Patents

Literature

49results about How to "Avoid direct abrasion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

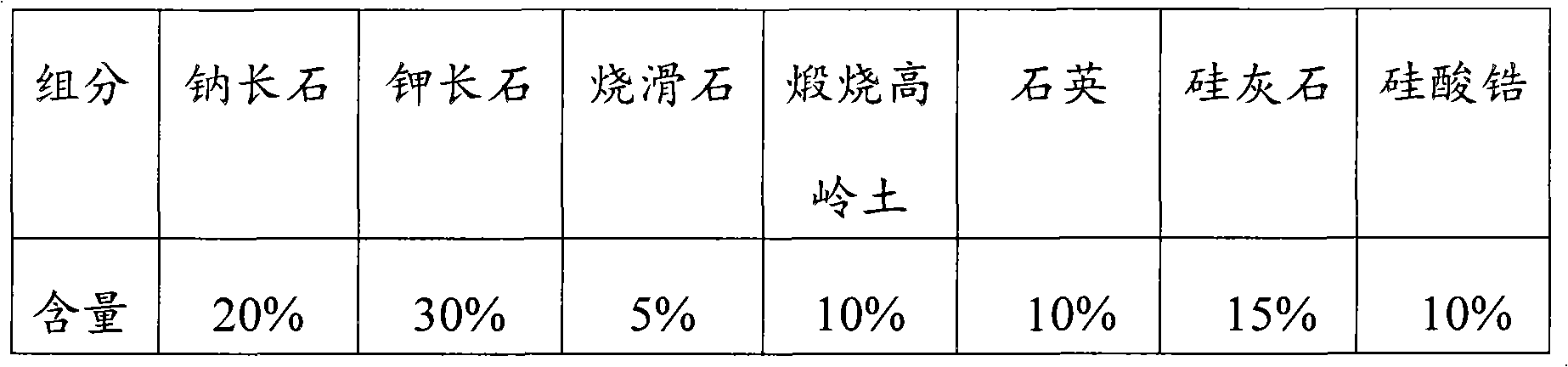

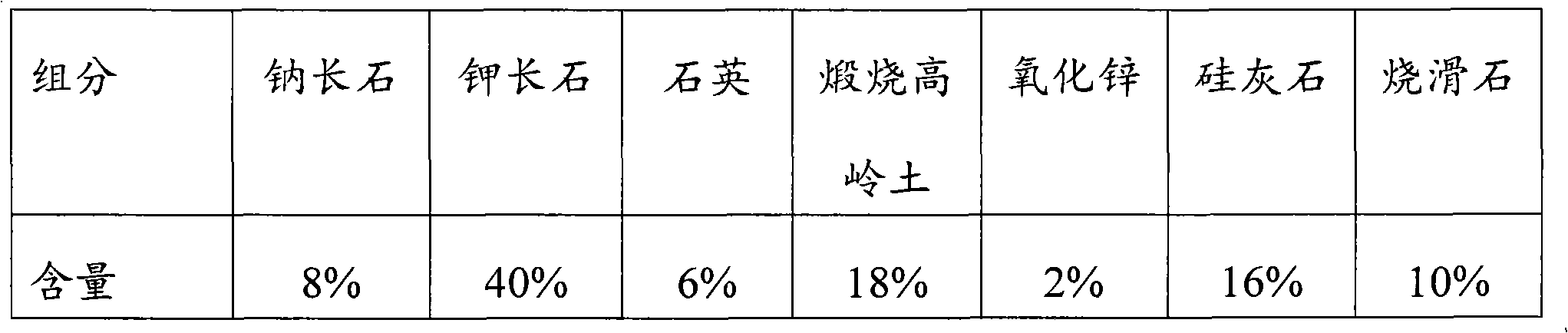

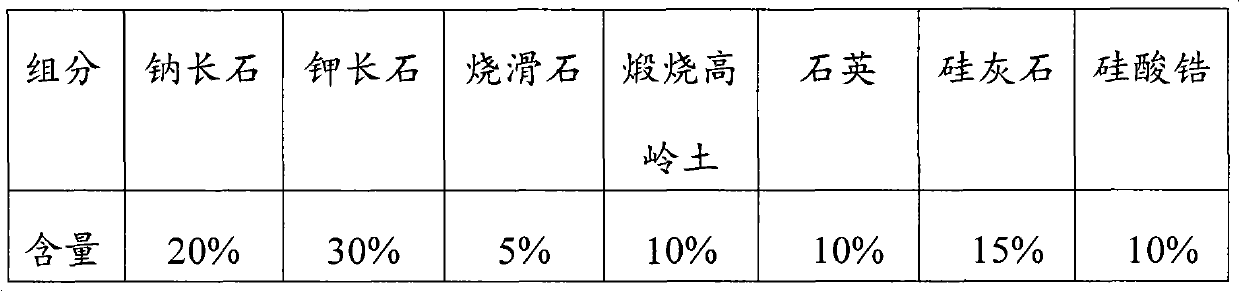

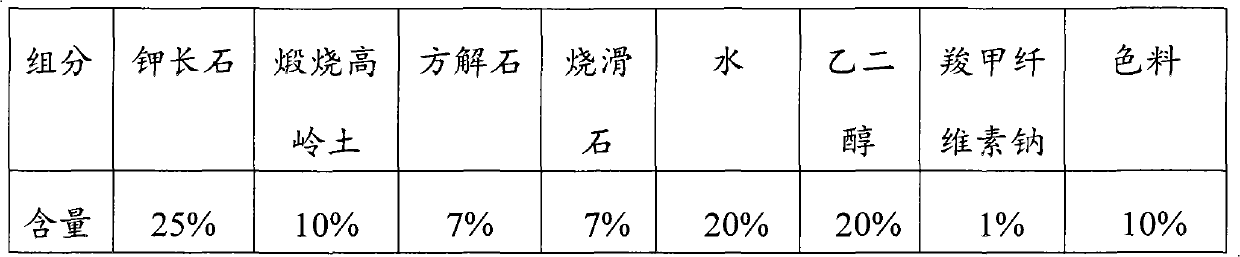

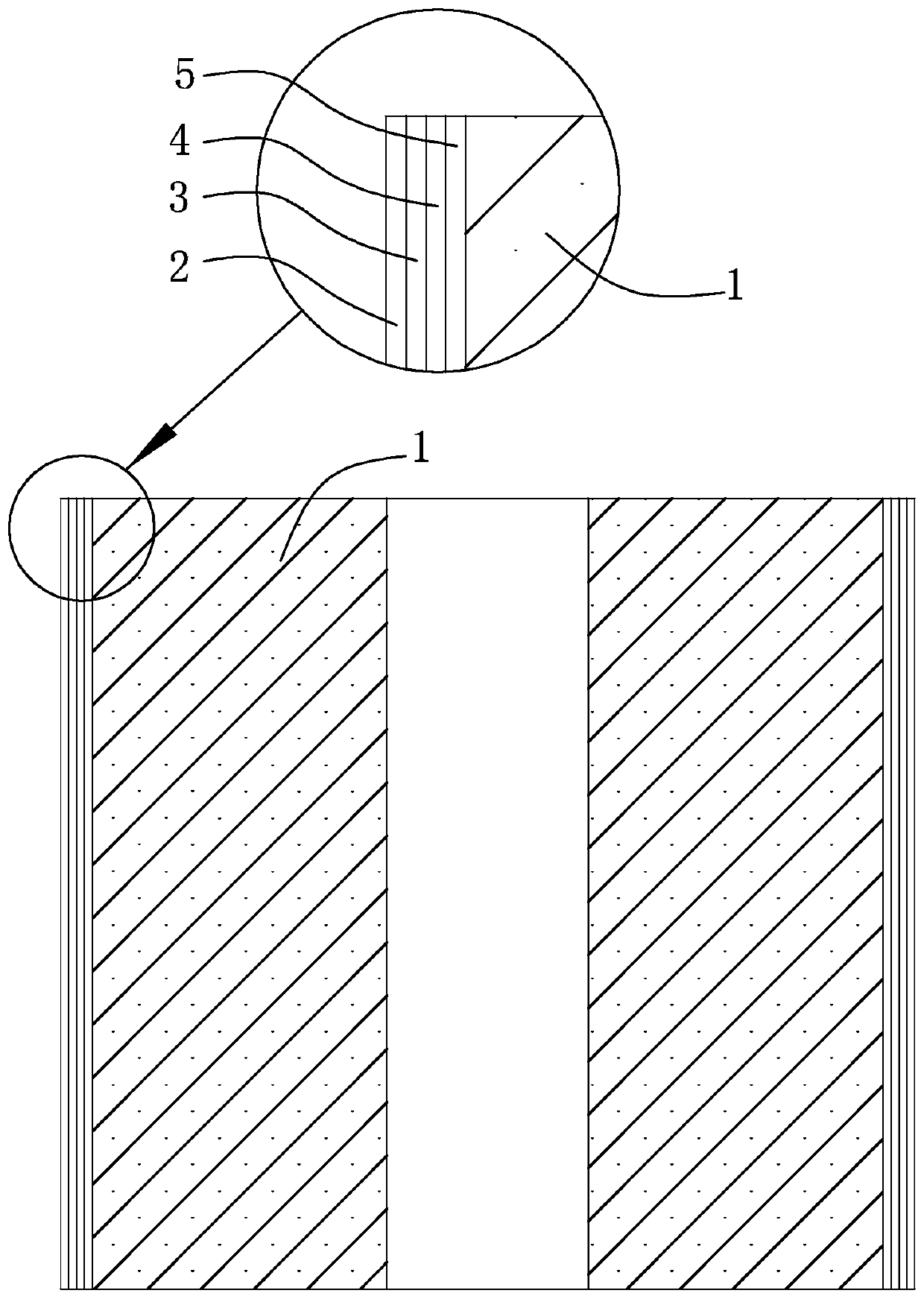

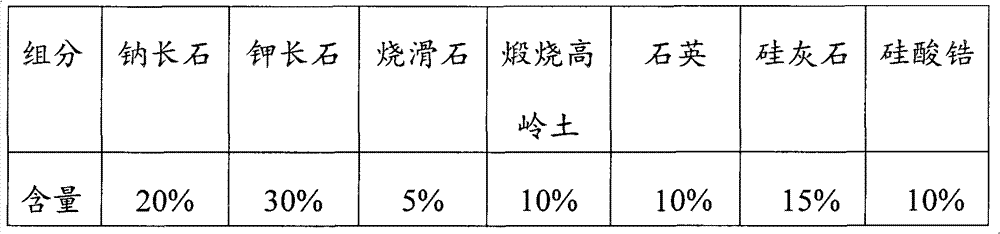

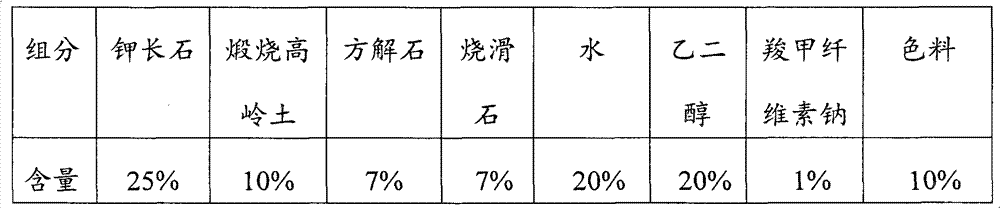

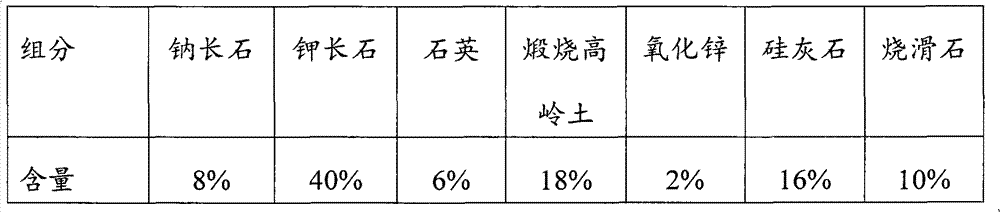

Imitated-marble tile

The invention discloses an imitated-marble tile comprising the following components in percentage by weight: 95-96.7% of blank, 1.5-2% of ground coat enamel, 0.15-0.9% of fancy glaze and 1.6-2.1% of transparent overglaze. The imitated-marble tile provided by the invention has the fine grain similar to that of natural marble and has the hierarchy and the transparent feeling of natural stone; flower color is in glaze to avoid that the flower color of the tile is directly abraded, thus prolonging the service life of the tile, and keeping the integrity and the naturalness of the follower color for a long term.

Owner:霍镰泉

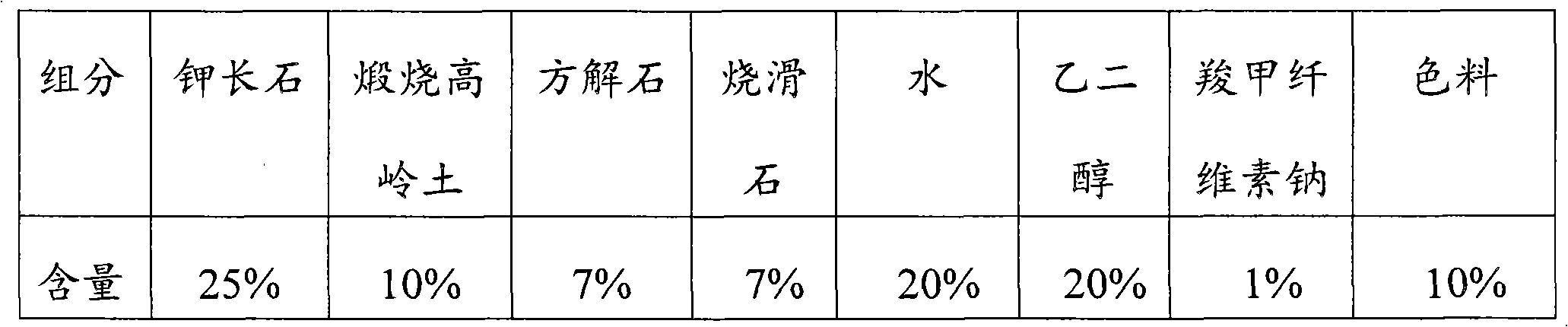

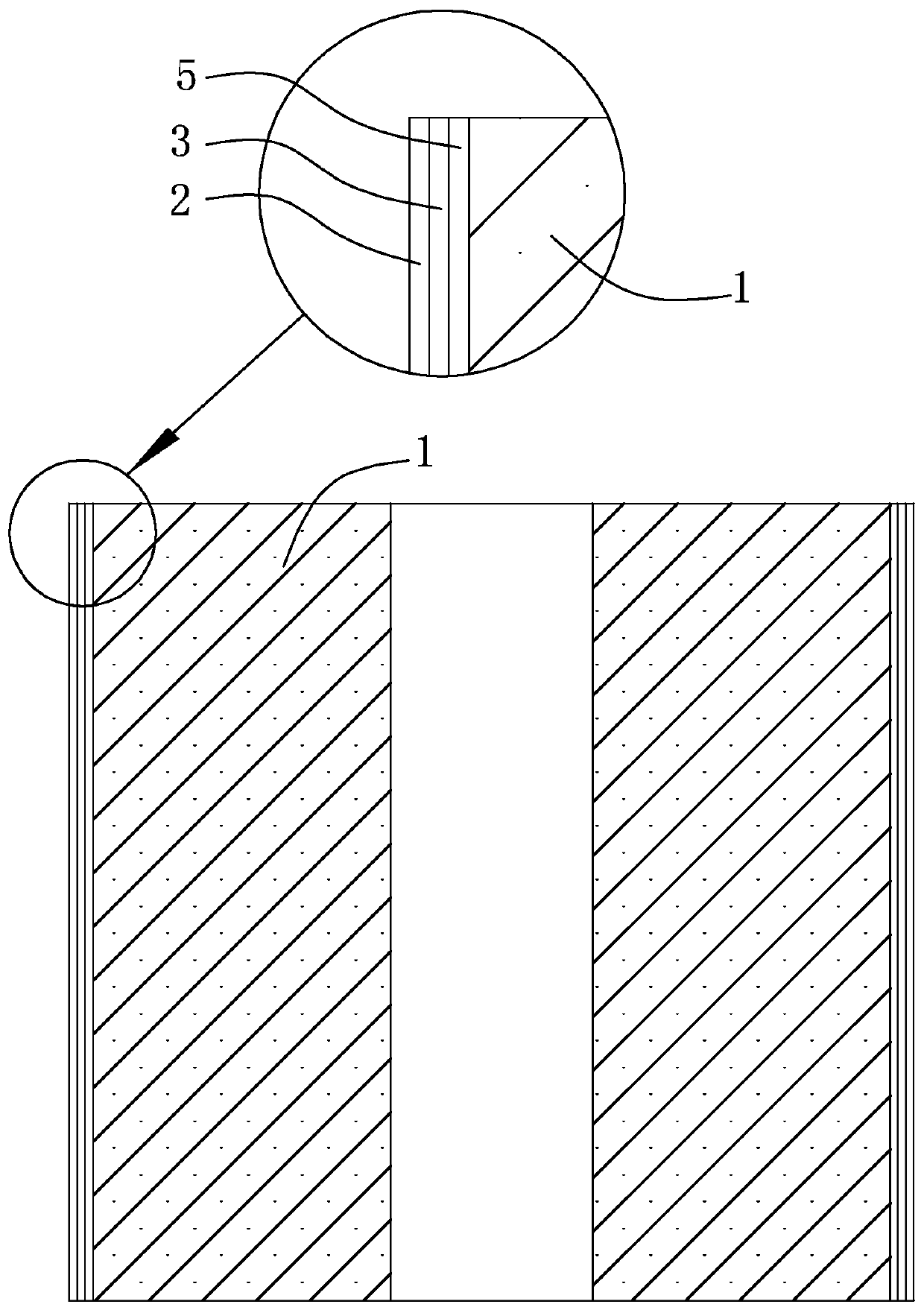

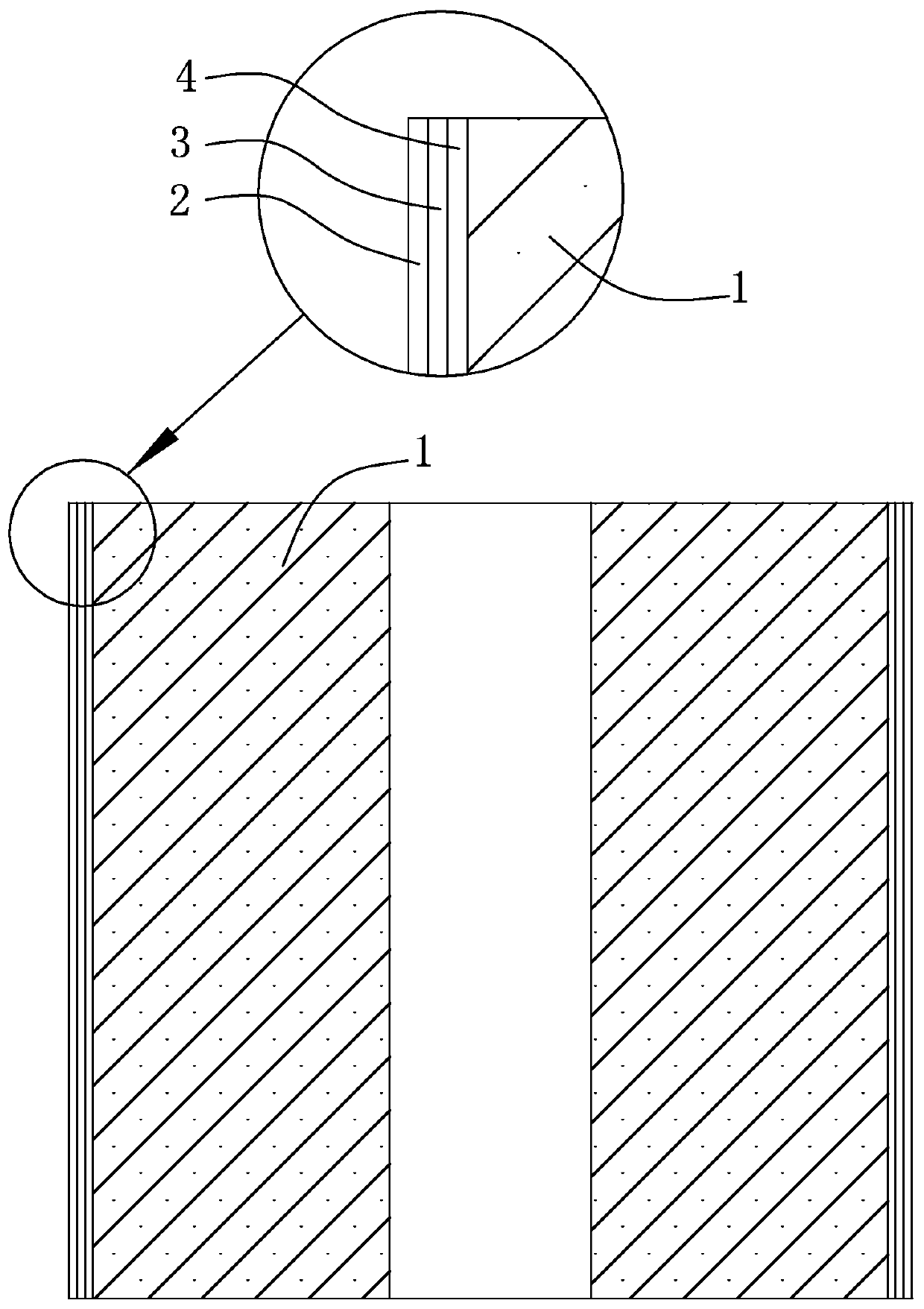

Process for producing artificial marble ceramic tiles

The invention discloses a process for producing artificial marble ceramic tiles. The process comprises the following steps of: (1) preparing the following components in percentage by weight: 1.5 to 2 percent of ground glaze, 0.15 to 0.9 percent of fancy glaze, 1.6 to 2.1 percent of transparent cover glaze and 95 to 96.7 percent of blank; (2) drying the blank after being molded by a pressing machine; (3) applying the ground glaze to the dried blank; (4) printing the fancy glaze; (5) applying the transparent cover glaze; (6) putting the blank into a kiln for firing; (7) polishing for the first time; (8) polishing for the second time; and (9) edging to obtain products. The artificial marble ceramic tiles produced by the process of the invention have fine grains which are approximately similar to that of natural marbles, and have stereovision and transparency of the natural marbles at the same time; patterns and colors are positioned among glazes so as to ensure that the patterns and the colors are not directly worn when the ceramic tiles are used; the service life of the ceramic tiles are prolonged; and the completeness and naturalness of the patterns and the colors of the tiles are kept for a long time.

