Patents

Literature

74results about How to "Avoid changing angles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

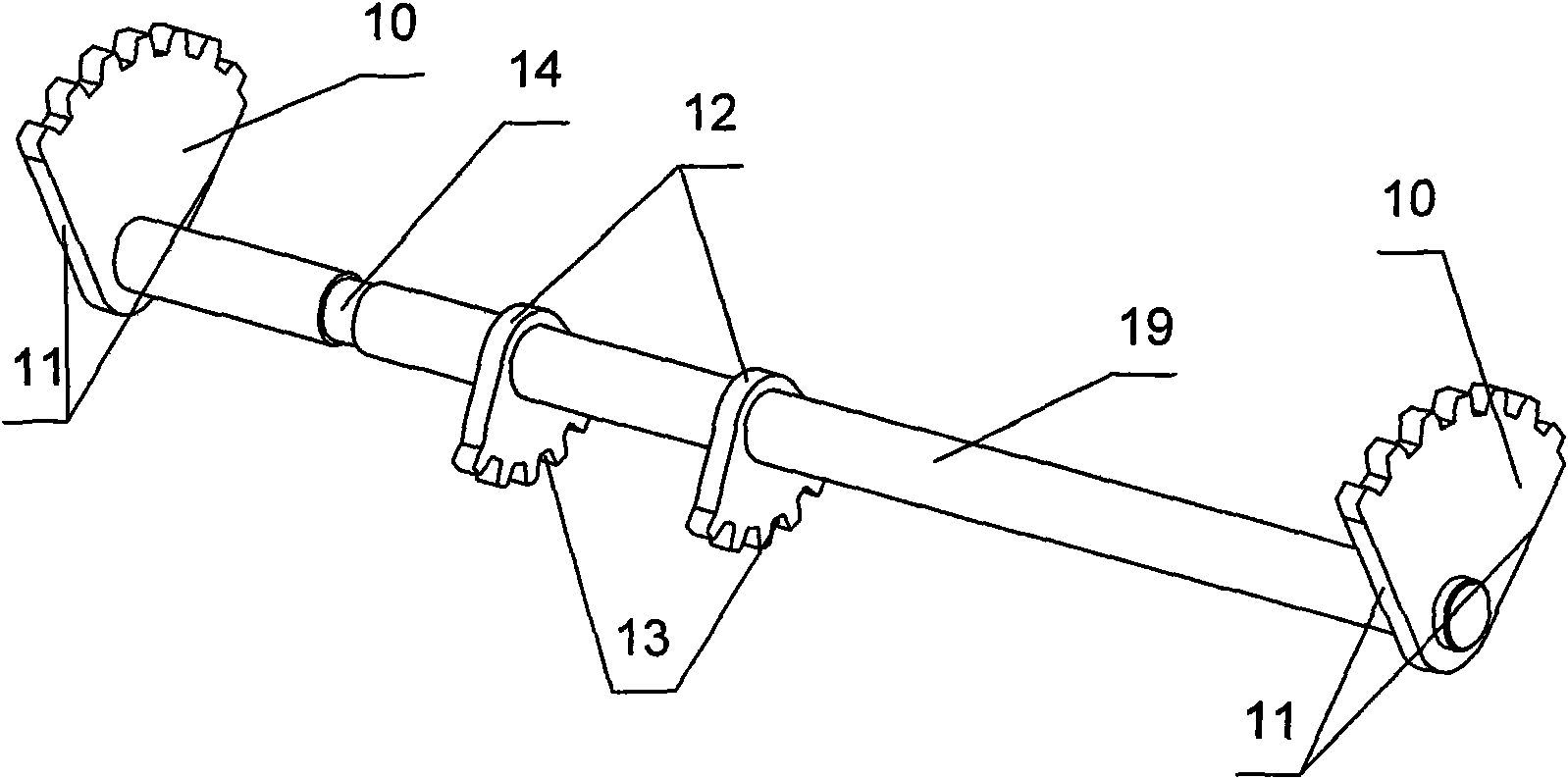

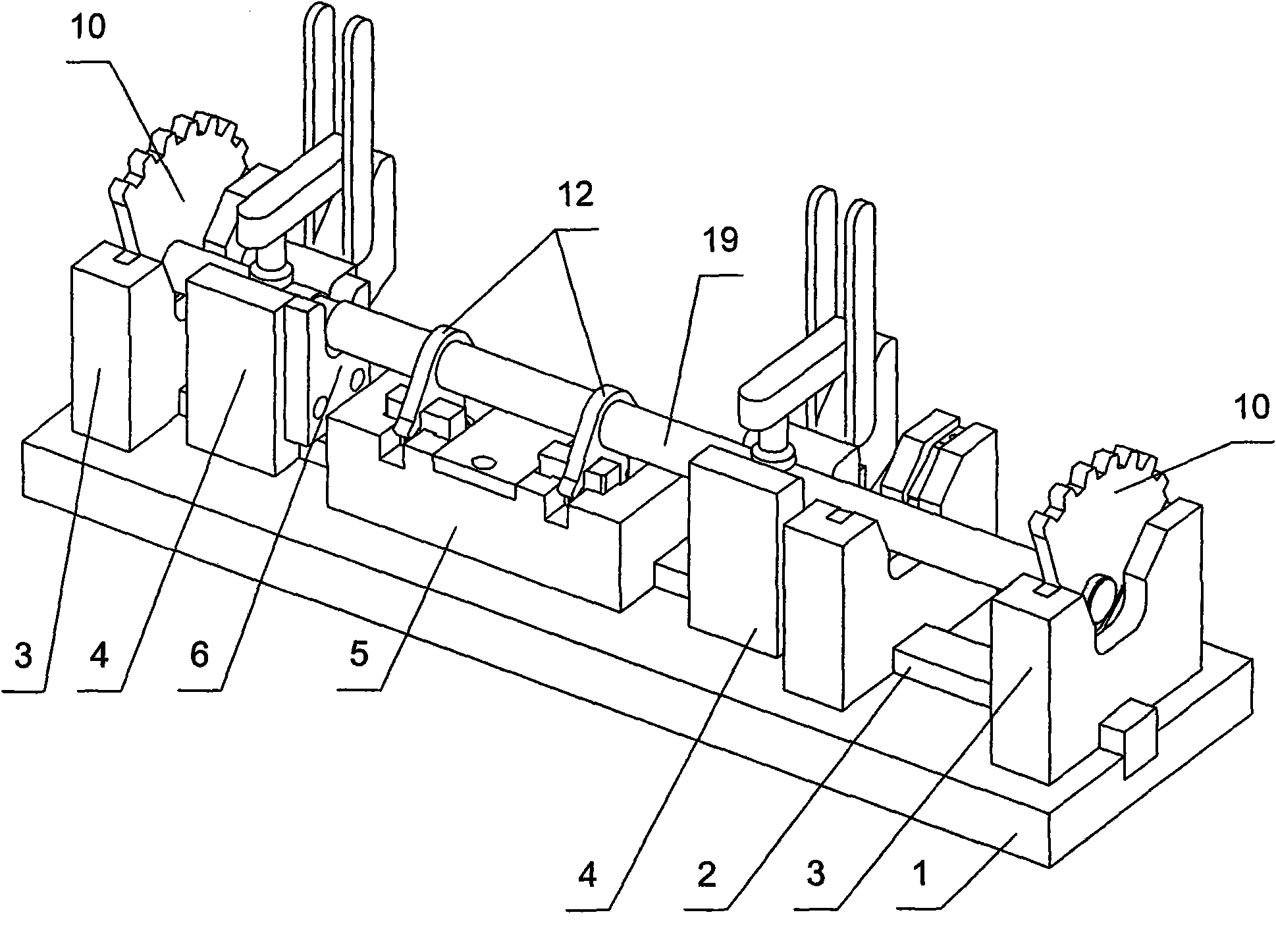

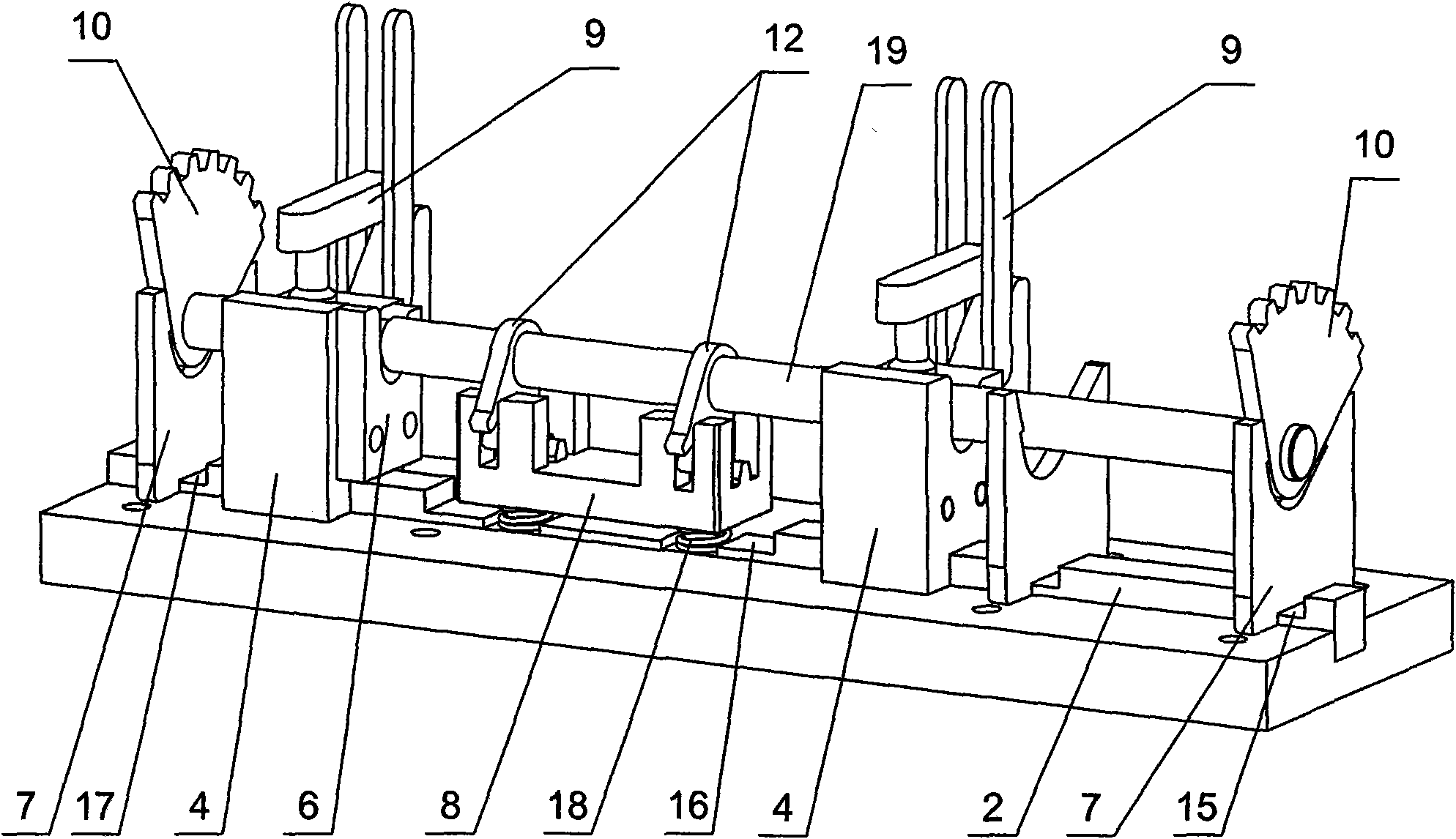

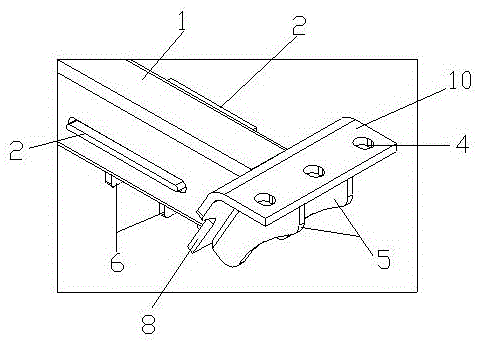

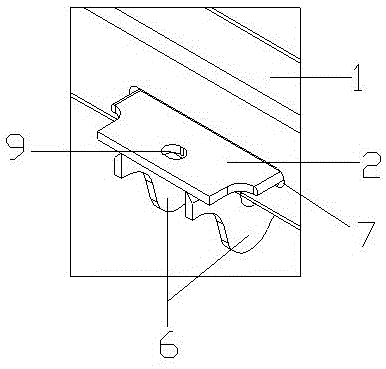

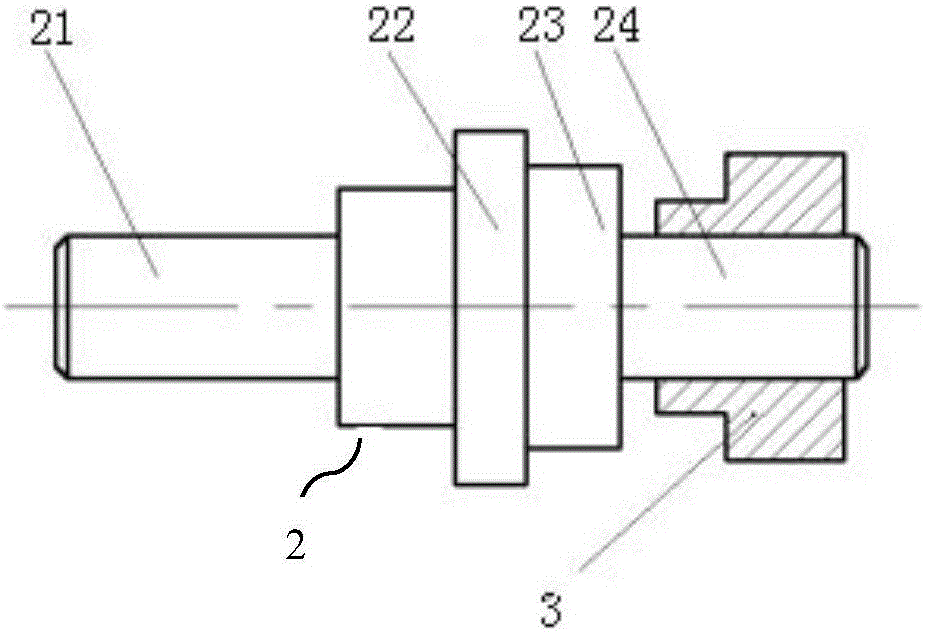

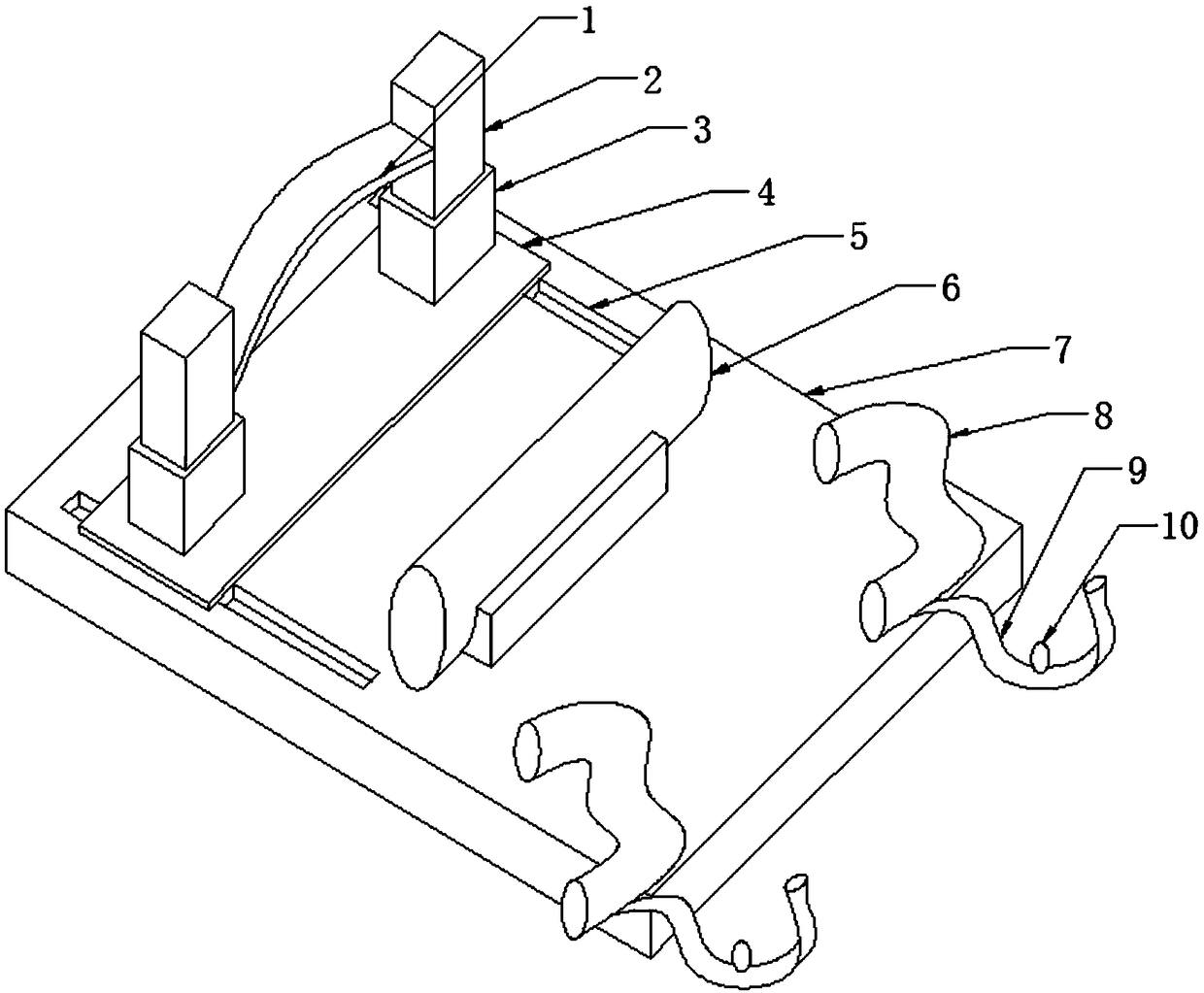

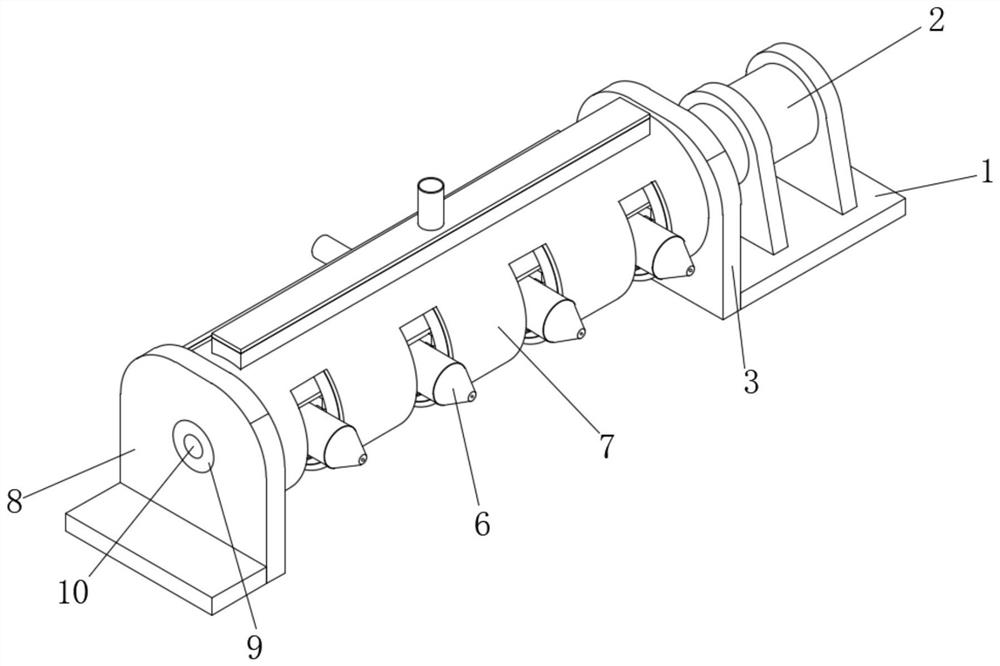

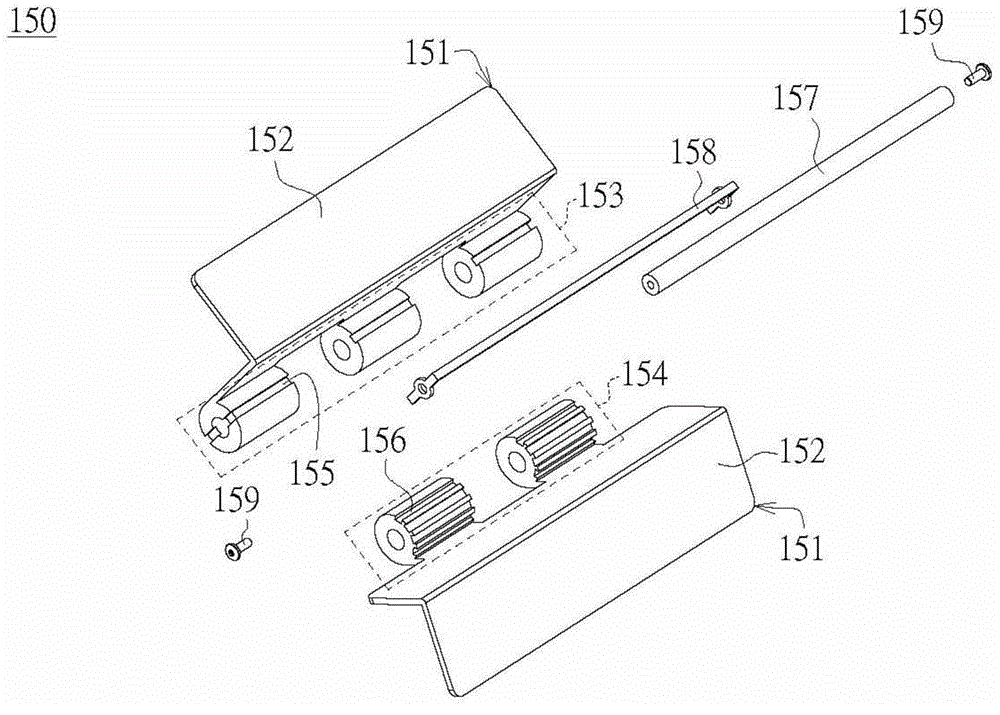

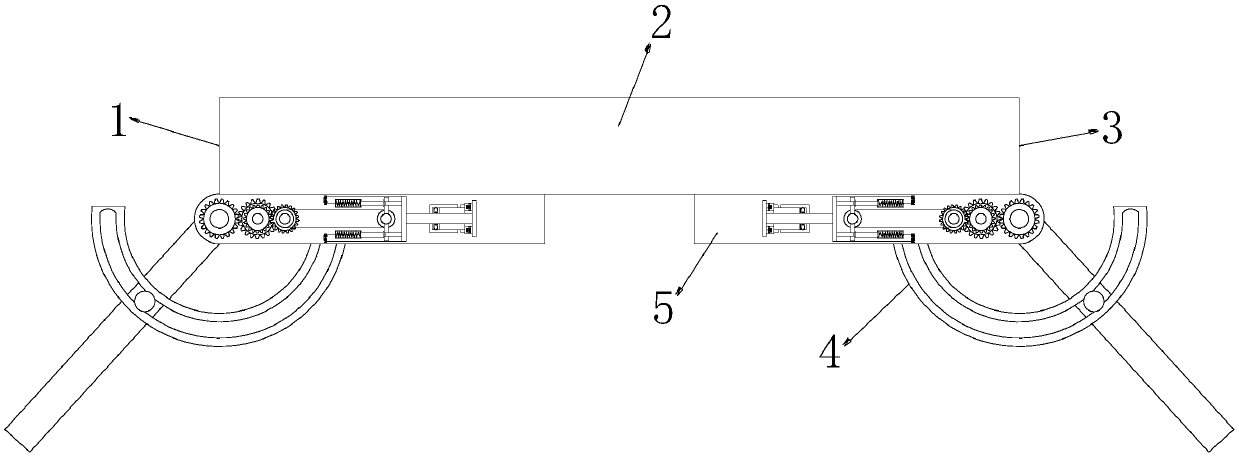

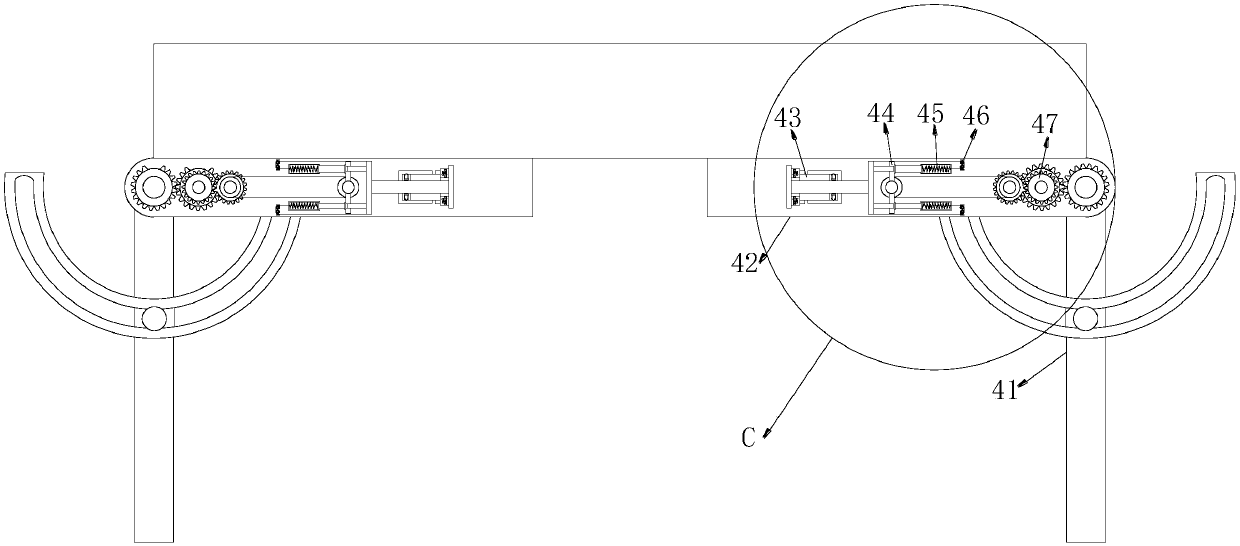

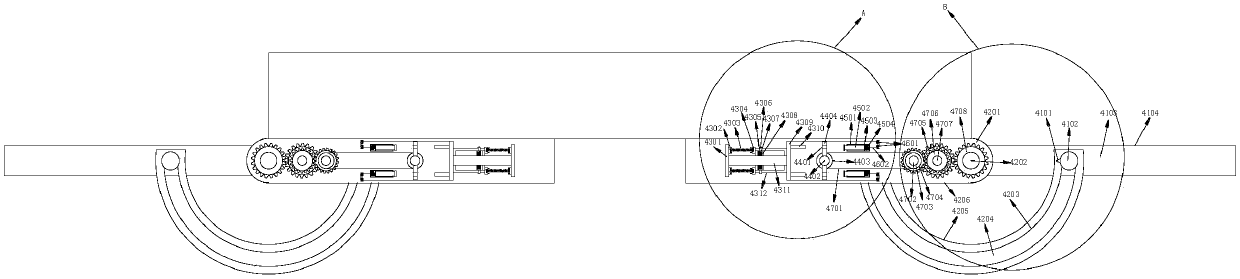

Rotating shaft welding fixture of drawer seat drive mechanism of low-voltage switch board

ActiveCN101628369AEasy clampingEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesGear wheelLow voltage

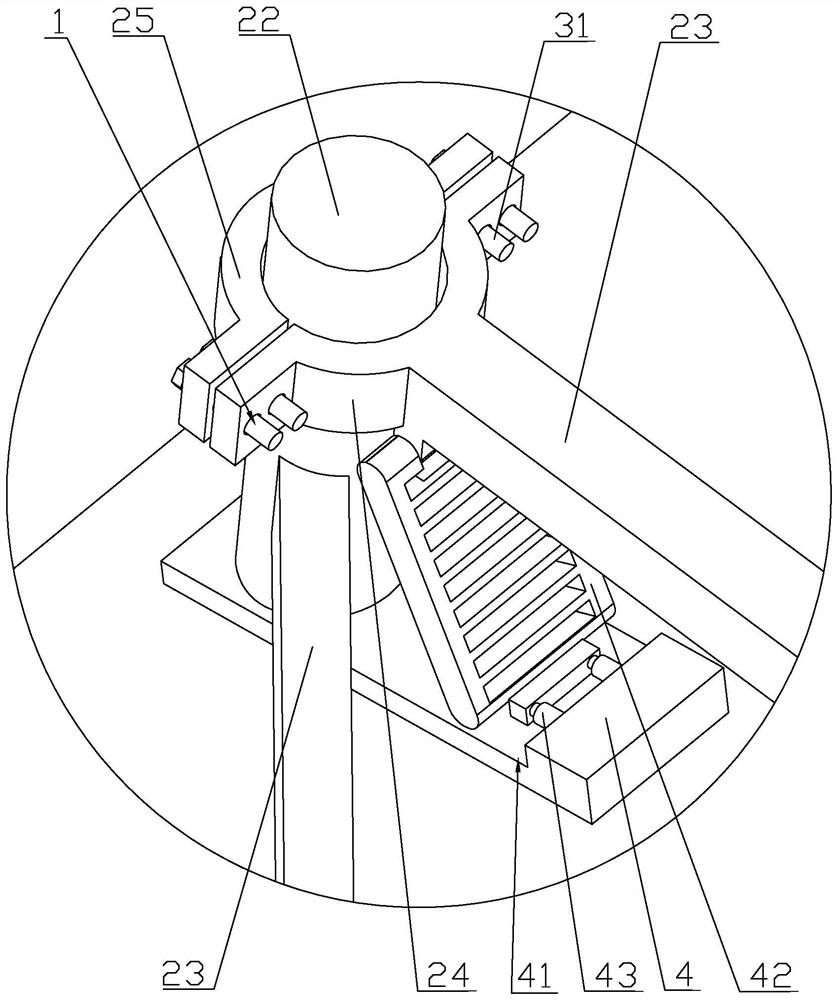

The invention discloses a rotating shaft welding fixture of a drawer seat drive mechanism of a low-voltage switch board, which has the technical scheme that a locating square bar is fixed in a square groove on a soleplate, both ends and the middle of the locating square bar are provided with locating notches, a guide block corresponding to small segment gears and a position locating block corresponding to big segment gears are fixed on the locating notches, a gear angle locating block is fixed in the position locating block, and a locating slide rod is fixed in the guide block; two shaft angle locating blocks are fixed on the soleplate between the position locating block and the guide block, and the side faces of the shaft angle locating blocks are fixed with a shaft direction locating block matched with a lantern ring groove on a rotating shaft; two clamps are respectively fixed on the two shaft angle locating blocks and are distributed at two sides of the two small segment gears, and two springs are arranged under the locating slide rod and are opposite to the two small segment gears in the vertical direction; the four segment gears are clamped and welded once, thereby enhancing the welding precision and having precise location and convenient and quick clamp.

