Patents

Literature

79results about How to "Improve equipment level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sublevel shrinkage caving stage open stope afterwards filling mining method

InactiveCN101881169ALarge amount of filling at one timeIncrease production capacityUnderground miningSurface miningEarth surfaceComputer science

The invention discloses a sublevel shrinkage caving stage open afterwards filling mining method. In the earlier stage of stoping, caved ores are utilized to support surrounding rocks on a top tray, and in the later stage of stoping, a goaf area is filled with fillers to control ground pressure so as to achieve safe and efficient mining. Ore blocks are mined in two steps, mining blocks in step two are stoped after the mining blocks in step one are stoped and filled. After the ores are completely let out, the goaf area is filled with the fillers to control the ground pressure. Because the stoping modes of sublevel ore caving, sublevel shrinkage, final ore drawing and empty area afterwards filling are adopted, the mining method has large one-time filling amount and low cost; the method adopts middle-deep hole drilling and blasting and carry scraper ore removal, and the device has high level and large production capacity; the method has the advantages of large production capacity of the sublevel caving method and the stage open stope method, high recovery rate of the filling method, and earth surface protection; the safety is good, and drilling, ore removal and other operations are all carried out in a sublevel drilling and ore removal approach roadway; and the ores can be removed in advance, and the ores can be removed partially after the first sublevel is ready.

Owner:NORTHEASTERN UNIV +1

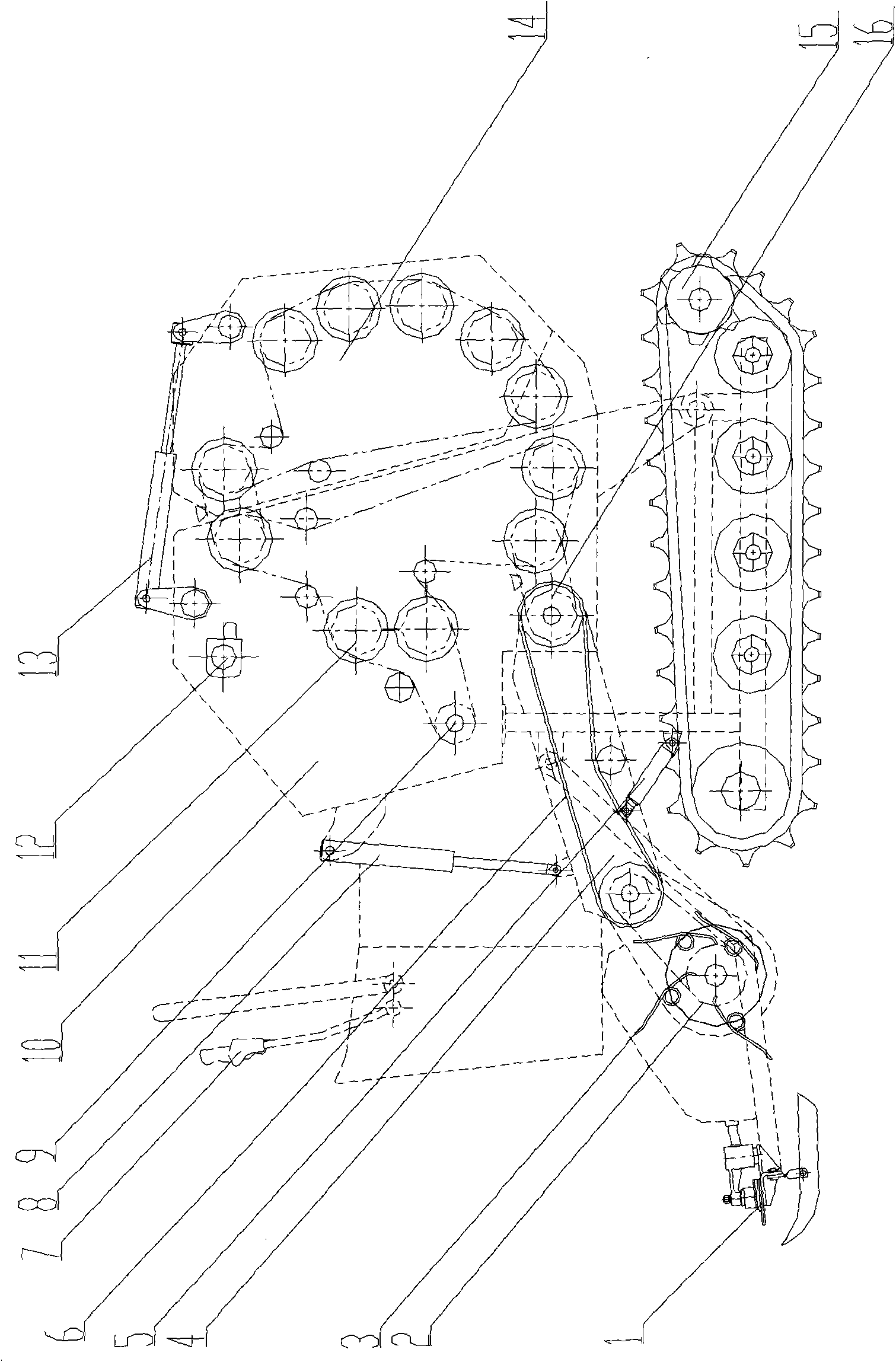

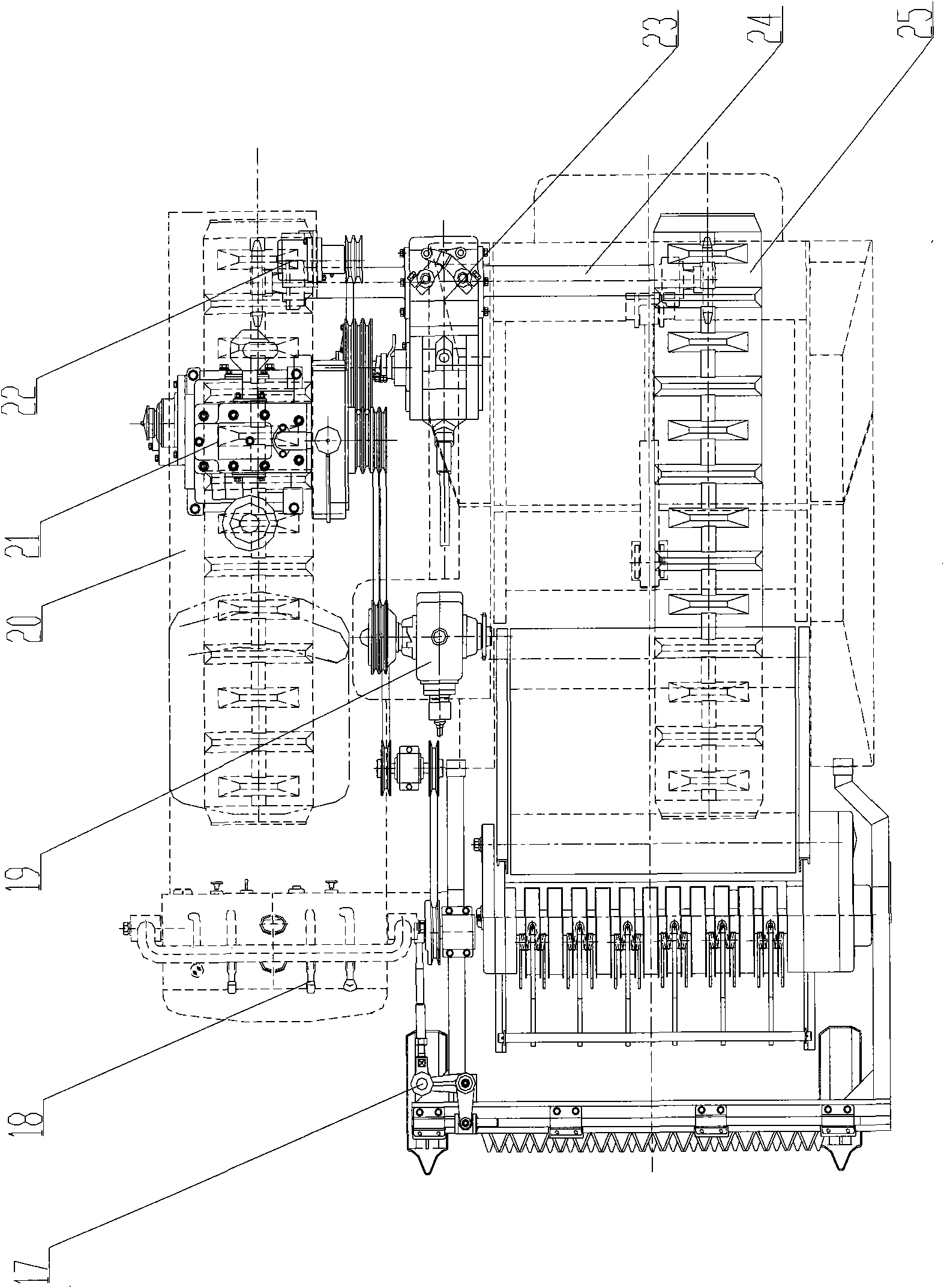

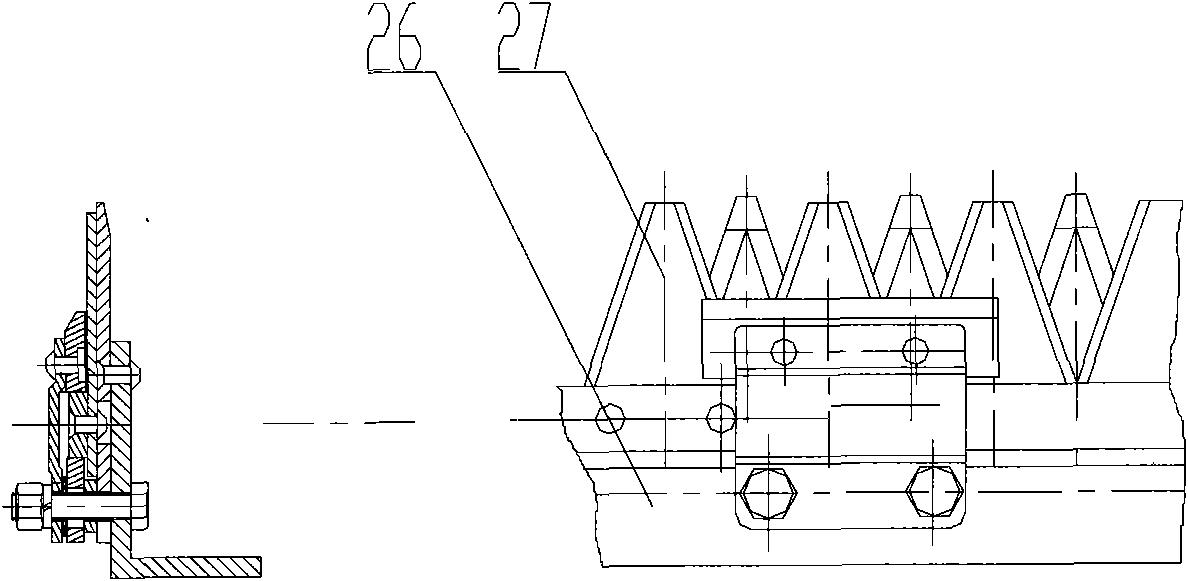

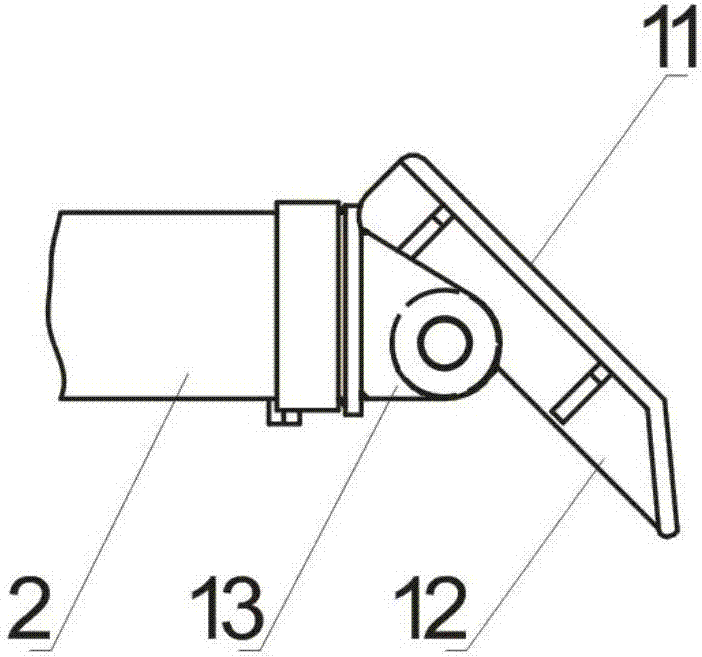

Method for cutting, picking up and bundling straw stalks and device thereof

InactiveCN101622927AImprove work efficiencyReduce labor intensityLoadersAgricultural undercarriagesAgricultural engineeringControl theory

The invention discloses a method for cutting, picking up and bundling straw stalks and a device thereof. The invention is characterized of adopting a self propelled chassis which takes a rubber track as a walk part, and installing a set of device for cutting, picking up and bundling the straw stalks especially for recycling the straw stalks on the chassis. The device for cutting, picking up and bundling the straw stalks adopts the self propelled chassis which takes the rubber track as the walk part; the chassis is provided with a stander; the stander is provided with an engine; the output shaft of the engine is provided with two sets of belts; one set of belt is connected with a walk speed changer by a rubber belt; the other set of rubber belt on the engine is connected with a work speed changer of the device for cutting, picking up and bundling the straw stalks; one end of the output shaft of the a work speed changer is provided with a belt wheel and is connected with the device for cutting, picking up and bundling the straw stalks by the belt; and the output shaft of the other end of the work speed changer is connected with a device for picking up and bundling by means of chain drive.