Owner:霍镰泉

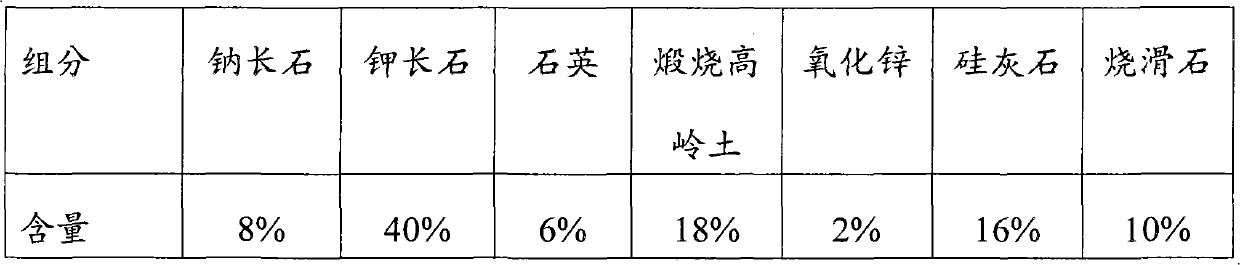

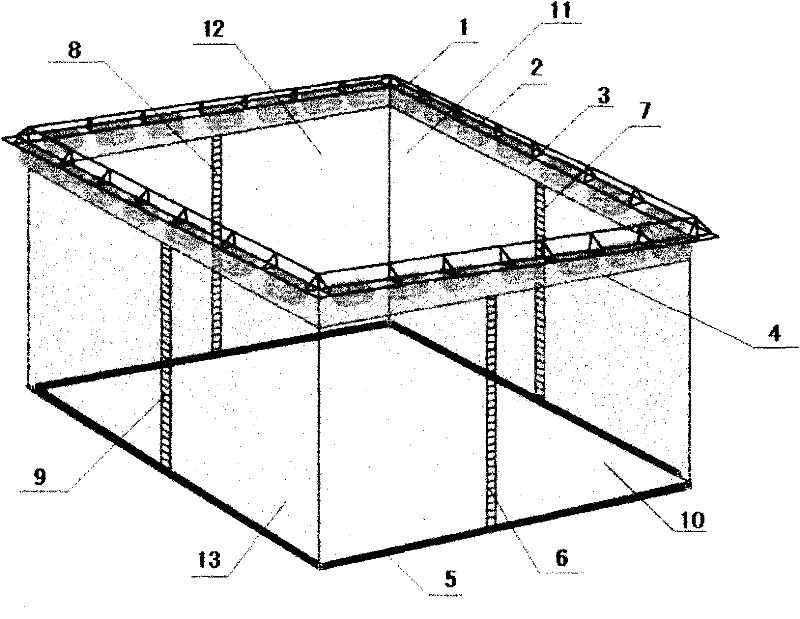

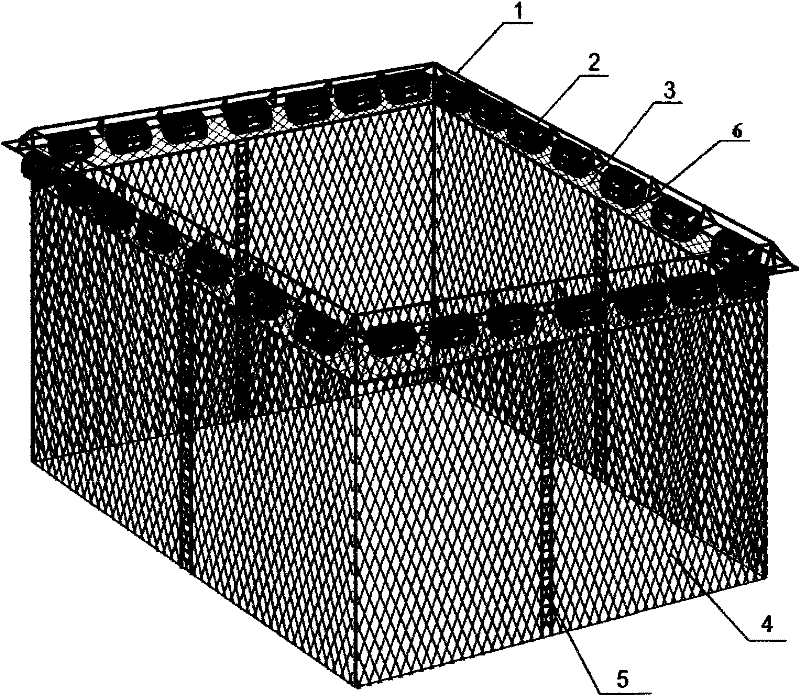

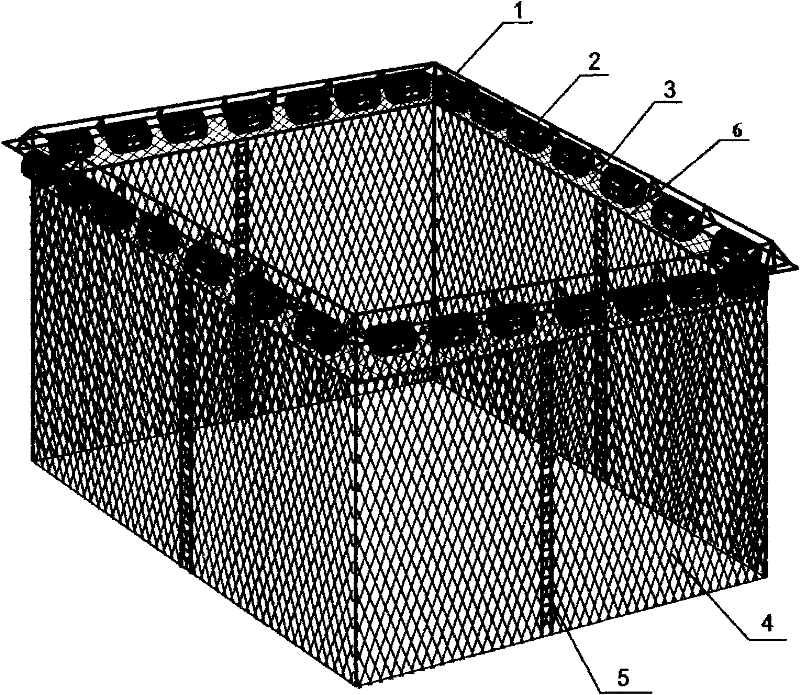

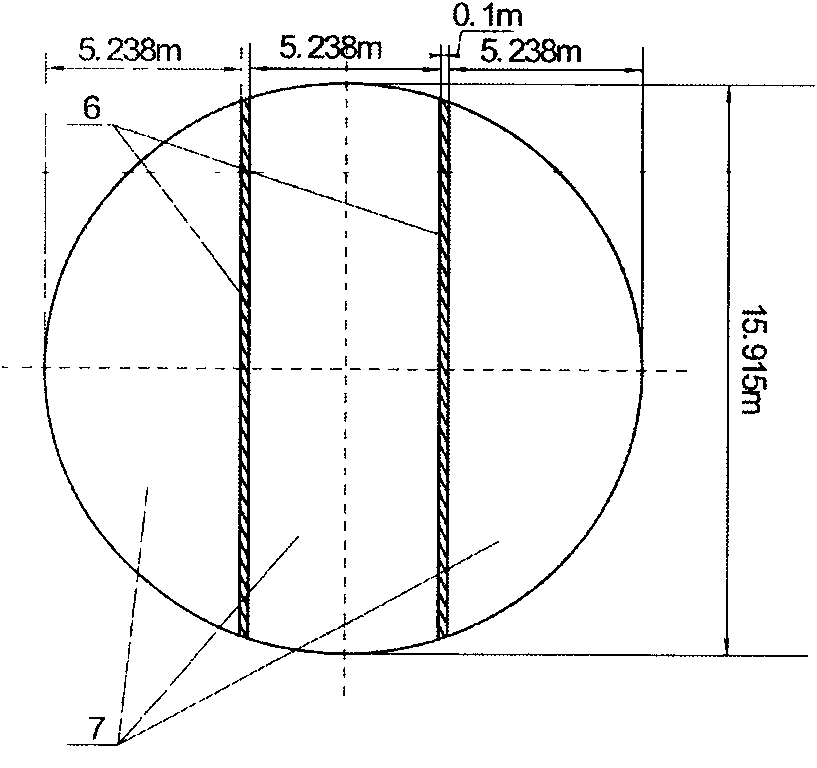

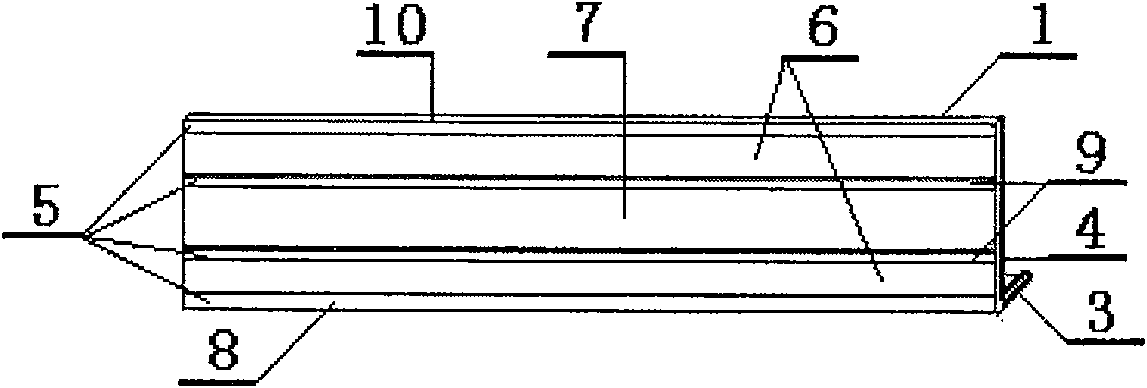

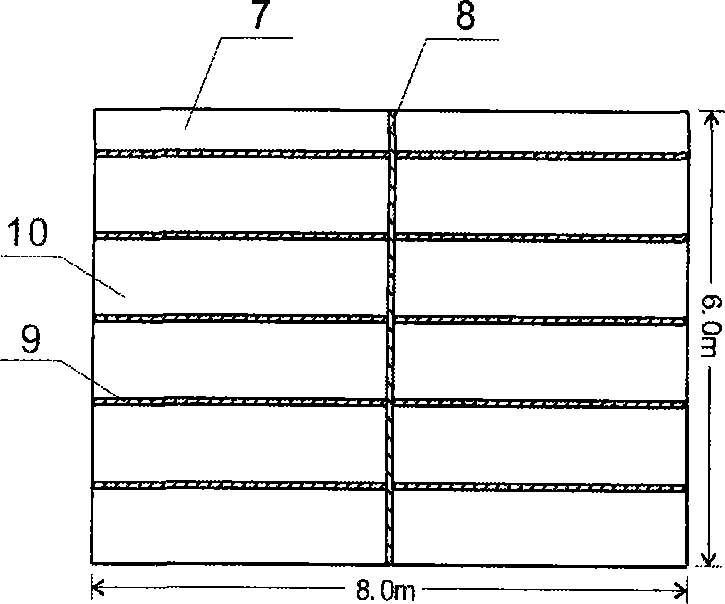

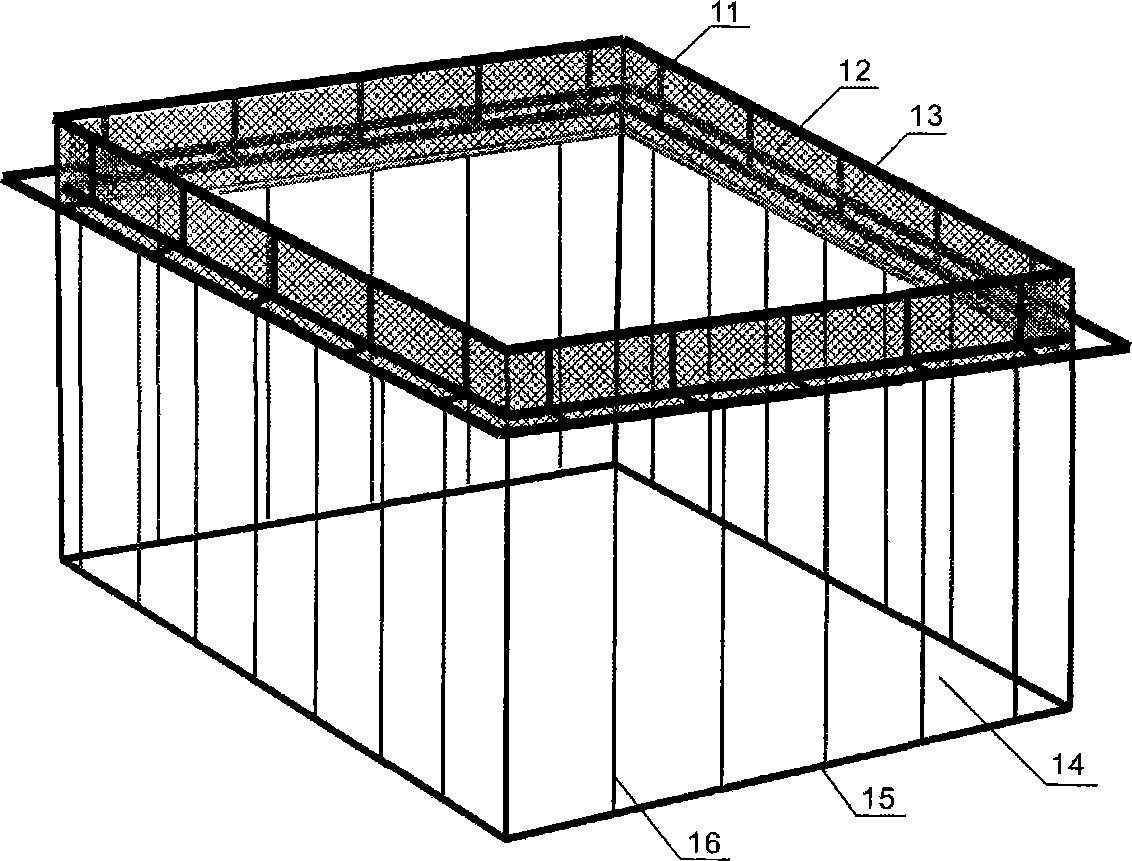

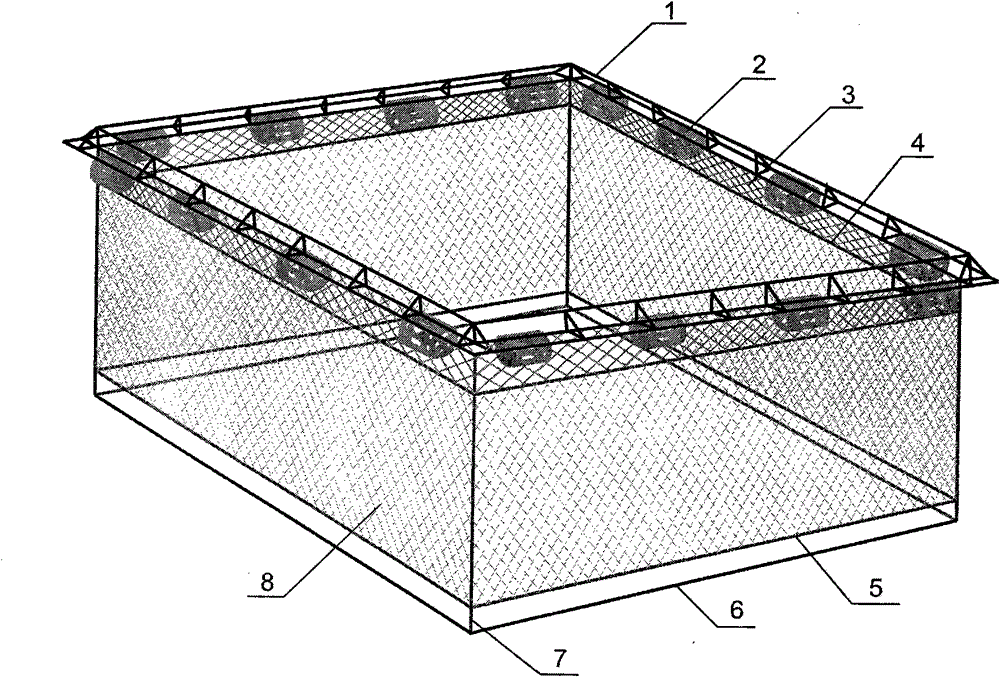

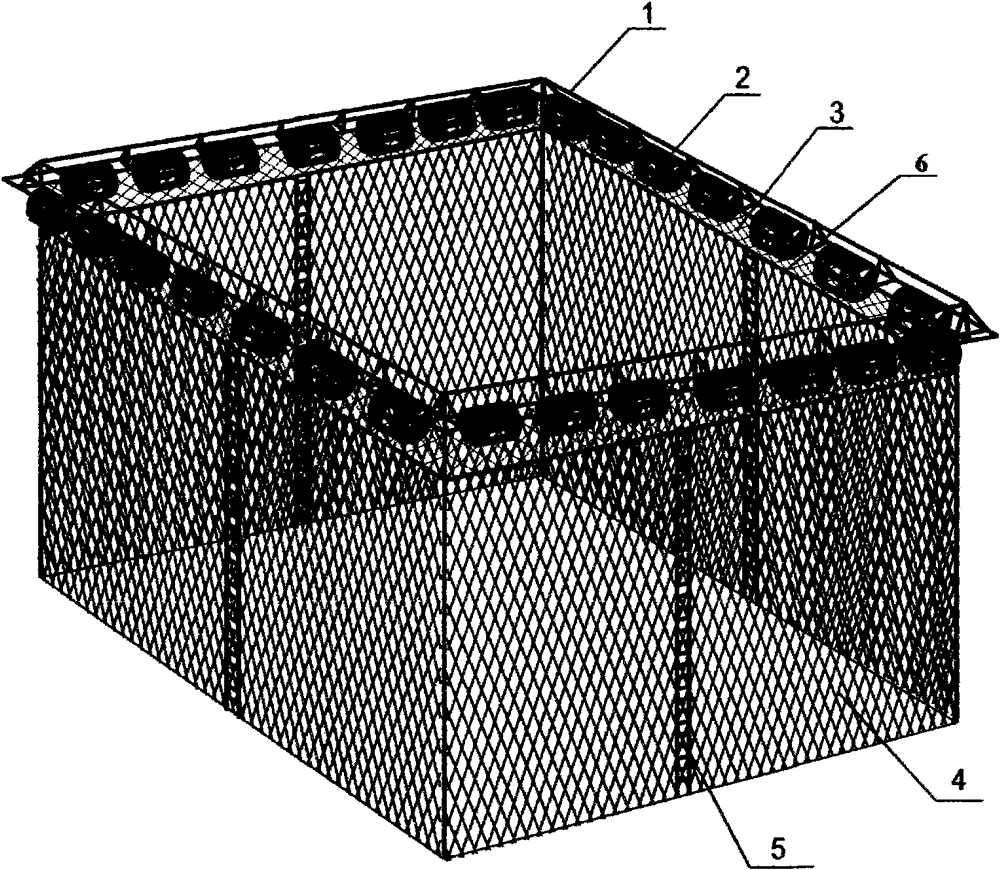

Combined fishnet square net cage used for mariculture

InactiveCN102239817AReduce deformation and volume lossImprove volume retentionClimate change adaptationPisciculture and aquariaDouble rowSeawater

The invention discloses a combined fishnet square net cage used for mariculture, relating to a mariculture net cage. In the combined fishnet square net cage, a cupronickel B10 stretching net, a brass HA177-2 stretching net, a high-strenght single-fast-knot polyethylene fibre net, a high-strength nylon warp knitting net, a fishing high-strength polyethylene monofilament rope, a galvanized iron pipe and a cylindrical foam buoy are adopted. The combined fishnet square net cage is characterized in that a frame system used for the net cage is of a square double-row galvanized iron pipe frame structure. In a fishnet system used for the net cage, a double-layer synthetic fibre fishnet serves as a first fishnet, a combined copper alloy stretching net serves as a second fishnet, and the first fishnet and the second fishnet are in longitudinal semi-soft connection; a square synthetic fibre fishnet is in a combined fishnet form of the fishnets used for the net bottom of the net cage; the combined fishnet used for the net bottom of the net cage is hung on the square double-row galvanized iron pipe frame; and the square double-row galvanized iron pipe frame of the net cage is connected with a float line frame of a mooring system by a mooring rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

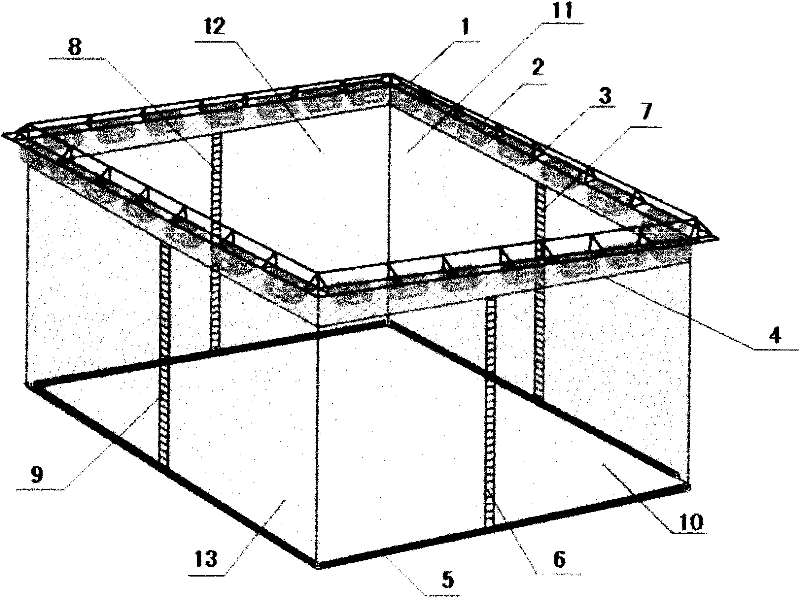

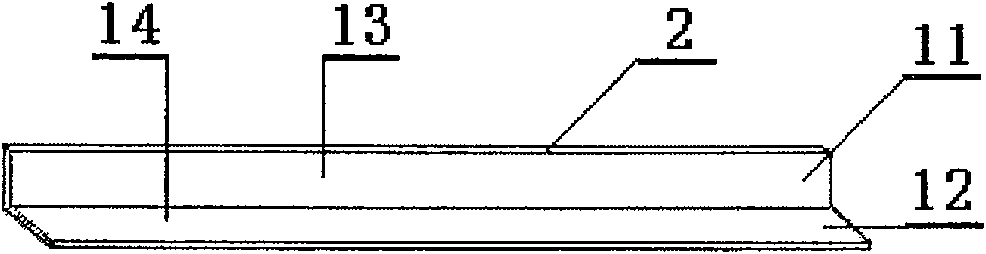

Combined box body system used for floating net cage and mated frame system thereof

ActiveCN102239814AImprove the box volume retention rateImprove antifouling functionClimate change adaptationPisciculture and aquariaPolyamideEngineering

The invention provides a combined box body system used for a floating net cage and a mated frame system thereof, relating to a seawater cultivation floating net cage. A copper alloy inclined square mesh, a copper alloy weaving mesh, high-strength polyamide warp knitting fishnet, ropes, a galvanized iron pipe and foam buoys. The combined box body system is characterized in that a floating net cageframe system comprises two rows of square galvanized iron pipe frames; the foam buoys are distributed below the two rows of galvanized iron pipe frames; the fishnet system of a net cage body combinesa first high-strength polyamide warp knitting fishnet, a second copper alloy inclined square mesh and the copper alloy weaving mesh used for the bottom of the net cage'; the edge installing wire ropeof the fishnet at the bottom of the net cage is assembled on a square high-strength polyamide pipe frame; the high-strength polyamide pipe frame and a horizontal wire rope at the lower edge of the second copper alloy inclined square mesh are connected by an ultrahigh-strength rope; and a vertical force net is installed in the vertical direction of the fishnet and extends to the edge wire rope of the copper alloy weaving mesh used for the bottom of the net cage.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

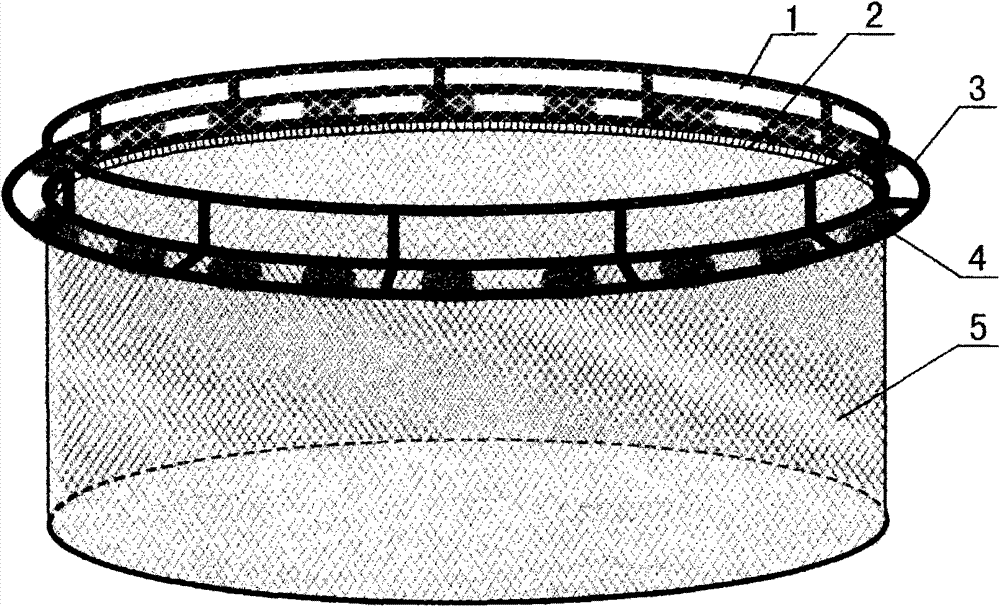

Method for manufacturing antifouling and antibiosis type yellow croaker net cage

InactiveCN102763610AReduce harmImprove survival rateClimate change adaptationPisciculture and aquariaAntibiosisEngineering

The invention discloses a method for manufacturing an antifouling and antibiosis type yellow croaker net cage, which relates to a method for manufacturing a mariculture net cage. According to the invention, the method for manufacturing the antifouling and antibiosis type yellow croaker net cage adopts a buoyancy force system and a netting system, and is characterized in that the buoyancy force system adopts a combination buoyancy force form of 'an anti-aging high-density polyethylene double-floating-pipe cylindrical frame structure + 18 cube cystosepiments with each edge length of 60cm; the netting system adopts a combination structure netting form of 'a first box longitudinal netting + a second box longitudinal netting + a net cage bottom netting; the net cage bottom netting is assembledon a circular high-density polyethylene pipe support which is wrapped with a layer of polyamide multifilament wrap knitting net; and three cross lacing lines are installed at the bottom of the net cage, a polypropylene rope is tied at the cross point of the cross lacing lines, and two foam float bowls which are externally wrapped by double-layer seawater corrosion protection canva and nylon nets are tied at the other end of the polypropylene rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

