A preparation method of cellulose flame-retardant modified composite phenolic foam

A technology of phenolic foam and cellulose, which is applied in the field of composite material preparation, can solve problems such as the difficulty of mixing cellulose evenly, and achieve the effects of promoting application, improving mechanical properties, and increasing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

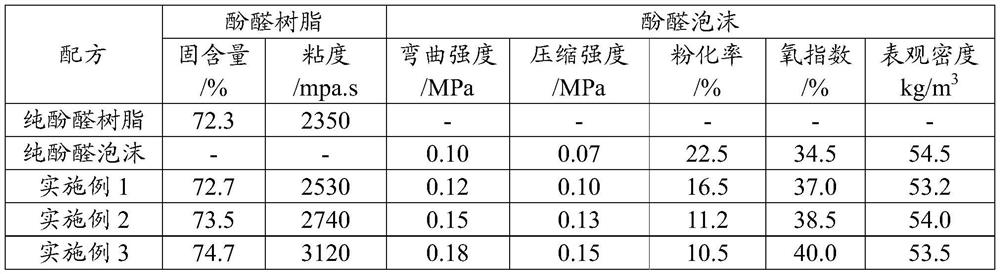

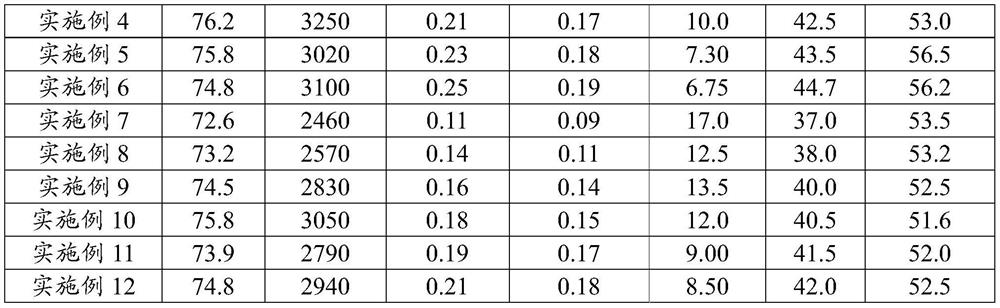

Examples

Embodiment 1

[0019] (1) Preparation of DOPO-g-ITA: Using xylene as solvent, under nitrogen protection, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10- Add oxide (DOPO) and itaconic acid (ITA) into the reactor, reflux at 120°C for 4 hours, cool to 110°C, filter with suction, wash with acetone several times, and dry to obtain DOPO-g-ITA solid White powder. (2) Preparation of DOPO-g-ITA flame retardant grafted ethyl cellulose: dissolve the dried ethyl cellulose (water content 2 CO 3 , react at 120°C for 8h, then filter with suction, wash and dry at 60°C to obtain DOPO-g-ITA flame retardant grafted ethyl cellulose.

[0020](3) Preparation of flame retardant grafted ethyl cellulose modified phenolic resin: according to the molar ratio of formaldehyde and phenol is 1.8:1, the molar ratio of 50wt.% NaOH and phenol is 0.15:1, add 1mol in the reaction vessel Phenol and DOPO-g-ITA modified ethyl cellulose, which accounted for 2% of the mass of phenol, were heated to 90-95°C for 30-40 minutes, and th...

Embodiment 2

[0023] (1) Preparation of DOPO-g-ITA: Using xylene as solvent, under nitrogen protection, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10- Add oxide (DOPO) and itaconic acid (ITA) into the reactor, reflux reaction at 125°C for 4.5h, cool to 110°C, wash with acetone several times after suction filtration, and obtain DOPO-g-ITA after drying Solid white powder.

[0024] (2) Preparation of DOPO-g-ITA flame retardant grafted ethyl cellulose: dissolve the dried ethyl cellulose (water content 2 CO 3 React at 125°C for 8.5h, then filter with suction, wash and dry at 65°C to obtain DOPO-g-ITA flame retardant grafted ethyl cellulose.

[0025] (3) Preparation of flame retardant grafted ethyl cellulose modified phenolic resin: according to the molar ratio of formaldehyde and phenol is 2.0:1, the molar ratio of 50wt.% NaOH and phenol is 0.16:1, add 1mol phenol and DOPO-g-ITA modified ethyl cellulose accounting for 10% of the mass of phenol, heated to 93°C for 35 minutes, then added 0.5mol p...

Embodiment 3

[0028] (1) Preparation of DOPO-g-ITA: Using xylene as solvent, under nitrogen protection, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10- Add oxide (DOPO) and itaconic acid (ITA) into the reactor, reflux at 130°C for 5 hours, cool to 110°C, filter with suction, wash with acetone several times, and dry to obtain DOPO-g-ITA solid White powder.

[0029] (2) Preparation of DOPO-g-ITA flame retardant grafted ethyl cellulose: dissolve the dried ethyl cellulose (water content 2 CO 3 React at 130°C for 9 hours, then filter with suction, wash and dry at 70°C to obtain DOPO-g-ITA flame-retardant grafted ethyl cellulose.

[0030] (3) Preparation of flame retardant grafted ethyl cellulose modified phenolic resin: according to the molar ratio of formaldehyde and phenol is 2.2:1, the molar ratio of 50wt.% NaOH and phenol is 0.17:1, add 1mol phenol and phenol DOPO-g-ITA modified ethyl cellulose with 20% mass was heated to 95°C for 40 minutes, then added 0.55mol paraformaldehyde, 1.56mol wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com