Inner-support and reverse-construction-technique column perpendicularity controller

A technology of verticality and controller, which is applied in the field of verticality control of vertical columns, internal supports, and verticality controllers of reversed vertical columns. problem, to achieve the effect of controlling verticality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

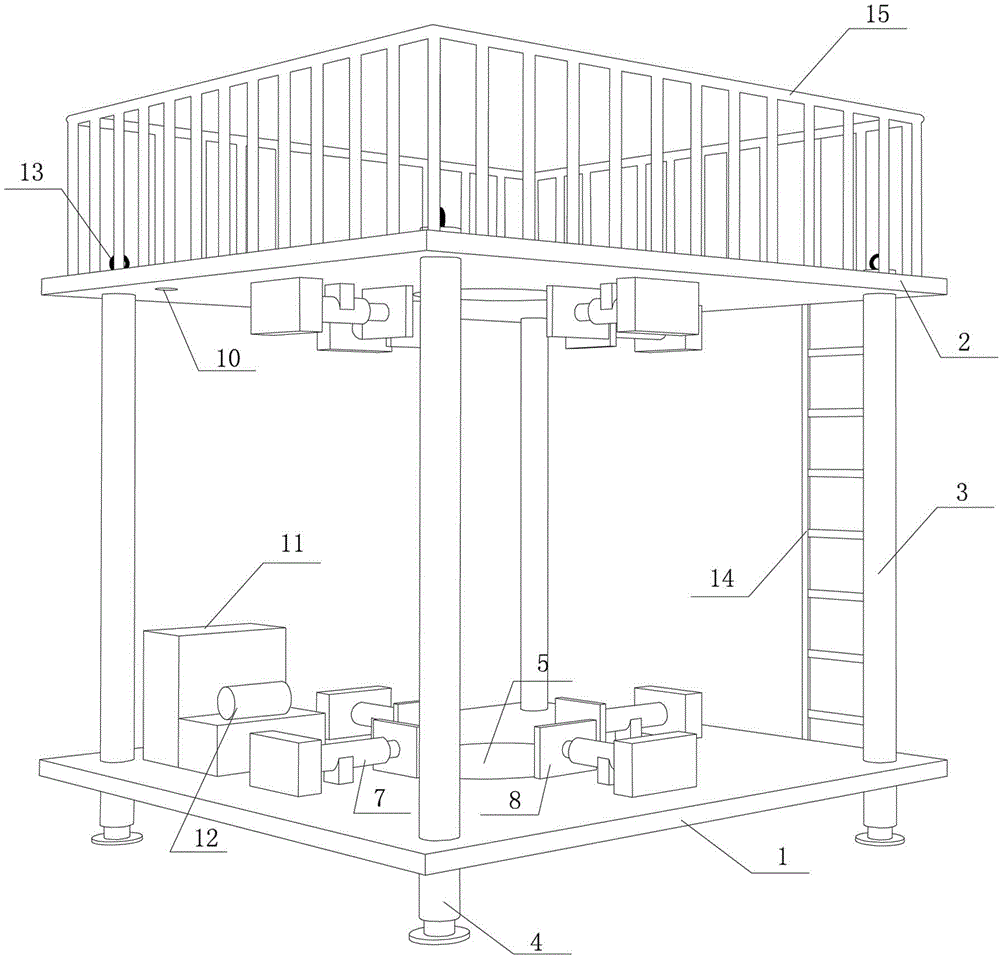

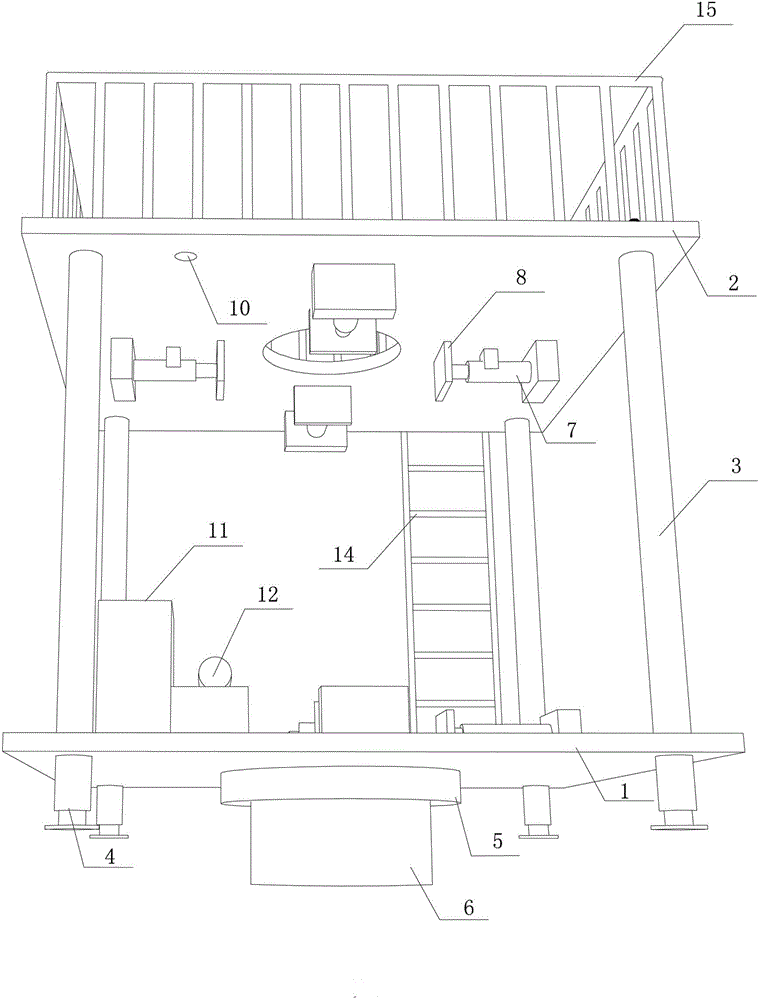

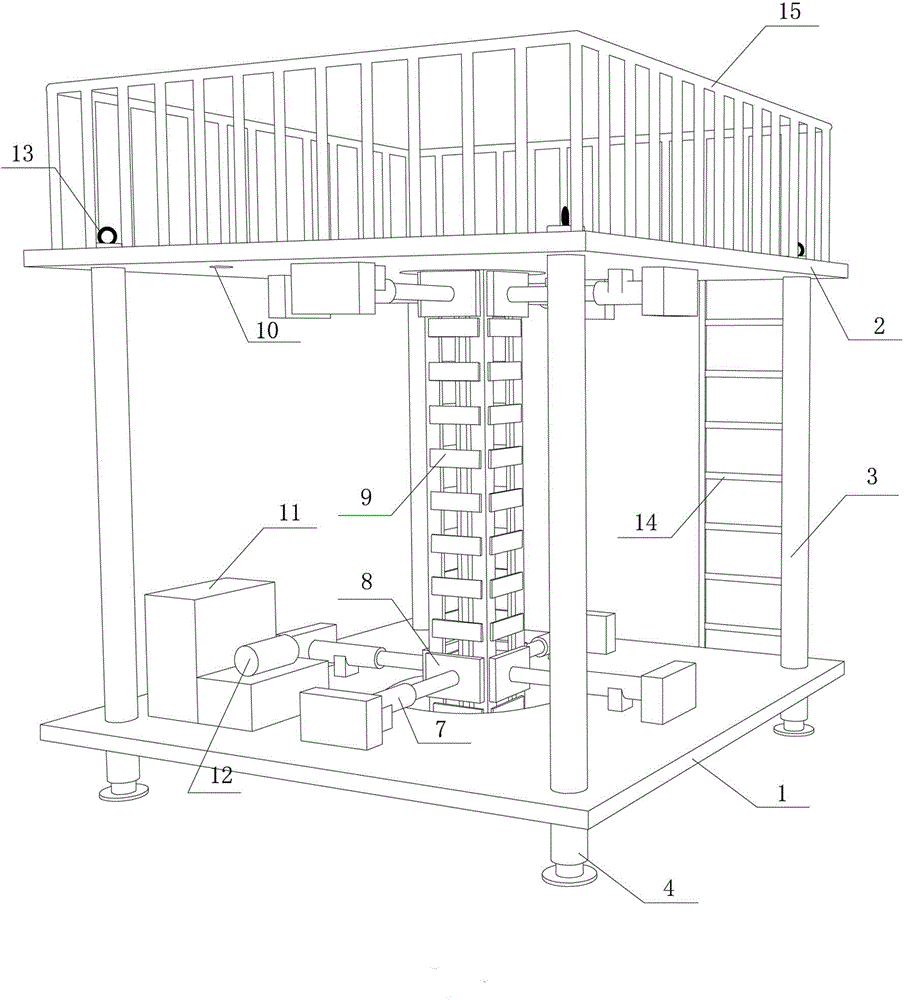

[0027] Such as figure 1 , figure 2 As shown, a column verticality controller with internal support and reverse method is used for the case where the irrigation column is a cube. The spacing is 2000mm, and each column 3 is provided with a hydraulic support leg 4, which is used to adjust the levelness when the site is uneven, so as to ensure that the bottom plate 1 and the top plate 2 are both level; there is a circular hole of the same size in the center of the bottom plate 1 and the top plate 2 , the sleeve 5 is connected to the peripheral edge of the round hole of the bottom plate 1, and the distance between the sleeve 5 and the casing 6 is positioned so that the round hole and the casing 6 are on the same axis; Four hydraulic jacks 7 are evenly arranged on the circumference of the hole, and the distance between the hydraulic jacks 7 and the center of the round hole is equal; a splint 8 is set at the front of the hydraulic jack 7, and the splint 8 is a flat plate for clampi...

Embodiment 2

[0030] A column verticality controller with internal support and reverse method, which is used when the pouring column is a steel pipe column. The splint 8 at the front is a curved plate, and the tool type column is a steel pipe column matched with the pouring column.

[0031] Application proof: Since there is a scale accurate to 1mm on the hydraulic top, after the eight hydraulic jacks squeeze the column, the deviation of the upper and lower hydraulic jacks can be controlled within 1mm, and the distance between the bottom plate and the top plate is greater than or equal to 2000mm, so the verticality of the column It can be controlled within 0.5‰, which can effectively control the verticality of the column to meet the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com