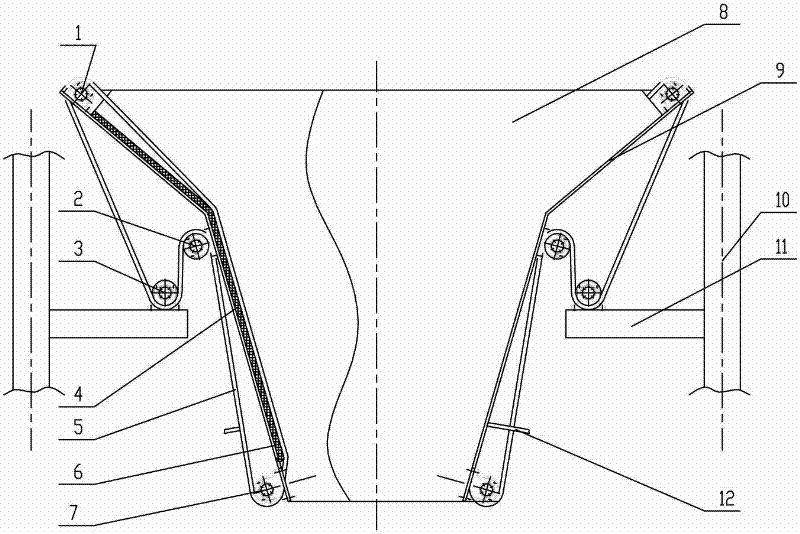

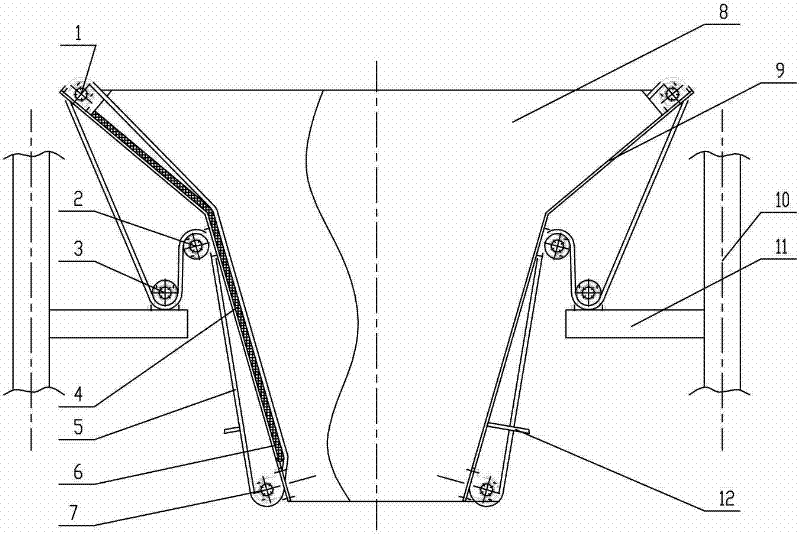

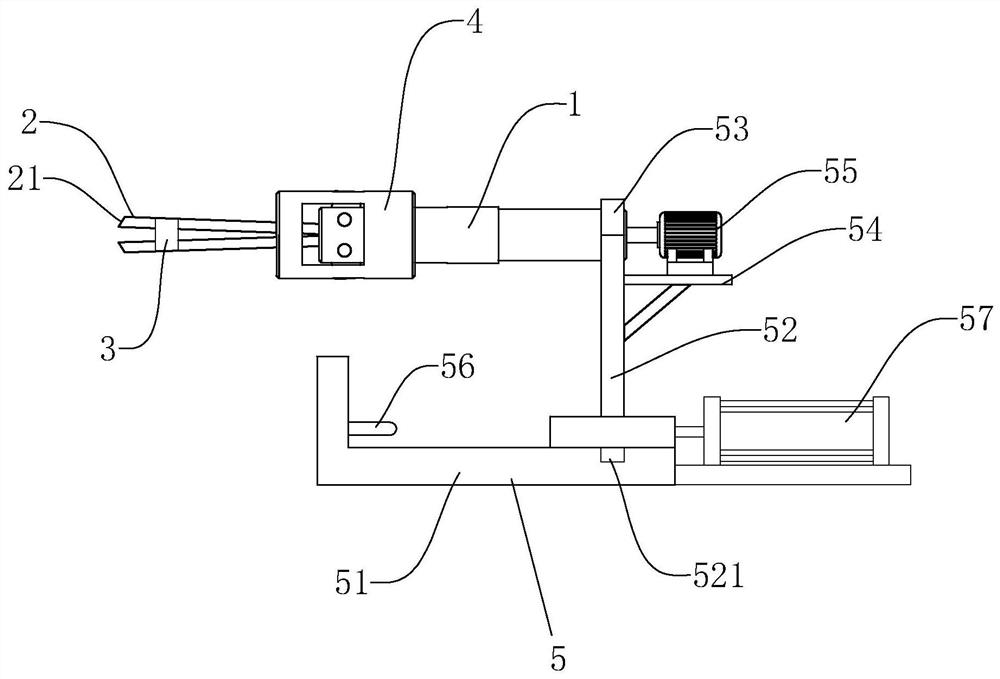

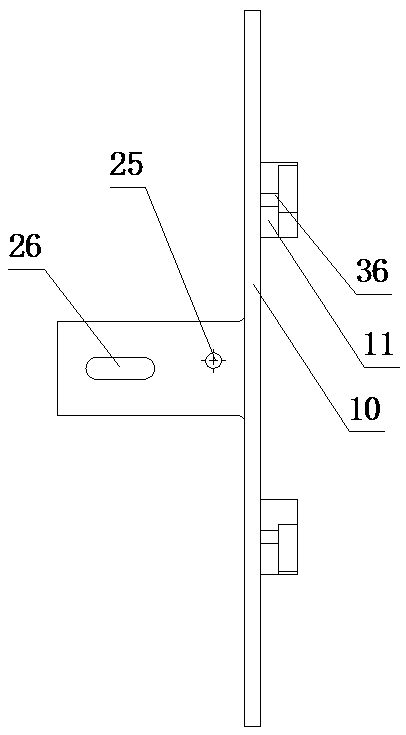

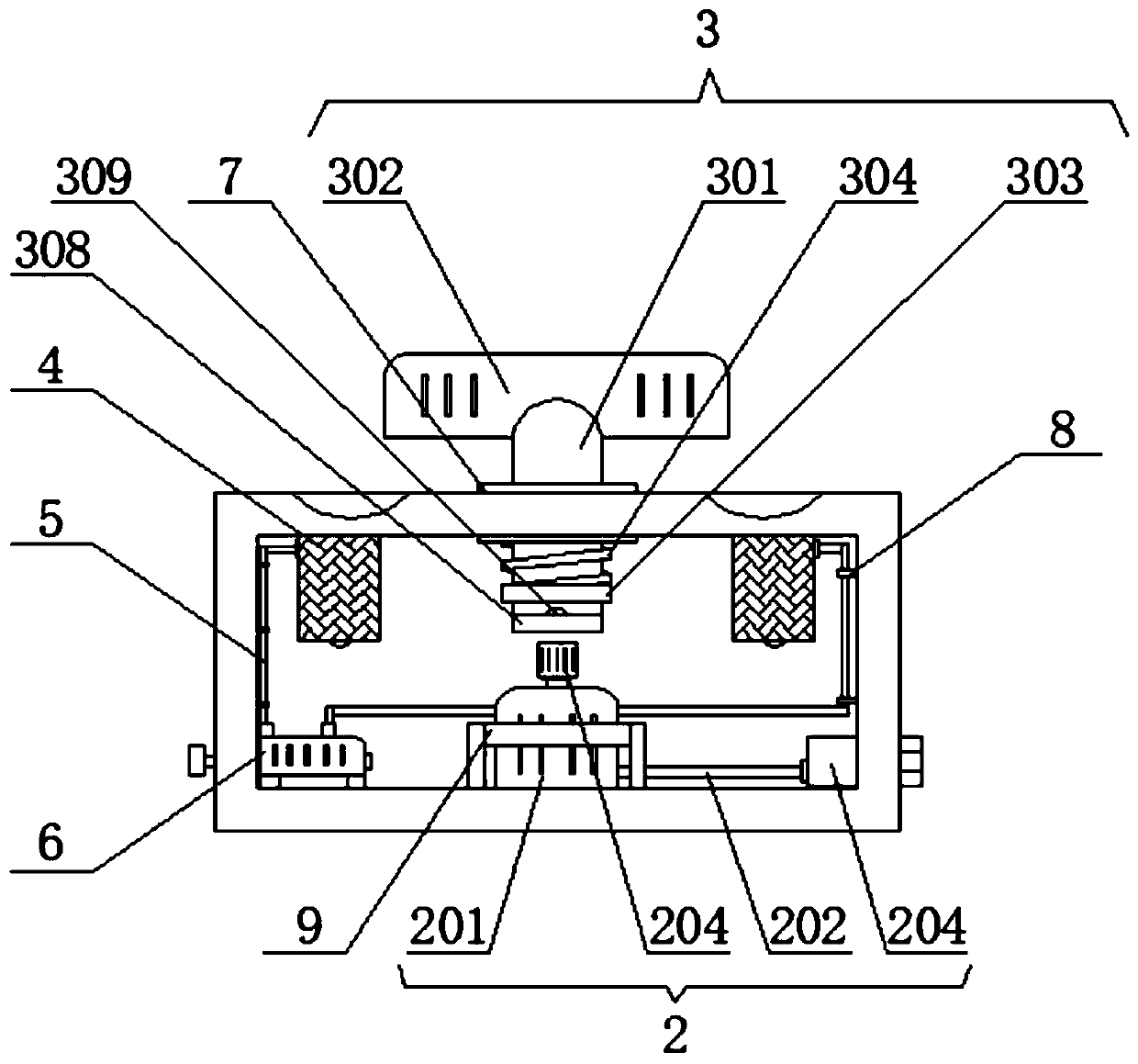

Anti-sticking material bulk cargo storage bin

ActiveCN102491015AGuaranteed cleanlinessAvoid direct abrasionLarge containersBulk cargoDevice breakage

The invention relates to an anti-sticking material bulk cargo storage bin. The storage bin is characterized in that two corresponding side plates of the bulk cargo storage bin are such side plates that the lower part gradient is 70 degrees, and the upper part gradient is 50 degrees; the top ends and the bottom ends of the two side plates are respectively provided with a top guide hole and a bottom guide hole, the inner walls of the two side plates are provided with lining boards, and the outer walls of the two side plates are provided with wing plates; the two side plates are respectively provided with an anti-sticking material mechanism; and each anti-sticking material mechanism comprises a support, a tension roller arranged on the support, a top guide roller arranged on the top of each wing plate, a bottom guide roller arranged on the bottom of each wing plate, a bearing base arranged on the middle of each wing plate, a driving roller rotatably connected with the bearing base, a motor connected with the driving roller, a strap which can pass through the top guide hole and the bottom guide hole and is respectively connected with the top guide roller, the tension roller, the driving roller and the bottom guide roller, and a U-shaped scraper arranged on the lower part of each wing plate. The bulk cargo storage bin provided by the invention has the advantages of reducing the labour intensity of workers, and avoiding occurrence of accident of next stage equipment damage caused by bulk dropping due to excessive sticky materials.

Owner:NORTHERN ENG & TECH CORP MCC

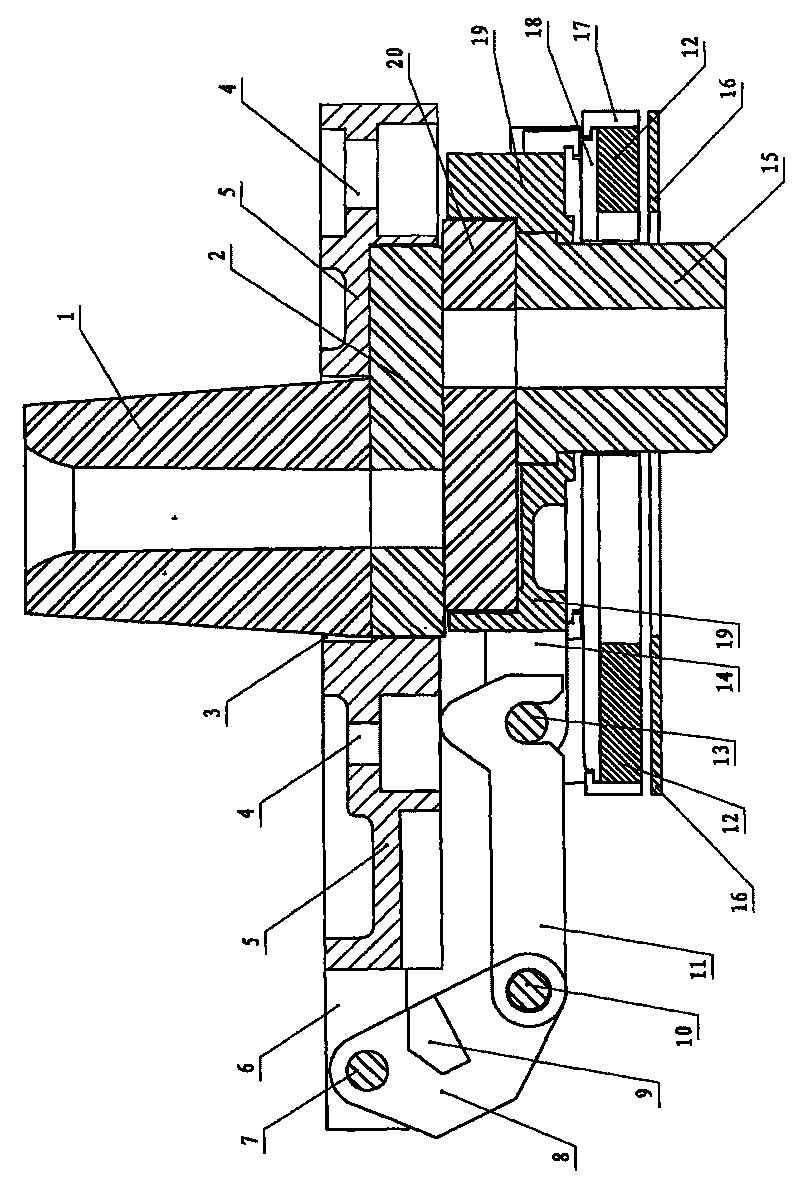

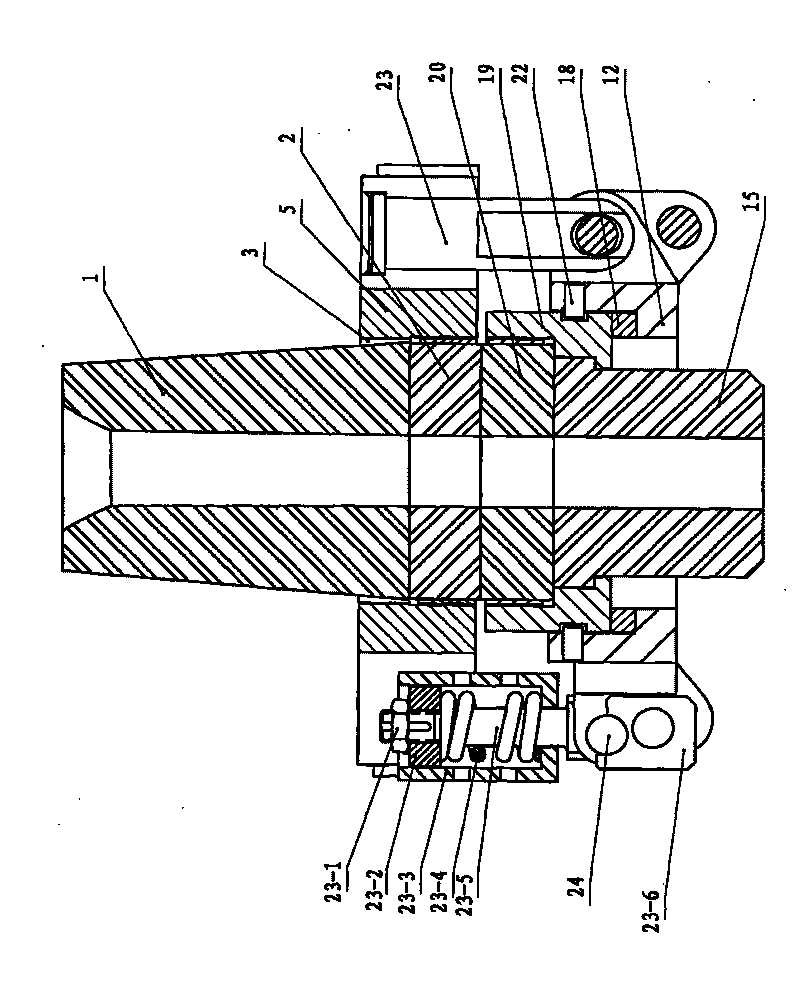

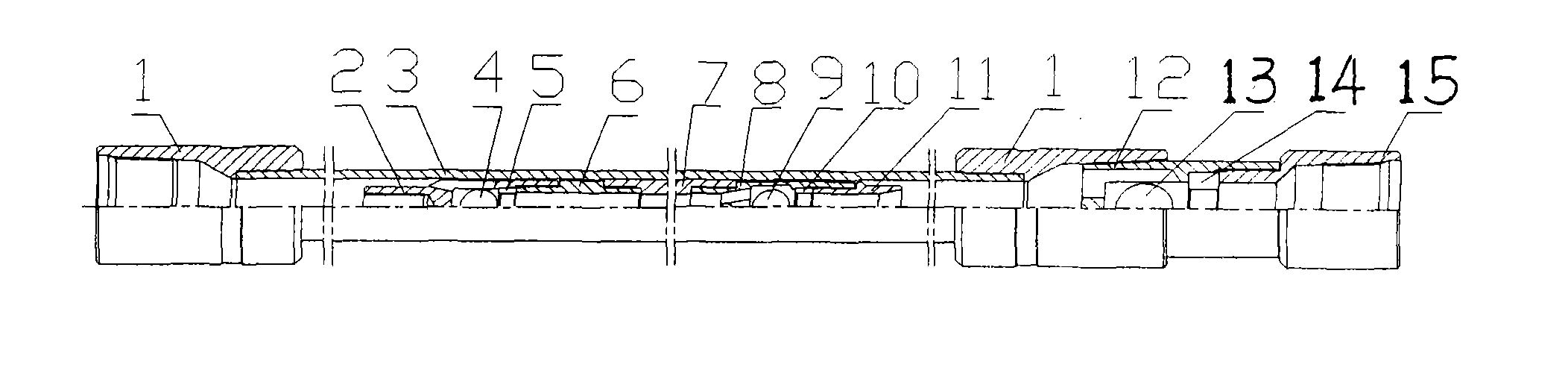

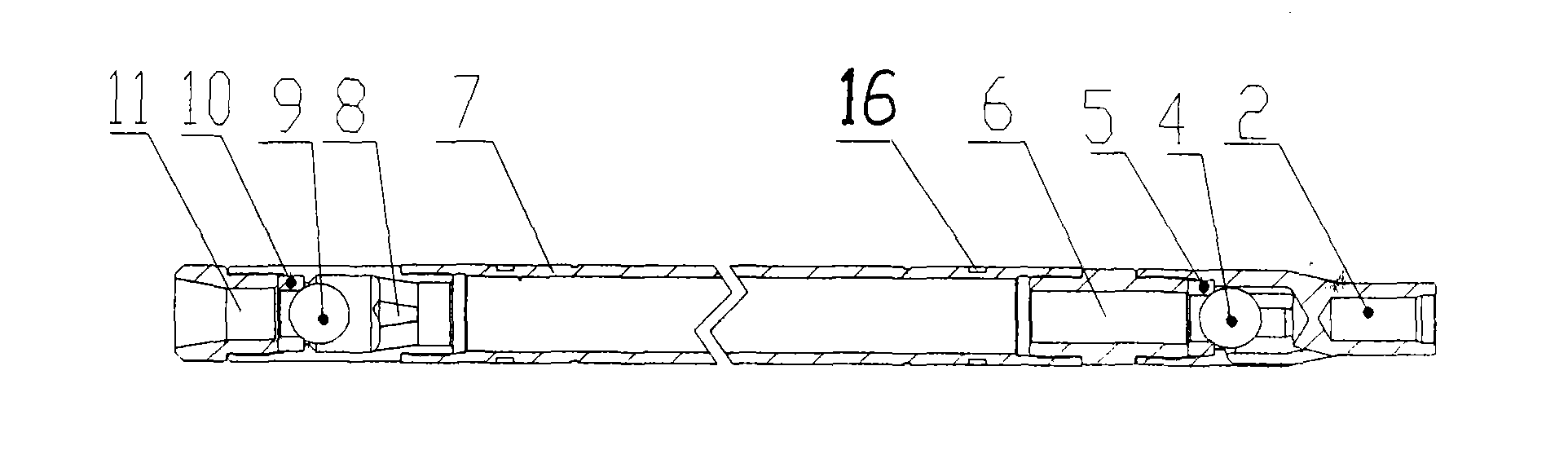

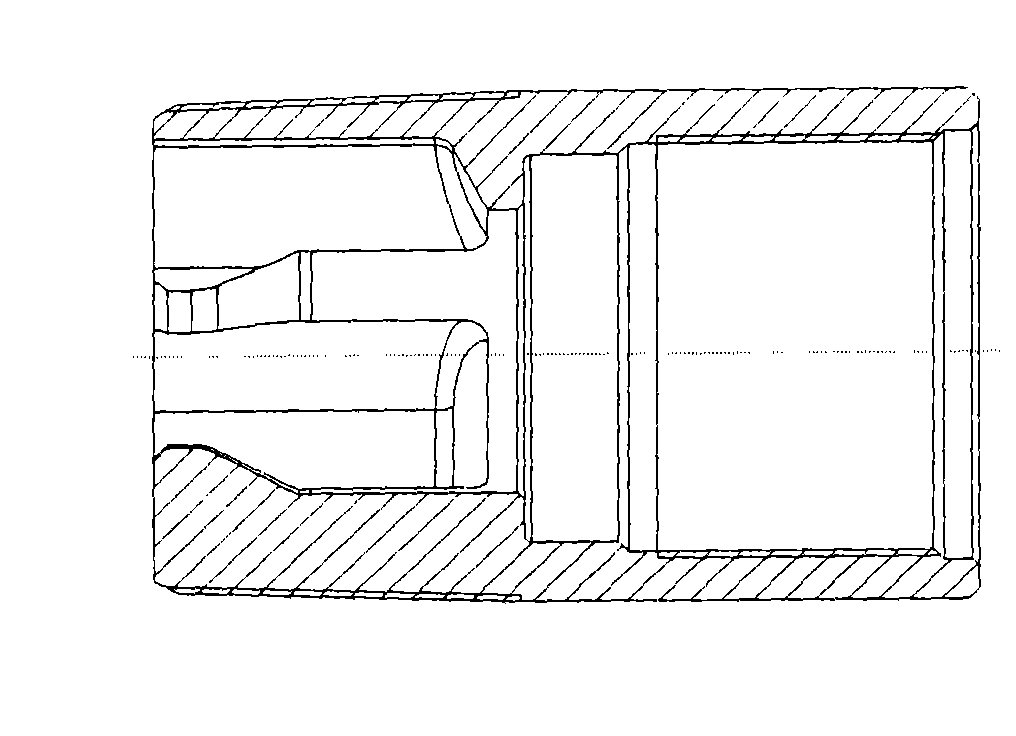

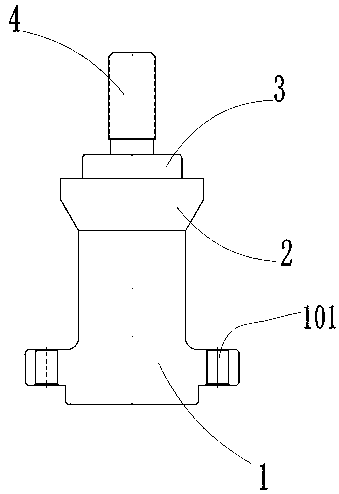

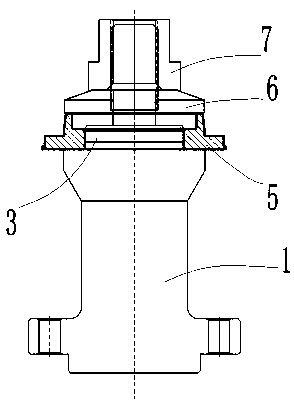

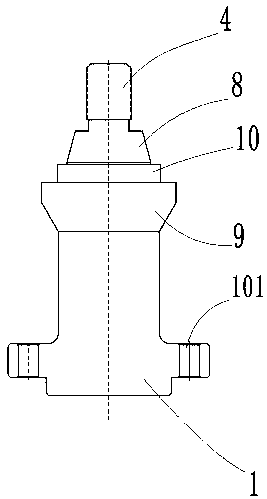

Sliding nozzle device

The invention relates to a sliding nozzle device which comprises a pedestal, sliding plate bricks and a sliding support, wherein a pulley is arranged between the pedestal and the sliding support, a spring locking mechanism is respectively arranged at both outer sides of the pedestal and the sliding support, a link mechanism formed by a rocking arm and a hook bar is respectively hinged at one end part of the pedestal and the sliding support, an upper sliding plate brick chamber is arranged in the middle on the lower surface of the pedestal, an upper sliding plate brick is installed in the chamber, a through hole is arranged at the upper part of the chamber, an upper nozzle is installed at the upper part of the chamber, a lower sliding plate brick chamber is arranged in the middle on the upper surface of the pulley, a lower sliding plate brick is installed in the chamber, a lower nozzle mounting hole is arranged at the lower part of the chamber of the pulley, a step type snap ring is arranged on the inner edge of the hole, and a lower nozzle with steps is installed in the lower nozzle mounting hole; the chambers for installing the upper sliding plate brick and the lower sliding plate brick inside the pedestal and the pulley are both oblong chambers respectively provided with a small circular arc at one end and a large circular arc at one end, and the large circular arc and the small circular arc are in tangent transitional connection; and the device has lower cost, convenient operation and accurate control, and is very beneficial to popularization and application.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

