended service lifeCable/conductor manufactureBrakeGear wheel

The invention discloses a connecting device for a stranding machine, which comprises a connecting shaft for connecting a stranding cage brake disc and a carrier gear, wherein the connecting shaft is sleeved with a shaft sleeve matched with the connecting shaft, the periphery of the shaft sleeve is provided with a first convex part and a second convex part, and the connecting shaft is arranged in the shaft sleeve in a close fit way. According to the invention, the gear of the stranding machine does not shake in the high-speed rotation process.

Owner:CHONGQING TAISHAN CABLE

Method for manufacturing antifouling and antibiosis type yellow croaker net cage

InactiveCN102763610BReduce harmImprove survival rateClimate change adaptationPisciculture and aquariaAntibiosisEngineering

The invention discloses a method for manufacturing an antifouling and antibiosis type yellow croaker net cage, which relates to a method for manufacturing a mariculture net cage. According to the invention, the method for manufacturing the antifouling and antibiosis type yellow croaker net cage adopts a buoyancy force system and a netting system, and is characterized in that the buoyancy force system adopts a combination buoyancy force form of 'an anti-aging high-density polyethylene double-floating-pipe cylindrical frame structure + 18 cube cystosepiments with each edge length of 60cm; the netting system adopts a combination structure netting form of 'a first box longitudinal netting + a second box longitudinal netting + a net cage bottom netting; the net cage bottom netting is assembledon a circular high-density polyethylene pipe support which is wrapped with a layer of polyamide multifilament wrap knitting net; and three cross lacing lines are installed at the bottom of the net cage, a polypropylene rope is tied at the cross point of the cross lacing lines, and two foam float bowls which are externally wrapped by double-layer seawater corrosion protection canva and nylon nets are tied at the other end of the polypropylene rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Multi-purpose wall switch protection cover

The invention discloses a multi-purpose wall switch protection cover, comprising a wall switch and a wall switch protection cover at the outside of the wall switch, wherein the wall switch is embeddedon a wall, the wall switch protection cover at the outside of the wall switch is hinged to a hinge seat through a hinge shaft, and the hinge seat is fixedly disposed at a lower right end of a mounting block. In the multi-purpose wall switch protection cover disclosed by the invention, when the wall switch protection cover is opened, a neck in the surface can be used for placing a mobile phone orthe like, so that the mobile phone can be charged conveniently, multiple groups of airflow holes on a lower surface of the wall switch protection cover can output air to serve as a hair dryer, the lower end of the wall switch protection cover is sealed in a lower end sealing neck through a rubber sealing block, so that the sealing property of the wall switch protection cover is relatively high.