Owner:株洲联合收割机有限公司

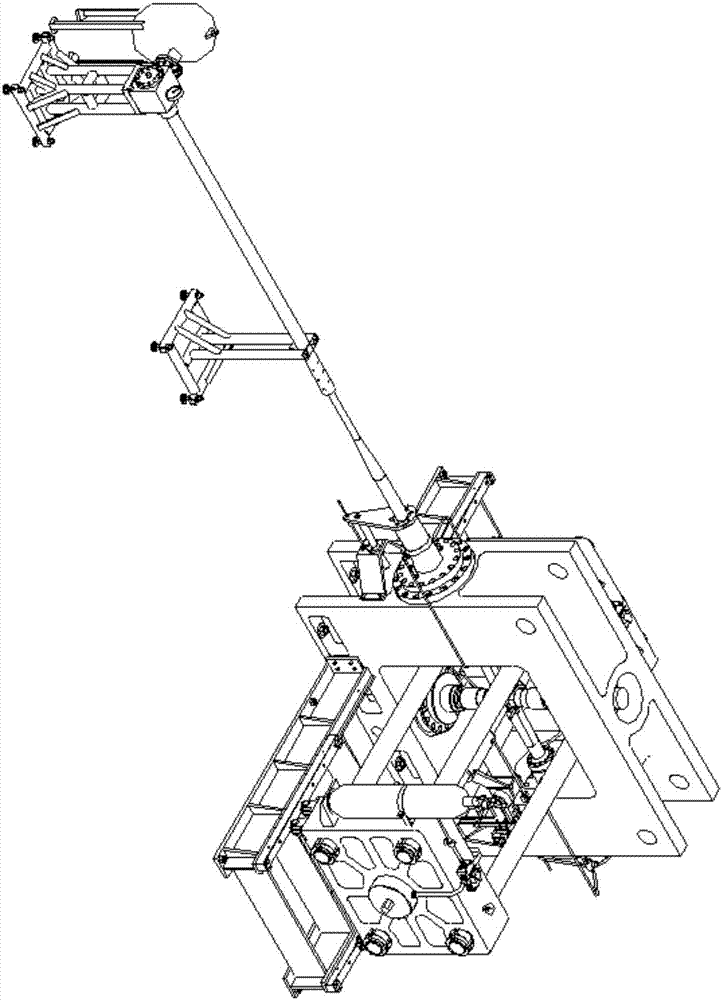

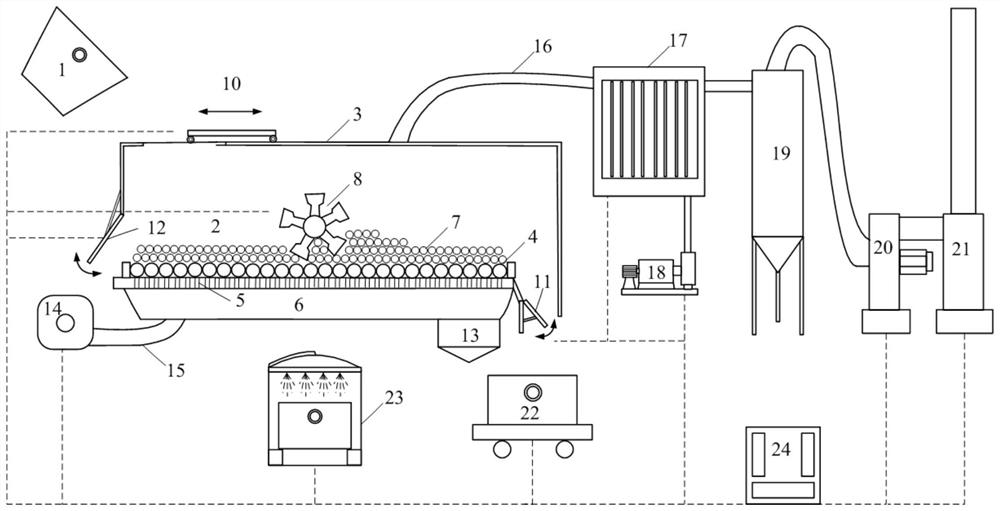

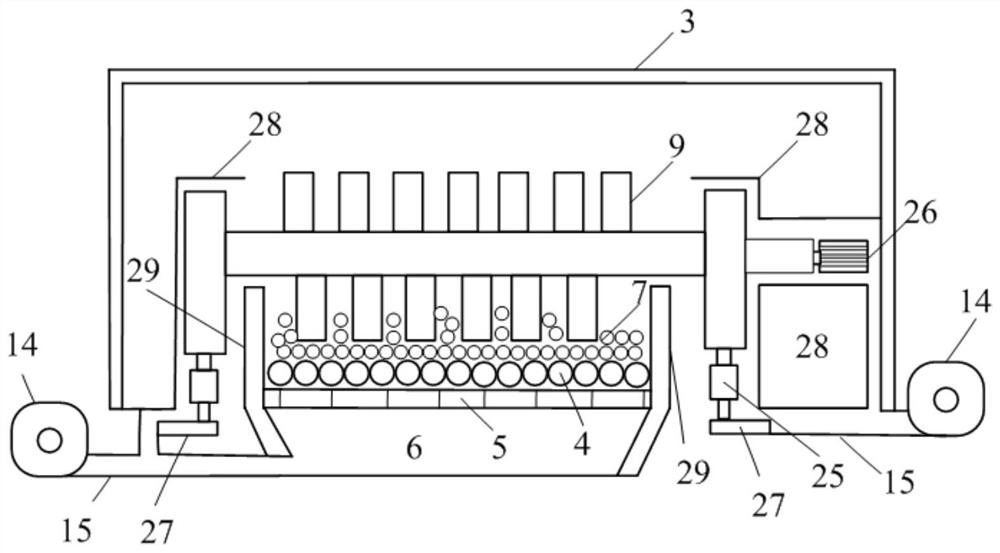

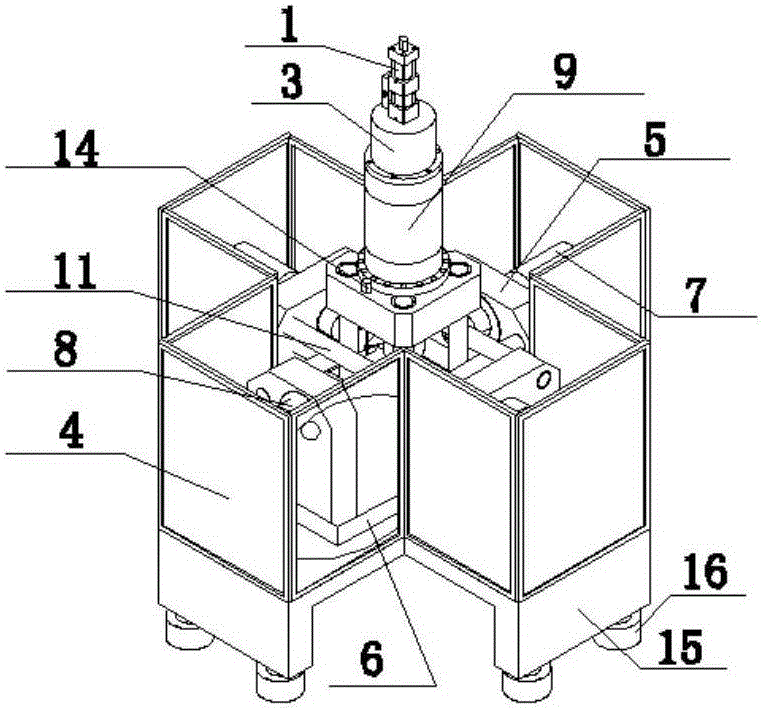

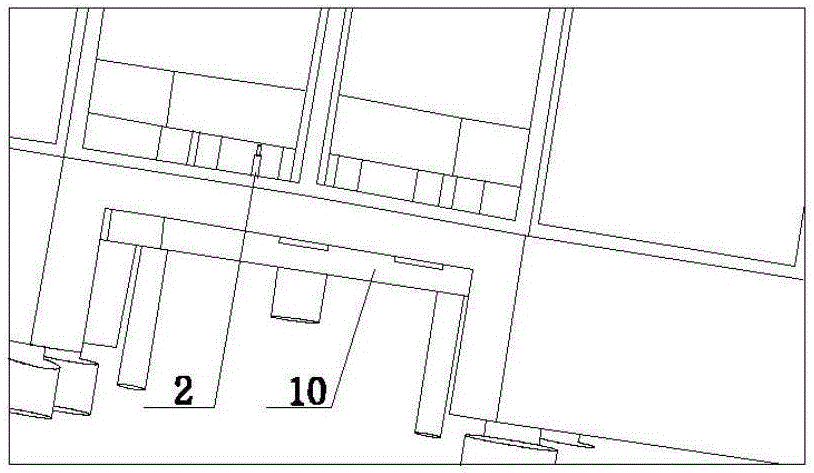

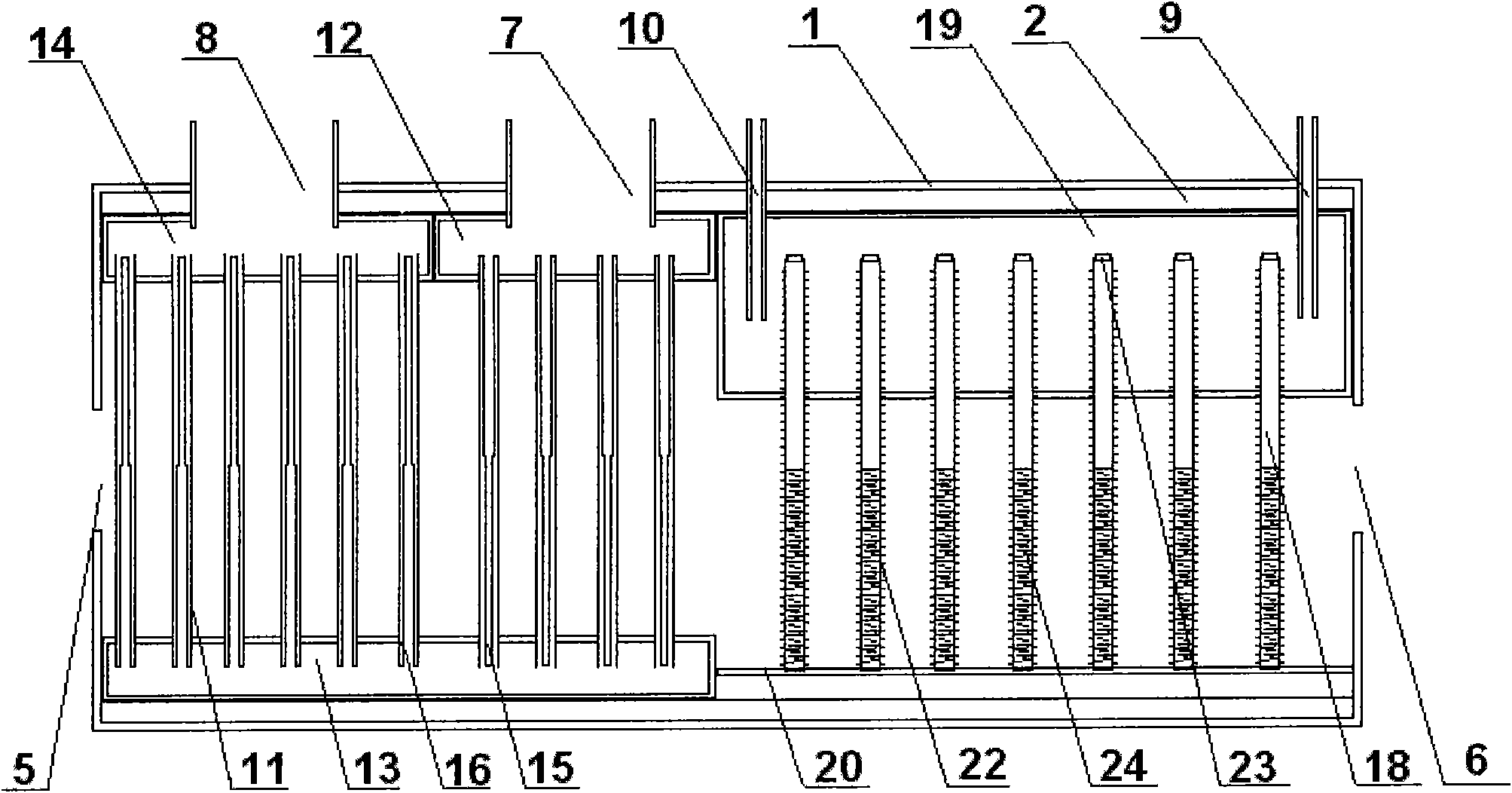

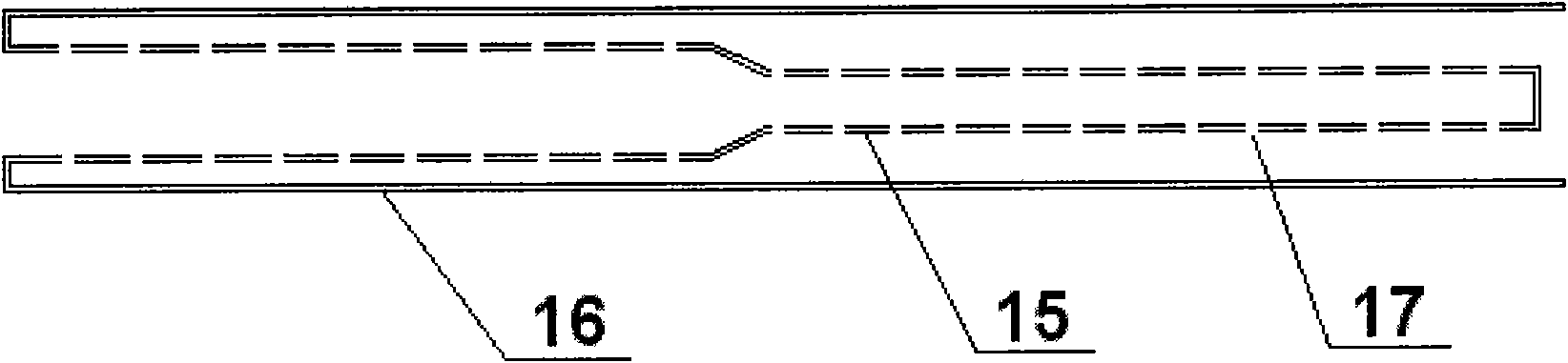

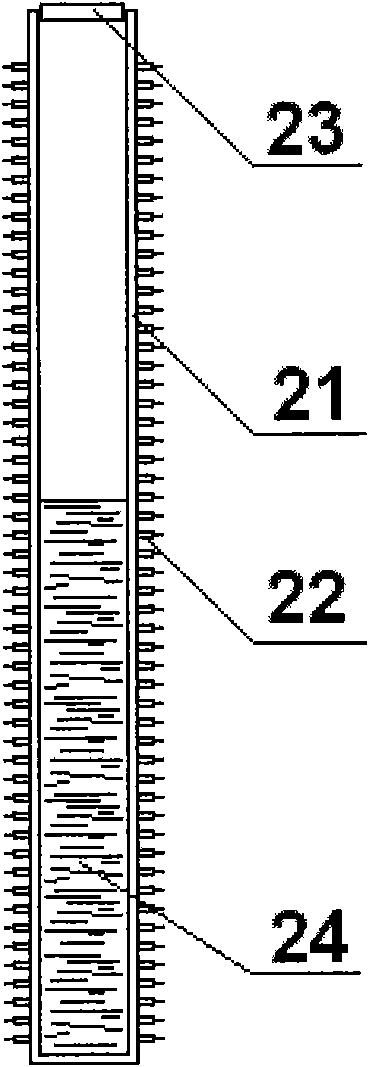

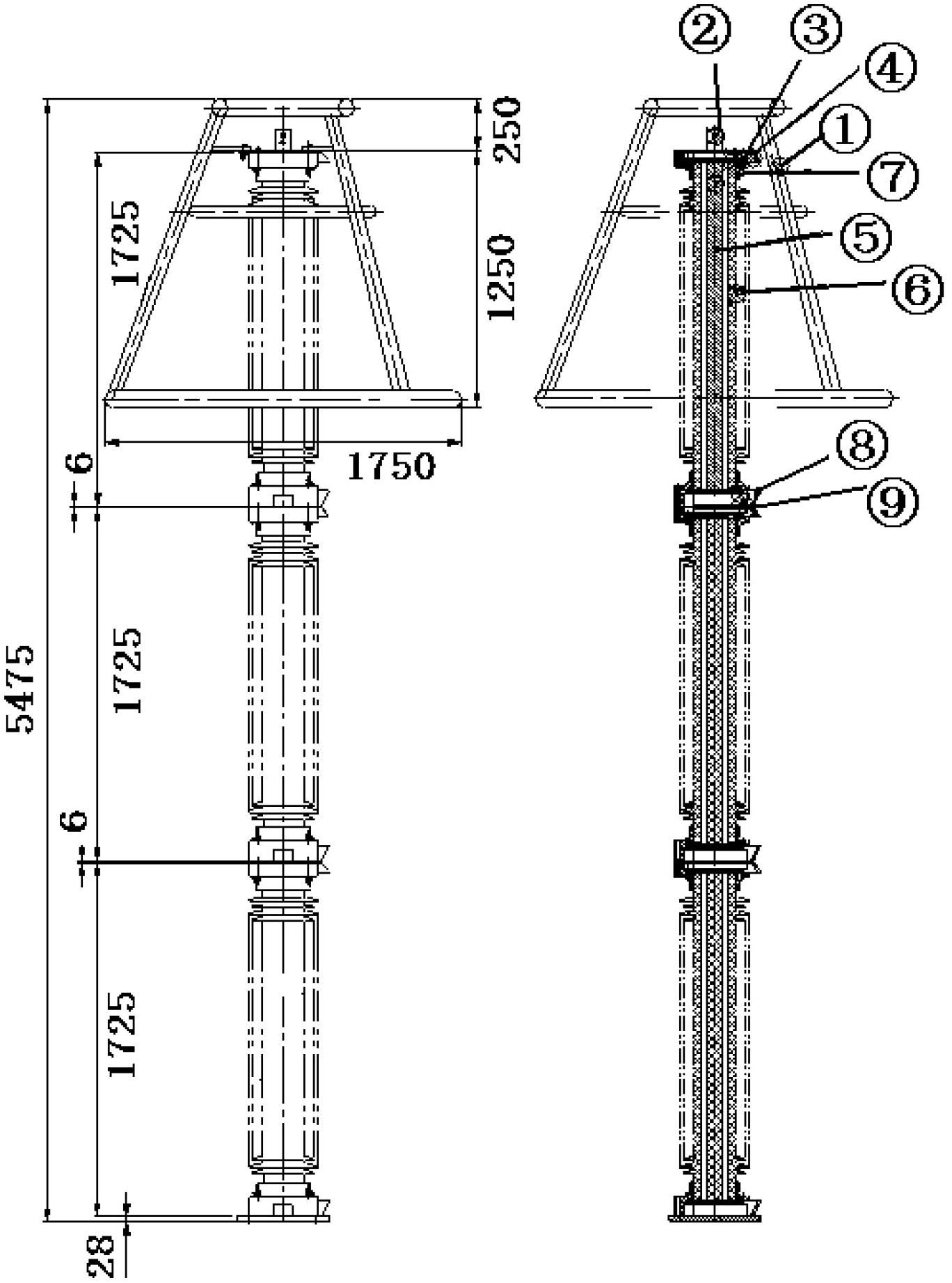

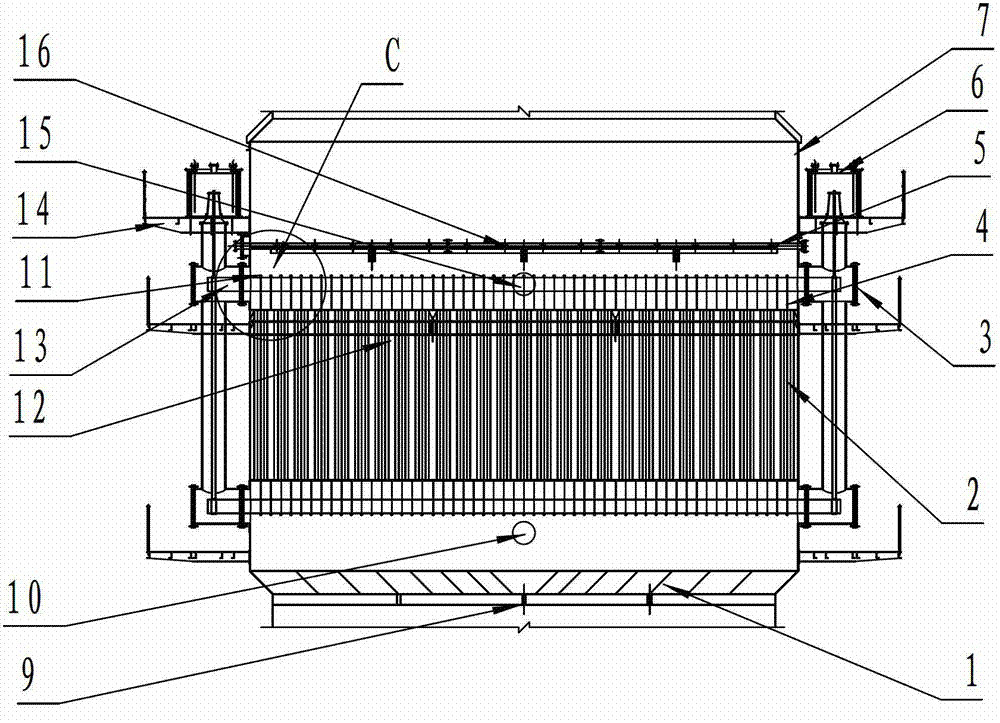

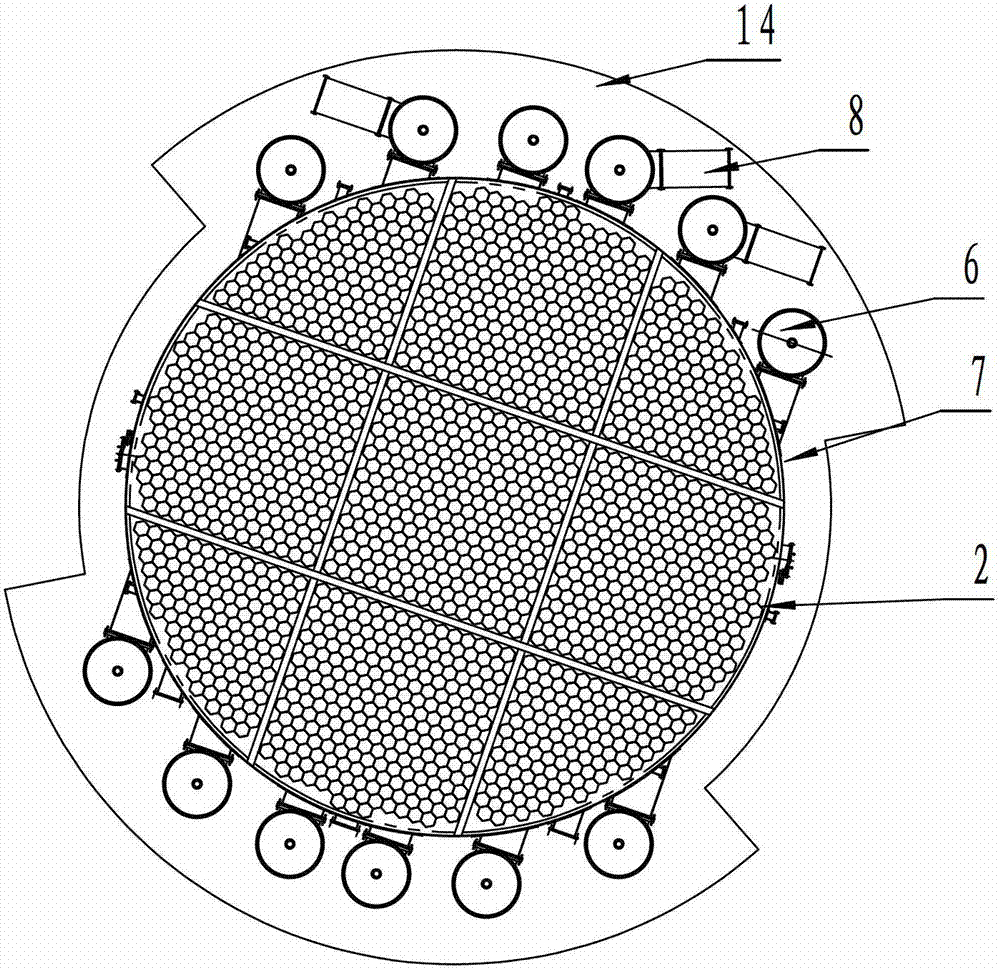

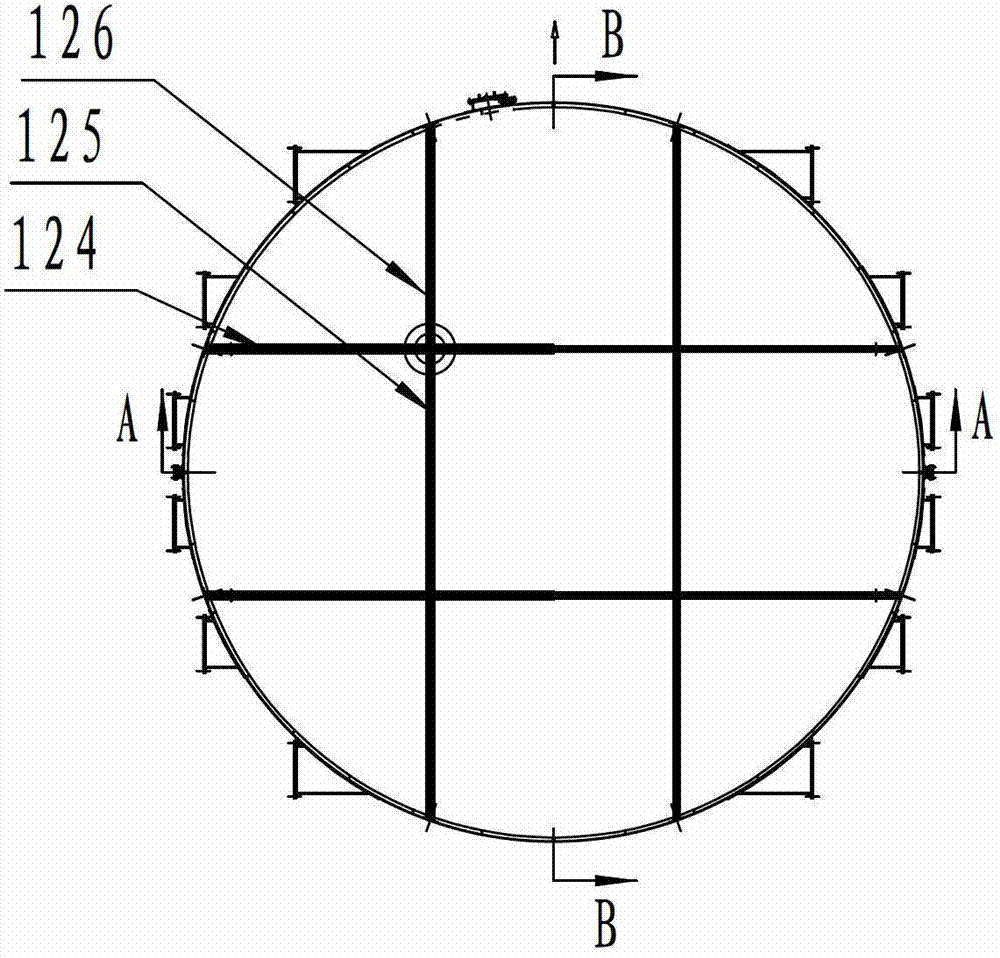

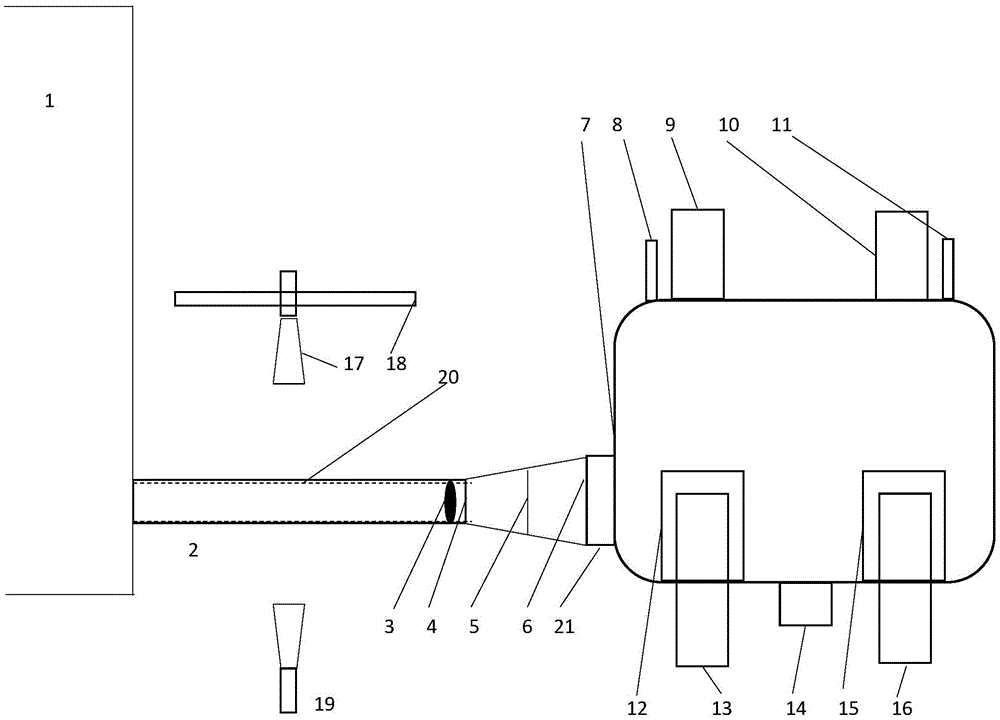

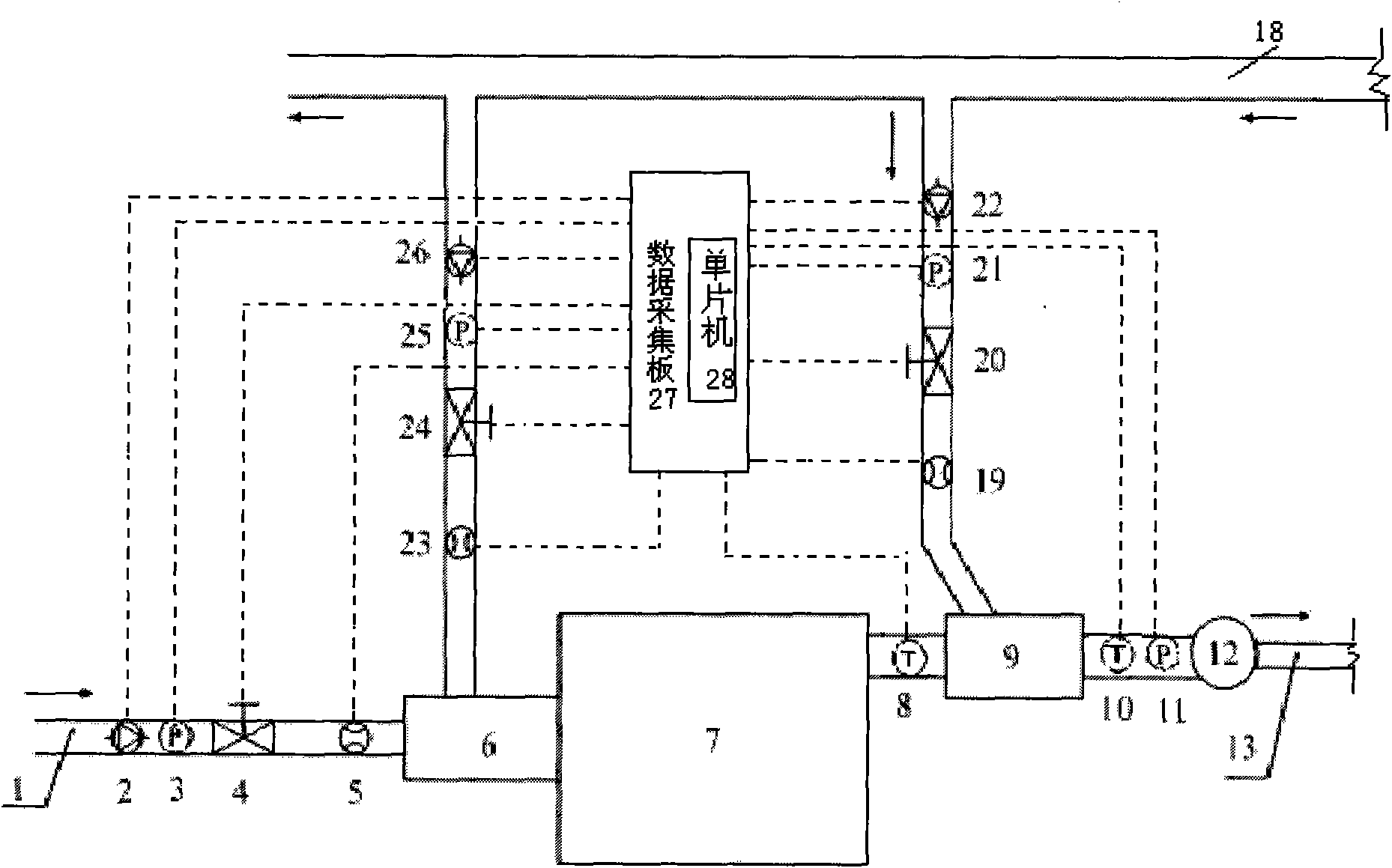

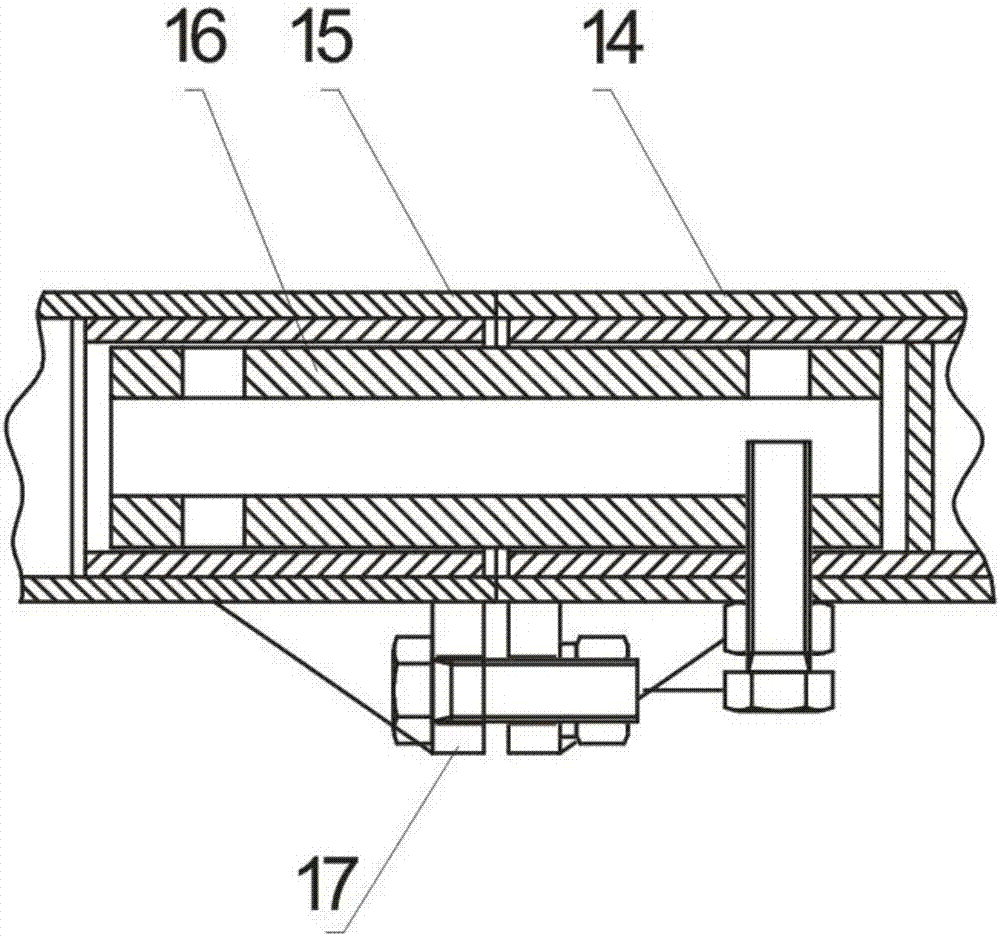

Hopkinson pressure bar-based true triaxial dynamic-static coupling loading and unloading test system

InactiveCN107014689AImprove targeting and effectivenessImprove theoretical research level and equipment levelMaterial strength using tensile/compressive forcesWave loadingStatics

The invention discloses an experimental device for static-dynamic coupling loading of coal and rock samples and particularly relates to a Hopkinson pressure bar-based true triaxial dynamic-static coupling loading and unloading test system. The Hopkinson pressure bar-based true triaxial dynamic-static coupling loading and unloading test system is suitable for mine impact power disaster mechanism research and laboratory simulation and reconstruction, dynamic, controllable and different dynamic-static coupling loading of the coal and rock samples can be achieved, multiple stress-wave loading modes of a coal and rock material can be simulated, and the impact phenomenon of field coal and rock mass can reappear through the true triaxial characteristic of the system. The Hopkinson pressure bar-based true triaxial dynamic-static coupling loading and unloading test system mainly comprises a static loading pressure device for applying static loads to three directions, a dynamic loading device for applying dynamic loads to an X direction and an instant unloading drop device. A mechanism that coal mass induces impact failure under the action of stress waves such as a mine earthquake is researched through combination of an axial static-dynamic device and confining pressure, a whole rock burst generation model under the static-dynamic loading condition is built, the resultant action of various influence factors is researched and a theoretical basis is provided for mine earthquake-induced impact and control.