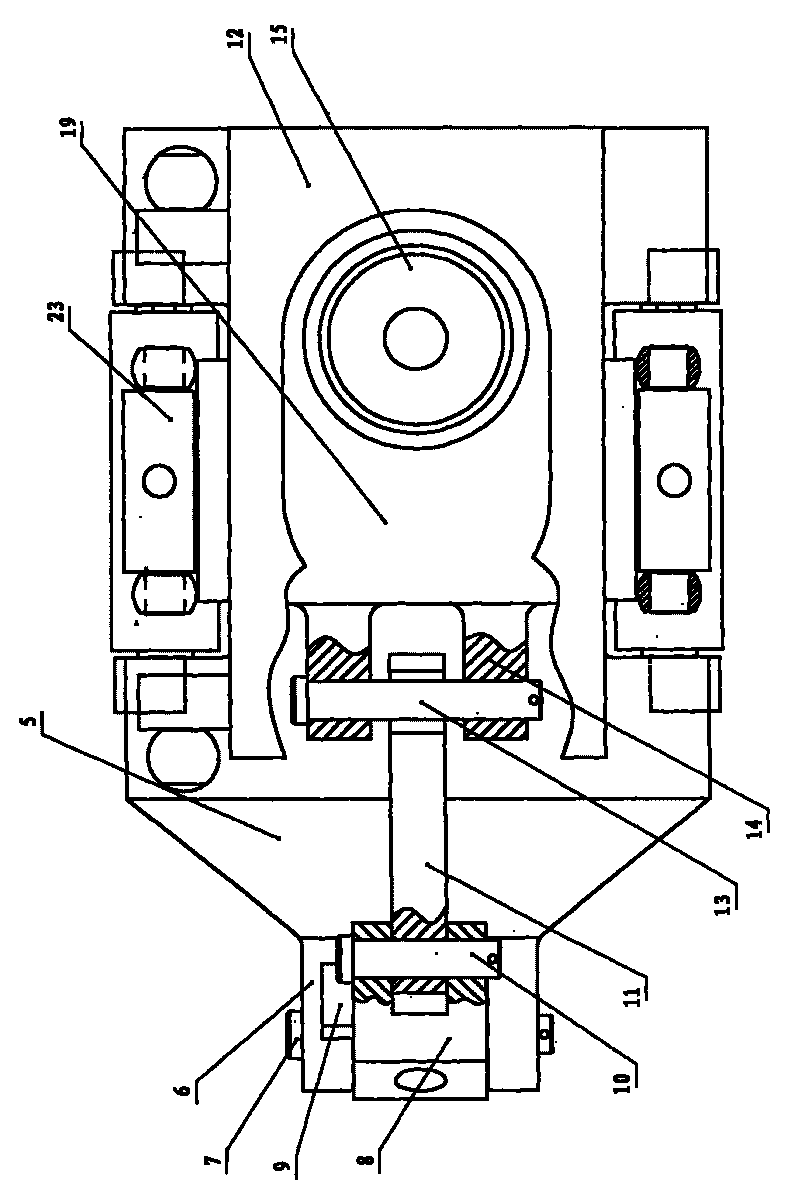

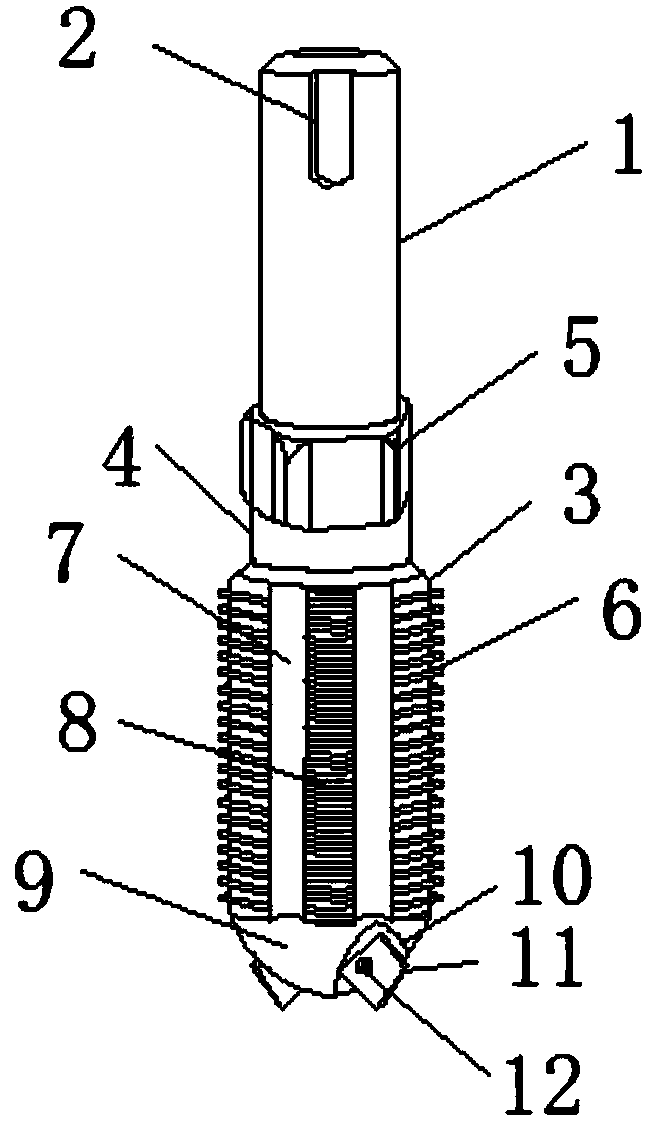

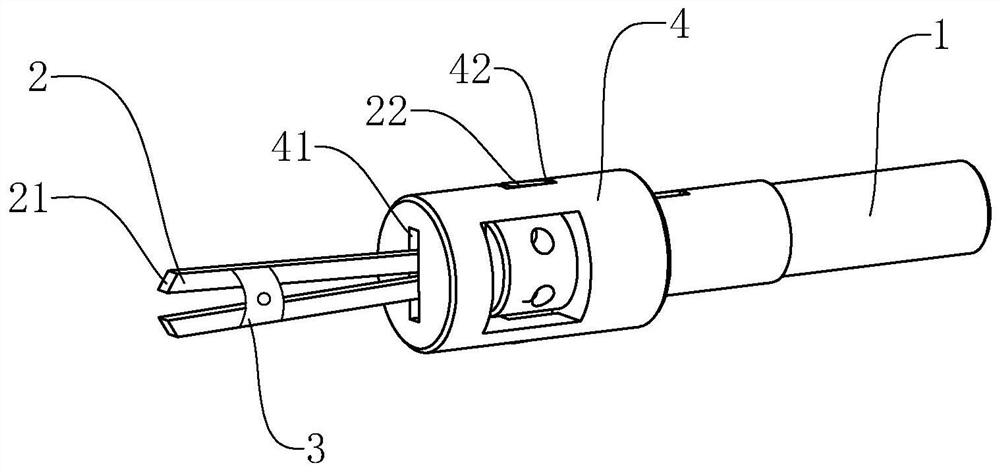

Automatic cleaning screw for track end face bearing

ActiveCN109443078AGuaranteed service lifeAvoid direct abrasionHeat transfer modificationRotary device cleaningEvaporatorNozzle

The invention relates to an automatic cleaning screw for a track end face bearing. A hook head shaft moving together with the cleaning screw enables the cleaning screw to generate axial reciprocatingcleaning screw movement under the action of the track end face of a nozzle bearing, and simultaneously achieves slow rotation required for avoiding abrasion, so that the automatic cleaning capabilityof dirt is improved, and the uniformity of dirt cleaning is remarkably improved. Under the action of a positioning bearing tube, the hook head shaft can maintain coaxiality with the center line of a heat exchange tube when rotating, so that the possibility of abrasion between the cleaning screw near a pipe orifice and the inner wall of the heat exchange tube caused by rotating and shaking of the hook head shaft is avoided. The nozzle bearing is produced by injection molding of abrasion-resistant engineering plastics; and therefore, the track end face bearing has automatic spiral cleaning, simple structure, little resistance, convenient manufacture and good universality, and is suitable for tubular condenser, evaporator and crystallizer where tube pass feed liquid can generate dirt.

