Marine ranching dike netting gear component assembly method

A technology for marine pastures and dams, applied in the field of marine pasture embankments and nets, can solve the problems of anti-marine biofouling, net pile wear, losses of farmers or farming enterprises, etc., to improve service life and equipment level, and increase safety. , the effect of strong improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

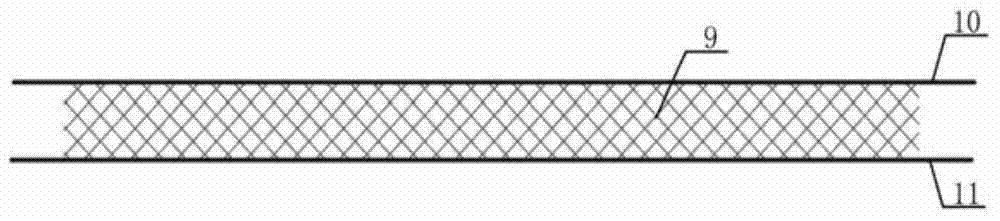

[0010] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings:

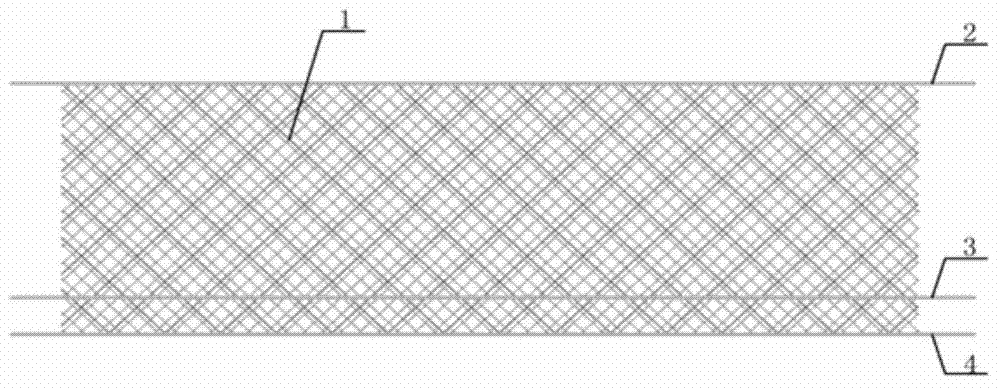

[0011] First, the ultra-high molecular weight polyethylene fiber with a linear density of 176tex is warped into an ultra-high molecular weight polyethylene fiber yarn with a linear density of 176tex. Net weaving structure and longitudinal heat setting treatment. 19 ultra-high molecular weight polyethylene fiber yarns with a linear density of 176tex are processed into a small-mesh ultra-high molecular weight polyethylene warp with a specification of "UHMWPE-176tex×29-46" by a warp knitting machine. Weaving net;

[0012] Use the antifouling agent for fishing nets to carry out antifouling treatment on the small-mesh ultra-high molecular weight polyethylene warp-knitted net, and obtain the antifouling-treated small-mesh ultra-high molecular weight polyethylene warp-knitted net after drying;

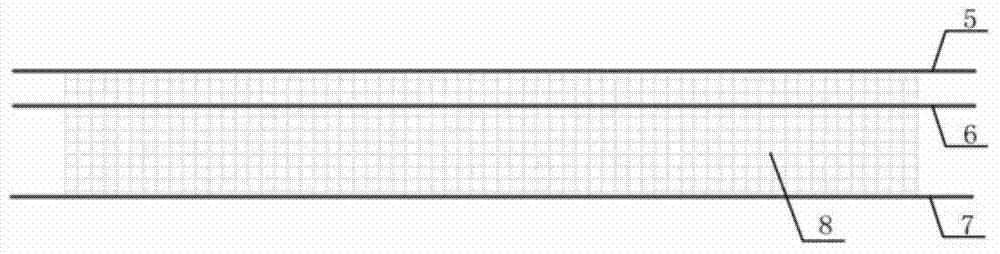

[0013] The ultra-high molecular weight polyethylene fiber with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com