Owner:CHINA UNIV OF MINING & TECH +1

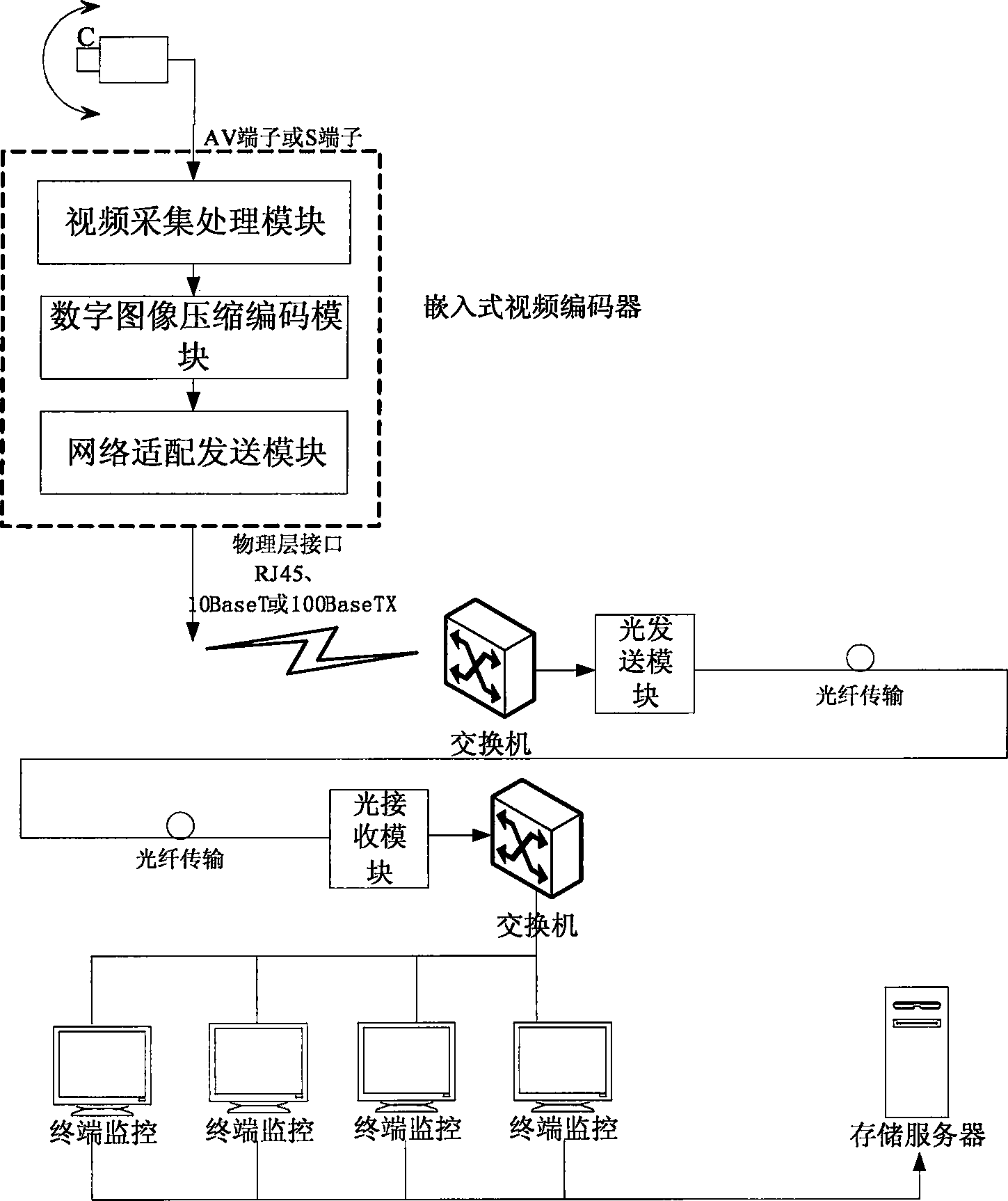

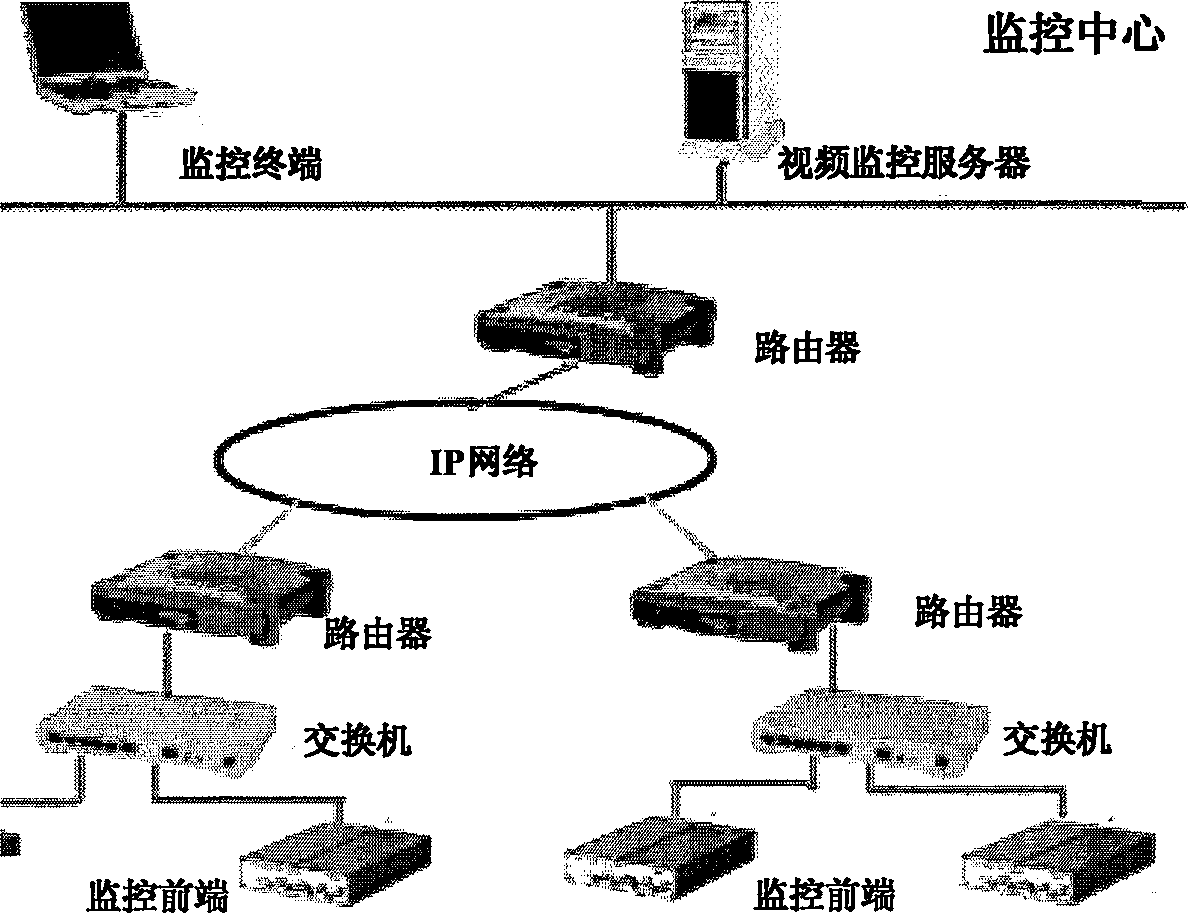

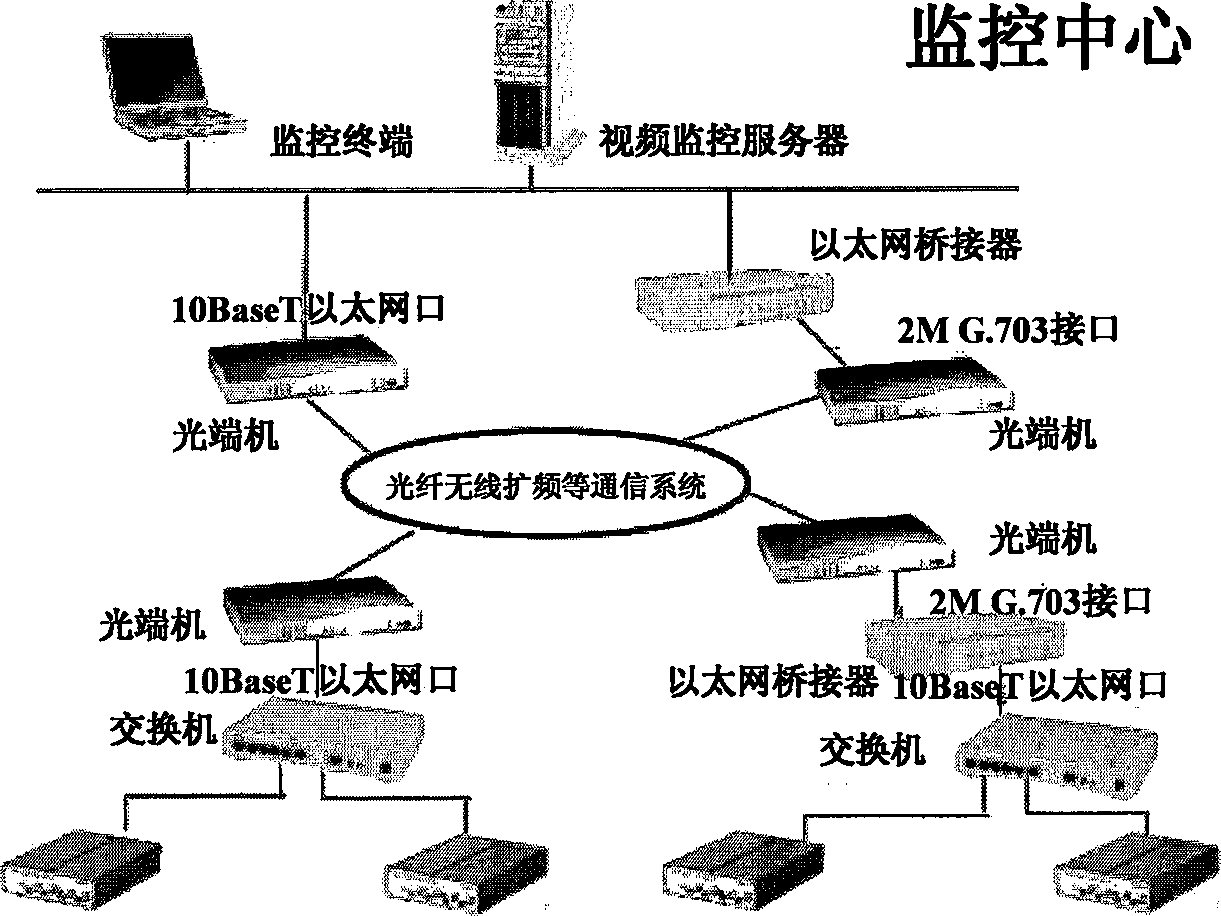

Embedded type network video monitor and control system

InactiveCN1874502AEasy installationImprove equipment levelClosed circuit television systemsImage signalImaging Signal

The invention is designed for solving the technical problems of image long-distance distortionless transmission, image real time requirement and image compressed coding. The system comprises: a front end monitoring device used for collecting the video signal within the monitored range and processing the collected signals into an image signal format capable of being transmitted in data network; a data network used for transmitting the image signals to the supervision center; and a supervision center used for receiving the image signals from the data network and transmitting them the relevant supervision terminals.

Owner:孙强 +1

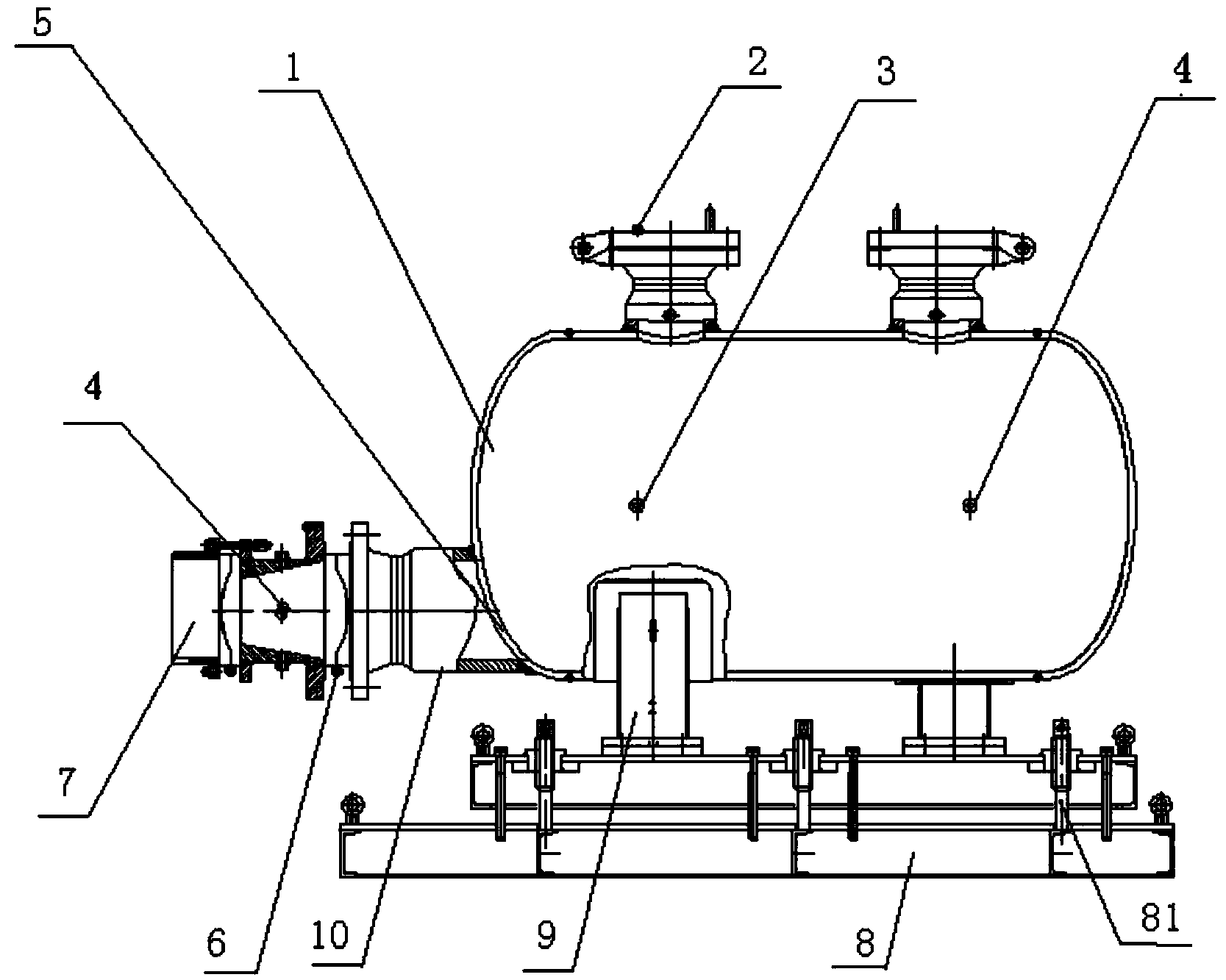

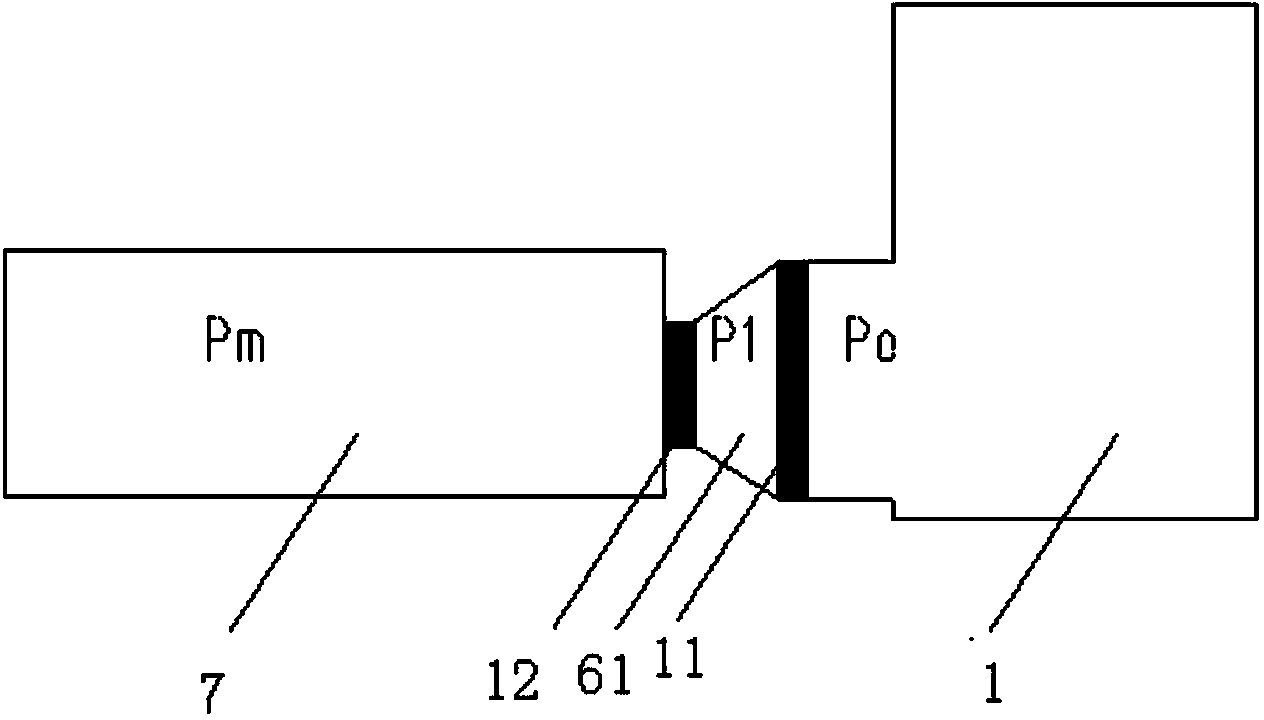

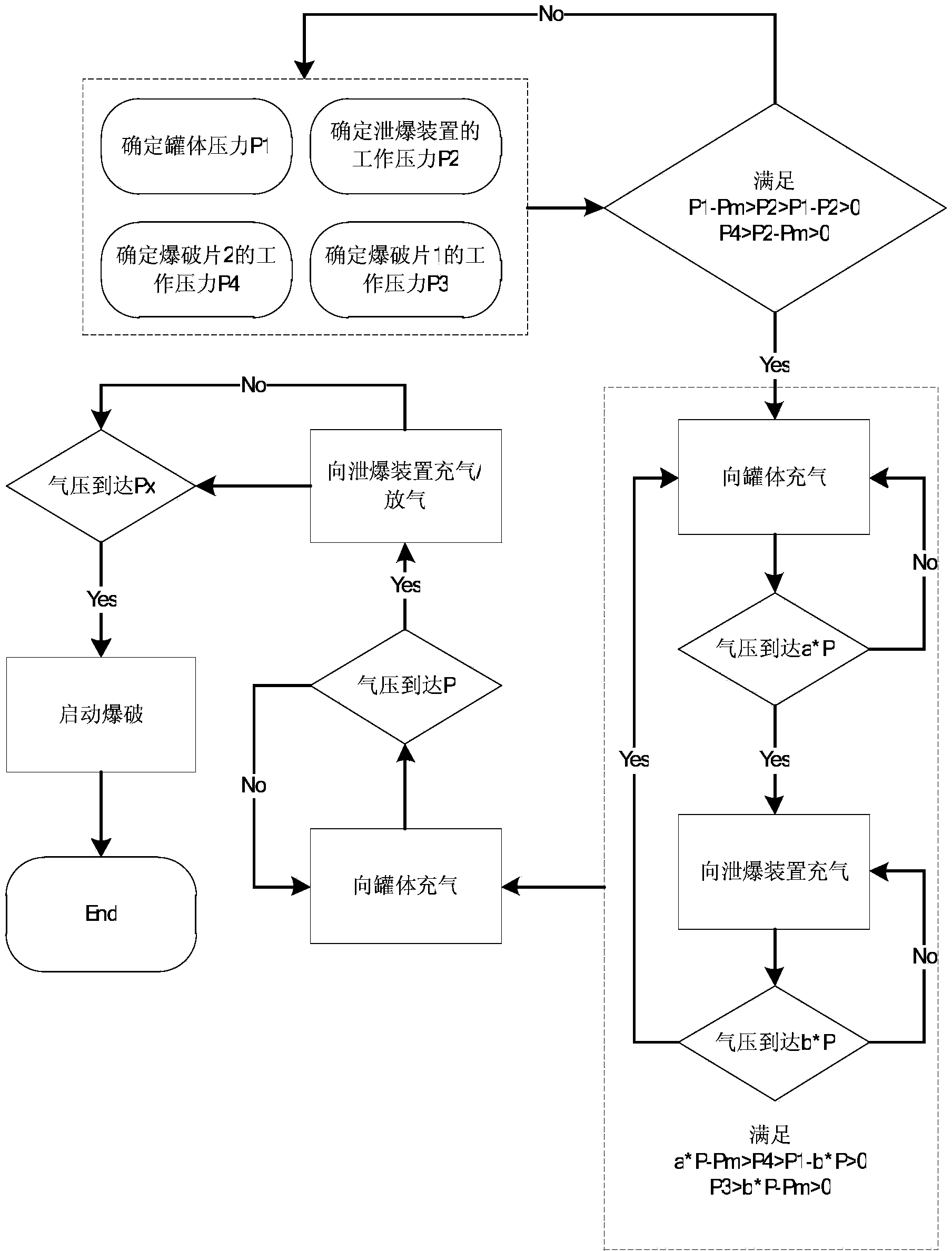

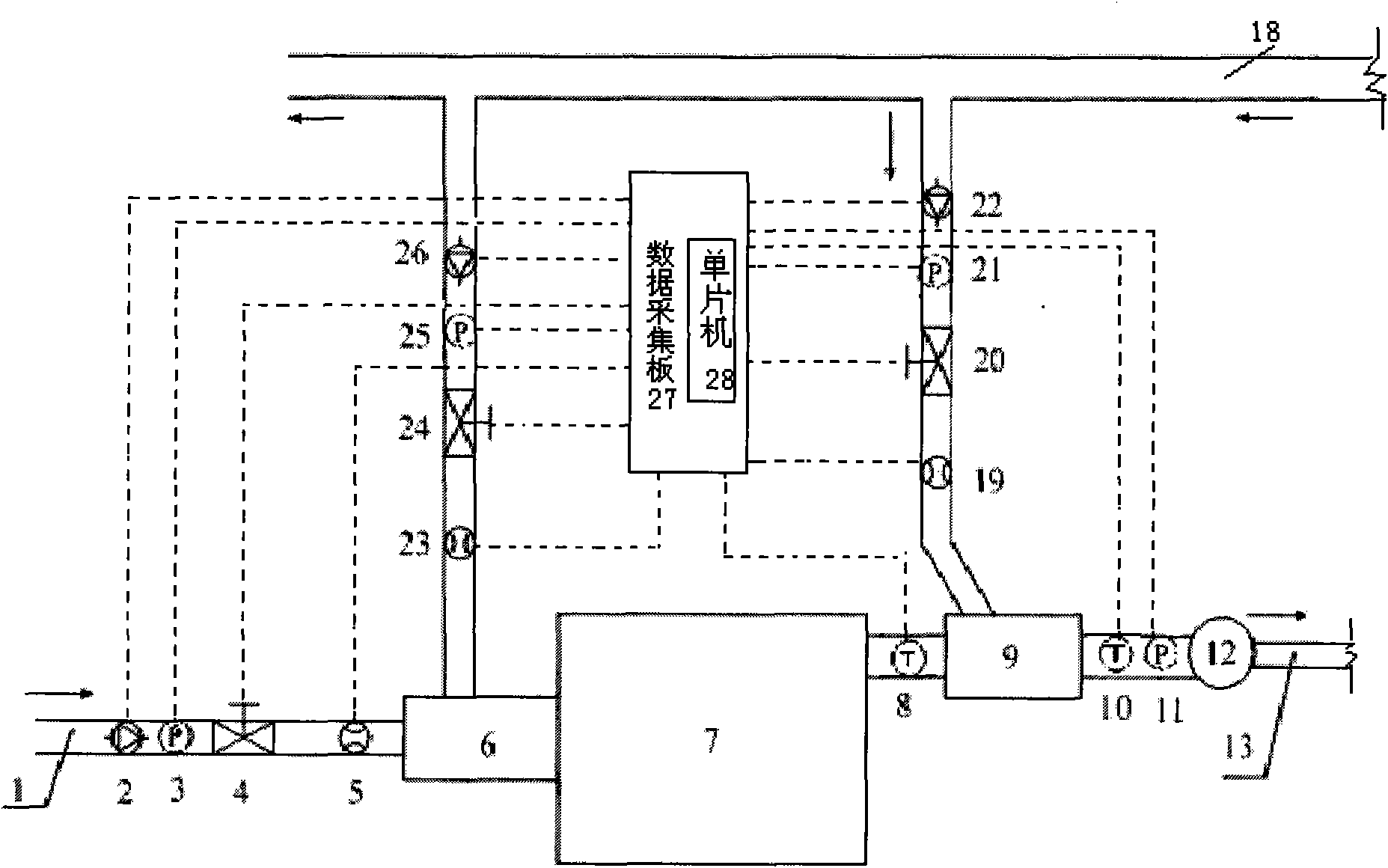

Simulation experimental method for dynamic effect of coal and gas outburst

InactiveCN104181282AImprove protection technology and equipment levelShort opening timeFuel testingProcess engineeringExperimental system

