Pit cover tipping device

A boring pit and turning mechanism technology, applied in the field of metallurgy, can solve problems such as poor stability of steel slag, aging and spalling of plant column cement, affecting column strength and rigidity, etc., achieves good separation effect of slag and steel, eliminates unstable factors, and improves The effect of grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

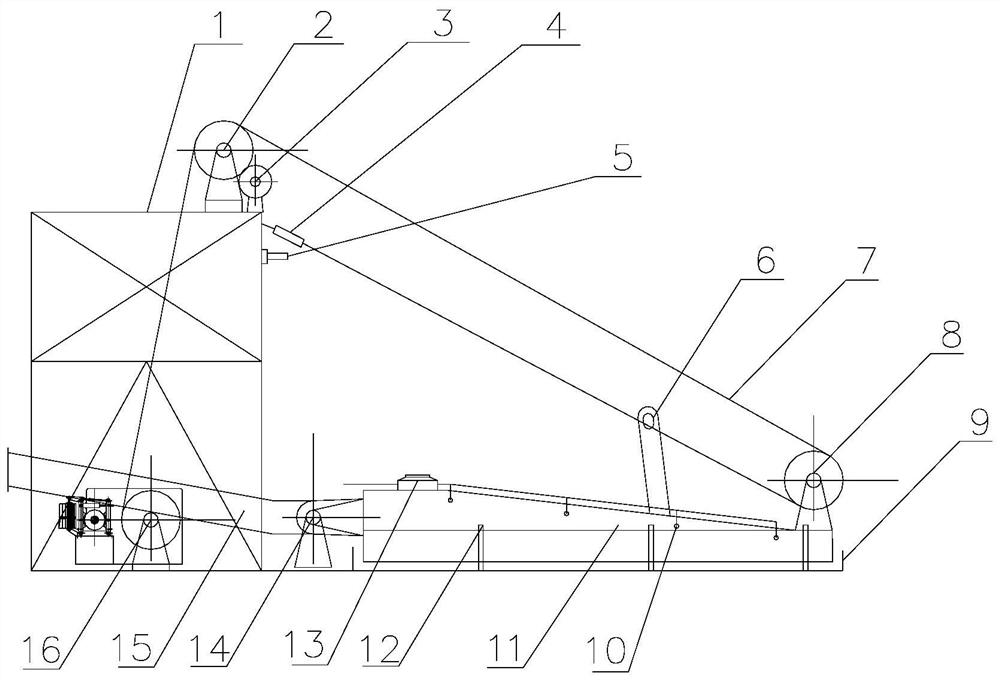

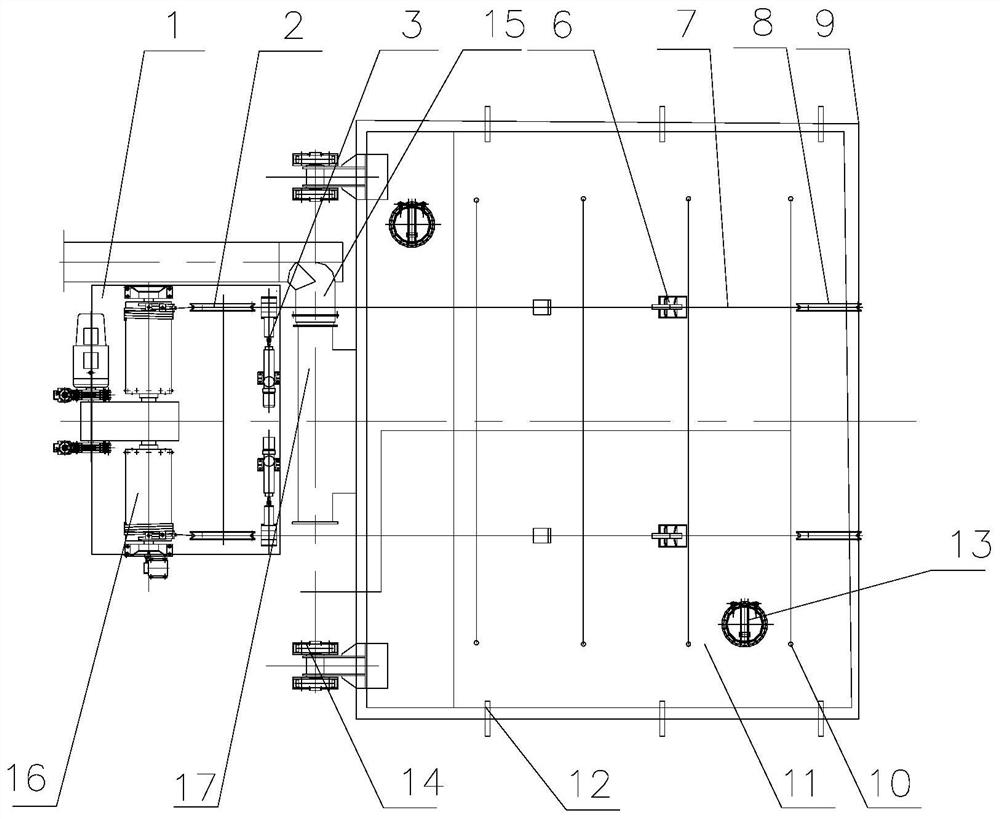

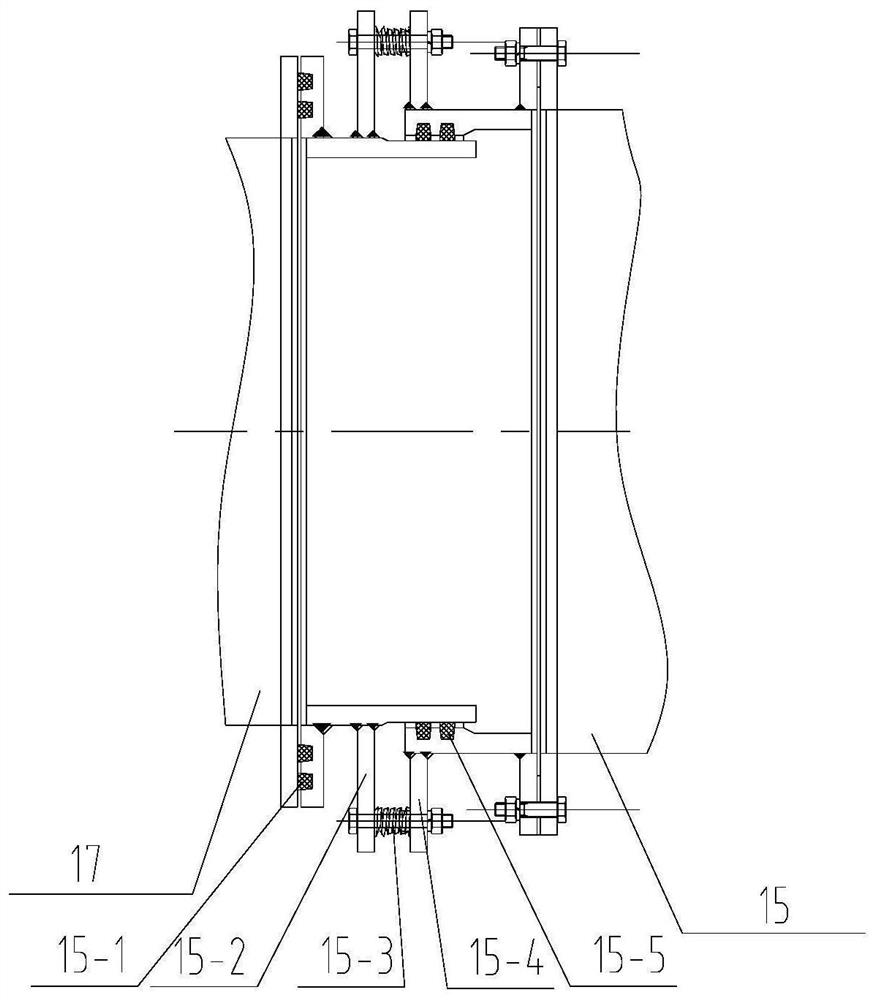

[0031] See Figure 1-Figure 5 , a pit cover tilting device, comprising a pulley overturning mechanism, a pit cover 11, a water seal groove 9, a stuffy cover water spray mechanism 10, and a smoke discharge pipe 15, one end of the pit cover 11 is hinged to the side of the stuffy pit, The pit cover 11 is flipped open and closed by the pulley turning mechanism, the water seal groove 9 is arranged around the pit cover 11 and the side of the boring pit, the pit cover 11 is provided with a smoke exhaust pipe joint 17, and the smoke Gas discharge pipe 15 is provided with smoke inlet pipe joint 15-4 (seeing image 3 ), the rotatable and sealed connection between the smoke exhaust pipe joint 17 and the smoke intake pipe joint 15-4, and a stuffy cover water spray mechanism 10 is provided on the inner wall of the pit cover 11 top.

[0032] The stuffy cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com