Owner:浙江建装工程技术研究有限公司

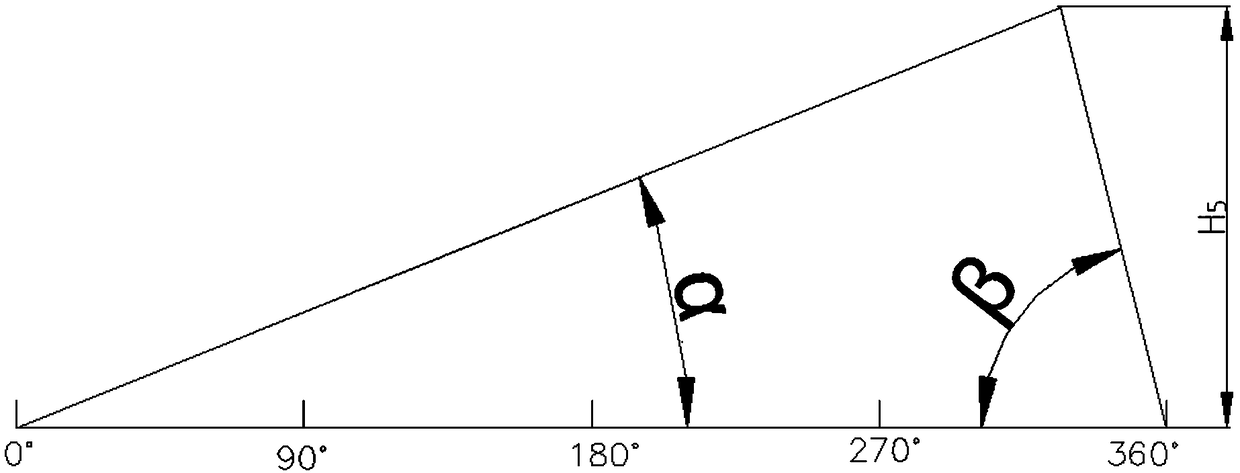

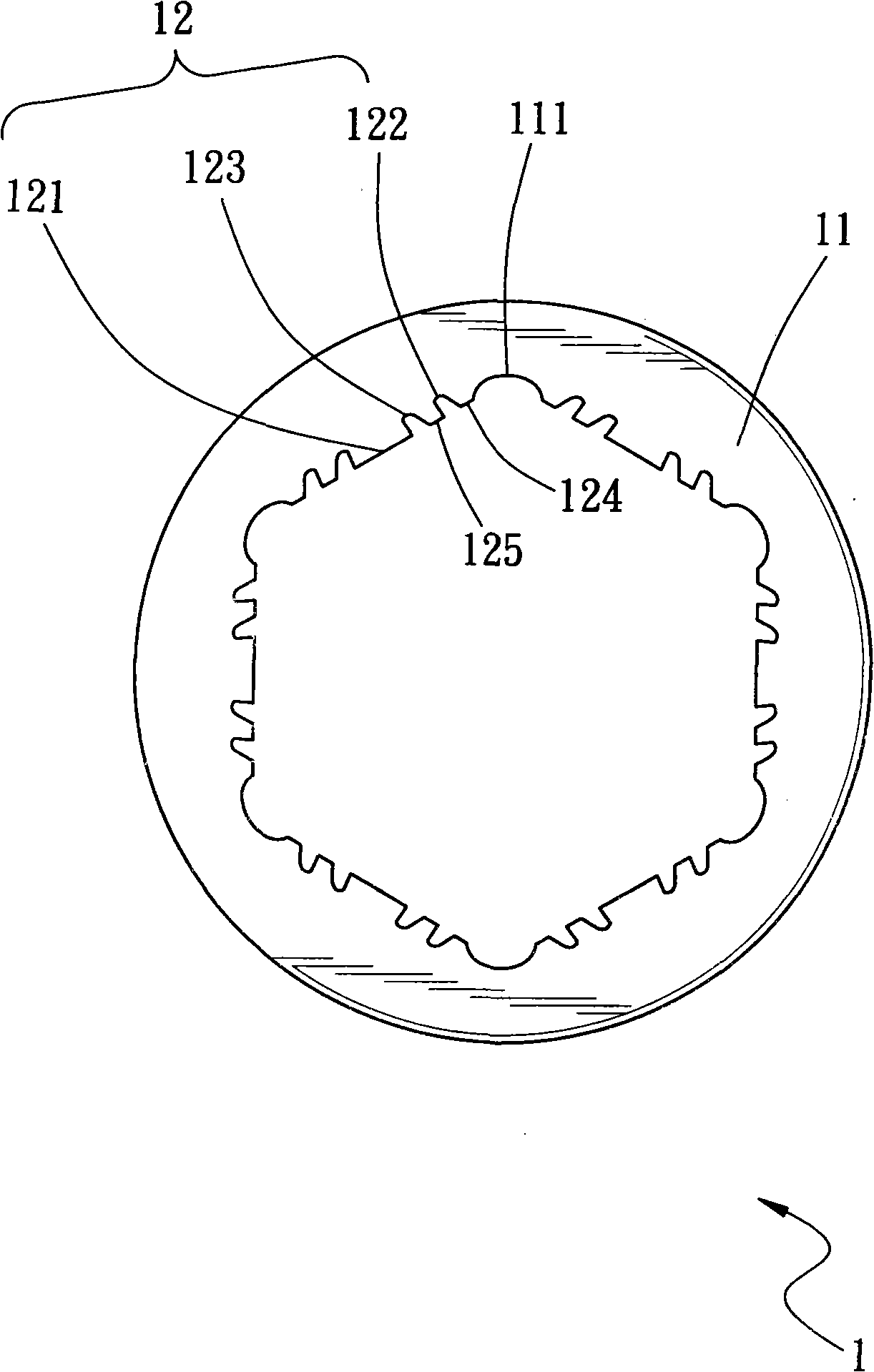

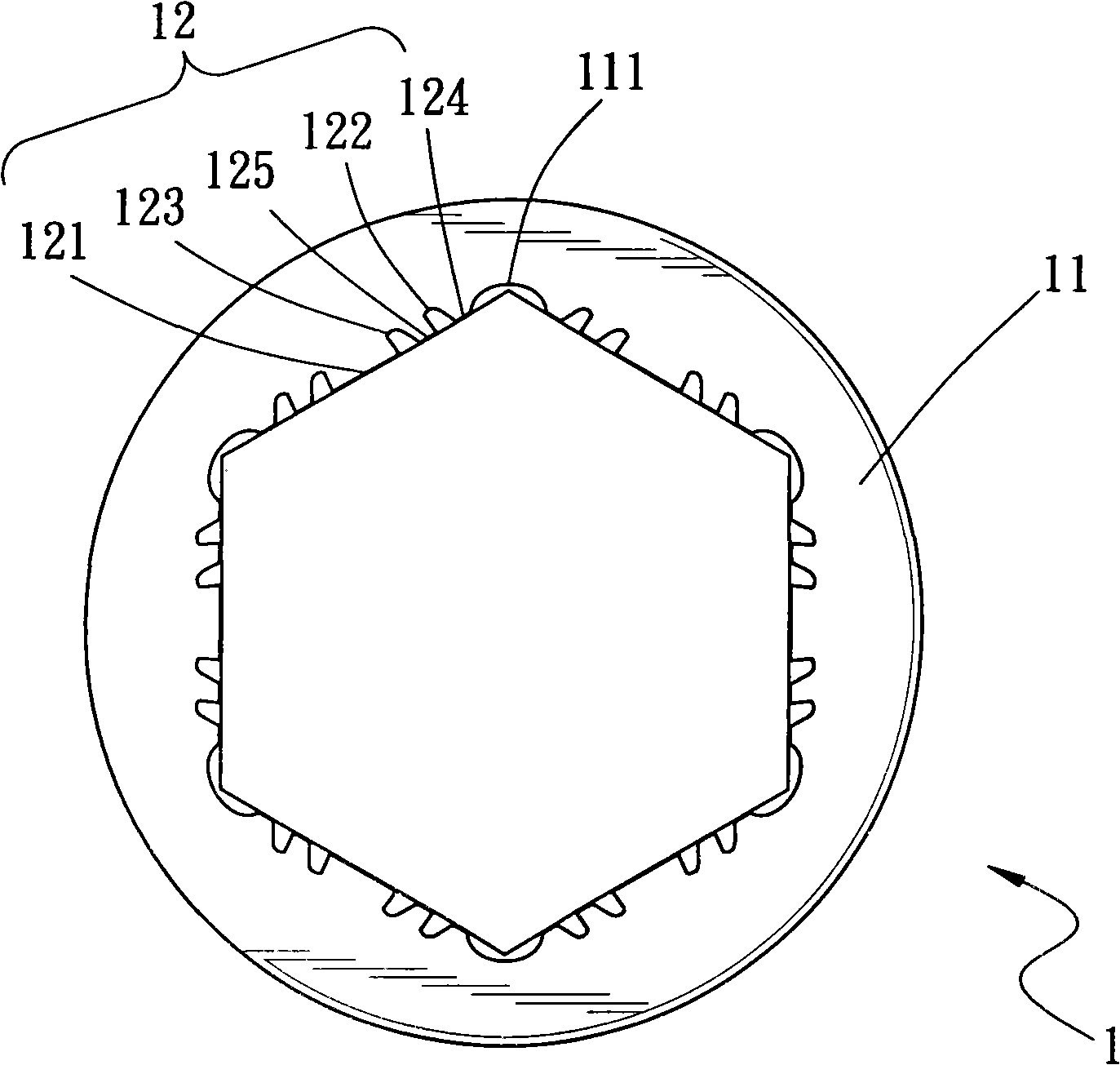

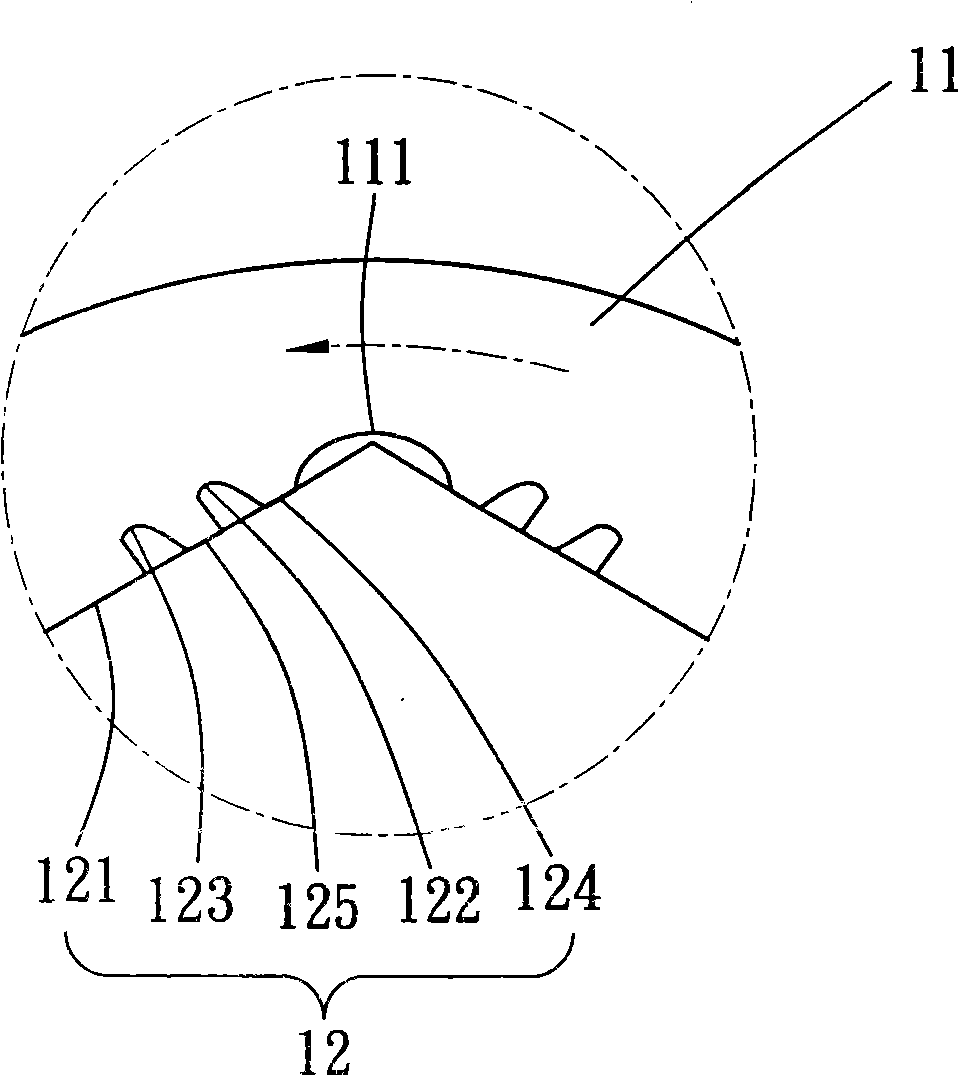

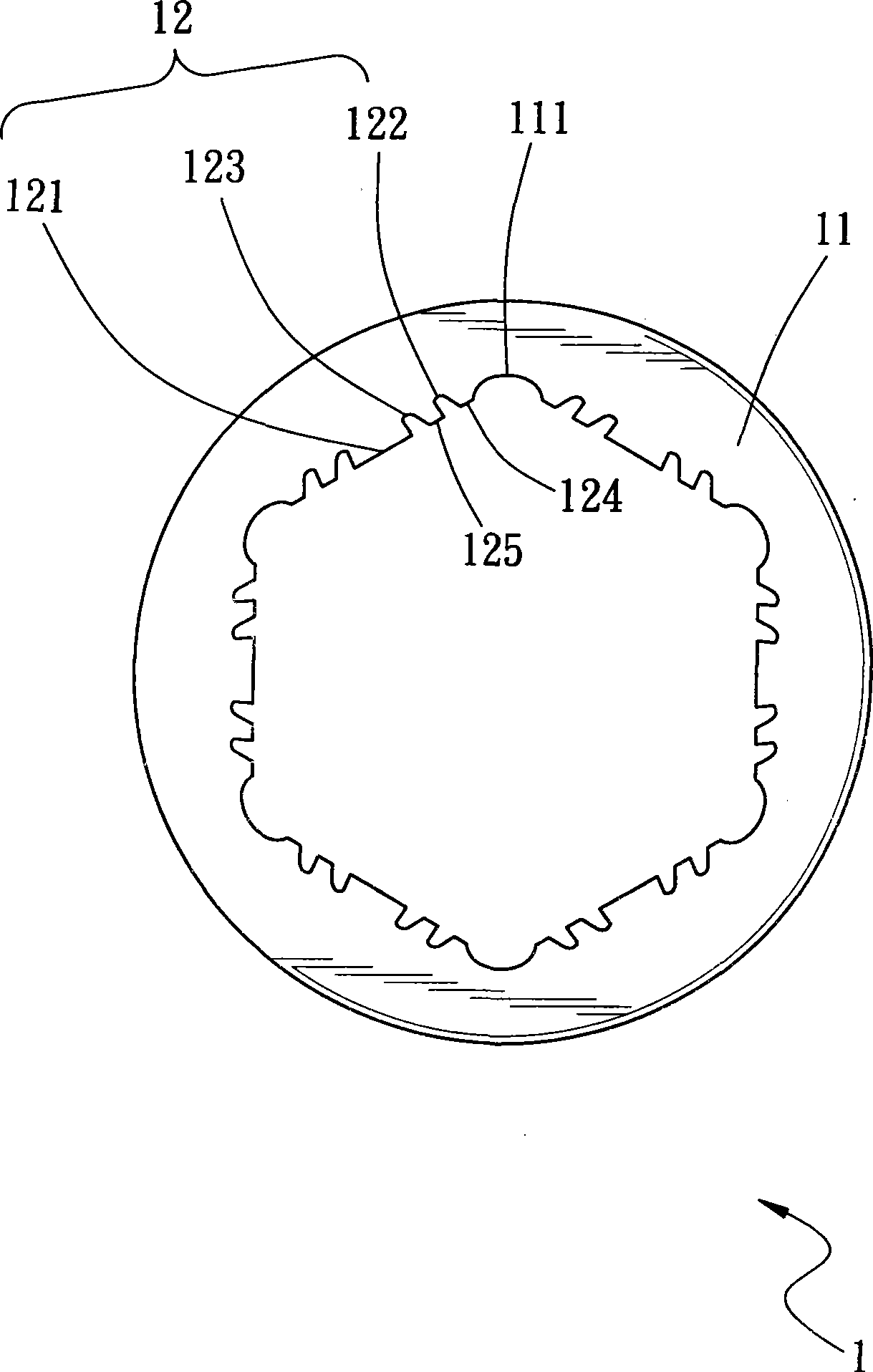

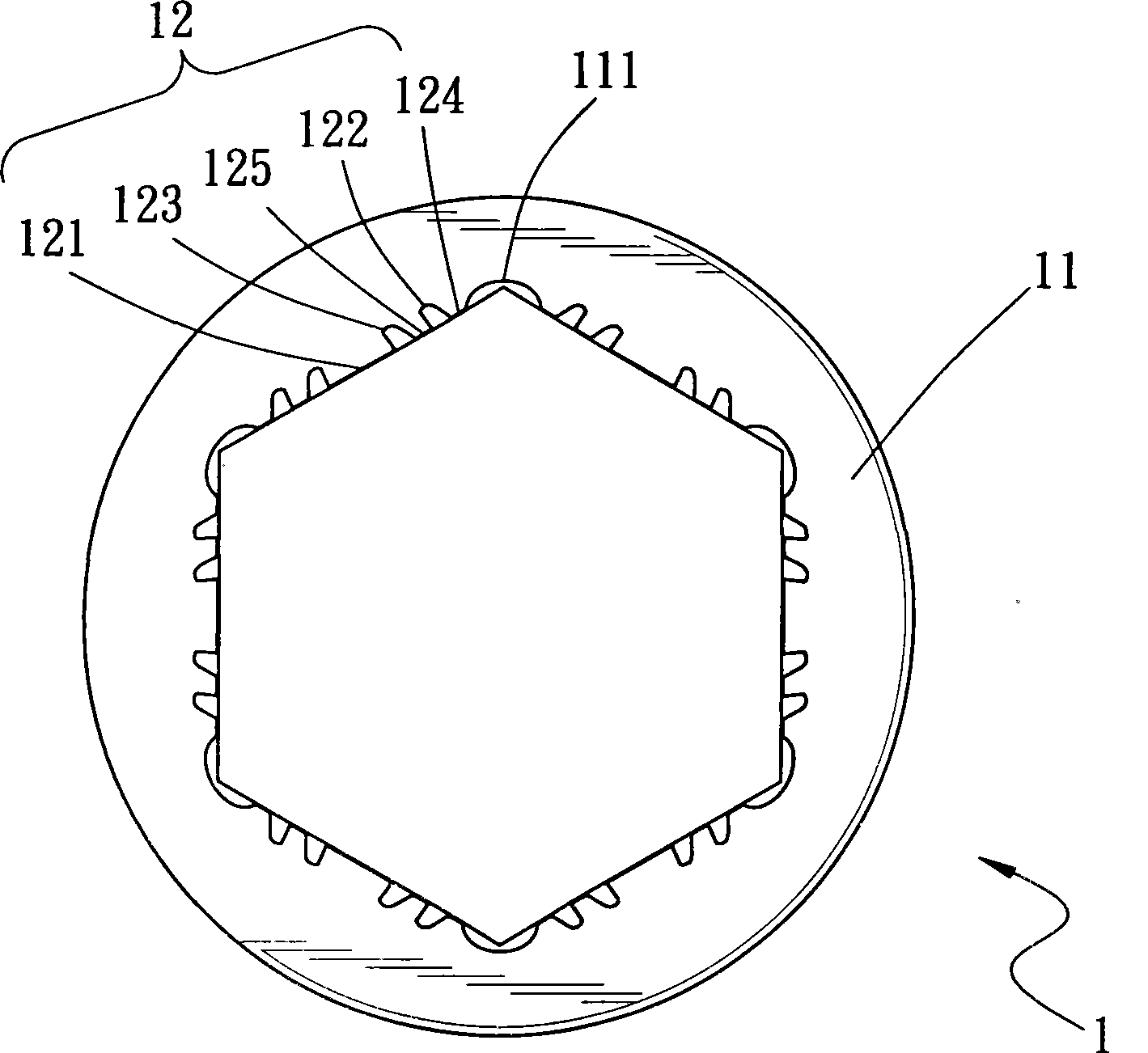

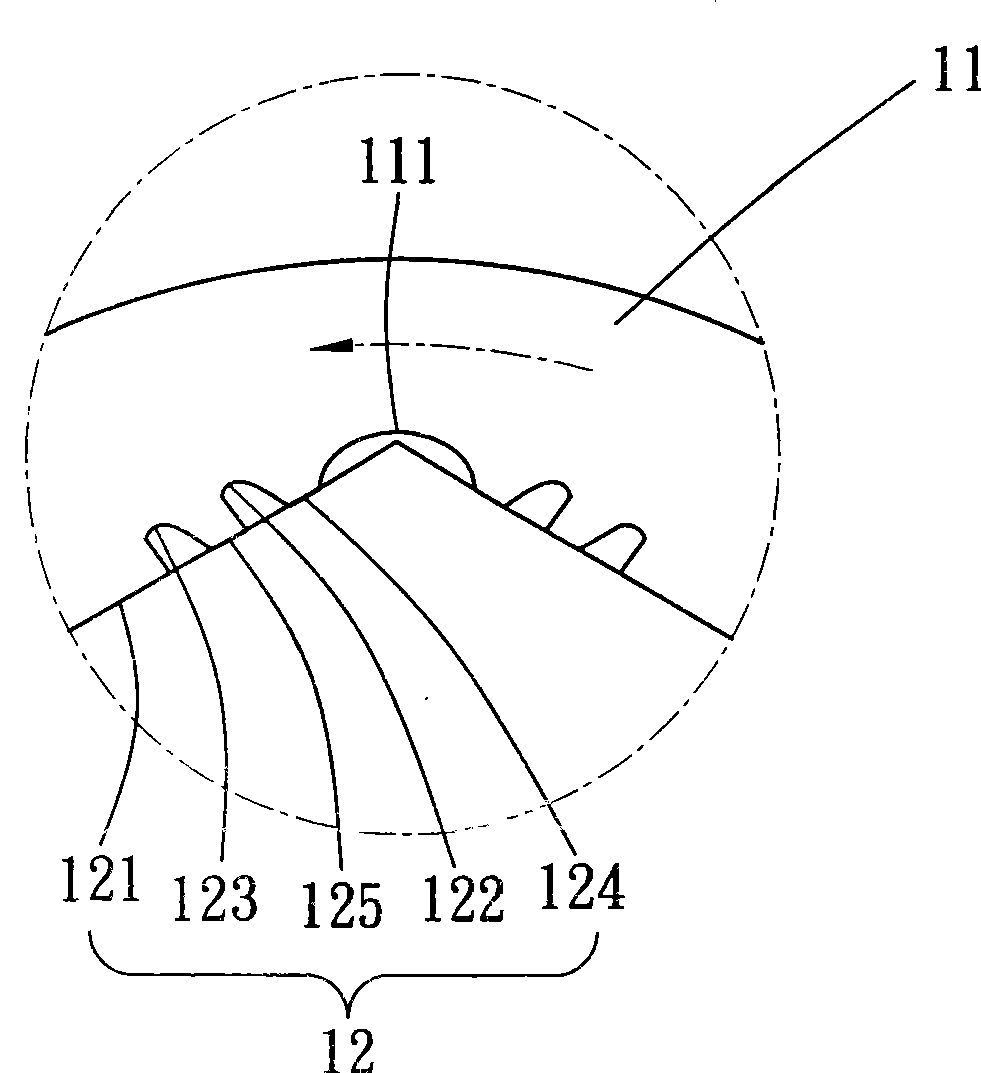

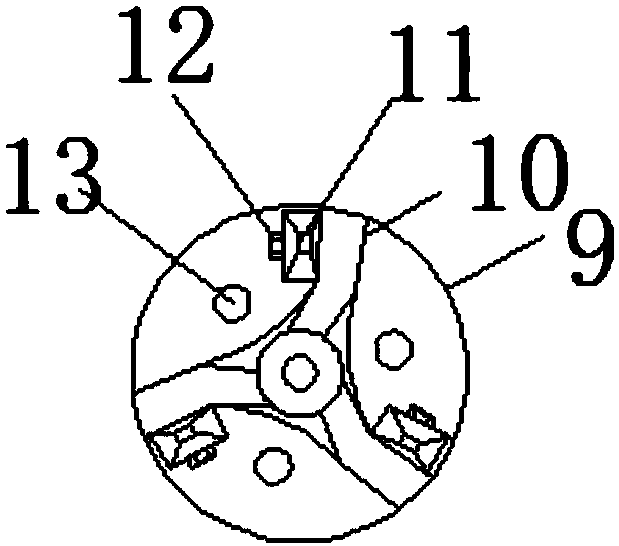

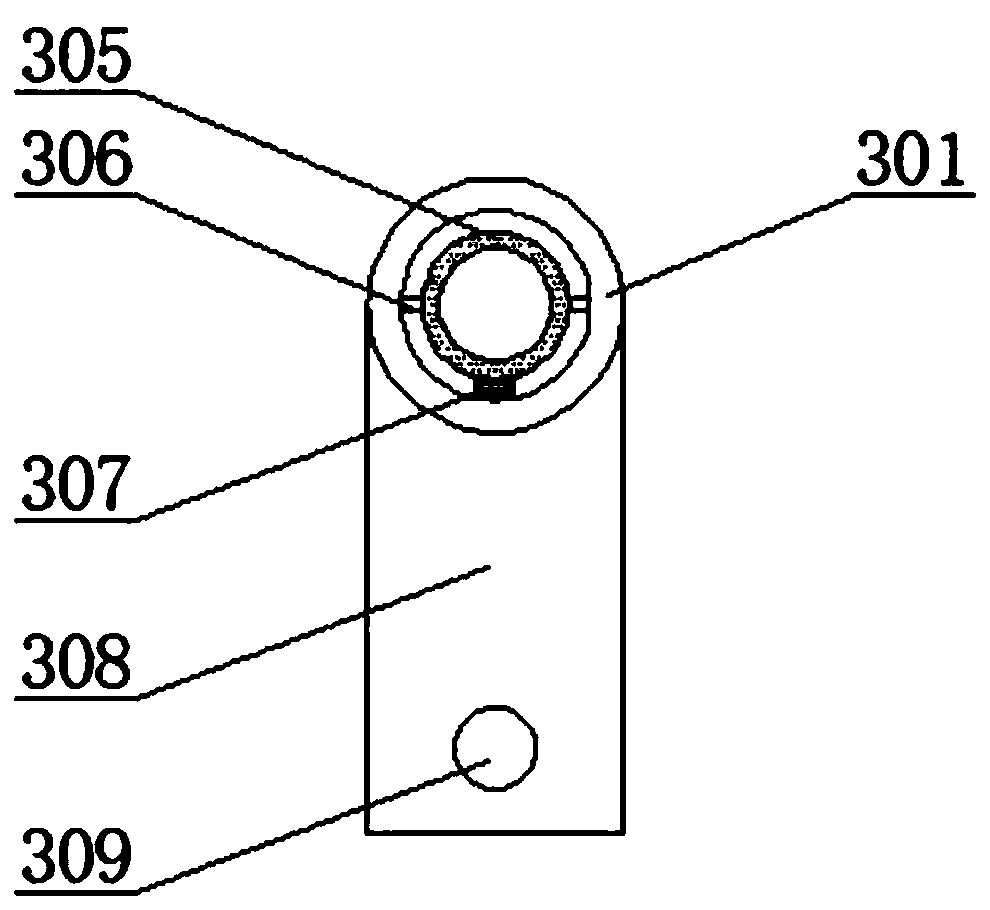

Tooth shaped structure of screwing tool

InactiveCN101332591APrevent collapseAvoid direct abrasionSpannersWrenchesLine segmentStress concentration

The invention discloses a tooth-shaped structure of a bolt fixing tool. The tooth-shaped structure comprises a drive part, a looping part is concavely arranged inside the drive part; the inner periphery of the looping part is a hollow structure and is approximately a polygonal structure, the intersectional angle between edges of the polygonal structure of the looping part are respectively provided with an escape groove, the escape groove is a recessed arc structure, an opening of the escape groove and an opening of the adjacent escape groove take on a straight edge, the straight edge is a lank line section; a top surface is respectively arranged at the center of the straight edges between two adjacent escape grooves, the top surface is in a planar straight line section structure, the top surface is arranged at the straight edge between the two adjacent escape grooves and is superposed on the straight edge; a first groove and a second groove are respectively recessed between the escape groove and the top surface, the first groove is closer to the escape groove, the second groove is closer to the top surface, the first and the second grooves are arranged in line symmetry with another first and second grooves; based on the intermediate vertical line of the distance between the two side walls of the escape groove with the arc structure, the first and the second grooves are arranged in line symmetry with another first and second grooves by the central vertical line of the distance between the two side walls of the arc structure of the escape grooves. The tooth-shaped structure of a bolt fixation tool can not cause slipping and bruting of the bolt fixing part resulting from the stress concentration of point contact.

Owner:谢智庆

Sponge wheel structure

PendingCN109968223AExtended service lifeEasy to useSupport wheelsGlass/slag layered productsHeat conductingEngineering

Owner:瑞安市祥研科技有限公司

Advanced ceramic pipe type defueling pump

InactiveCN101649828AEasy clearanceAvoid direct abrasionPositive displacement pump componentsFlexible member pumpsAlloy coatingZirconia Toughened Alumina

The invention relates to an advanced ceramic pipe type defueling pump, comprising a pump cylinder, a plunger piston, an upper traveling valve assembly, a lower traveling valve assembly and a strandingvalve assembly. The advanced ceramic pipe type defueling pump is characterized in that the inner wall of a steel-based pipe of the pump cylinder is provided with an advanced ceramic protection layerwith high temperature resistance, abrasion resistance and corrosion resistance, which is used as an lining; the outer surface of a rod body of the plunger piston is previously provided with grooves atintervals, alloy coatings with abrasion resistance and corrosion resistance is sprayed on the grooves, and zirconia toughening alumina ceramic rings are embedded into the surfaces of the alloy coatings inside the grooves.

Owner:吉林省大多天盛金属陶瓷技术有限公司

Tooth shaped structure of screwing tool

InactiveCN101332591BPrevent collapseAvoid direct abrasionSpannersWrenchesStress concentrationEngineering

The invention discloses a tooth-shaped structure of a bolt fixing tool. The tooth-shaped structure comprises a drive part, a looping part is concavely arranged inside the drive part; the inner periphery of the looping part is a hollow structure and is approximately a polygonal structure, the intersectional angle between edges of the polygonal structure of the looping part are respectively provided with an escape groove, the escape groove is a recessed arc structure, an opening of the escape groove and an opening of the adjacent escape groove take on a straight edge, the straight edge is a lank line section; a top surface is respectively arranged at the center of the straight edges between two adjacent escape grooves, the top surface is in a planar straight line section structure, the top surface is arranged at the straight edge between the two adjacent escape grooves and is superposed on the straight edge; a first groove and a second groove are respectively recessed between the escapegroove and the top surface, the first groove is closer to the escape groove, the second groove is closer to the top surface, the first and the second grooves are arranged in line symmetry with another first and second grooves; based on the intermediate vertical line of the distance between the two side walls of the escape groove with the arc structure, the first and the second grooves are arranged in line symmetry with another first and second grooves by the central vertical line of the distance between the two side walls of the arc structure of the escape grooves. The tooth-shaped structure of a bolt fixation tool can not cause slipping and bruting of the bolt fixing part resulting from the stress concentration of point contact.

Owner:谢智庆

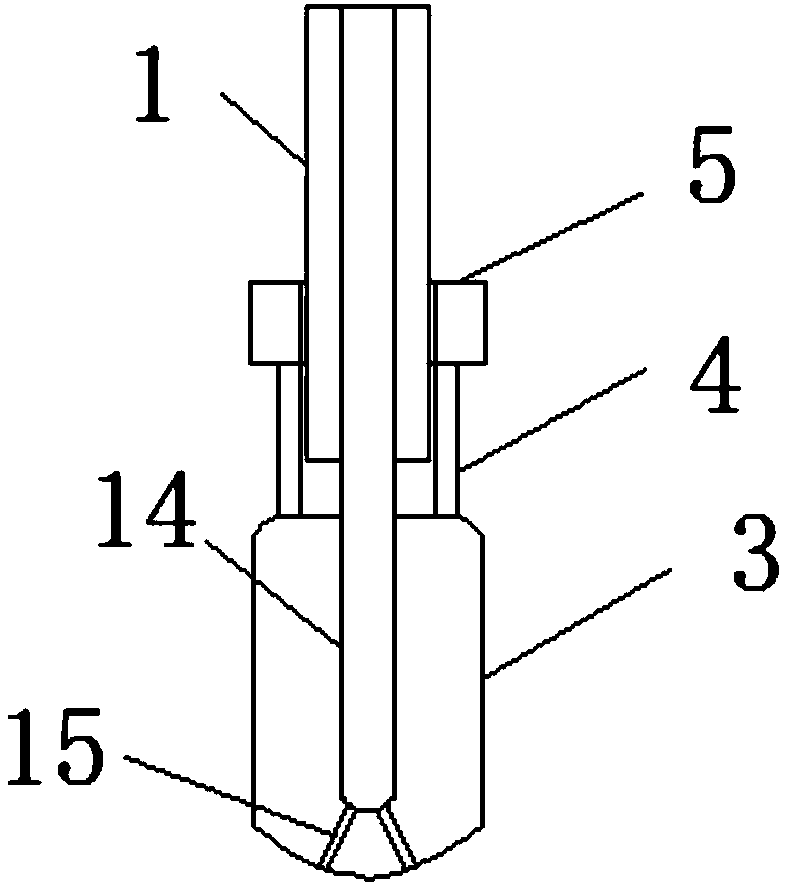

Combined type milling cutter

The invention discloses a combined type milling cutter. The combined type milling cutter comprises a spindle, a clamping groove, a rotator, a connecting barrel, a connecting unit, a milling edge, scrap guide grooves, a hairbrush, a drilling bit, stoppers, cutting blocks, a fixing bolt, liquid outlets, a channel and branch pipes. The combined type milling cutter has the advantages that one end of the spindle is provided with threads, and the spindle is connected with the rotator through the connecting nut; the rotator is provided with a plurality of the scrap guide grooves uniformly distributed, which can timely guide out material scraps; the rotator is also provided with the hairbrush which can eliminate burrs produced during a milling process to improve the cleanliness of milled surfaces;the drilling bit is provided with a plurality of the stoppers which are connected with a plurality of the high-hardness cutting blocks, which can mill and drill high-hardness materials; the inside ofthe combined type milling cutter is provided with the channel allowing cooling liquid to flow in, which then flow out via the liquid outlets at the tops of the branch pipes to cool down the combinedtype milling cutter and further to avoid excessive wearing.

Owner:常州苏德工具有限公司

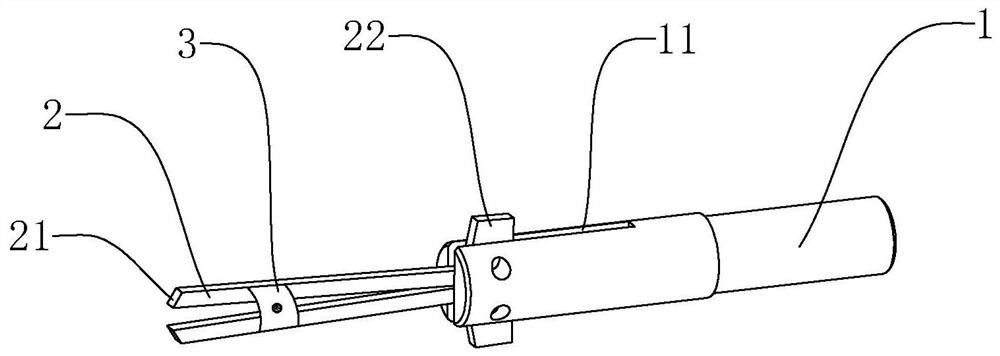

Air conditioner stop valve inner hole deburring device

ActiveCN113210750AExtended service lifeAvoid damageFeeding apparatusLarge fixed membersKnife bladesGlobe valve

The invention discloses an air conditioner stop valve inner hole deburring device. The air conditioner stop valve inner hole deburring device comprises a cutter handle and elastic blades, a strip-shaped notch is formed in a center of the front end of the cutter handle, the elastic blades are fixedly connected into the strip-shaped notch, the elastic blades are symmetrically arranged with the cutter handle as a center, and the distance between the two elastic blades is gradually increased from the position of the strip-shaped notch to the end away from the strip-shaped notch; and cleaning assemblies are symmetrically arranged on two sides of the elastic blades, each cleaning assembly comprises an arc-shaped shifting piece, a connecting piece, a compression spring and a brush, the connecting pieces are arranged in the arc-shaped shifting pieces, the brushes are arranged at the outer ends of the connecting pieces, and the compression springs are located between the connecting pieces and the arc-shaped shifting pieces. The device has the beneficial effects of being good in burr cleaning effect, long in service life and capable of preventing burrs on the inner wall from being bonded.

Owner:三花股份(江西)自控元器件有限公司

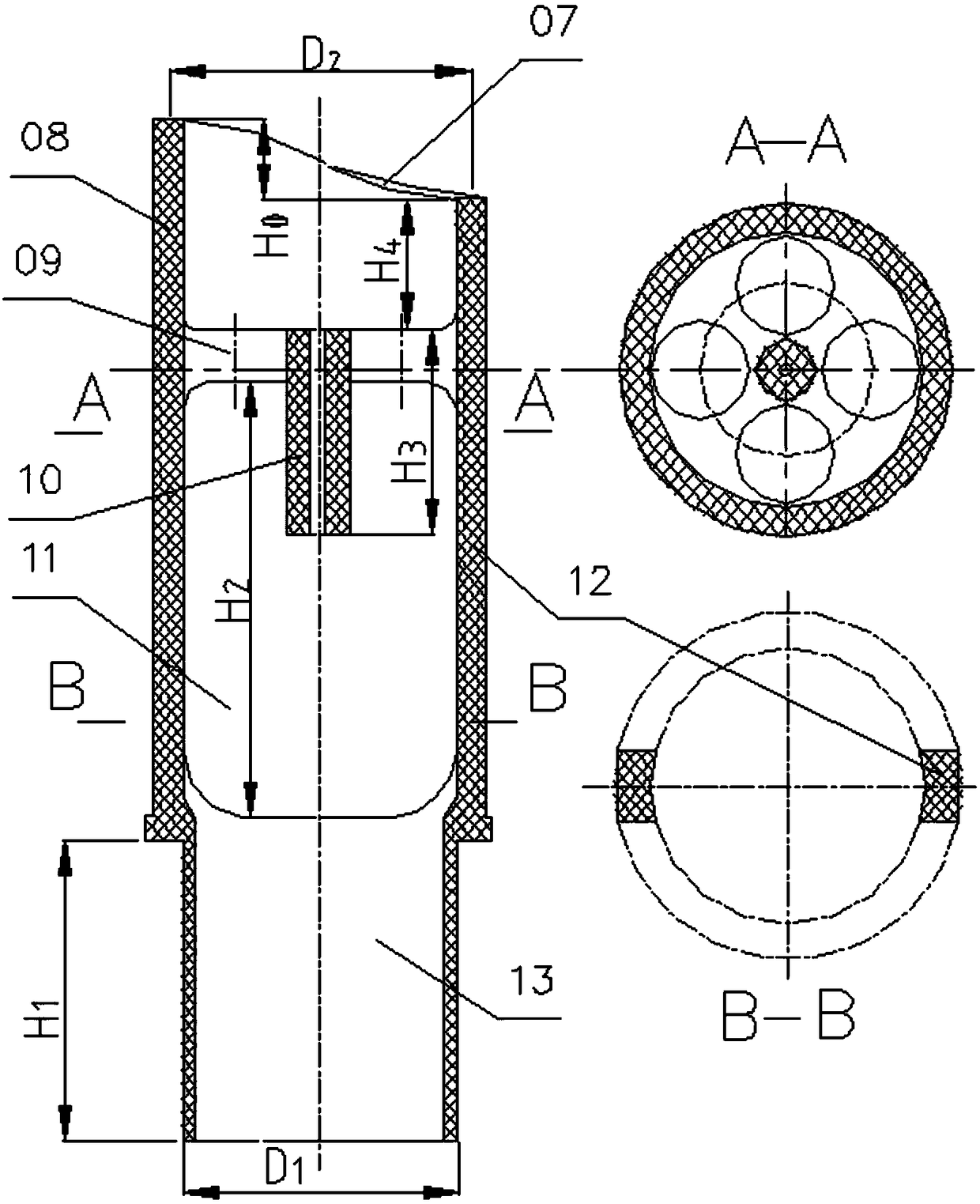

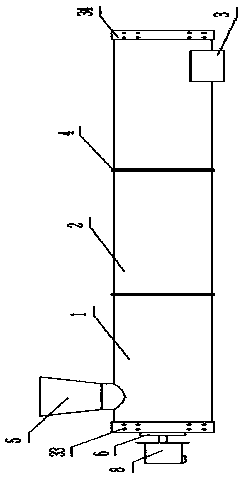

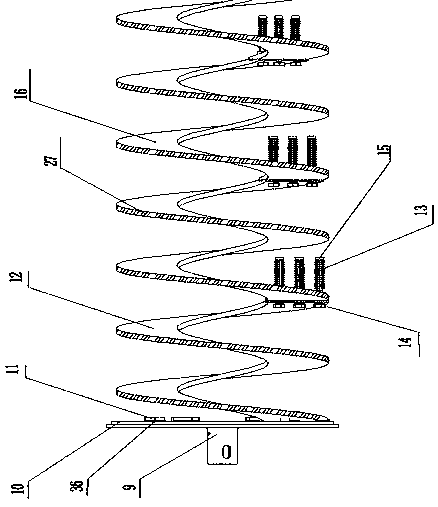

Yak feed feeding device

The invention relates to a yak feed feeding device. The yak feed feeding device comprises a motor, a motor connecting coupler and a coupler connecting shell and is characterized in that the shell comprises a first fixing seat, a plurality of sleeves connected end to end are connected to the right side of the first fixing seat, a feed inlet is welded to the upper portion of the sleeve directly connected with the first fixing seat, a flange is fixed inside the sleeve with the feed inlet, the flange is connected with a spiral end cover, spiral pieces are welded to the spiral end cover, the welding end of each spiral piece is provided with first connecting screw holes, a limit boss is connected to the outer sides of the first connecting screw holes, the other end of each spiral piece is provided with second connecting screw holes, a connecting groove is fixed to the outer sides of the second connecting screw holes, the second connecting screw holes of each spiral piece are connected with the first connecting screw holes of the corresponding adjacent spiral piece through rotary columns, a roller sleeve sleeves one end of each rotary column, a retaining plate is connected to the bottom of the spiral piece which is furthest away from the spiral end cover, a discharge outlet is welded below the last sleeve, and a second fixing seat is connected to the tail end of the last sleeve. By the yak feed feeding device convenient in maintenance and replacement, defects in the prior art can be overcome, and batch feed conveying can be achieved.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

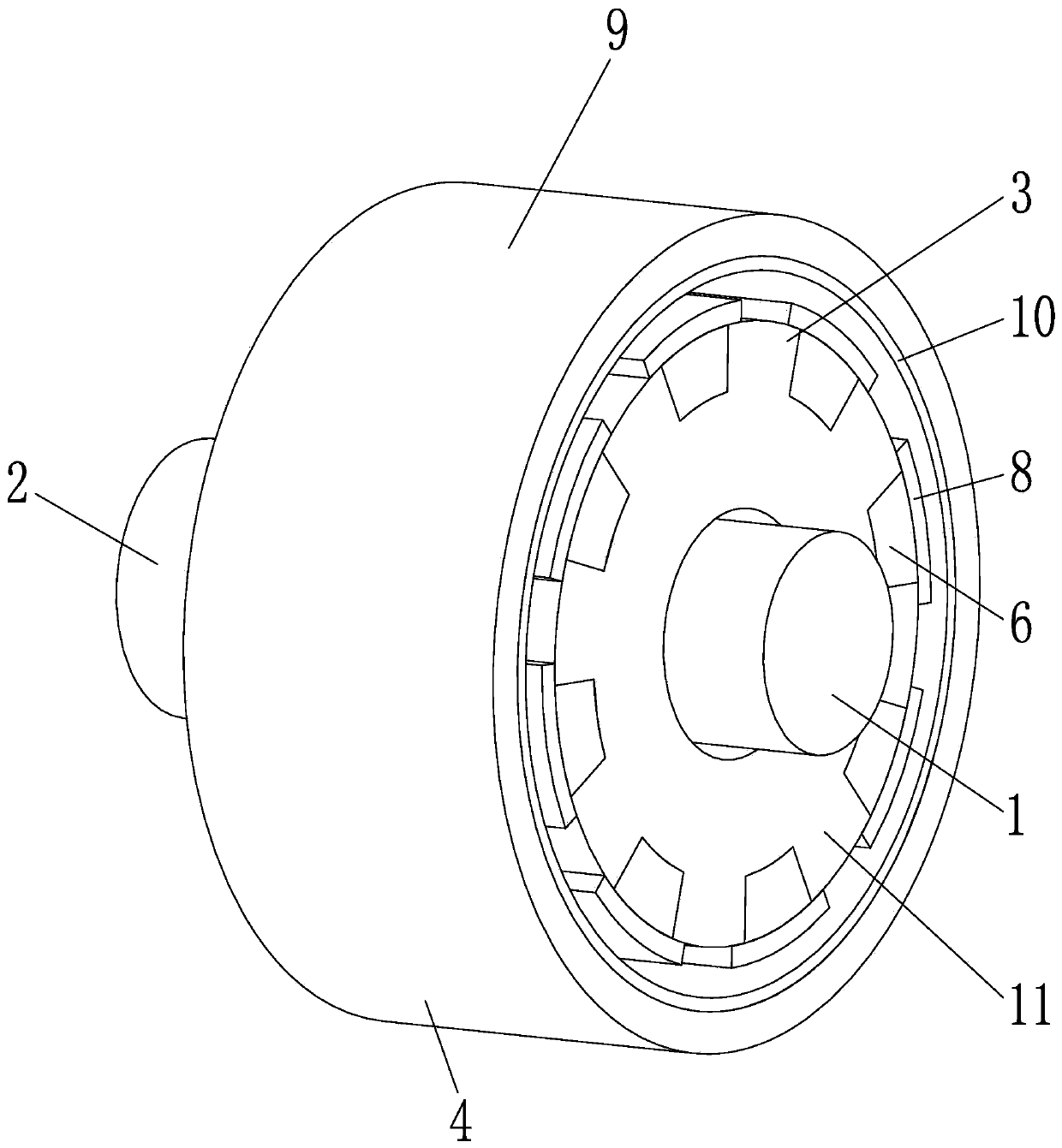

Gear hobbing machining tool and gear hobbing machining method

PendingCN108746886ALow costGuaranteed machining accuracyGear-cutting machinesGear teethHobbingEngineering

The invention discloses a vehicle part machining technology. The gear hobbing machining tool, comprises a base and an expansion sleeve which is matched with the base, wherein the expansion sleeve is used for sleeving a column body of the base, the base comprises a section of expansion sleeve mounting column which is correspondingly designed with the expansion sleeve; the contact surfaces of the expansion sleeve mounting column and the expansion sleeve are conical surfaces cooperating with each other, a plurality of expansion holes are formed in the expansion sleeve, and the outer ring surfaceof the expansion sleeve is a gear tooth mounting surface corresponding to a machined product. The expansion sleeve used in the gear hobbing machining tool is in direct contact with the machined product, so that the product cannot be directly worn on a base column body in a machining process, the expansion sleeve can be directly replaced after being worn, the whole base does not need to be scrapped, so that the cost is saved, and the machining precision is guaranteed; the desigh of the expansion holes of the expansion sleeve provides a certain counter force and buffering force, and is suitablefor installation and machining of the machined product, so that use requirements and the machining precision are better met.