The invention discloses a simulation experimental method for a dynamic effect of coal and gas outburst. The simulation experimental method comprises the following steps: A, preparing a coal and gas outburst experimental system, wherein the system comprises a pressure container and a pipeline system which are fixed on the ground, a material inlet, an inflating hole and a sensor hole are formed in the pressure container, an outburst hole is formed in the pressure container, the outburst hole is connected with an explosion discharging device, the explosion venting device comprises a diameter variable pipe, a first bursting piece and a second bursting piece, whether the diameter variable pipe and the pressure container are inflated is controlled by a control chip according to the pressure intensity measured by the first sensor and the second sensor; B, filling coal particles into the pressure container from the material inlet; and C, gradually inflating the pressure container and the diameter variable pipe for increasing the pressure, and controlling the first bursting piece and the second bursting piece to be burst, so that the coal and gas outbursts. According to the simulation experimental method for the dynamic effect of the coal and gas outburst, the overall experimental effect of the dynamic effect is guaranteed to the maximal extent, and theoretical basis is provided for protecting and controlling the disaster of the coal and gas outburst.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

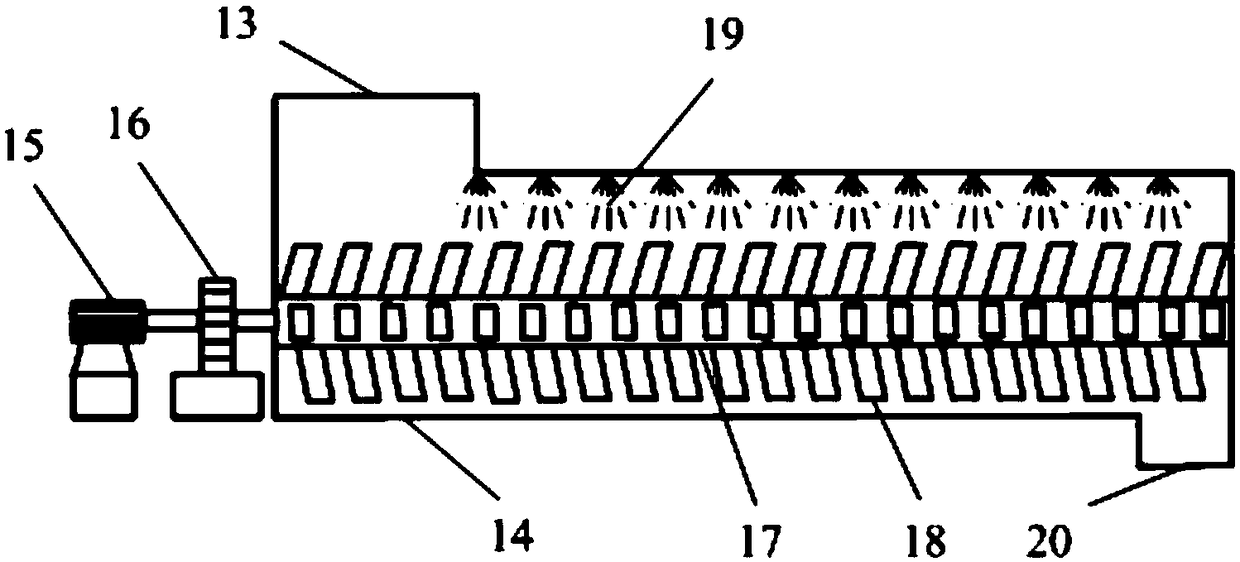

High-temperature steel slag bottom blowing air cooling crushing waste heat recovery device and method

PendingCN111850194AImprove pulverization rateImprove processing efficiencyExhaust gas handlingRecycling and recovery technologiesSlagDust control

The invention relates to a high-temperature steel slag bottom blowing air cooling crushing waste heat recovery device and method. A crushing bed is adopted as a high-temperature steel slag treatment carrier, a crusher is adopted for efficiently crushing steel slag, meanwhile, cold air is introduced into a bottom blowing air cooling box to solidify and cool the high-temperature steel slag, and meanwhile, the crusher rotates at a certain speed, moves forwards and backwards and rotates to crush the steel slag. A heat exchanger and a generator are adopted for cooling the high-temperature steel slag to generate high-temperature waste heat for recovery and power generation. The crushing capacity is high, the steel slag treatment efficiency is greatly improved, and meanwhile, waste heat recoveryand power generation can be realized by adopting air cooling heat exchange. Efficient crushing and waste heat recovery of the high-temperature steel slag are realized, a steel slag water cooling system device is omitted, a simple dry dust removal mode is adopted to replace a wet flue gas treatment system caused by a previous water cooling process, the advantages of being high in automation degree,small in space occupation, good in leakproofness, low in system investment, capable of achieving ultra-clean emission and the like are achieved, and the comprehensive economic benefits of steel slagtreatment are improved.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

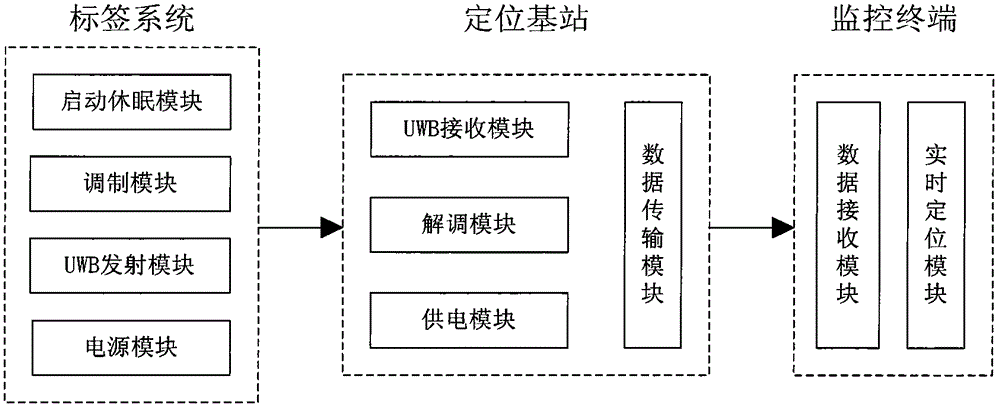

Multi-base networking UWB three-dimensional positioning system for indoor positioning and positioning method thereof

InactiveCN104902563ASolve the impossible indoor positioning problemRealize indoor real-time high-precision positioning requirementsPosition fixationTransmissionComputer moduleEngineering

The invention discloses a multi-base networking UWB three-dimensional positioning system for indoor positioning and a positioning method thereof. The positioning system comprises a tag system, a positioning base station, and a monitoring terminal. The tag system comprises a start dormancy module, a modulation module, a UWB emitting module, and a power module. The positioning base station comprises a UWB receiving module, a demodulation module, a data transmission module, and a power supply module. The monitoring terminal comprises a data receiving module and a real-time positioning module. The positioning method of the positioning system is implemented by the steps of starting, modulation and demodulation, positioning, real-time monitoring, and the like. By adopting the system and the method of the invention, the requirement of indoor real-time high-precision positioning can be satisfied, the problem of indoor positioning which cannot be realized by GPS and other global navigation satellite systems is solved, and the technical level and equipment level of our country in the field of indoor positioning are enhanced effectively.

Owner:梁步阁

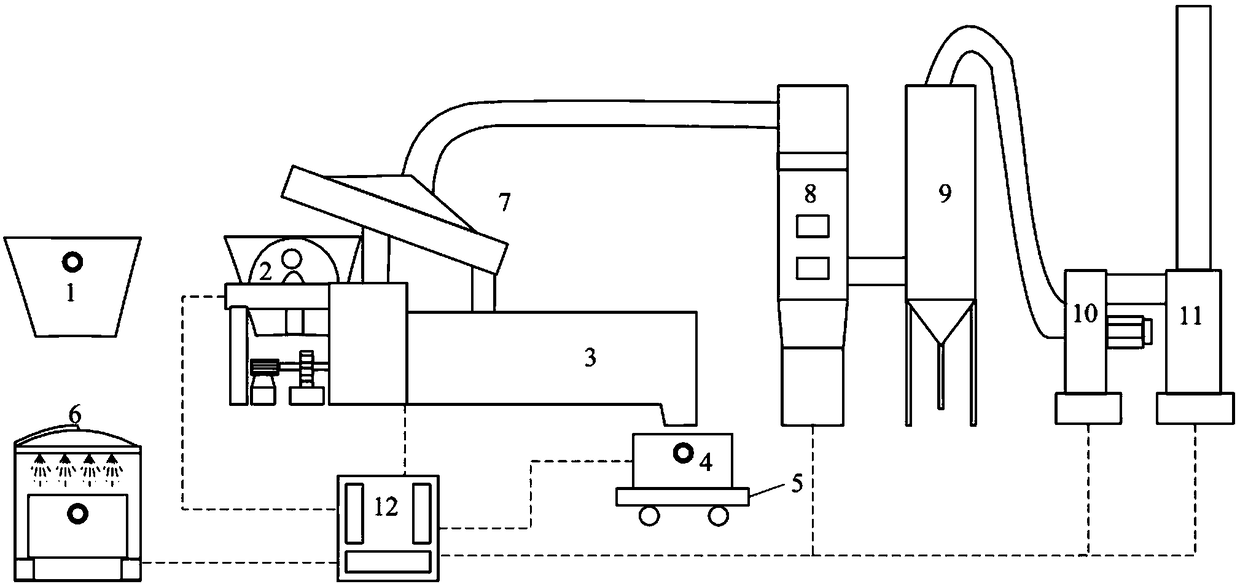

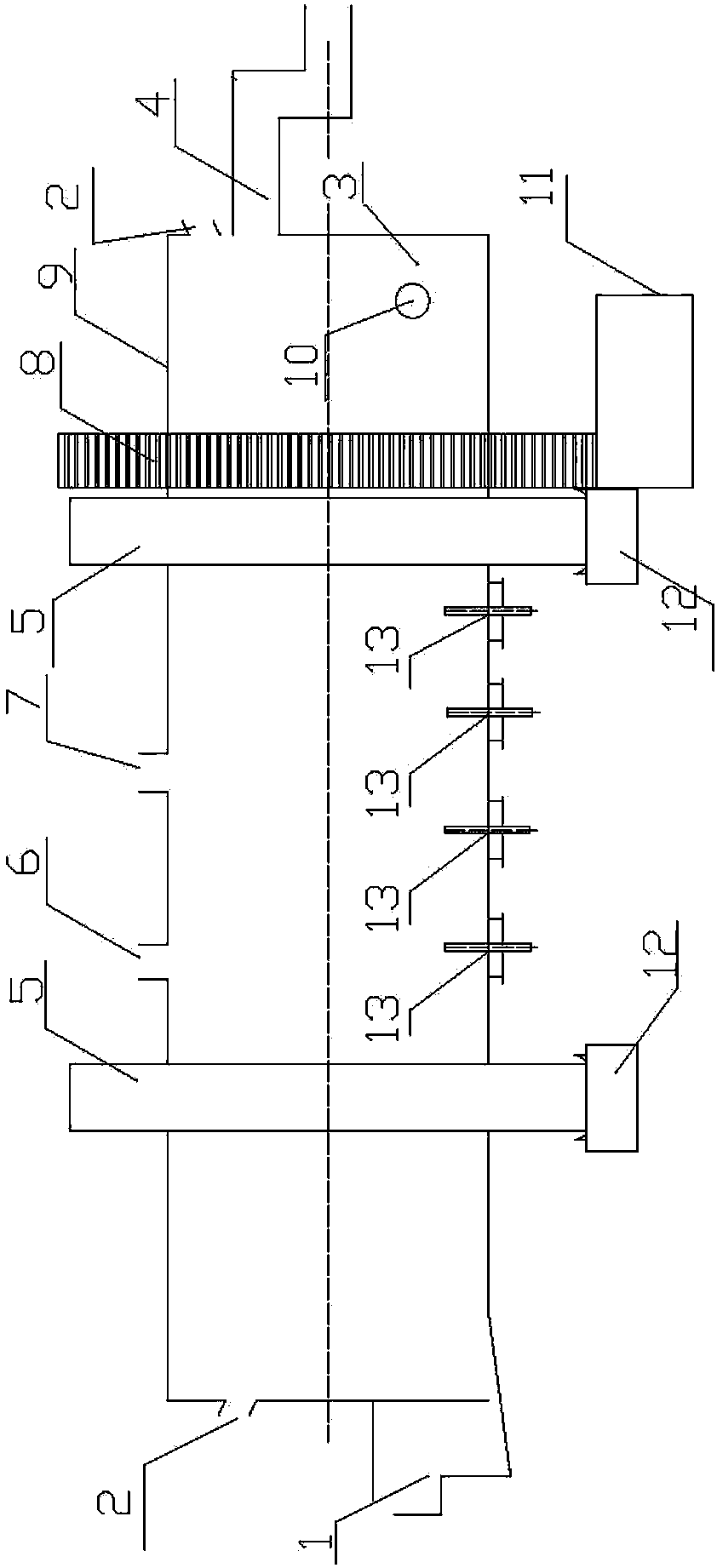

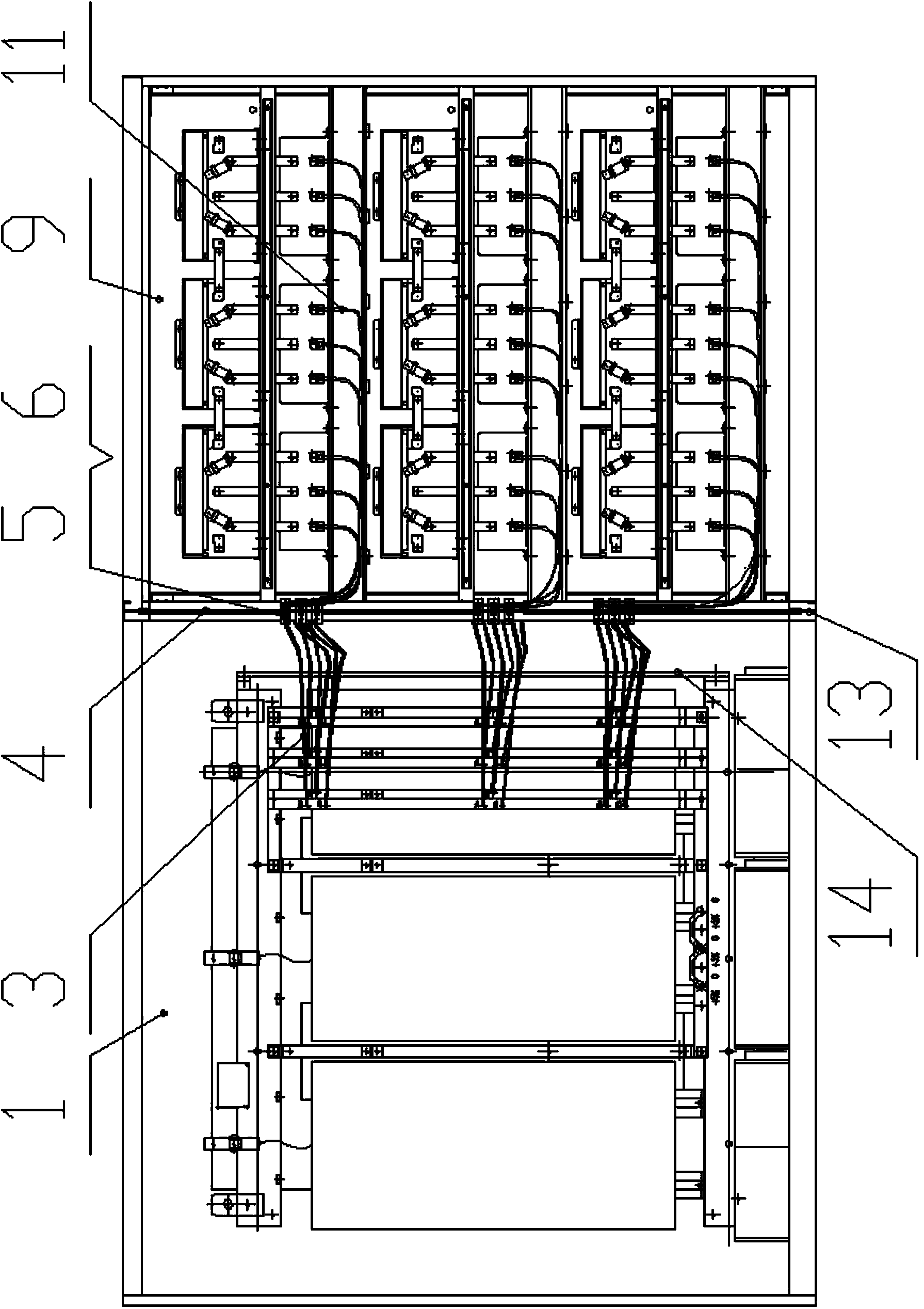

Melted steel dreg spiral crushing device and method

PendingCN109112238AHigh degree of automationGood production continuityRecycling and recovery technologiesBatch productionFlue gas

The invention relates to a melted steel dreg spiral crushing device and method. The melted steel dreg spiral crushing device comprises a dreg tank (1), a rollover machine (2), a spiral crusher (3), aslag groove (4), a dreg discharging machine (5), a hot suffocating tank (6), a flue gas treatment system and a control system (12); the rollover machine is used for pouring dreg; the fixed shaft of the spiral crusher can be used for continuously crushing melted steel dreg; the melted steel dreg can be continuously poured into the spiral crusher; the spiral crusher is used for crushing the steel dreg and driving the steel dreg to a dreg outlet while being rotated according to a certain speed; the device has the advantages that continuous production of steel dreg treatment is realized, a previous batch production manner is changed and the steel dreg treatment efficiency is greatly improved.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +2

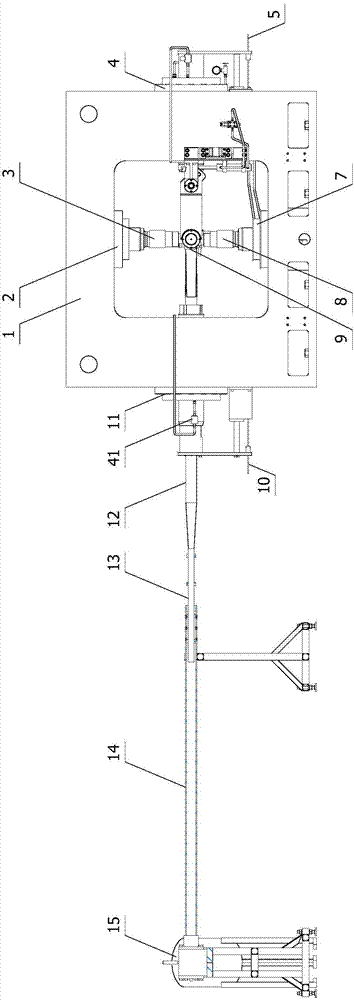

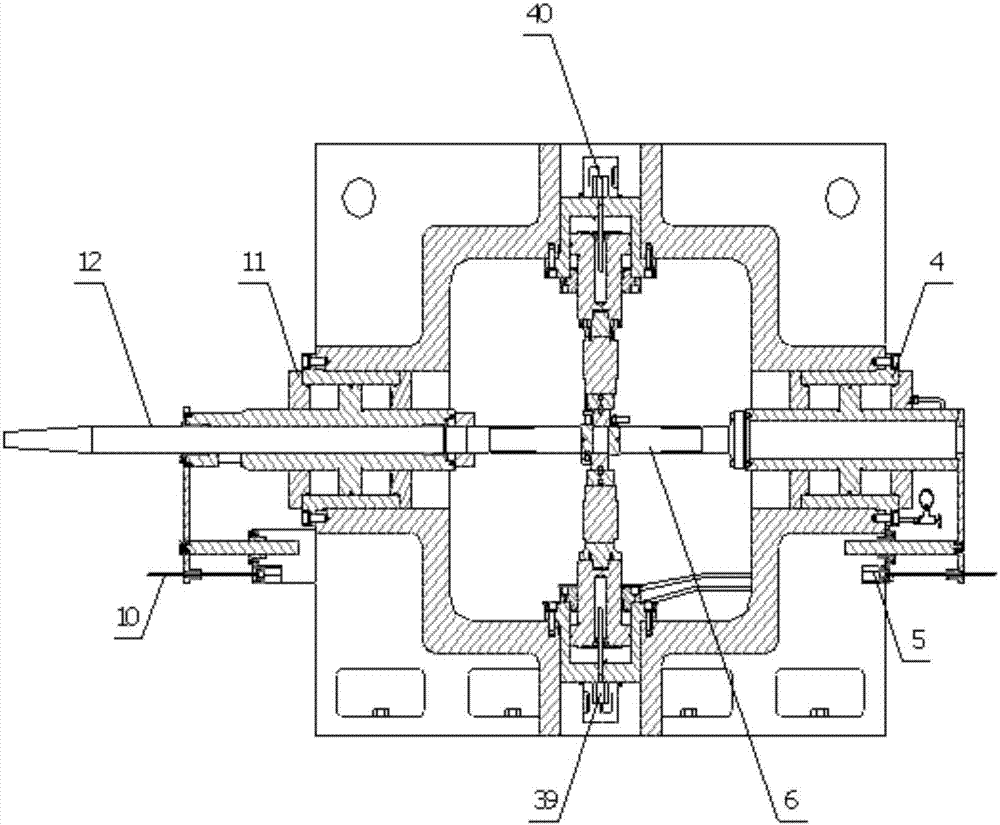

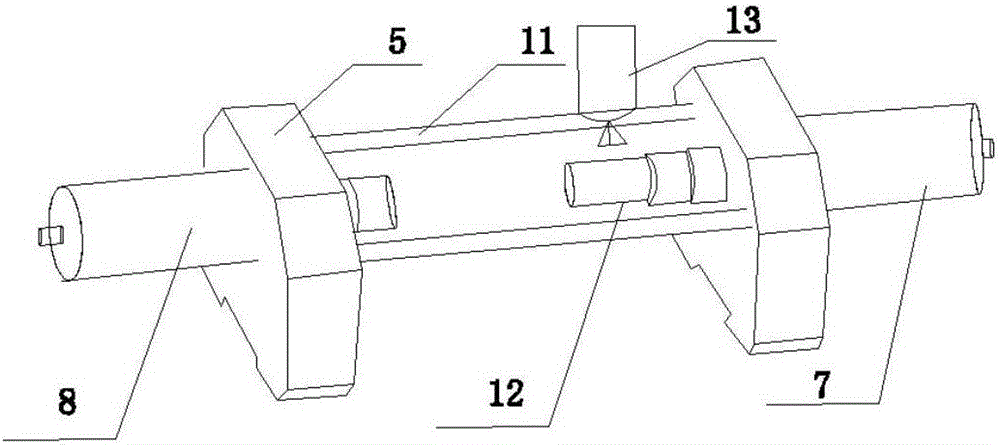

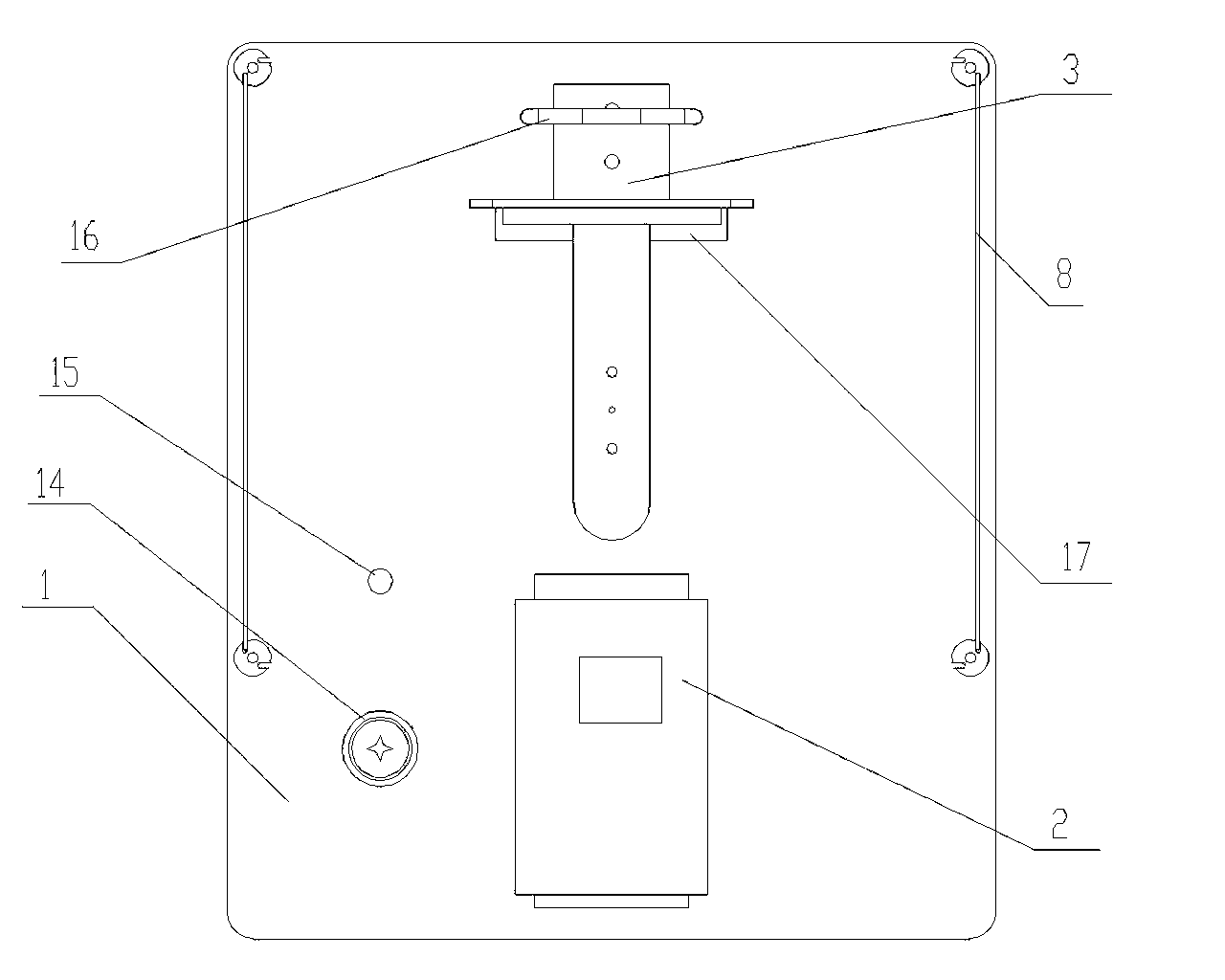

Coal-rock sample real triaxial vertical dynamic-static loading tester

ActiveCN106840892AImprove targeting and effectivenessImprove theoretical research level and equipment levelMaterial strength using tensile/compressive forcesCoalPiston cylinder

The invention relates to a coal-rock sample real triaxial vertical dynamic-static loading tester, which is applicable to reappeared impact mineral pressure, rock explosion and other coal-rock power disasters during a underground mine mining process. The testing system is composed of a triaxial loading system, a measurement control system, and a power loading system; X and Y axes are provided with double high-frequency response servo cylinders of four-pillar and two-pillar single piston cylinders, and installed on the same one horizontal platform driven by a lifting servo mechanism along the Z axis direction, wherein one direction of the Y axis is provided with an unloading cylinder to realize the rapid unloading of stress at one face; the Z axis is provided with a four-pillar hollow type dual-piston rod single servo cylinder, and configured with a resilience type displacement sensor, the measurement data feeds back to the lifting servo mechanism, and guarantees that the loading center of the horizontal X and U axes is always intersected at one point and the center point is unchanged. The high-speed servo cylinder is installed on the Z axis for providing the power source. The tester can simulate the real triaxial vertical dynamic-static loading state of the coal-rock sample, the Z-axis impact power loading state, the Y-axis fixing rate or rapid stress unloading state.

