Open pile control device

A technology of pile clamping and clamping piles, which is applied in the direction of sheet pile walls, buildings, foundation structures, etc., can solve the problems that cannot meet the requirements of the verticality of pile formation and the control of prefabricated pipe piles at the speed of pile unloading, etc., and achieve the solution of clamping load Evenly distributed loading and the effect of improving pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

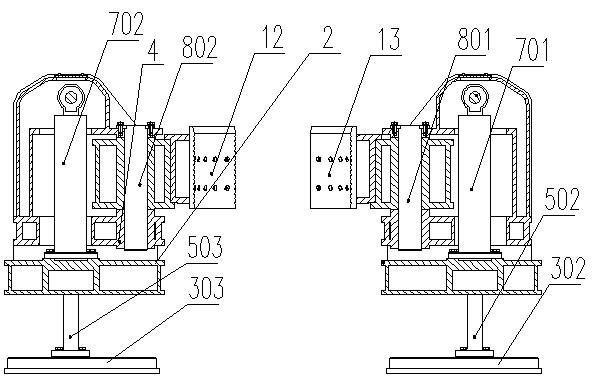

[0029] Such as Figure 1 to Figure 6 In the pile controller shown in Embodiment 1, one end of the connecting plate 1 is connected to the pile controller through a sliding sleeve 19, and the other end is hinged to the waist-shaped hole of the lug of the main machine for pile foundation construction through a pin 18. The connecting plate 1 can slide in the sliding sleeve 19; the pile controller can rotate up and down around the pin shaft 18, and can slide along the waist hole, so as to adapt to the posture change when the pile controller is vertically adjusted , to ensure the accuracy of the pile hole position. The first platform 2 is the supporting part of the pile control device. One end of the oil cylinder seat of the two pressure-drawing cylinders 701, 702 is fixed on the first platform 2. The pile clamping platform 4 above the platform 2 is hinged, and the expansion and contraction of the pressing and pulling oil cylinders 701 and 702 can drive the lifting of the pile clam...

Embodiment 2

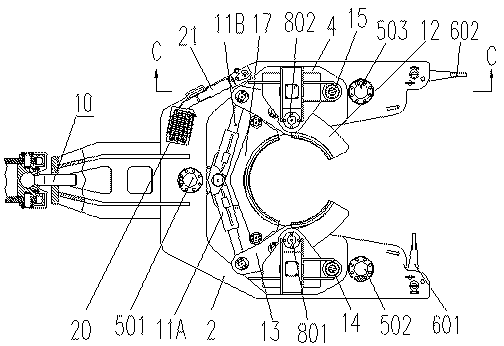

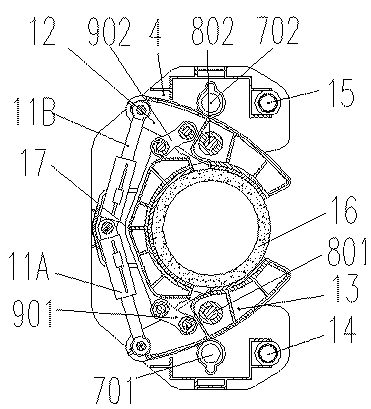

[0032] Such as Figure 7 to Figure 11In the pile controller shown in Embodiment 2, one end of the sliding rod 10 is connected to the pile controller and can slide axially on the first platform 2; The pile control device can rotate around the spherical hinge point and slide along the waist-shaped hole. This connection method has more degrees of freedom, and can completely compensate for the composite angle and position changes caused by the vertical adjustment of the pile control device, which is convenient for pile control. The device is aligned with the pile position. The first platform 2 is the supporting part of the pile control device. One end of the oil cylinder seat of the two pressure-drawing cylinders 701, 702 is fixed on the first platform 2. The pile clamping platform 4 above the platform 2 is hinged, and the expansion and contraction of the pressing and pulling oil cylinders 701 and 702 can drive the lifting of the pile clamping platform 4 and the pile clamping mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com