Owner:EATON HUINENG LOW-VOLTAGE ELECTRICAL (JIANGSU) CO LTD

Suspended structure for heavy equipment

ActiveCN105035112APrevent fallingGood for dispersing forceUnderframesAngular variationHeavy equipment

A suspended structure for heavy equipment comprises two suspended cross beams which are arranged oppositely, the two ends of each suspended cross beam are both provided with a lifting lug plate, each lifting lug plate is provided with multiple lifting lug holes, the faces, opposite to each other, of the two suspended cross beams are both provided with multiple connecting plates, each connecting plate is provided with a connecting hole, and each connecting plate is provided with multiple reinforcing ribs connected to the corresponding suspended cross beam. According to the suspended structure for the heavy equipment, the connecting plates penetrate through the suspended cross beams, the contact stress of the connecting plates and the suspended cross beams is dispersed, and the range of the force capable of being borne by the connecting plates is enlarged; by means of the reinforcing ribs, the functions of protection, support and deformation avoiding on the connecting plates are achieved, vertical plates are connected with the lifting lug faces and the welding faces, and angular variations of the lifting lug faces and the welding faces are avoided.

Owner:CRRC NANJING PUZHEN CO LTD

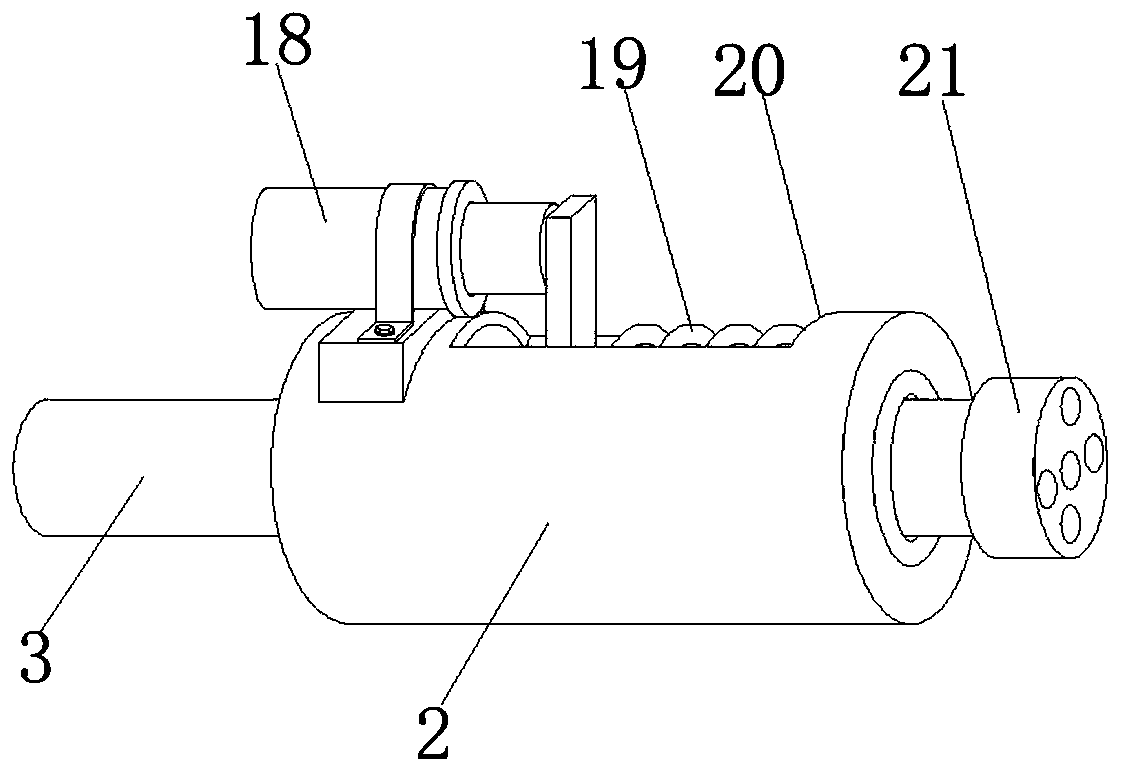

Centering measurement apparatus for measuring center distance of two intersecting holes in intersecting hole system

ActiveCN105841587AEliminate machining errorsEliminate the effects of detectionMechanical clearance measurementsEngineeringCam

The invention discloses a centering measurement apparatus for measuring the center distance of two intersecting holes in an intersecting hole system. The centering measurement apparatus comprises a two-hole positioning and centering device including an elastic centering expanding sleeve, a centering pull bar, a centering pressure bar, an eccentric wheel compacting mechanism and a positioning pin, a variable-pitch cam mechanism including a handle, a servo-actuated eccentric cam, a bearing positioning circular section and a cooperative column, and an auxiliary centering mechanism, wherein the two-hole positioning and centering device is inserted in a first hole system of a part to be measured, the eccentric wheel compacting mechanism is rotated to move the centering pull bar and centering pressure bar and open the elastic centering expanding sleeve to center the first hole system, and the variable-pitch cam mechanism and the auxiliary centering mechanism are inserted in two sides of a second hole system of the part to be measured. The handle is rotated to drive the cam to rotate, so that the rim of the cam is tangent to the excircle of the elastic centering expanding sleeve, and angle scales corresponding to different center distances of the first hole system and the second hole system are radially marked on the end face of the servo-actuated eccentric cam. The actual center distance of the intersecting holes of the part to be measured can be rapidly obtained by observing the angle graduation lines, and rapid and accurate measurement is realized.

Owner:CHONGQING JIANSHE IND GRP

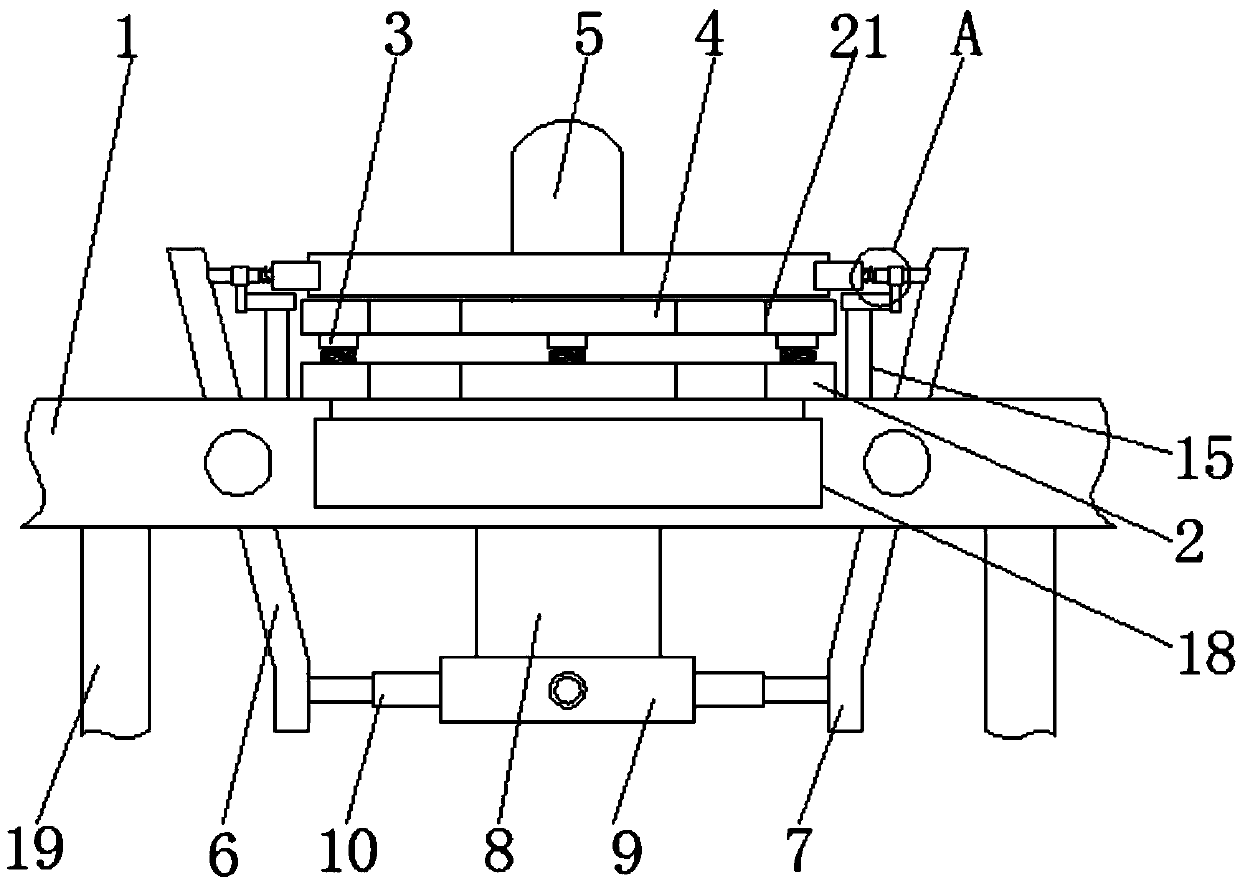

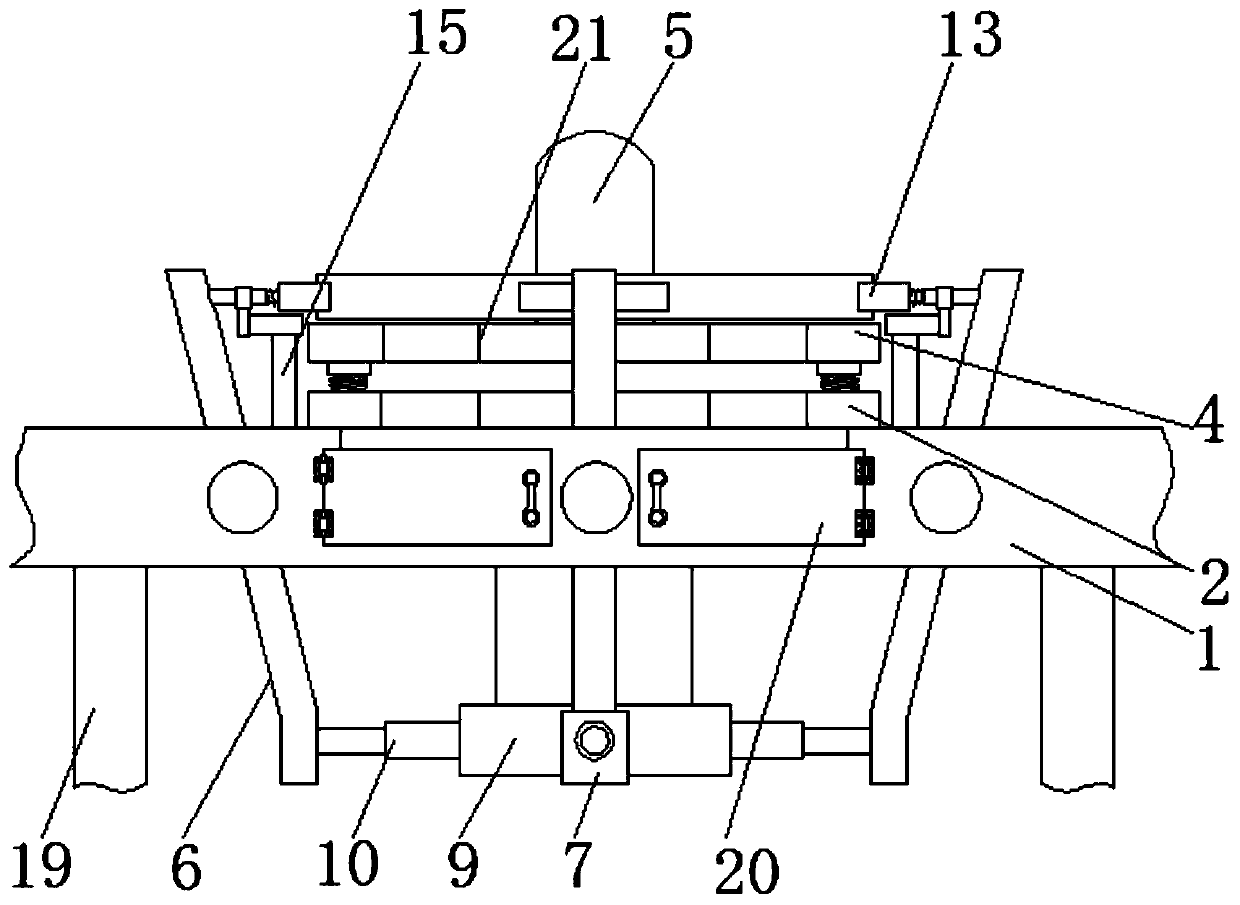

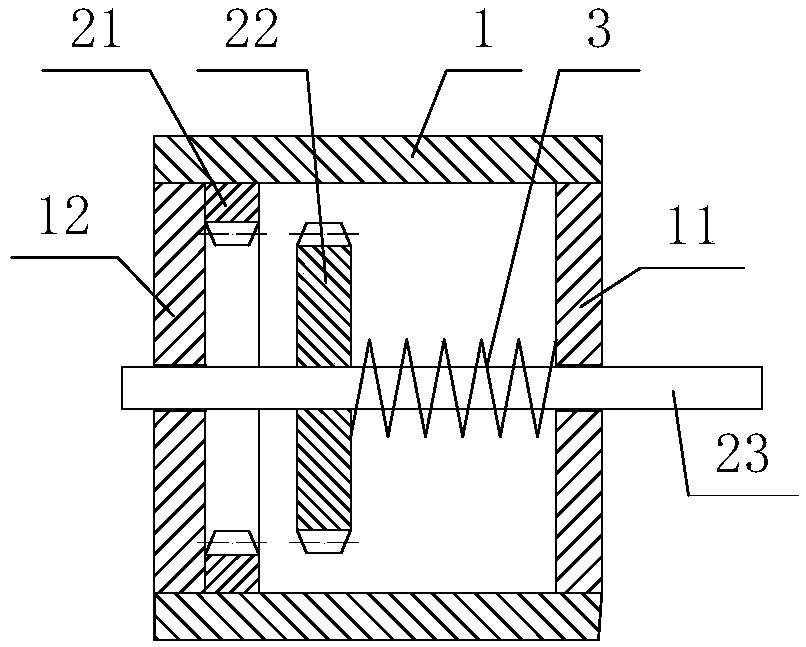

Brake pad clamping mechanism for automobile brake pad drilling

InactiveCN109531212AImprove shock absorption strengthReduce shockPositioning apparatusMaintainance and safety accessoriesMechanical engineeringBrake pad

The invention discloses a brake pad clamping mechanism for automobile brake pad drilling and relates to the technical field of automobile brake pads. The brake pad clamping mechanism comprises a worktable, wherein a first placement plate is fixedly connected to the top of the worktable, the top of the first placement plate is fixedly connected with a second placement plate through a connecting device, the top of the second placement device is fixedly connected with a guiding column, rotary rods are rotatably connected to the periphery of the inside of the worktable, vertical plates are fixedlyconnected to the bottoms of the rotary rods, and supporting columns are fixedly connected to the bottom of the worktable. The brake pad clamping mechanism for automobile brake pad drilling can utilize the cooperation of telescopic rods, the rotary rods, connecting columns, first spring and sliding columns to drive the rotary rods to rotate, can cooperate with the first springs and the sliding columns to drive a clamping device to clamp a brake pad, and the rotation range of the rotary rods is larger, so that the clamping device can clamp different sizes of brake pads, and the application range of the mechanism is greatly widened.

Owner:枣阳神虎摩擦材料有限责任公司

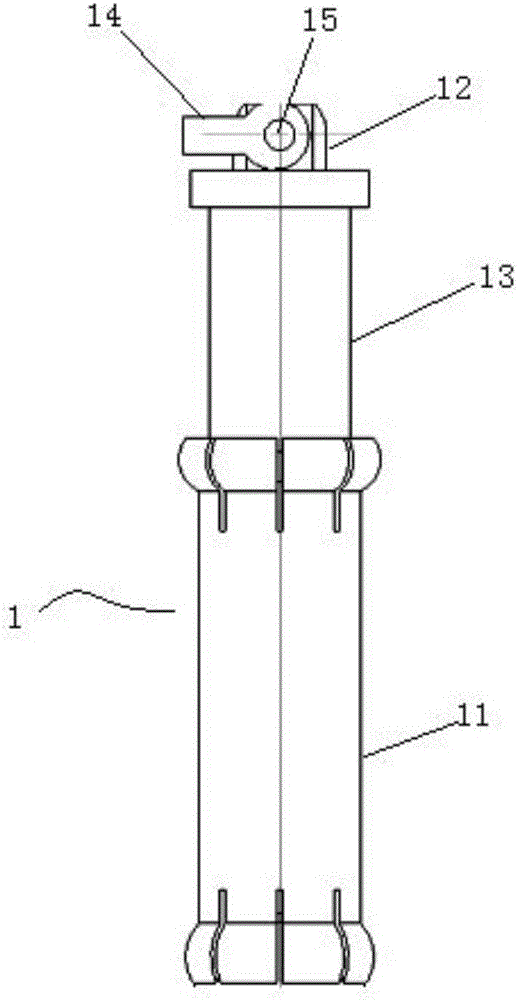

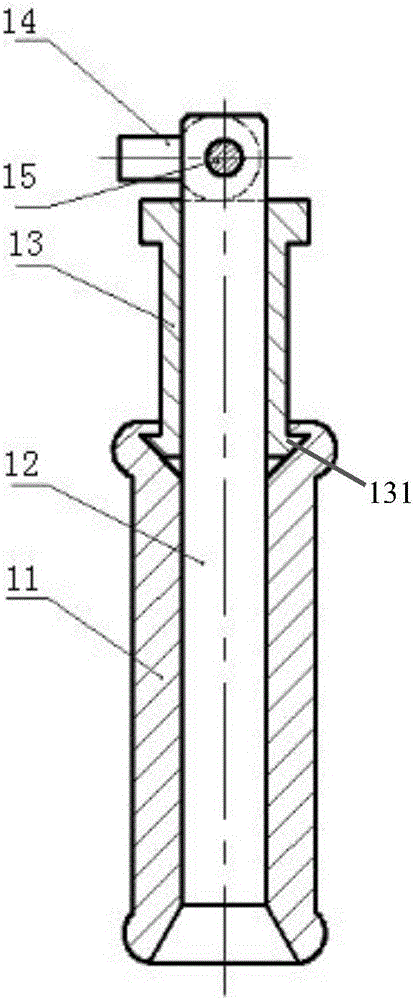

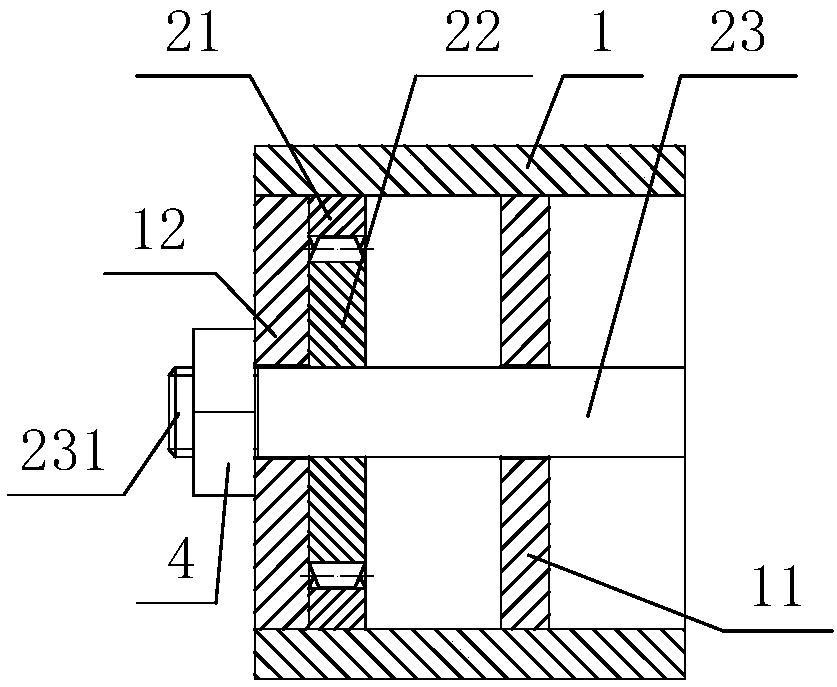

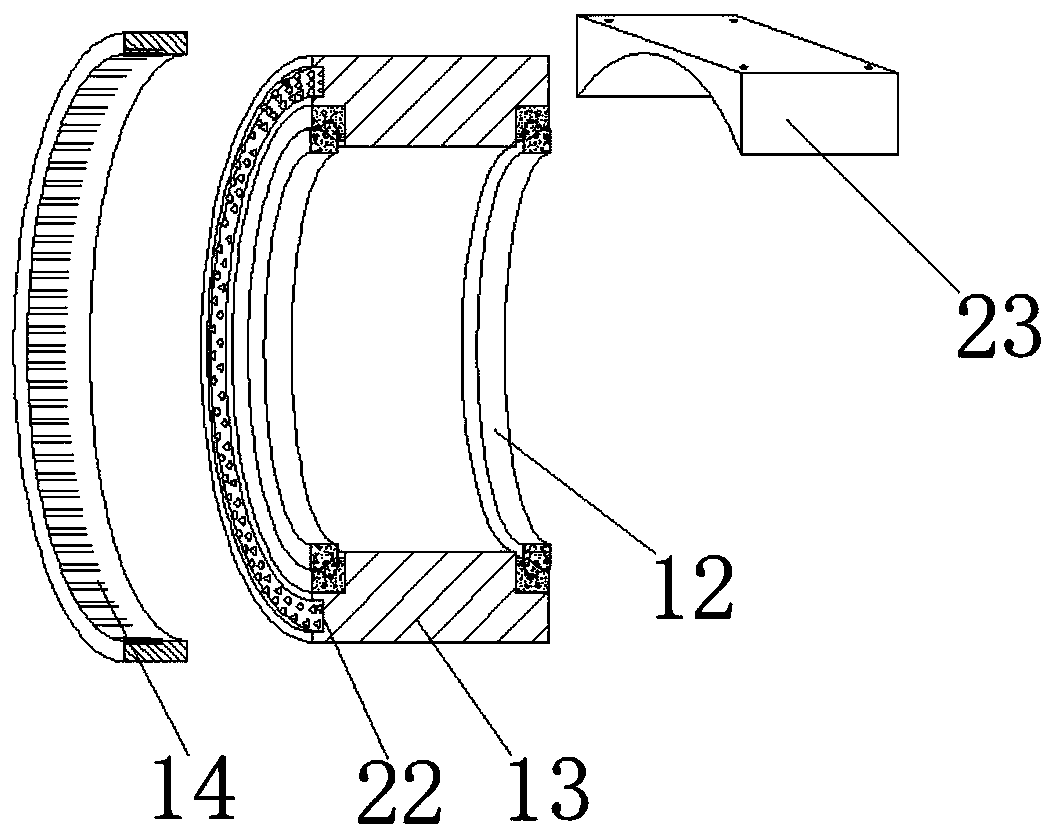

Adjusting apparatus as well as spectacles with same

PendingCN107748448AExtended service lifeOvercome the problem that the tilt angle cannot be adjustedNon-optical partsEngineeringMechanical engineering

The invention provides an adjusting apparatus. The adjusting apparatus comprises a positioning tube, an angle adjusting assembly and an elastic member; the angle adjusting assembly comprises a gear ring, a gear and a circular shaft which are coaxially arranged, inner teeth are arranged on the inner circumferential wall of the gear ring, outer teeth are arranged on the outer circumferential wall ofthe gear, the gear ring and the gear are engaged by virtue of the inner teeth and the outer teeth, and the circular shaft is fixedly connected with the gear; the gear ring and the gear are respectively arranged inside the positioning tube, the gear ring is fixedly connected with the positioning tube, one end of the positioning tube is provided with a first barrier wall, the first barrier wall isprovided with a first circular hole coaxial with the circular shaft, and one end of the circular shaft penetrates through the first circular hole and is in clearance fit with the first circular hole;and the elastic member is disposed between the gear and the first barrier wall. The invention also provides spectacles with the adjusting apparatus. The adjustment requirement can be met by virtue ofthe adjusting apparatus, and the problem that an oblique angle between a spectacle leg and a lens frame of the existing spectacles and the problem for adjusting a width of a nose support can be solved.

Owner:上海新镜汇眼镜有限公司

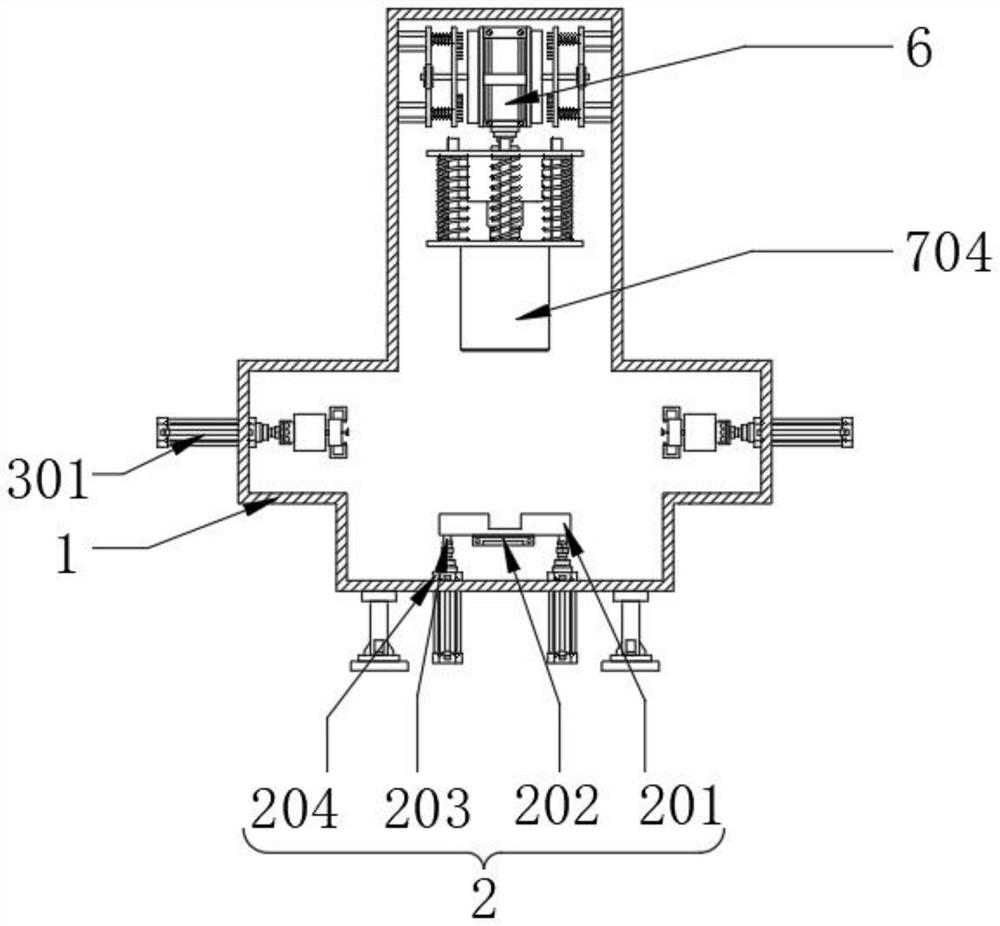

Cervical traction device

InactiveCN108771577ASmooth correction processAvoid changing anglesElectrotherapyMagnetotherapy using permanent magnetsPhysical medicine and rehabilitationBody positions

The invention discloses a cervical traction device in the field of medical apparatuses and instruments. The cervical traction device comprises a base, wherein a head positioning mechanism, a neck supporting pillow and shoulder constraint straps are sequentially connected on the base in one direction. The head positioning mechanism comprises two extensible arms respectively connected to two opposite sides of the base, and a tensioning belt with an upwards arched middle is connected between the extensible arms. The number of the shoulder constraint straps is two, the two shoulder constraint straps are respectively located on two opposite sides of the base, one end of each shoulder constraint strap is fixedly connected with the base, and the other end of each shoulder constraint strap is detachably connected with the base. When the cervical traction device is used for correcting the cervical vertebra, generally, body discomfort is caused and further spontaneous shaking is very likely to occur due to the fact that the body position in a corrected state is different from an ordinary non-normal position. By adopting the scheme, the spontaneously shaking head and shoulders at two ends ofthe neck are fixed, angle change of the head and shoulders is avoided, and the smooth cervical vertebra correcting process is ensured.