Owner:山东开亿基因科技有限公司

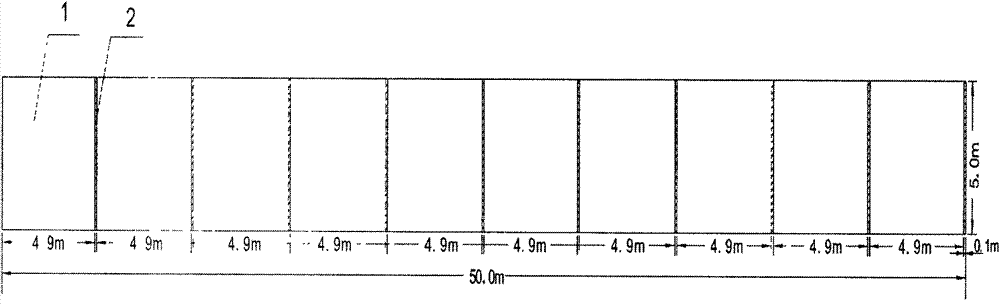

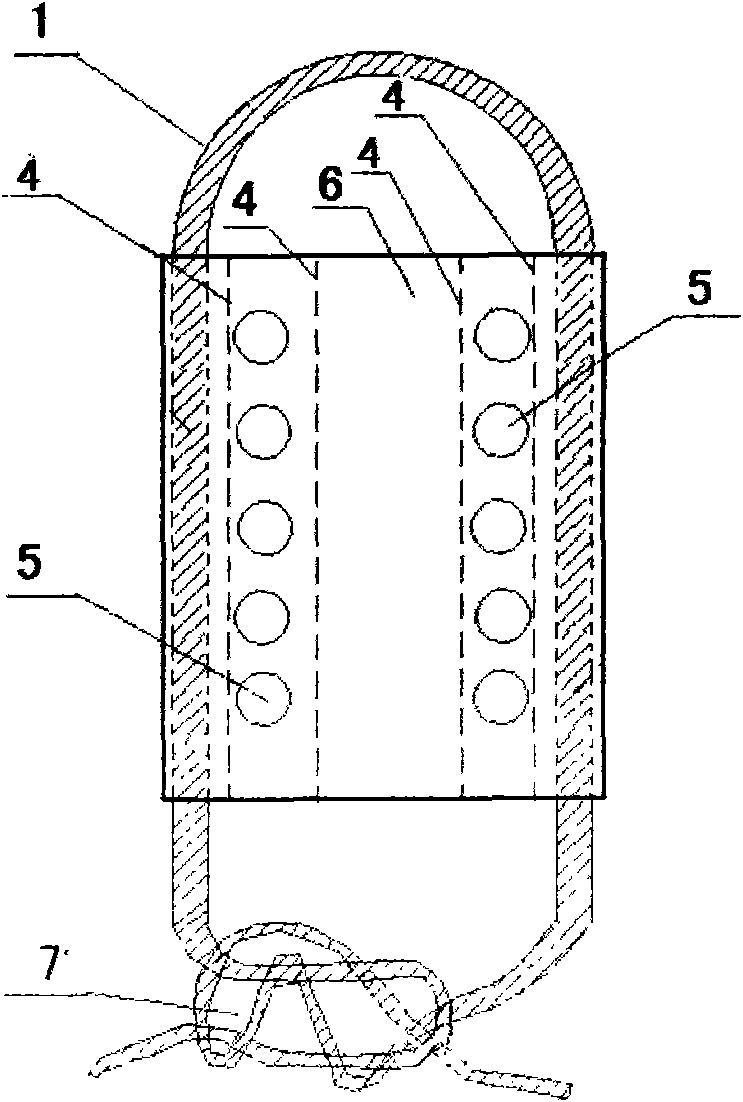

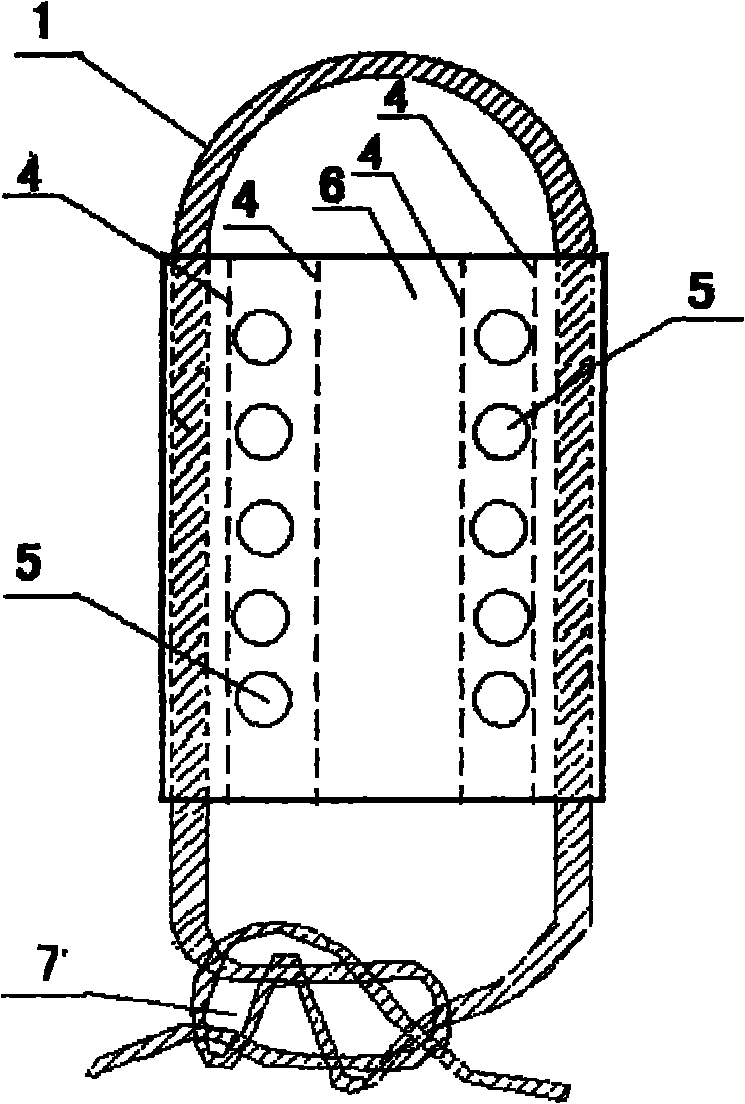

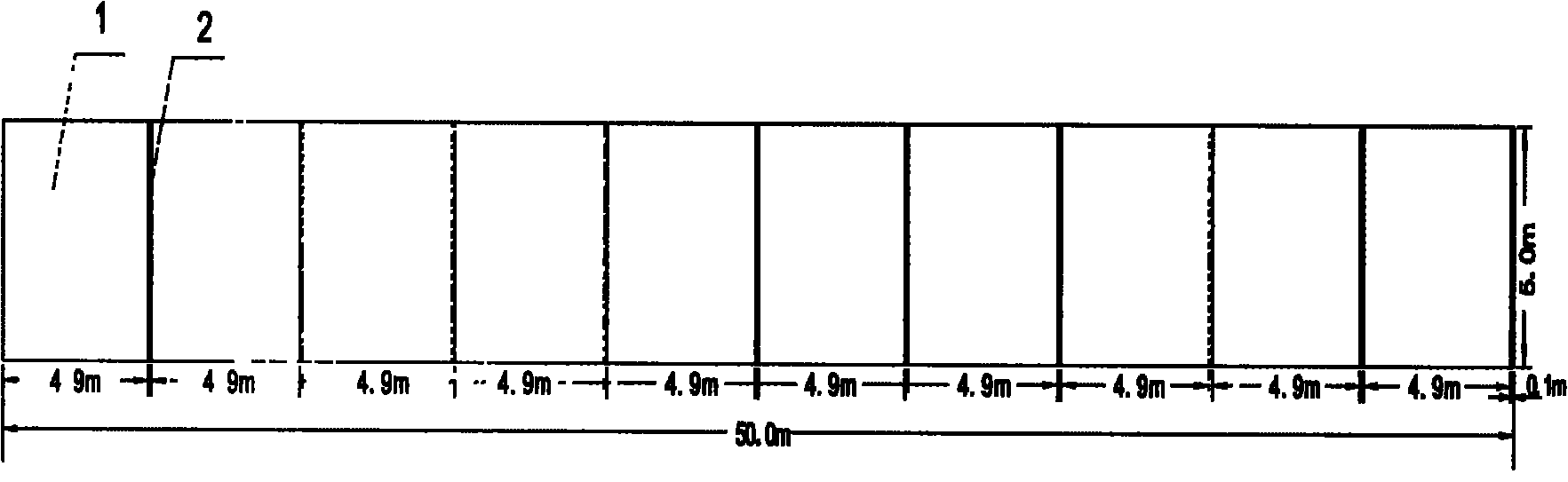

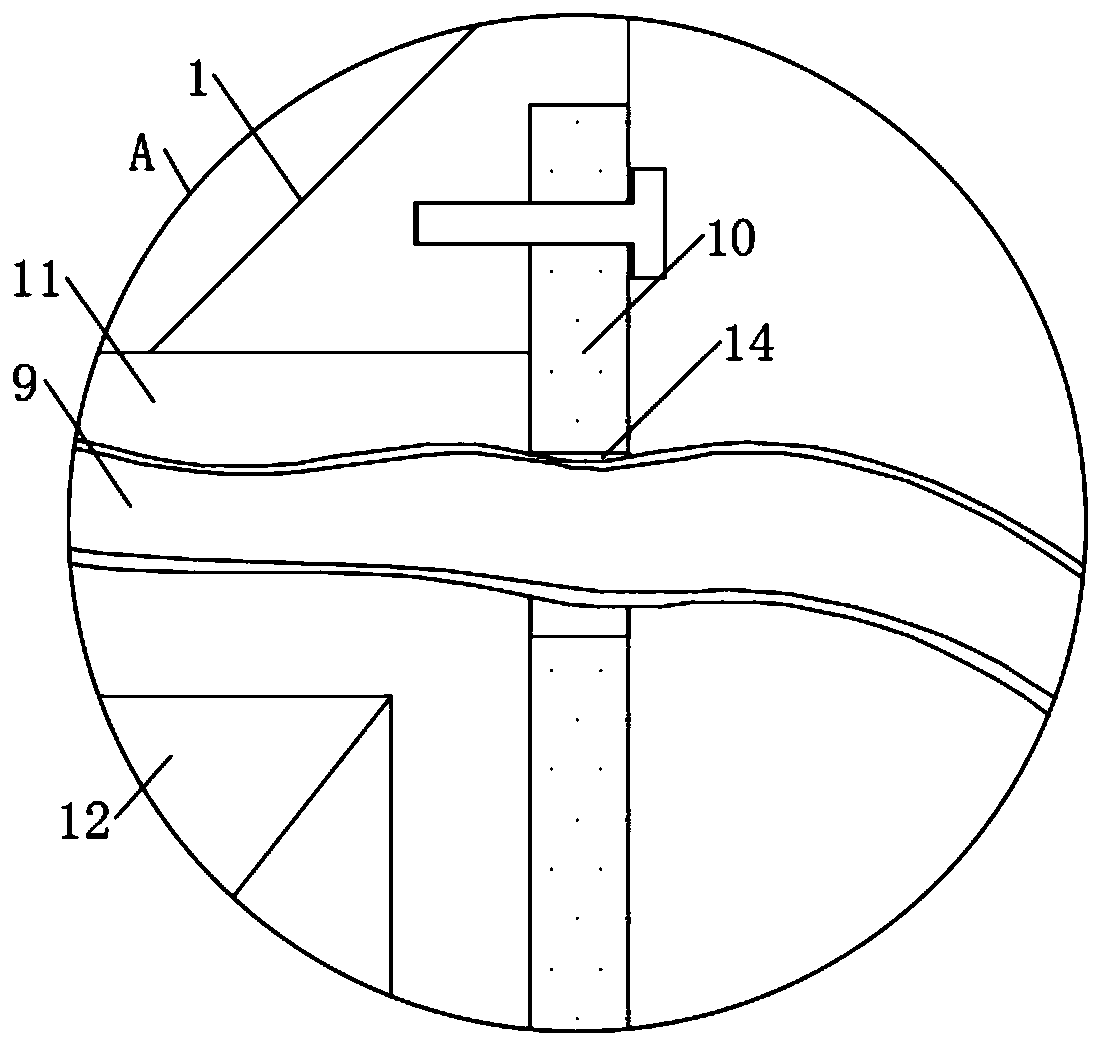

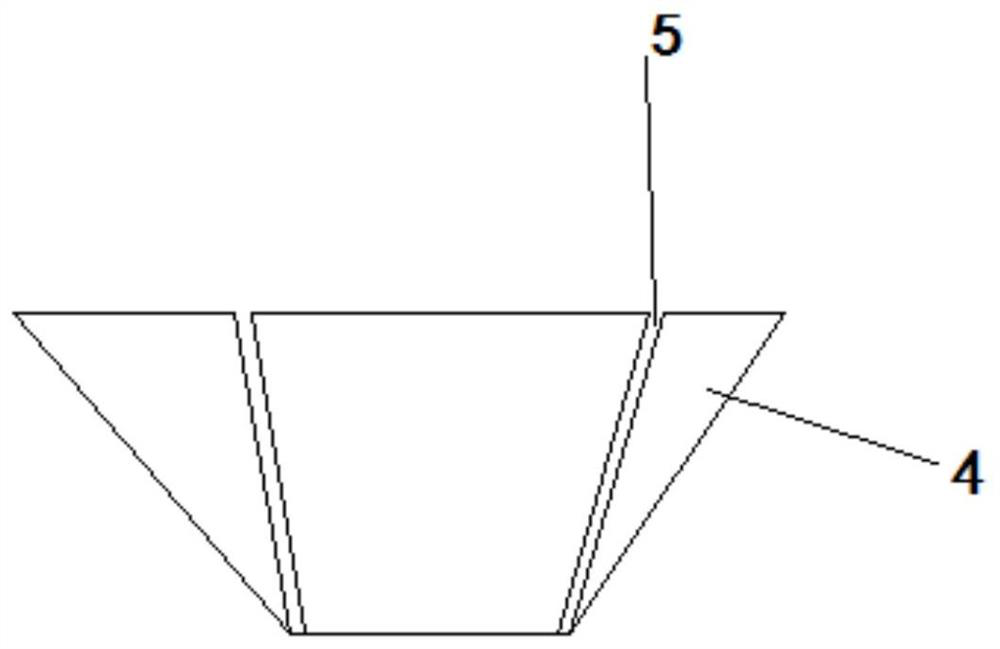

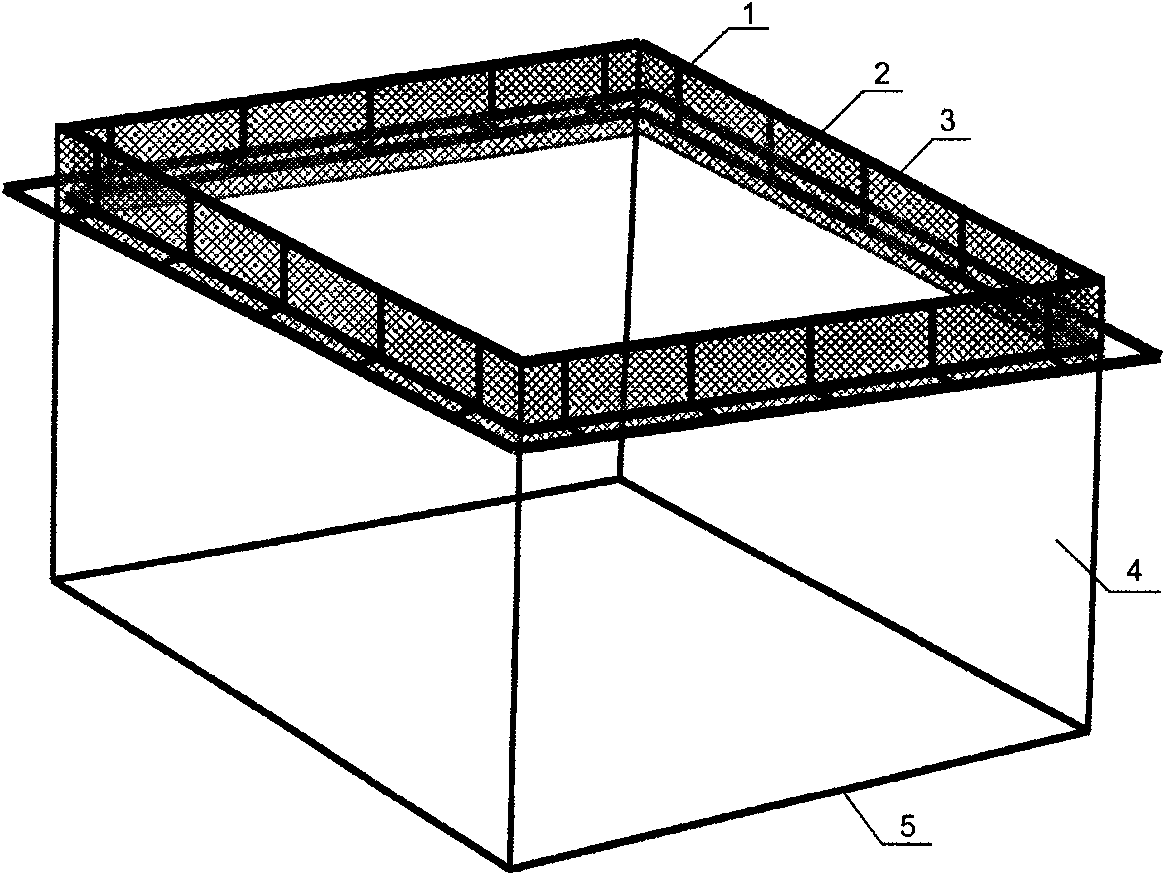

Stain-repellent stretch net cage for farming large yellow croaker

InactiveCN102763611BReduce harmImprove farming efficiencyClimate change adaptationPisciculture and aquariaMaricultureCompound structure

A stain-repellent stretch net cage for farming large yellow croaker relates to a cage for mariculture of the large yellow croaker. The stain-repellent stretch net cage for farming large yellow croaker is provided with a floating system and a net system and is characterized in that the floating system is in a rectangular frame structure with double floating pipes, the net system is in a combined structure of a longitudinal cage upper end net, a longitudinal cage lower end net and a cage bottom net; the cage bottom net is fitted on a frame wrapped with a synthetic fiber mesh, and the frame is connected with lower edge horizontal ropes of the longitudinal cage lower end net; after the longitudinal cage lower end net is connected with the cage bottom net, vertical man ropes longitudinally disposed along the longitudinal cage upper end net from upper horizontal ropes of the longitudinal cage upper end net extends to edge ropes of the cage bottom net; crossing man ropes are added to the bottom of the cage, crossing man ropes are added along diagonals of the bottom of the cage, a high-strength polypropylene rope is tied to an intersection of the two crossing man ropes arranged along the diagonals of the bottom of the cage, and a cylindrical foam float is tied to the other end of the high-strength polypropylene rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

