Deep foundation pit support construction process

A technology for deep foundation pit support and construction technology, which is applied in basic structure engineering, sheet pile walls, excavation, etc., can solve the difficult construction operation of construction personnel and excavation equipment, the occupation of deep foundation pit space, and the easy obstruction of construction by horizontal steel support. Personnel operation and other issues to achieve the effect of avoiding the reduction of support strength, reducing the deposition of rainwater, and avoiding soil erosion or collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

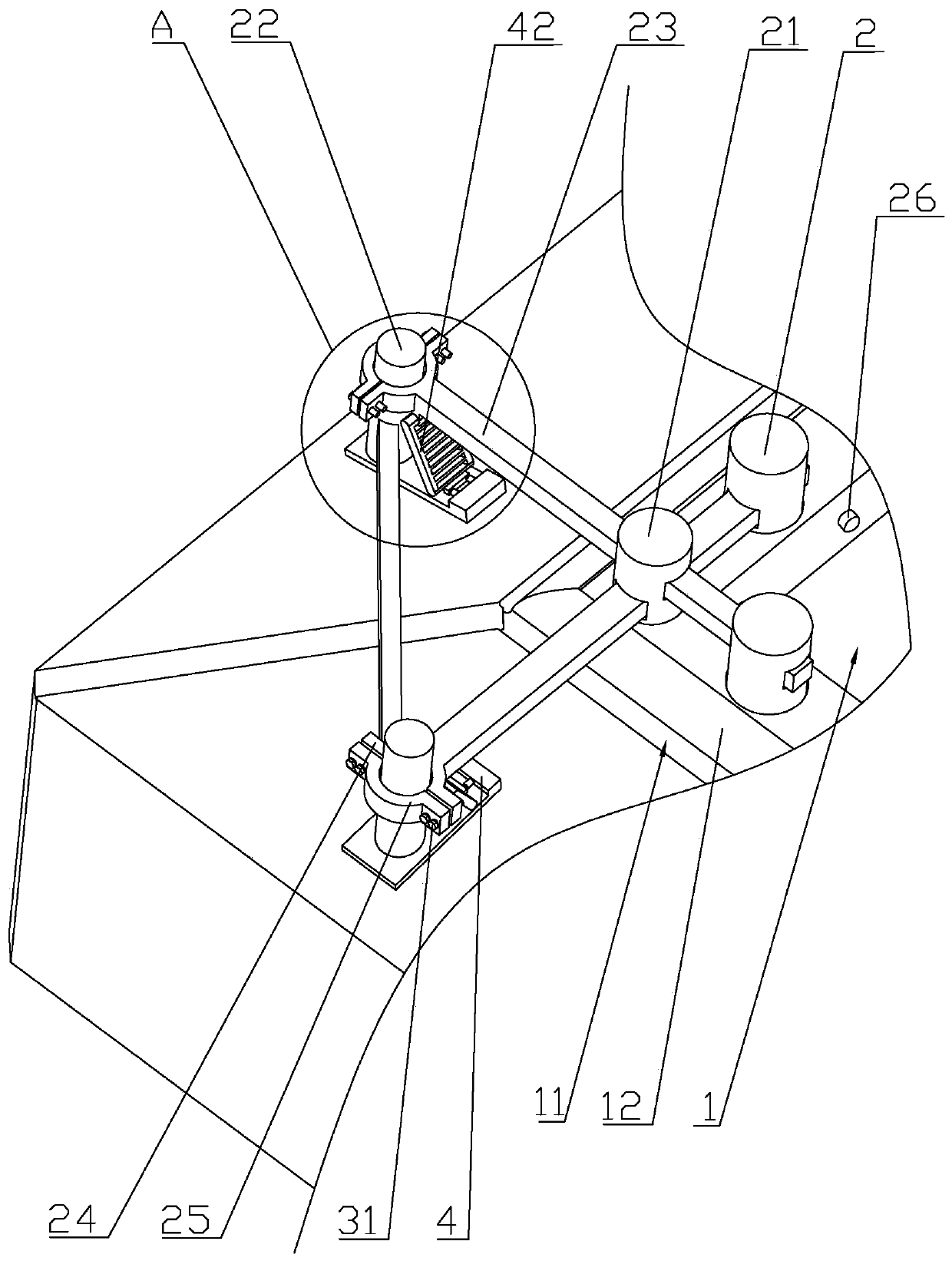

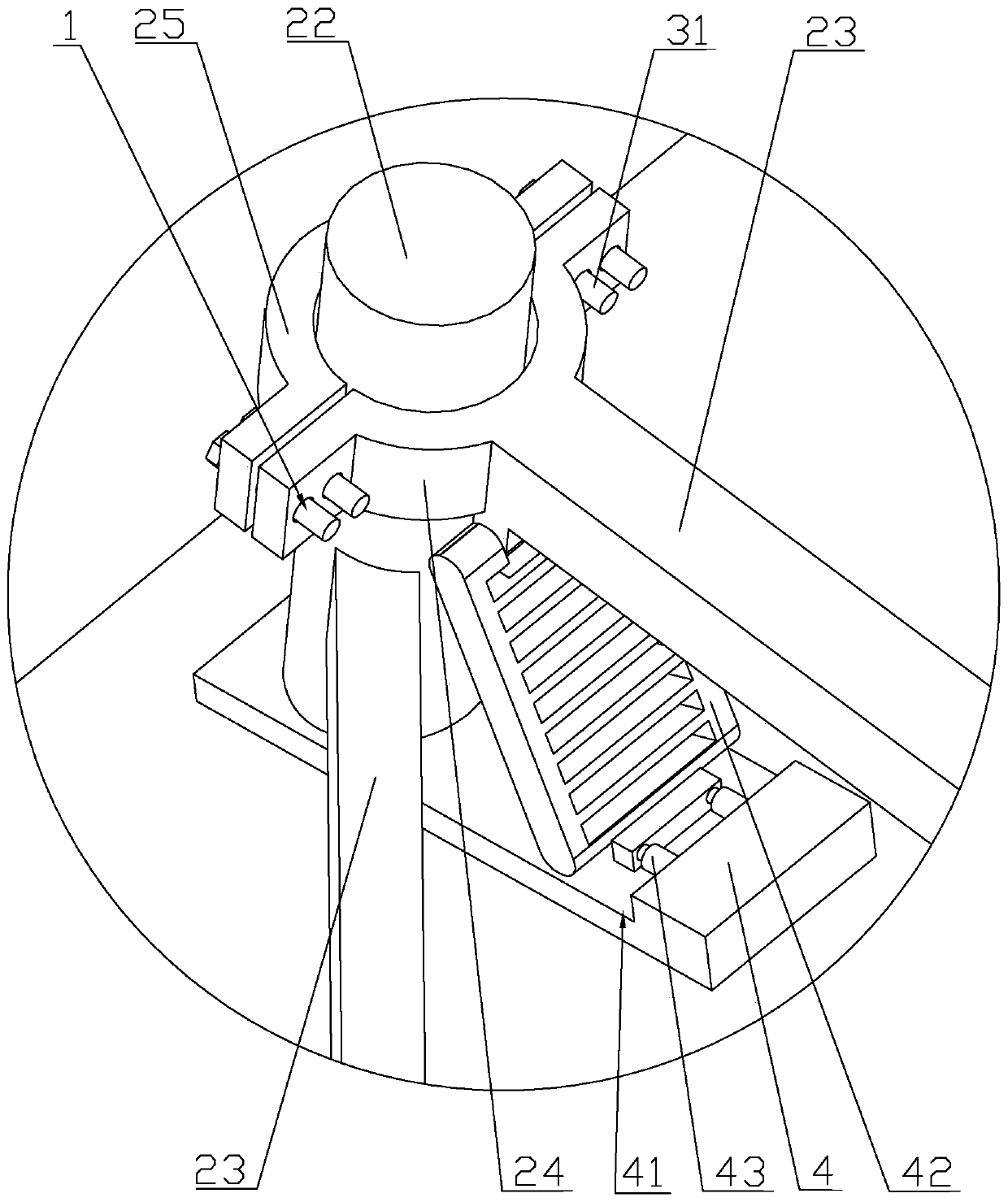

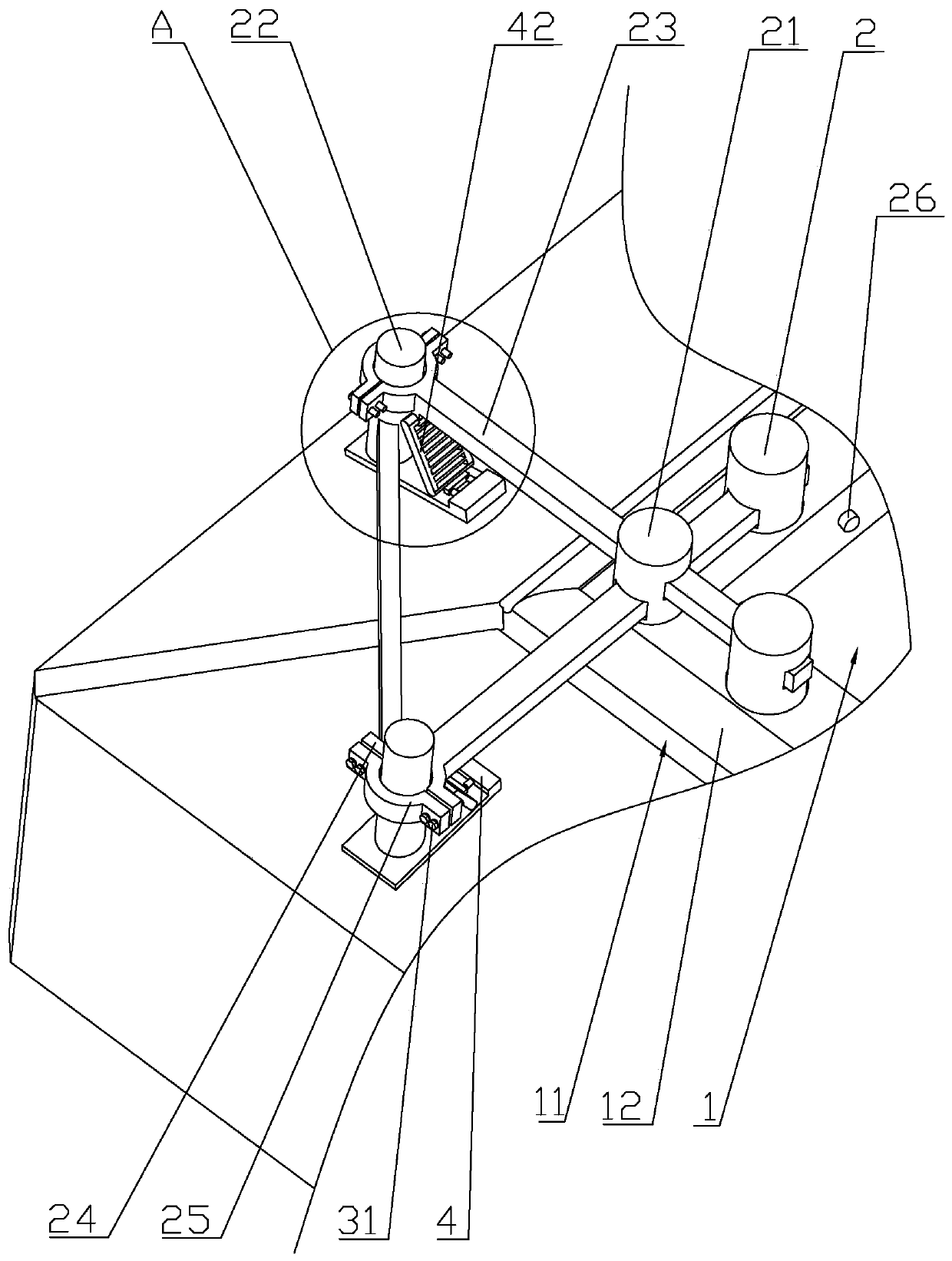

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] refer to figure 1 , is a deep foundation pit support construction process disclosed by the present invention, comprising the following steps: Step S100: firstly, at the construction site, a groove is pre-dug along the edge of the deep foundation pit 1, and concrete is poured in the groove to form an enclosure 12. The top surface of the enclosure 12 is arc-shaped, and its convex arc faces to the outside of the deep foundation pit 1, so that when the rainwater contacts the enclosure 12, it will flow to the outside of the deep foundation pit 1 under the guidance of the arc top surface. , so as to prevent rainwater from pouring back into the deep foundation pit 1 and affect the construction, and at the same time fix the edge of the deep foundation pit 1 to prevent objects such as stones from falling and causing casualties.

[0037] Afterwards, the enclosu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com