Owner:CHINA UNIV OF MINING & TECH +1

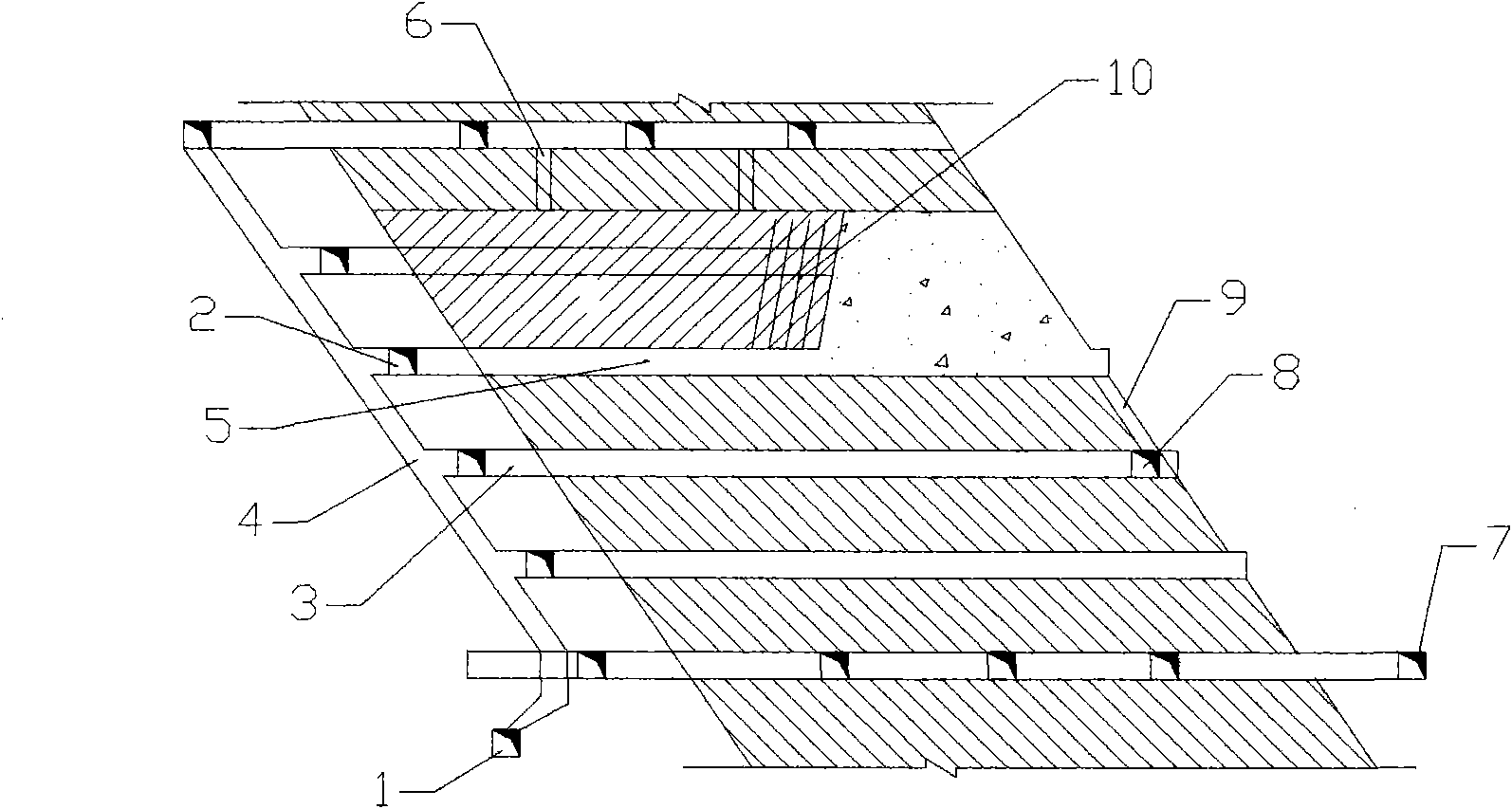

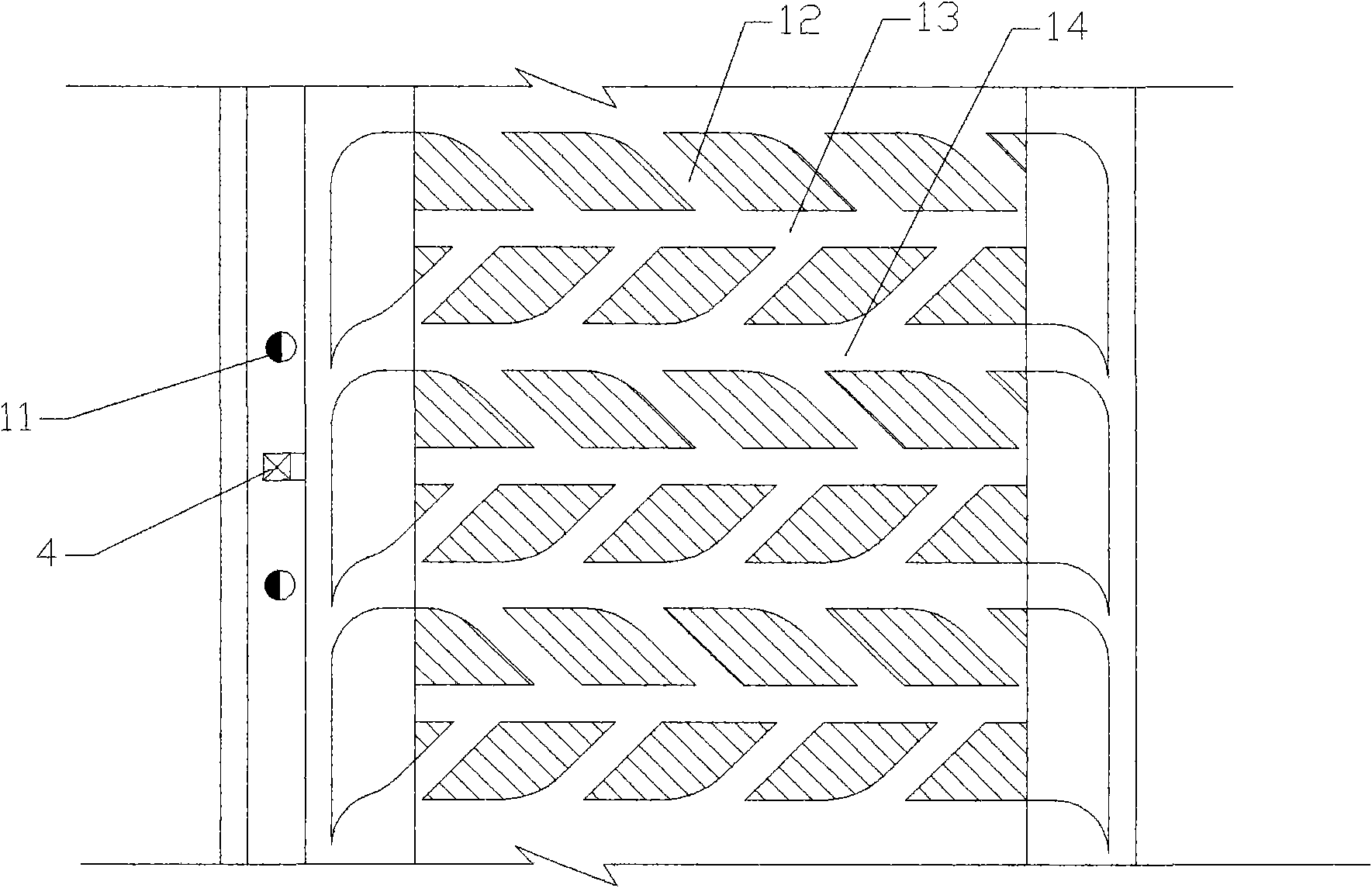

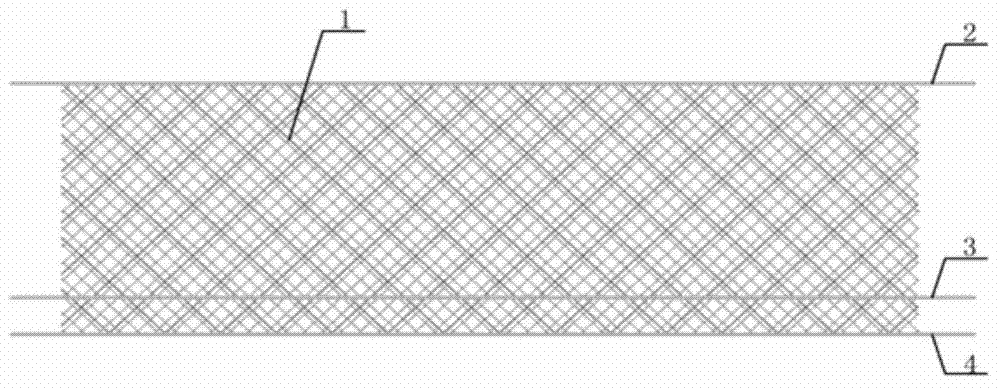

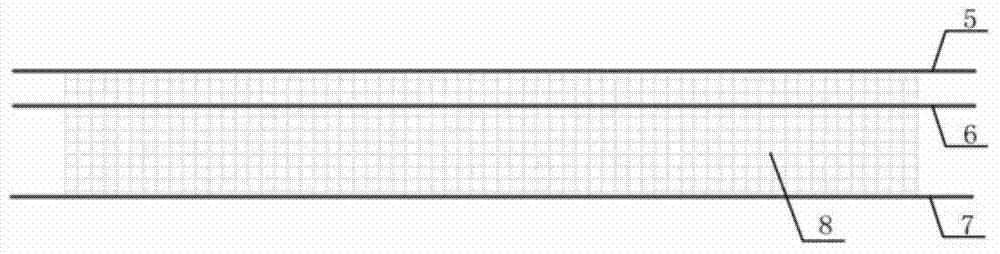

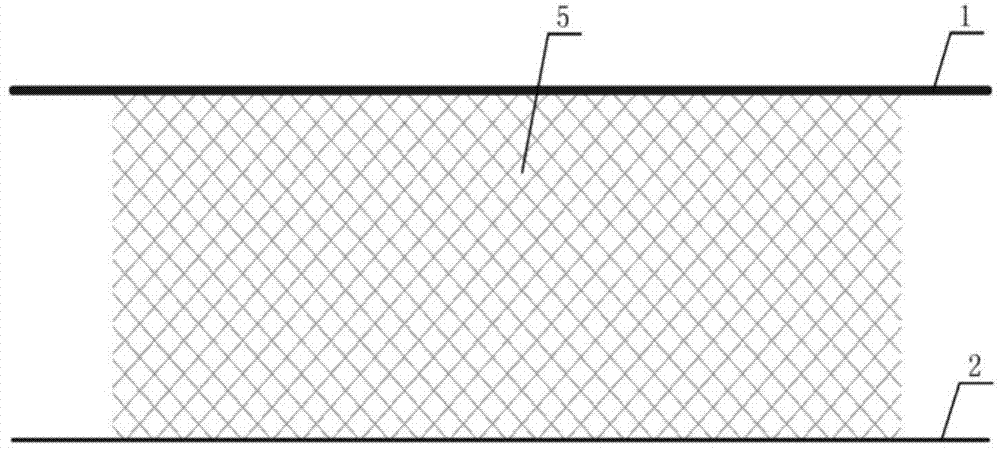

Water-proof coiled material without tire heat construction, manufacturing method and equipment thereof

InactiveCN101220699AGood extension performanceEasy constructionRoof covering using flexible materialsSynthetic resin layered productsEngineeringAsphalt

The invention provides a thermally-constructed waterproof coiled material without base material and the manufacturing method and equipment thereof. The product is a coiled material formed by two layers of polyolefine films (or one layer of polyolefine film and one layer of sand) with a layer of modified asphalt between the two. A film decoiling equipment uncloses a polyolefine film winding roller and guides thereof to a transmission steel band which drives the polyolefine film to move forward and coats the modified asphalt on the polyolefine film by a blade coating groove. At the same time, water is sprayed on the surface of the transmission steel band, which rapidly cools down the temperature of the modified asphalt, and a film-sticking device sticks the polyolefine film on the surface of the modified asphalt and thereby the waterproof coiled material is formed. The cooled product is guided into a constant tension bounding device by the transmission band, and is then transferred to a reeling machine for coiling and leaving the production line. During the waterproof construction, the waterproof coiled material can be adhered on a foundation course only by melting the waterproof coiled material. Once the foundation course cracks, the coiled material can not be torn off and the waterproof course can not be destroyed. Furthermore, the product can be used as a hot-melting waterproof putty to treat the weak links of buildings.

