Bump punching mechanism for solar panel bracket

A technology for solar panels and punching, which is applied in the field of punching mechanisms, can solve the problems of low installation efficiency, complex structure, and many parts, and achieves the effect of improving installation efficiency and simplifying the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

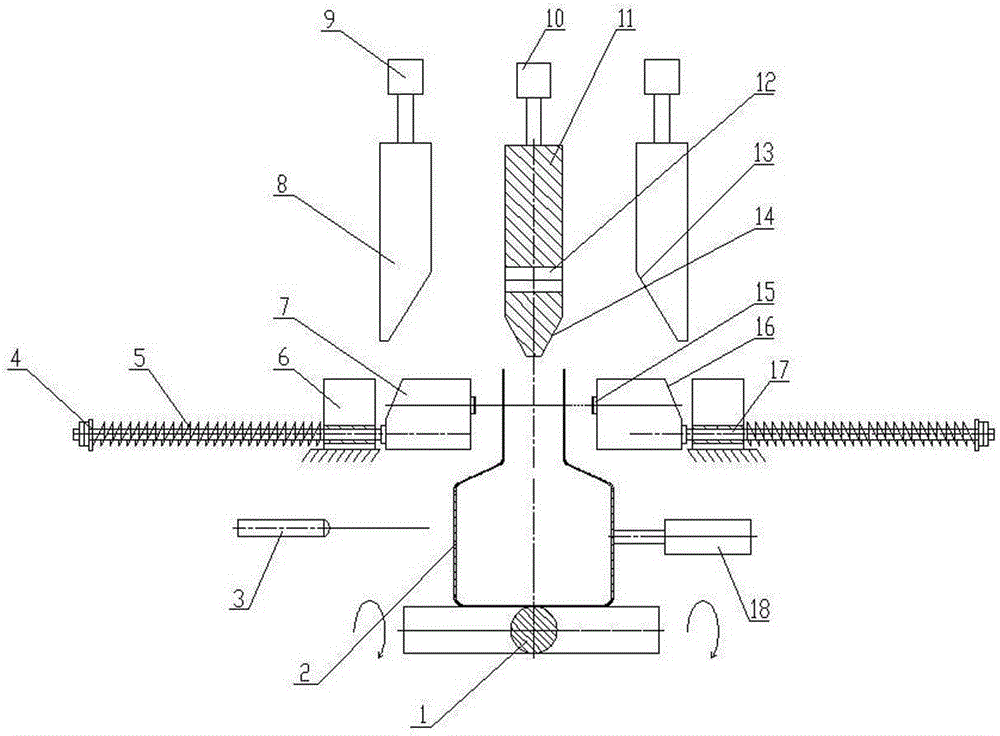

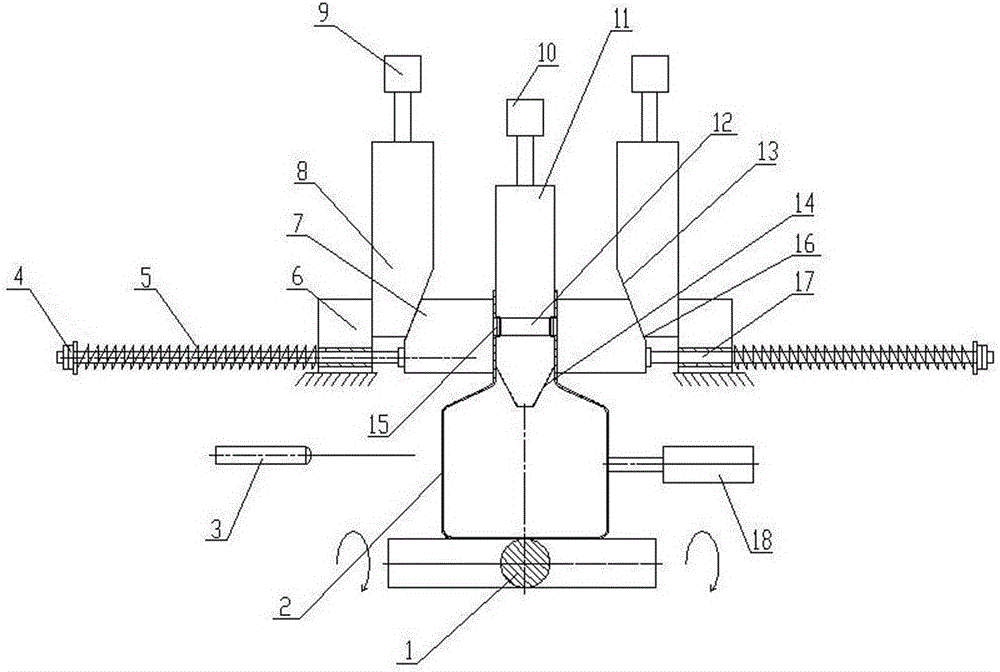

[0013] Such as figure 1 As shown, the flushing mechanism for the solar panel support of the present invention includes a base on which is placed a bottle-shaped cross section, 2. Supports 6 are fixed on the bases on both sides of the profile steel 2, and two transverse rod holes are processed on the same level on the support 6. Corresponds to the neck of the bottle. Push rods 17 are installed in the transverse rod holes, and the two are in a sliding fit. The two ends of the push rod 17 all protrude from the two ends of the corresponding transverse rod holes, and the inner ends of the two push rods 17 on the same support 6 are fixed with top tight blocks 7, and the two top fast block 7 adjacent surfaces Protruding heads 15 are arranged in the middle of the longitudinal direction. The outer ends of the ejector rods 17 are all fixed with stoppers 4, and the section of ejector rods 17 between the stoppers 4 and the adjacent bearings 6 are all covered with springs 5. A template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com