Positioning method of prefabricated box beam embedded steel plates

A pre-embedded steel plate and positioning method technology, applied in bridges, manufacturing tools, bridge construction, etc., can solve the problems of cumbersome adjustment process, non-reusable, waste, etc., and achieve the effect of ensuring the quality of the box girder and convenient operation of angle adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

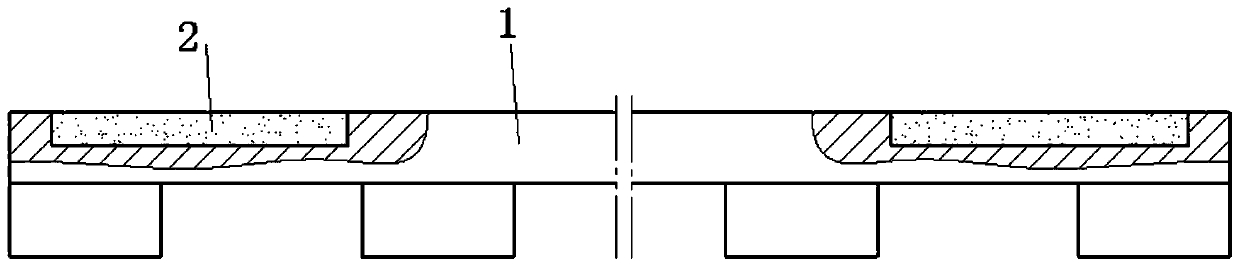

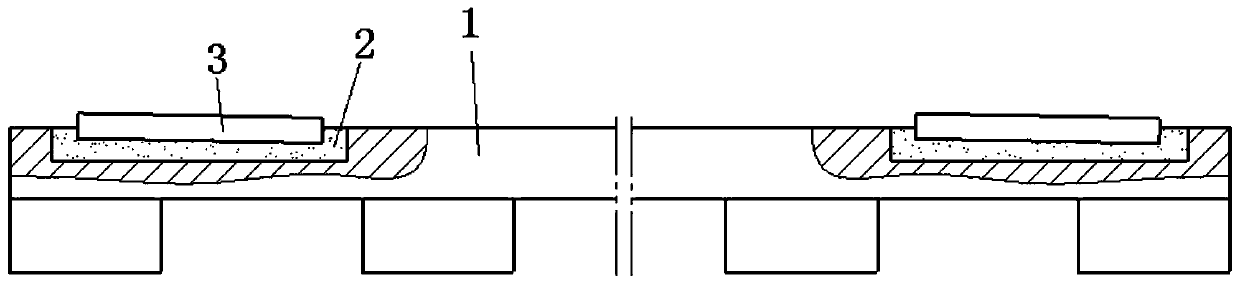

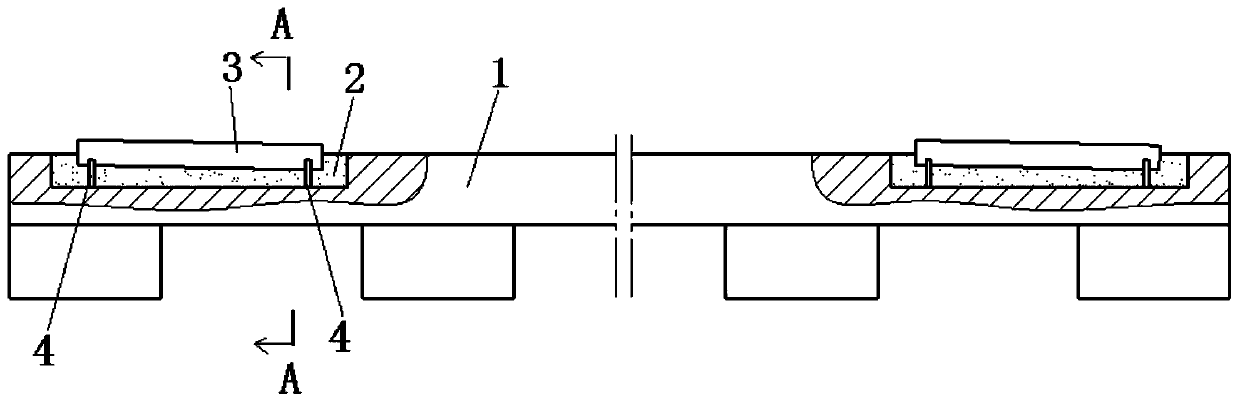

[0025] The prefabricated box girder prefabricated steel plate positioning method comprises the following steps: A, prepare box girder prefabricated pedestal 1 and positioning bar 4, two bunkers 2 are arranged on the box girder prefabricated pedestal 1, and the length and width of bunker 2 are all than prefabricated The length and width of the steel plate 3 are large, and the bunker 2 is filled with fine sand; B. Put a pre-embedded steel plate 3 into the middle of a bunker 2, and knock the pre-embedded steel plate 3 so that the lower part of the pre-embedded steel plate 3 is buried in fine sand , and make the inclination angle of the upper surface of the pre-embedded steel plate 3 meet the design requirements; C, remove the fine sand on both sides of the end of the pre-embedded steel plate 3, insert the positioning rod 4 into the fine sand and in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com