Method for manufacturing high-power annular inductor

A technology of toroidal inductors and manufacturing methods, which is applied in inductor/transformer/magnet manufacturing, coil manufacturing, inductors with magnetic cores, etc., can solve problems such as the size limitation of powder magnetic cores, and achieve improved equipment level, low cost, and reduced equipment. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation steps of the invention are divided into three parts: the preparation of the ring magnetic core, the preparation of the inductance coil and the assembly of finished products.

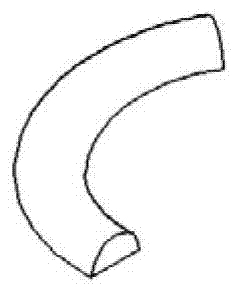

[0025] 1. Preparation of ring magnetic core: ① According to the required magnetic core diameter and magnetic flux leakage size required by the inductance, the magnetic core is decomposed into two halves from the diameter direction in the structural design stage, and decomposed into more than 3 semi-circular arc magnets along the circumferential direction. block (see figure 2 ).

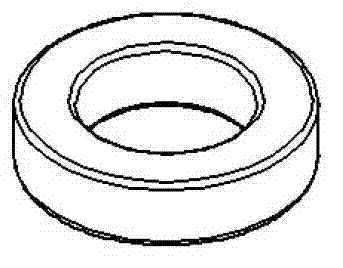

[0026] The cross-section of the annular magnetic core is designed to be circular to facilitate demoulding during the pressing process. During the assembly process, the circular smooth structure greatly reduces the assembly difficulty and high assembly efficiency. The smooth circular cross-section can make the magnetic force line distribution of the magnetic core during work. Uniform, no magnetic di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com