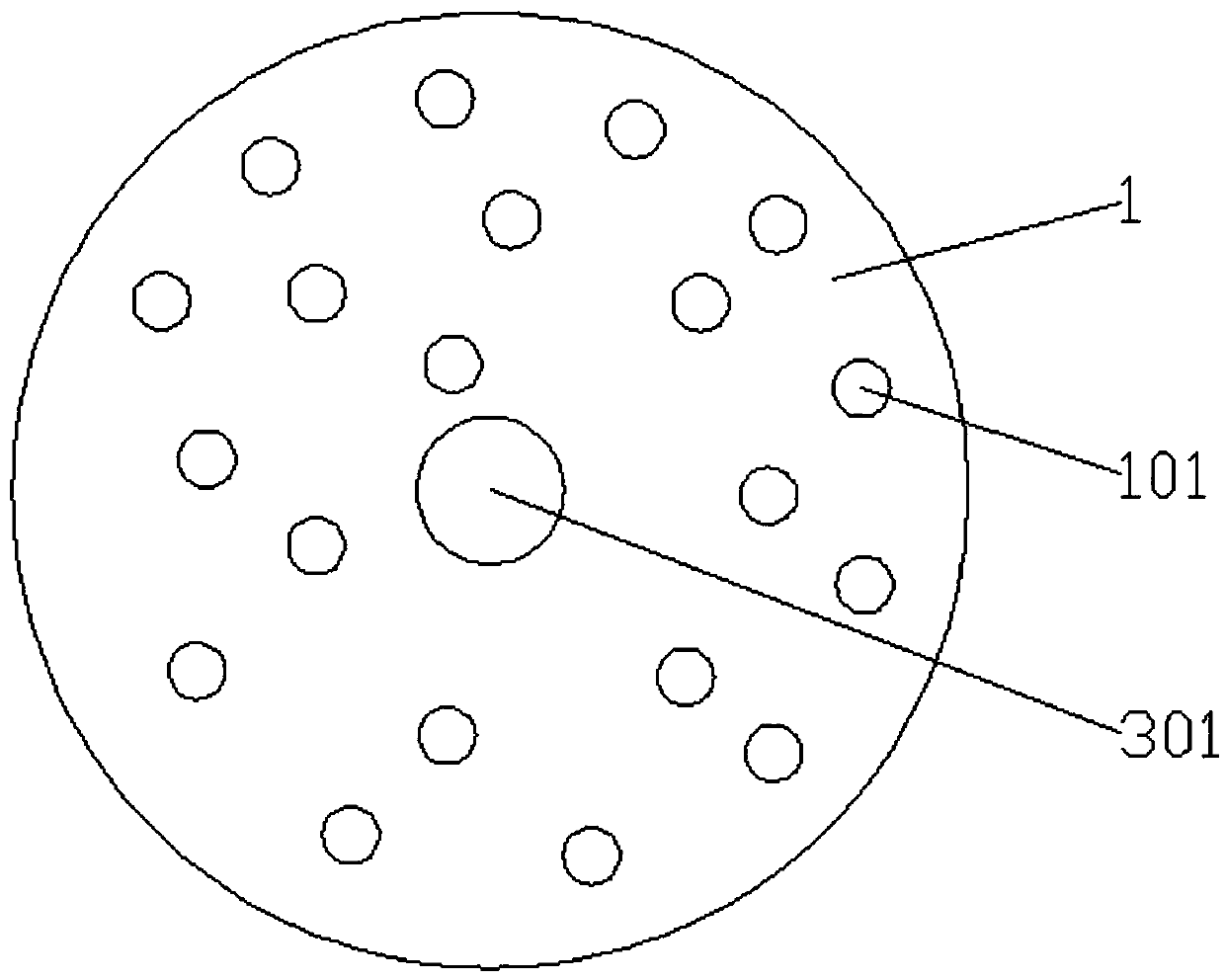

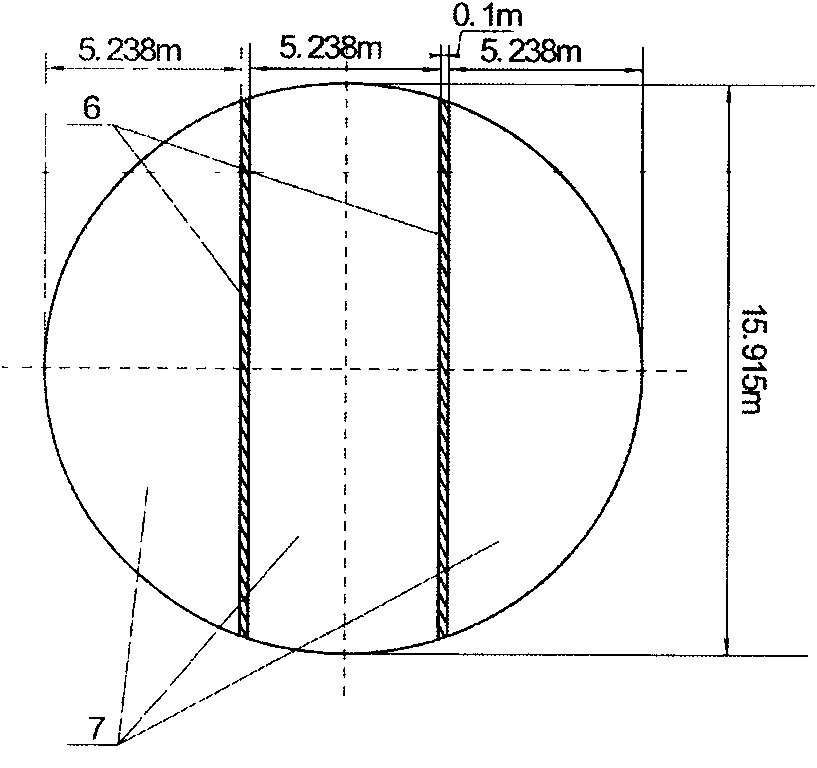

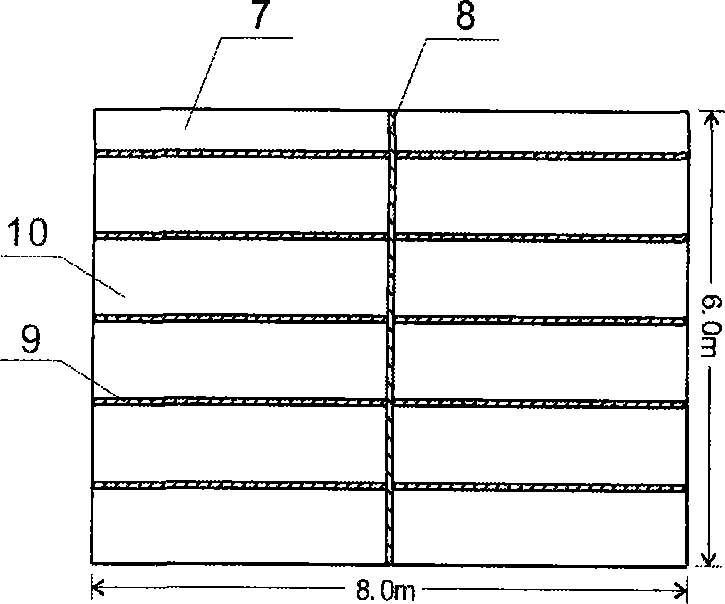

Cylindrical copper-alloy netting net cage for aquaculture

InactiveCN102239816BExtended service lifeImprove the box volume retention rateClimate change adaptationPisciculture and aquariaMooring systemPolyamide

The invention relates to a cylindrical copper-alloy netting net cage for aquaculture. The cylindrical copper-alloy netting net box adopts a high-strength single-dead-knot polyethylene-fiber net, a high-strength polyamide warp knitting net and a copper-alloy rhombic net and is characterized in that a buoyancy system of the net cage is in a combined structure of black high-density polyethylene double floating pipes and cylindrical floaters; a netting system for the net cage consists of a double-layer synthetic-fiber netting as a netting I, a copper-alloy rhombic net as a netting II and a high-strength polyamide warp knitting net as a combined netting for the bottom of a net cage body; the netting I and the netting II of the net cage body are flexibly connected by a longitudinal netting; side bolsh lines and lacing lines are assembled on the netting for the bottom of the net cage body, and horizontal lines and vertical lacing lines are arranged on the netting on the side surface of the net cage body; the combined netting for the net cage body is hung on an armrests and a floating pipe inner frame of a net cage frame; an outer frame of the floating pipe frame is connected with a floating rope frame of a fixed mooring system by mooring ropes, and the fixed mooring system of the net cage is used for fixing the floating rope frame in the sea areas for aquaculture by anchors, wood piles, anchor ropes, floating balls and floating ball connecting ropes.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