Owner:CHINA BUILDING MATERIAL TEST & CERTIFICATION GRP SUZHOU

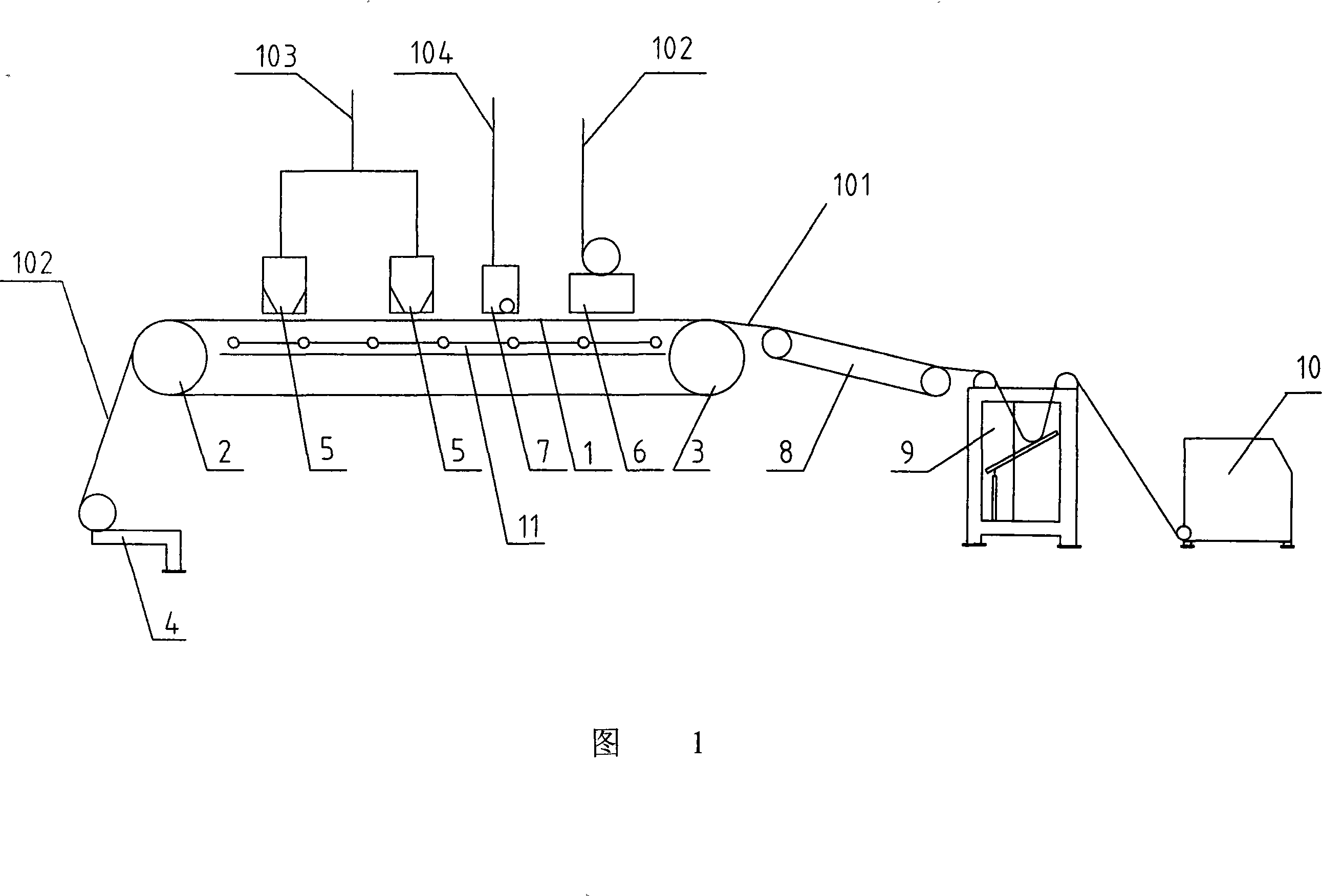

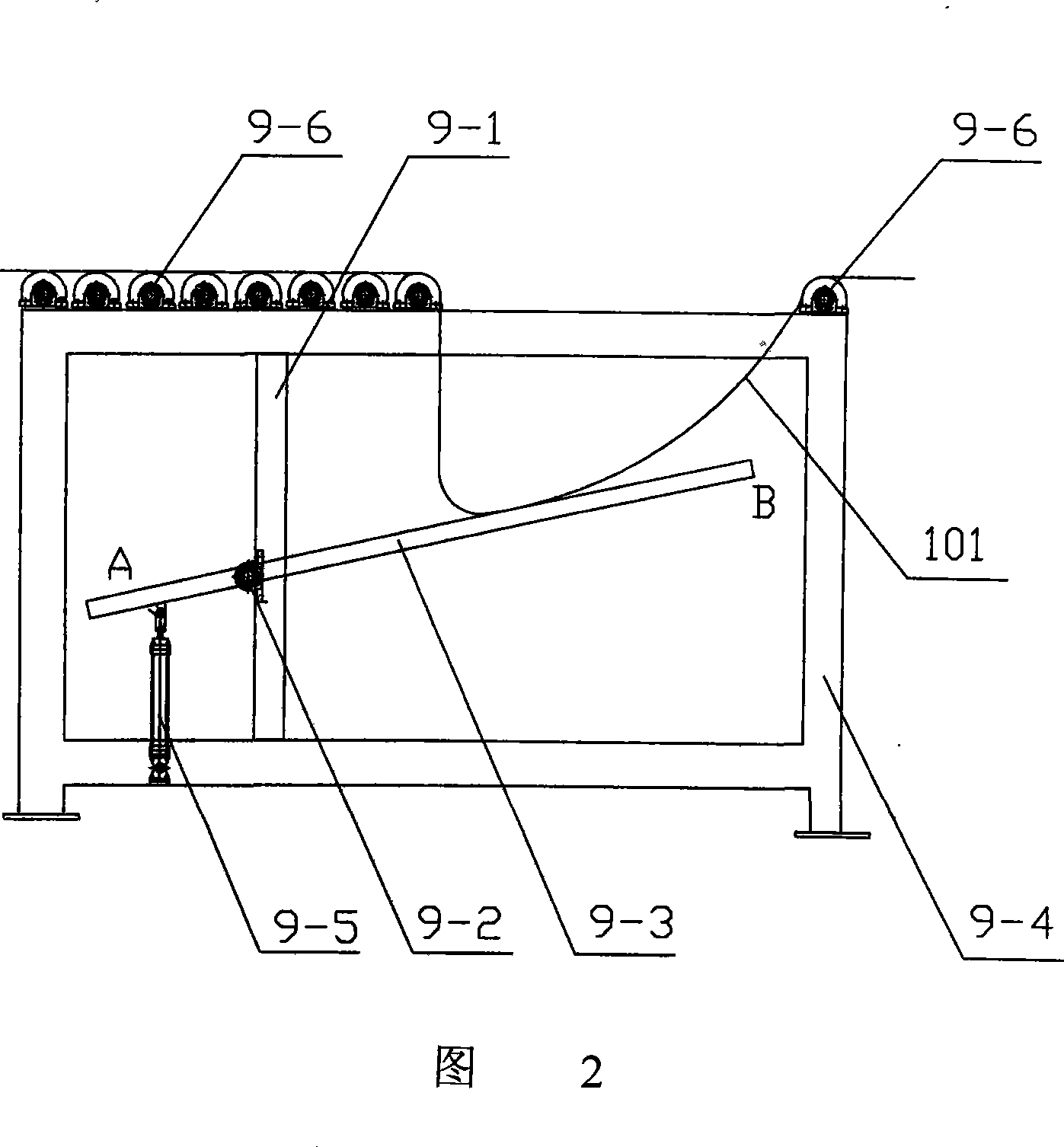

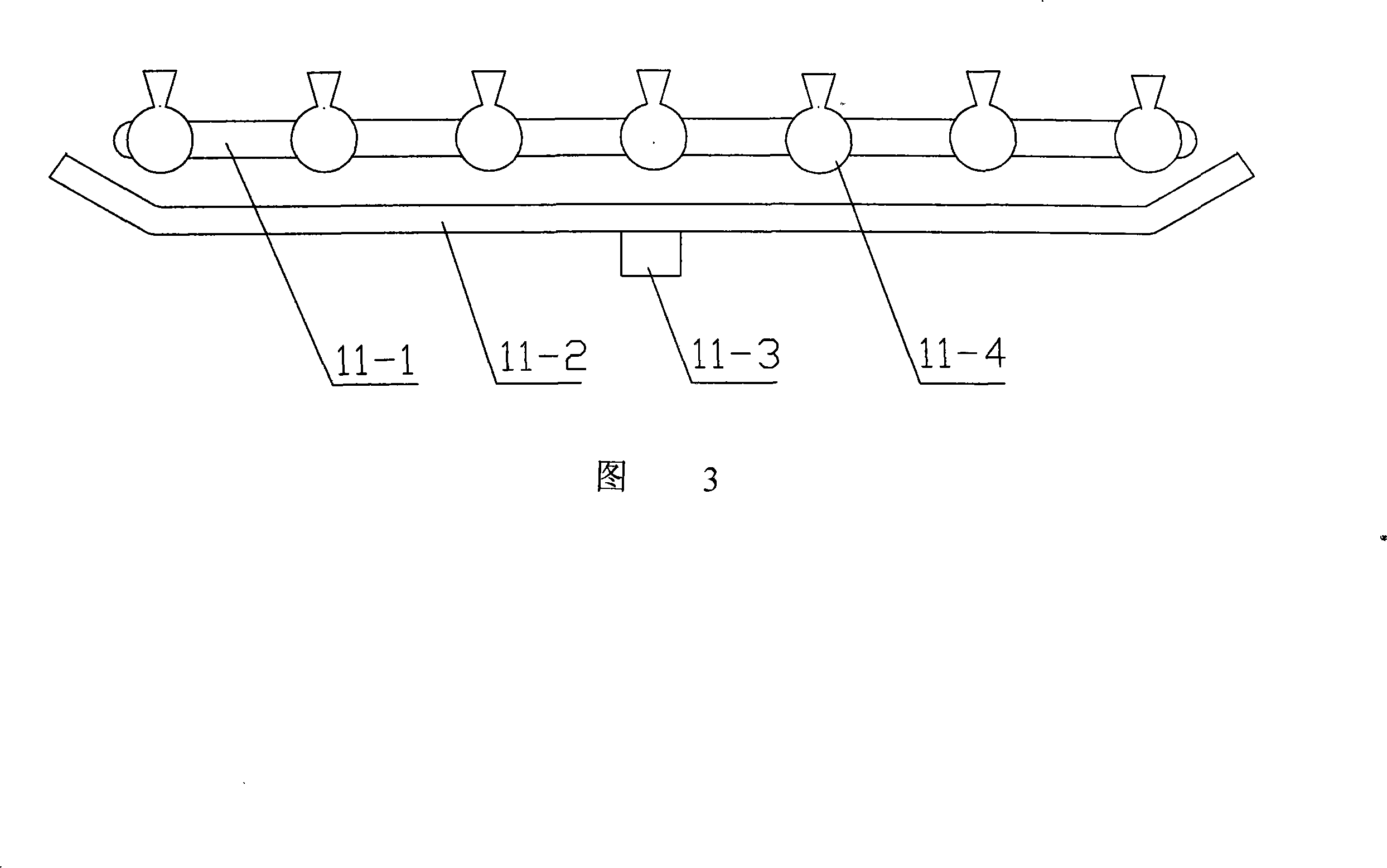

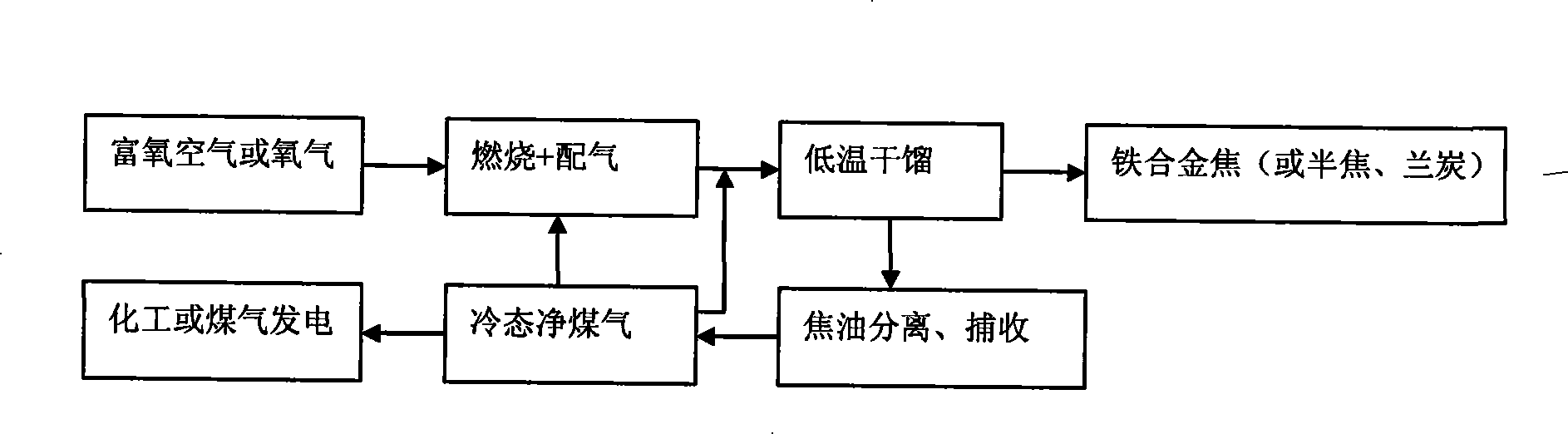

Coal gas internal heating low-temperature cracking process

The invention discloses a coal-gas internal-heat retorting method, which comprises leading oxygen-enriched or pure oxygen to produce high-temperature discharge gas with burning gas in a burner outside of a furnace to be basal heat resource which is needed by coal carbonization, mixing high-temperature discharge gas which is produced with cold coal gas which is produced in the restoring process after removing coke tar, preparing high-temperature circulation gas whose temperature is 680-810 DEG C, drumming high-temperature circulation gas into an internal heating type coal gas retort, heating coal in the furnace in non oxidation or weak oxidation, and achieving none combustion cycle of cycle part gas. The method which is utilized can effectively lower nitrogen content in coal gas, improve heat value of coal gas, improve coke tar yield, and improve semi-coke quality.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Multi-stage waste heat recovery device of industrial furnace high-temperature flue gas

InactiveCN101586918AImprove equipment levelImprove energy utilizationIncreasing energy efficiencyWaste heat treatmentFlue gasProcess engineering

The aim of the invention is to research and develop a multi-stage waste heat recovery device of industrial furnace high-temperature flue gas, which is suitable for recovering the waste heat of 200 DEG C-1200 DEG C flue gas, simultaneously preheats the mediums of burning medium, steam, heat water, etc. used for production and living, settles the industrial problems of different recycling devices required by different devices and energy wastage and has low production cost. The heat exchanging core body is composed of two components of a high-intermediate-temperature segment heat exchanging core body and a low-temperature segment heat exchanging core body. The low-temperature segment heat exchanging device absorbs the heat of the flue gas after heat exchange so that the temperature of the discharge flue gas is lower than 200 DEG C.

Owner:哈尔滨前程科技发展有限公司

Marine ranching dike netting gear component assembly method

The invention discloses a marine ranching dike netting gear component assembly method, wherein a double-layer fiber net, a medium-soft connection net and a woven net are used. The marine ranching dike netting gear component assembly method is characterized in that an upper margin line of the woven net and a lower line of the double-layer fiber net are bound and tightened with a single fast knot through a sixteen-strand polyester woven rope with the diameter of 4.6mm and are spaced by 5cm; next, a lower line of the medium-soft connection net and a connecting steel cable on the woven net are bound and tightened with a single fast knot through a sixteen-strand polyester woven rope with the diameter of 4.6mm and are spaced by 5cm; then, an upper line of the medium-soft connection net and a connecting net line on the double-layer fiber net are bound and tightened with a single fast knot through a sixteen-strand polyester woven rope with the diameter of 4.6mm and are spaced by 5cm; after an upper line of the double-layer fiber net, the upper line of the medium-soft connection net, the lower line of the medium-soft connection net, a lower margin line of the woven net and the double-layer fiber net are subjected to anti-dirt treatment, a large-mesh ultra-high molecular weight polyethylene warp knitting net is directly bound, connected and fixed to a marine ranching dike netting gear pile.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

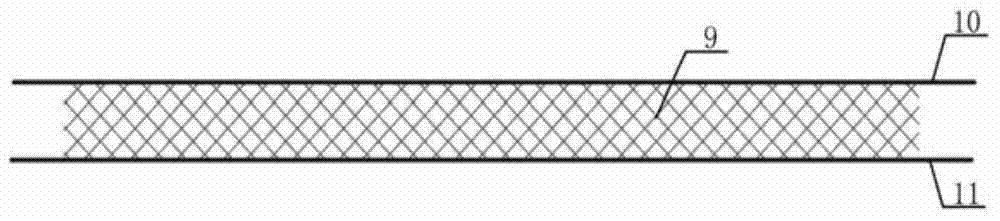

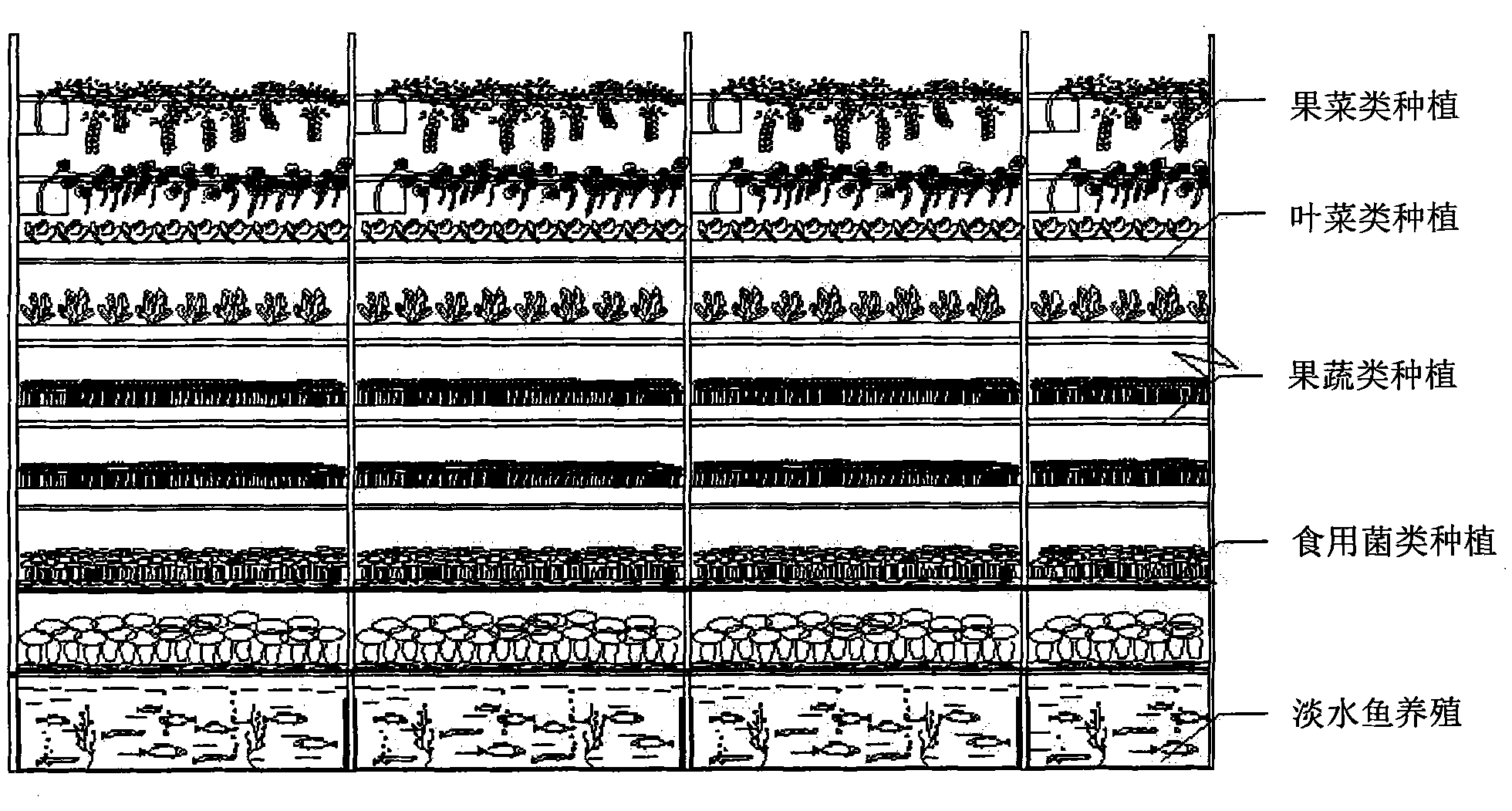

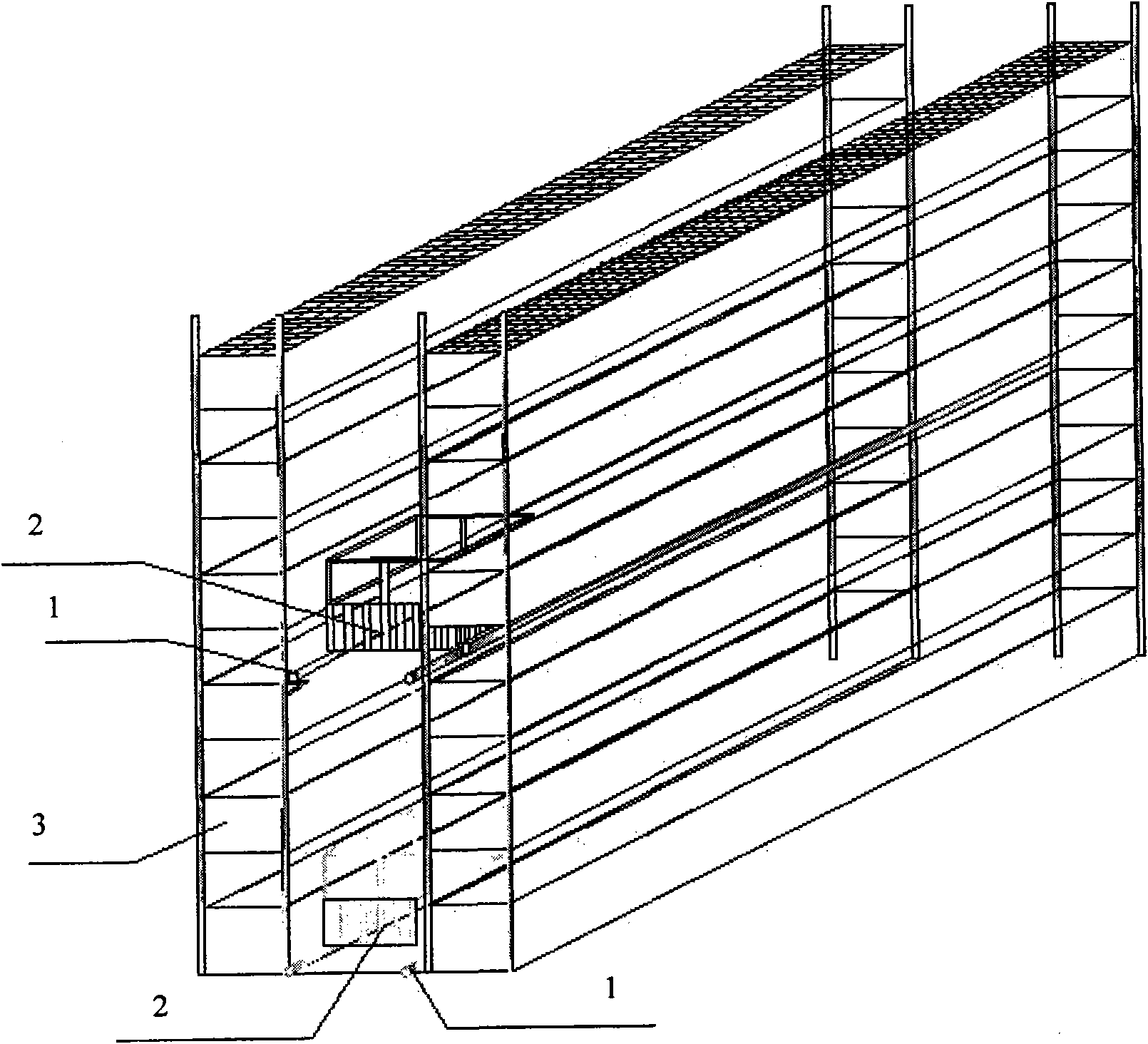

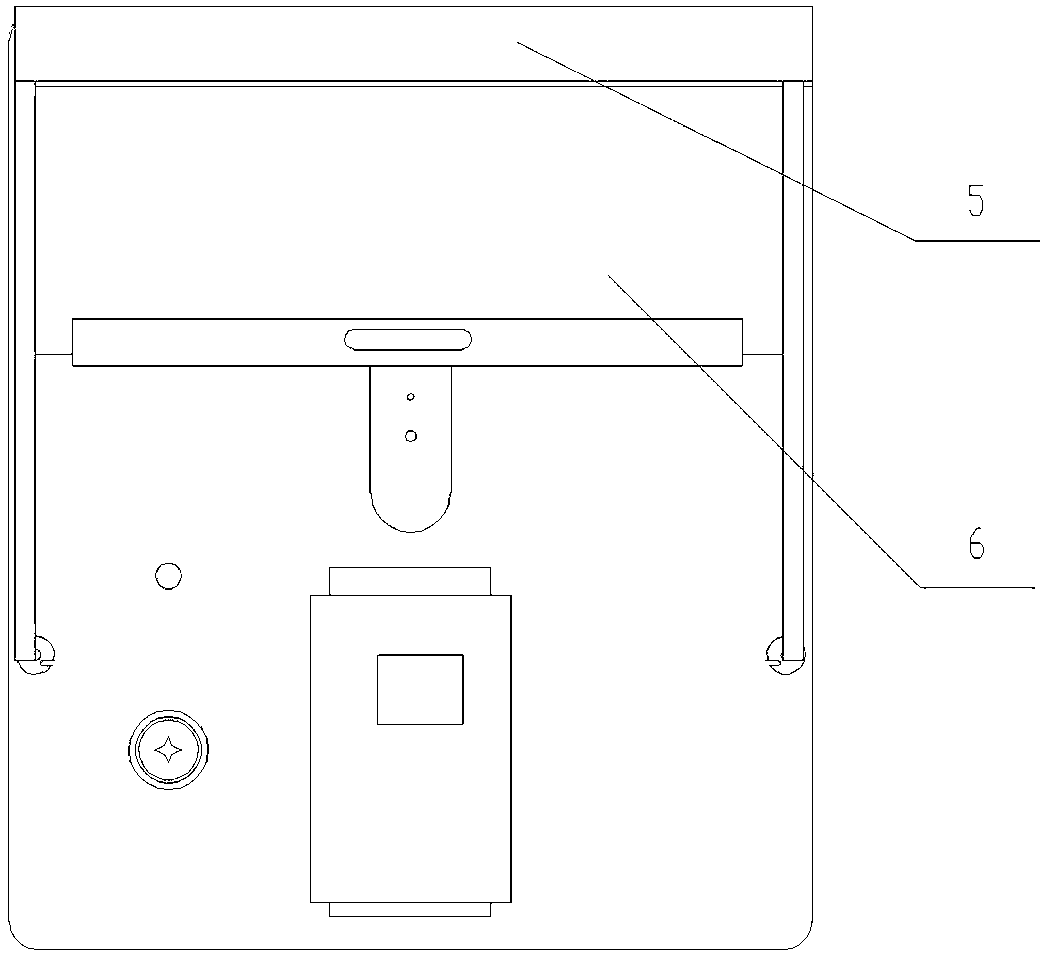

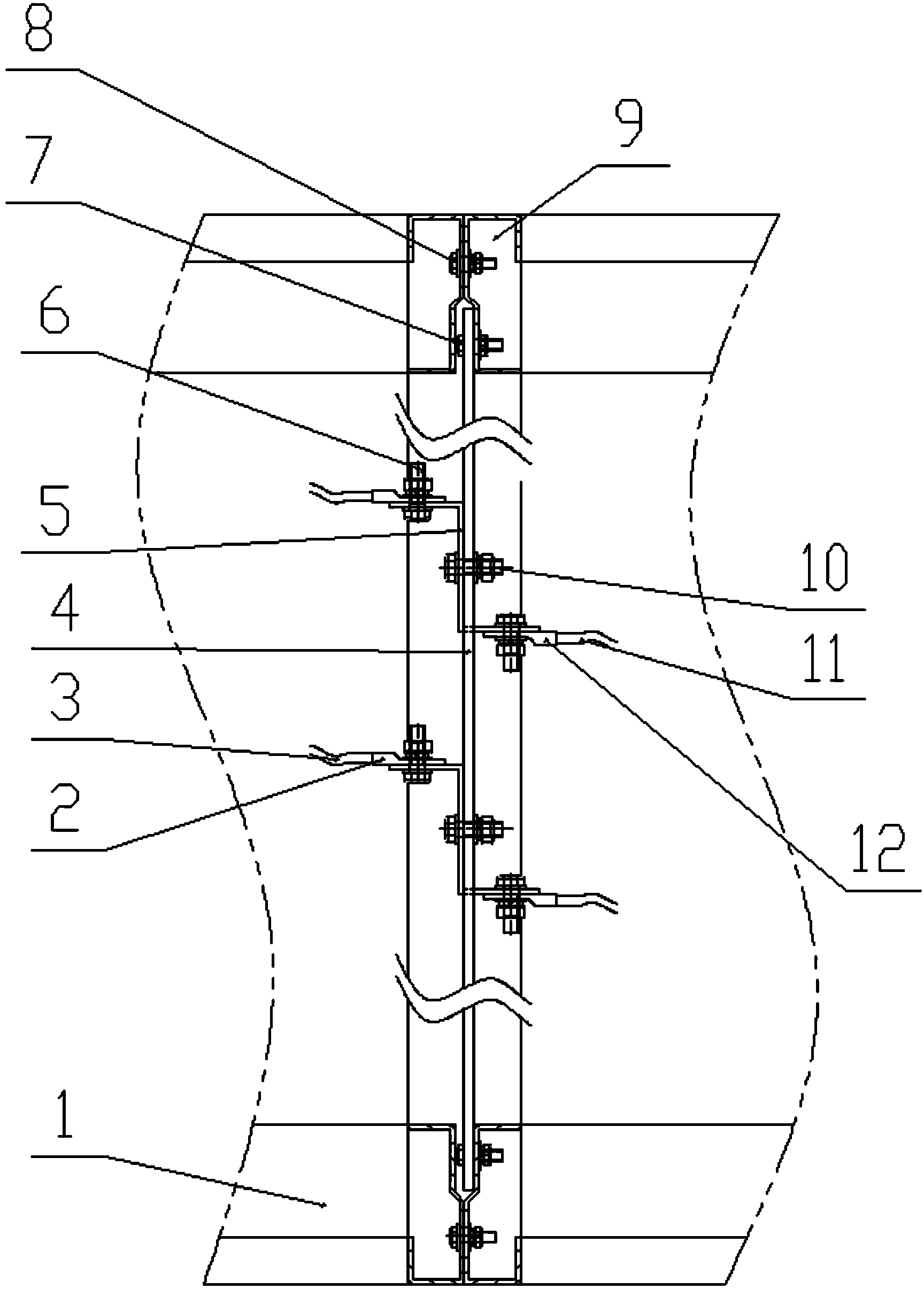

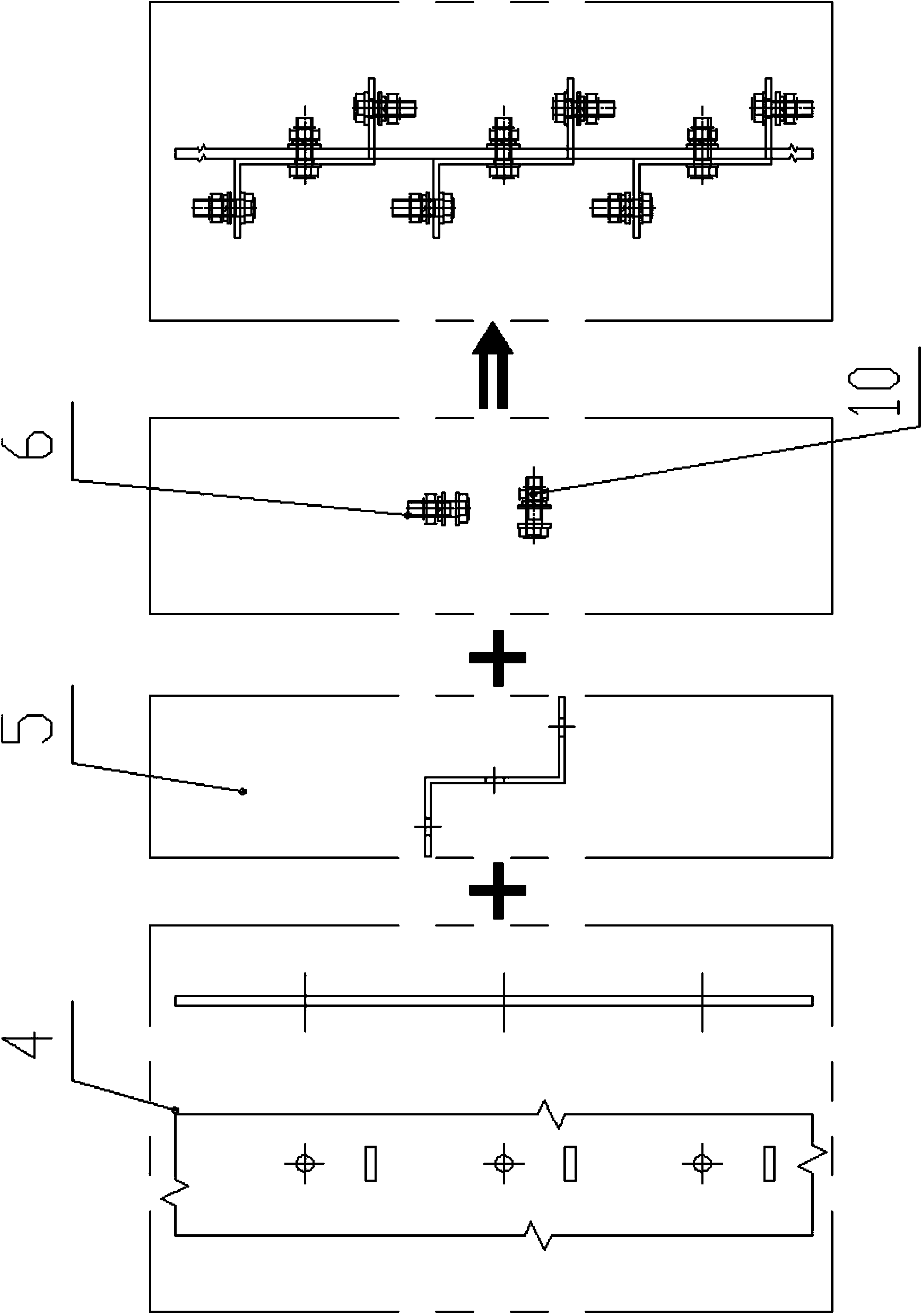

Three-dimensional ecological cultivation method for organisms

InactiveCN102067794AEfficient use ofImprove equipment levelClimate change adaptationPisciculture and aquariaGreenhouse productionEnvironmental index

The invention belongs to the technical field of protected agriculture, in particular relating to a three-dimensional ecological cultivation method for organisms. The method provided by the invention is characterized in that a cultivation space is vertically divided into multiple layers; and according to the environmental indexes such as illumination, temperature, humidity, carbon dioxide and the like of each layer, a species is cultivated on each layer of which the environmental indexes are suitable for the growth of the species. Meanwhile, the invention also provides a three-dimensional cultivation frame for implementing the method; the three-dimensional cultivation frame is of a vertical layered structure with the layer number greater than 1, comprises a strut as well as a detachable beam, a mesh, a fixing bolt, a cultivation container, an irrigation and backflow pipeline and light supplementing or illuminating facility on each layer, and is arranged in the cultivation space. According to the invention, different needs of different species on the environmental indexes such as temperature, humidity, illumination and the like are fully considered, the growth difference of the organisms is reduced, the management on greenhouse production is more convenient, and the resource waste is effectively reduced.

