Hopkinson pressure bar-based true triaxial dynamic-static coupling loading and unloading test system

A technology of Hopkinson compression bar and test system, applied in the field of true three-axis dynamic and static combined loading and unloading test system, can solve the problems that the environmental characteristics of coal-rock dynamic disasters cannot be truly simulated, hinder the breakthrough of coal-rock dynamic disaster theory, and achieve improvement Theoretical research level and equipment level, improving effectiveness and pertinence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the embodiment of the patent of the present invention is described in detail: this embodiment is implemented under the premise of the technical solution of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to Examples described below.

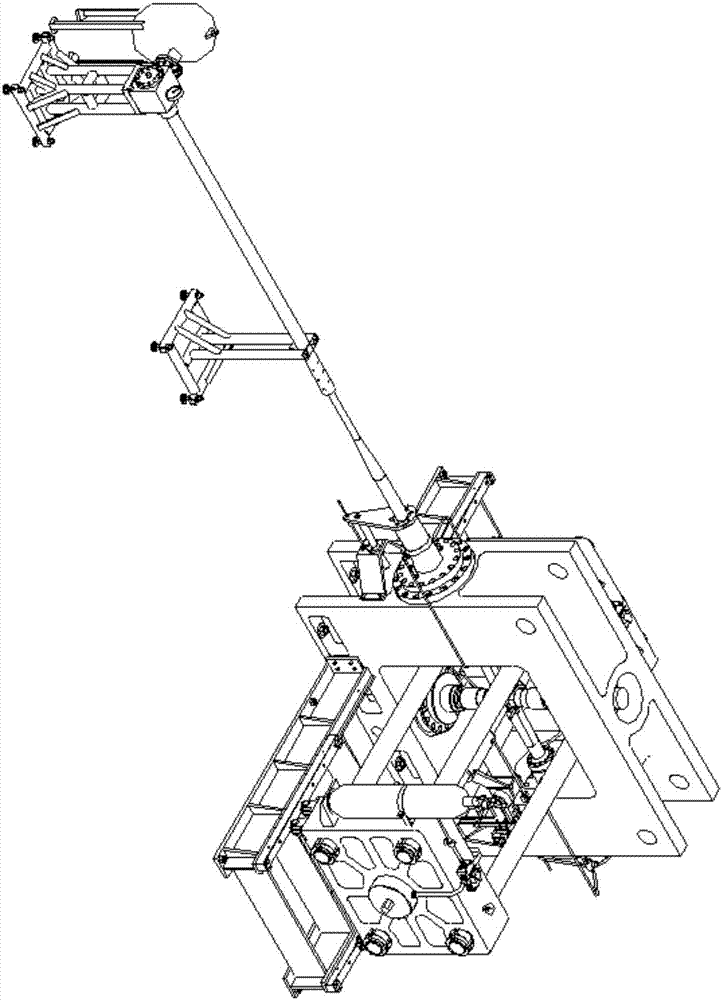

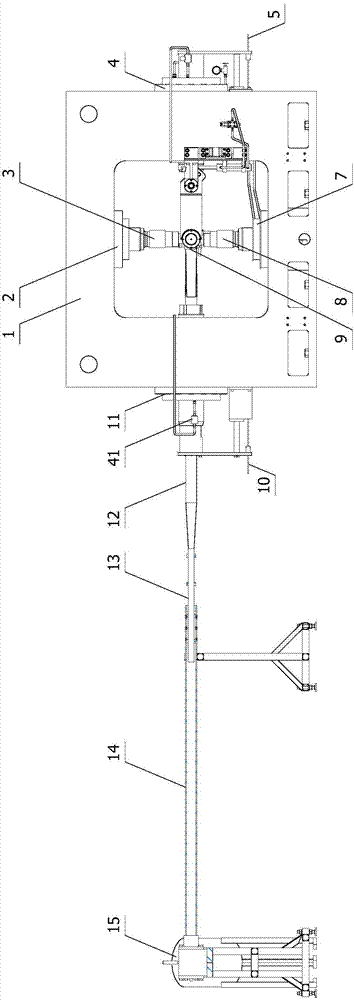

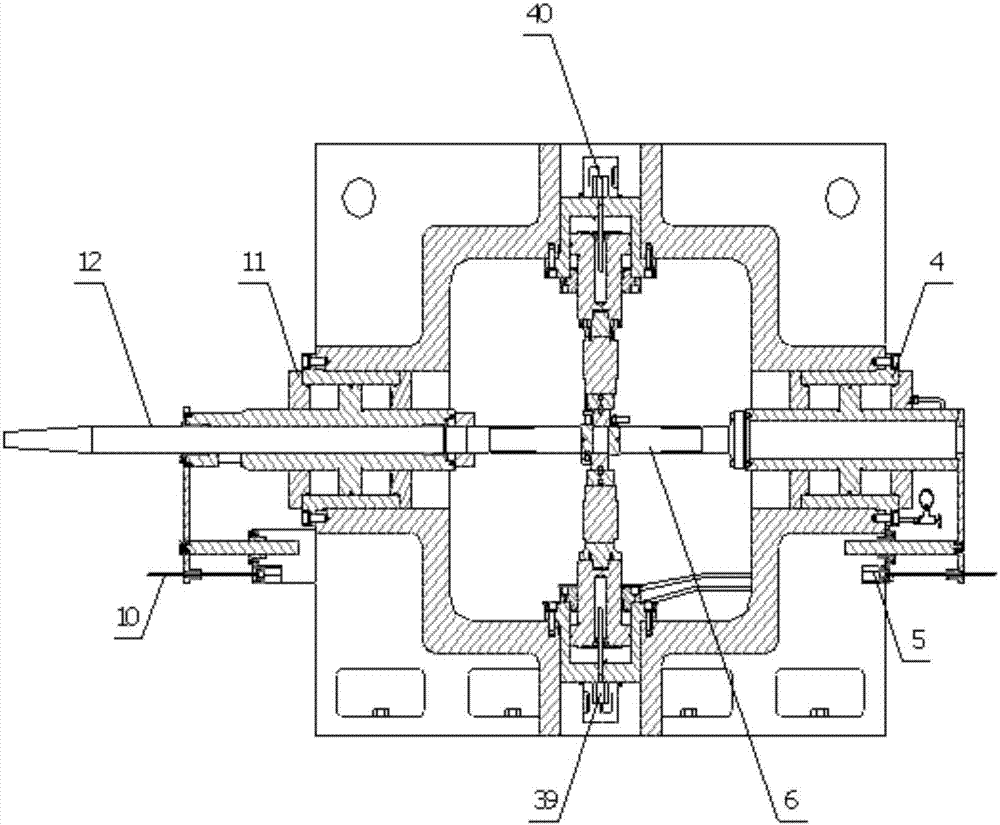

[0022] The invention comprises a static load pressure device for applying static load in three directions of X, Y and Z, a dynamic load device for applying dynamic load in X direction, and an instant unloading drop device. Wherein, the static load pressure device includes an XZ-axis cylinder block 1, a Z-axis upper oil cylinder 2 installed on the XZ-axis oil cylinder block 1, and a Z-axis upper load sensor 3 fixed on the XZ-axis oil cylinder block 1; The dynamic load device in the X direction consists of the X-axis right cylinder 4, the transmission rod 6 installed on the X-axis right cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com