Round metal net cage structure and preparation method thereof

A net cage and circular technology, which is applied in the field of circular metal net cages, can solve the problems of metal net clothing wear and tear and cage materials, and achieve the effects of reducing net weight, improving waterproof performance, and energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

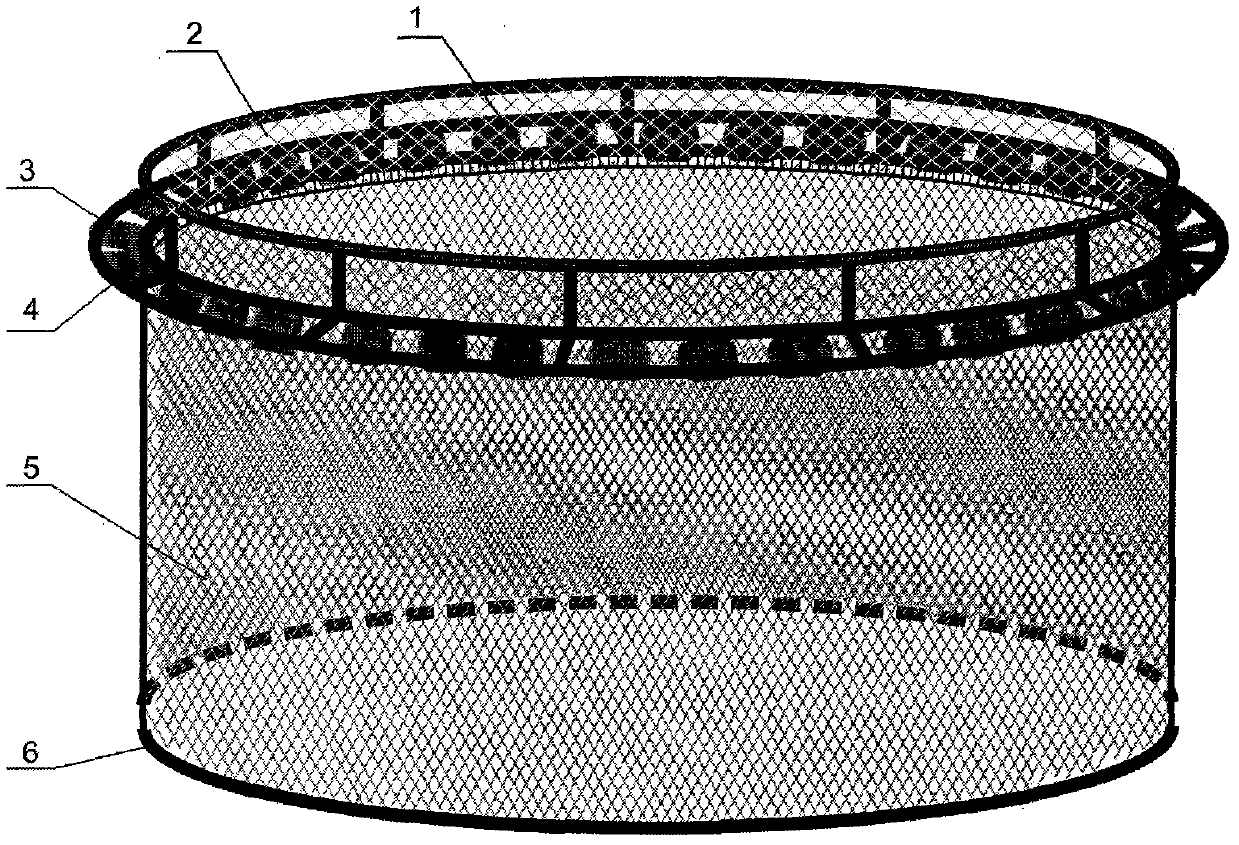

[0007]The netting of the cage body of the present invention is composed of ultra-high-strength woven nets as the first netting in the longitudinal direction of the cage body + the metal oblique net as the second netting in the longitudinal direction of the net cage body + the synthetic fiber netting as the netting body The bottom net is composed of a composite structure net. The first net in the vertical direction of the cage body (2 in the figure) adopts a super-high-strength braided net after resin treatment. The height of the ultra-high-strength braided net is 0.5 to 1.3 meters. Such as can take height to be 0.5 meters or bigger 1.2 meters or 1.3 meters; The height of the first net clothing is 0.3 meters larger than the vertical height of the upper column on the net cage frame (3 in the figure); The circular nets at the bottom of the cage body have the same circular diameter; the upper and lower horizontal line ropes installed on the upper and lower edges of the ultra-high-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com