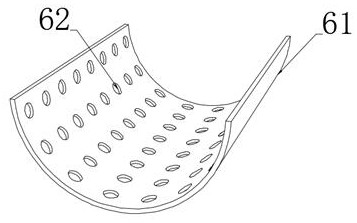

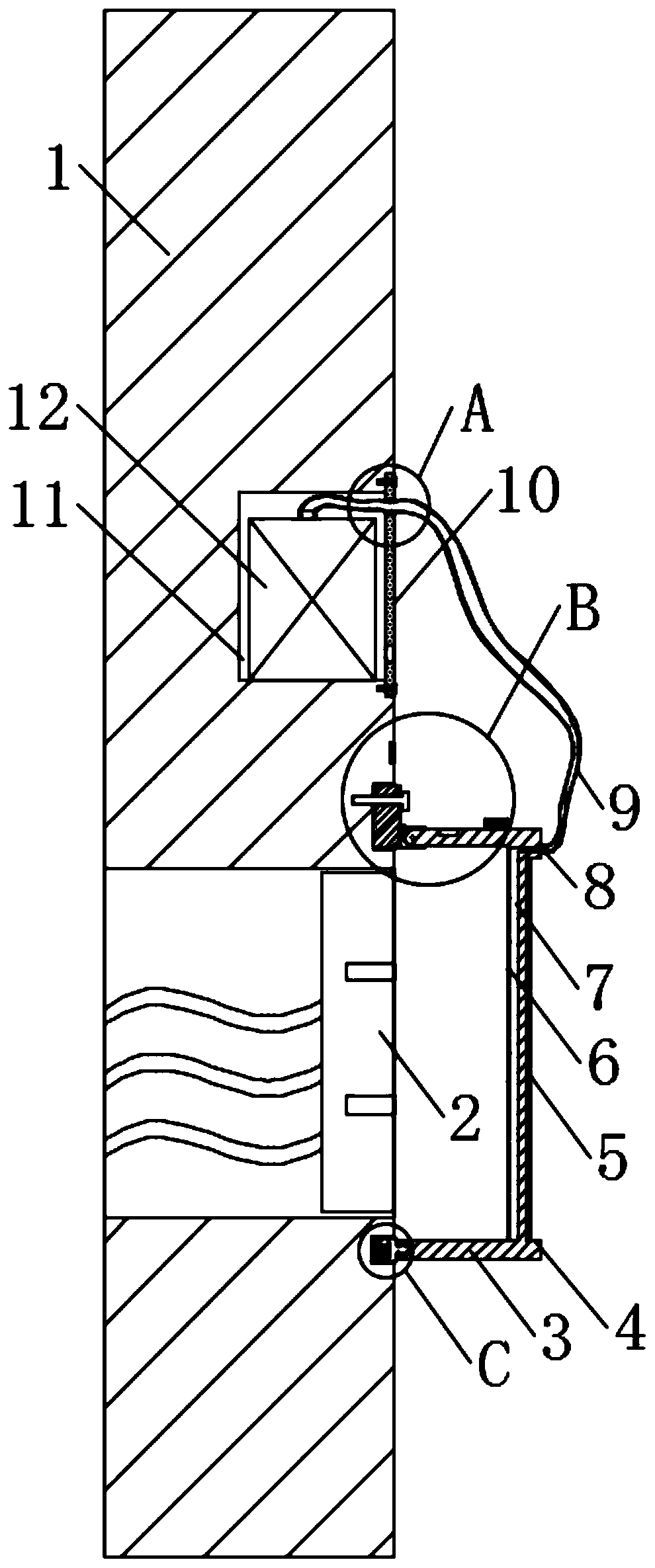

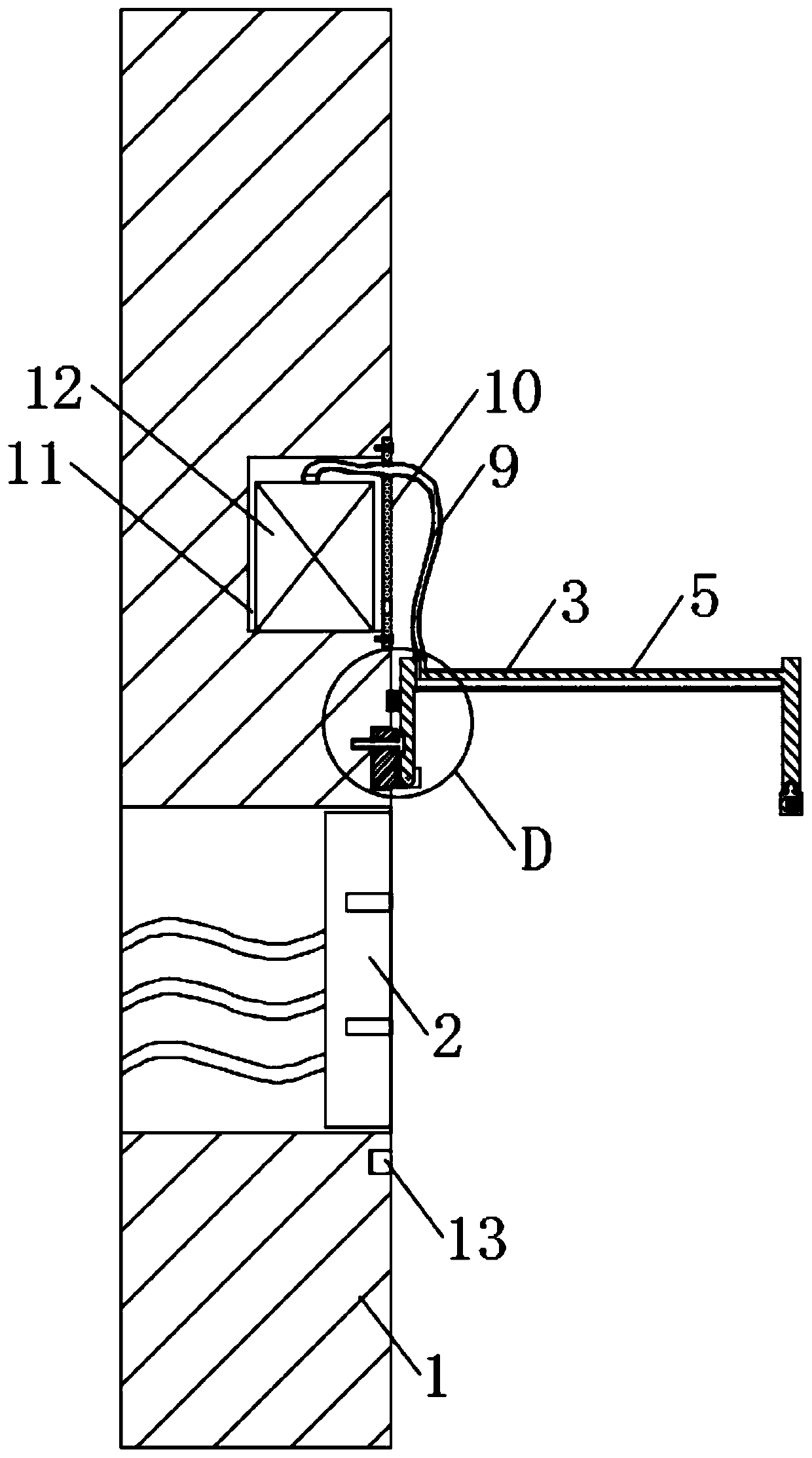

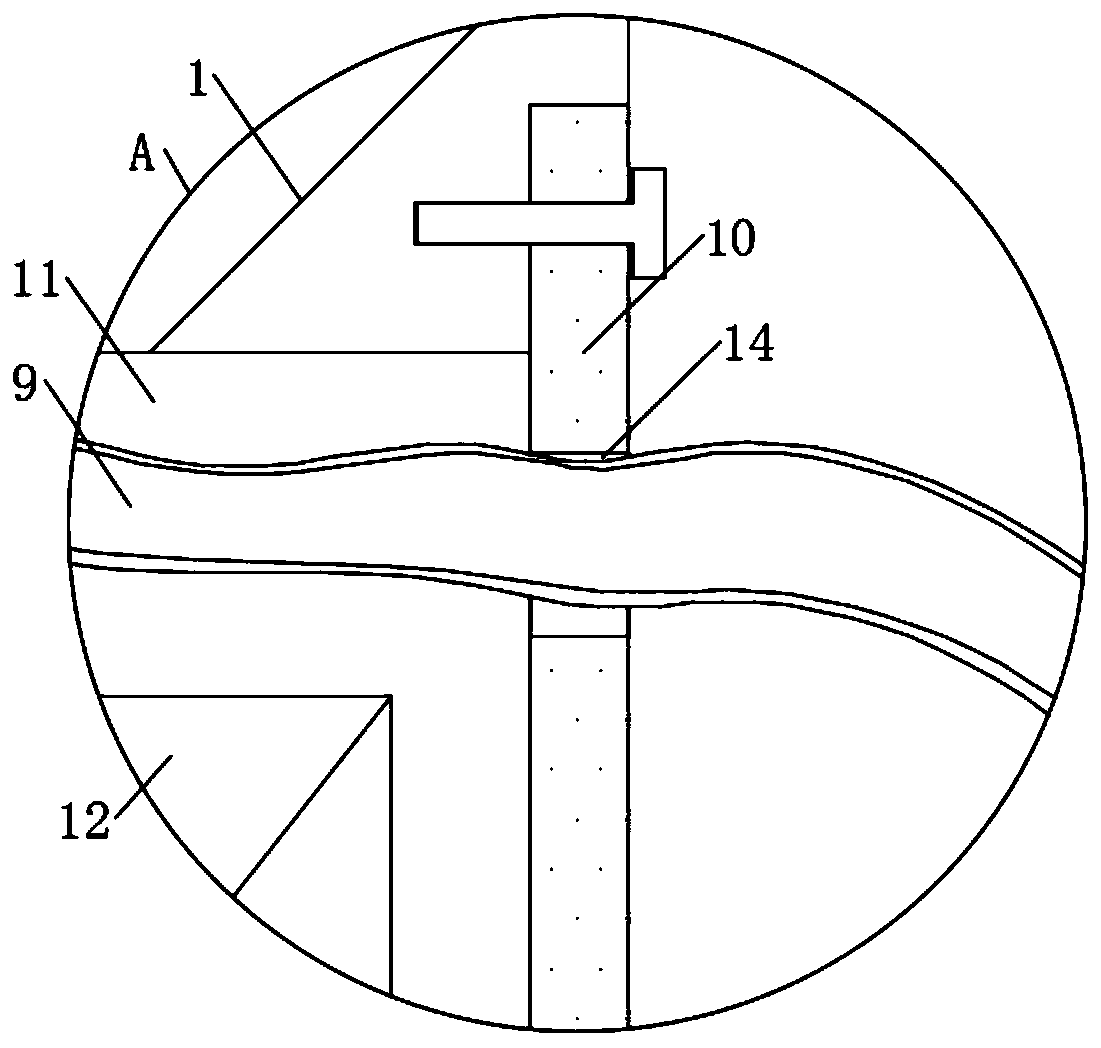

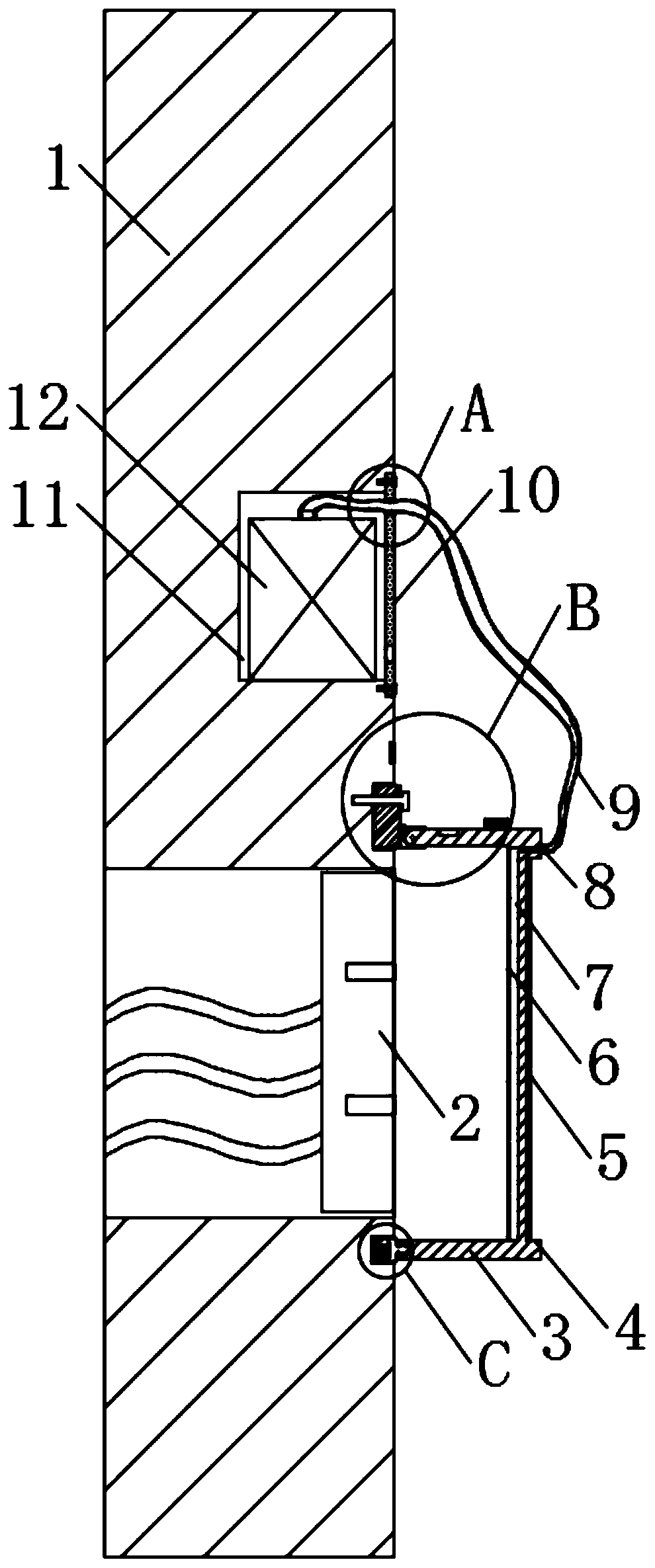

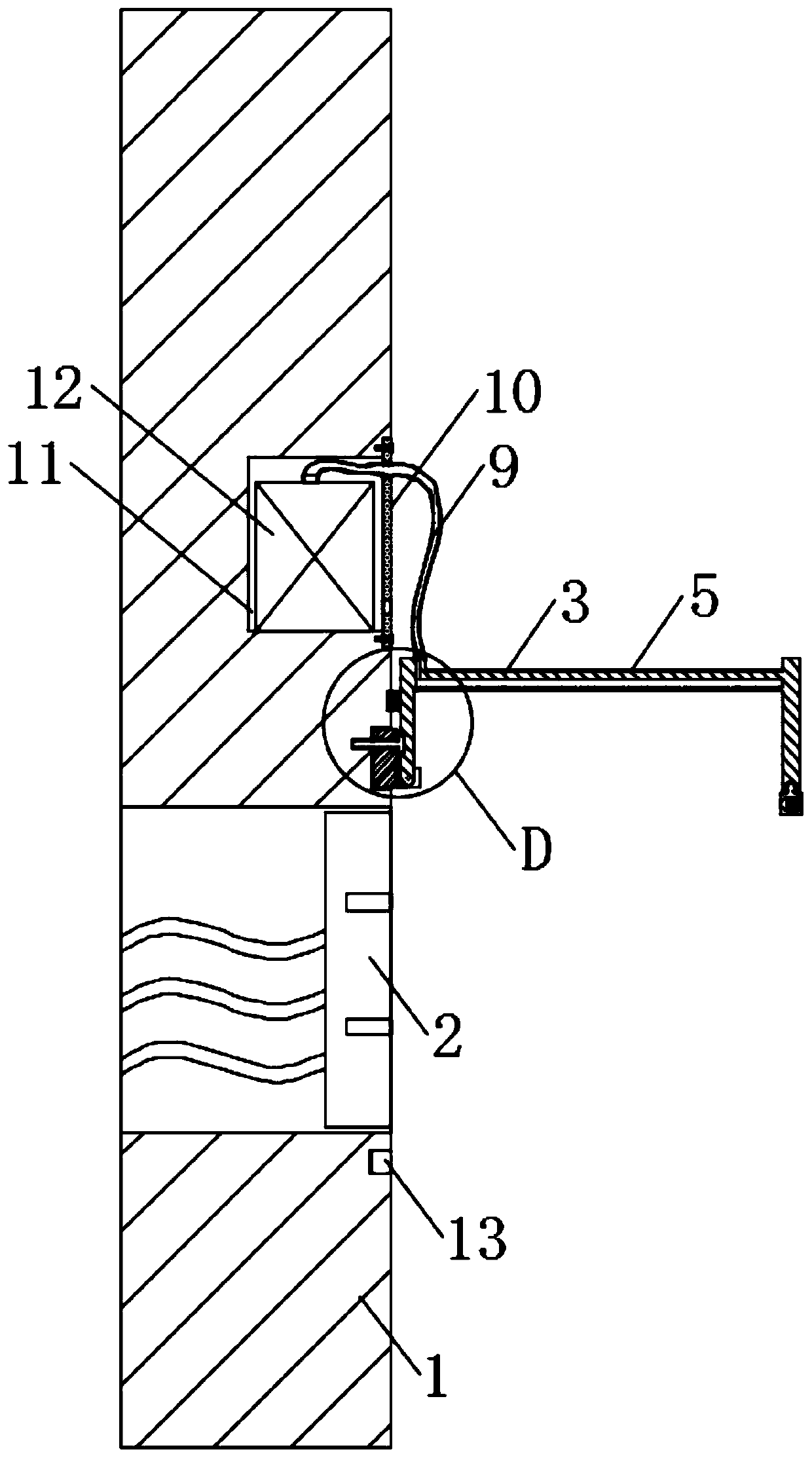

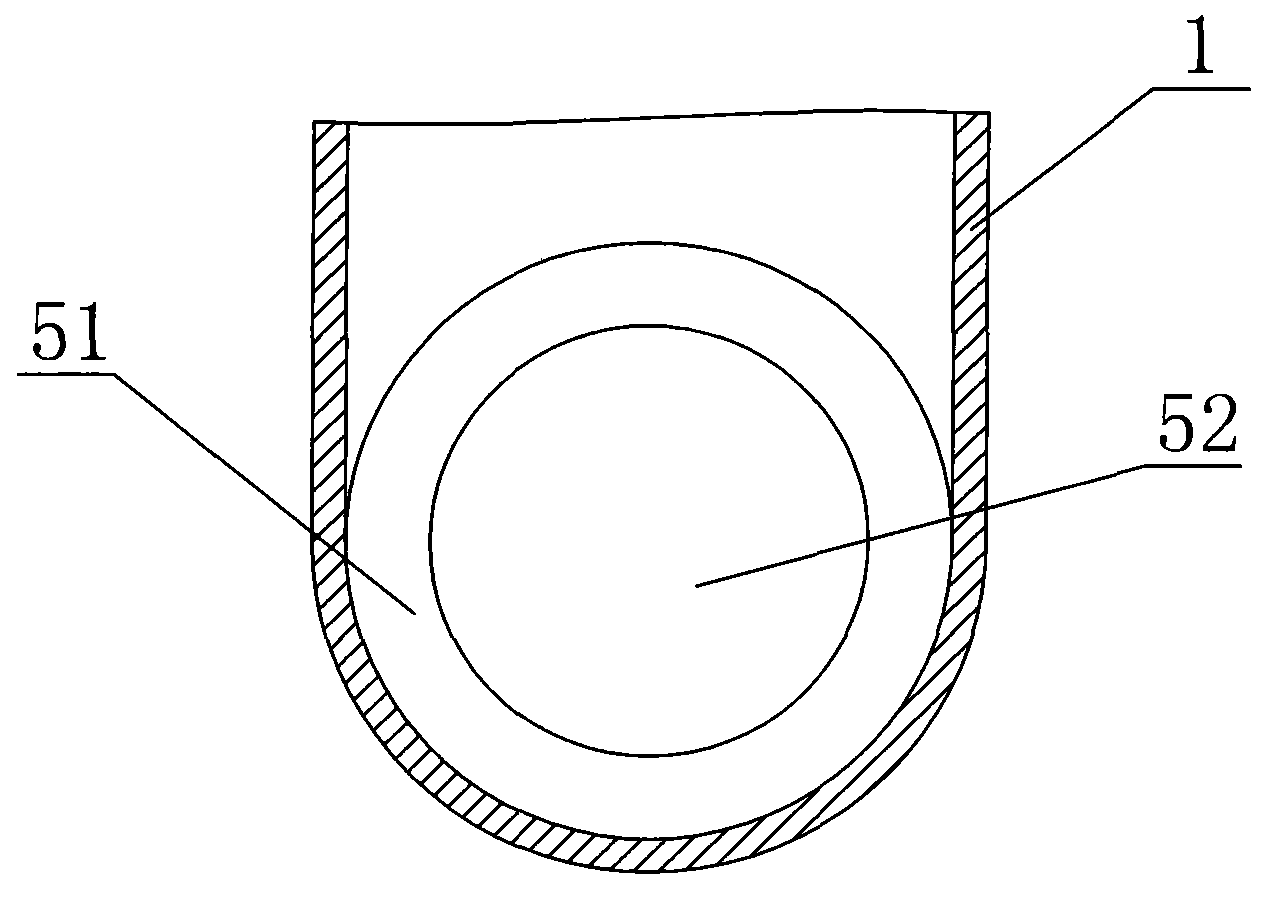

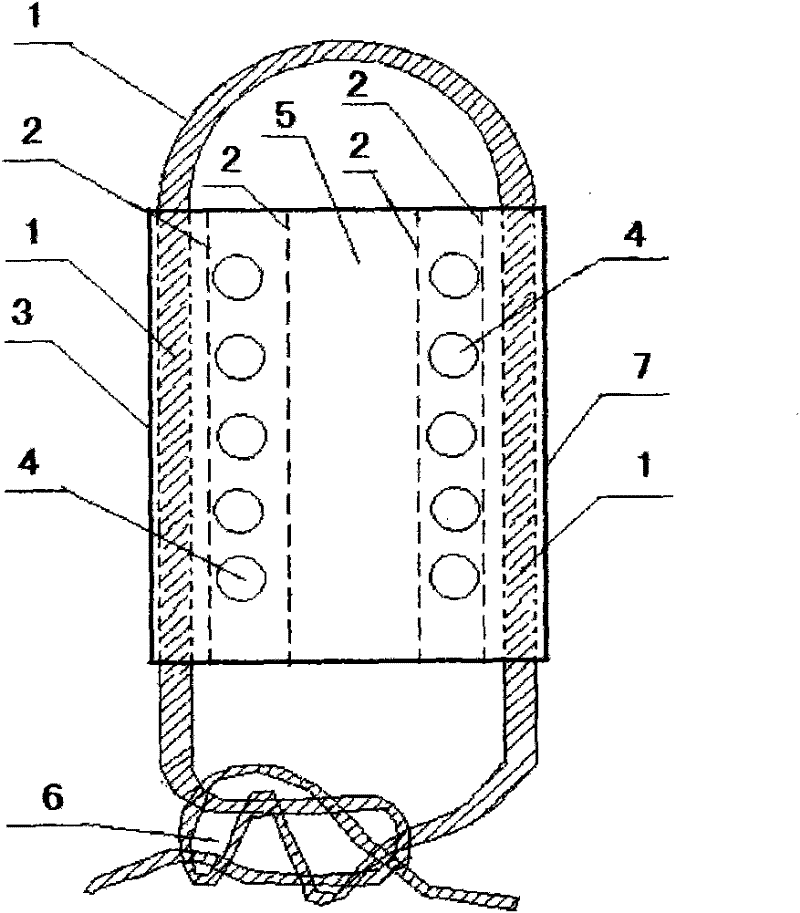

A kind of sheath used for retractor in spinal surgery

ActiveCN110916732BReduce the size of the forceReduce direct wear and tearSurgerySpinal columnReoperative surgery

The invention discloses a sheath used for a retractor for spinal surgery, which comprises a plate-shaped sheath body made of elastic material. The plate-shaped sheath body is composed of a plurality of sheath units, and one side of the sheath unit is provided with There is an adhesive layer, and the adhesive layer is provided with anti-adhesive paper, and the other side of the sheath unit is provided with a plurality of trumpet-shaped protrusions, and the openings of the horn-shaped protrusions face the outside of the sheath unit. The invention has the characteristics of simple, quick and safe operation.

