A small photovoltaic power generation device that automatically follows the sun

A photovoltaic power generation and automatic follow-up technology, applied in the field of solar energy utilization, can solve the problems of large volume of photovoltaic devices, inability to choose installation, low conversion rate, etc., to improve the aesthetics, avoid excessive heating, and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

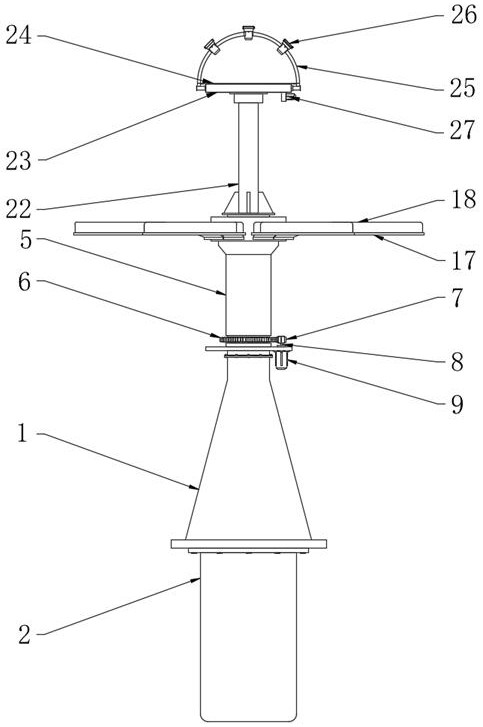

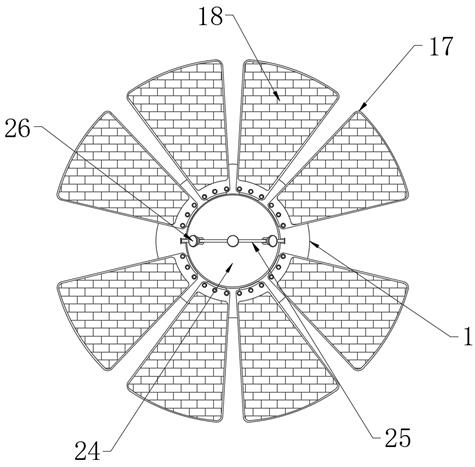

[0032] A small photovoltaic power generation device that automatically follows sunlight, comprising a base 1, a first extension tube 5 and a second extension tube 22, the diameter of the base 1 decreases from bottom to top, and a bottom case 2 is installed on the bottom of the base 1, while The central axis of the bottom case 2 and the central axis of the base 1 are on the same vertical line, and the base 1, the first extension tube 5 and the second extension tube 22 are all hollow structures, which facilitate the wiring of the device inside;

[0033]The first extension tube 5 is installed on the top of the base 1, and the central axis of the first extension tube 5 is on the same vertical line as the central axis of the base 1, and the distance between the upper part and the lower part of the first extension tube 5 is The connection method is a rotary connection, wherein the lower part of the first extension tube 5 is a circular tube structure, and the upper part of the first e...

Embodiment 2

[0036] The features of this embodiment that are the same as those of Embodiment 1 will not be repeated here. The difference between this embodiment and Embodiment 1 is that in this embodiment, the base 1 includes a battery 3 and a main control module 4; the battery 3 is installed in Inside the bottom case 2, and the top of the battery 3 extends to the inside of the base 1; the main control module 4 is installed on the upper end inside the base 1, and the main control module 4 is electrically connected to the battery 3, and the bottom case 2 is wrapped on the outside of the battery 3, Moreover, the bottom case 2 is buried under the ground during use, which effectively avoids the radiant heat of the sun, improves the heat dissipation rate of the battery 3 as a whole, and ensures that the low temperature state is maintained during the working process.

Embodiment 3

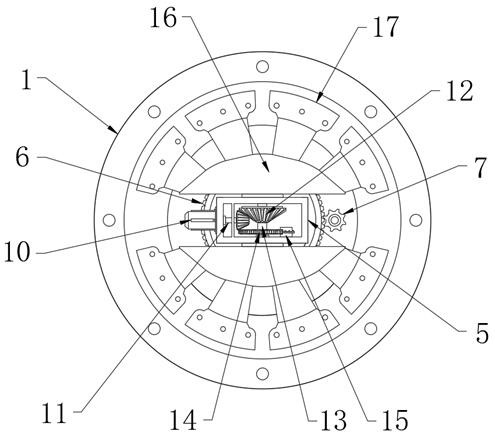

[0038] The features of this embodiment that are the same as those of Embodiment 1 will not be repeated. The difference between this embodiment and Embodiment 1 is that, in this embodiment, the first extension tube 5 includes a transmission disc 6, a first servo motor 9, a first Two servo motors 10 and chucks 14, the drive disc 6 is installed on the lower outer wall of the first extension tube 5, and the drive disc 6 is meshed with a driving wheel 7; the first servo motor 9 is installed on the first extension tube 5, and the top of the first servo motor shaft 8 forms a rotating structure through the first servo motor shaft 8 and the driving wheel 7; the second servo motor 10 is installed on the upper side of the first extension tube 5, and One end of the second servo motor 10 is rotatably connected with a second servo motor shaft 11; the second servo motor shaft 11 runs through the outer wall of the first extension tube 5 to cooperate with the bevel gear set 12 and the main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com