Owner:余庆县中医医院

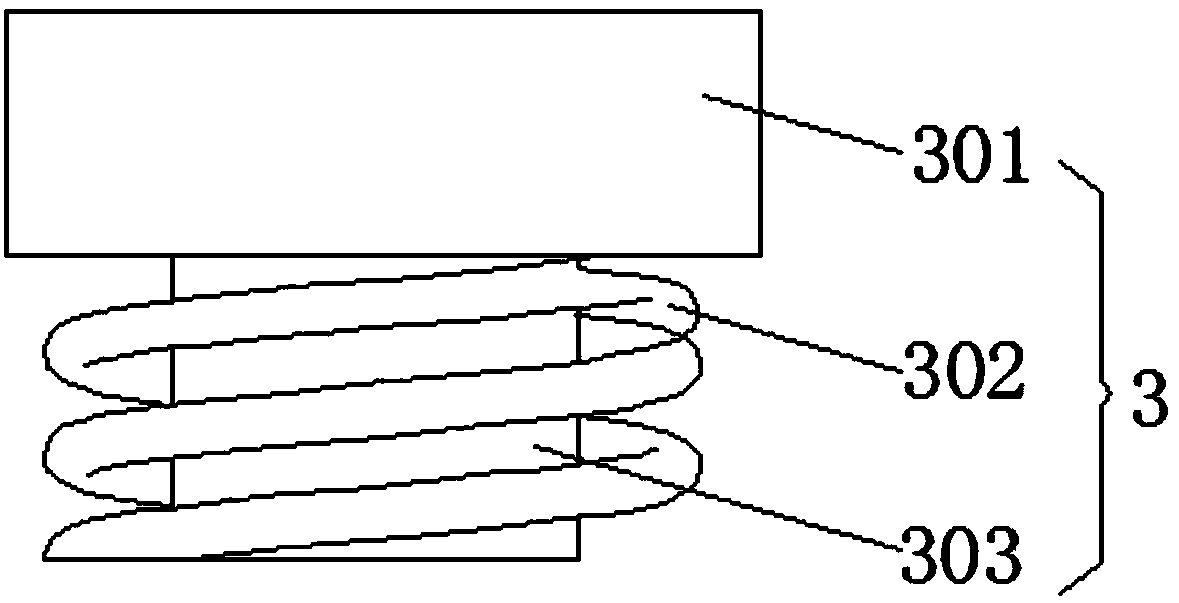

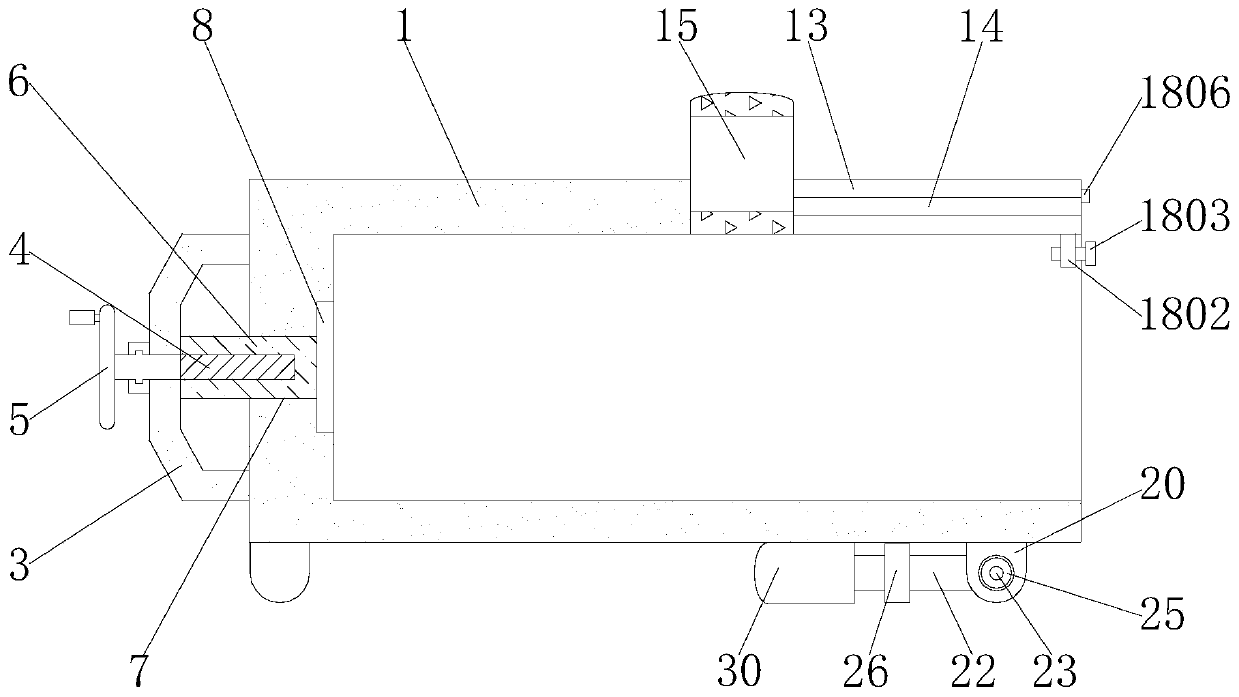

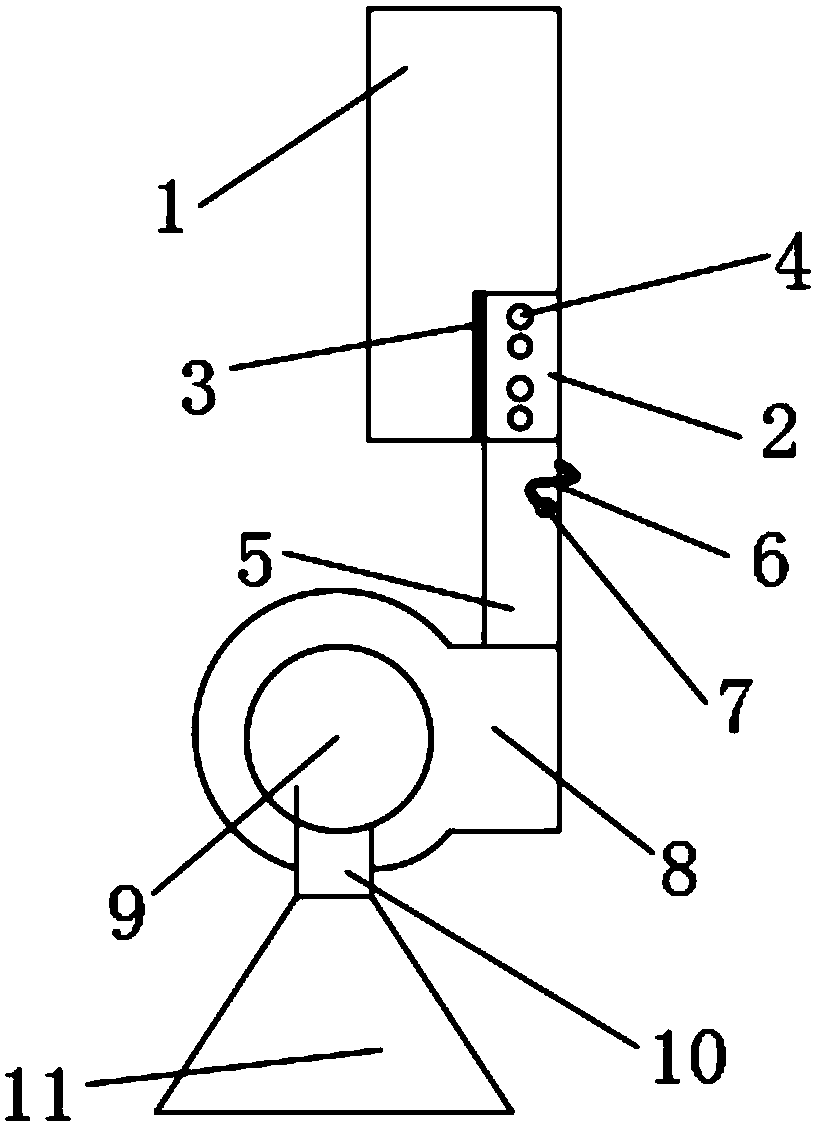

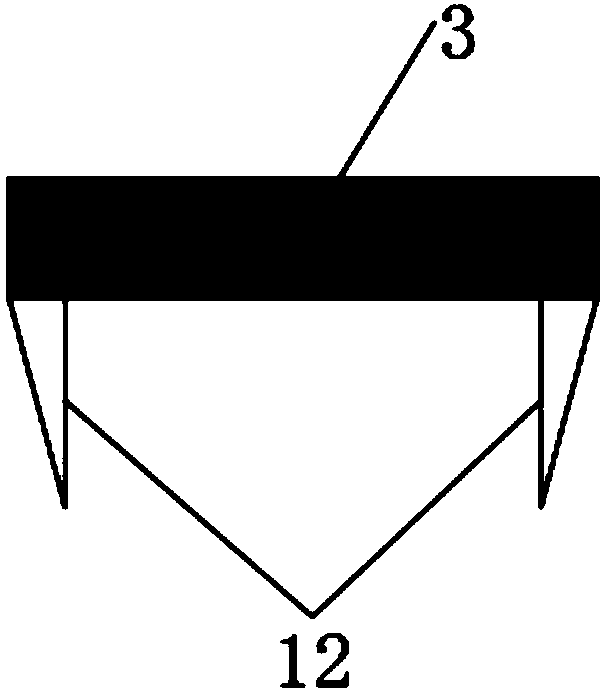

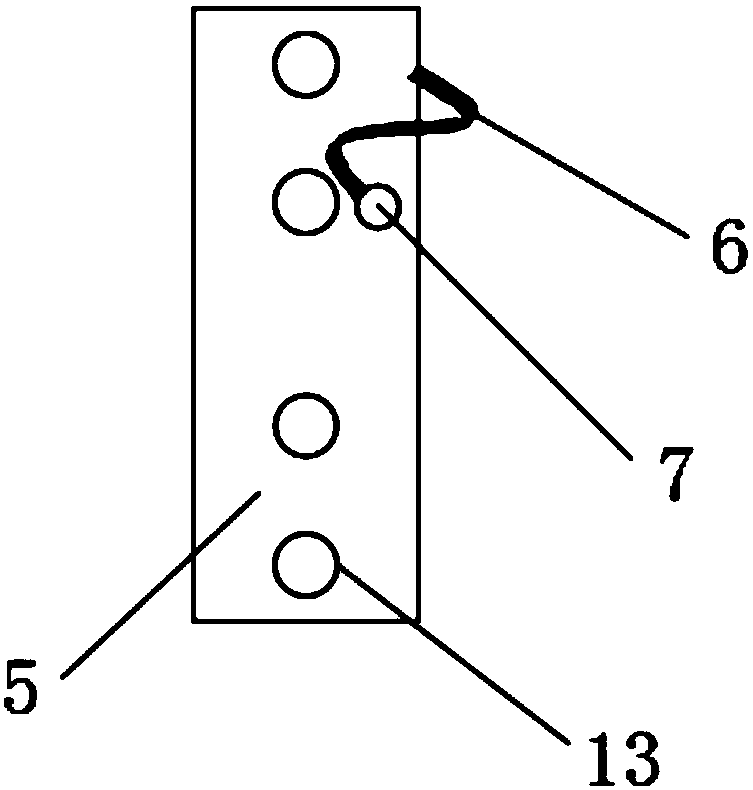

Welding support device convenient to finely adjust for quartz-crystal resonator processing

InactiveCN110000497AEasy to fixAccelerate cooling and drying rateWelding/cutting auxillary devicesAuxillary welding devicesQuartz crystal resonatorArchitectural engineering

The invention discloses a welding support device convenient to finely adjust for quartz-crystal resonator processing. The welding support device convenient to finely adjust for quartz-crystal resonator processing comprises a processing table, a water pump, a stepping motor and a fixed cross rod, wherein support legs are fixedly arranged under the processing table; a placement table is connected onto the support legs; the water pump is arranged on the placement table; one end of the water pump is connected with a water guiding pipe; the upper end of the water guiding pipe is connected with a condenser pipe; a movable block is connected to the outer side of a support rod; a fixed sliding sheet is connected to the inner side of the movable block; a connecting tooth block is arranged on the outer side of the movable block; a connecting frame is arranged in a welding frame; and a connecting ratchet is fixed to the inner surface of the connecting frame. According to the welding support device convenient to finely adjust for quartz-crystal resonator processing, the connecting frame and the connecting ratchet are arranged, and the connecting ratchet on the surface of the connecting frame on the inner side of the welding frame rotates on the connecting tooth block on the surface of the movable block in a meshing way through rotating the welding frame, so that a welding head angle on thelower part of the welding frame is finely adjusted conveniently.

Owner:HUNAN UNIV OF ARTS & SCI

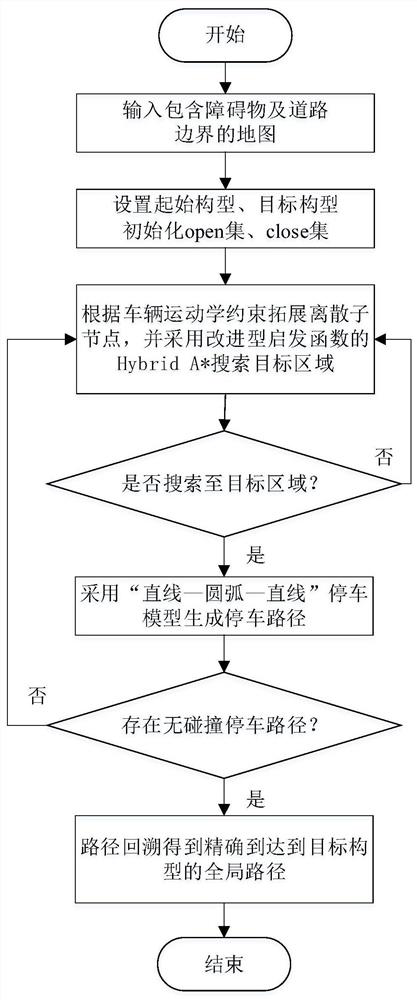

Unstructured road vehicle path planning method

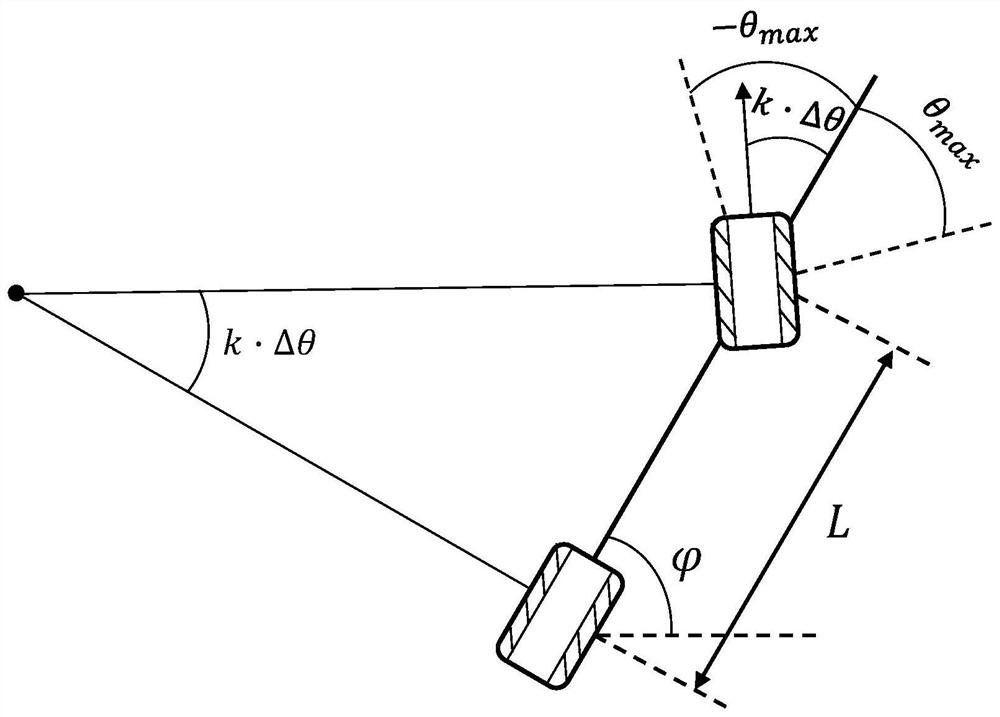

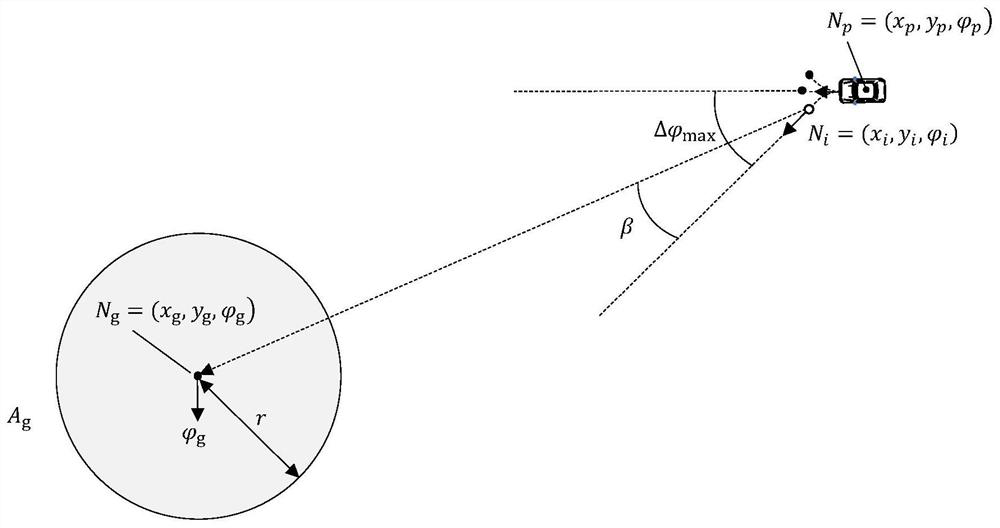

ActiveCN111857148AReduce in quantityAvoid changing anglesPosition/course control in two dimensionsVehiclesArtificial intelligenceTransport engineering

The invention discloses an unstructured road vehicle path planning method which comprises the following steps: 1, inputting a map containing obstacles and road boundaries, and setting an initial configuration Ns, a target configuration Ng and a target area Ag; 2, setting that the initial open set only comprises an initial configuration Ns; 3, selecting a node with the minimum cost from the open set; 4, judging whether the node Ni exists in the open set or not; 5, judging whether the node Ni searches the target area Ag or not; 6, generating a parking path accurately reaching the target configuration by adopting a linear-arc-linear parking model; 7, judging whether each parking path generated in the step 6 collides with an obstacle or not; and 8, path backtracking. According to the unstructured road vehicle path planning method provided by the invention, the vehicle path can be effectively planned by setting the steps 1 to 8.

Owner:HUNAN UNIV

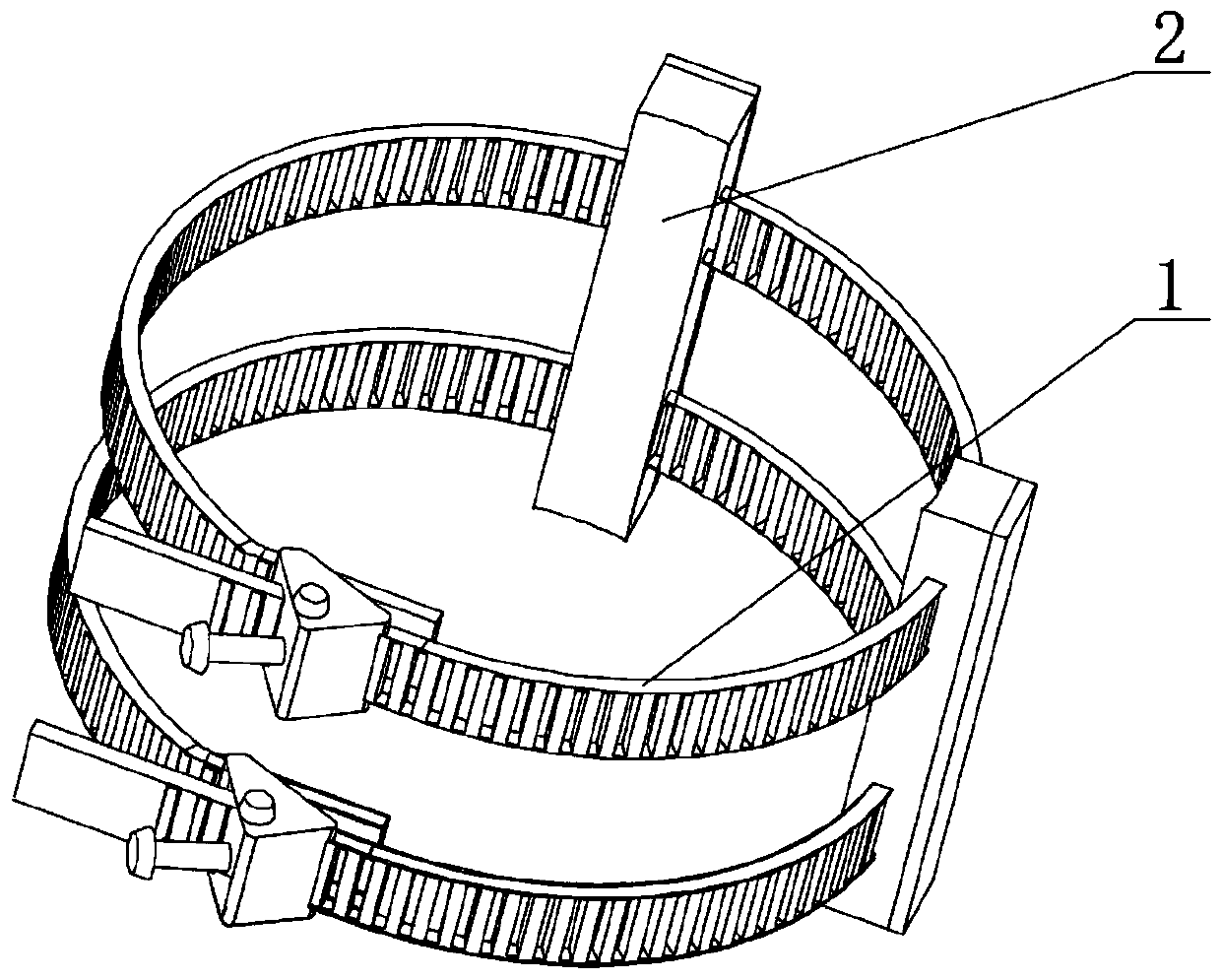

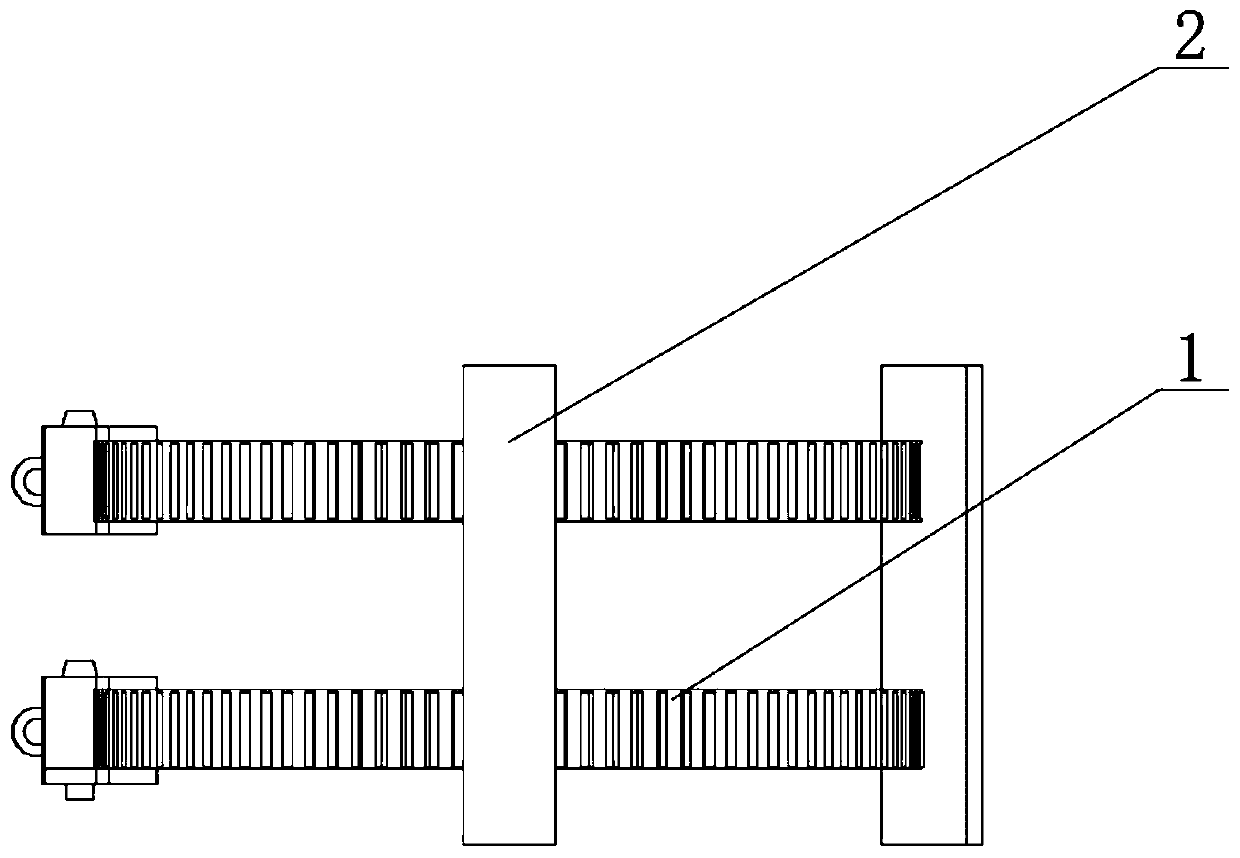

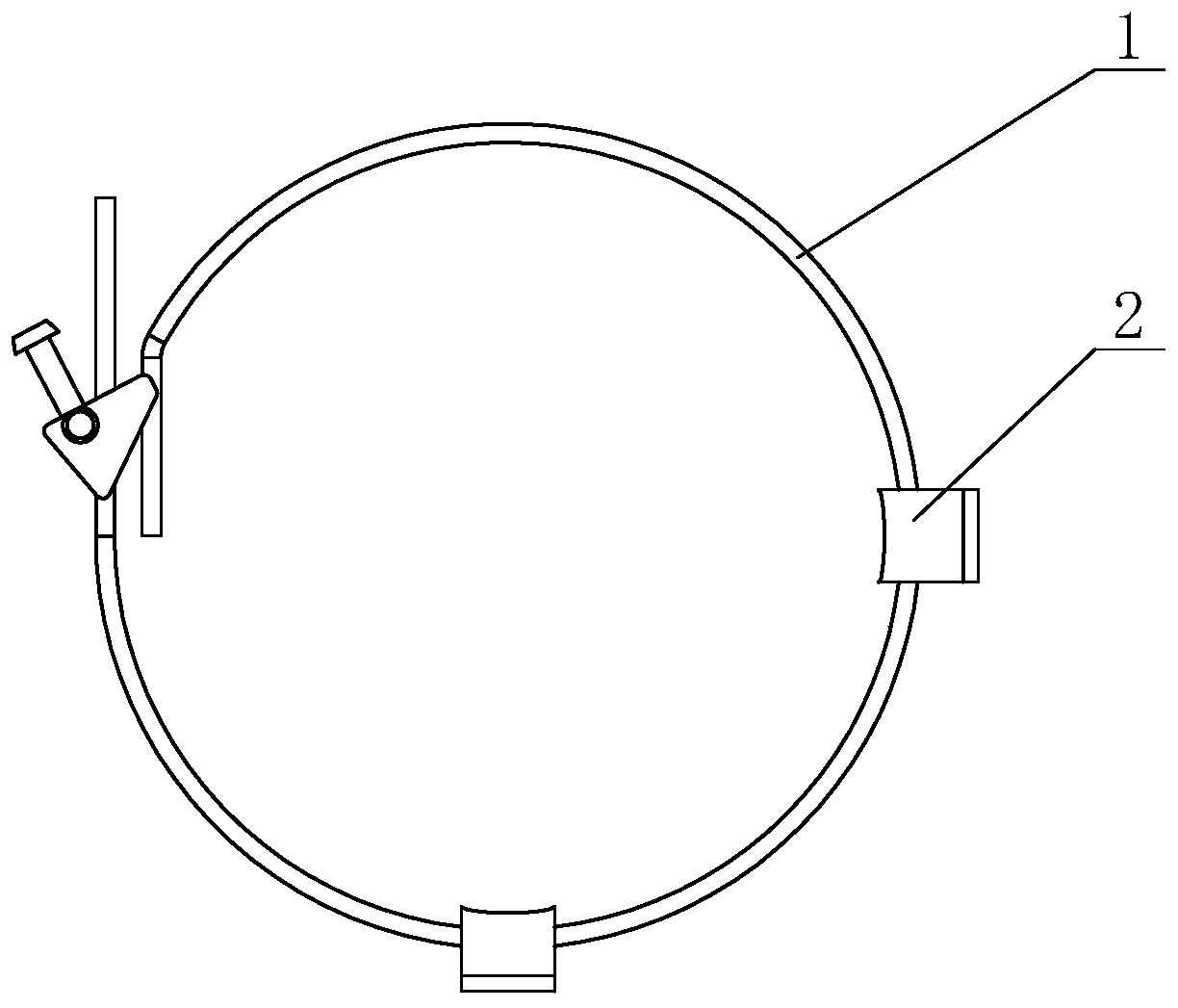

Device assisting C-arm machines with accurate shooting

ActiveCN110179490AFixed effective durationFixed durationRadiation beam directing meansEngineeringLaser beams

The invention discloses a device assisting C-arm machines with accurate shooting, and relates to the field of medical instruments. The device assisting C-arm machines with accurate shooting comprisestelescopic circular hoops, wherein a plurality of mounting seats are arranged on the circular hoops; the mounting seats are detachably and fixedly connected to the circular hoops; a battery frame is arranged in each mounting seat; a laser lamp placing groove is formed in one side of the battery frame; a laser lamp is arranged in each laser lamp placing groove; an emission hole is formed in each mounting seat; each emission hole is communicated with each laser lamp placing groove; each laser lamp is a cross laser lamp; and each emission hole is eccentrically arranged against each laser lamp. The device has the beneficial effects that: the device can effectively and continuously fix the laser lamps, avoids the change of the laser beam angle caused by the displacement of the laser lamps, conveniently replaces the lost laser lamps, has a simple structure, can be installed on C-arm machines of different types easily, has low manufacturing cost and high cost performance, and can be popularized and applied all over the country.

