Energy-conservation and consumption-reduction type obliquely-square net cage for cultivating large yellow croakers

A technology of oblique squares and net cages, which is applied in the fields of application, fish farming, and climate change adaptation. Water exchange is not smooth and other problems, to achieve significant economic and ecological benefits, improve bait utilization coefficient, improve the effect of tank volume retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

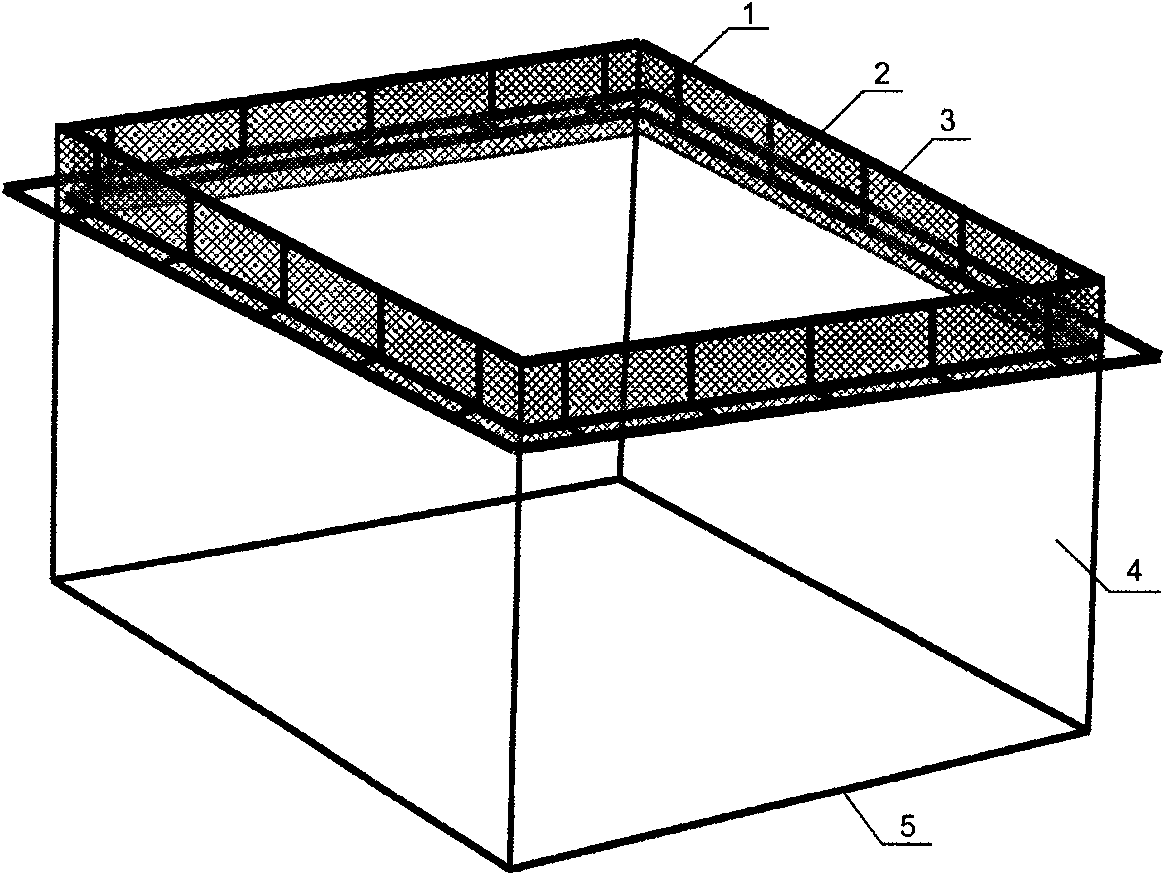

[0007] The present invention is made up of buoyancy system and net clothes system. The buoyancy system is a rectangular frame with double floating tubes (1 in the figure) composed of an inner frame and an outer frame. The rectangular frame with double floating tubes is made of durable high-density polyethylene floating tubes. The durable high-density polyethylene double floating tubes The outer diameter of the tubes is 249mm-560mm, for example, a floating tube with an outer diameter of 250mm can be used; the inner frame is parallel to the outer frame and the distance between the inner and outer frames is 10cm-33cm, for example, a distance of 25cm can be used; the floating tube between the inner frame and the outer frame can be used The durable high-density polyethylene connecting ring is connected, the inner frame is 8.0m×6.0m, and the inner frame is connected with the first net in the longitudinal direction of the cage body with ultra-high-strength Dyneema rope;

[0008]The n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com