Owner:BAZHONG YUXIANG MACHINERY MFG

Improved sealing ring structure for horizontal middle opening double suction pump

InactiveCN102221011AGuaranteed gap sealAvoid direct abrasionPump componentsPumpsImpellerWear resistant

The invention provides an improved sealing ring structure for a horizontal middle opening double suction pump, which can effectively solve the problem that an impeller is easy to wear because a sealing ring is directly sleeved on the impeller in the prior art so as to reduce cost for replacing and maintaining equipment. The sealing ring structure comprises a sealing ring arranged at the inlet of an impeller, and is characterized in that: an impeller wear-resistant ring is arranged between the sealing ring and the impeller; and the sealing ring is in clearance fit with the impeller wear-resistant ring.

Owner:HITACHI PUMP MFG WUXI

Pressure type temperature controller used for controlling refrigeration compressor to be on and off

InactiveCN109813019AReduce wear and tearImprove stability and securityAc-dc conversionRefrigeration safety arrangementElectricityRefrigeration compressor

The invention discloses a pressure type temperature controller used for controlling a refrigeration compressor to be on and off, and relates to the technical field of temperature controllers. The pressure type temperature controller comprises a shell, a power supply mechanism is arranged on the inner bottom wall of the shell, a conversion mechanism is arranged on the top of the power supply mechanism, two symmetric inverters are fixedly connected to the inner top wall of the shell, the output ends of the two inverters are electrically connected with first wires, a voltage stabilizer is fixedlyconnected to the inner bottom wall of the shell, the ends, away from the two inverters, of the two first wires are electrically connected with the input end of the voltage stabilizer, the power supply mechanism comprises a mobile power source, a second wire, a charging plug and a first collecting ring, the mobile power source is arranged on the inner bottom wall of the shell, the input end of themobile power source is electrically connected with the second wire, and the end, away from the mobile power source, of the second wire is electrically connected with the charging plug. The pressure type temperature controller used for controlling the refrigeration compressor to be on and off has the advantage of being high in temperature adjusting speed efficiency.