Owner:杨军 +1

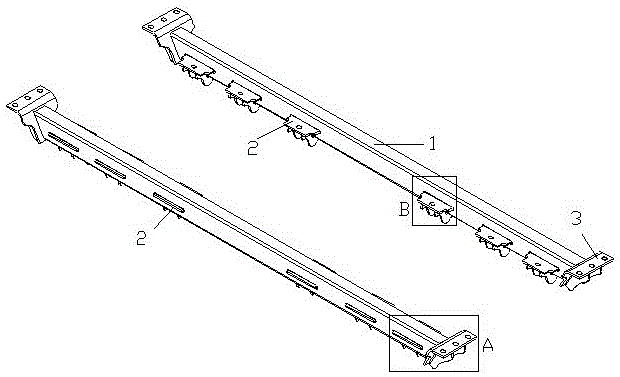

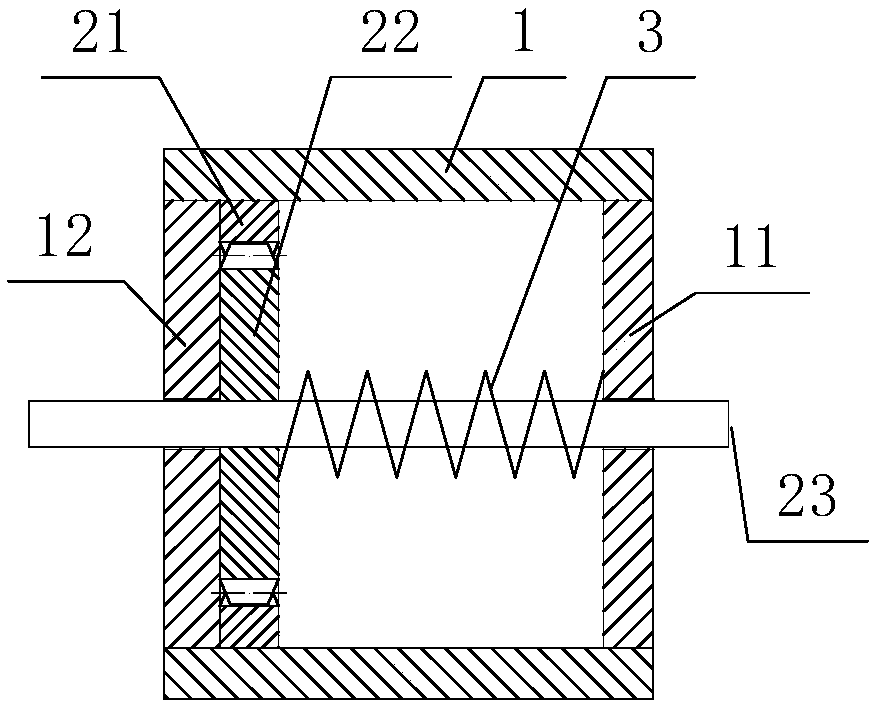

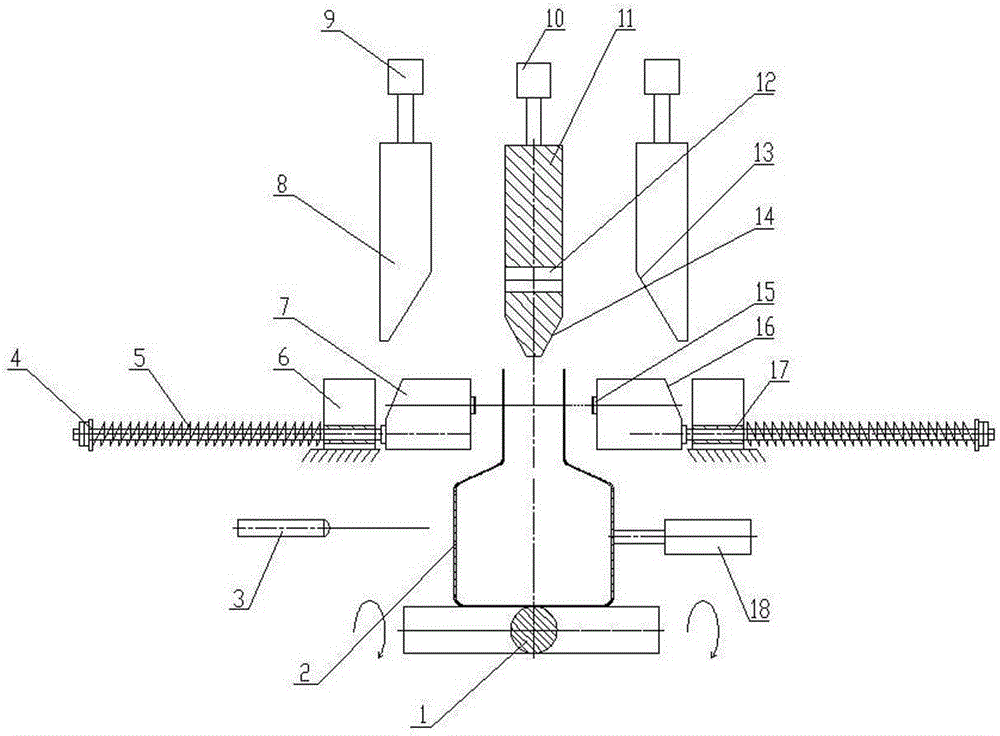

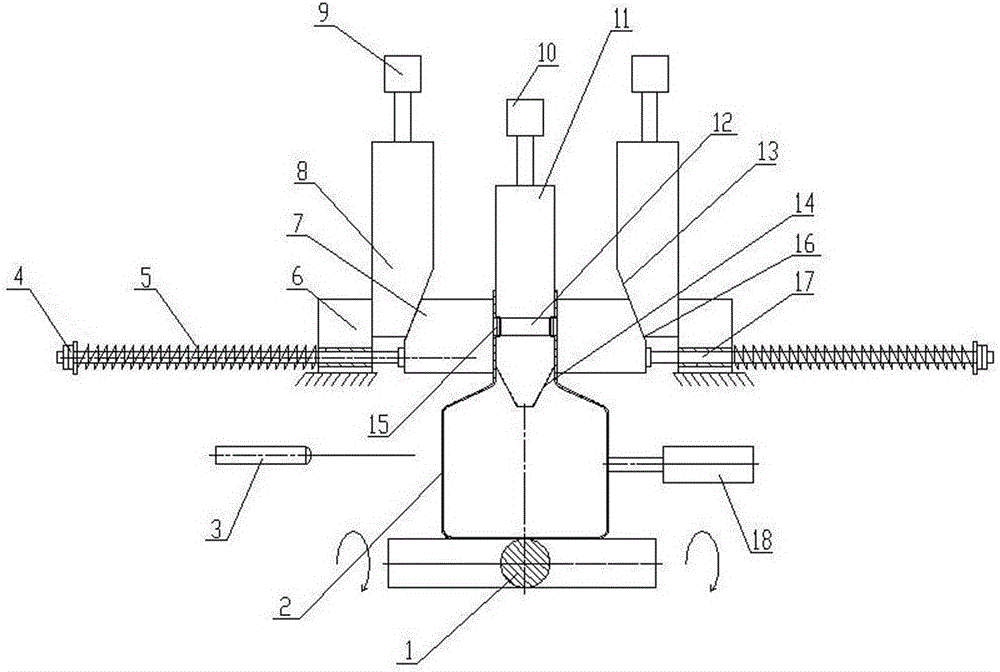

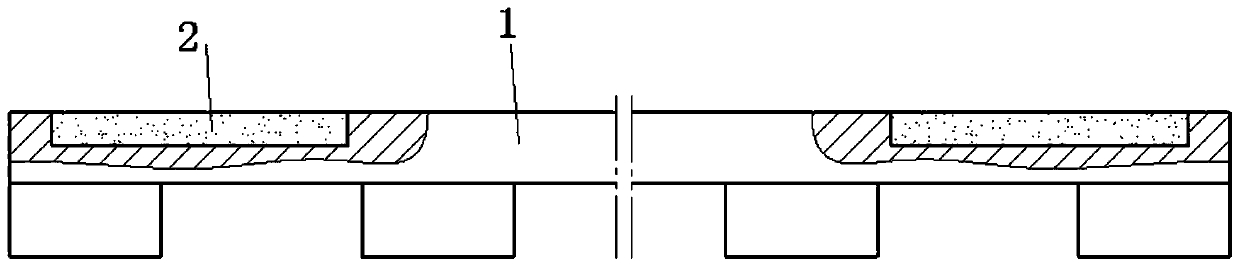

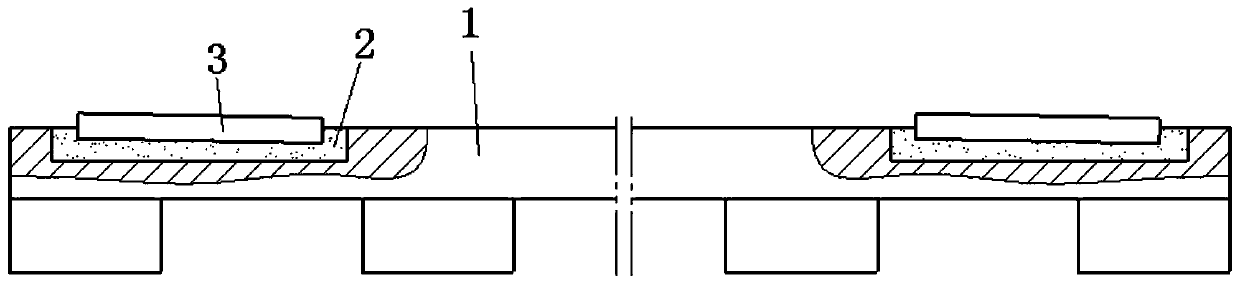

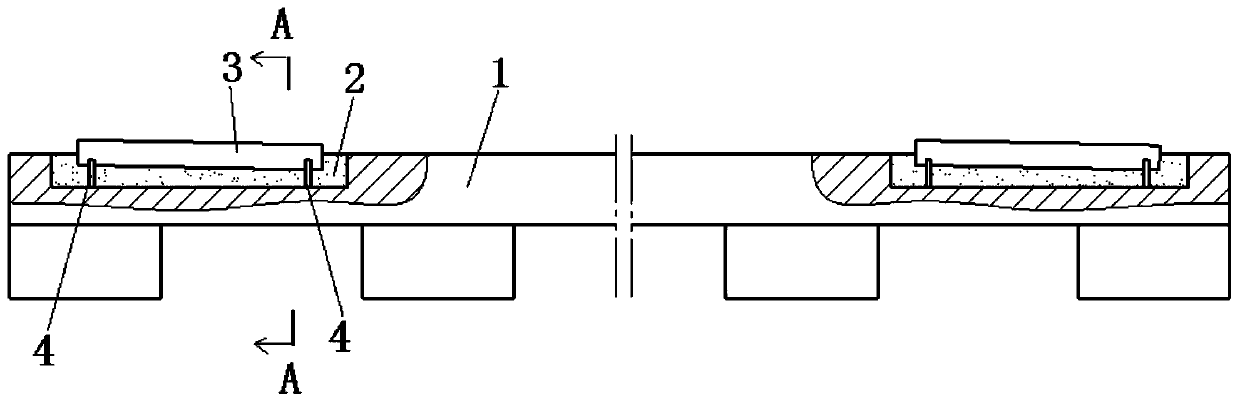

Bump punching mechanism for solar panel bracket

The invention discloses a bump punching mechanism for a solar panel bracket. The bump punching mechanism comprises a base, wherein profile steel with a bottle-shaped cross section is arranged on the base. The bump punching mechanism is characterized in that supports are arranged on the base on two sides of the profile steel, and two transverse rod holes are formed in the same horizontal plane of each support; ejector rods are arranged in the transverse rod holes, ejecting blocks are fixed at inner ends of the two ejector rods on the same support, and bulges are arranged on adjacent surfaces of the two ejecting blocks; stop blocks are arranged at outer ends of the ejector rods, and a spring is arranged on an ejector rod section between each stop block and the adjacent support; a template is arranged above a gap between the two ejecting blocks, a cross hole is formed in the template, and the upper edge of the template is connected with a first push-and-pull mechanism; inserting plates and second push-and-pull mechanisms are arranged on two sides of the template; during working, bumps which are bulged inwards are punched on steel plates on two sides of a bottleneck part of the profile steel by the bulges on the adjacent surfaces of the two ejecting blocks and the cross hole by the virtue of the two inserting plates and the second push-and-pull mechanisms. With the adoption of the bump punching mechanism for the solar panel bracket, the mounting efficiency of a solar panel and solar receiving efficiency can be improved.

Owner:江苏惠汕新能源集团有限公司

Cradle head spraying device for dry fog dust suppression

ActiveCN112090208AReduce distanceReduce the amount of waterUsing liquid separation agentEngineeringSlide plate

The invention relates to the technical field of dry fog dust suppression, and discloses a cradle head spraying device for dry fog dust suppression. The width of a height adjusting sheet is continuously increased from top to bottom, so that when a rotating device rotates anticlockwise in Figure 5, the distance between a guide wheel and the inner wall of a limiting sleeve is continuously increased under the action of the height adjusting sheet, a volume reduction sliding plate moves on the right side in Figure 8, the distance between the volume reduction sliding plate and a movable plate in theinner cavity of a containing cavity shell is reduced, the containing cavity in the containing cavity shell is reduced, the amount of water entering the inner cavity of the containing cavity shell froman air guide pipe is reduced, and the amount of water acted by one-time air pressure release is reduced. The problem that water cannot be torn into small enough liquid drops due to the fact that theenergy required for overcoming the gravity of the water is increased after the angle is changed is solved, the device can form the small liquid drops with the qualified size in different rotating angles, and the working stability of the device is improved.

Owner:马鞍山市方正机械制造有限责任公司

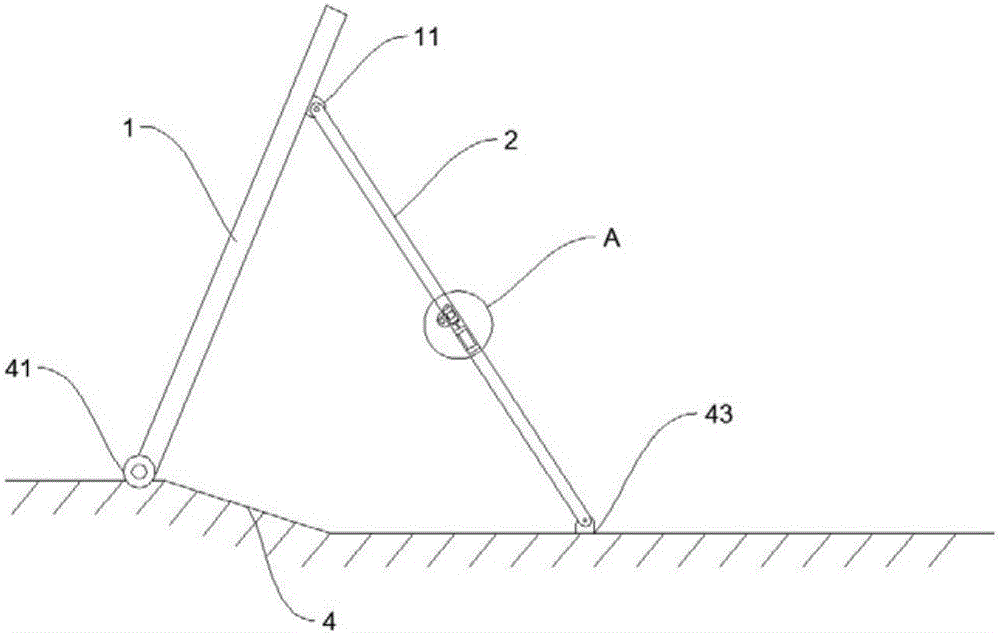

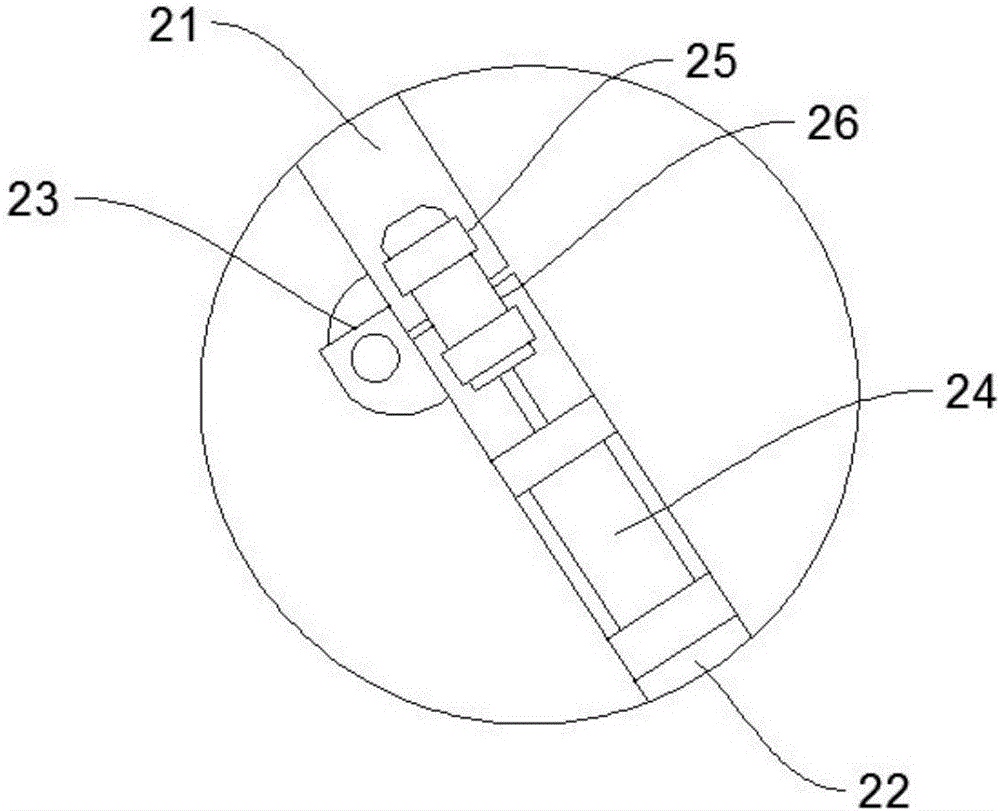

Folding rod self-locking type hydraulic dam

The invention discloses a folding rod self-locking type hydraulic dam, and belongs to the field of hydraulic dams. The problems that an existing hydraulic dam is large in hydraulic cylinder supporting dam body loss, and sediment is likely to block a groove fixedly installed in the hydraulic cylinder are solved. The folding rod self-locking type hydraulic dam comprises a dam body, a folding rod, a hydraulic cylinder and a dam foundation. The bottom of the dam body is fixed to the dam foundation through a bearing pedestal and can be folded by winding a shaft. The folding rod is a foldable rigid rod, and the middle of the folding rod is hinged, wherein one end of the folding rod is movably connected to the dam body through a dam connecting base, and the other end of the hydraulic cylinder is movably connected to the back face of the dam body. The middle of the folding rod is hinged, one folding direction is fixed and cannot be folded in the fixed direction. A self-locking device is arranged on the folding rod. The folding rod can be locked and can be prevented from being folded in the other folding direction. The folding rod replaces the hydraulic cylinder for supporting, and no groove needs to be formed.

Owner:肖广汇

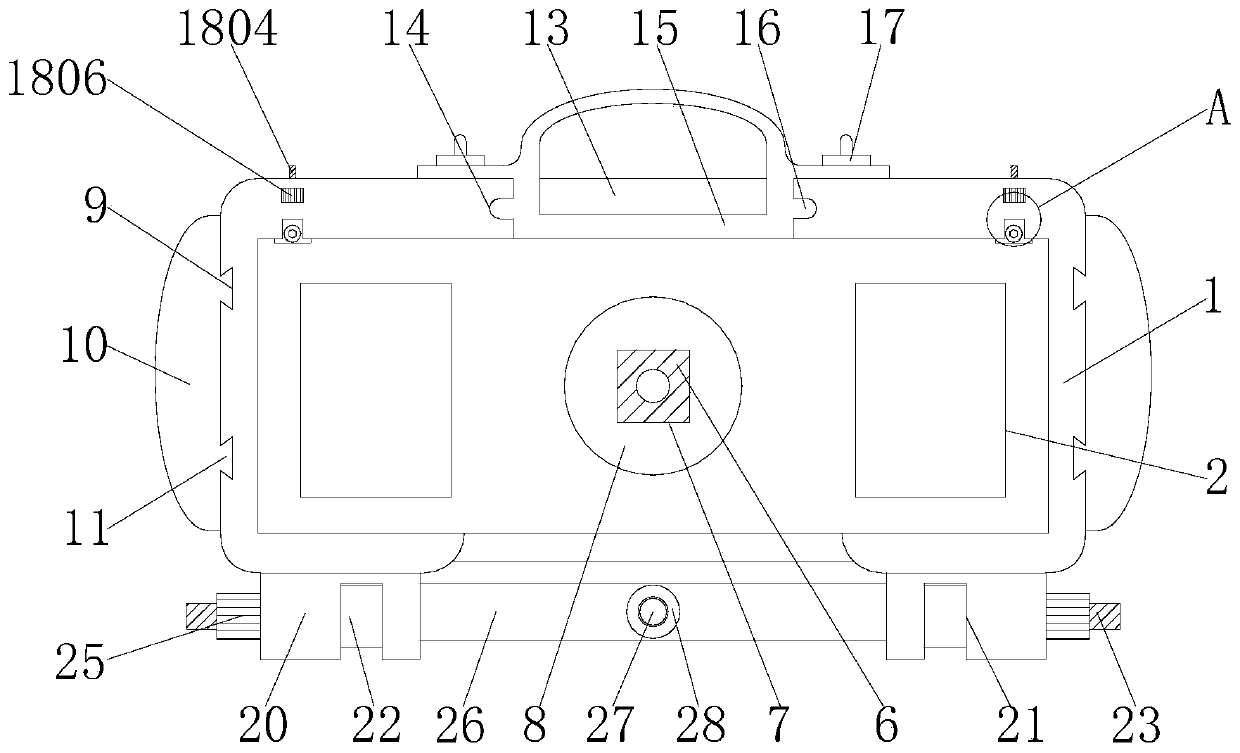

Protection device for network quality and safety tester

ActiveCN110913624AEasy to fixEasy to adjust the angleCasings/cabinets/drawers detailsData switching networksTester deviceEngineering

The invention discloses a protection device for a network quality and safety tester. The device comprises a protective frame, a cushion and a handle, through holes are formed in the two ends of the surface of one side of the protective frame; a bracket is mounted in the center of the surface of the same side of the through hole; clamping grooves are formed in the two ends, perpendicular to the side face of the through hole, of the protection frame, the buffering cushion is connected and fixed in the clamping grooves through clamping plates, the interior of the support is connected with a rotating frame in a penetrating mode through a bolt rod, a first spring is connected to the bolt rod, and a first knob is connected to the end, close to the first spring, of the bolt rod. The protection device for the network quality and safety tester is provided with the bolt bar; by unscrewing the first knob on the bolt rod, one end of the bolt rod is loosened to extrude the rotating frame, then therotating frame is rotated to a certain angle according to needs, and then the first knob is screwed down to enable the bolt rod to clamp and fix the rotating frame, so that the angle of the device isconveniently adjusted.