Owner:汪晓云

Method for manufacturing high-power annular inductor

ActiveCN102930971AGuaranteed demandSimple processTransformers/inductances magnetic coresCoils manufactureInductorEngineering

The invention relates to a method for manufacturing a high-power annular inductor, comprising the following steps: manufacturing an annular magnetic core, manufacturing an inductance coil and assembling to obtain a finished product. The high-power annular inductor manufactured by adopting the method comprises the annular magnetic core and the inductance coil. The annular magnetic core comprises more than three semi-arc shaped magnetic blocks along the circumference, wherein each semi-arc shaped magnetic block is equally divided into upper and lower halves; the surface of each semi-arc shaped magnetic block is coated with an insulating layer with a thickness of 0.2-0.5mm; the joints of the combined upper and lower semi-arc shaped magnetic blocks are arrayed in a mutual staggered way; the inductance coil is a spiral ring coil winded from a hard wire; the spiral ring coil is combined together with the semi-arc shaped magnetic blocks; and the annular magnetic core is sleeved coaxially and impregnated and cured into the whole product. The method overcomes the problems that the powdery magnetic core of the traditional annular inductor is restricted in size and can not be made from the large-area hard wire, the annular inductor is enabled to develop towards high power, and the requirement on the inductance inductor in the modern power electronics field is met.

Owner:NINGXIA YINLI ELECTRICAL CO LTD

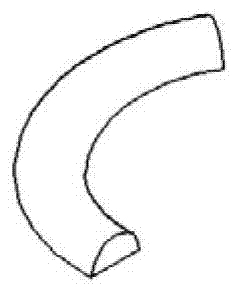

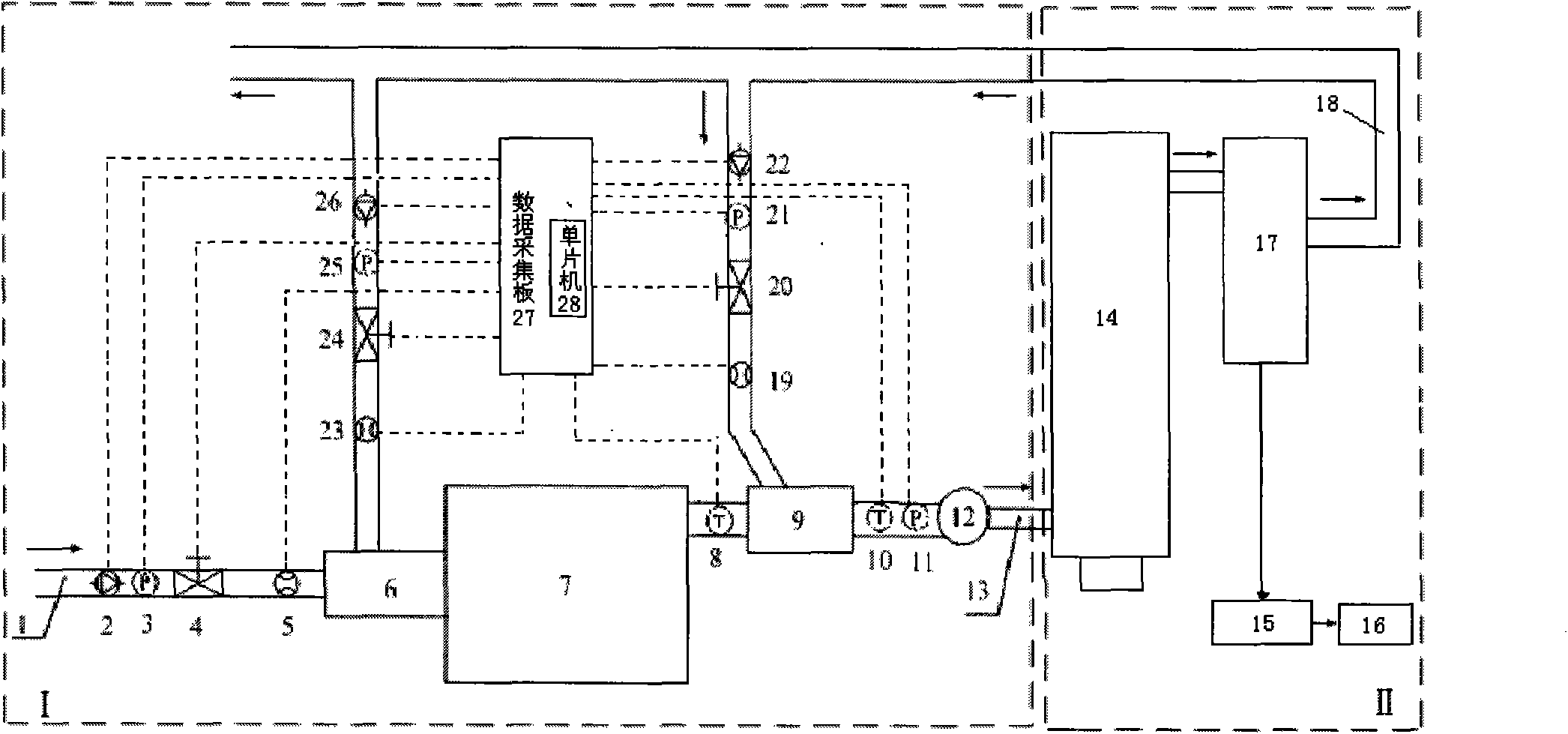

Autonomous multi-mode composite pipe positioning and exploration system and implementing method thereof

ActiveCN104777510AAchieve positioningFulfilling location exploration requirementsSeismologyUltrasonic sensorData acquisition

The invention discloses an autonomous multi-mode composite pipe positioning and exploration system and an implementing method thereof. The positioning and exploration system comprises a sensing module, a data acquisition module, a multi-mode composite processing module, a calibration module, an off-line trajectory generation module, a pipeline track positioning and displaying module and an autonomous traction and movement platform, wherein the sensing module comprises a sonar sensor, an ultrasonic sensor, an MEMS (micro-electromechanical system) sensor and a speed and distance measuring module; the data acquisition module comprises a data acquisition device, a data packaging device and a data sending device; the multi-mode composite processing module comprises a data receiving and subpackaging device, a multifunctional ARM processor, a data packaging device and a data storage device; the off-line trajectory generation module comprises a computer and related data processing software. With the adoption of the system, positioning and exploration requirements of a long-distance pipe buried deep underground can be met, a laying trajectory of the pipe can be obtained, the pipe can be positioned, and the current problem about exploration of the pipe can be solved.

Owner:梁步阁

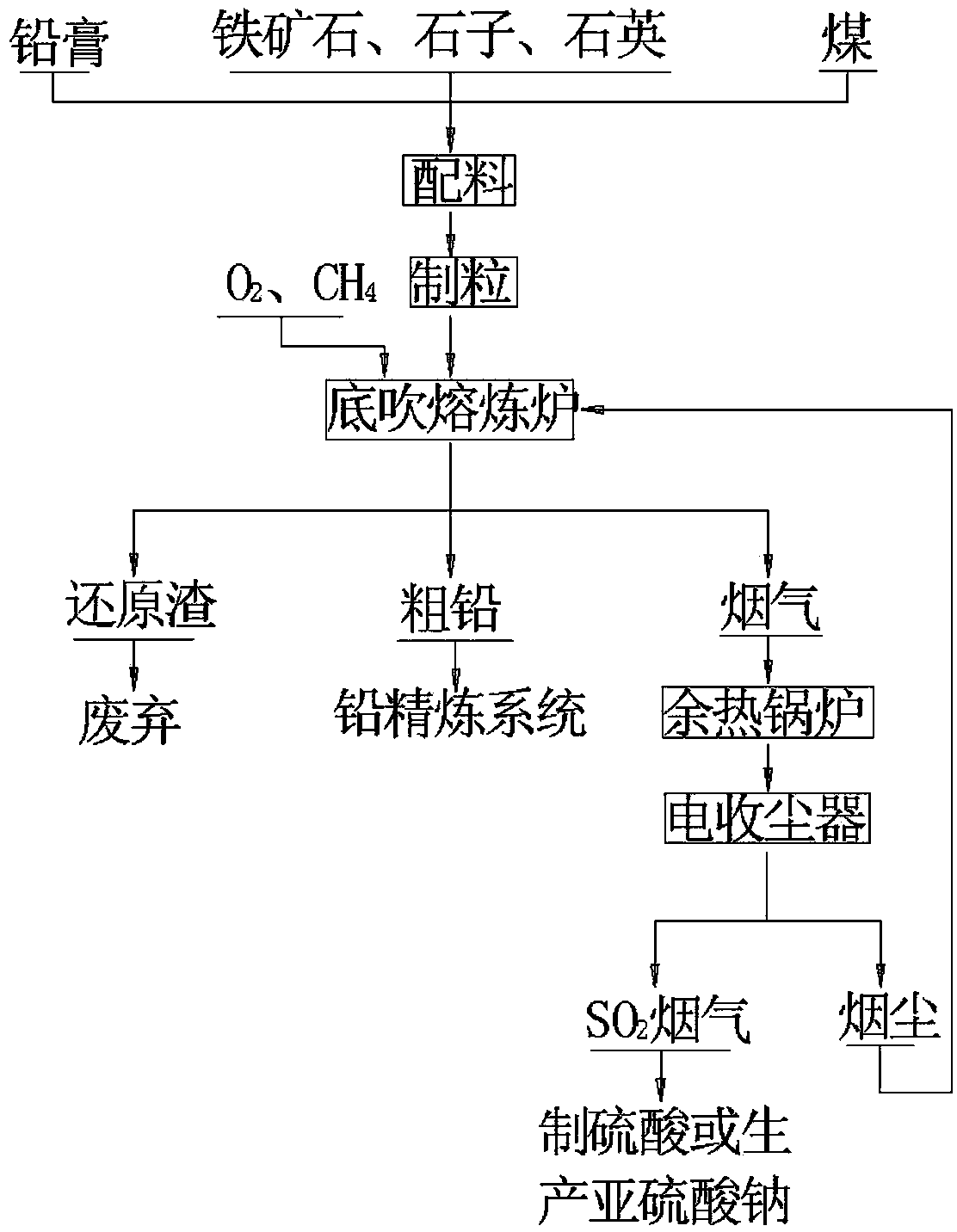

Device and technology for smelting and processing secondary lead materials to generate lead bullion by adopting bottom blowing furnace hearth

InactiveCN103451444AImprove airtightnessImprove environmental performanceHigh concentrationMelting tank

The invention belongs to the field of nonferrous metallurgy, and particularly relates to a device and technology for smelting and processing secondary lead materials to generate lead bullion by adopting a bottom blowing furnace hearth. Bullion lead materials are matched with pulverized coal, then limestone, pebbles, iron ore and other solvents are added to the mixture according to slag types and pelletizing is carried out, the lead bullion and reducing slag are output through the processing of a bottom blowing smelting furnace, the lead bullion is sent to a refining system, the content of valuable metal in the reducing slag is low, and the reducing slag is deposited as waste slag. Meanwhile, waste heat recovery is carried out on the output high concentration SO2 smoke and dust collection is carried out on the output high concentration SO2 smoke through a dust collection system, then the high concentration SO2 is sent to a sulfuric acid preparing system or a sodium sulfite preparing system to produce sulfuric acid or sodium sulfite products, and smoke dust is returned to carry out dosing. According to the device and technology for smelting and processing the secondary lead materials to generate the lead bullion by adopting the bottom blowing furnace hearth, lead plaster of secondary lead can be processed economically and effectively, and the process device is strong in leakproofness, good in environmental protection effect, high in efficiency of heat utilization, convenient to operate, high in automation level, low in labor intensity, long in service life of the furnace and high in metal direct recover rate, and effectively solves the problems that energy consumption is high, efficiency of heat utilization is low, and environmental protection effects are poor in the smelting and recovering process of lead-bearing materials.

Owner:HENAN YUGUANG GOLD & LEAD

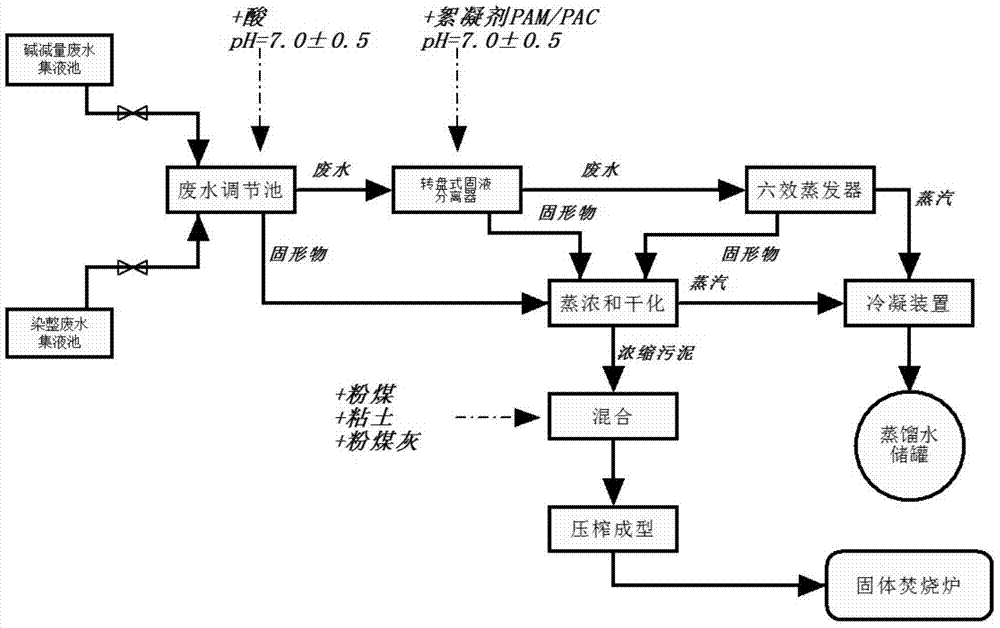

Wastewater zero discharge method in manufacturing process of island superfine fiber synthetic leather

InactiveCN103693792ASolve the technical bottleneck of zero emissionQuality improvementSludge treatment by de-watering/drying/thickeningBiofuelsFiberAluminium chlorohydrate

The invention discloses a wastewater zero discharge method in a manufacturing process of island superfine fiber synthetic leather. The method comprises the following steps: merging an alkali-minimization wastewater and a dyeing wastewater into a wastewater regulating reservoir, or merging the alkali-minimization wastewater into the wastewater regulating reservoir; adding acid to the wastewater regulating reservoir to form a solid matter; transferring the wastewater after the solid matter is cleaned into a turntable solid-liquid separator; adding a polyacrylamide flocculant and a polyaluminium chloride flocculant; evaporating the solid matter and the sludge obtained by solid-liquid separation in an evaporation tank, and simultaneously collecting distilled water in a condensation manner; transferring the wastewater from solid-liquid separation into a multi-effect evaporator to evaporate, and collecting distilled water by condensation; merging the residual residue in the evaporator into a sludge concentrating tank to continue to process. The production of the island superfine fiber synthetic leather is taken as a basic system, and is combined with collection, treatment and comprehensive utilization technologies of the production wastewater and the solid matter, the technical bottlenecks of wastewater zero discharge in the production process is solved, and the island superfine fiber synthetic leather which is friendly to environment and high in quality can be produced.

Owner:FUJIAN KELISHENG SUPERFINE FIBER

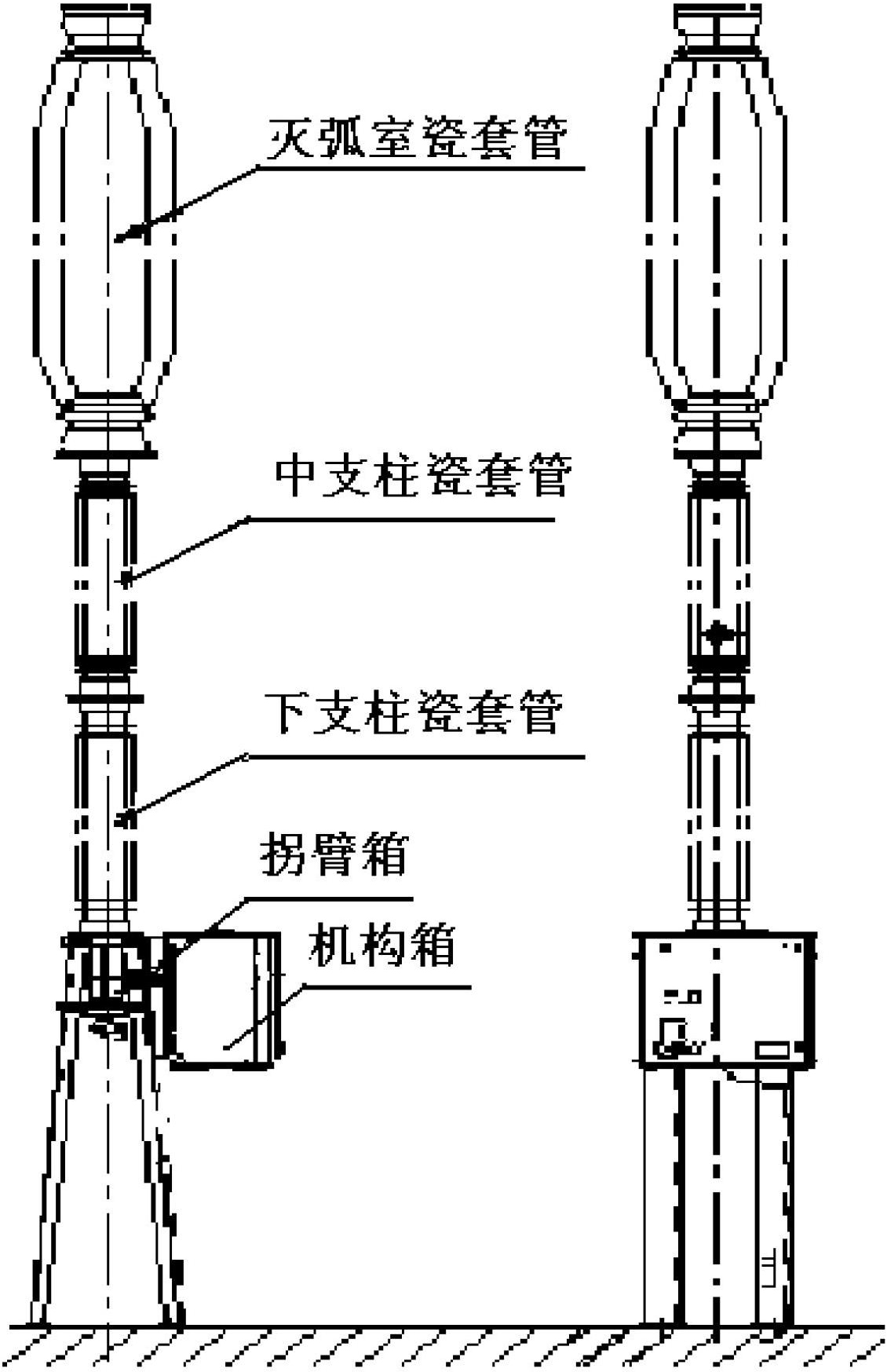

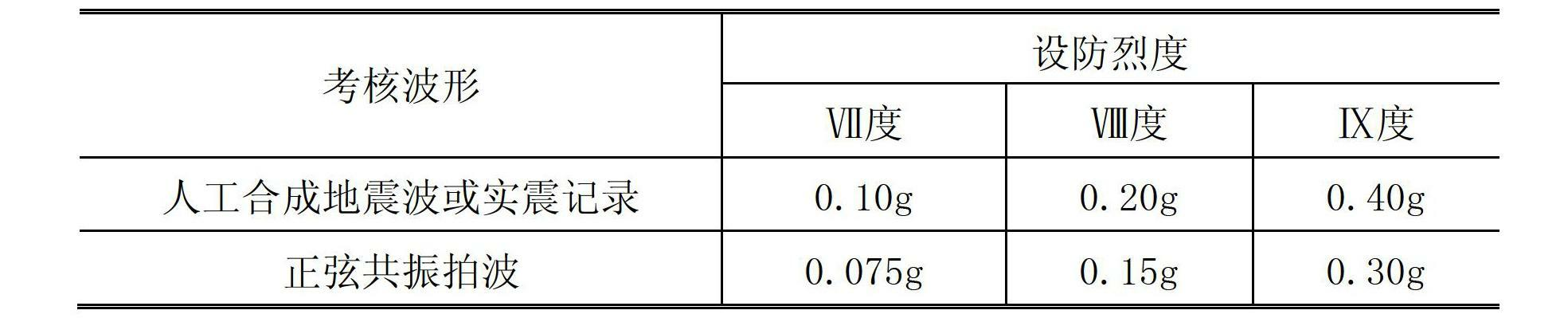

Three-grade seismic fortification method for electrical equipment

InactiveCN102664357AConsistent level of fortificationClear conceptAnti-seismic devicesPeak valueAcceleration Unit

The invention provides a three-grade seismic fortification method for electrical equipment. The method comprises the following steps of: dividing a seismic fortification level and defining acceleration peak values of different seismic inputs; determining a seismic fortification target; and checking the seismic capacity of the electrical equipment. On the basis of the self seismic capacity of the electrical equipment, a unified seismic fortification level is preset, so the fortification levels of an equipment manufacturer, engineering design and an owner are accordant, and the three-grade seismic fortification method for the electrical equipment has the characteristics of clear concept, convenience for operation and the like; moreover, according to the current economic and social development level of China, on the basis of a check criteria in the seismic fortification level provided by the invention, seismic requirements of the electrical equipment of China can be remarkably improved, great practical significance is provided for guarantee of the seismic reliability of the electrical equipment under various types of seismic action; and the method is applicable to seismic design and check of various kinds of electrical equipment in a voltage grade of 35 kV or over, and can be reference for the seismic design and check of other types of equipment.

Owner:CHINA ELECTRIC POWER RES INST +1

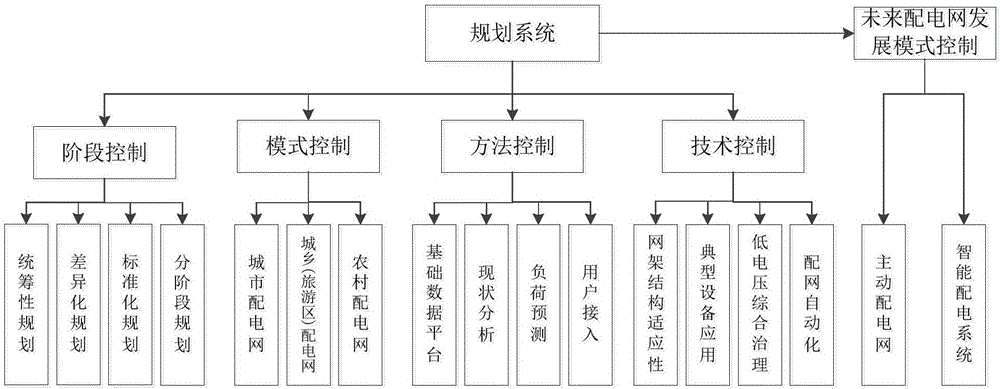

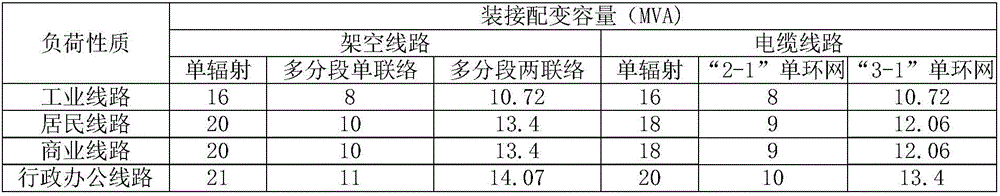

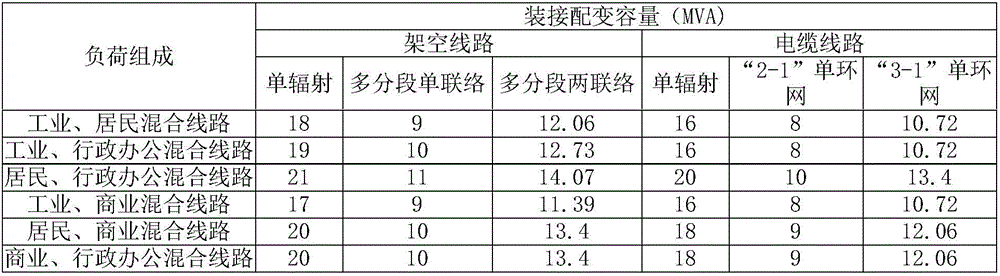

Distribution network transformation and construction analyzing and planning system

The invention provides a distribution network transformation and construction analyzing and planning system, which comprises a stage control subsystem, a mode control subsystem, a method control subsystem and a technology control subsystem. The distribution network transformation and construction analyzing and planning system dynamically controls the stage of management planning through the stage control subsystem, controls the transformation and construction mode through the mode control subsystem controls the specific procedures of the planning through the method control subsystem, and select the appropriate technical model in the planning through the technology control subsystem to form a closed-loop whole-process planning management. By the distribution network transformation and construction analyzing and planning system, the planning of design of the distribution network is led and proceeded in order. Urban and rural overall development and supply are guaranteed. The system is unified in standard, safe, economic, intelligent, environment-friendly, upgraded, and innovative.