Owner:YANGZHOU UNIV

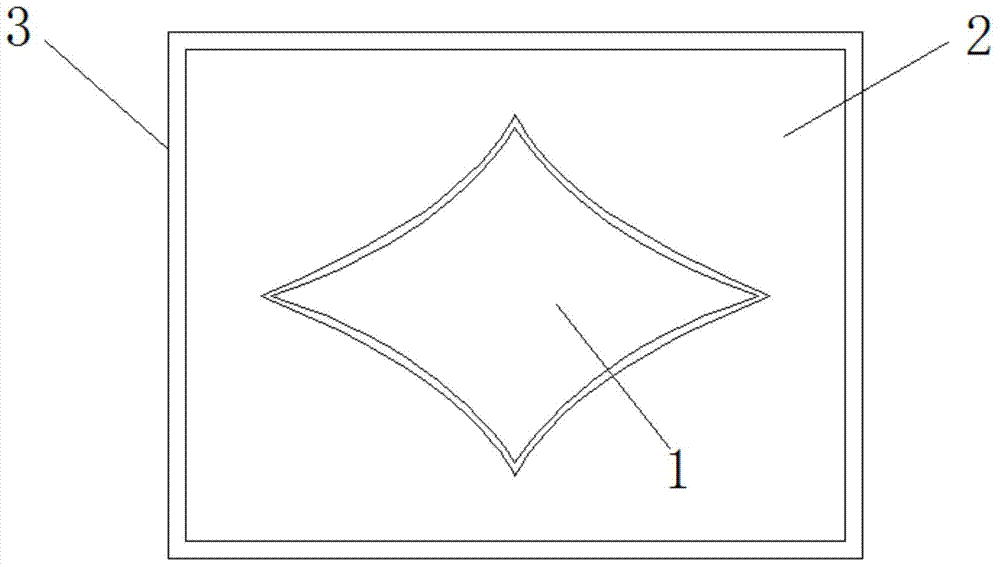

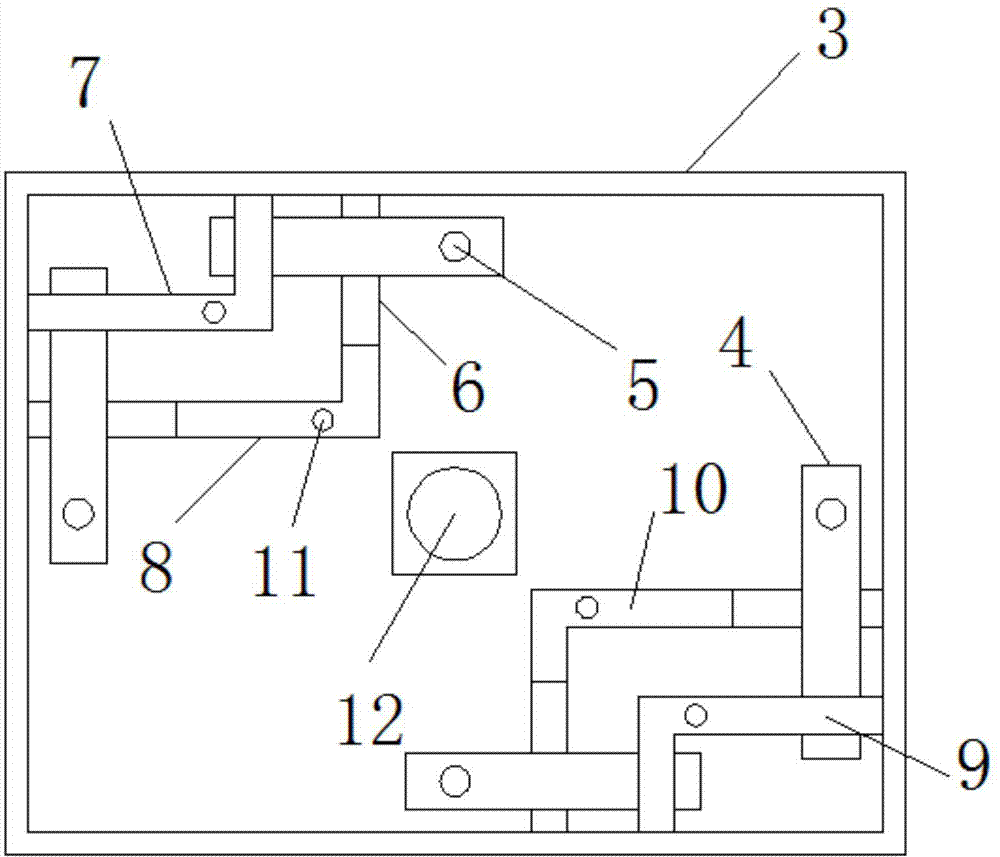

Novel four-way switch

InactiveCN104733210APlay a protective effectReduce direct wear and tearElectric switchesEngineeringSwitch box

The invention relates to a novel four-way switch. The novel four-way switch structurally comprises a rectangular switch box, a switch box cover and a four-way button. The four-way button is movably connected to the switch box cover in an embedded mode. The bottom of the four-way button is vertically connected with four plastic push rods. The upper ends of the four push rods are fixedly connected to the front end, the rear end, the left end and the right end of the four-way button respectively. The four side walls in the switch box are each connected with an elastic on-off rotating mechanism, and the lower ends of the four push rods penetrate through the switch box cover to be connected with the corresponding elastic on-off rotating mechanisms respectivley. The four-way button can continue to normally work after a button in one direction or buttons in two or more directions break down, and unnecessary losses are reduced.

Owner:江苏慕林智造科技股份有限公司

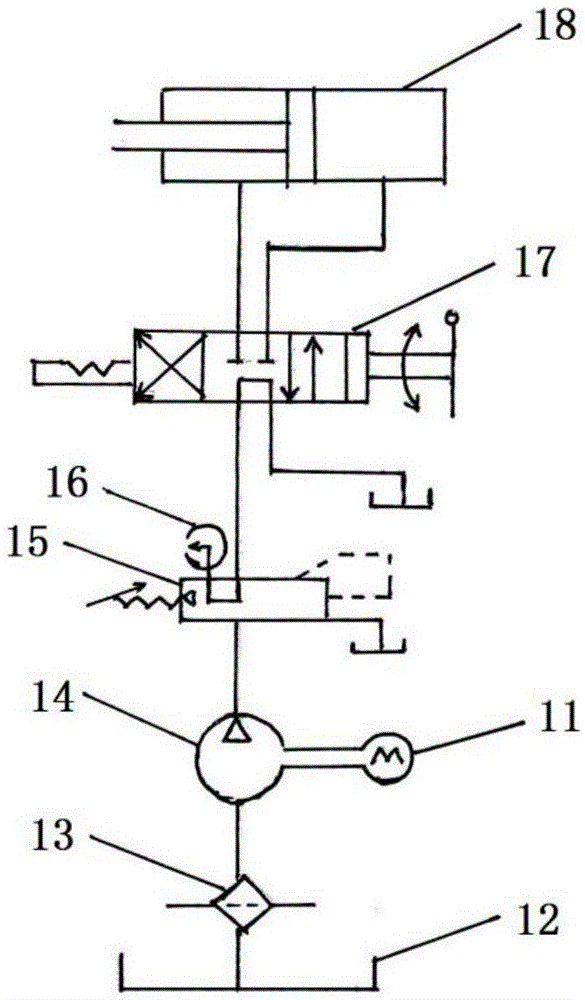

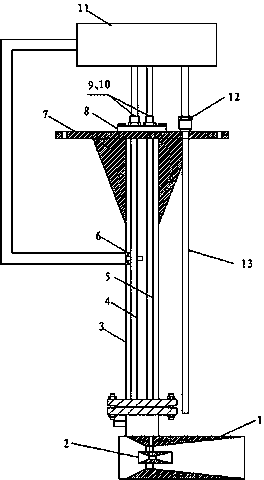

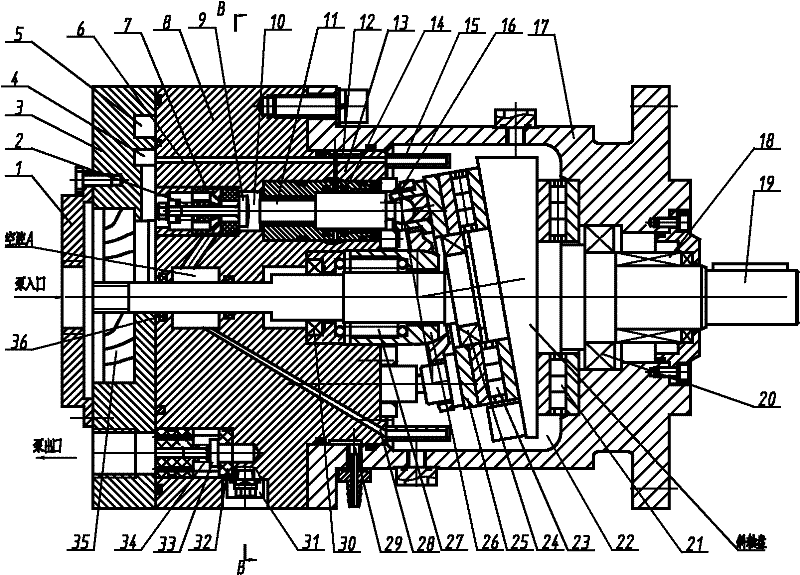

Self water-replenishing flat valve plunger type extra-high pressure water pump

ActiveCN101956688BImprove self-priming performanceMake up water pump smallerPump installationsPositive-displacement liquid enginesReciprocating motionHydraulic pump

The invention provides a self water-replenishing flat valve plunger type extra-high pressure water pump, which mainly comprises a cavity, a cooling unit, a rotating main shaft and a plunger flow-distribution unit. The cooling unit comprises a cooler and a water-replenishing pump; and the plunger flow-distribution unit comprises a flat valve component and a plunger skid shoe component. The plungerskid shoe component divides the cavity into a pressure chamber and an oil lubrication chamber which are independent from each other. The water-replenishing pump presses water at a water pump inlet into the cooler under the drive of the rotating main shaft, then the water flows into the flat valve component from the cooler to cool the oil lubrication chamber and provide low-pressure pressure waterfor the flat valve component, and simultaneously, the plunger skid shoe component performs reciprocating motion under the drive of the rotating main shaft to ensure that the flat valve component performs water absorbing and draining motions through the water pump inlet and a water pump outlet. The self water-replenishing flat valve plunger type extra-high pressure water pump solves the problems of over-high lubricating oil temperature and insufficient self-adsorption when an oil-water separation type hydraulic pump is used on shore, thereby reducing the running cost and improving the service life of the water pump.

