Hydraulic bracket intelligent control method for adaptive support of fully mechanized coal face surrounding rock

A self-adaptive control technology for fully mechanized mining face, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problem that the adaptability of the hydraulic support fixed structure cannot meet the dynamic support requirements of surrounding rocks, and achieve enhanced support Improve the accuracy and overall ability of support, improve the overall support effect, and ensure the effect of production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

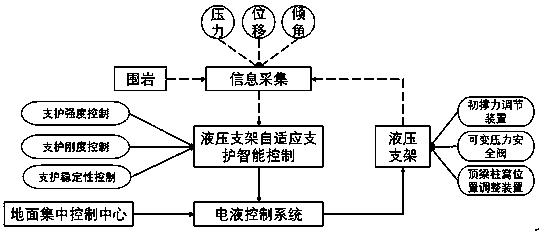

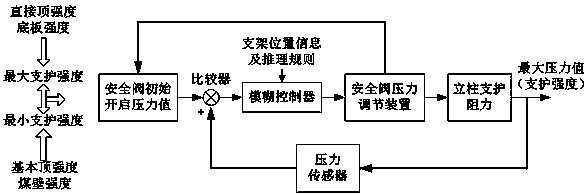

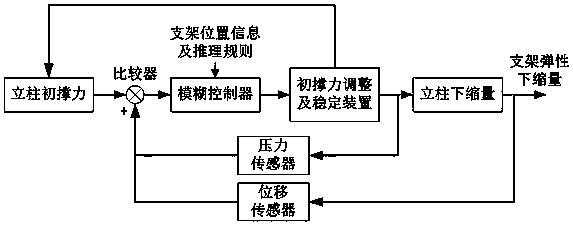

[0022] (1) Based on figure 1 In the logic diagram of the control method shown, the hydraulic support adaptive support intelligent control program obtains the surrounding rock and hydraulic support data through the information acquisition module, controls the hydraulic support through the electro-hydraulic control system and uploads the control status to the ground centralized control center. Wherein, the dotted arrow indicates the flow direction of the collected data, and the solid arrow indicates the flow direction of the control data. The information acquisition module includes pressure, inclination, displacement and other sensors, which are responsible for the collection of information such as the position, attitude, and force state of the support; the intelligent control program of the adaptive support of the hydraulic support includes the control of support strength, stiffness and stability. Data processing, calculation, storage and intelligent decision-making, and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com