Owner:耿昭

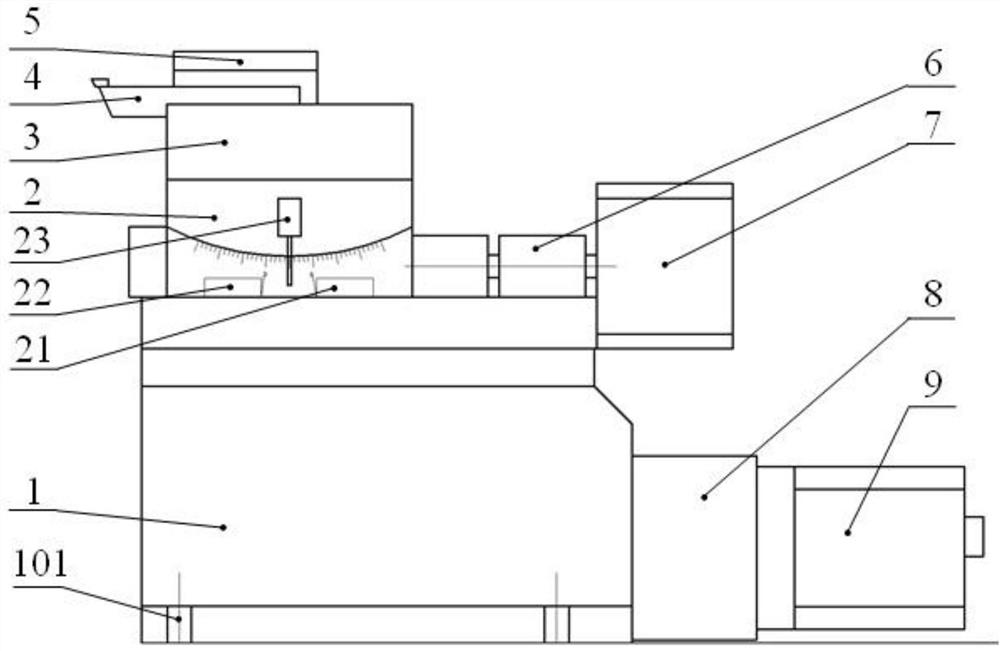

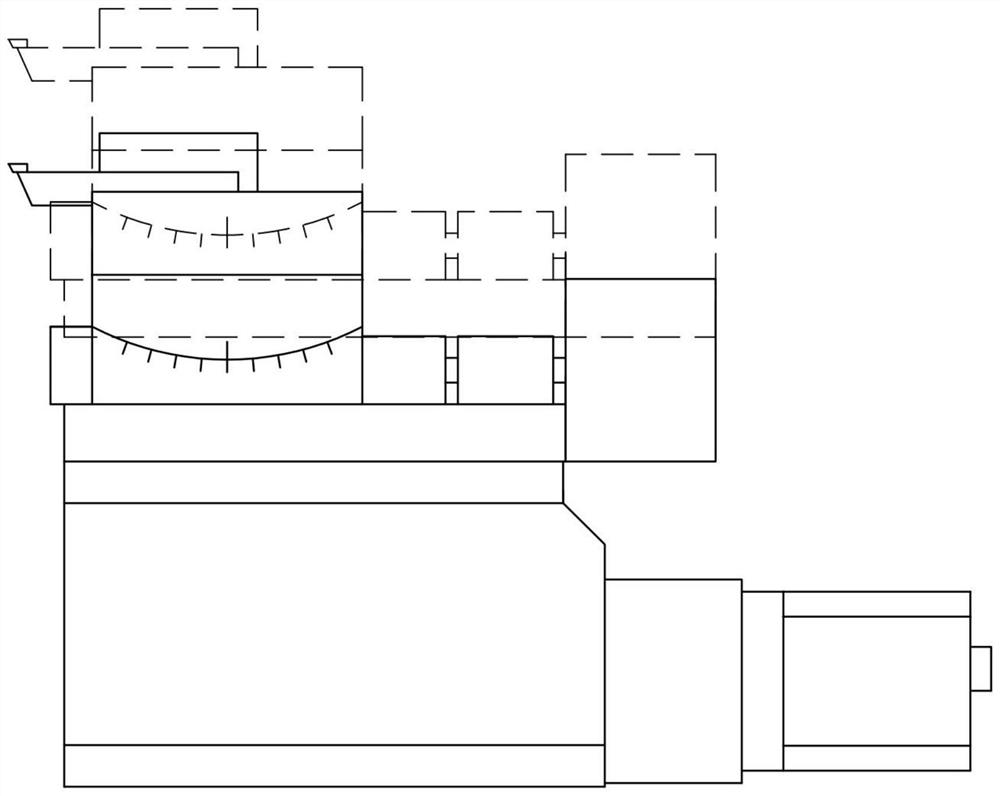

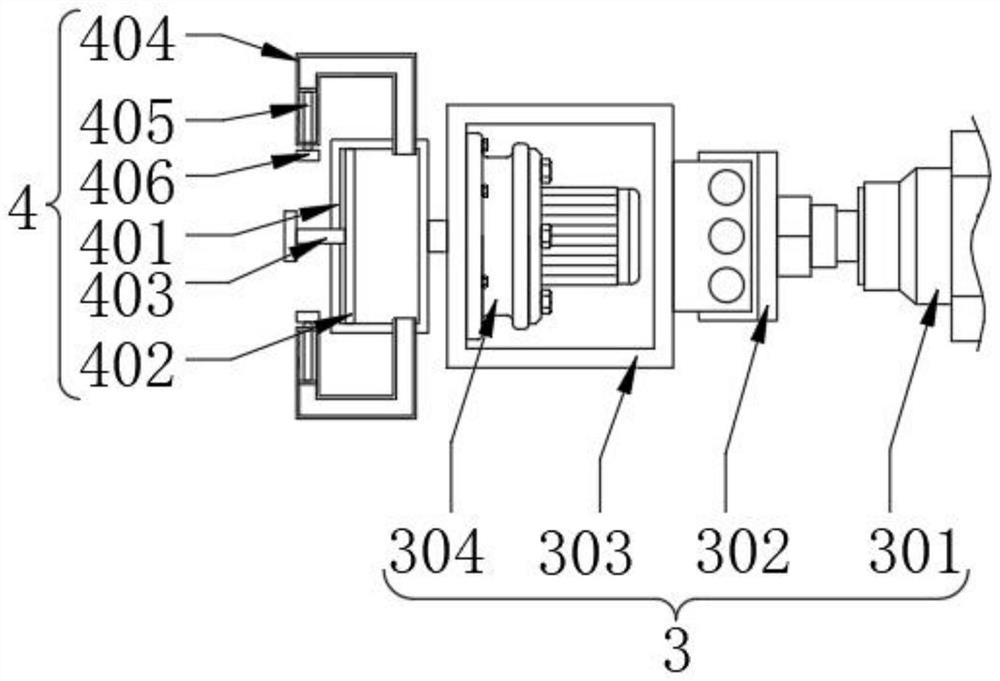

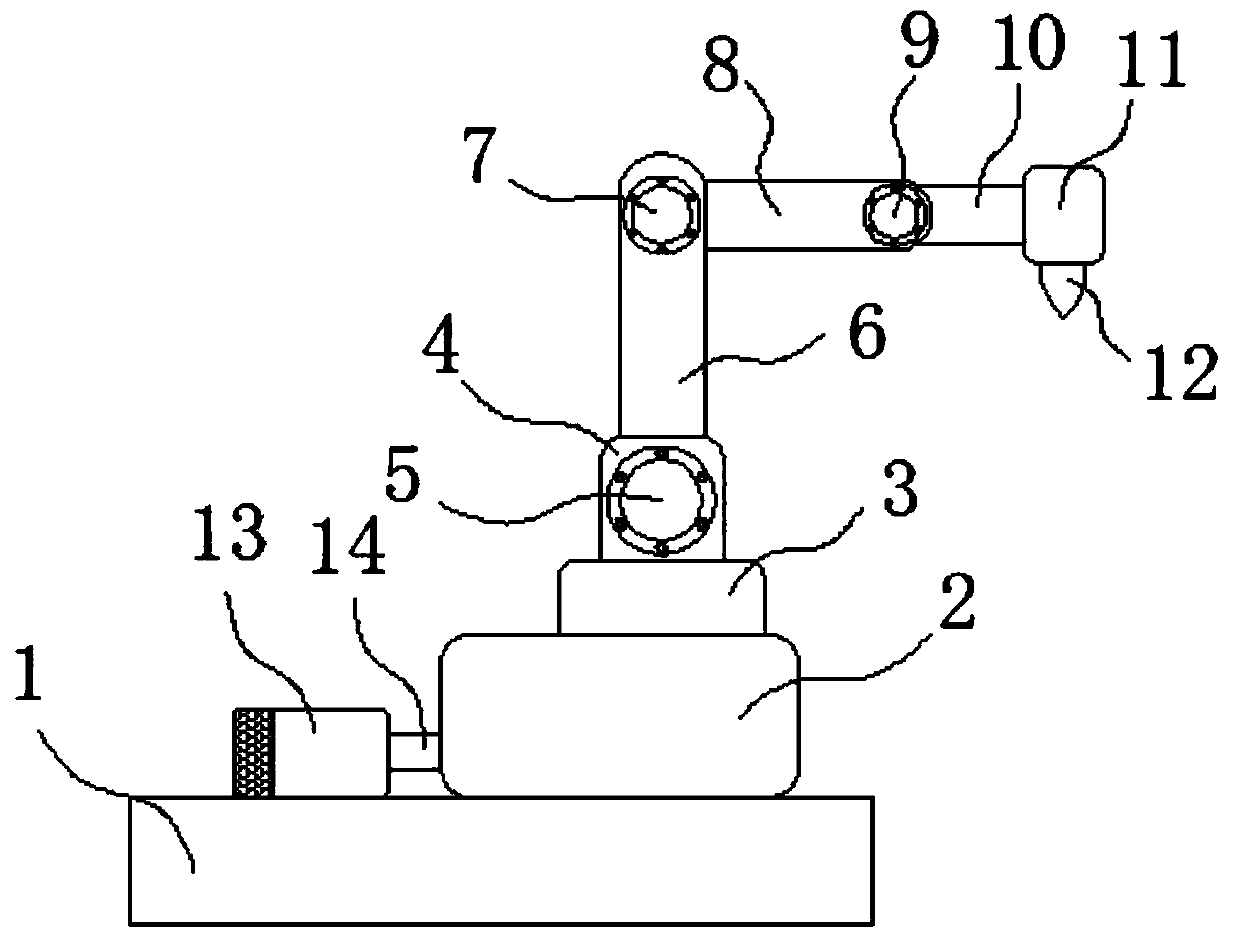

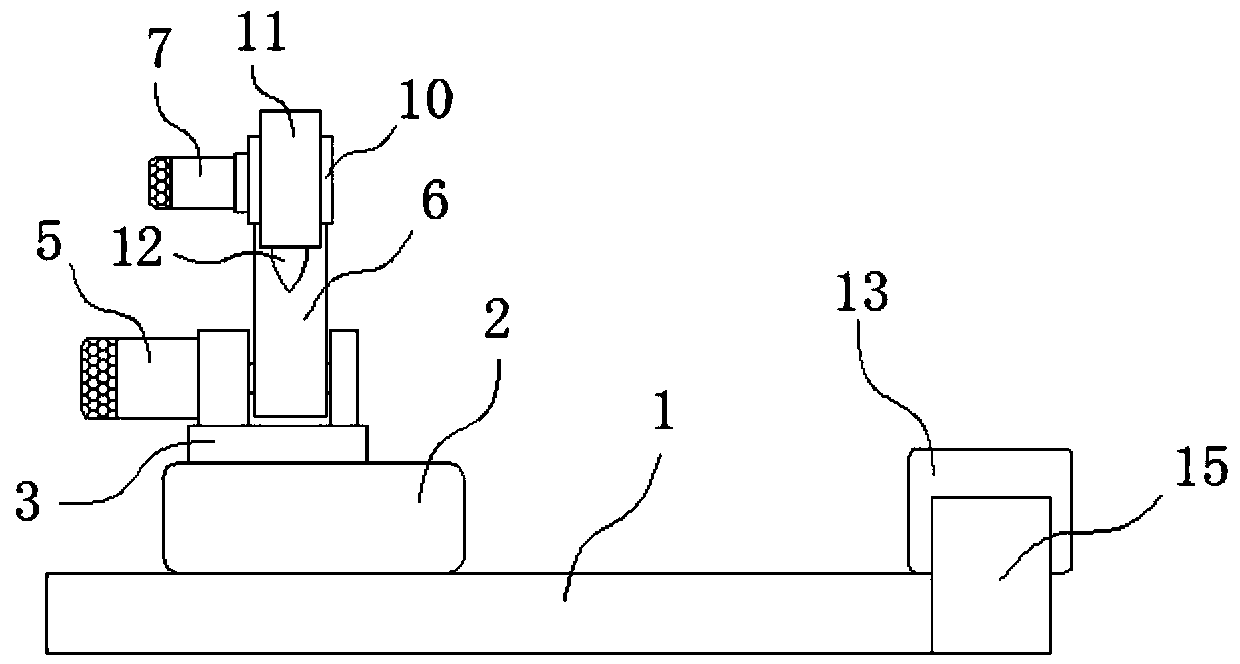

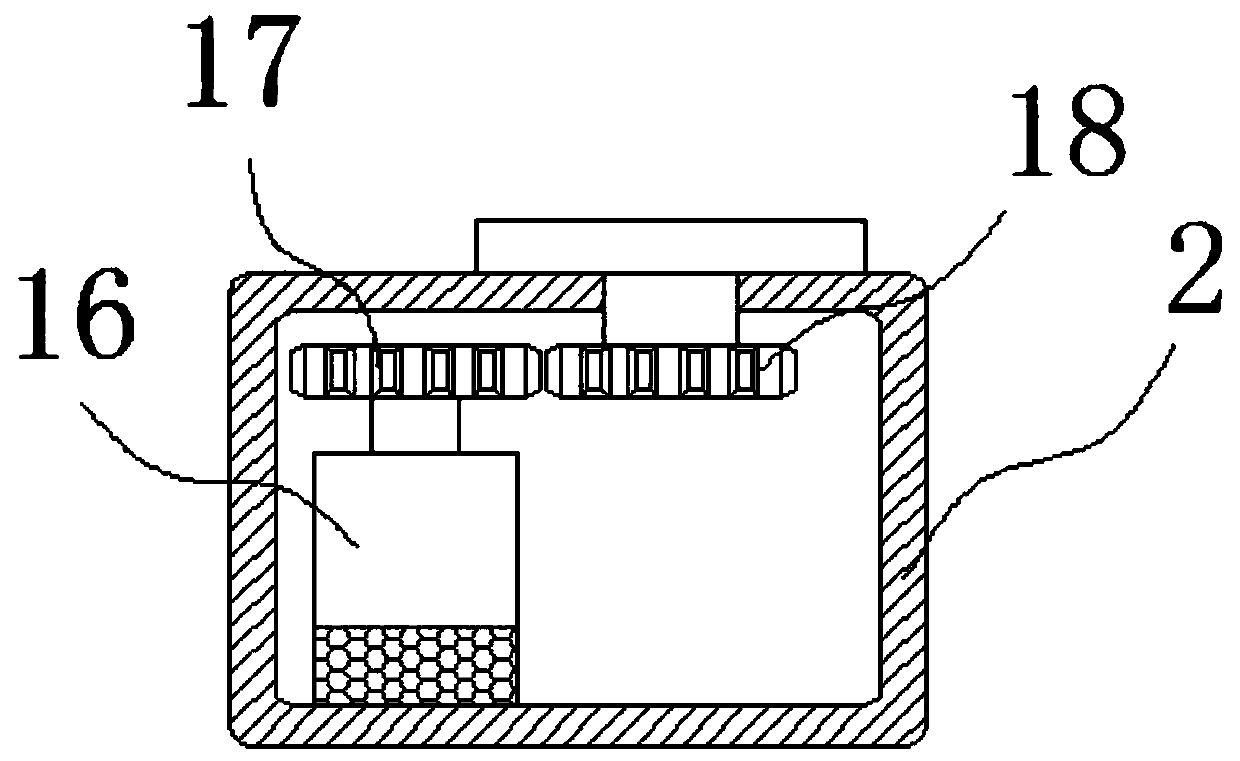

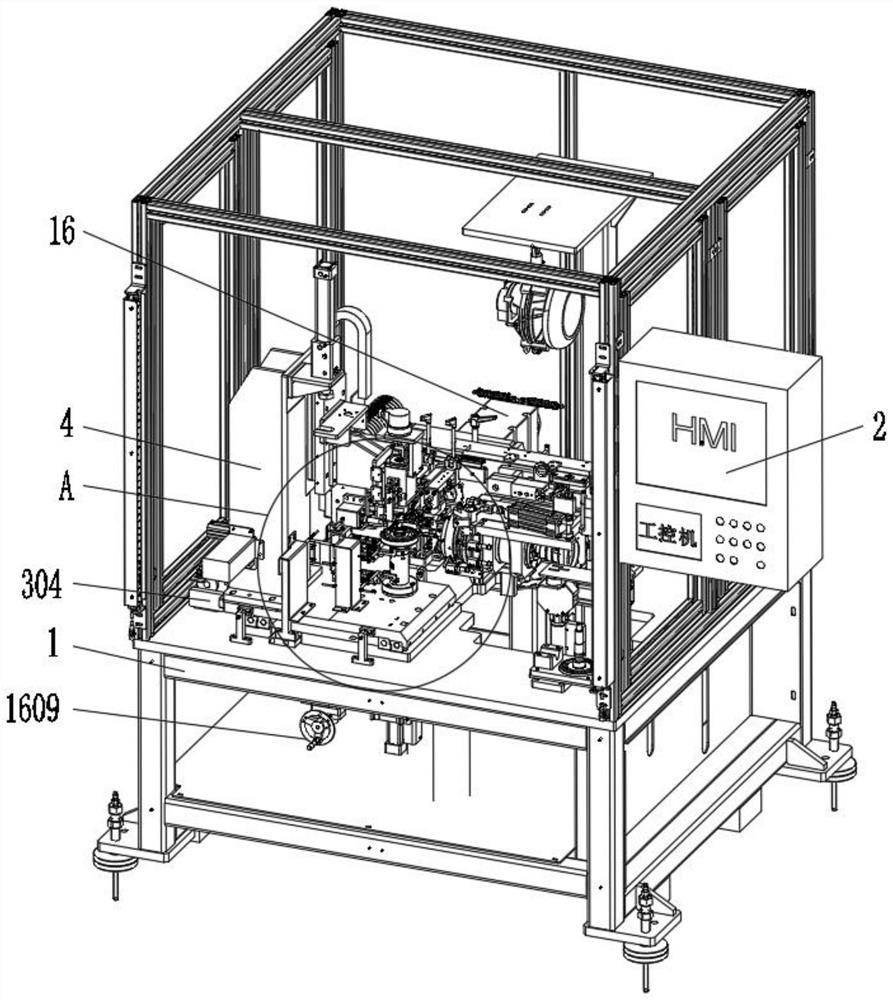

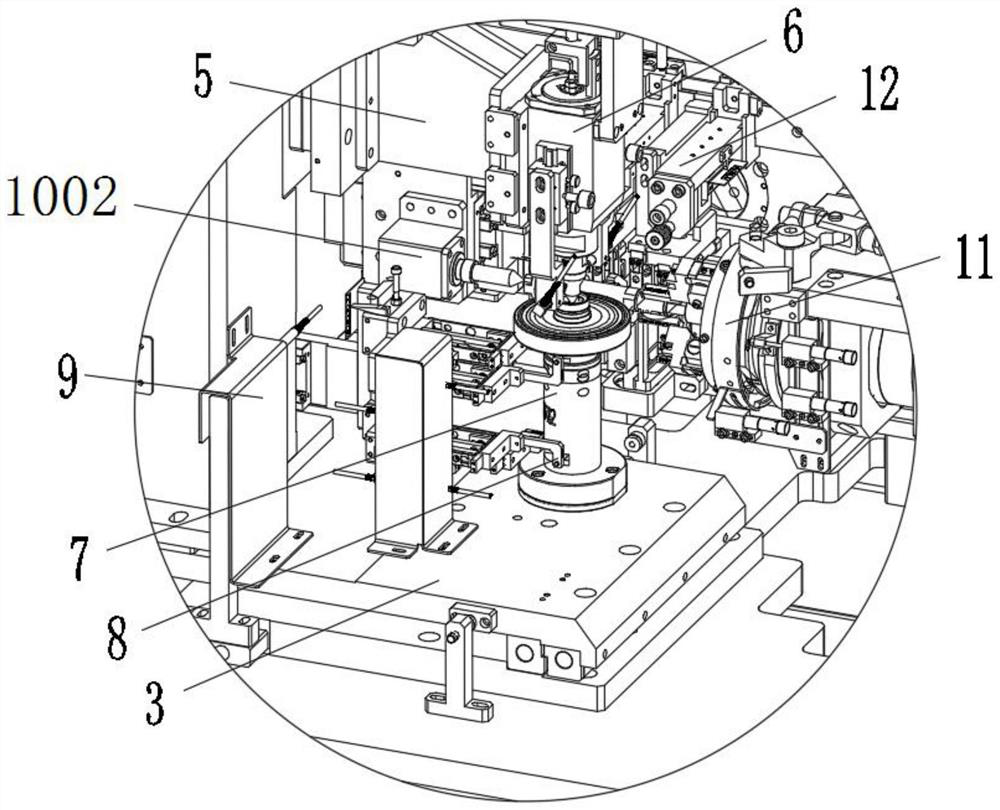

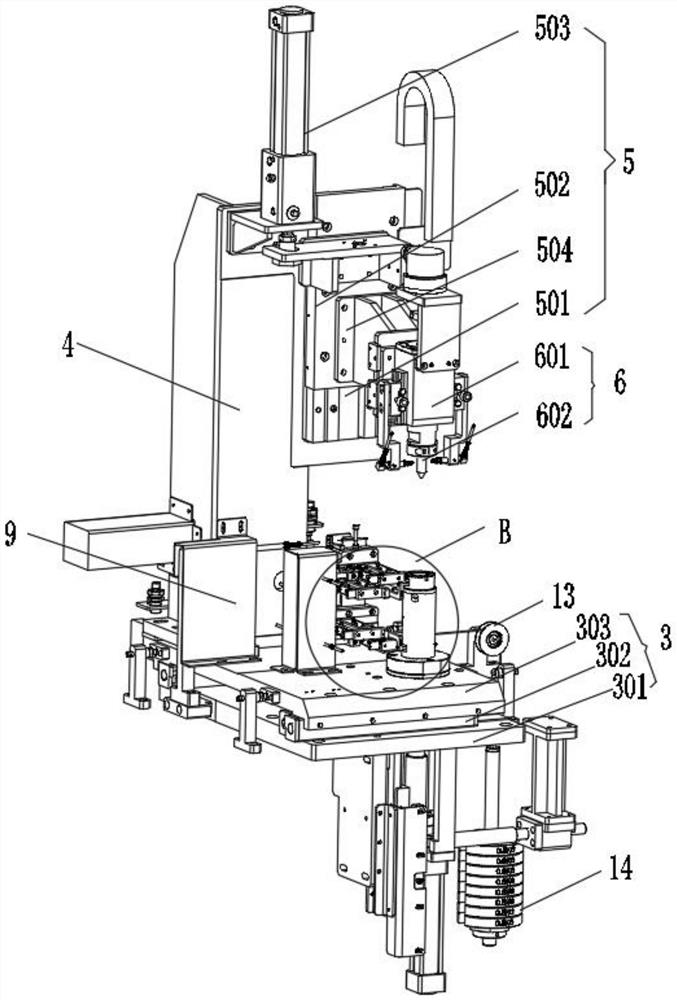

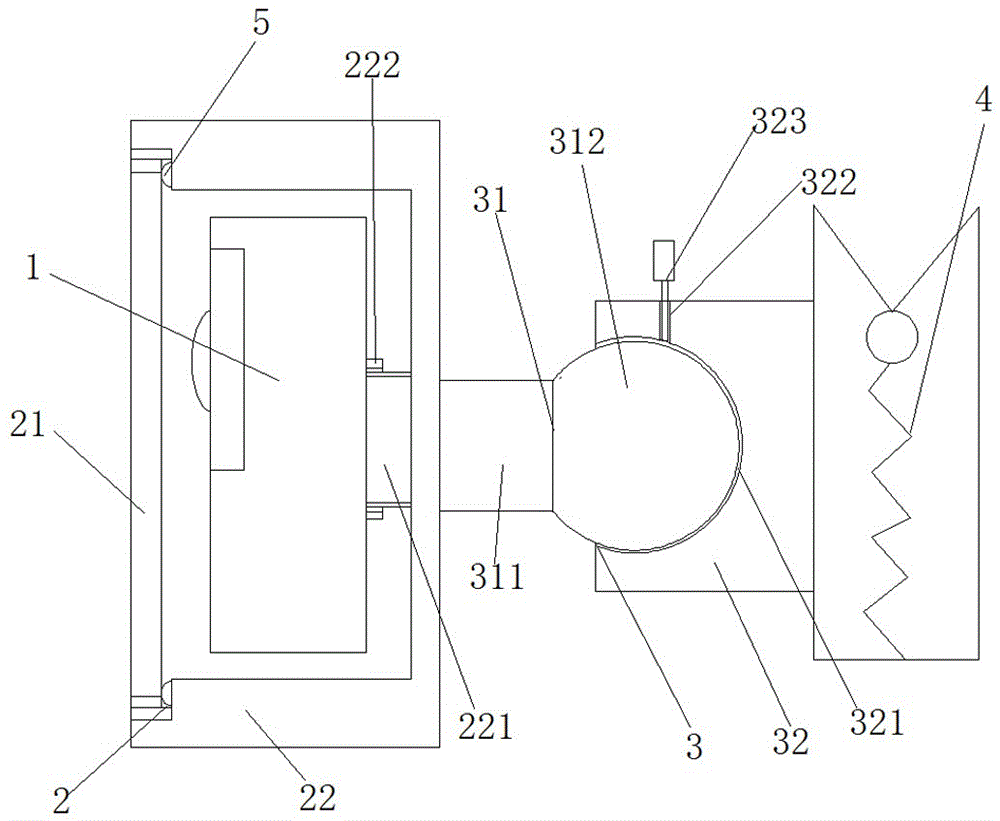

Device capable of adjusting rake angle and height of diamond cutter and adjusting method thereof

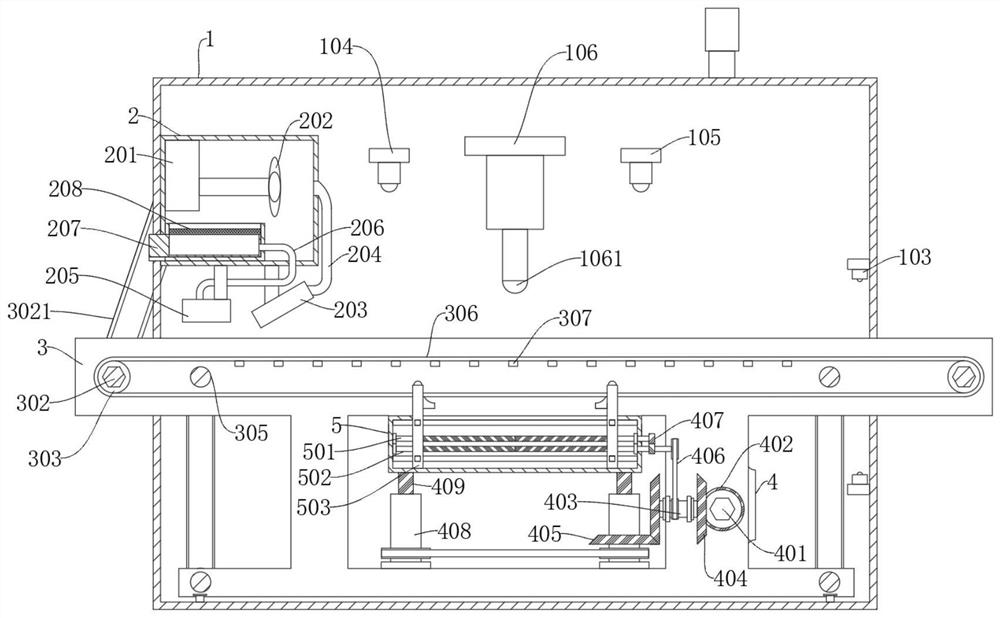

ActiveCN113245905AImprove the efficiency of process testingFully automatedAutomatic control devicesFeeding apparatusElectric machineryEngineering

The invention discloses a device capable of adjusting the rake angle and height of a diamond cutter and an adjusting method thereof, and belongs to the technical field of ultra-precision machining. A vertical displacement table is driven by a second stepping motor and arranged on an ultra-precision machine tool, an angle displacement table driven by a first stepping motor is arranged on the vertical displacement table, and a tool installation base is arranged on the angle displacement table. The diamond cutter is placed on the cutter mounting base and is fixed through a cutter fixing block; The first stepping motor and the second stepping motor are controlled by a controller. The angle displacement table is provided with a rotation limiting mechanism. The vertical displacement table, the ultra-precision machine tool and the angle displacement table are assembled. A diamond cutter is mounted on the cutter mounting base and fixed. The circle center position of the angle displacement table is measured. The cutting edge position of the diamond cutter is measured, the distance between the cutting edge of the diamond cutter and the circle center of the angle displacement table is calculated, and the rotating angle and the cutting edge rotating radius of the diamond cutter is input, so that the rake angle of the diamond cutter is rotated to a required angle. According to the invention, the efficiency of the cutting rake angle parameter process test is improved.

Owner:HARBIN INST OF TECH

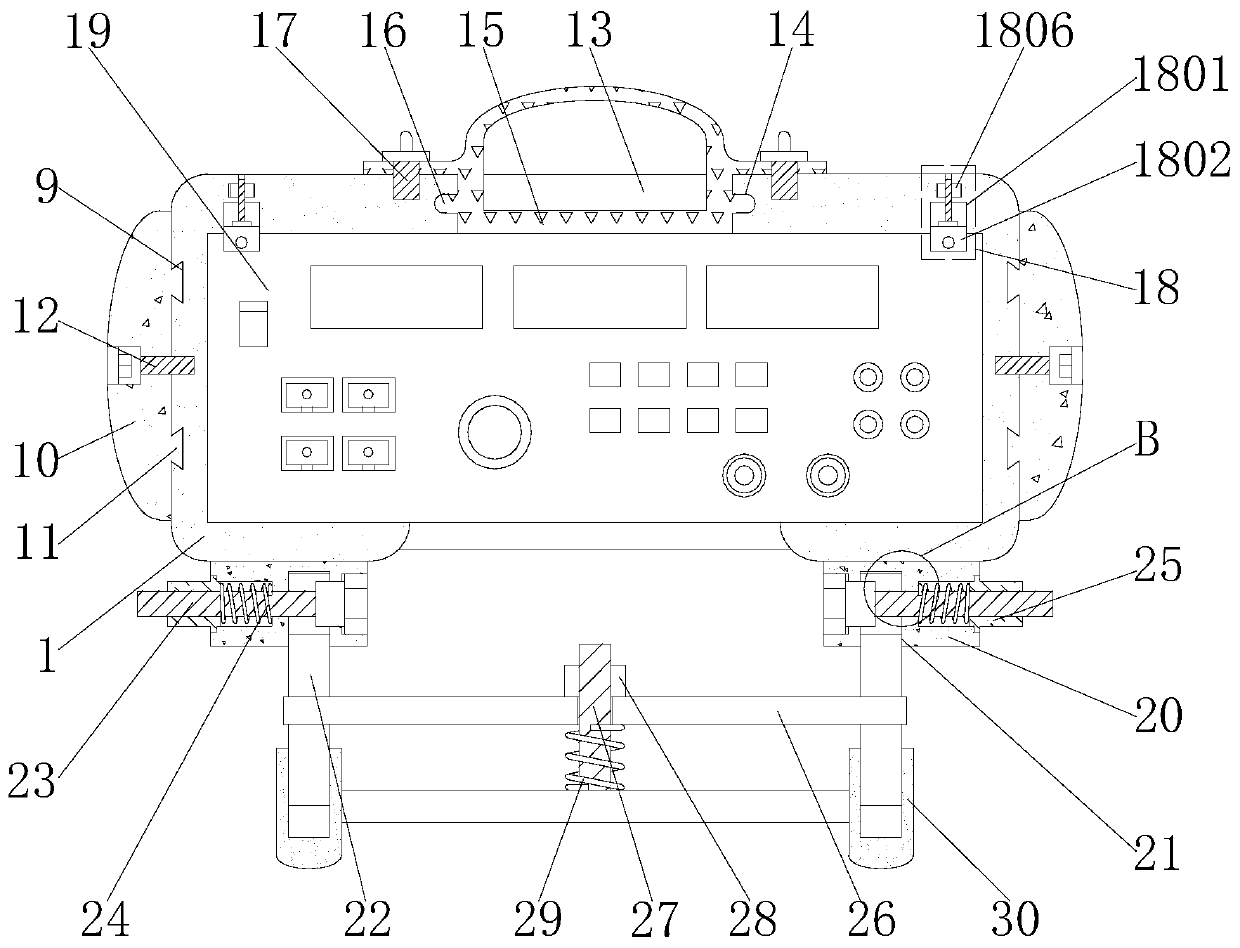

Detection device for precision hardware production

InactiveCN113790951AEasy to liftEasy to transportMaterial strength using tensile/compressive forcesInvestigating material hardnessComputer hardwareRecovery performance

The invention discloses a detection device for precise hardware production, and belongs to the technical field of hardware detection. The detection device for precision hardware production comprises a mounting box and further comprises a detection assembly arranged on the mounting box. a dust removal assembly arranged on the mounting box; a mounting frame connected into the mounting box in a sliding manner; and a transportation assembly arranged on the mounting frame. According to the invention, the two sets of mounting frames are made to move close to each other or move away from each other at the same time, so that the distance between the two conveying belts can be adjusted conveniently, plates of different widths and trays containing parts can be conveyed conveniently, and the initial position between the two sets of clamping rods can be adjusted. Therefore, compression resistance testing can be conveniently carried out on the plates with different lengths, the toughness and the recovery performance of the plates can be detected by comparing the pictures of the plates before and after being pressed, and the detection effect on hardware workpieces is improved.