Owner:HUAZHONG UNIV OF SCI & TECH

Protective valve seat structure of gate valve

The invention discloses a protective valve seat structure of a gate valve, comprising a valve body, wherein through holes are arranged in the valve body, a flashboard mutually matched with the through holes is arranged in the valve body, the upper end of the flashboard is connected with a valve rod arranged on the valve body, a diagonal upper guard plate is fixedly arranged in the through hole at one side of the flashboard, and a separate lower guide plate is fixedly arranged in the through hole at the other side of the flashboard. The invention has the advantages that simple structure and convenient operation are realized; the arranged diagonal upper guard plate can prevent materials from entering a guide rail region of the flashboard during the material falling down process so as to reduce the material stacking phenomenon of the guide rail region of the flashboard, keep the flashboard to flexibly open and close, reduce the direct abrasion of the flashboard from the materials and prolong the service life of the flashboard; the arranged separate guide plate can support the flashboard when the flashboard is closed so as to prevent the deformation of the flashboard due to the material load; simultaneously, the residual materials in the guide rail region of the flashboard can be cleared during the flashboard opening and closing processes, thus the blocking phenomenon of the flashboard can be avoided.

Owner:江苏鑫通环保科技有限公司

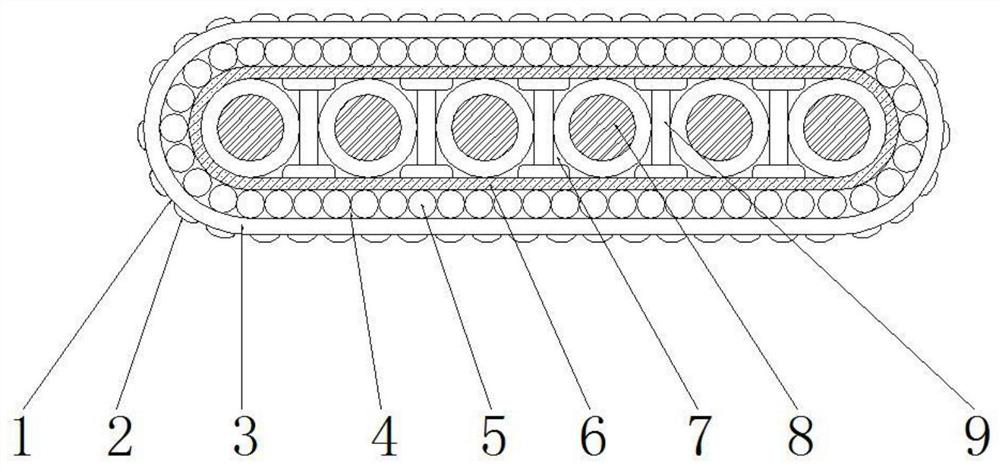

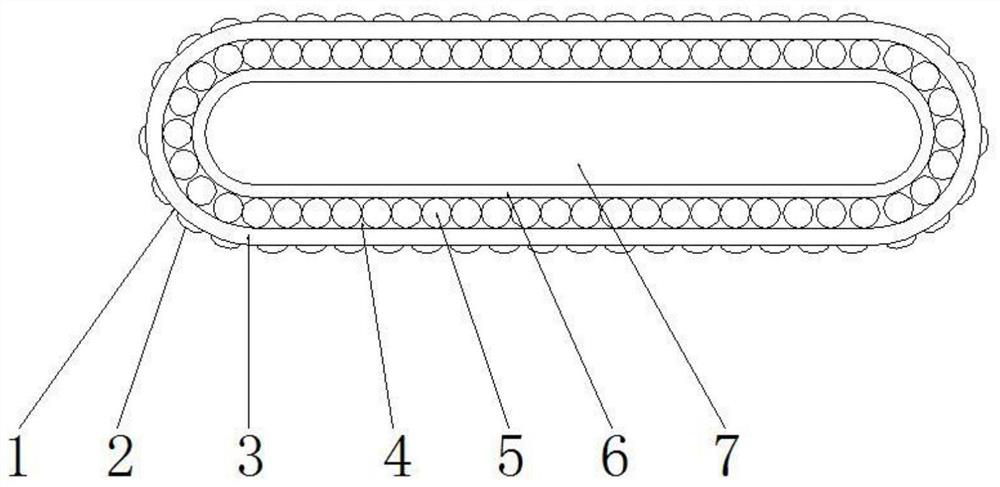

Reinforced rubber cable for mine

InactiveCN111724937AReduce wearReasonable structureFlat/ribbon cablesThermometer applicationsReinforced rubberElectric cables

The invention discloses an enhanced rubber cable for a mine. The enhanced rubber cable comprises a cable, a first protective layer and an inner filling layer, wherein the inner filling layer is arranged in the cable, a plurality of groups of conductive cores are wrapped in the inner filling layer, a group of supporting plates are arranged between two adjacent groups of conductive cores, meanwhile,a second protective layer is arranged outside the inner filling layer, a first protective layer is arranged outside the second protective layer, multiple sets of anti-pressing lines are arranged in the first protective layer, every two adjacent sets of anti-pressing lines on the left side and the right side are right in contact, and meanwhile an outer skin layer is arranged outside the first protective layer. The enhanced rubber cable is advantaged in that a problem that when a rubber cable in the prior art is used in a mine, a protective layer on a surface of the cable is damaged due to thefact that the rubber cable needs to be frequently dragged, and consequently conductor wire cores in the cable are exposed in air to cause safety is solved.

Owner:广州形银科技有限公司

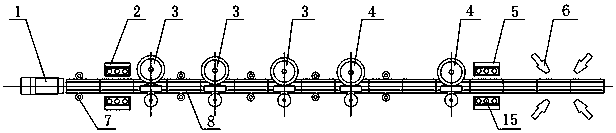

A kind of equipment and method of push-roll forming track

InactiveCN106270321BRealize the function of transmissionSimple structureMetal rolling arrangementsLight railEngineering

The invention discloses equipment and a method for pushing and rolling molding of a rail. The equipment comprises a thrust device 1, a heating device 2, roller devices 3, reshaping and straightening devices 4, a reheating device 5 and an atomizing and spraying device 6 which are arranged sequentially; and a guide component 7 is arranged on the equipment to guide movement of a steel blank 8. The metal pushing and rolling technology is as follows: at the state that metal reaches the rolling temperature through induction heating, the steel blank is pushed by the thrust device, is rolled, is subjected to reeling and is straightened by longitudinal columns of molds and is heated and subjected to spraying treatment to reach the light rail parameter requirements, the manner combines metal extrusion, rolling and online heat treatment, the investment is lower than that of a traditional manner, the production organization is flexible, the cost is relatively low, the technology is applicable to medium and small-sized enterprises, and other kinds of like profile steel can be produced with the rolling method and changed combination manners and structures of hole patterns.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

Stirring equipment for broken plastic

The invention relates to the technical field of waste plastic reprocessing equipment, and particularly relates to stirring equipment for broken plastic. The stirring equipment for the broken plastic comprises a charging barrel, a feeding device, a material stirring device, an air equalizing device and a heating device. The feeding device comprises a feeding bin, a feeding hopper, a first screw rod, a second screw rod, a first screw blade and a second screw blade, wherein the screw direction of the second screw blade is opposite to that of the first screw blade. The material stirring device comprises a stirring motor, a stirring shaft and the screw stirring blades. The air equalizing device comprises a main air pipe, an annular air equalizing pipe and a gourd-shaped air equalizing nozzle. The heating device comprises a shell, two supporting plates, an insulating ring and a heating pipe. The stirring equipment for the broken plastic has the characteristics of low labor and material costand easy discharging of dust and moisture.

