Light-weight telescopic flexible hydraulic shield support frame

A cover bracket and flexible technology, applied in the field of coal mining facilities, can solve problems such as unsuitable mining of steeply inclined coal seams, and achieve the effects of improving coal mine safety production and equipment level, reducing its own weight, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with specific embodiments of the present invention and corresponding drawings.

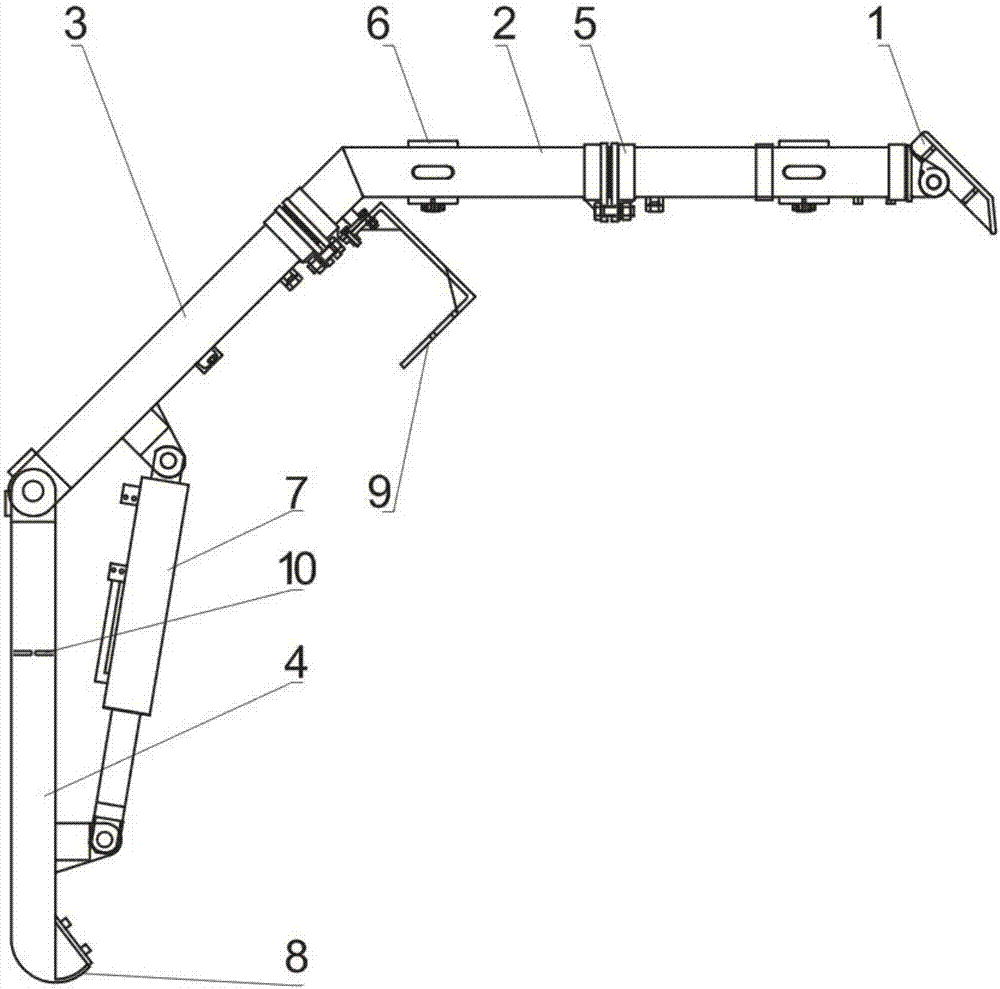

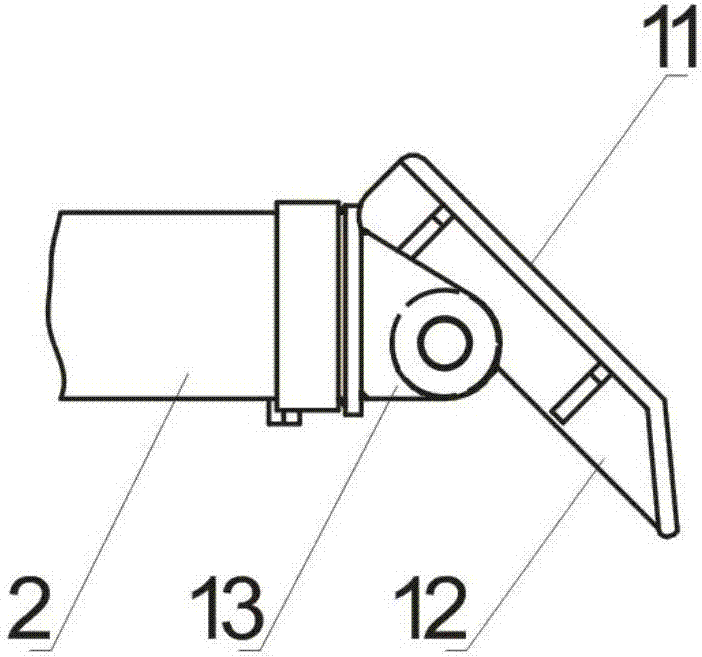

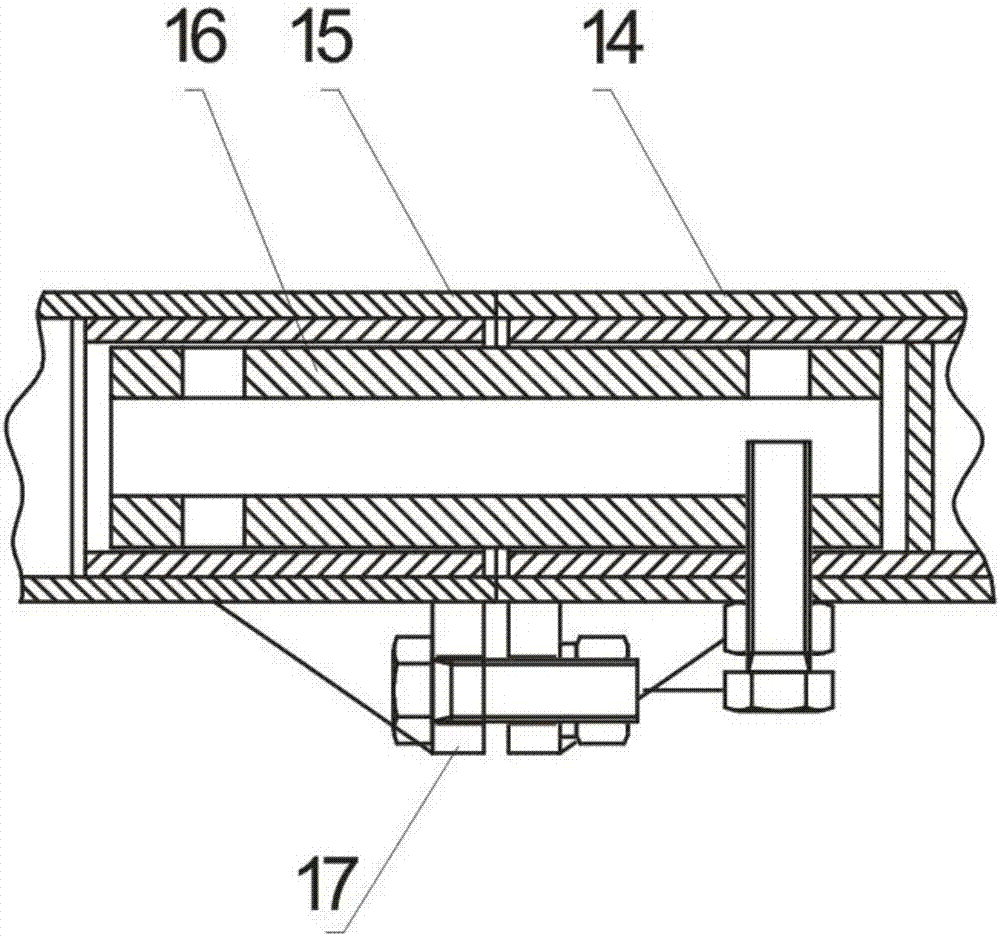

[0030] The light-duty scalable flexible hydraulic cover support of the present invention is generally three side-by-side splicing, and then forms a set of cover support hydraulic control unit groups, and multiple sets of cover support hydraulic control unit groups are arranged on the coal mining face to jointly form the coal mining face. support. In order to connect multiple sets of cover bracket hydraulic control unit groups, slots are slotted in the middle of both sides of the top beam for installation of connecting plates or connecting chains between frames.

[0031] The gap between the light-duty retractable and flexible hydraulic cover supports in a cover support hydraulic control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com