Owner:深圳市嘉业精密科技有限公司

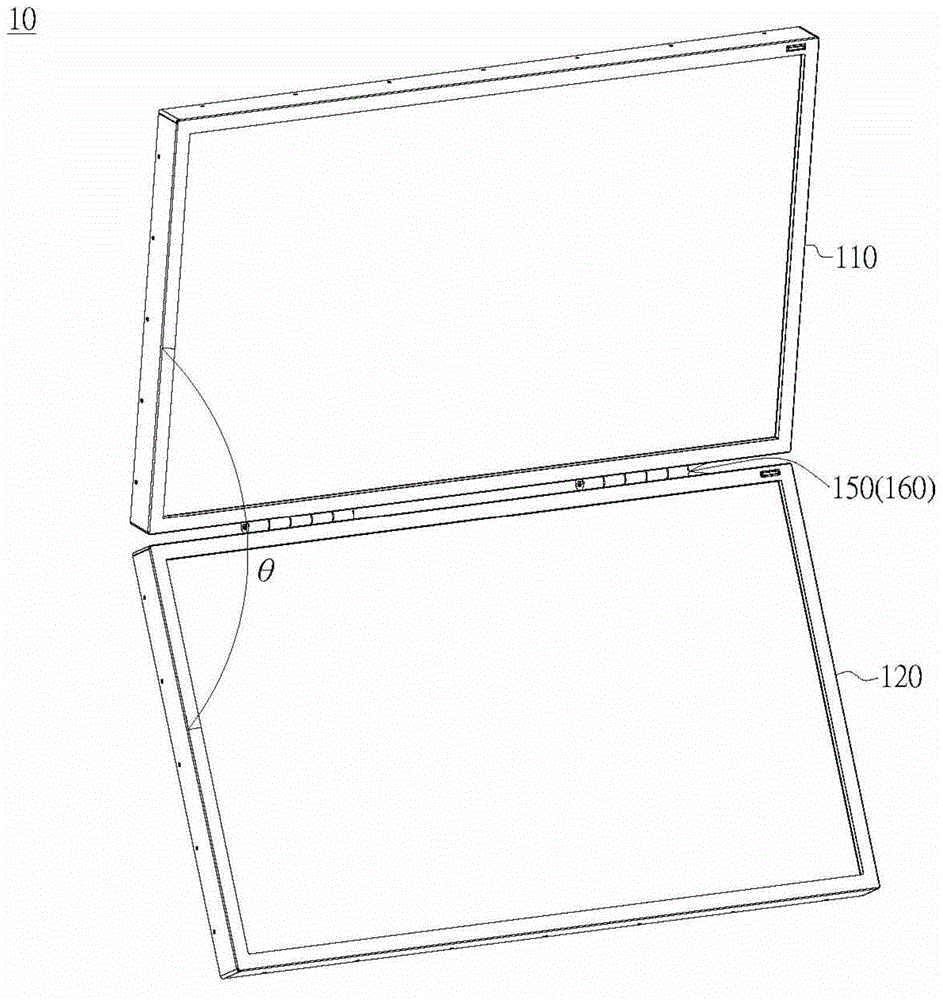

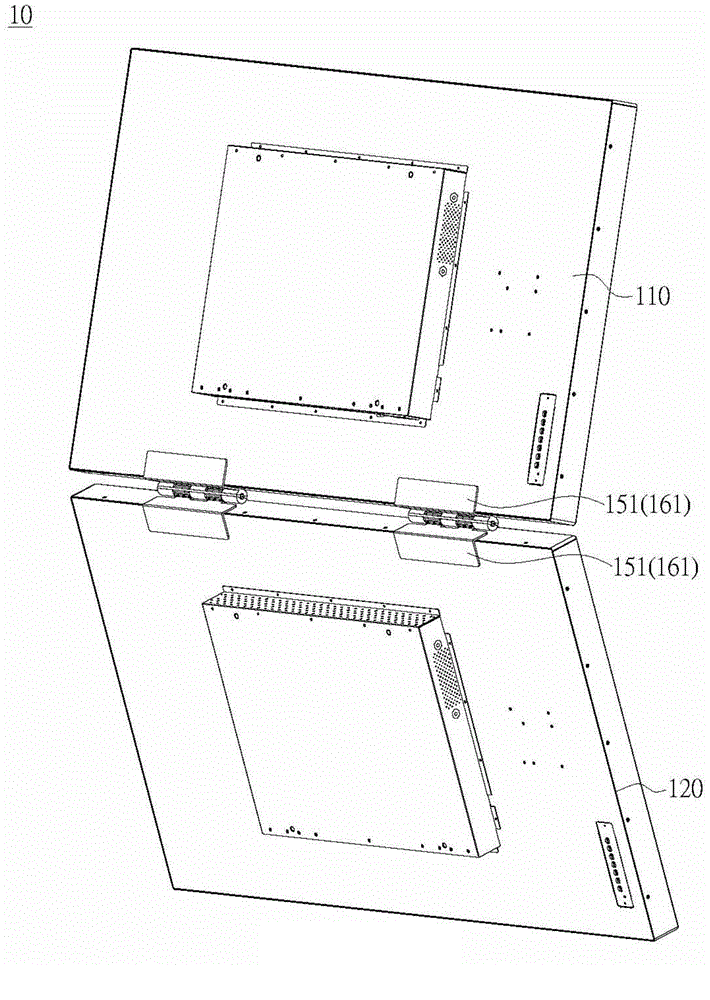

Display device

InactiveCN104791376AAvoid changing anglesImprove structural strengthPivotal connectionsIdentification meansDisplay deviceComputer science

The invention discloses a display device, and aims to adjust the inclined angle between displays. The display device comprises a first display, a second display and a first connecting structure, wherein the first connecting structure comprises two first adapters, a first pivot and a first fixing part; both the two first adapters comprise first ends and second ends; the first end of one first adapter is connected with first display, while the first end of the other first adapter is connected with the second display; the second end of one first adapter is provided with a first pivoting part, while the second end of the other first adapter is provided with a second pivoting part; the first pivoting part is provided with a first clamping part; the second pivoting part is provided with a complex number of first aligning parts; the first pivot penetrates through the first pivoting part and the second pivoting part; the first fixing part is clamped with the first clamping part and is selectively clamped with one of the first aligning parts so as to limit the first pivoting part from rotating relative to the second pivoting part.

Owner:QISDA SUZHOU +1

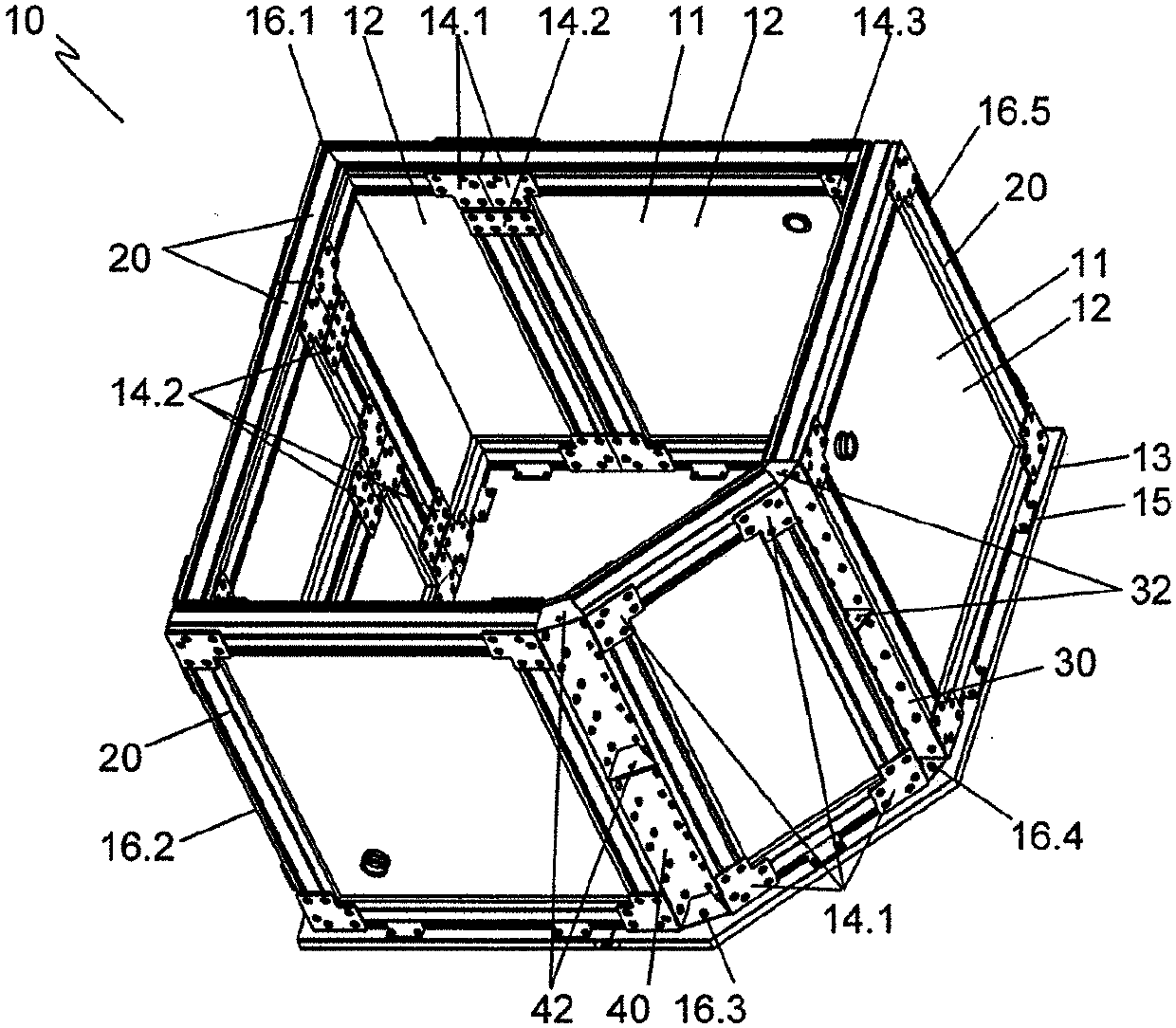

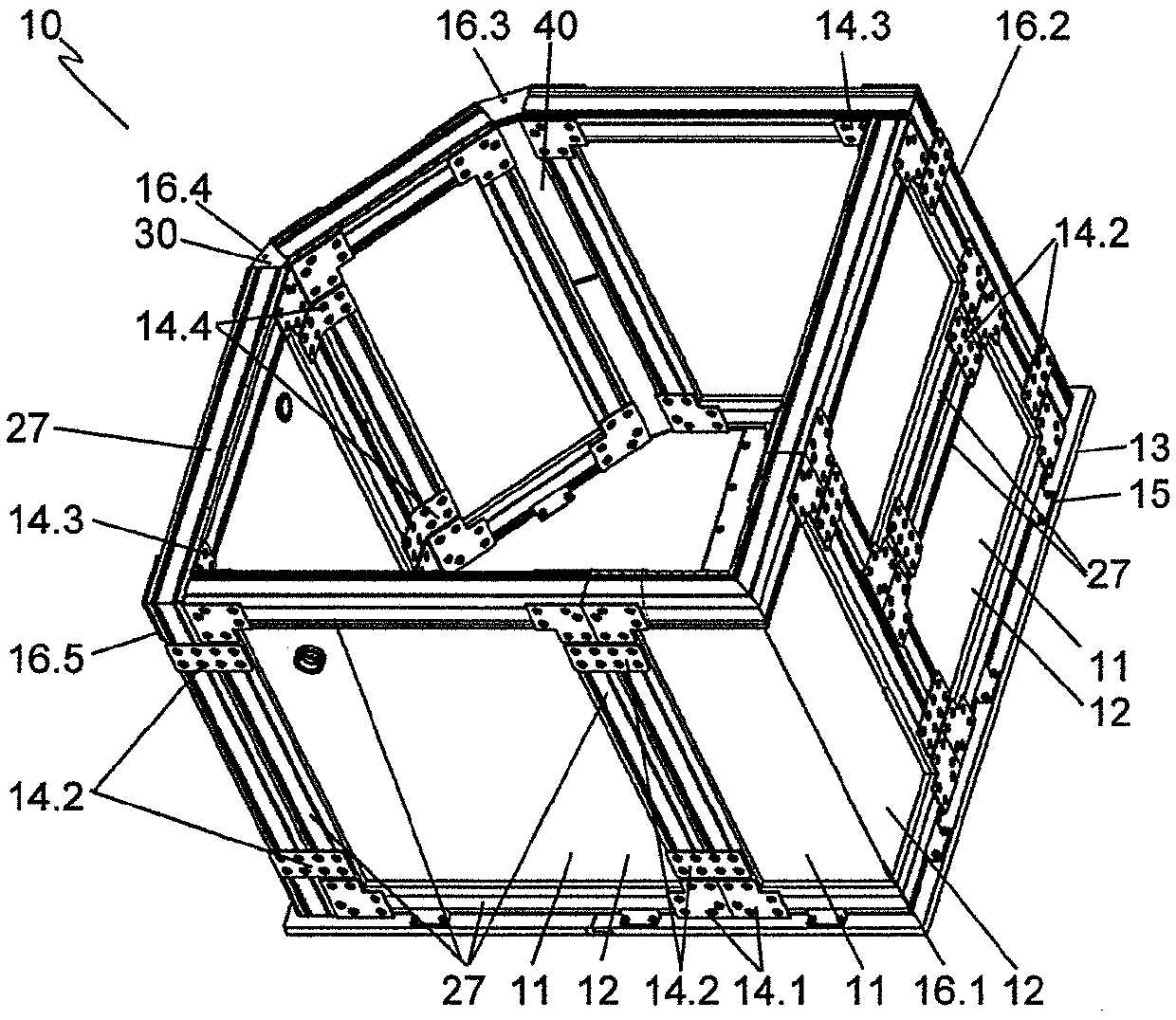

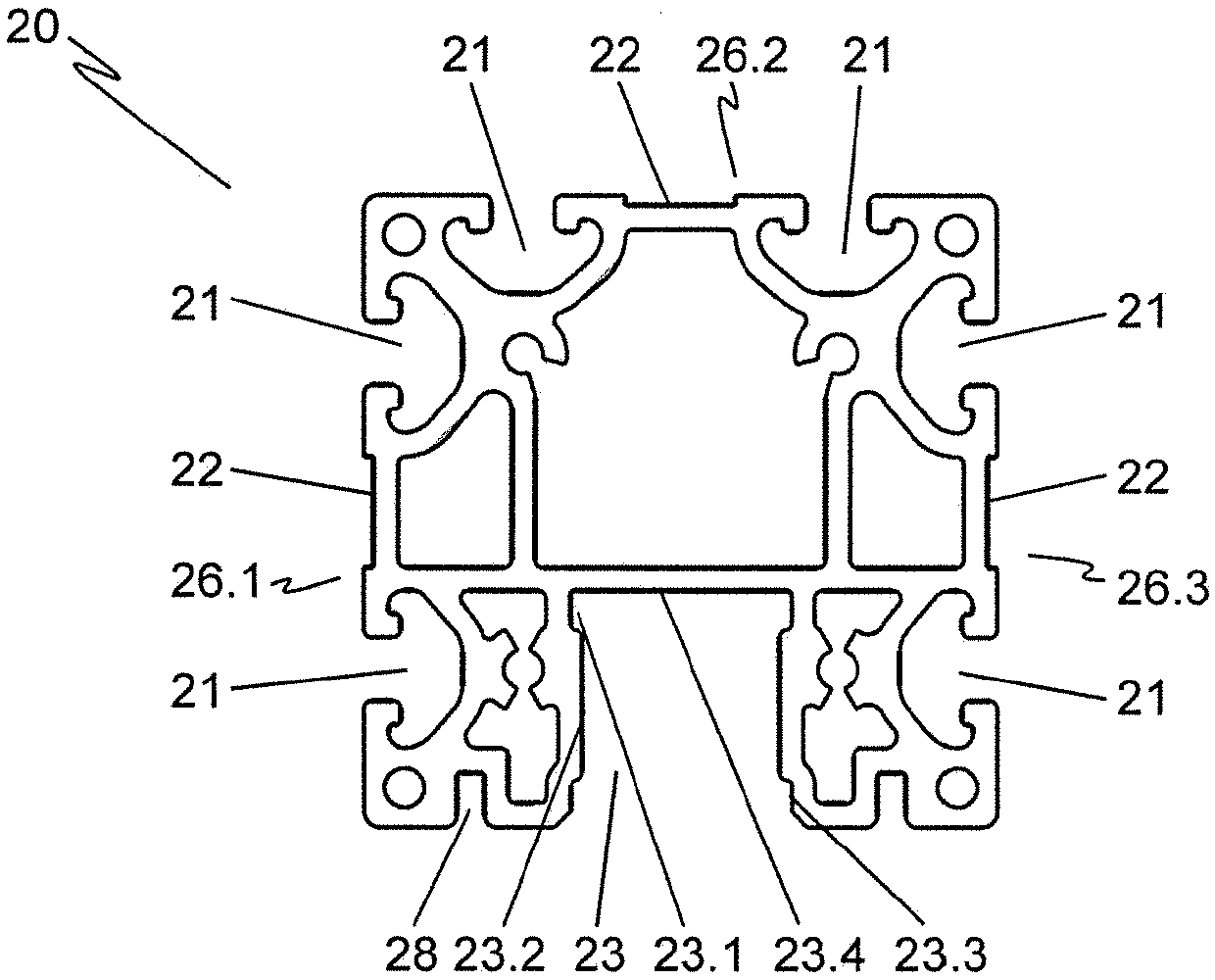

Frame profiled element, wall element, and framework for a clean gas chamber

ActiveCN107949680AAvoid flowIncreased bending stiffnessWallsWindow/door framesNuclear engineeringGas chamber

The invention relates to a frame profiled element, a wall element, and a framework of a clean gas chamber. The structure of the clean gas chamber enables simple assembly of the clean gas chamber at the location of use of the clean gas chamber, wherein the dimensions of the clean gas chamber can be easily adapted to the requirements of the systems to be enclosed.

Owner:布劳恩惰性气体系统有限公司 +1

Fold line device

ActiveCN108672598ALarge adjustment rangeFavorable fold line operationMetal working apparatusEngineeringPolygonal line

The invention discloses a fold line device. The fold line device structurally comprises a first round hole, a hollow pipe, a second round hole, a fold line device and a dust-proof cover, wherein the first round hole is formed in one end of the hollow pipe, the second round hole is formed in the other end of the hollow pipe, and the second round hole and the first round hole are of a concentric circle structure. Compared with the prior art, the fold line device has the beneficial effects that through the combination arrangement of a rotating fold line plate, an auxiliary fold line plate turnover mechanism, a rotating handle fixing mechanism, a driving force mechanism, a telescopic fixing mechanism, a pulley block and a second-stage gear set, the fold line device is provided with the function of adjusting the angle of the fold line, a multi-angle bending and folding are achieved, and the angle of the fold line ranges from 0 degree to 180 degrees, and the adjusting range of the angle of the fold line is wide; and meanwhile, after the angle of the fold line is adjusted, the driving force mechanism can be fixed, so that the angle change caused by the fact that the folding line plate issubjected to large force in the folding line process is effectively prevented, consequently, the phenomenon that a secondary gear set and the driving force mechanism are reversed is avoided, and the operation of the fold line is further facilitated.

Owner:南城县工业与科技创新投资发展集团有限公司

Metal cutting machine tool for household metal ornaments

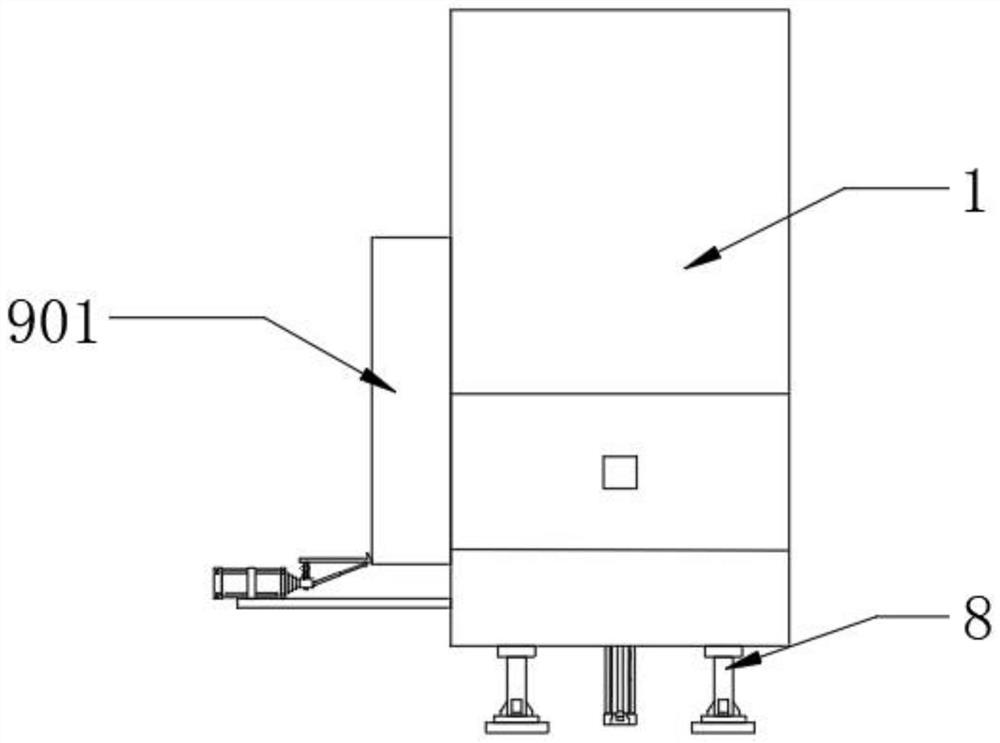

ActiveCN114309815AGuaranteed levelFixed tightlyMaintainance and safety accessoriesStructural engineeringMachine tool

The invention relates to a metal cutting machine tool for household metal ornaments.The metal cutting machine tool comprises a shell and supporting feet, a lifting assembly is arranged on the lower wall of the interior of the shell and comprises a lifting block, a gradienter, a movable connector and a first air cylinder, the gradienter is installed in the middle of the lower end of the lifting block, and the lower end of the movable connector is connected with the first air cylinder; the two first air cylinders are symmetrically arranged about the central axis of the lifting block, the supporting feet are located at the lower end of the shell, and a feeding assembly is arranged at the front end of the shell. The metal cutting machine tool for the household metal accessories has the beneficial effects that the metal cutting machine tool for the household metal accessories can keep a workpiece horizontal, the stability of the machine tool is improved, the machine tool can tightly fix the workpiece to be machined, the cutting stability of the machine tool is improved, the angle of a cutter can be adjusted through the machine tool, and machining of the machine tool is facilitated; the equipment can prevent a cutter from splashing to damage the equipment, and the equipment can balance stress, so that stable feeding can be realized.