Owner:江苏汇商电器有限公司

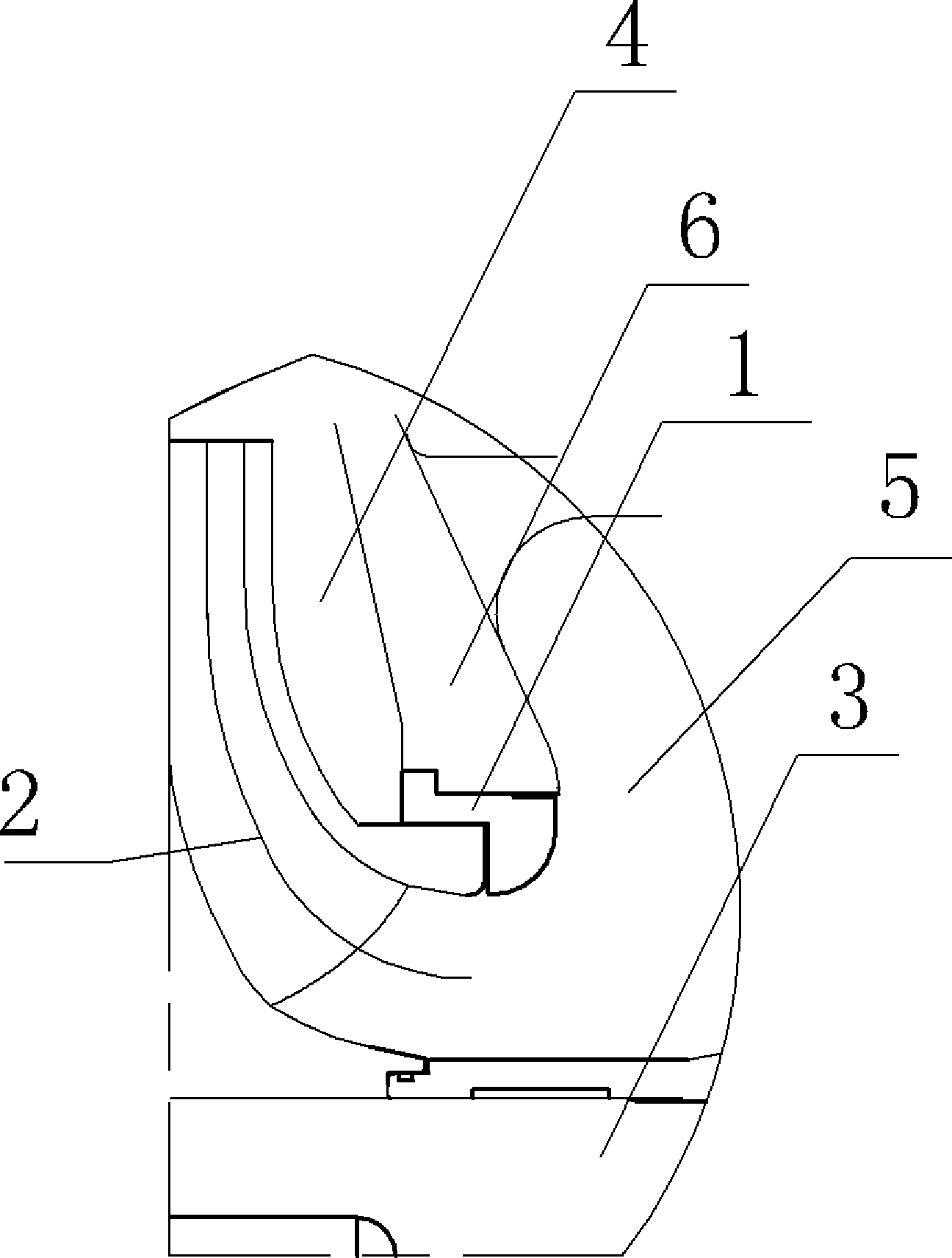

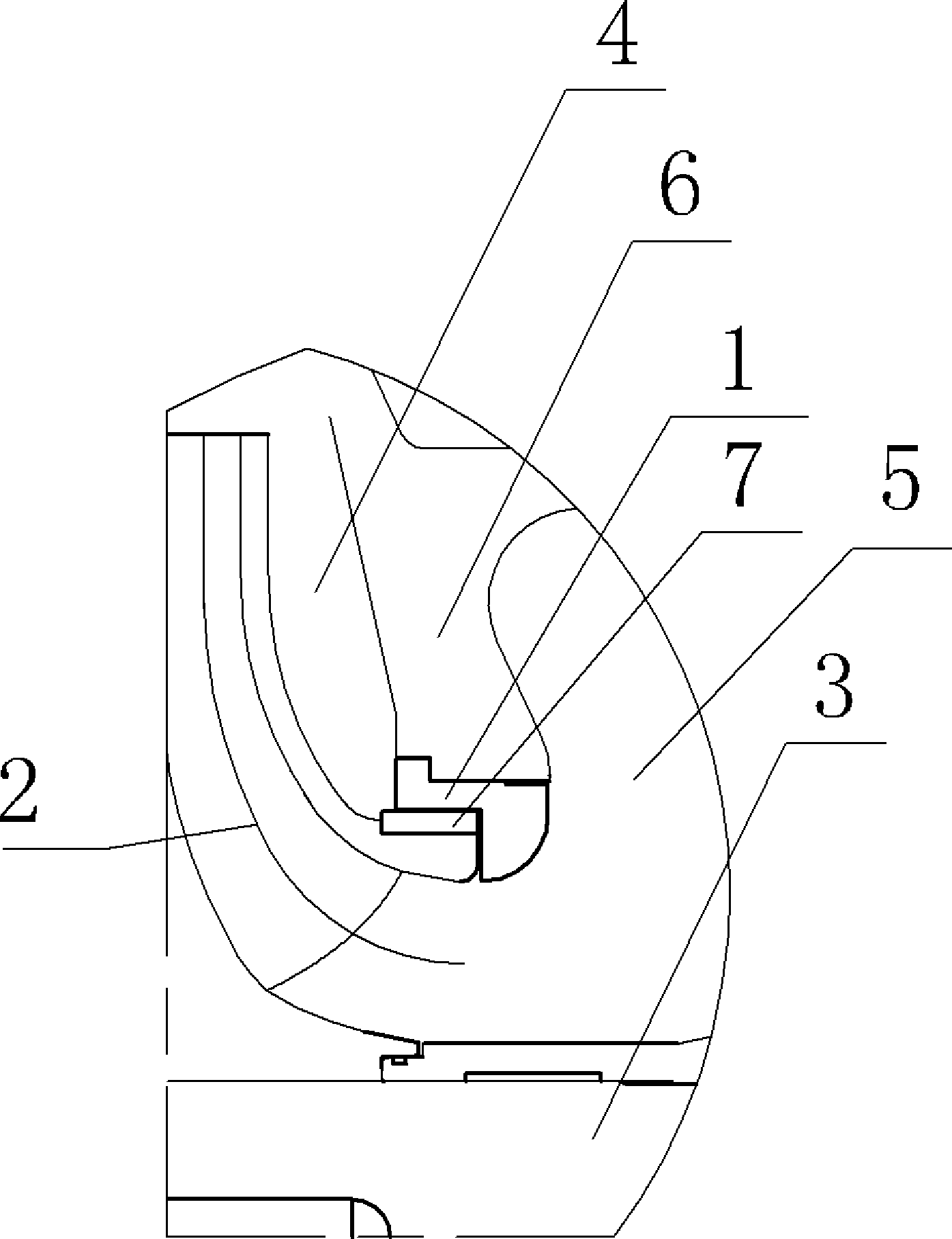

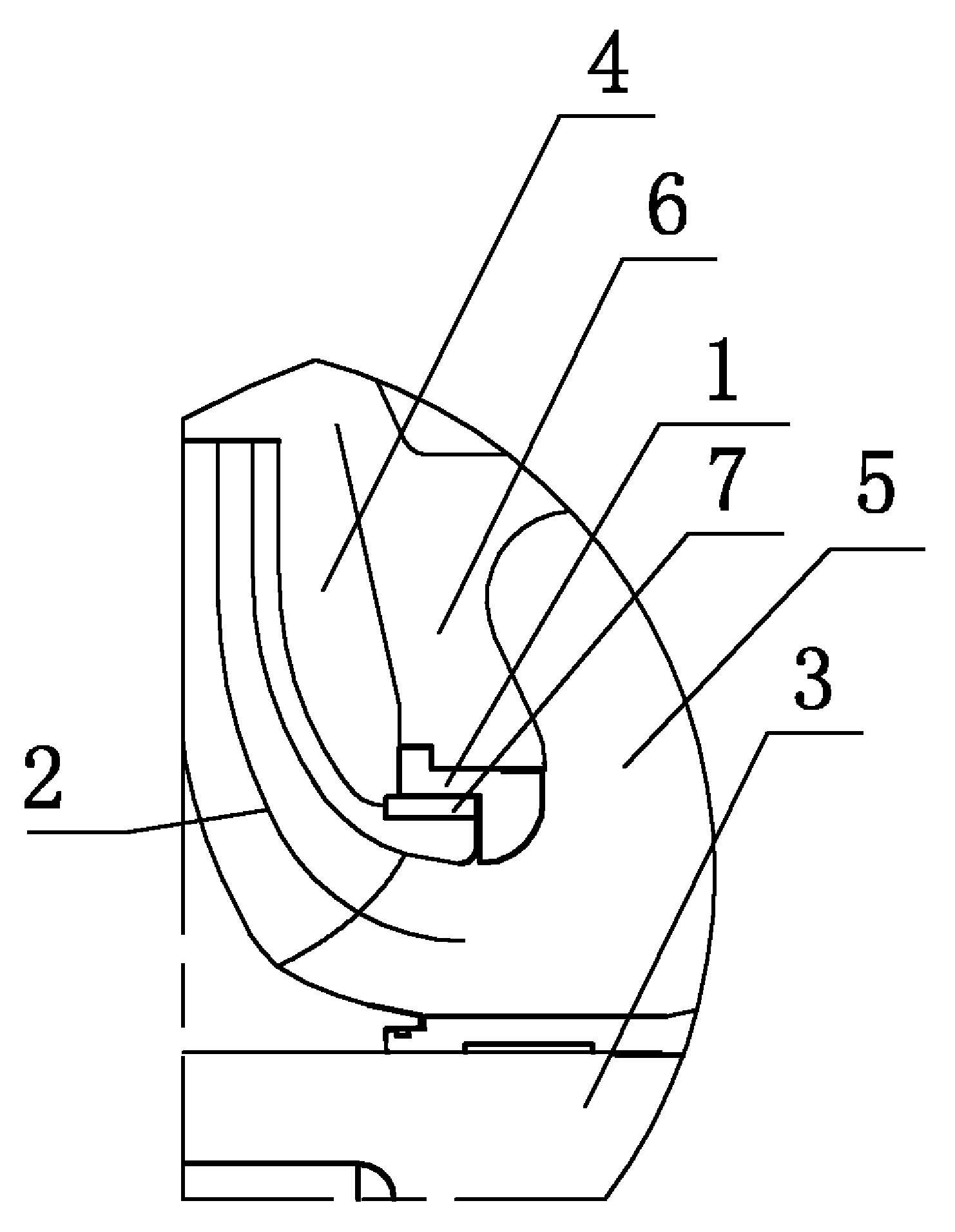

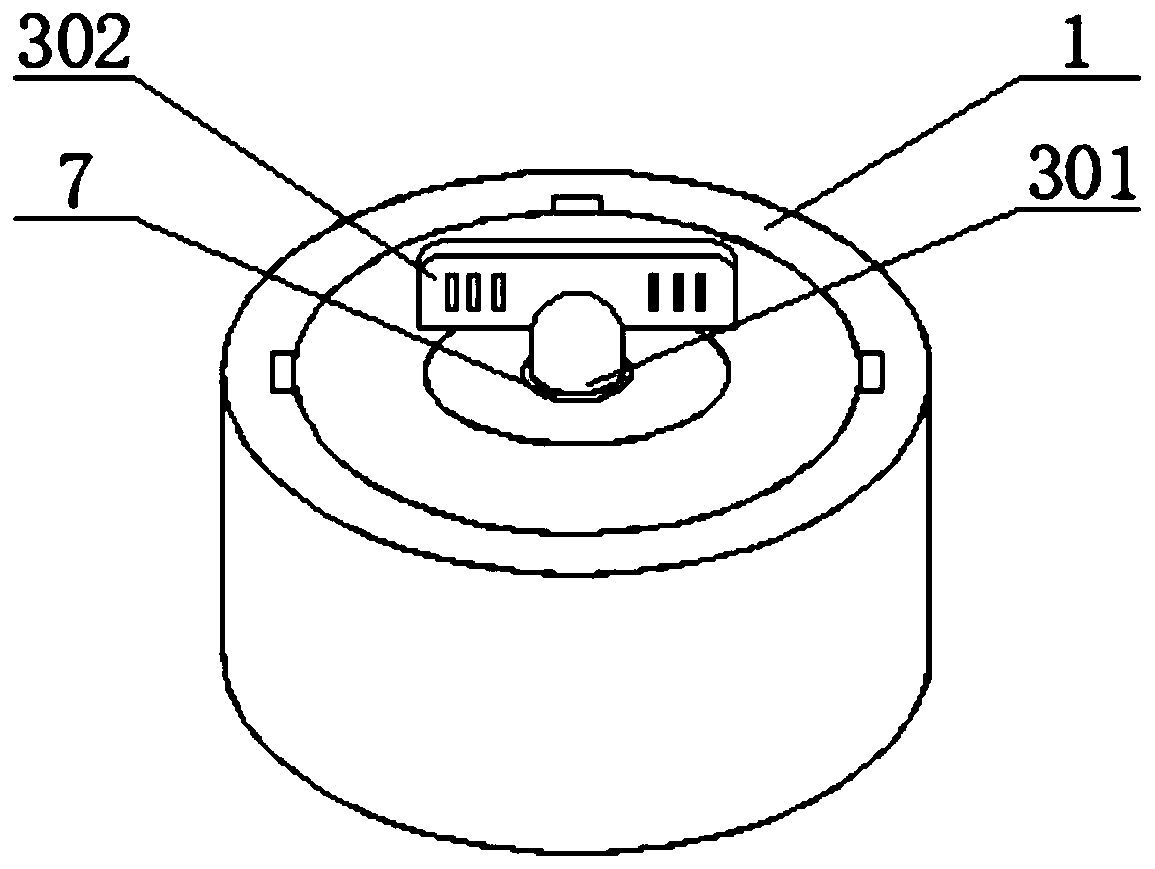

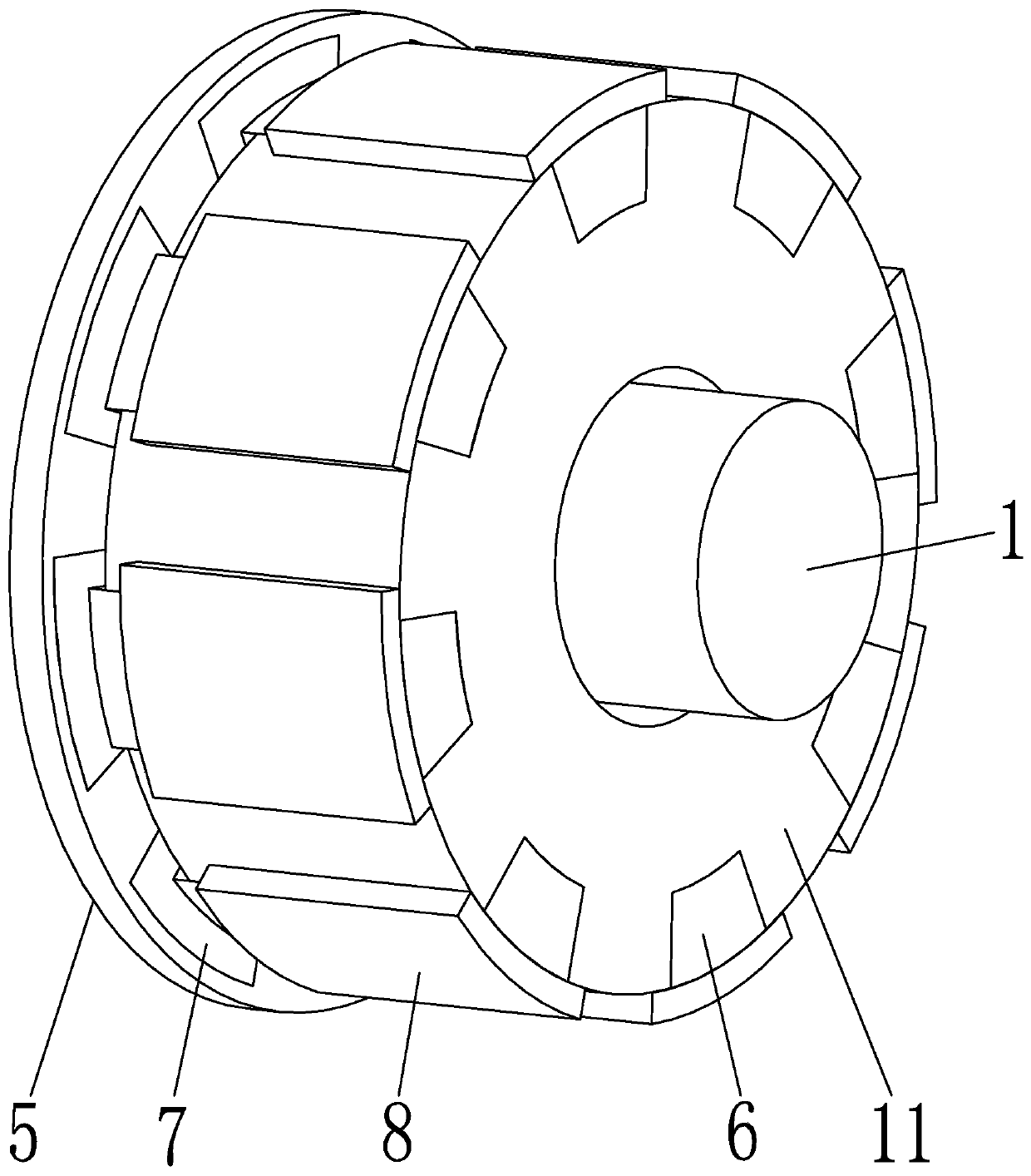

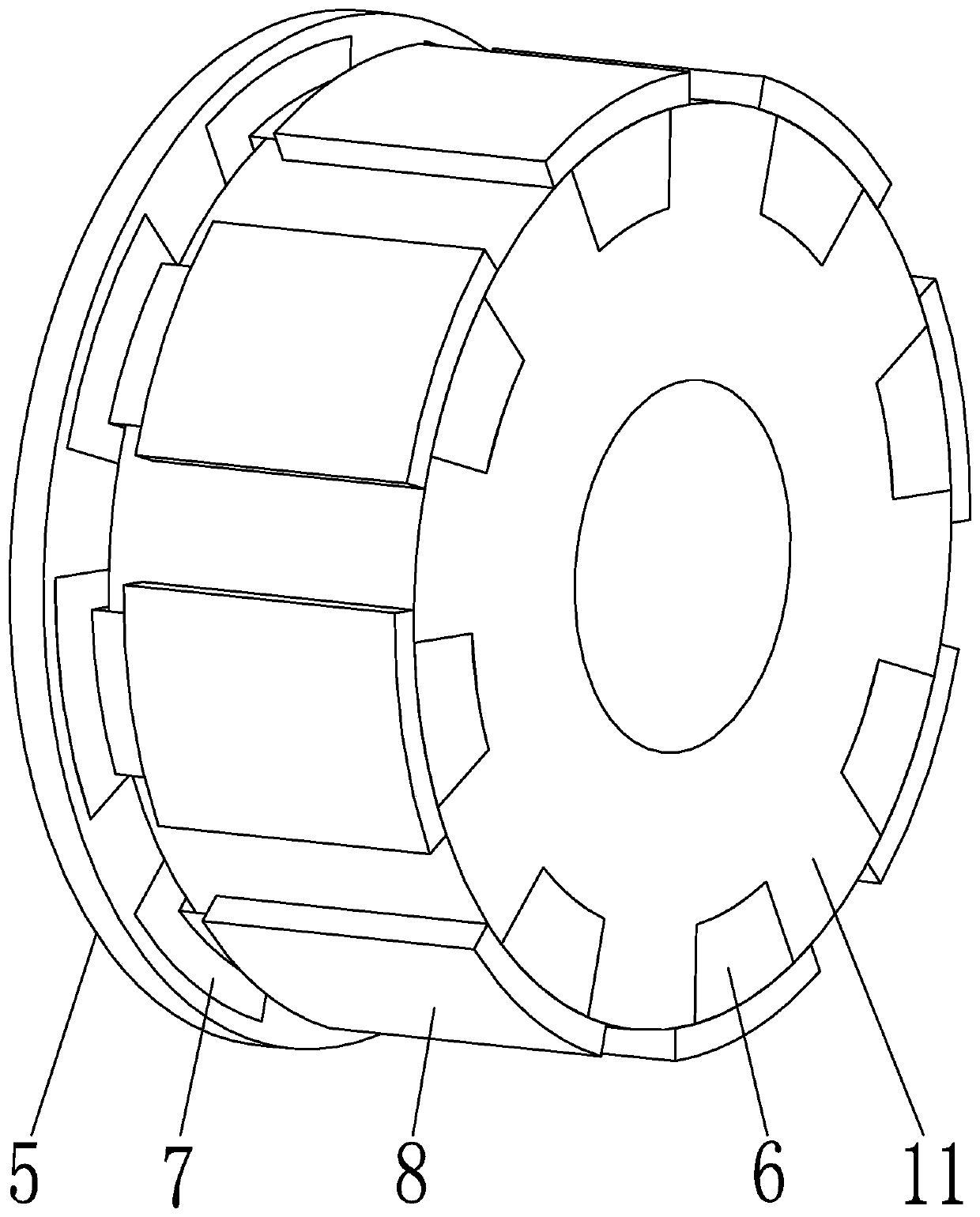

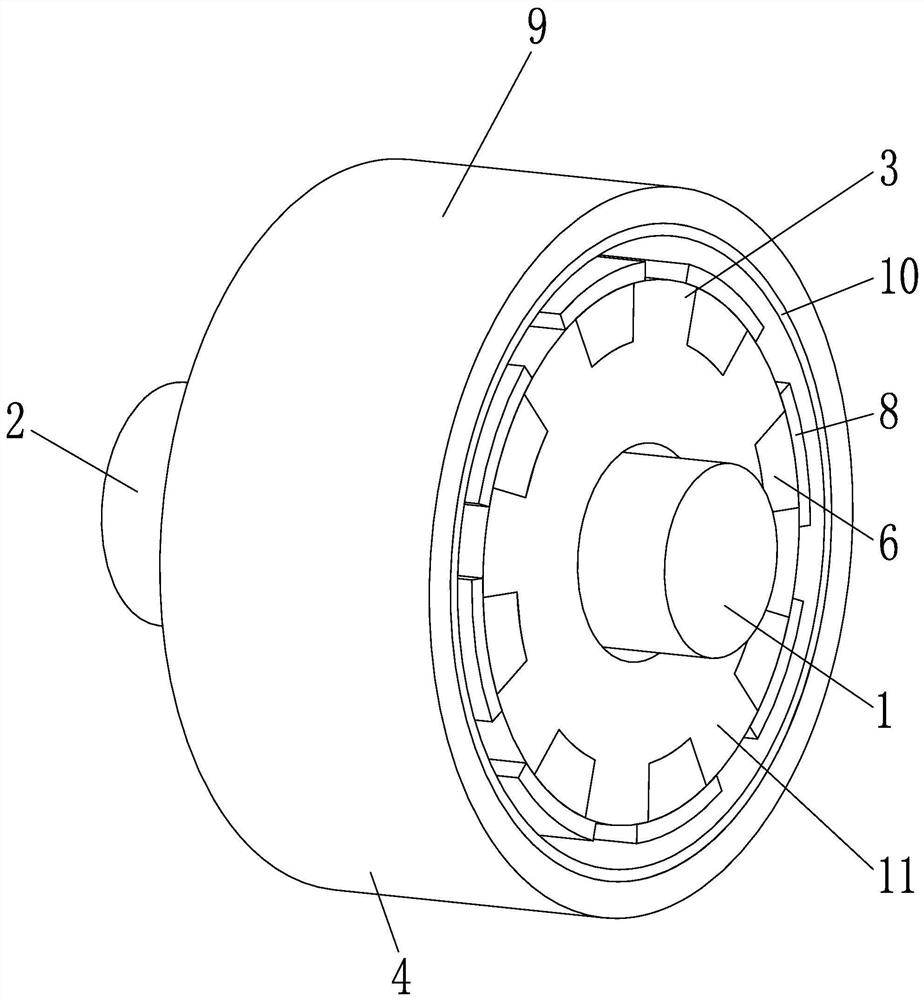

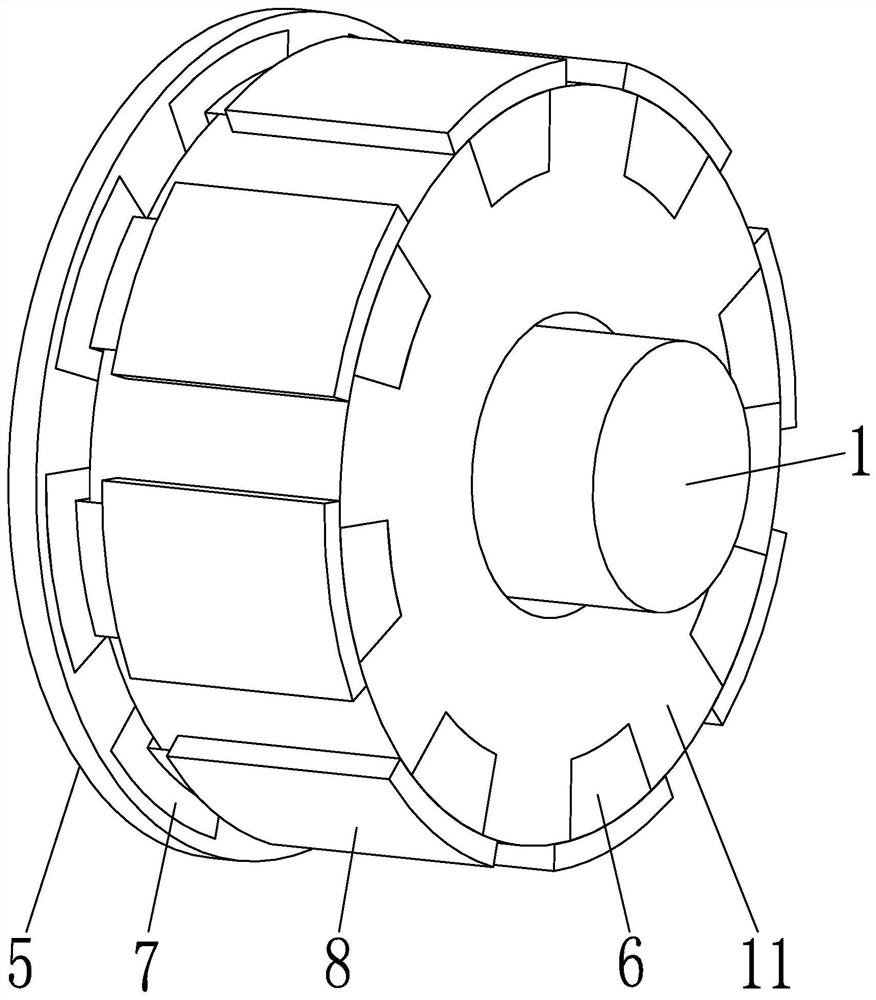

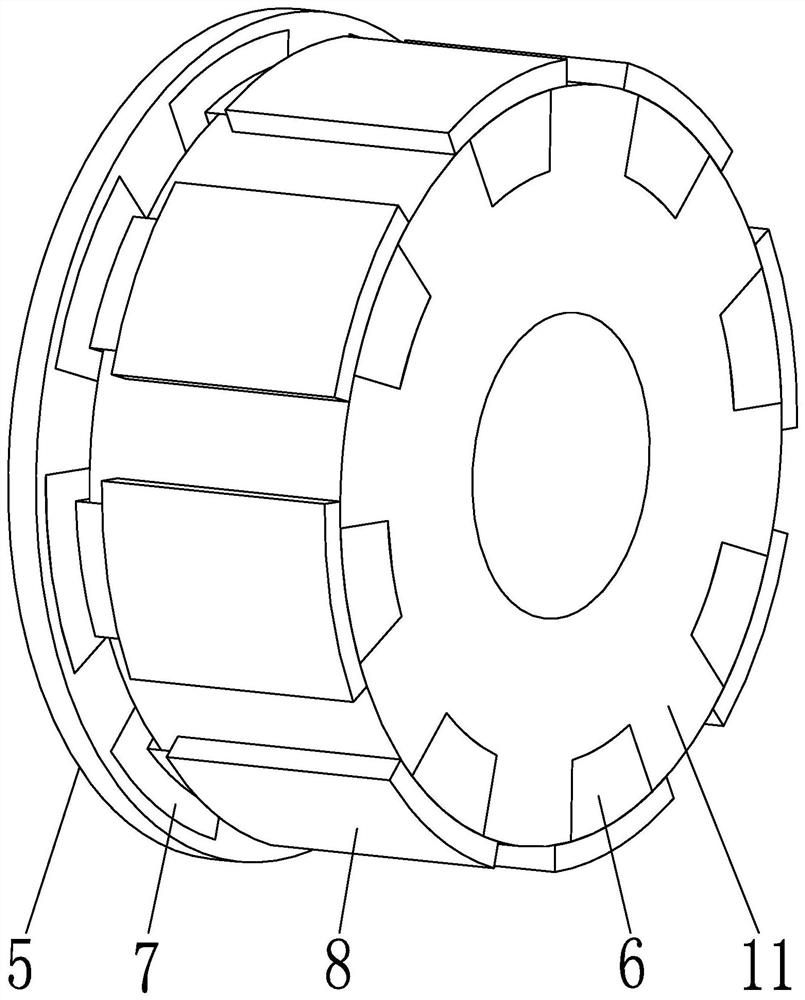

Permanent magnet clutch and assembling method thereof

ActiveCN111193378ARealize the separation functionExtended service lifeManufacturing stator/rotor bodiesPermanent-magnet clutches/brakesDrive shaftMagnetic poles

The invention discloses a permanent magnet clutch and an assembling method thereof. The permanent magnet clutch comprises a driving disc and a driven disc. The driving disc comprises a driving inner shaft, a magnet fixing disc, a plurality of first magnetic rings, a driving outer shaft, a plurality of back iron blocks and a plurality of second magnetic rings. The driven disc comprises a driven shaft, an outer sleeve and an inner sleeve. The magnet fixing disc is coaxial with the driving inner shaft, the first magnetic rings are installed on the magnet fixing disc, and the magnetic poles of every two adjacent first magnetic rings are arranged oppositely. The driving inner shaft is sleeved with the driving outer shaft, and the back iron blocks are embedded into the outer wall of the drivingouter shaft. The second magnetic rings are fixed to the driving outer shaft, and the magnetic poles of every two adjacent second magnetic rings are arranged oppositely. The second magnetic rings coverthe corresponding back iron blocks and are separated from the inner sleeve. The outer sleeve is sleeved outside the driving outer shaft, is fixed with the driven shaft and accommodates the driving disc. The inner sleeve is fixed on the inner wall of the outer sleeve. A master part and a slave part in the clutch are not in direct contact, so that mechanical abrasion of the clutch is avoided, the lubricating requirement is reduced, and the clutch has the advantages of vibration isolation and noise reduction.

Owner:HEFEI UNIV OF TECH

Imitated-marble tile

The invention discloses an imitated-marble tile comprising the following components in percentage by weight: 95-96.7% of blank, 1.5-2% of ground coat enamel, 0.15-0.9% of fancy glaze and 1.6-2.1% of transparent overglaze. The imitated-marble tile provided by the invention has the fine grain similar to that of natural marble and has the hierarchy and the transparent feeling of natural stone; flower color is in glaze to avoid that the flower color of the tile is directly abraded, thus prolonging the service life of the tile, and keeping the integrity and the naturalness of the follower color for a long term.

Owner:霍镰泉

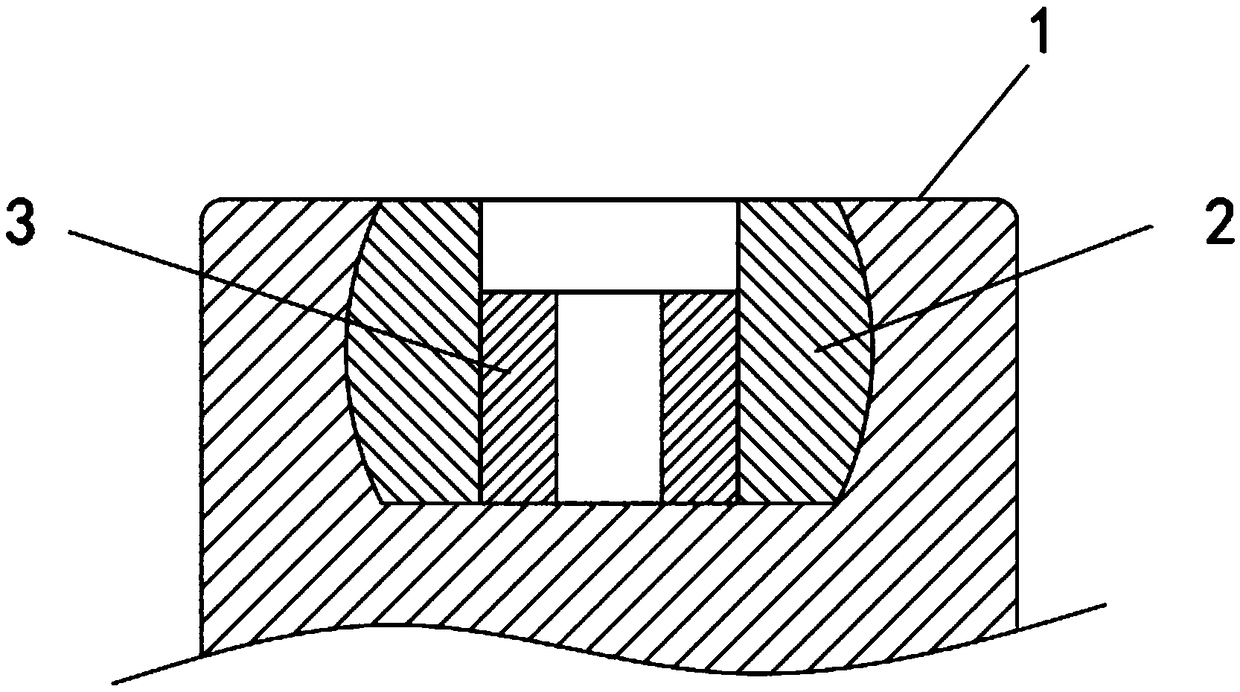

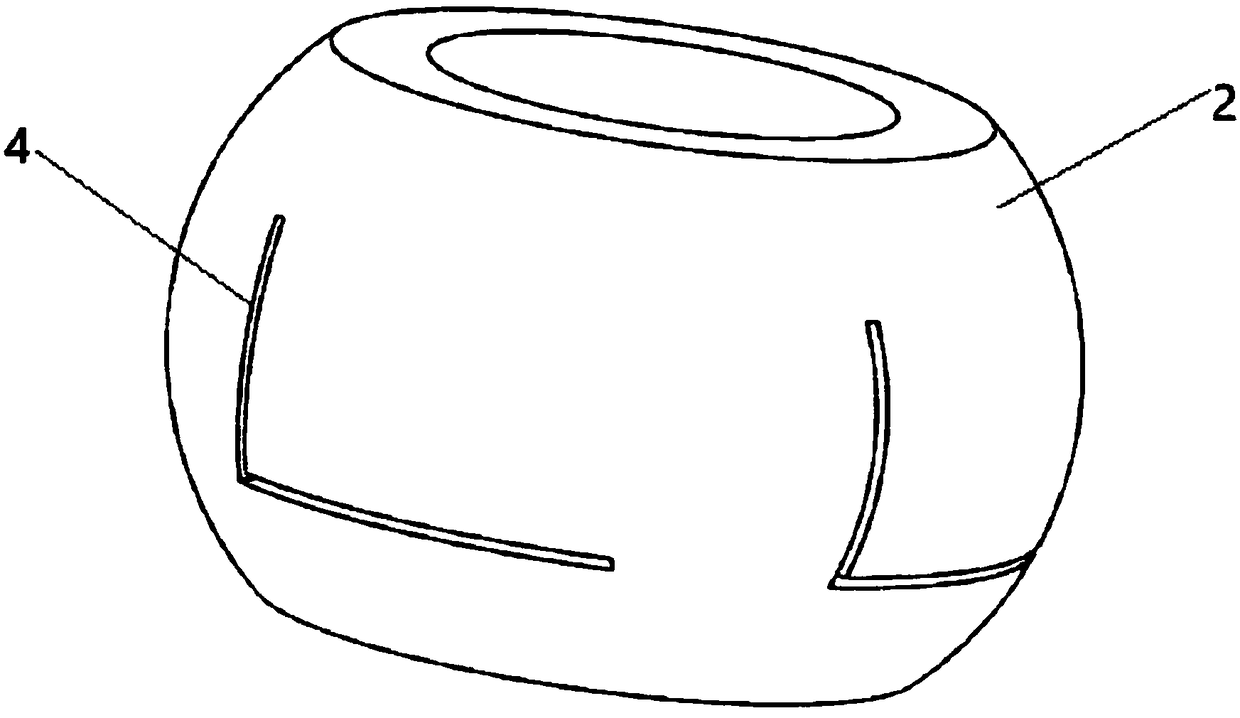

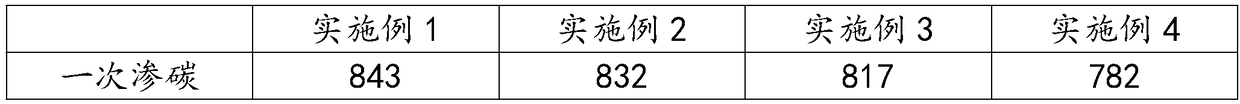

High-strength mold preparation process for automatic processing

InactiveCN109465611AAvoid damageGuaranteed service lifeSolid state diffusion coatingFurnace typesInterference fitHigh intensity

The invention discloses a high-strength mold preparation process for automatic processing, comprising a preparation step of a mold sleeve, a preparation step of an insertion ring and a preparation step of a mold core; the mold in the process comprises the mold sleeve, the insertion ring provided on the inner side of the mold sleeve and the mold core provided on the inner side of the insertion ring; the peripheral wall of the insertion ring is provided with four L-shaped through grooves, and the four L-shaped through grooves are evenly distributed in the peripheral wall of the insertion ring. The insertion ring is arranged on the inner side of the mold sleeve, and the mold core is arranged on the inner side of the insertion ring, and no interference fit is needed between the mold sleeve andthe mold core, thereby avoiding damage to the mold sleeve and the mold core during disassembly, and ensuring the service life of the mold sleeve and the mold core; the carburization is carried out twice in the process of heat treatment of the mold, the thickness of a carburized layer is increased, and the mold has high strength performance under the pressure of concentrated pressure; and the quenching oil is improved so that the quenched mold has low roughness degree and is easy to dye and electroplate, while ensuring the quality of mold quenching.

Owner:江苏雨顺自动化科技有限公司

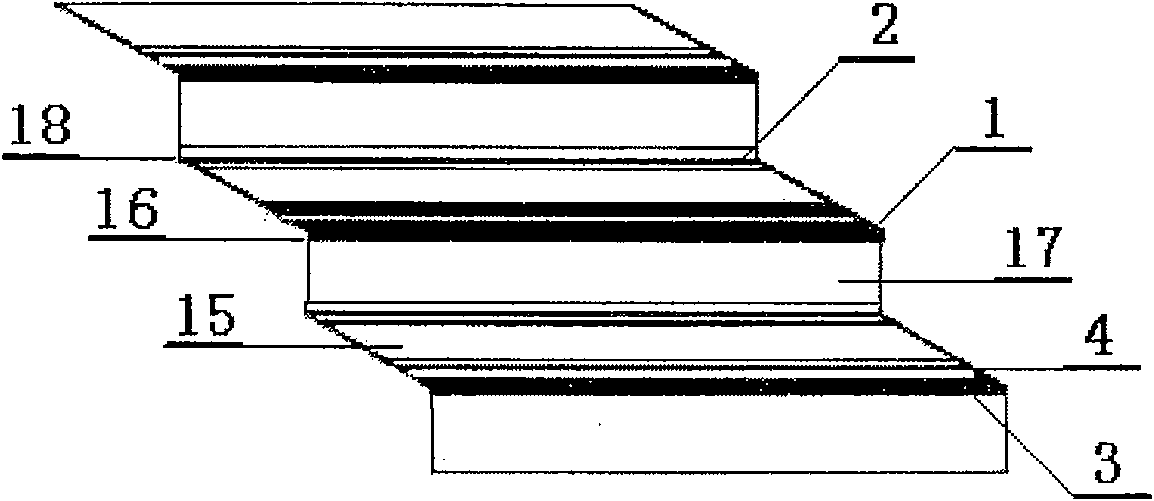

Stairs caution device

The invention relates to a stair safety attention device, which is formed by combining a bottom bed attention strip which consists of narrow bending edges and a wide main working face, and a corner attention strip which consists of a working face A and a working face B, wherein the narrow bending edges are L-shaped slats vertical to each other; the working face A and the working face B are equilateral L-shaped slats vertical to each other; the wide working face is provided with slightly convex antiskid parting strips and slightly concave green luminated attention zones and red reflective attention zones; and the working face A and the working face B are provided with green luminated attention zones and red reflective attention zones respectively. When the stair safety attention device is used, the bottom bed attention strip is arranged on an outer corner of a main face of a stair, and the corner attention strip is arranged on an inner corner of the main face of the stair; the width, depth and height of each stair are displayed through combination and match of the automatic illuminating of the green luminated attention zones, reflective prompt of the red reflective attention zones,the bottom bed attention strip and the corner attention strip, so as to provide convenience and accuracy for people to judge the stair, and effectively improve the safety for walking on the stair.

Owner:李豪

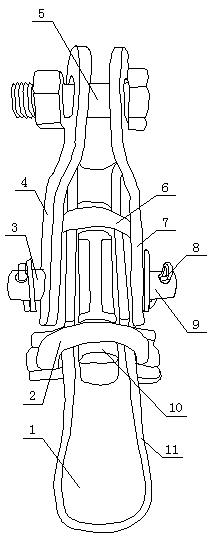

Strain clamp not needing to be wound by aluminum armor tape

PendingCN107749603AExtended service lifeReduce tanglingAdjusting/maintaining mechanical tensionSuspension arrangements for electric cablesStructural engineeringMechanical engineering

Owner:STATE GRID CORP OF CHINA +1

Method for manufacturing antifouling and antibiosis type yellow croaker net cage

InactiveCN102763610BReduce harmImprove survival rateClimate change adaptationPisciculture and aquariaAntibiosisEngineering

The invention discloses a method for manufacturing an antifouling and antibiosis type yellow croaker net cage, which relates to a method for manufacturing a mariculture net cage. According to the invention, the method for manufacturing the antifouling and antibiosis type yellow croaker net cage adopts a buoyancy force system and a netting system, and is characterized in that the buoyancy force system adopts a combination buoyancy force form of 'an anti-aging high-density polyethylene double-floating-pipe cylindrical frame structure + 18 cube cystosepiments with each edge length of 60cm; the netting system adopts a combination structure netting form of 'a first box longitudinal netting + a second box longitudinal netting + a net cage bottom netting; the net cage bottom netting is assembledon a circular high-density polyethylene pipe support which is wrapped with a layer of polyamide multifilament wrap knitting net; and three cross lacing lines are installed at the bottom of the net cage, a polypropylene rope is tied at the cross point of the cross lacing lines, and two foam float bowls which are externally wrapped by double-layer seawater corrosion protection canva and nylon nets are tied at the other end of the polypropylene rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

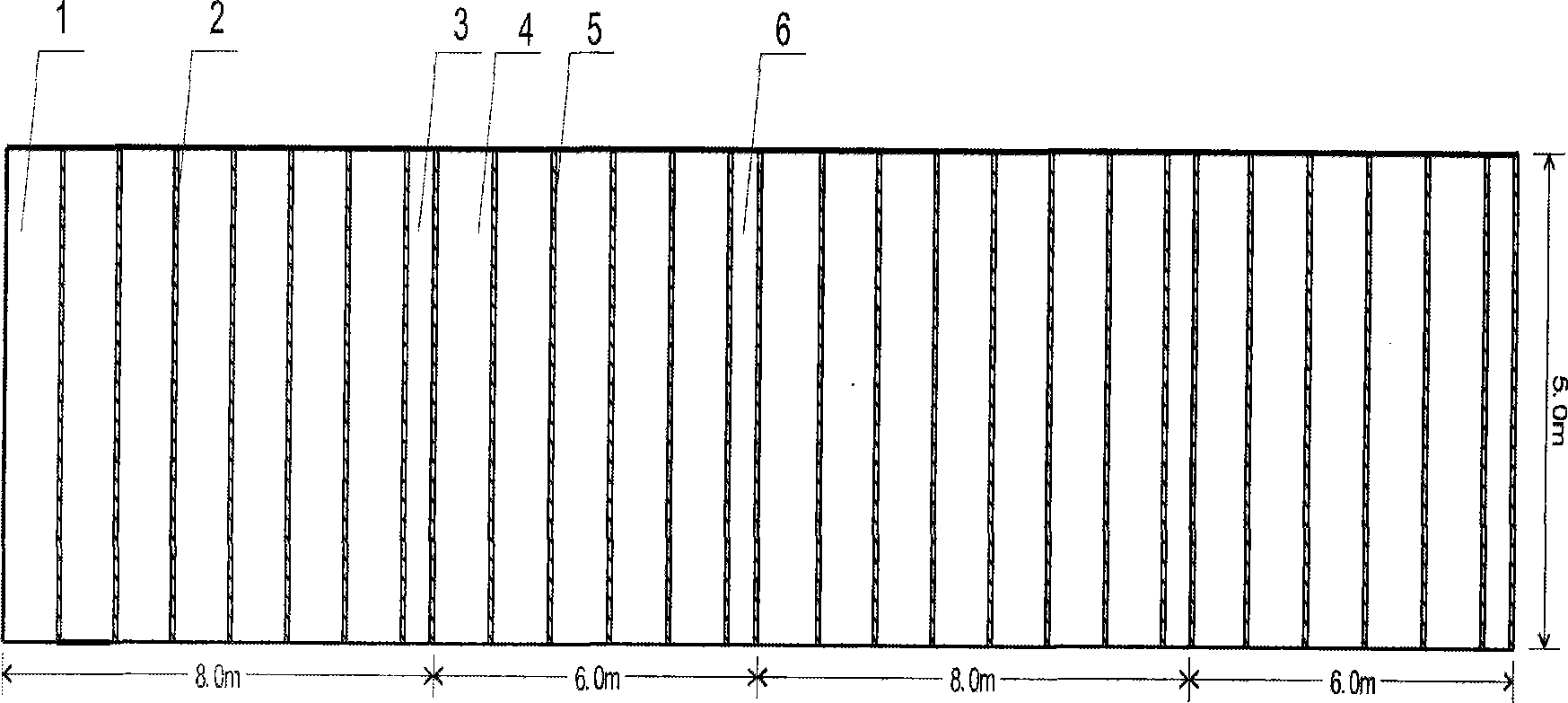

Stain-repellent stretch net cage for farming large yellow croaker

InactiveCN102763611BReduce harmImprove farming efficiencyClimate change adaptationPisciculture and aquariaMaricultureCompound structure