Owner:德清意欣塑料制品有限公司

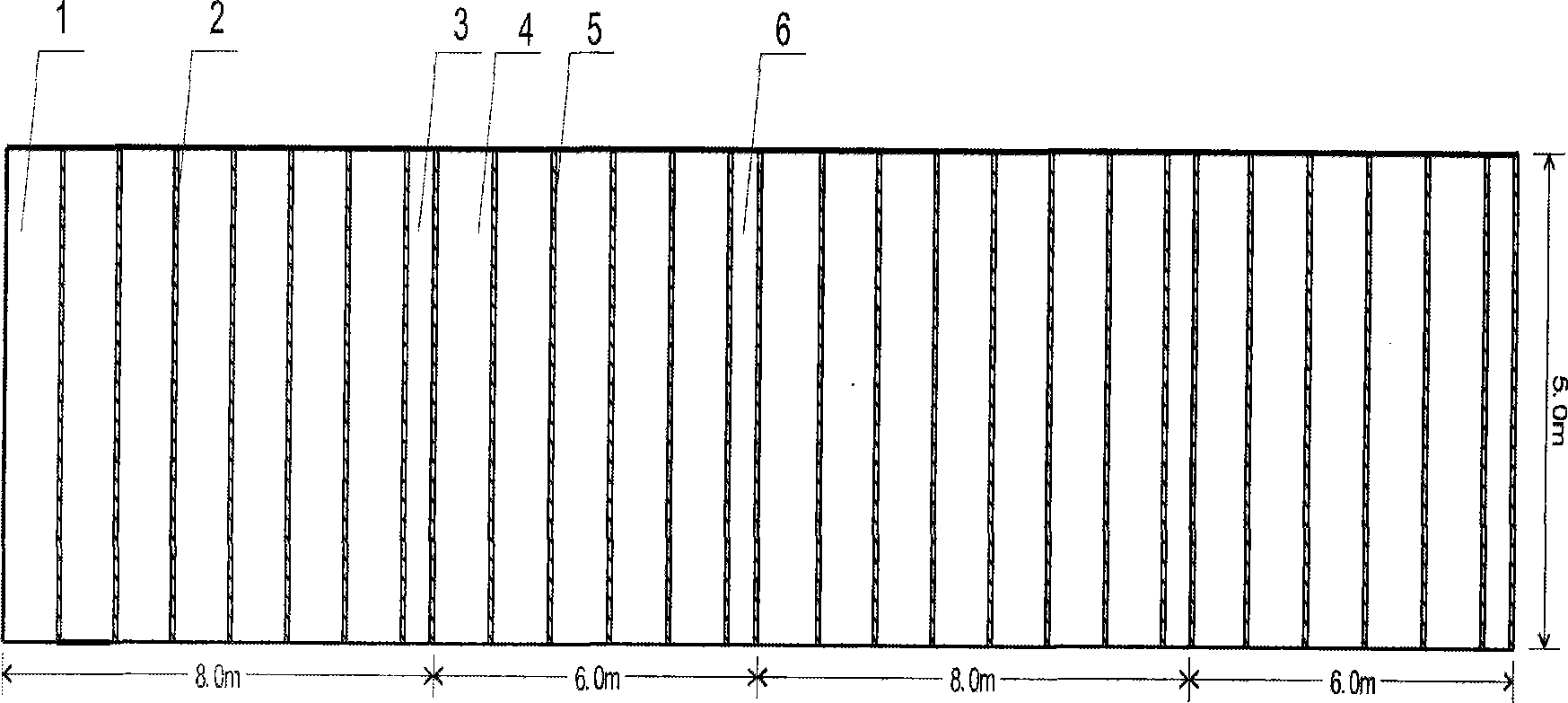

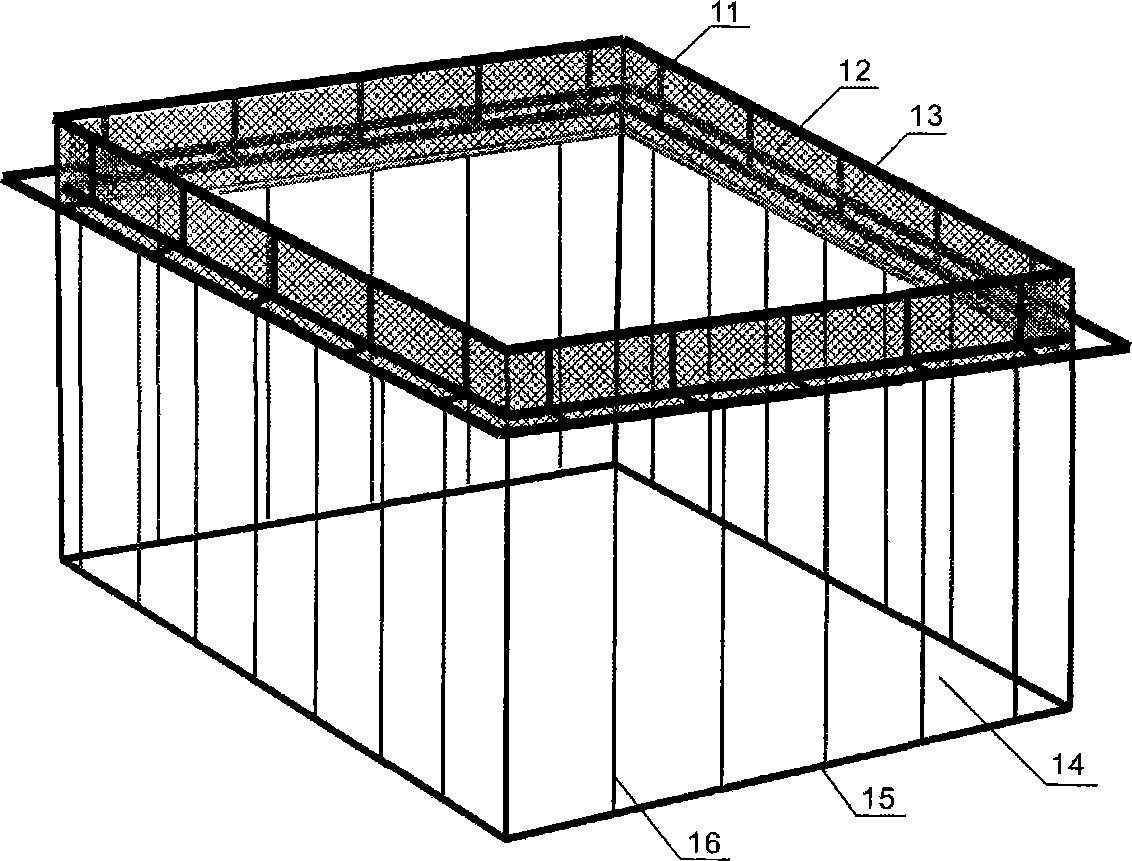

Energy-conservation and consumption-reduction type obliquely-square net cage for cultivating large yellow croakers

InactiveCN102763612BImprove volume retentionReduce the strength of impacting the cage bodyClimate change adaptationPisciculture and aquariaMaricultureEngineering

The invention discloses an energy-conservation and consumption-reduction type obliquely-square net cage for cultivating large yellow croakers, which is used for mariculture. The technical scheme provided by the invention is that the energy-conservation and consumption-reduction type obliquely-square net cage consists of a buoyancy force system and a netting system, and has the characteristics that the buoyancy force system consists of an inside casing and an outside casing, and the inside casing is connected with a first net cage body longitudinal netting through an ultra high strength dyneema rope; the netting system adopts a combination structure netting form of 'a first box longitudinal netting + a second box longitudinal netting + a net cage bottom netting'; the net cage bottom netting is assembled on a pipe support; micropores are punched in a pipe of the pipe support every 1 meter; after being connected with the net cage bottom netting, the second net cage body longitudinal netting extends to an edge line of the net cage bottom netting along netting longitudinally-installed vertical lines from an upper horizontal line of the box longitudinal first netting; a cross lacing line is additionally arranged at the bottom of the net cage, crossed lacing lines are additionally arranged along the diagonal directions of the bottom of the net cage; and a cross point of the two crossed lacing lines along the diagonal directions of the bottom of the net cage is tied by a rope, and a foam float bowl which is externally wrapped by seawater corrosion protection canva and a nylon net is tied by the other end of the rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Half-soft state connecting method between copper alloy woven meshes for cage

InactiveCN102084830BQuality improvementImprove mechanical propertiesClimate change adaptationPisciculture and aquariaMetallurgyMaterials science

The invention discloses a half-soft state connecting method between copper alloy woven meshes for a cage, relates to connection of copper alloy woven meshes for the cage, and provides a method for splicing the copper alloy woven meshes for the cage. In the method, sea anchoring cloth, ropes, suture lines and tarpaulin rings are adopted, and the method is characterized in that: the sea anchoring cloth, the ropes, the suture lines and the tarpaulin rings are assembled into half-soft state connecting pieces; the half-soft state connecting pieces are arranged between two copper alloy woven meshes; one end of a high-strength polyethylene rope is fixed at a net joint which is 3 meshes away from the splicing edge of the copper alloy woven meshes; the other end of the high-strength polyethylene rope passes through ring plates of the half-soft state connecting pieces and meshes of the woven meshes in turn; the other end of the high-strength polyethylene rope is fixed at a net joint which is 4 meshes away from the splicing edge of the copper alloy woven meshes; and the half-soft state connecting pieces are spliced with the other copper alloy woven mesh in the adjacent two copper alloy wovenmeshes together. The method is used for splicing the adjacent two copper alloy woven meshes in the cage.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Assembly type movable stair

The invention relates to an assembly type movable stair. The assembly type movable stair comprises a folding stair body and a bearing frame, supports are arranged above the folding stair body, rotating shafts are arranged on surfaces of upper ends of the supports, baffle plates are arranged on outer sides of the rotating shafts, containing grooves are formed in lower portions of front ends of the baffle plates, fixing frames are arranged at front ends of side faces of the folding stair body, fixing holes are formed in middle parts of front ends of the fixing frames, screws are arranged on inner sides of the fixing holes, the bearing frame is arranged below the folding stair body, a rubber pad is arranged at an upper end of the bearing frame, and a groove is formed in the bearing frame. The assembly type movable stair is provided with the baffle plates, a user manually pulls down the baffle plates along the rotating shafts and clamps the baffle plates to the containing grooves in upper ends of the lower supports, and therefore the supports and the baffle plates are combined into handrails to limit the user to a certain degree, the user is prevented from directly falling off due to force majeure factors, and potential safety hazard of the device is reduced.

Owner:JIANGSU SUZHONG CONSTR GROUP

A straddle-mounted chassis device

ActiveCN103661465BShorten the design cycleIncrease loading capacityBogiesBogie-underframe connectionsBogieDISC assembly

The invention relates to a cross-mounting bottom frame device. The cross-mounting bottom frame device comprises a transversely arranged middle beam assembly, four end sleeper beam assemblies connected with the front and back sides of the two ends of the middle beam assembly respectively, two middle sleeper beam assemblies connected with the front and back sides of the middle of the middle beam assembly respectively, a bottom frame center disc assembly arranged on the upper surface of the middle beam assembly between the two middle sleeper beam assemblies, two steering frame center disc assemblies arranged at the lower surfaces of the two ends of the middle sleeper beam assembly between the two end sleeper beam assemblies respectively, two lower side bearings arranged on the upper surfaces of the free ends of the two middle sleeper beam assembly respectively, and four upper side bearings installed on the lower surfaces of the free ends of the four end sleeper beam assemblies respectively, wherein the middle beam assembly is of a fish-belly-shaped box type structure, the end sleeper beam assemblies and the middle sleeper beam assemblies are respectively of a box structure with the fixed end being gradually thinned to the free end, the length of each end sleeper beam assembly in the horizontal direction is larger than that of each middle sleeper beam assembly, and the height of each end sleeper beam assembly in the vertical direction is smaller than that of each middle sleeper beam assembly. The cross-mounting bottom frame device can combine two double-shaft steering frames into a four-shaft steering frame.

Owner:CRRC QIQIHAR ROLLING CO LTD

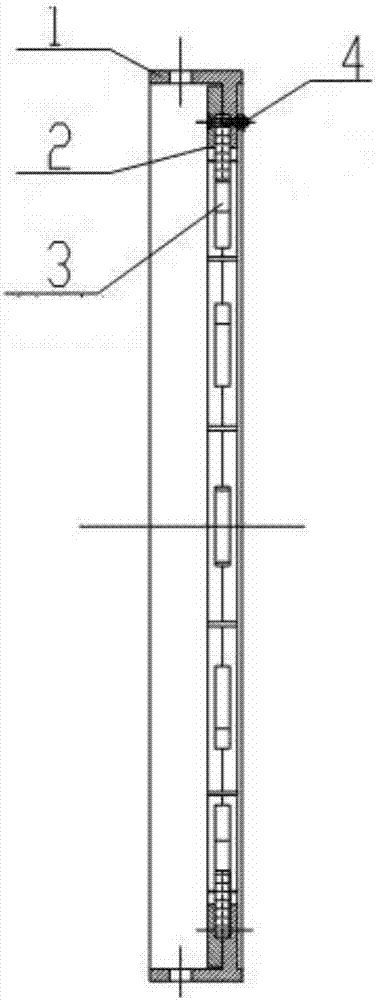

Plunger type water pump

ActiveCN101956684BReduce volumeLower thermal equilibrium temperaturePositive displacement pump componentsPositive-displacement liquid enginesWater useReciprocating motion

The invention provides a plunger type water pump which mainly comprises a cavity body, a rotary main shaft and a plunger distributing unit, wherein the plunger distributing unit comprises a distributing valve assembly, a plunger piston shoe assembly and a supporting valve assembly; the plunger piston shoe assembly divides the cavity body into a high-pressure cavity and a low-pressure cavity mutually independent; the high-pressure cavity is communicated with the liquid of the distributing valve assembly; and the low-pressure cavity is communicated with the liquid of the supporting valve assembly. The plunger piston shoe assembly driven by the rotary main shaft reciprocates to impel the distributing valve assembly and the supporting valve assembly to cooperate, thus the distributing valve assembly sucks and discharges water through a water pump inlet and a water pump outlet, and simultaneously the supporting valve assembly provides liquid lubrication for the rotary unit. High-pressure water output by the extra-high pressure pump of the invention is mutually independent of the low-pressure water used for static pressure supporting and lubrication, thus ensuring the volumetric efficiency of the water pump in the extra-high pressure condition, ensuring the liquid supporting and lubrication of a friction pair in a high-speed heavy-load condition, and improving the service life of the water pump.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com