Dry distillation medium generating system for internal heat type low-temperature dry distillation and automatic control method

A generation system and internal heating technology, applied in the direction of special dry distillation, general control system, combustion method, etc., can solve the problems of increasing the processing pressure of the gas purification system, the difficulty of comprehensive utilization of waste gas, and insufficient combustion of gas, etc., to achieve the improvement of technology and equipment level, easy gas purification, and the effect of realizing comprehensive utilization of co-production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

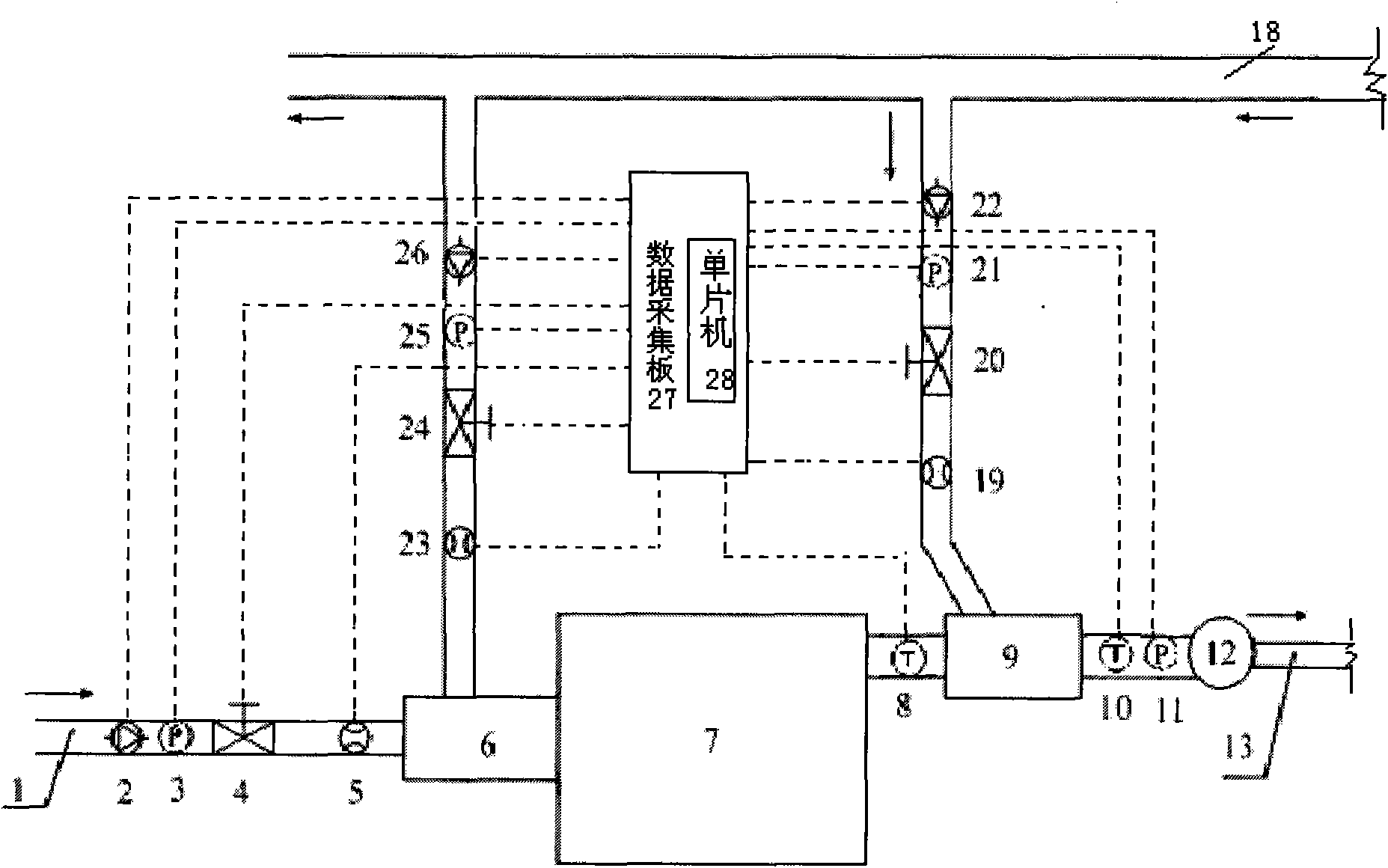

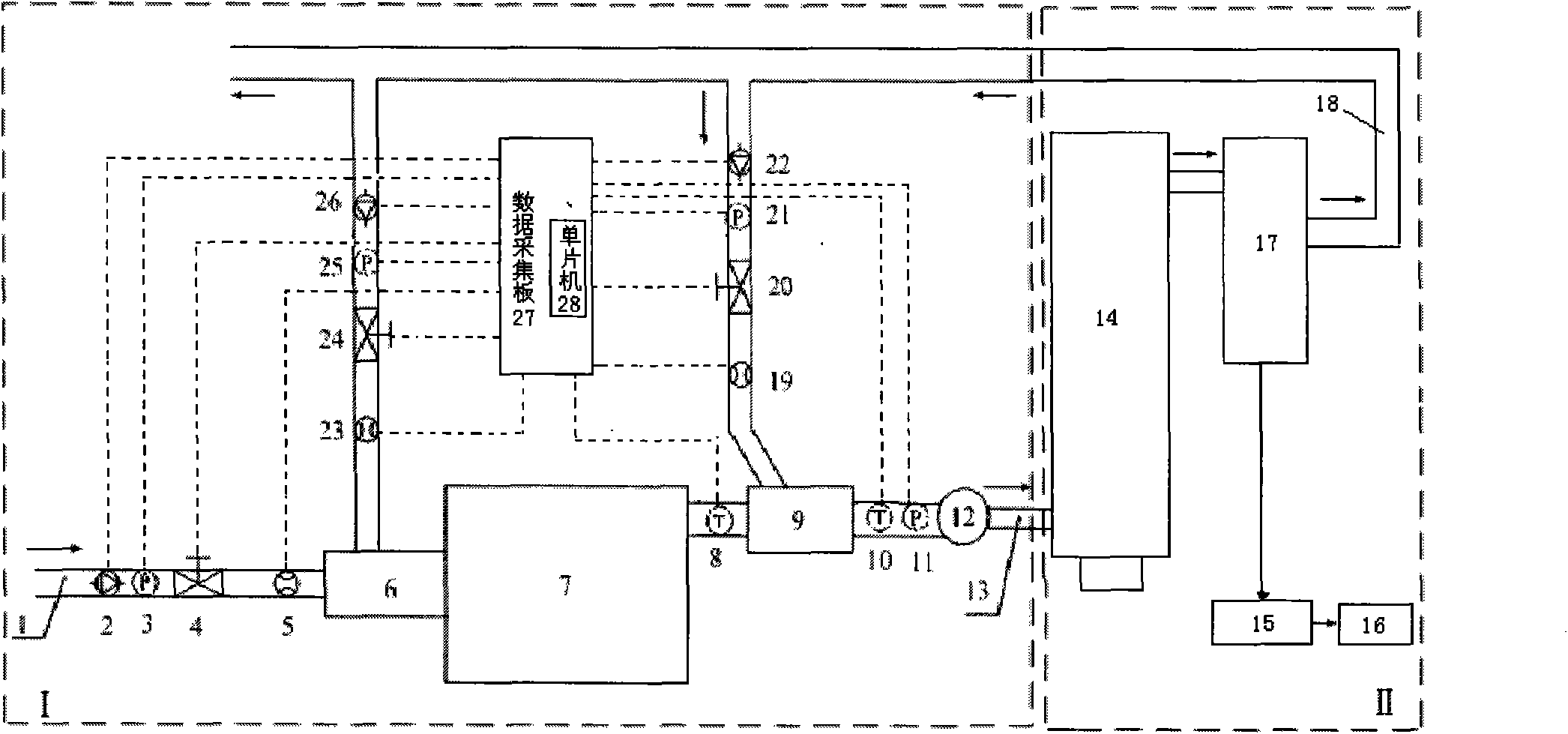

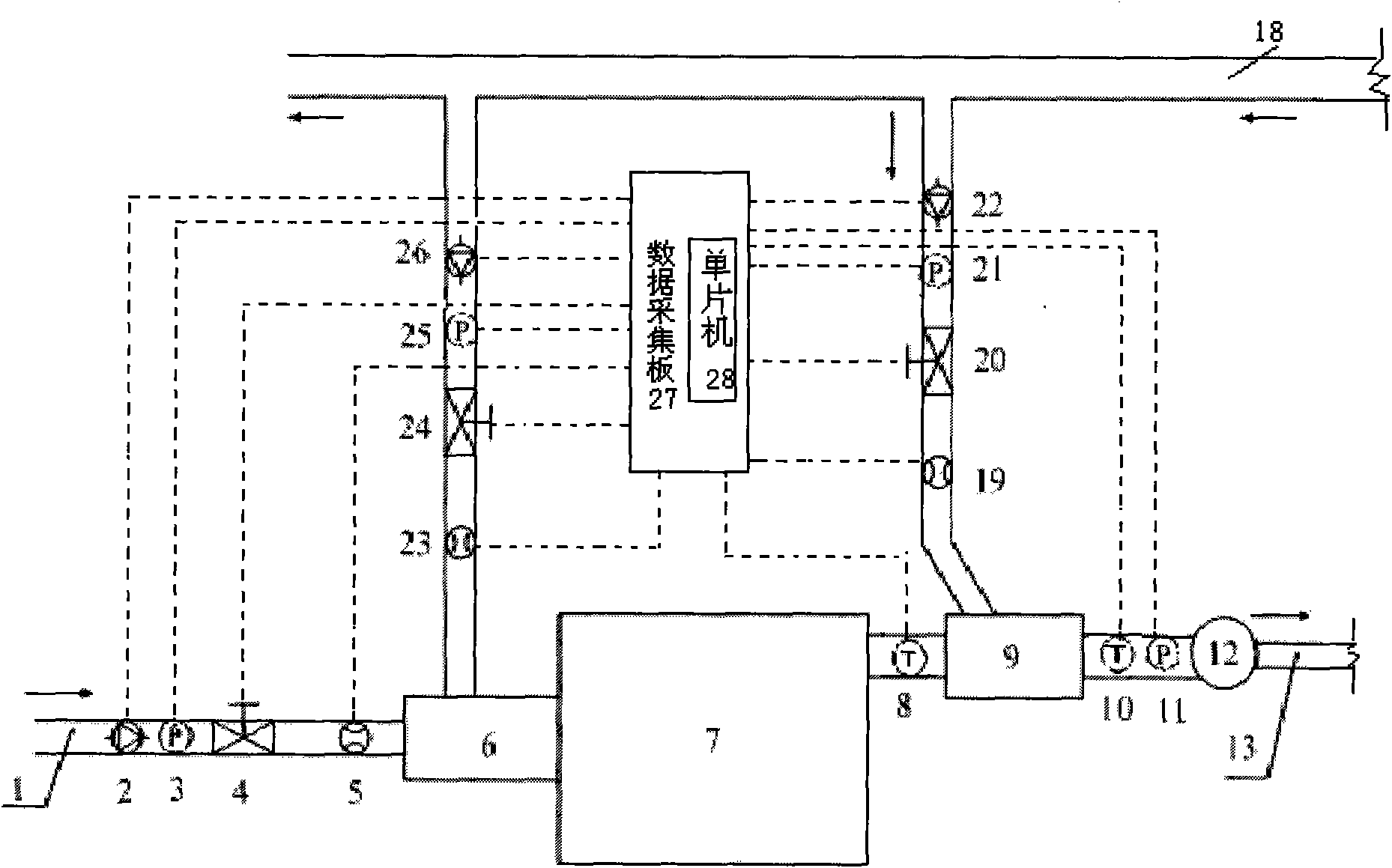

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: annual production plant application of 600,000 tons of semi-coke (passing into oxygen-enriched air)

[0049] (1) Basic information

[0050] The semi-coke production adopts a vertical square furnace, which originally uses air to support combustion, and the coke ratio of coal (Shenmu coal) is 1.68:1. The tar yield is about 7.8%, and the remaining gas volume per ton of coal is 580m 3 About, gas calorific value 1700-1900kcal / Nm 3 , The gas is consumed by small-scale gas-fired power generation. The power generation is mainly for self-use, and a small amount of gas is burned and discharged. The gas sample composition is: H 2 11.0%, CO 11.2%, CO 2 5.9%, CH 4 13.29%, C2-C5 1.24%, calorific value 1779kcal / m 3 .

[0051] (2) Application result

[0052] Change the combustion-supporting air to oxygen-enriched air (oxygen-enrichment rate is 30%), apply the carbonization medium generation system of the present invention, the coal-coke ratio is reduced to 1.66...

Embodiment 2

[0053] Embodiment 2: annual production plant application of 600,000 tons of semi-coke (feeding pure oxygen)

[0054] (1) Basic information

[0055] The semi-coke production adopts a vertical square furnace, which originally uses air to support combustion, and the coke ratio of coal (Shenmu coal) is 1.67:1. The tar yield is about 7.8%, and the remaining gas volume per ton of coal is 570m 3 About, gas calorific value 1700-1900kcal / Nm 3 , The gas is consumed by small-scale gas-fired power generation. The power generation is mainly for self-use, and a small amount of gas is burned and discharged. The gas sample composition is: H 2 11.8%, CO 10.9%, CO 2 6.1%, CH 4 12.39%, C2-C5 1.24%, and the rest is nitrogen. Calorific value of gas 1768kcal / m 3 .

[0056] (2) Application result

[0057] Now change the combustion-supporting air to pure oxygen, apply the dry distillation medium generating system of the present invention, the coal-coke ratio is reduced to 1.63:1, the tar ...

Embodiment 3

[0058] Embodiment 3: annual production of 1,500,000 tons of semi-coke industrial zone application (feeding pure oxygen)

[0059] (1) Basic information:

[0060] In the industrial park, there are two production enterprises with an annual output of 600,000 tons of semi-coke, and one production enterprise with an annual output of 200,000 tons of semi-coke. Both of them use vertical square furnaces with air-assisted combustion and a coal-to-coke ratio of 1.65:1. The tar yield is about 8%, and the remaining gas volume per ton of coal is 580m 3 About, gas calorific value 1700-1900kcal / Nm 3 , The gas is consumed by gas-coal hybrid power generation, and the generator efficiency is about 39%. The average composition of the sampled gas is: H 2 12.1%, CO 10.6%, CO 2 6.5%, CH 4 14.39%, C2-C5 1.04%, and the rest is nitrogen. Calorific value 1849kcal / m 3 .

[0061] (2) Application result

[0062] It adopts the method of centrally setting up the air separation oxygen generator and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com