A stain-repellent stretch net cage for farming large yellow croaker relates to a cage for mariculture of the large yellow croaker. The stain-repellent stretch net cage for farming large yellow croaker is provided with a floating system and a net system and is characterized in that the floating system is in a rectangular frame structure with double floating pipes, the net system is in a combined structure of a longitudinal cage upper end net, a longitudinal cage lower end net and a cage bottom net; the cage bottom net is fitted on a frame wrapped with a synthetic fiber mesh, and the frame is connected with lower edge horizontal ropes of the longitudinal cage lower end net; after the longitudinal cage lower end net is connected with the cage bottom net, vertical man ropes longitudinally disposed along the longitudinal cage upper end net from upper horizontal ropes of the longitudinal cage upper end net extends to edge ropes of the cage bottom net; crossing man ropes are added to the bottom of the cage, crossing man ropes are added along diagonals of the bottom of the cage, a high-strength polypropylene rope is tied to an intersection of the two crossing man ropes arranged along the diagonals of the bottom of the cage, and a cylindrical foam float is tied to the other end of the high-strength polypropylene rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

A kind of permanent magnet clutch and its assembly method

ActiveCN111193378BRealize the separation functionExtended service lifePermanent-magnet clutches/brakesManufacturing stator/rotor bodiesDrive shaftMechanical wear

Owner:HEFEI UNIV OF TECH

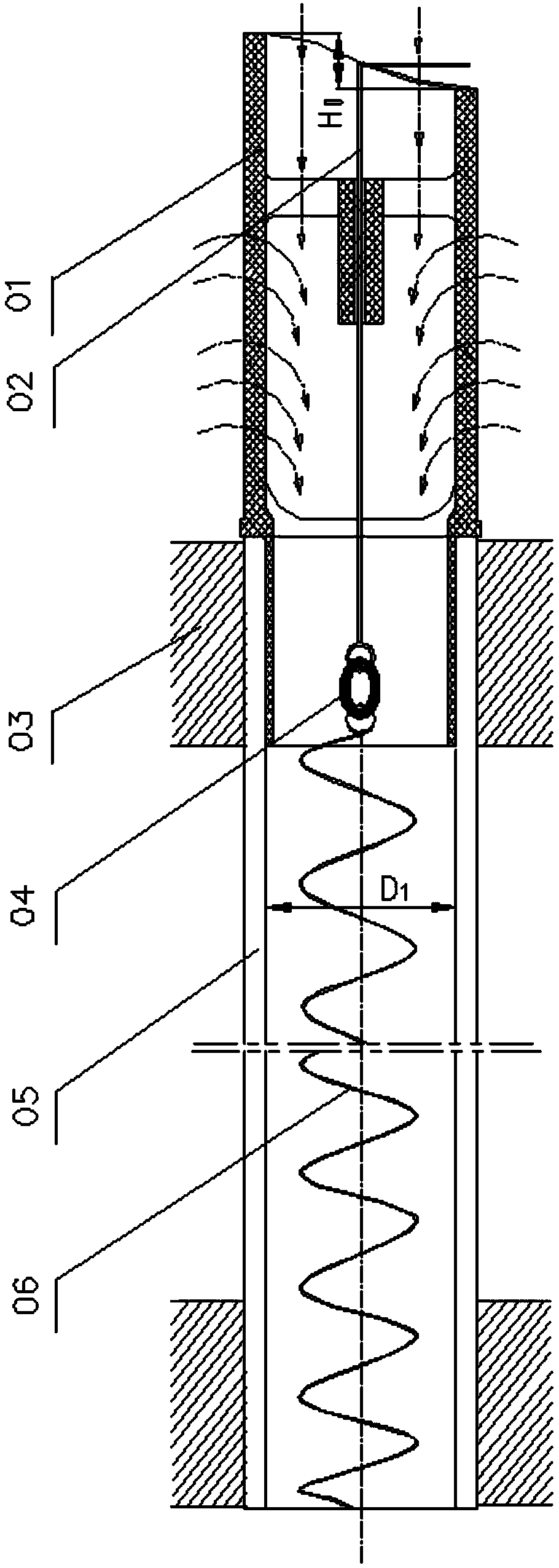

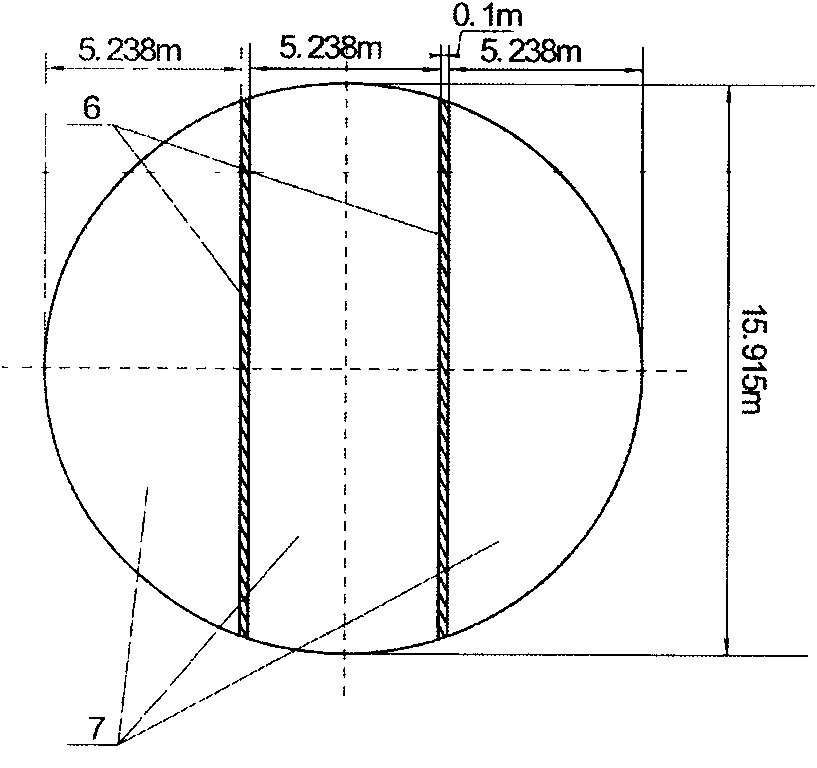

Cylindrical copper-alloy netting net cage for aquaculture

InactiveCN102239816BExtended service lifeImprove the box volume retention rateClimate change adaptationPisciculture and aquariaMooring systemPolyamide

The invention relates to a cylindrical copper-alloy netting net cage for aquaculture. The cylindrical copper-alloy netting net box adopts a high-strength single-dead-knot polyethylene-fiber net, a high-strength polyamide warp knitting net and a copper-alloy rhombic net and is characterized in that a buoyancy system of the net cage is in a combined structure of black high-density polyethylene double floating pipes and cylindrical floaters; a netting system for the net cage consists of a double-layer synthetic-fiber netting as a netting I, a copper-alloy rhombic net as a netting II and a high-strength polyamide warp knitting net as a combined netting for the bottom of a net cage body; the netting I and the netting II of the net cage body are flexibly connected by a longitudinal netting; side bolsh lines and lacing lines are assembled on the netting for the bottom of the net cage body, and horizontal lines and vertical lacing lines are arranged on the netting on the side surface of the net cage body; the combined netting for the net cage body is hung on an armrests and a floating pipe inner frame of a net cage frame; an outer frame of the floating pipe frame is connected with a floating rope frame of a fixed mooring system by mooring ropes, and the fixed mooring system of the net cage is used for fixing the floating rope frame in the sea areas for aquaculture by anchors, wood piles, anchor ropes, floating balls and floating ball connecting ropes.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

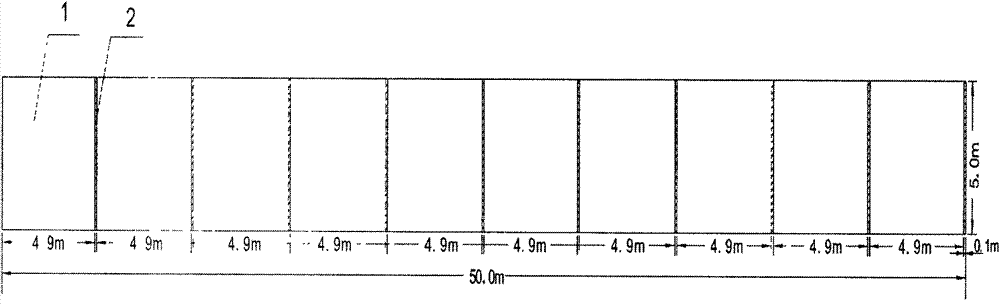

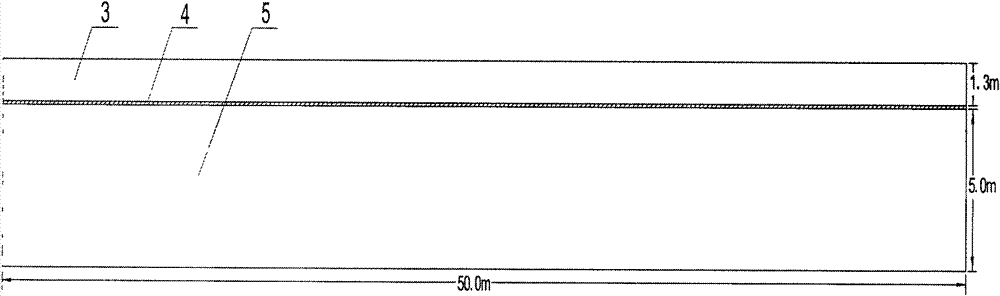

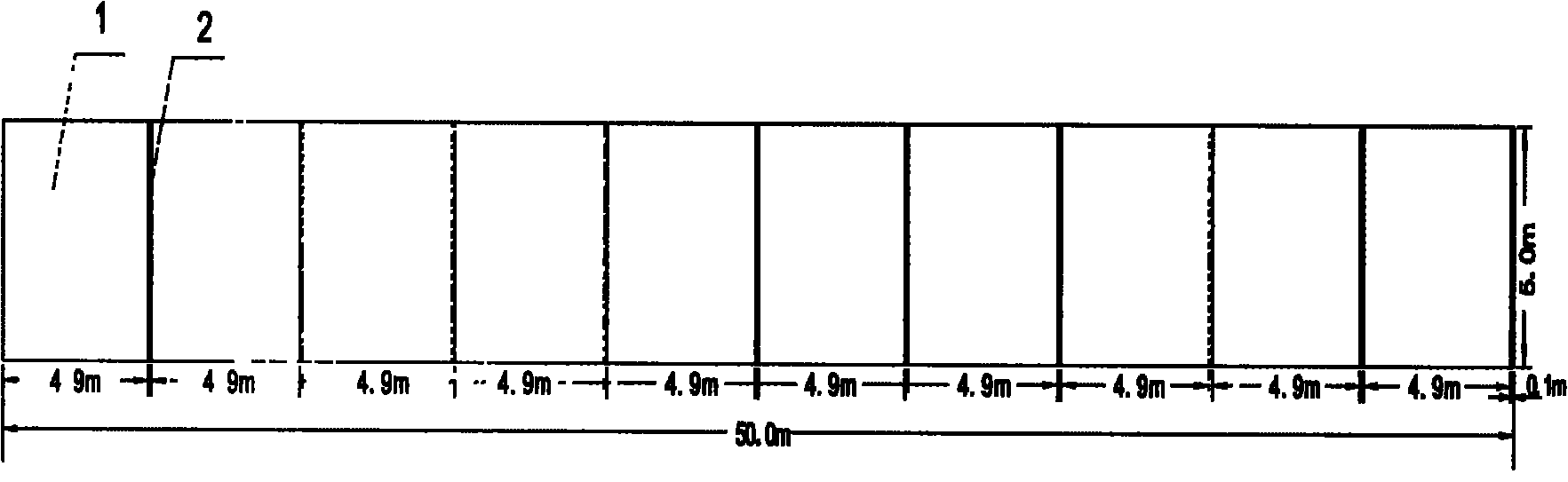

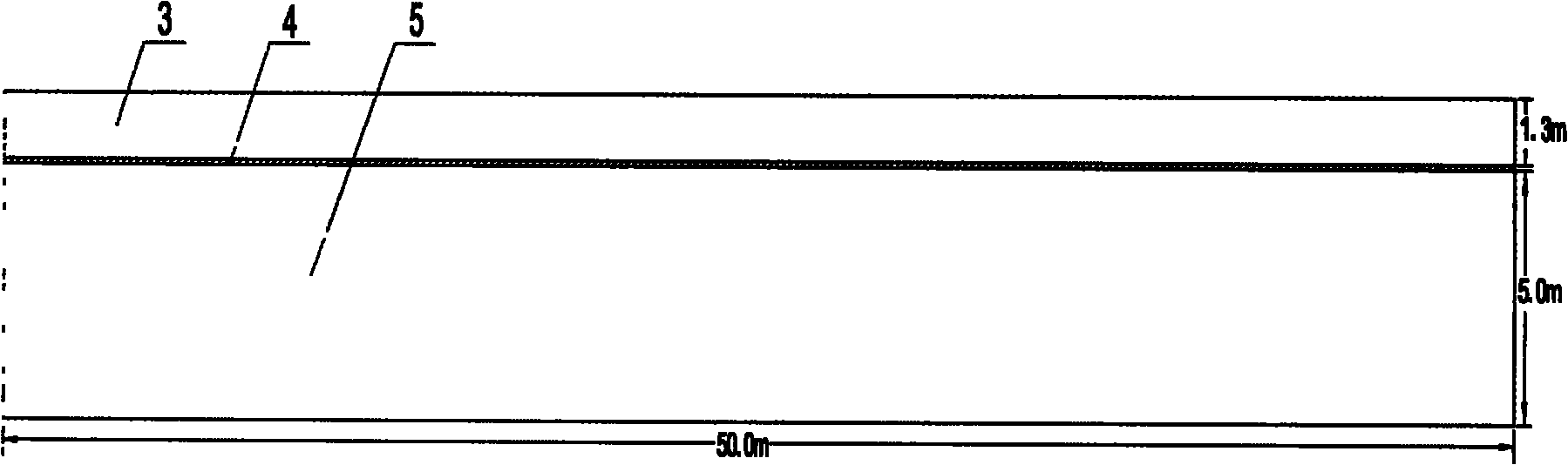

Turbot cultivation net cage having anti-pollution function

InactiveCN102308763BSolve the rustExtended service lifeClimate change adaptationPisciculture and aquariaPollutionMaterials science

The invention discloses a turbot cultivation net cage having an anti-pollution function, and relates to a turbot cultivation net cage. The turbot cultivation net cage uses a hot-dip galvanized iron pipe, a cylindrical plastic foam floating ball, a high-strength single fast knot polyethylene net, a high-strength nylon warp knitting net, an anti-pollution copper alloy rhombus net, a high-strength fishing polyethylene rope, an ultrahigh-strength rope and high-strength fishing lines and is characterized in that: a net cage floating support is welded into a top frame and a bottom frame by using the hot-dip galvanized iron pipe; the cylinder plastic foam floating ball under the lower surface of the bottom frame of the floating support is coated with waterproof cloth and a small-mesh waste netting; a netting system for the net cage consists of a double-layer synthetic fiber netting serving as a first netting and the anti-pollution copper alloy rhombus net serving as a second netting; the first netting and the second netting are connected in a vertical half-soft mode; the net bottom of the net cage is hung with a square galvanized iron pipe framework with edges of 5.0 meters; and the net cage floating support is connected with a floating rope frame through a cable and tied on a berth fixing system.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

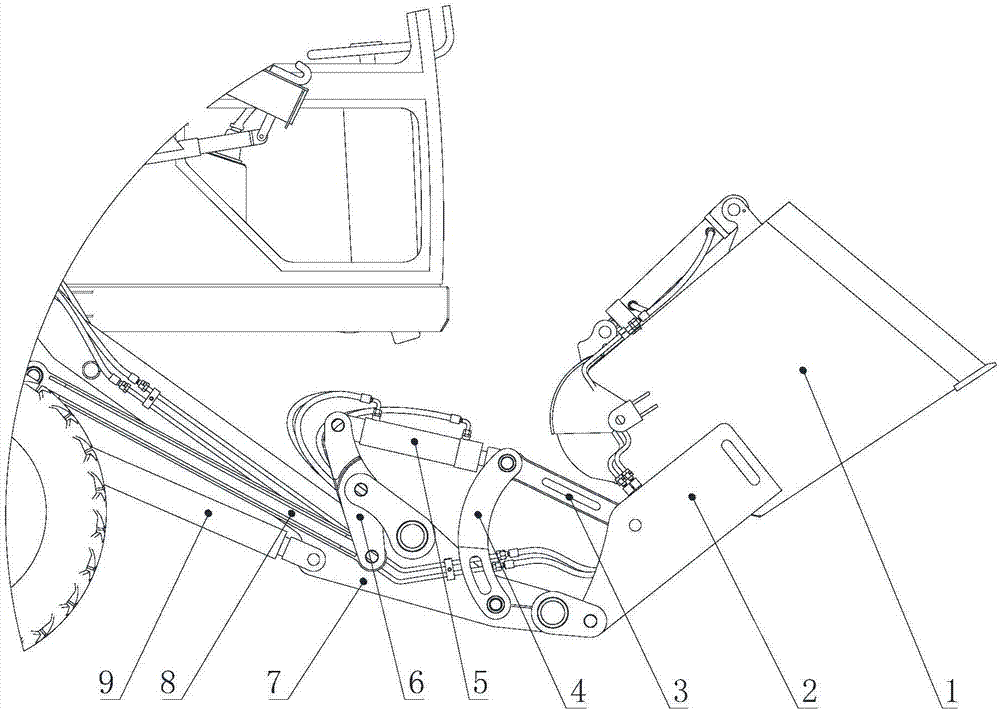

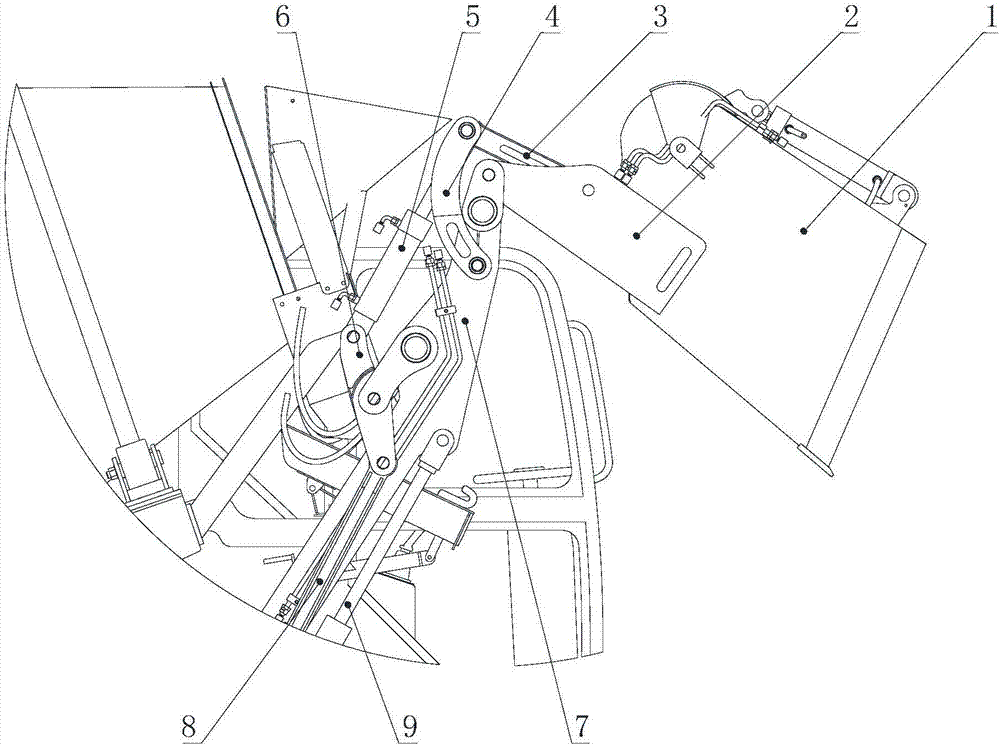

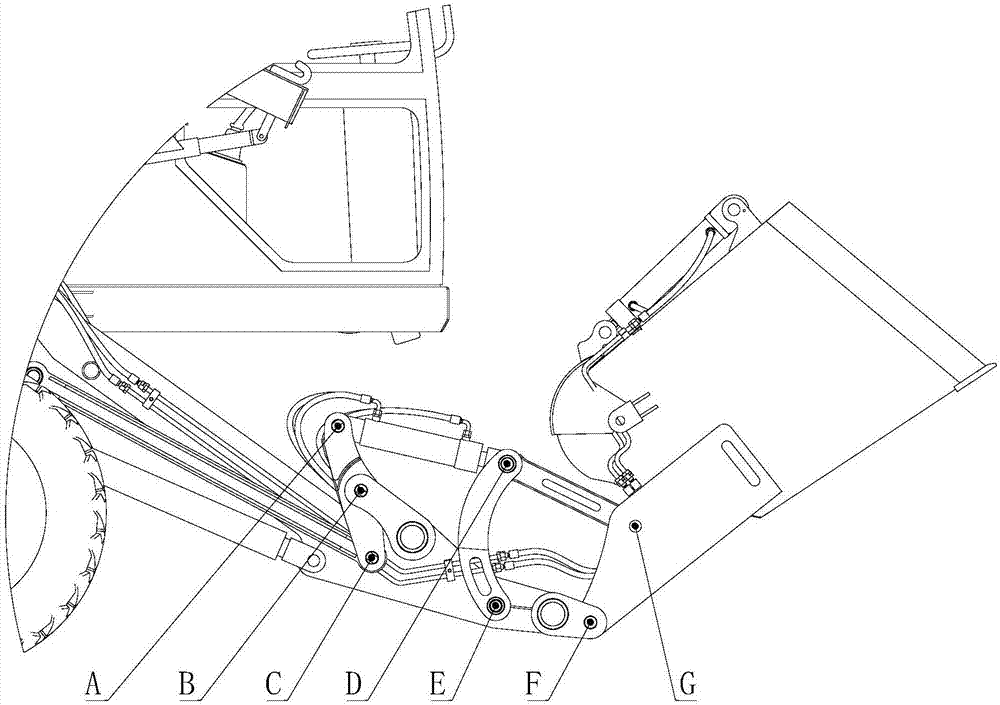

Bucket lifting mechanism and engineering vehicle using same

The invention discloses a bucket lifting mechanism and an engineering vehicle using the mechanism. The action execution part of the power device is hinged on the boom, the end of the boom is provided with the lifting and tilting device, one side of the lifting and tilting device is hinged with one end of the pull rod, and the lifting and tilting device The other side is used to connect the bucket. Using this lifting and tilting device can make the bucket complete the unloading action in the lifted state, avoiding the need to pour out the material in the bucket when the traditional self-loading mixer truck needs to first Putting down the boom, overturning the bucket to dump the material, and then retracting and lifting the bucket is complicated and time-consuming. An engineering vehicle uses the above-mentioned bucket lifting mechanism to load, unload, transfer, and accumulate other materials and garbage, and realize "one machine with multiple functions".

Owner:莱州市鲁樽机械有限公司

Combined box body system used for floating net cage and mated frame system thereof

ActiveCN102239814BImprove the box volume retention rateImprove antifouling functionClimate change adaptationPisciculture and aquariaPolyamideBuoy

The invention provides a combined box body system used for a floating net cage and a mated frame system thereof, relating to a seawater cultivation floating net cage. A copper alloy inclined square mesh, a copper alloy weaving mesh, high-strength polyamide warp knitting fishnet, ropes, a galvanized iron pipe and foam buoys. The combined box body system is characterized in that a floating net cageframe system comprises two rows of square galvanized iron pipe frames; the foam buoys are distributed below the two rows of galvanized iron pipe frames; the fishnet system of a net cage body combinesa first high-strength polyamide warp knitting fishnet, a second copper alloy inclined square mesh and the copper alloy weaving mesh used for the bottom of the net cage'; the edge installing wire ropeof the fishnet at the bottom of the net cage is assembled on a square high-strength polyamide pipe frame; the high-strength polyamide pipe frame and a horizontal wire rope at the lower edge of the second copper alloy inclined square mesh are connected by an ultrahigh-strength rope; and a vertical force net is installed in the vertical direction of the fishnet and extends to the edge wire rope of the copper alloy weaving mesh used for the bottom of the net cage.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com