Owner:深圳市美雅嘉琦家居饰品有限公司

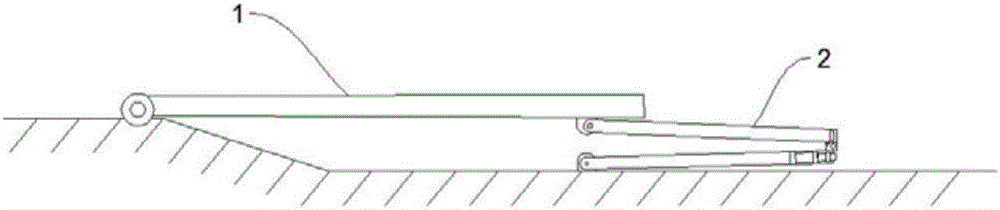

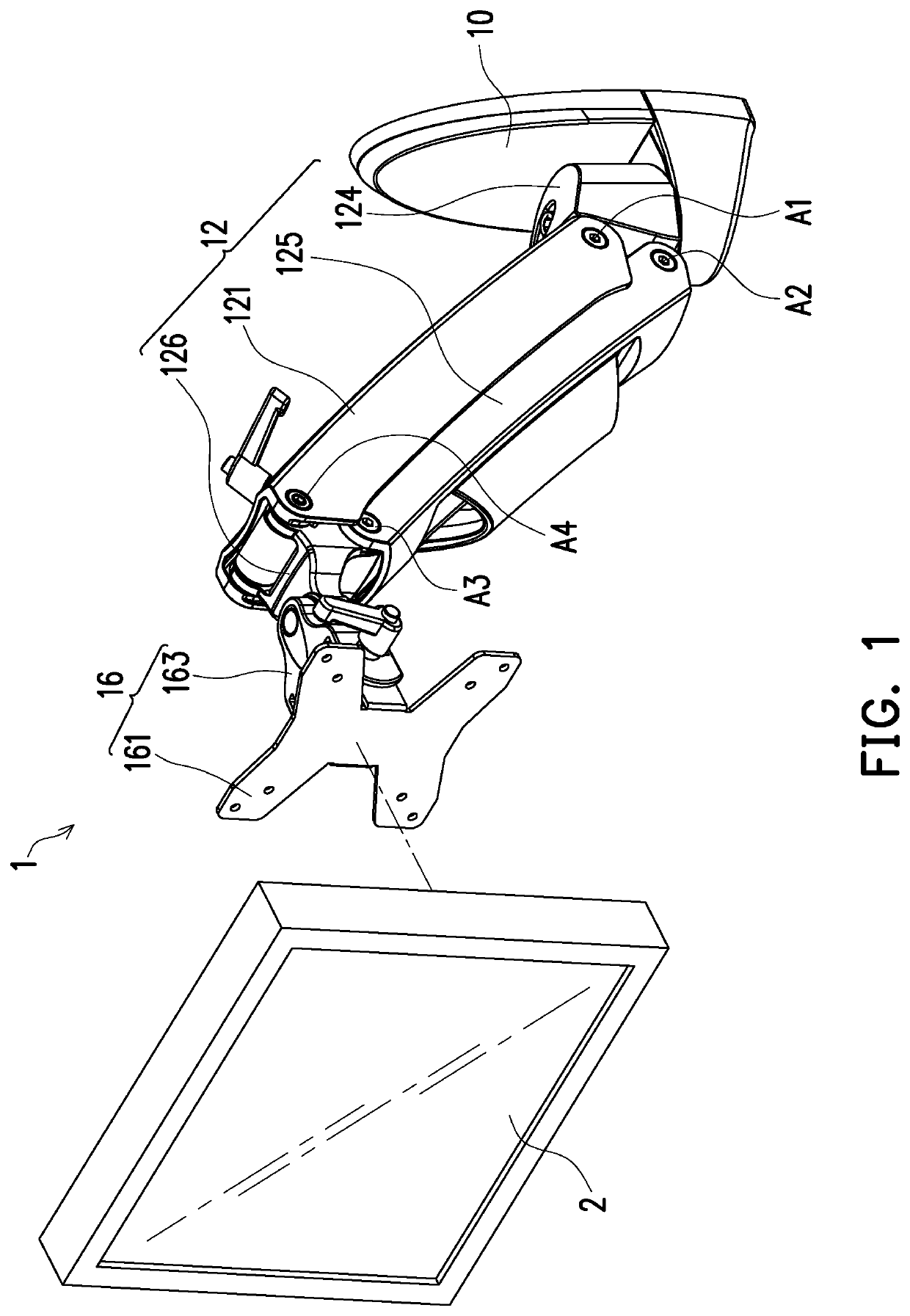

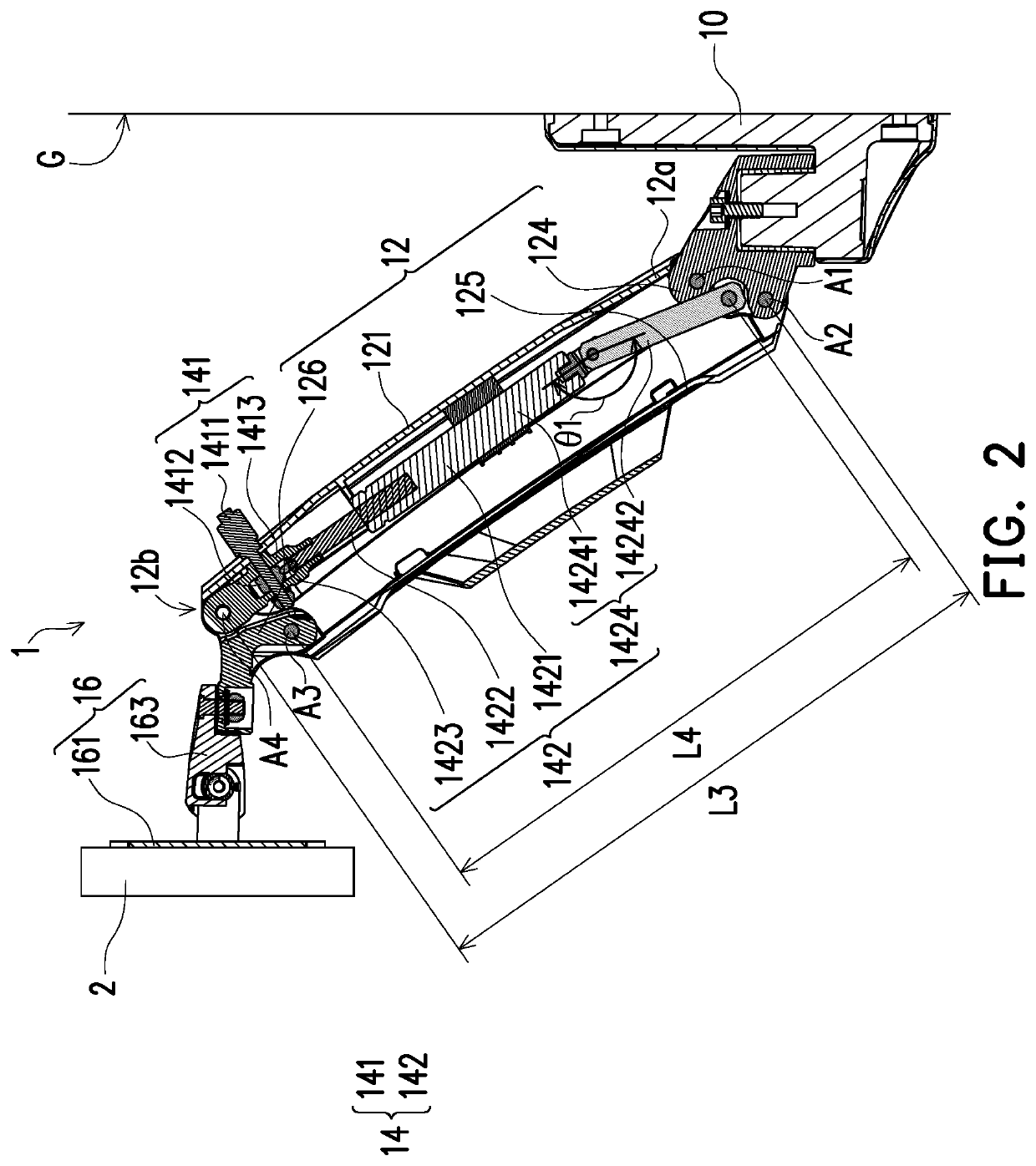

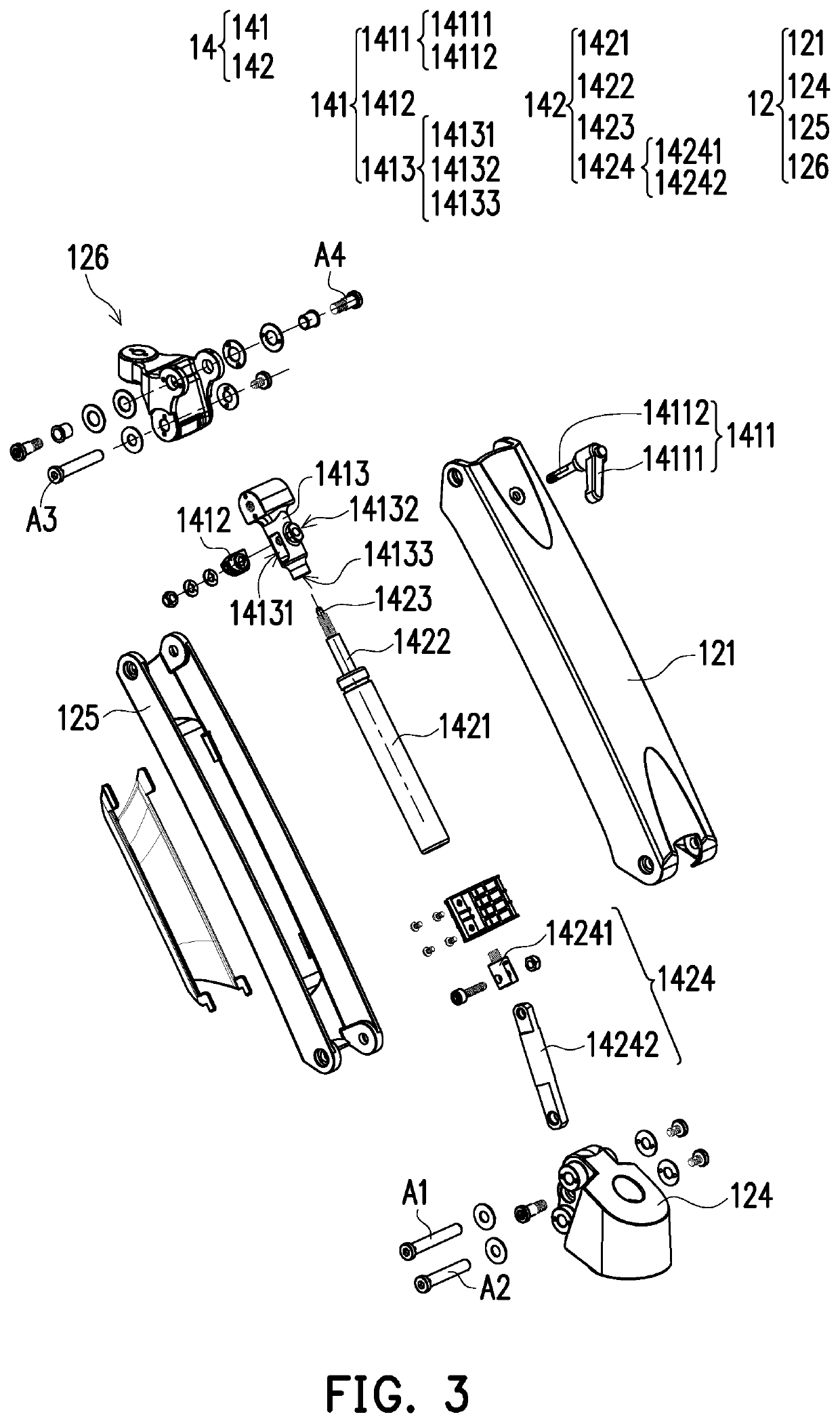

Support device

A support device includes a base, a support arm, an air spring unit, and a hinge. The base is mounted on a reference surface; a first end of the support arm is pivotally connected to the base; the air spring unit is disposed in the support arm, and includes a switch assembly having a rotatable cam and an air spring, the cam has a first and a second lock points; the air spring provides a supporting force to the support arm, a tube thereof is disposed in the support arm, a piston rod thereof is telescopically disposed at a first end of the tube, and a release pin thereof is disposed at a second end of the tube. By adjusting the release pin abuts against the first lock point, a position of the hinge can be adjusted and then stopped at any position between the highest and lowest positions.

Owner:HUANG MING HSIEN

Positioning method of prefabricated box beam embedded steel plates

ActiveCN110172918AGuarantee the quality of the box girderAngle adjustment is easy to operateCeramic shaping apparatusBridge erection/assemblySteel platesBox girder

The invention discloses a positioning method of prefabricated box beam embedded steel plates, and relates to the technical field of box beam prefabrication. According to the positioning method of theprefabricated box beam embedded steel plates, the steel plates can be reliably positioned, and moving of the steel plates is not limited absolutely. The positioning method comprises the following steps: A, a box beam prefabricated pedestal and positioning rods are prepared, two sandpits are formed in the box beam prefabricated pedestal, the length and width of the sandpits are both larger than thelength and width of the embedded steel plates, and the sandpits are fully filled with fine sand; B, one of the embedded steel plates is placed into the middle of the corresponding sandpit, the embedded steel plate is struck to enable the lower part of the embedded steel plate to be embedded into the fine sand, and thus the inclination angle of the upper surface of the embedded steel plate meets the requirement; C, the corresponding positioning rods are inserted into the fine sand and the bottom of the sandpit, the tops of the positioning rods are lower than the surface of the box beam prefabricated pedestal and are subjected to point welding together with the embedded steel plate, and the two sides of the end of the embedded steel plate are each provided with the corresponding positioningrod; D, the sandpit is leveled; and E, the step B, the step C and the step D are repeated, and the corresponding embedded steel plate, positioning rods and fine sand are arranged in the other sandpit.

Owner:CHINA 19TH METALLURGICAL CORP

Computer display screen connecting mechanism

InactiveCN107869631AEasy to useEasy to adjustDigital data processing detailsStands/trestlesComputer engineering

The invention discloses a computer display screen connecting mechanism. The computer display screen connecting mechanism comprises a display screen; a guide groove is formed in the inner side of the display screen; the side part of the guide groove is connected with a guide rail; a through hole is formed in the outer side of the guide groove; the lower part of the guide groove is connected with aconnecting block; the side part of the connecting block is connected with a connecting rope; one end of the connecting rope is connected with a pin; the lower part of the connecting block is connectedwith a clamping ring; the clamping ring is rotationally connected with a damping rotating shaft; a support rod is arranged at the lower part of the damping rotating shaft; and a base is arranged at the lower part of the support rod. The guide groove is formed in the display screen, and the connecting block is arranged at the lower part of the guide groove, so that the height adjustment of the display screen is realized; and the display screen is fixed through the pin, so that the angle adjustment of the display screen is realized through the clamping ring and the damping rotating shaft, the height and angle adjustment of the display screen is conveniently and quickly realized, the adjustment demands of users on the display screen are met, and the provision of comfortable office and entertainment interfaces is facilitated.

Owner:WUXI XIELIAN INFORMATION TECH CO LTD

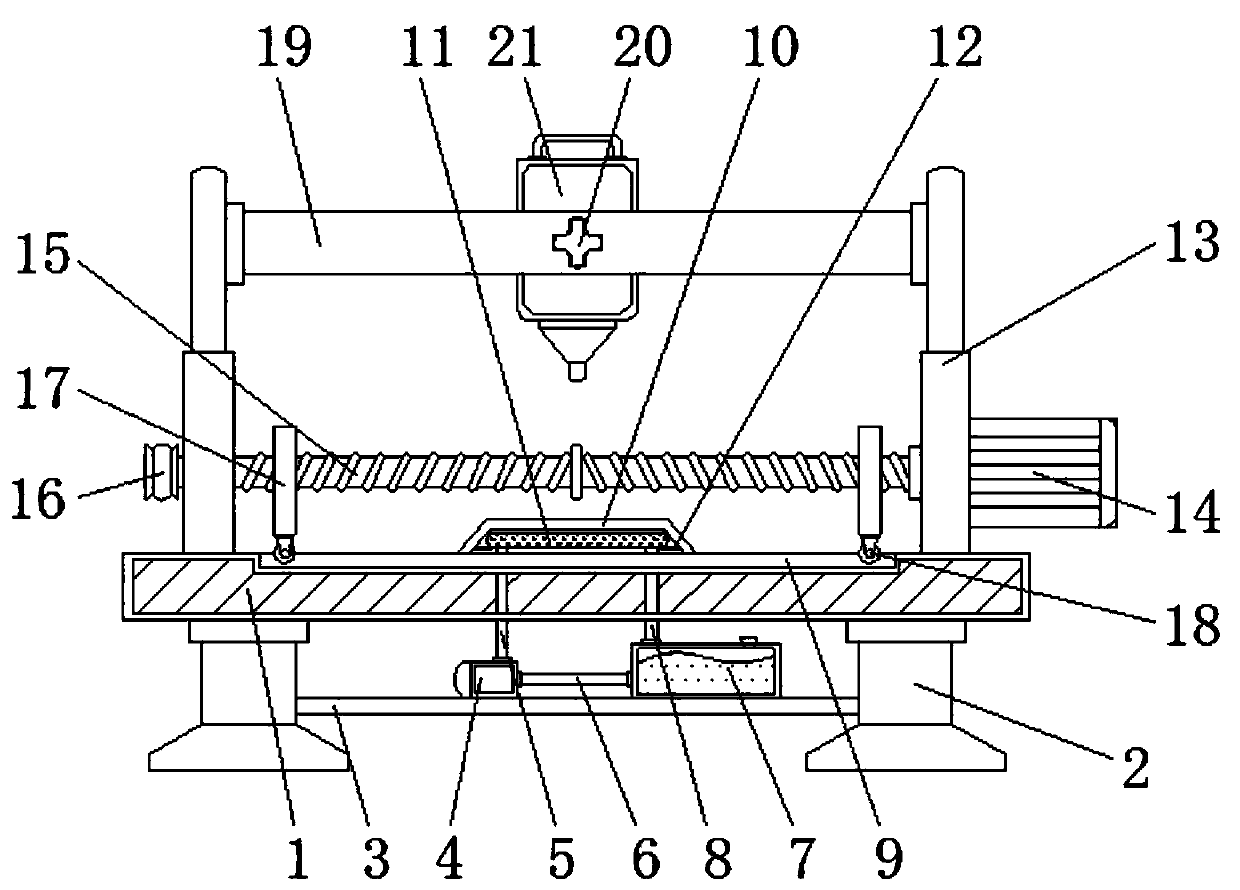

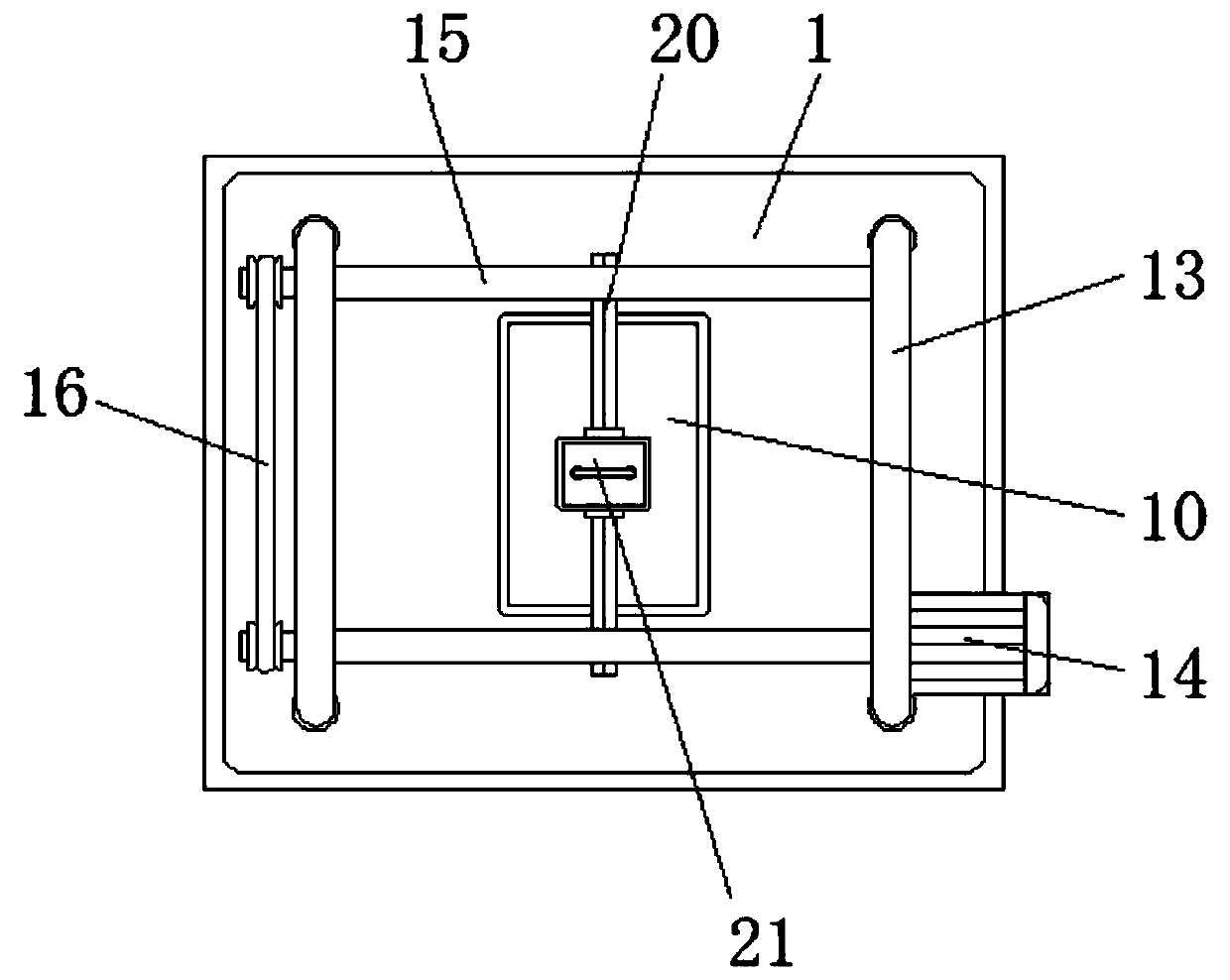

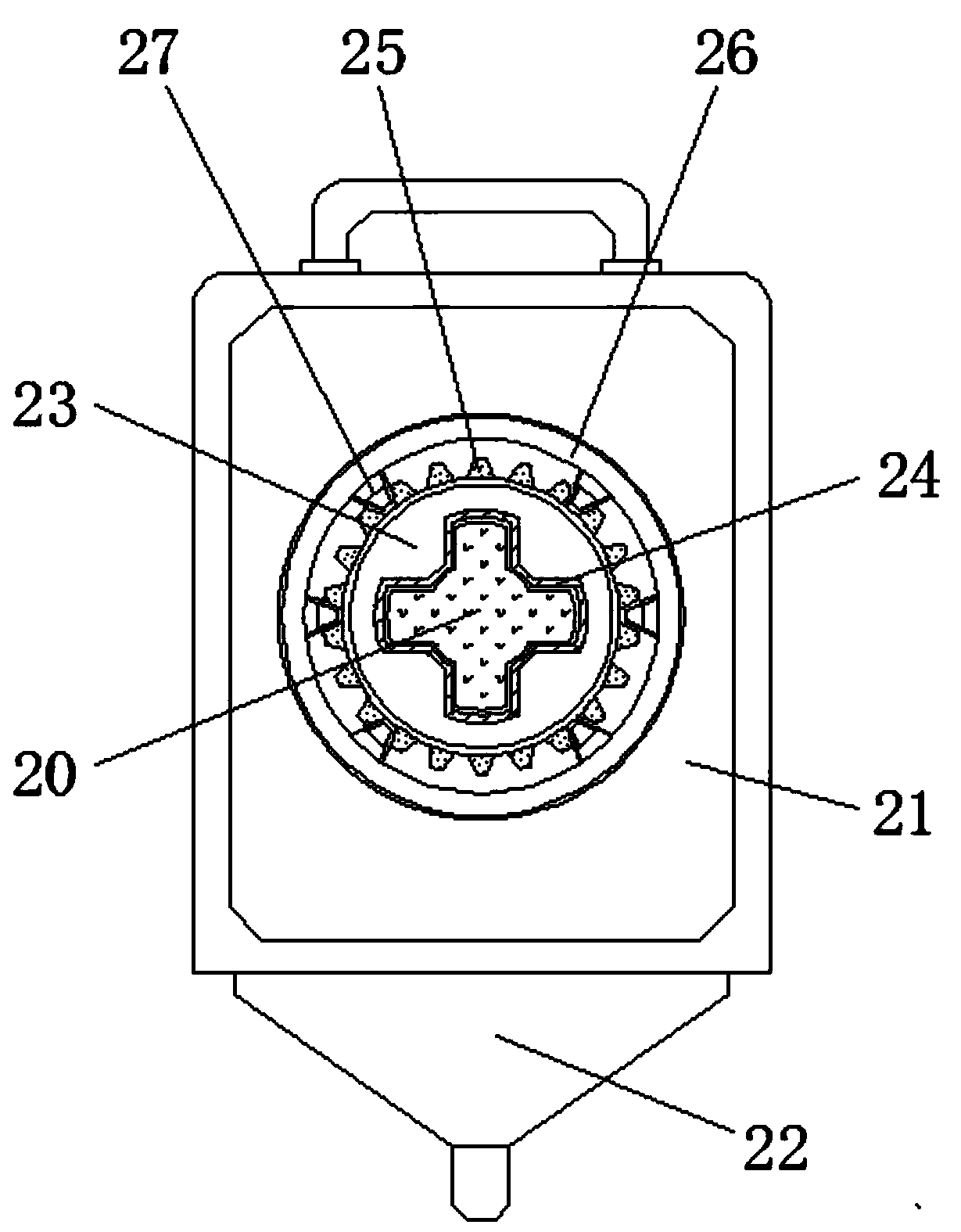

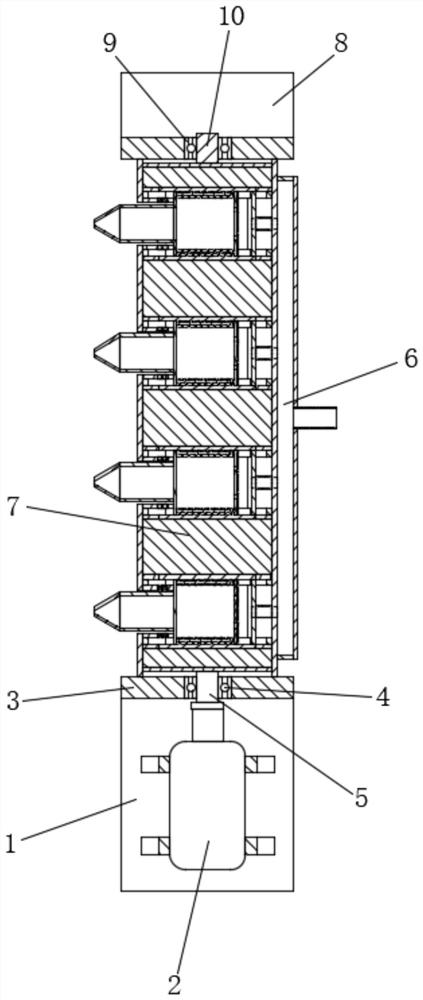

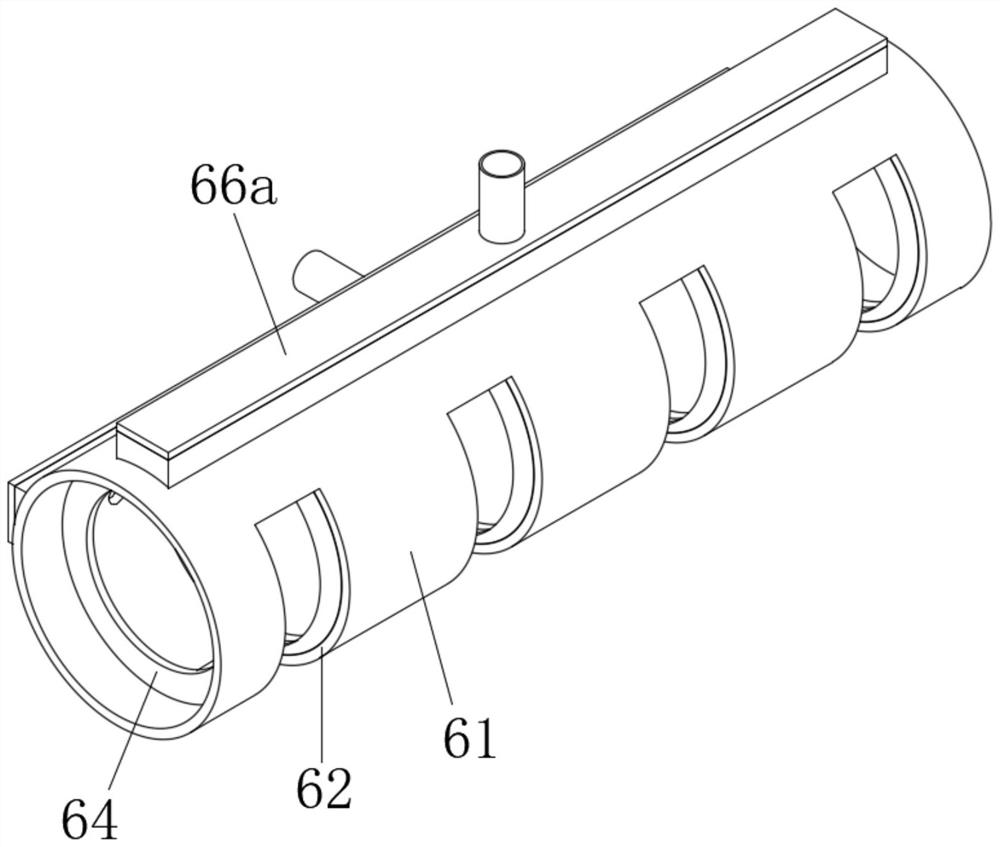

Clamping mechanical arm for 3D printer nozzle

InactiveCN111002298AImprove balanceAvoid changing anglesProgramme-controlled manipulatorAdditive manufacturing apparatusComputer printingGear wheel

The invention discloses a clamping mechanical arm for a 3D printer nozzle, which comprises a printer body. The printer body is connected with a mechanical arm structure through a rotating box. The topend of the mechanical arm structure is connected with a clamp. Clamping plates are connected to the two sides of the front end of the clamp. The inner sides of the two groups of clamping plates are connected with silica gel plates. A nozzle is clamped between the silica gel plates. A fifth stepping motor and a connecting shaft box are installed at one end of the printer body, the fifth stepping motor is in engaged connection with a second bevel gear through a first bevel gear, the second bevel gear is connected to a screw rod, a first sliding block is arranged at the bottom of the rotating box, and the first sliding block is in threaded connection to the screw rod. The mechanical arm is adopted for fixing and clamping the nozzle, the printing process is achieved, the motor is arranged formoving and adjusting the mechanical arm system, the mechanical arm can conduct all-around printing operation, the adjusting clamp is arranged, the silica gel plate and the spring are arranged on theclamp, and the nozzle is prevented from being damaged by clamping.