Owner:YUNNAN POWER GRID +1

Wet-type sintering desulfurization flue gas deep purification device

ActiveCN102962135AAvoid Equipment CorrosionReduce corrosion rateElectrode carrying meansExternal electric electrostatic seperatorHeavy metalsFlue gas

Belonging to flue gas purification devices, the invention especially discloses a wet-type sintering desulfurization flue gas deep purification device, i.e. a device using the wet-type sintering desulfurization flue gas purification technology. The purification device includes a shell that is installed at the upper part of a desulfurization tower and is a part of the desulfurization tower body. The device is characterized in that: the inside of the shell is equipped with vertically mounted precipitation anode tube bundles and corona electrodes. The precipitating electrode tube bundles are supported by tube bundles inside the tower and fixed in the shell. The upper and lower ends of the corona electrodes are respectively connected to corona electrode small beams at the upper side and lower side of a corona electrode large beam, two ends of which are hung on a hanging rod in a side tube. A flushing instrument and an upper gas chamber are disposed over the precipitation electrode, the lower part of the shell is equipped with a gas distribution instrument, and a lower gas chamber is disposed between the precipitation electrode and the gas distribution instrument. A tower body platform outside the shell is provided with insulation boxes and transformers. The device can effectively remove micro-fine dust, acidic fog drops, nitrogen oxides, heavy metals, sulfates and other harmful substances from flue gas, and the removal rate can reach over 90%.

Owner:SHANDONG GUOSHUN CONSTR GRP

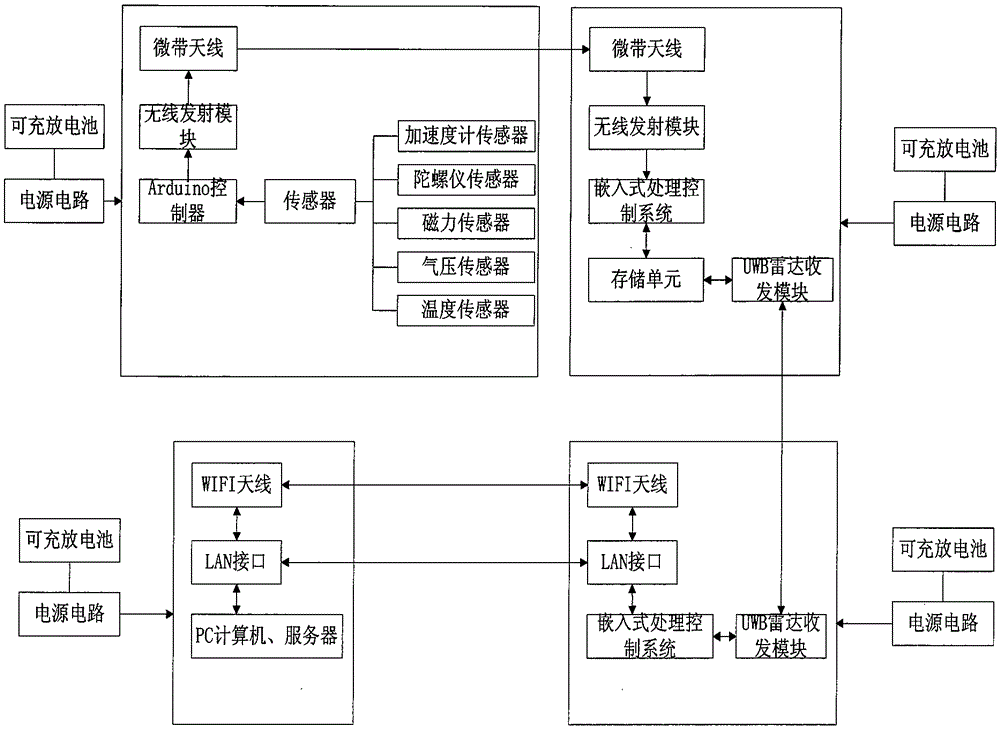

UWB autonomous positioning system for rescue in fire scene

ActiveCN105373141AImprove the level of technology and equipmentAchieving autonomous positioning requirementsControl using feedbackMicrostrip antennaMarine engineering

The invention relates to the technical field of indoor autonomous positioning, and especially relates to a UWB autonomous positioning system for rescue in a fire scene. The UWB autonomous positioning system comprises a shoe-borne autonomous positioning sensor, a UWB positioning module connected with the shoe-borne autonomous positioning sensor through wireless communication, and a UWB positioning network base station. Signal transmission is carried out between the shoe-borne autonomous positioning sensor and the UWB positioning module through a micro-strip antenna. Signal transmission is carried out between the UWB positioning network base station and the UWB positioning module through a UWB radar transceiver module. The UWB autonomous positioning system further comprises a background command platform including a PC or server, and the background command platform communicates with the UWB positioning network base station through a WIFI antenna or LAN interface. The requirement for real-time and high-accuracy fire scene rescue personnel autonomous positioning is satisfied, and guarantee is provided for the combat command of commanders outside the fire scene and the safety of fire fighters inside the fire scene.

Owner:梁步阁

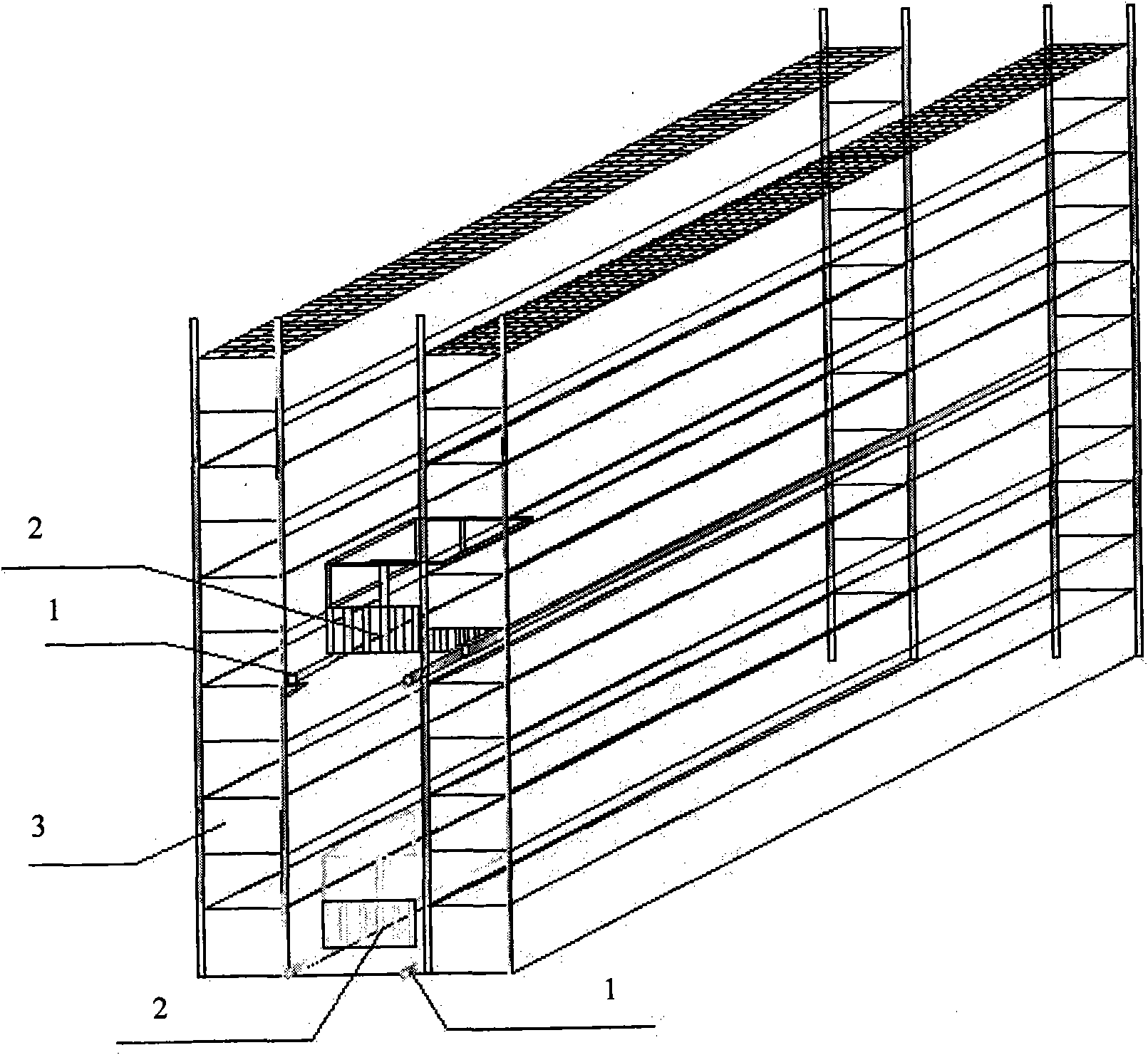

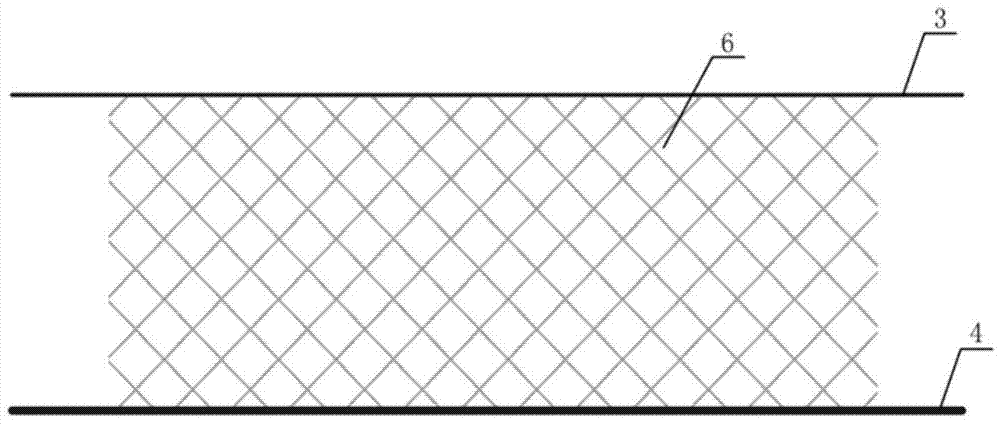

Processing method for large netting gear clothes of double-layer structure

ActiveCN103609496AIncreased service life and equipment levelsHigh strengthClimate change adaptationPisciculture and aquariaEngineeringUltra-high-molecular-weight polyethylene

A processing method for large netting gear clothes of a double-layer structure is characterized in that a small mesh ultra-high molecular weight polyethylene warp knitting net and a large mesh ultra-high molecular weight polyethylene warp knitting net are processed respectively; a head line is arranged on the upper edge in the length direction of the small mesh ultra-high molecular weight polyethylene warp knitting net which is 492m*11m and goes through anti-dirty treatment, and a foot line is arranged on the lower edge; a head line is arranged on the upper edge of the large mesh ultra-high molecular weight polyethylene warp knitting net which is 492m*11m and goes through anti-dirty treatment, and a foot line is arranged on the lower edge; the head line of the small mesh ultra-high molecular weight polyethylene warp knitting net which goes through the anti-dirty treatment and the head line of the large mesh ultra-high molecular weight polyethylene warp knitting net which goes through the anti-dirty treatment are bound into a head line of the large netting gear clothes of the double-layer structure; the foot line of the small mesh ultra-high molecular weight polyethylene warp knitting net which goes through the anti-dirty treatment and the foot line of the large mesh ultra-high molecular weight polyethylene warp knitting net which goes through the anti-dirty treatment are bound into a foot line of the large netting gear clothes of the double-layer structure.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

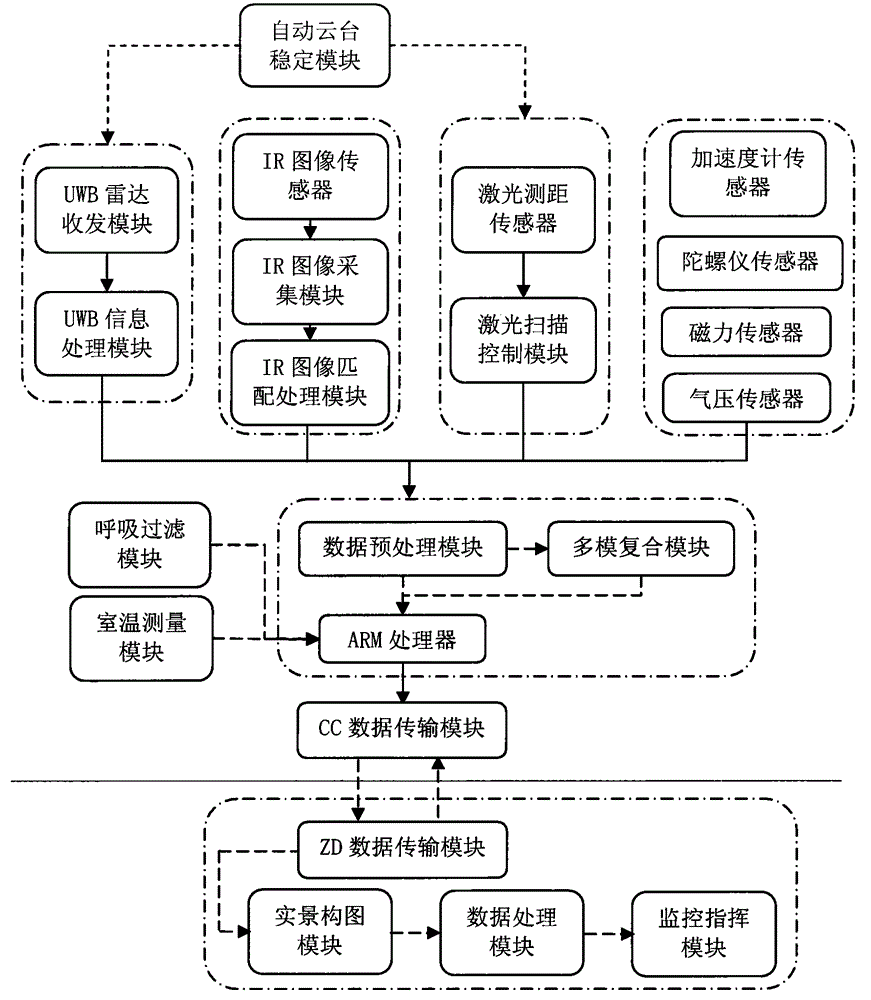

UWB autonomous positioning system and implementation method thereof

InactiveCN104914878ARealize the requirements of autonomous navigation and positioningEnsure safetyTarget-seeking controlComputer moduleComputer terminal

The invention discloses a UWB autonomous positioning system and an implementation method thereof. The system comprises multimode composite autonomous navigation positioning MSFL full-digitalization soldier helmet and an indoor real picture composition command guarantee ZHD terminal; the multimode composite autonomous navigation positioning MSFL full-digitalization soldier helmet comprises a UWB module, an IR infrared imaging module, an MEMS module, an LA laser distance measurement module, an automatic cloud platform stability module, a breath filtering module, an indoor temperature measurement module, a multimode composite processing module and an CC data transmission module; and the indoor real picture composition command guarantee ZHD terminal comprises a ZD data transmission module, a monitoring and command module, a data processing module and a real picture composition module. Picture composition is performed on indoor real sceneries by utilizing multimode composition, a real-time high-precision autonomous navigation positioning request is achieved, the safety guarantee is improved, and our county's technology level and equipment level on the aspects of indoor personnel autonomous navigation positioning, real picture composition and the like are effectively improved.

Owner:梁步阁

Gas explosion impact force detecting device and method

InactiveCN105424699AGood test resultsShort opening timeMaterial analysis by optical meansSlip sheetEngineering

The invention provides an experiment device capable of materializing and concreting impact force caused by explosions, and particularly provides a gas explosion impact force detecting device. According to the specific scheme, the device is characterized by comprising a buffer bin, a vent duct, a pipeline, an explosion bin and a camera part, the buffer bin is made of steel, the vent duct is connected with the pipeline and the explosion bin and provided with a vent film, the pipeline is an anti-explosion material pipeline and is transparent, the pipeline is internally provided with slip sheet chutes and slip sheets, the slip sheets are clamped in the chutes and can be pushed to slide, the explosion bin is the place where gas explosions are triggered, and the camera part comprises a movement camera, a movement camera bracket and a static camera. The invention further provides a gas explosion impact force detecting method using the gas explosion impact force detecting device.

Owner:SHANDONG UNIV OF SCI & TECH

Cable splicing operation platform

InactiveCN103293601AEnsure cutover safetyImproved cutover securityCoupling light guidesTerrainCircular disc

The invention discloses a cable splicing operation platform comprising a platform body with support legs. Two ends, in the horizontal direction, of the top of the platform body are provided with a groove for accommodating a splicer and a U-shaped clamping board for fixing a cable joint box. A rectangular fixing groove is formed at the inner top of the U-shaped clamping board and matches with a disc part of the cable joint box. Wind boards are arranged at a cable inlet of the platform body and on adjacent two sides. By the aid of the cable splicing operation platform, splicing workers can set up and place splicing equipment conveniently under various conditions, the cable splicer, an OPGW (optical fiber composite overhead ground wire) cable and the joint box can be fixed, cable breakage or core breakage due being mistakenly hit by external forces can be avoided, safe cutting and splicing of the cables can be guaranteed, the reliability rate, quality and efficiency of cable splicing can be increased, and quality and efficiency of cable splicing can be improved. The cable splicing operation platform can be assembled rapidly, and is adaptable to terrains, convenient to operate and carry, reasonable in structure, light in weight, durable and consistent to splicing specifications.

Owner:STATE GRID CORP OF CHINA +1

Dry distillation medium generating system for internal heat type low-temperature dry distillation and automatic control method

InactiveCN101818070ATake advantage ofImprove heat utilization efficiencyProgramme controlCombustible gas coke oven heatingCombustion chamberAutomatic control

The invention discloses a dry distillation medium generating system for internal heat type low-temperature dry distillation. The system comprises a combustor, a mixed combustion chamber and a fuel gas pipeline, wherein the input end of the combustor is connected with the fuel gas pipeline and also connected with an oxygen-enriched air or oxygen pipeline, and the output end of the combustor is connected with the mixed combustion chamber; the output end of the mixed combustion chamber is connected with a gas mixing chamber; the input end of the gas mixing chamber is connected with the fuel gas pipeline; the oxygen-enriched air or oxygen pipeline connected to the input end of the combustor is provided with a first pressurization fan, a first pressure measurement instrument, a first control valve and a first flow measurement instrument in order; and the fuel gas pipeline connected to the input end of the combustor is provided with a second pressurization fan, a second pressure measurementinstrument, a second control valve and a second flow measurement instrument in order. The system has the advantages of ensuring part of the fuel gas in a closed cycle, improving quality, reducing three-waste emission and improving tar yield so as to easily realize co-production among enterprises and comprehensive utilization of the fuel gas.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Power device combined cabinet connecting device

InactiveCN104319982ASimple structureNo need to disassembleCircuit arrangements on support structuresPower conversion systemsTransformerMaintainability

The invention discloses a power device combined cabinet connecting device. The power device combined cabinet connecting device comprises a plurality of base plates arranged between two different cabinet bodies, a plurality of transition connection copper bars arranged on the base plates, penetrating through the base plates and used for transition connection of cables between the two different cabinet bodies, a plurality of first fastening external members, a plurality of fourth fastening external members and a plurality of second fastening external members, wherein the cables are fixed to two ends of each transition connection copper bar through the corresponding fastening external members, the transition connection copper bars are fixed to the base plates through the fourth fastening external members, and the base plate is fixed between the two different cabinet bodies through the second fastening external members. By means of the power device combined cabinet connecting device, the technical problem that cable arrangement between a power unit module and a transformer is complicated, a manufacturing period is long and maintainability is poor can be effectively solved.

Owner:STATE GRID CORP OF CHINA +1

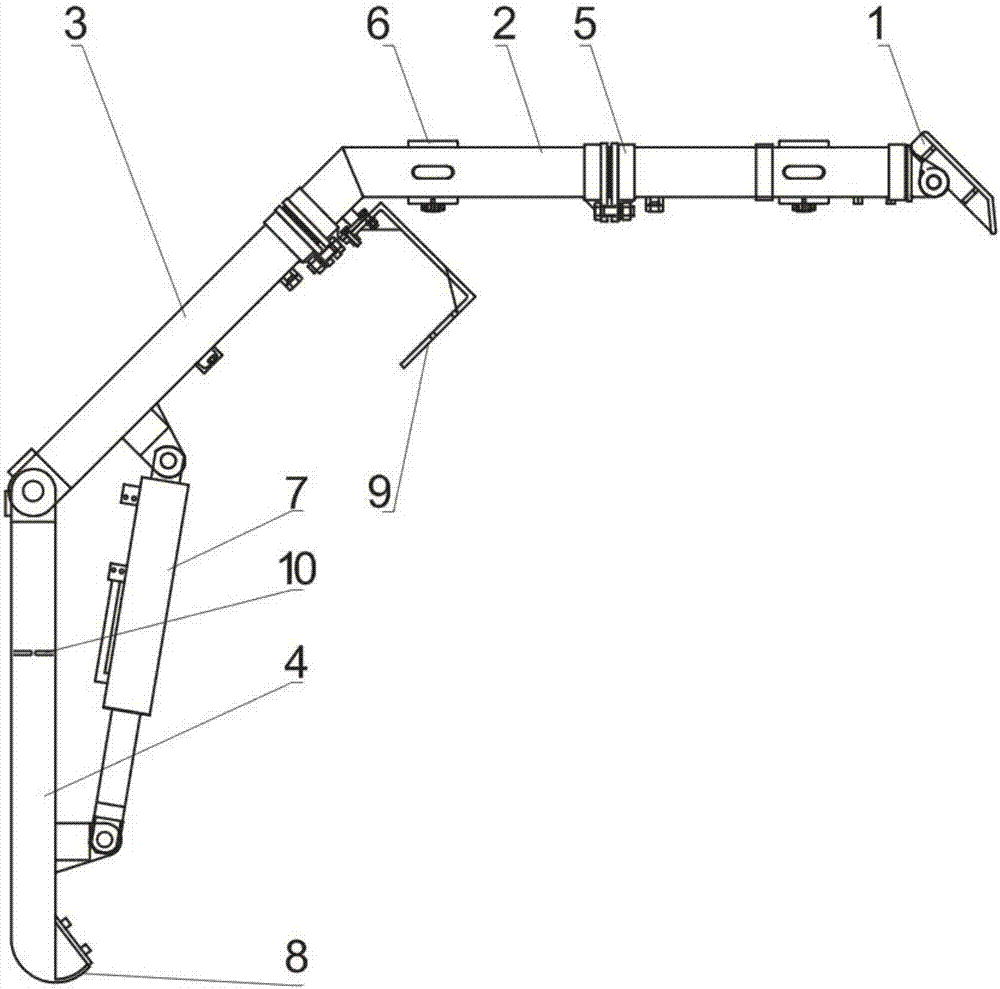

Light-weight telescopic flexible hydraulic shield support frame

InactiveCN107313795AReduce support strengthReduce your weightMine roof supportsMechanical engineeringUpper segment

The invention discloses a light-weight telescopic flexible hydraulic shield support frame, which is formed by sequentially connecting a top beam at the upper section, a shield beam at the middle section and a tail beam at the bottom end, wherein a guide beam is movably arranged at the front end of the top beam; the upper surface of the guide beam is a sliding surface; the sliding surface and the axial line of the top beam form an included angle; the shielding beam is hinged to the tail beam; a jack is used for supporting between the arm part of the shield beam and the arm part of the tail beam; and the tail end of the tail beam is provided with a slide boot used for sliding on a floor of a coal face. The light-weight telescopic flexible hydraulic shield support frame has the advantages that the support force is greater; the use is more flexible; the application range is wider; the installation and the use are convenient; and the automatic walking and moving can be reached. The light-weight telescopic flexible hydraulic shield support frame is mainly applicable to a false inclined and sharp inclined coal seam with the inclination angle being greater than 45 degrees or even a coal mining working face with the reverse condition, is applicable to a medium-thick coal seam or thicker coal seams, has certain applicability to the coal seam change, is applicable to a work face using inclined or false inclined wall type pitching inclined mining arrangement, and is applicable to a coal seam with a crushed roof.

Owner:四川广旺能源发展(集团)有限责任公司机械制造分公司

Litopenaeus vannamei transportation method capable of keeping litopenaeus vannamei alive without water

InactiveCN106719196AImprove survival rateReduce mortalityClimate change adaptationPisciculture and aquariaSocial benefitsPrawn

The invention discloses a litopenaeus vannamei transportation method capable of keeping litopenaeus vannamei alive without water. The method includes the steps of S1, placing the litopenaeus vannamei in water at the temperature of 15-20 DEG C, feeding carbon dioxide to anaesthetize the litopenaeus vannamei, and regulating the pH of the water to 5.5-6.5; S2, placing the anaesthetized litopenaeus vannamei on a low-temperature sponge, filling oxygen, sealing and transporting. The method has the advantages that the death rate of the litopenaeus vannamei during transportation can be lowered, reviving time is shortened, and activity after reviving is increased; the method is simple to operate, capable of increasing the equipment level of enterprises for keeping the litopenaeus vannamei alive without water and capable of increasing the survival rate of alive-keeping litopenaeus vannamei transportation; the method can evidently increase the economic benefits of alive-keeping enterprises, benefit litopenaeus vannamei farmers, promote the healthy development of litopenaeus vannamei industry and obtain good economic and social benefits.

Owner:GUANGDONG OCEAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com