High-temperature steel slag bottom blowing air cooling crushing waste heat recovery device and method

A waste heat recovery device and cold crushing technology, which is applied in the field of high-temperature molten steel slag for air-cooled crushing waste heat recovery, can solve the problems of high system investment, inability to recover waste heat, and discontinuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

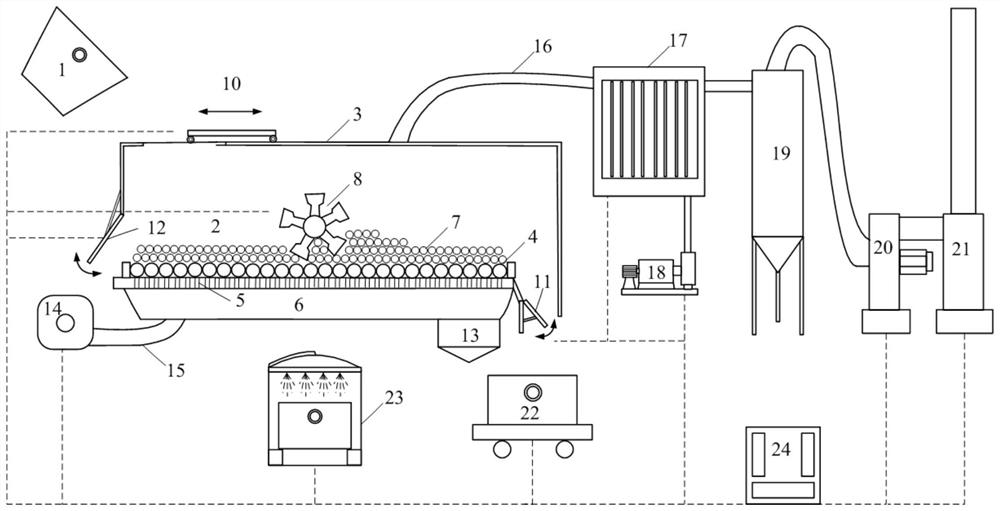

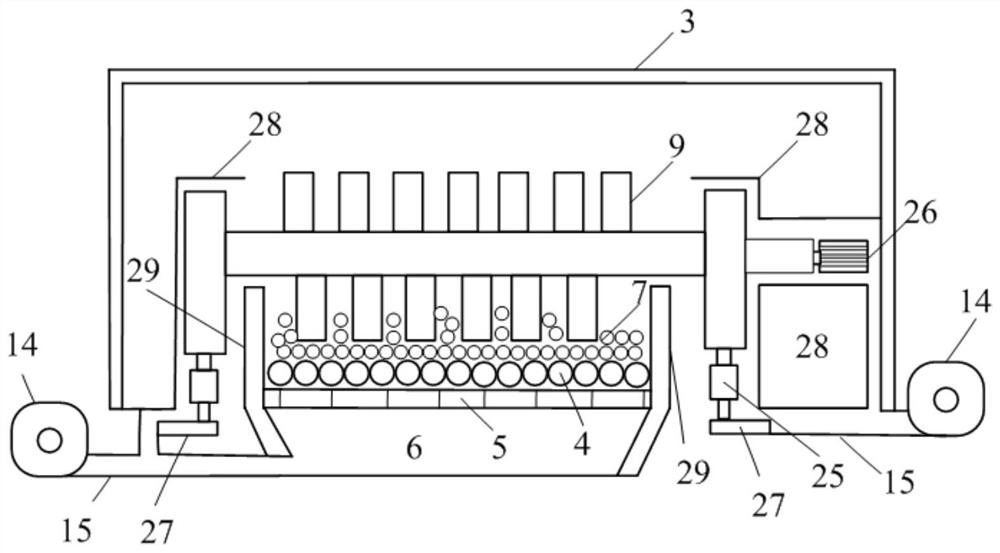

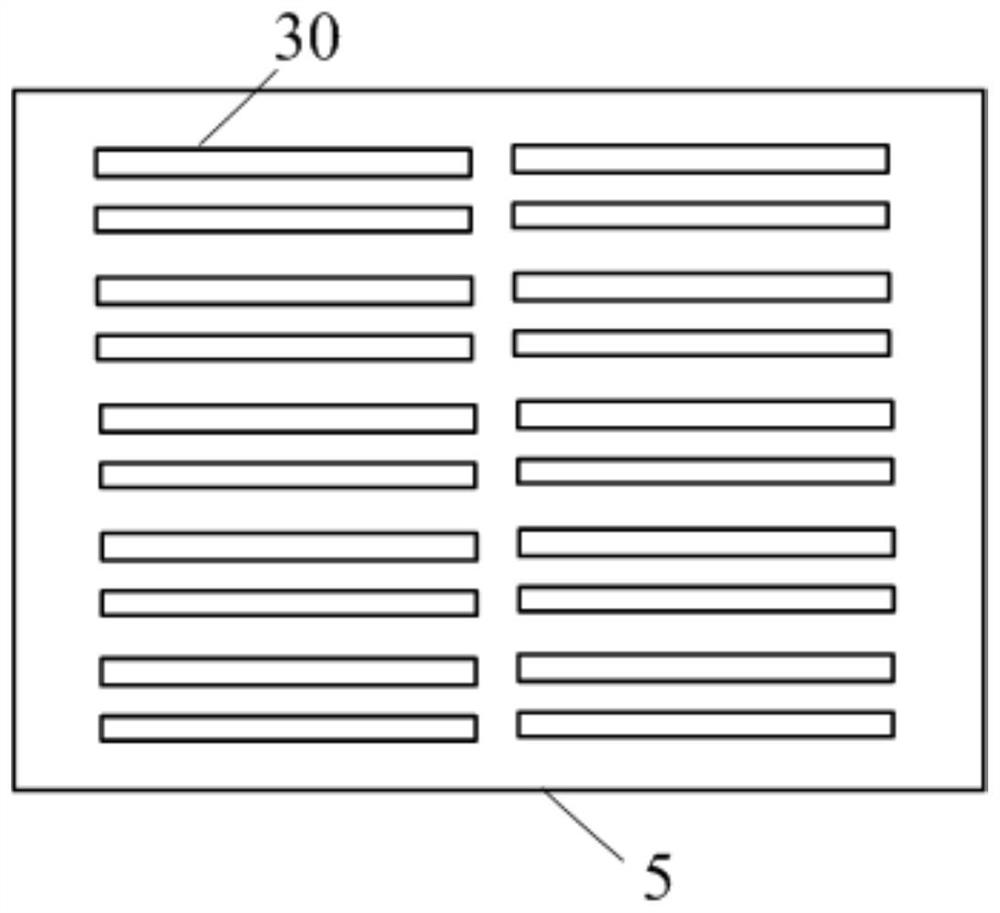

[0046] A high-temperature steel slag bottom air blowing cold crushing waste heat recovery system device such as figure 1 , figure 2 and image 3 As shown, the high-temperature steel slag bottom blowing cold crushing waste heat recovery system device includes: slag tank 1, crushing bed 2, airtight cover 3, crusher 8, bottom blowing cold box 6, hot stuffy tank 23, flue gas waste heat recovery system and control system 24. The crushing bed 2 includes a cold slag cushion 4 and a grate plate 5, the cold slag cushion 4 is above the grate plate 5; the airtight cover 3 is placed above the crushing bed 2; the airtight cover 3 includes a slag discharge port 10, The slag discharge port 11, the large slag discharge port 12, the slag discharge port 10 is above the airtight cover 3, the slag discharge port 11 is below the side of the airtight cover 3 away from the slag discharge port 10, and the large slag discharge port 12 is near the slag discharge port 10 The front of one side; the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com