Owner:芜湖英罗智能制造有限公司

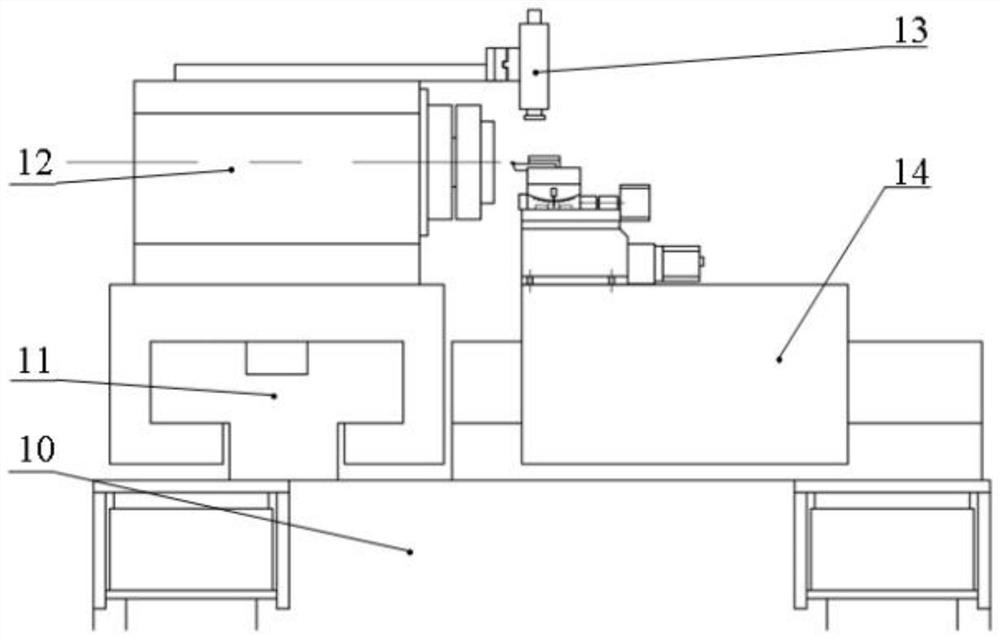

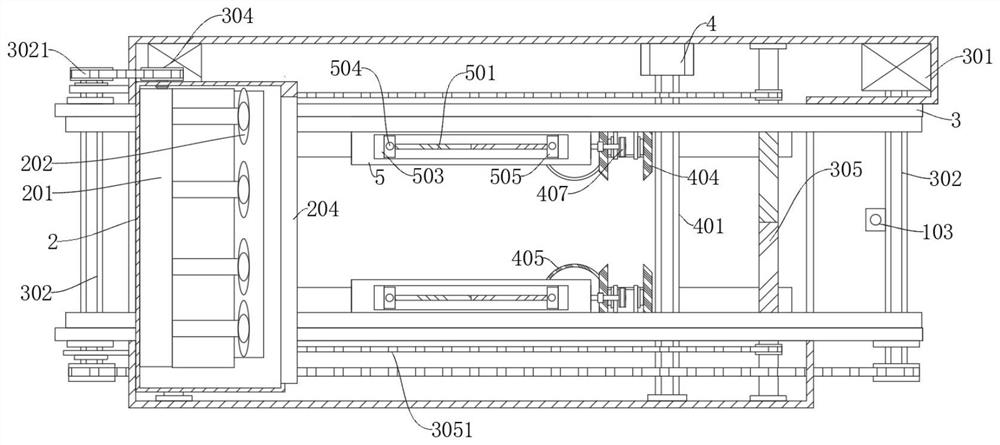

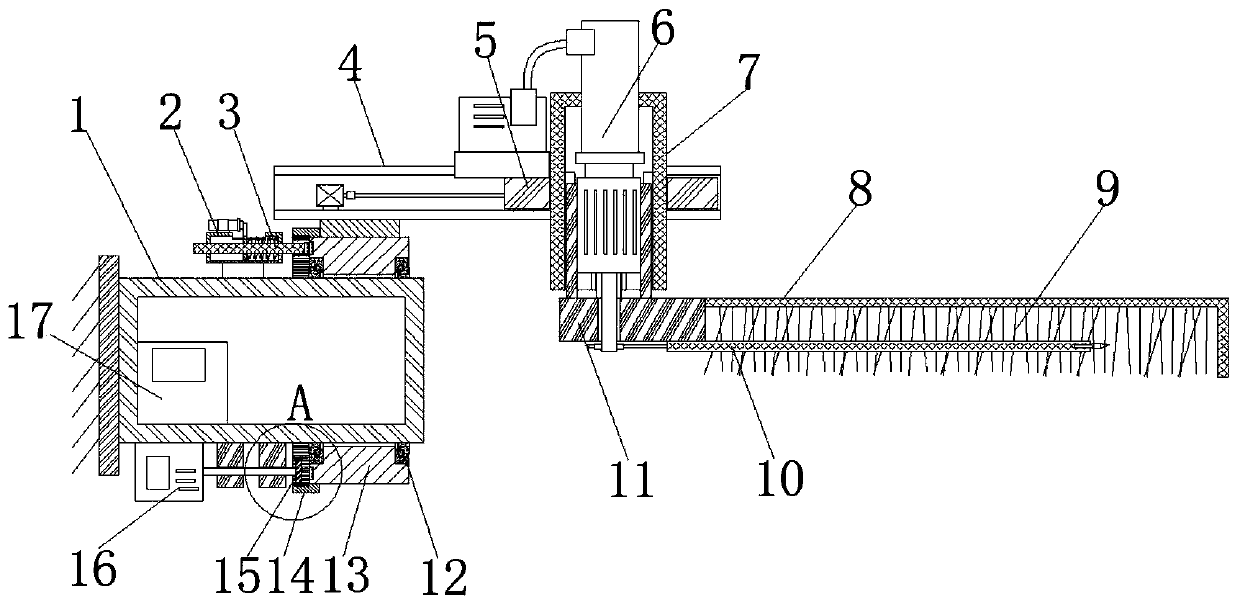

Worm and gear engagement detection device

PendingCN111879512ADetects the direction of runoutEasy meshMachine gearing/transmission testingUsing electrical meansDistance detectionEngineering

The invention relates to a worm gear and worm engagement detection device which comprises a worm gear positioning cylinder and a worm clamping mechanism, the worm gear positioning cylinder is fixedlyconnected to a linear sliding table, and the linear sliding table and the worm clamping mechanism are both fixedly installed on a workbench; a worm gear is arranged on the worm gear positioning cylinder, and a worm is arranged on the worm clamping mechanism; the device also includes an angle encoder which is used for detecting the meshing transmission ratio of the worm wheel and the worm, a seconddisplacement sensor which is used for detecting the radial run-out of the worm wheel, and a first displacement sensor which is used for detecting the meshing center of the worm wheel and the worm. According to the worm and gear engagement detection device, the angle encoder, the second displacement sensor and the first displacement sensor are used in cooperation, the meshing condition of the wormwheel and the worm is detected in three aspects of worm and worm wheel one-tooth meshing error and full-tooth meshing error detection, worm wheel and worm meshing maximum center distance detection, worm wheel and worm meshing minimum center distance detection, worm wheel and worm meshing radial run-out detection, the meshing condition is accurately reflected, and grouping is facilitated.

Owner:湖北恒隆凯迩必汽车电动转向系统有限公司

Green belt trimming device convenient to move, for municipal road maintenance

InactiveCN111213506AReduce flying distanceReduce distanceHedge trimming apparatusCuttersAgricultural engineeringStructural engineering

The invention belongs to the technical field of green belt trimming, in particular to a green belt trimming device convenient to move, for municipal road maintenance. In order to solve the problems that a trimming head of the device is completely exposed to one side of the outer side, so that the safety is low, and branch fragments caused in a trimming process are disorderly splashed to cause tremendous difficulty for later-stage cleaning, the invention provides the following scheme. The green belt trimming device comprises a supporting box adopting a cylindrical structure, wherein a cavity isformed in the supporting box, a rotating ring is rotatably connected to a position close to the end, of the circumference outer wall of the supporting box, a fixing seat is fixed to a position closeto the top end, of the outer wall of the rotating ring, two steel channel crossbeams which are mutually parallel are fixed to the top end of the fixing seat through bolts, openings of the two steel channel crossbeams are opposite, the same rectangular sliding framework is in sliding connection between the two steel channel crossbeams, and a fixing barrel is in clamping connection to the middle ofthe rectangular sliding framework. The green belt trimming device disclosed by the invention can block quickly-sputtered detritus from damaging passers-by, the fling off distance of the detritus can be reduced to a certain extent, the detritus can possibly fall to the position near tree roots, and the cleaning difficulty is reduced.

Owner:夏会森

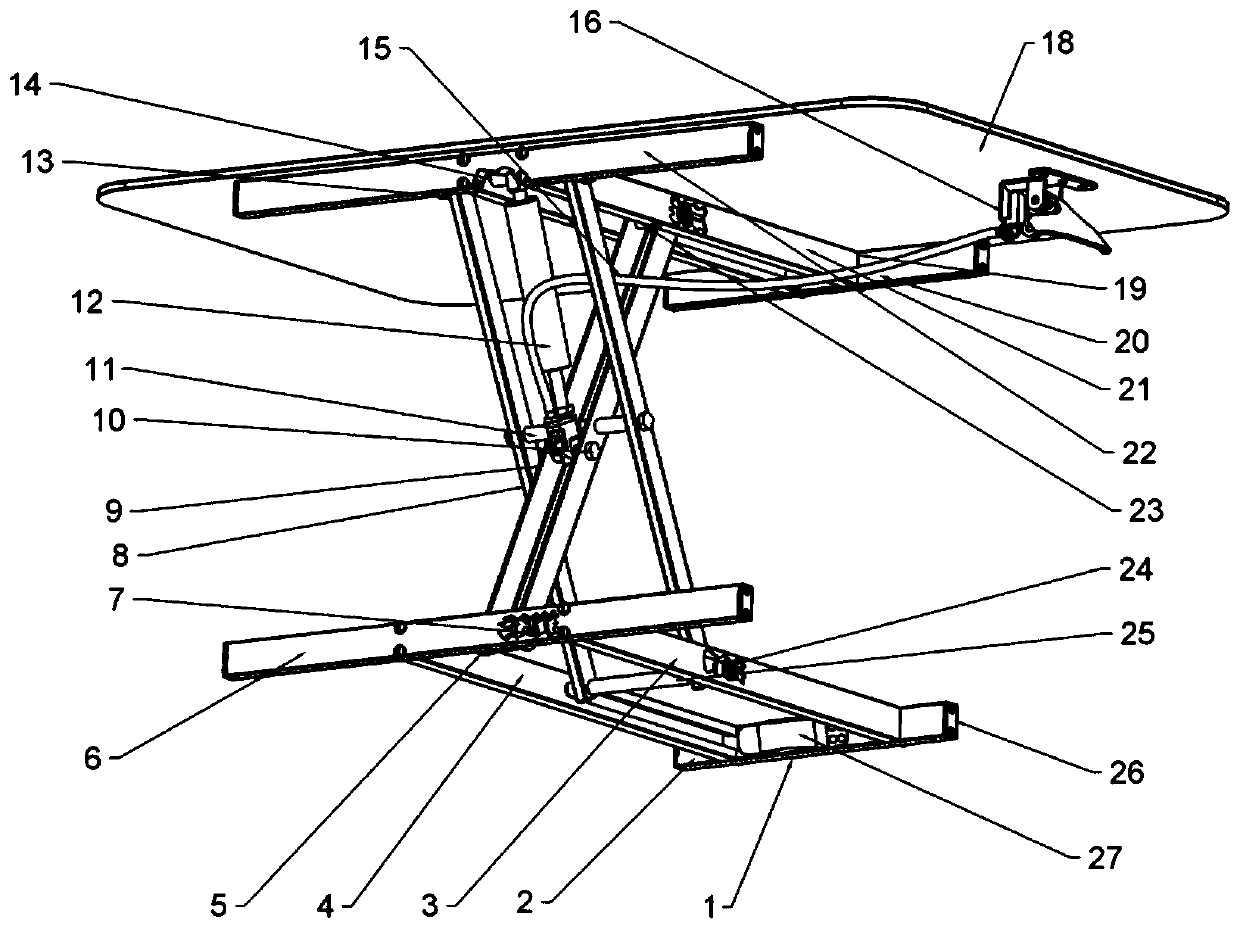

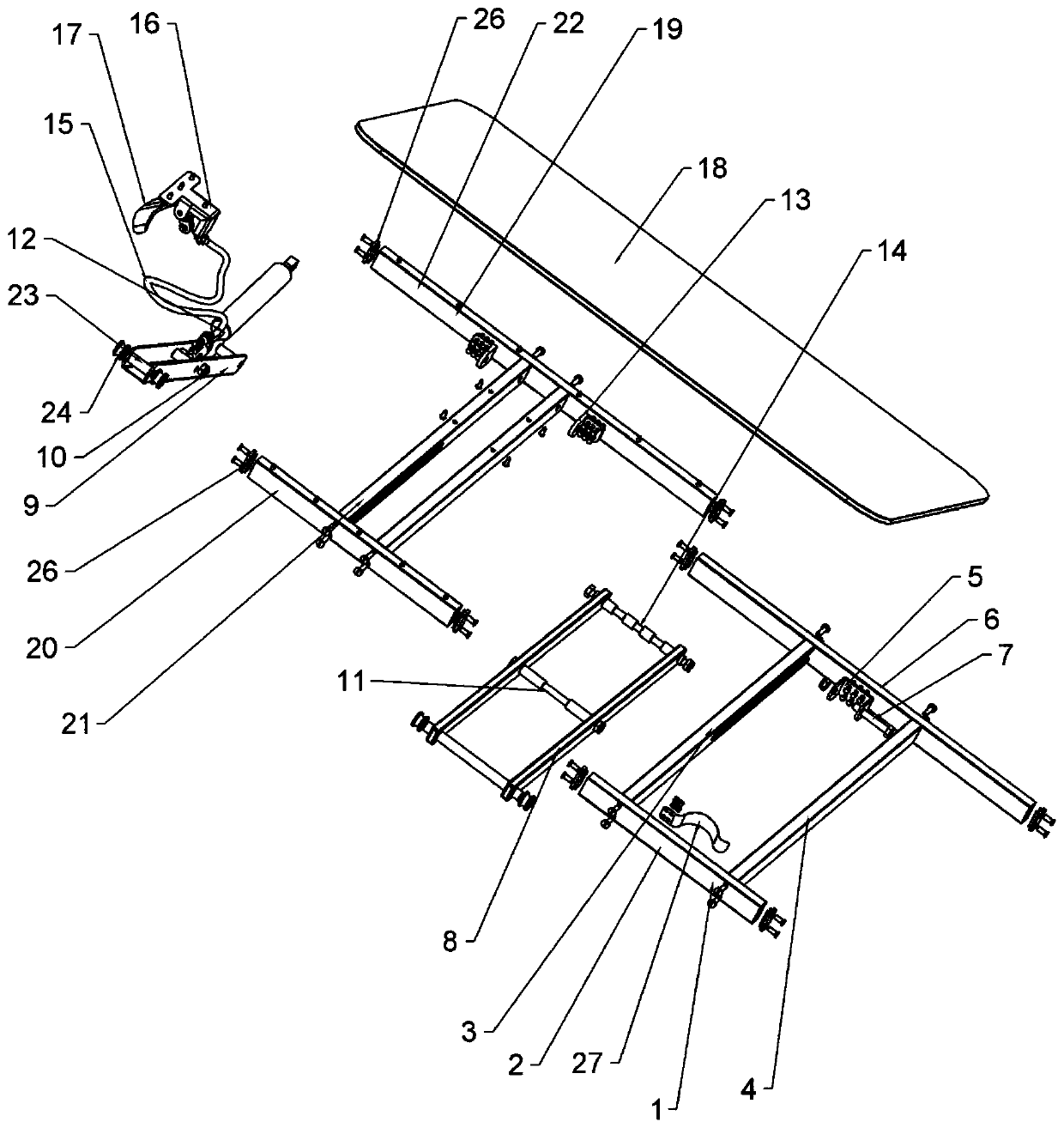

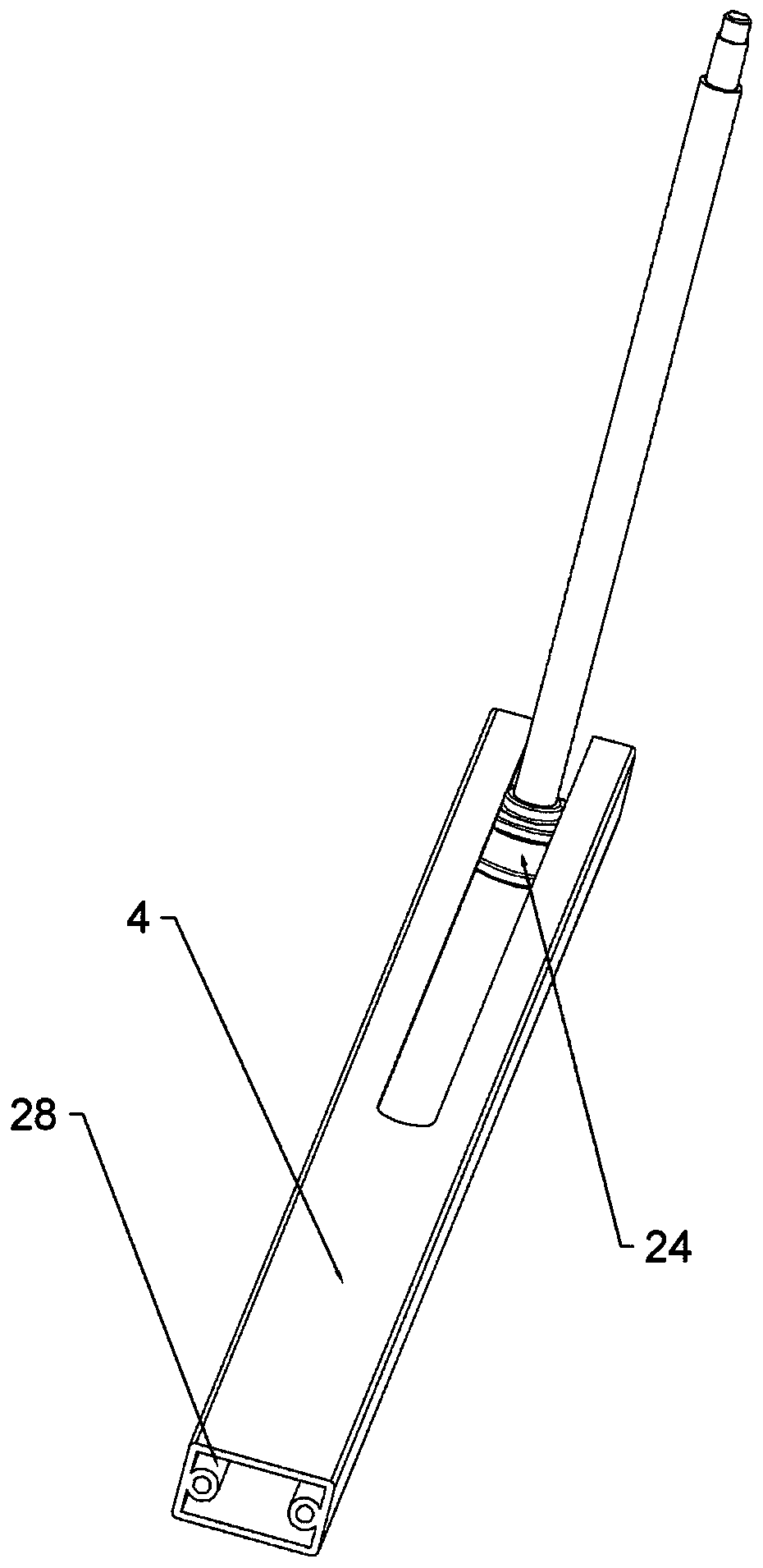

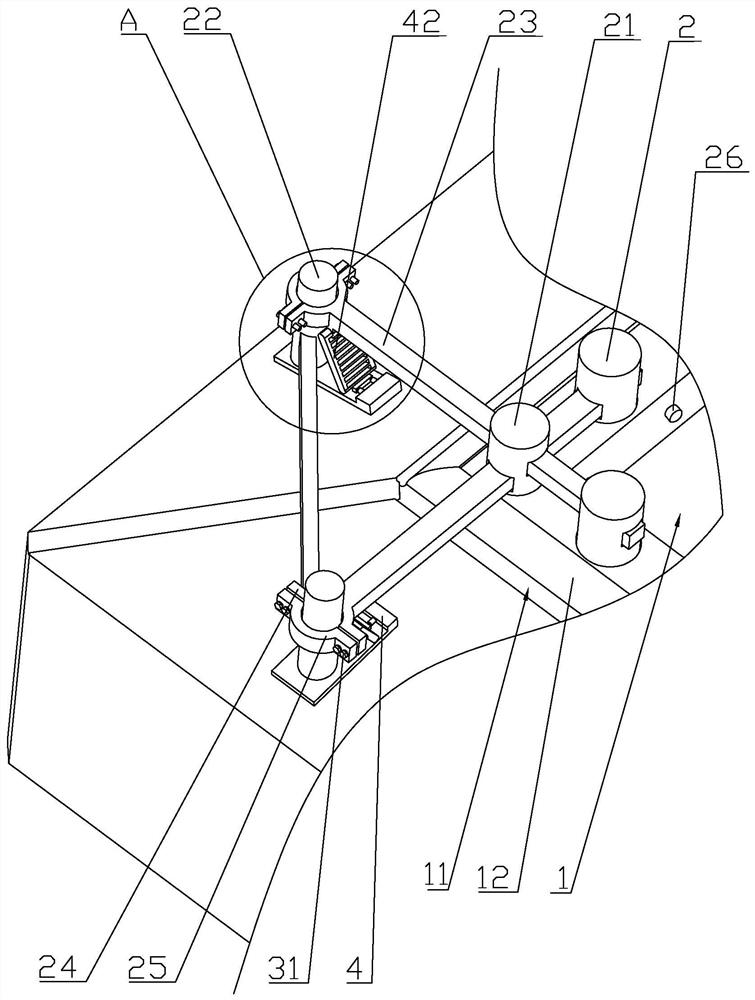

Slidable lifting folding desk

PendingCN109730442AChange angleAchieve liftingFoldable tablesStowable tablesIndustrial engineeringDesk

The invention relates to the field of office furniture and in particular discloses a slidable lifting folding desk. The slidable lifting folding desk comprises a base bracket, a fixed bracket and a table board panel and also comprises a pneumatic spring and two supporting parts. The two supporting parts comprise a first supporting part and a second supporting part. The middle parts of the first and second supporting parts are hinged. The lower end of the first supporting part is slidably connected to the base bracket and the upper end of the first supporting part is hinged to the fixed bracket. The upper part of the second supporting part is slidably connected to the fixed bracket and the lower end of the second supporting part is hinged to the base bracket. One end of the pneumatic springis hinged to one of the supporting part while the other end is hinged to the fixed bracket. A control part which controls the pneumatic spring is arranged on the lower end surface of the table boardpanel. The control part comprises an operating handle and a steel wire inhaul cable, the middle part of the operating handle is hinged to the fixed bracket, and two ends of the steel wire inhaul cableare separately connected to the handle and a pneumatic switch of the pneumatic spring. According to the slidable lifting folding desk, the table board panel is adjusted to any height as needed, so that demands of people are met.

Owner:宁波恒侯日用品有限公司

A construction technology for deep foundation pit support

ActiveCN110700281BControl verticalityImprove verticalityExcavationsBulkheads/pilesArchitectural engineeringSteel frame

The invention relates to a deep foundation pit support construction technology, and relates to the technical field of engineering facility construction. A single row of piles is arranged on the inside of the deep foundation pit, and the single row of piles is evenly distributed along the extension direction of the side wall of the deep foundation pit; At a position of 5 meters, the bottom of the fixed pile is lower than the preset lowest point of the deep foundation pit; S300: A horizontal steel frame is installed between the fixed pile and the single row of piles, and the two ends of the horizontal steel frame are connected to the fixed pile and the single row of piles respectively. The pile connection, the length direction of the horizontal steel frame is perpendicular to the side wall of the deep foundation pit. The invention has the effect of improving the verticality of the side wall of the deep foundation pit under the condition of reducing the occupation of the space in the deep foundation pit.

Owner:SHENZHEN DONGSHEN ENG CO LTD

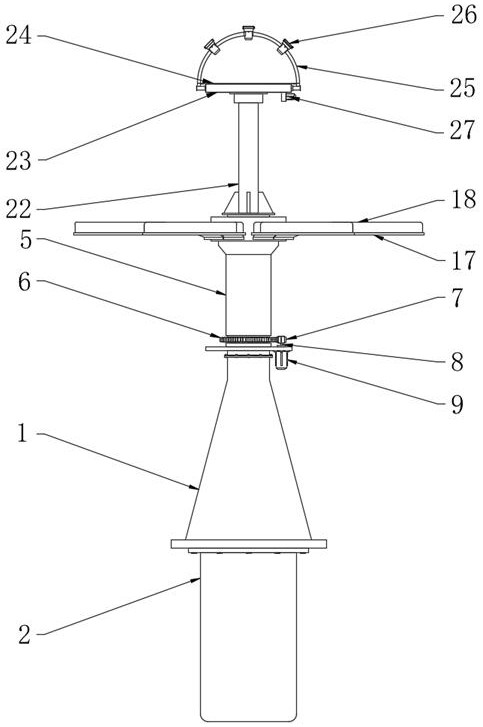

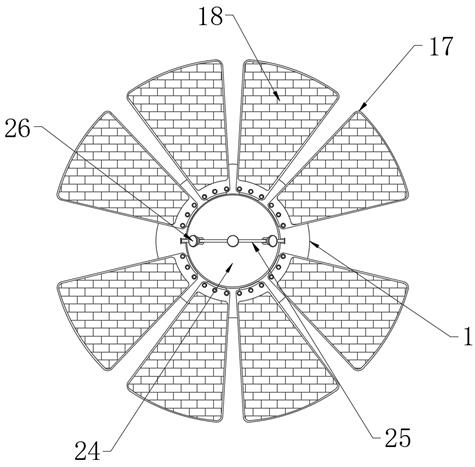

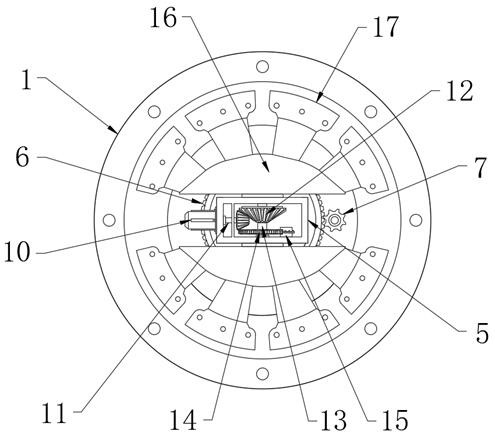

A small photovoltaic power generation device that automatically follows the sun

ActiveCN112600500BHeating up fastCompact structurePhotovoltaic supportsSolar heating energyFollow-the-sunEngineering

The invention discloses a small photovoltaic power generation device that automatically follows sunlight, which comprises a base, a first extension tube and a second extension tube, the diameter of the base decreases from bottom to top, and a bottom case is installed on the bottom of the base, and the bottom case The central axis of the base and the central axis of the base are on the same vertical line. The overall structure of the device is compact, in the form of a lamppost structure, with a small footprint and is suitable for various occasions. There are eight blade-type photovoltaic panels on the top. The umbrella-shaped structure is formed as a whole, which improves the overall aesthetics of the device. At the same time, the battery is buried under the ground with the bottom case, which can effectively prevent the sun from causing the battery to heat up too quickly, and the ground wrapping outside the bottom case can improve the overall heat dissipation efficiency and improve Use security.

Owner:东营金丰正阳科技发展有限公司

Miniature camera device capable of adjusting angle at will applied to diving mask

InactiveCN105635545AEasy to shootEasy to replaceTelevision system detailsColor television detailsEngineering

The invention discloses a miniature camera device capable of adjusting an angle at will applied to a diving mask. The miniature camera device comprises an integrated micro-camera, a waterproof cover, a visual window, a micro-camera mounting box, an integrated micro-camera mounting post, an inner thread ring, a rotary part, a movable part, a movable part connecting part, a clamping ball, a fixing part, a clamping ball cavity, an anti-skidding fixed hole, an anti-skidding fixed bolt, a clamping part and a waterproof ring. The miniature camera device capable of adjusting the angle at will applied to the diving mask has the beneficial effects that: an existing integrated miniature camera device after being reconstructed is applied to the diving mask, so that a diver can shoot the underwater scenes conveniently; the price is low; and the integrated miniature camera device can be taken down at any time and can shoot at normal times. Due to the setting of the rotary part, the camera not only can be rotated in a plane, but the angle of the camera also can be adjusted, and the shooting work can be carried out more conveniently.

Owner:CHENGDU KECHUANGGU TECH CO LTD

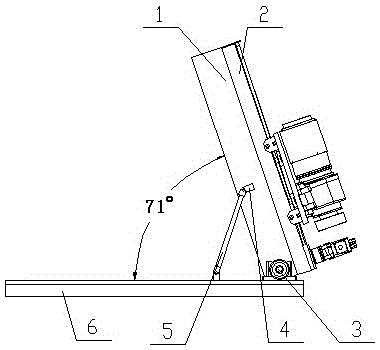

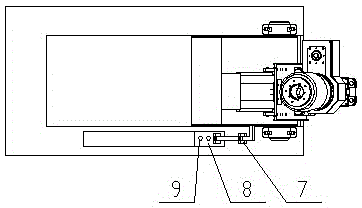

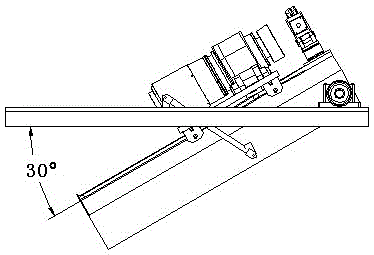

Universal device of subway interconnecting passage MJS reinforcing device power head

InactiveCN105003284ALarge adjustment rangeLittle influence from external factorsUnderground chambersTunnel liningUniversal structureFixed frame

The invention relates to a universal device of a subway interconnecting passage MJS reinforcing device power head. The universal device comprises a movable frame, a power head, a fixed frame, and a movable frame fixed locking device. The universal device is characterized in that the power head is arranged on the movable frame, the movable frame is rotatably connected with the fixed frame through a bearing and a bearing pedestal 3, so that the power head can be adjusted in any angle in the range of -30 DEG to 70 DEG. The movable frame fixed locking device is arranged between the fixed frame and the movable frame, and the movable frame fixed locking device is used for locking after angle adjustment of the power head 2. Through adding a universal structure frame on the rear of the power head, the power head can be adjusted in any angle in the range of -30 DEG to 70 DEG. After angle adjustment is completed, the power head is locked through a one-way cylinder added on a slideway and a strut on the rear end of a support. Aimed at part of relatively large tunnels, a lifting mechanism can be assembled on the lower part of the structure frame, and horizontal position of the device can be adjusted.

Owner:SHANGHAI FOUND ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com