Method for processing net-combined-type neritic square net cage

A combined, netting technology, applied in fish farming, application, climate change adaptation, etc., to reduce the harm of farmed fish, solve energy saving and consumption reduction, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings:

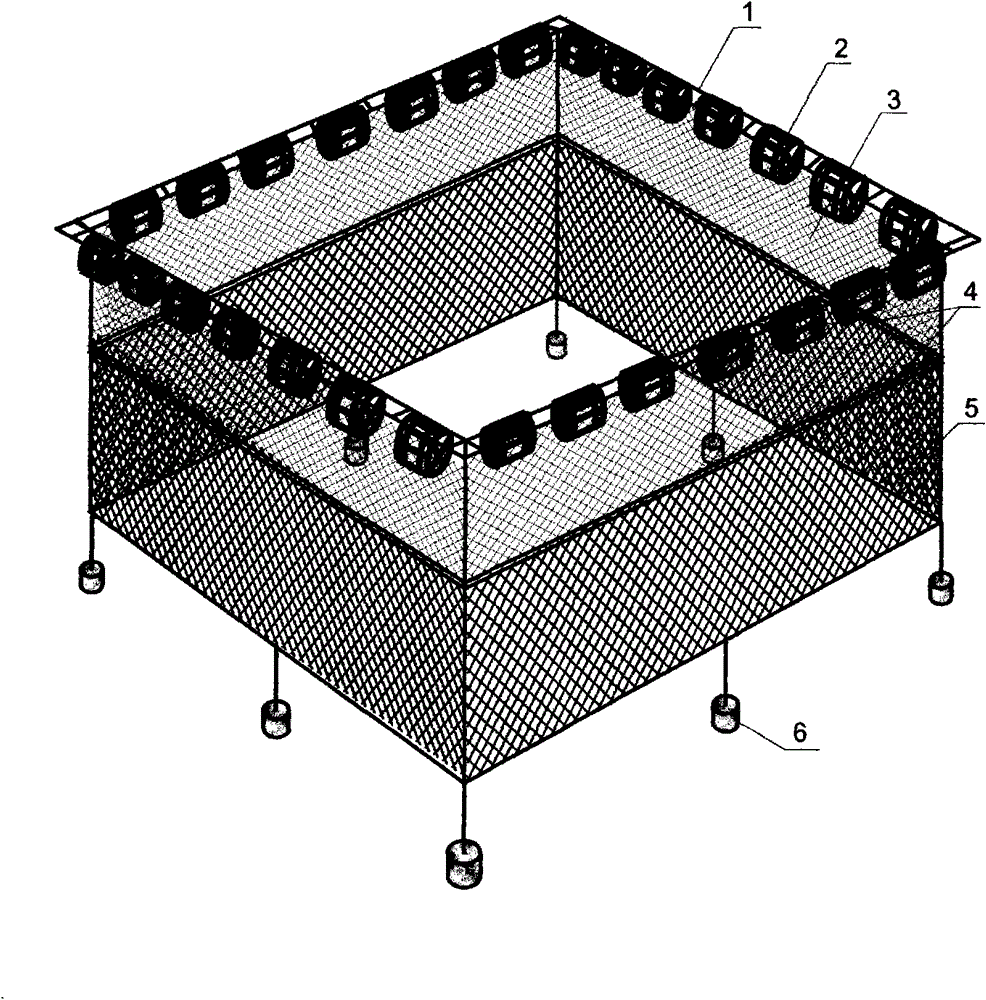

[0008]The present invention adopts high-strength ropes, high-strength nylon warp-knitted nets and copper alloy orthorhombic nets, and the buoyancy system of the net cage adopts a high-density polyethylene (hereinafter referred to as HDPE) double floating tube square frame structure (1 in the figure), and the frame is made of HDPE The diameter of the floating tube is 200mm. Two rows of HDPE floating tubes are assembled in parallel and the vertical distance between them is controlled at 20-30cm, for example, 23cm can be selected; The size of the frame is 5m × 5m, and the inner frame is connected with the netting of the first piece of netting in the longitudinal direction of the cage body with high-strength polyethylene rope; 28 cylindrical foam floats of the same specification are arranged under the HDPE double-floating tube frame (Fig. In 2) to provide bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com