Worm and gear engagement detection device

A technology of worm gear and detection device, which is applied in the direction of measuring device, electric device, machine gear/transmission mechanism test, etc., and can solve the problem of inaccurate detection of worm gear and worm meshing detection equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

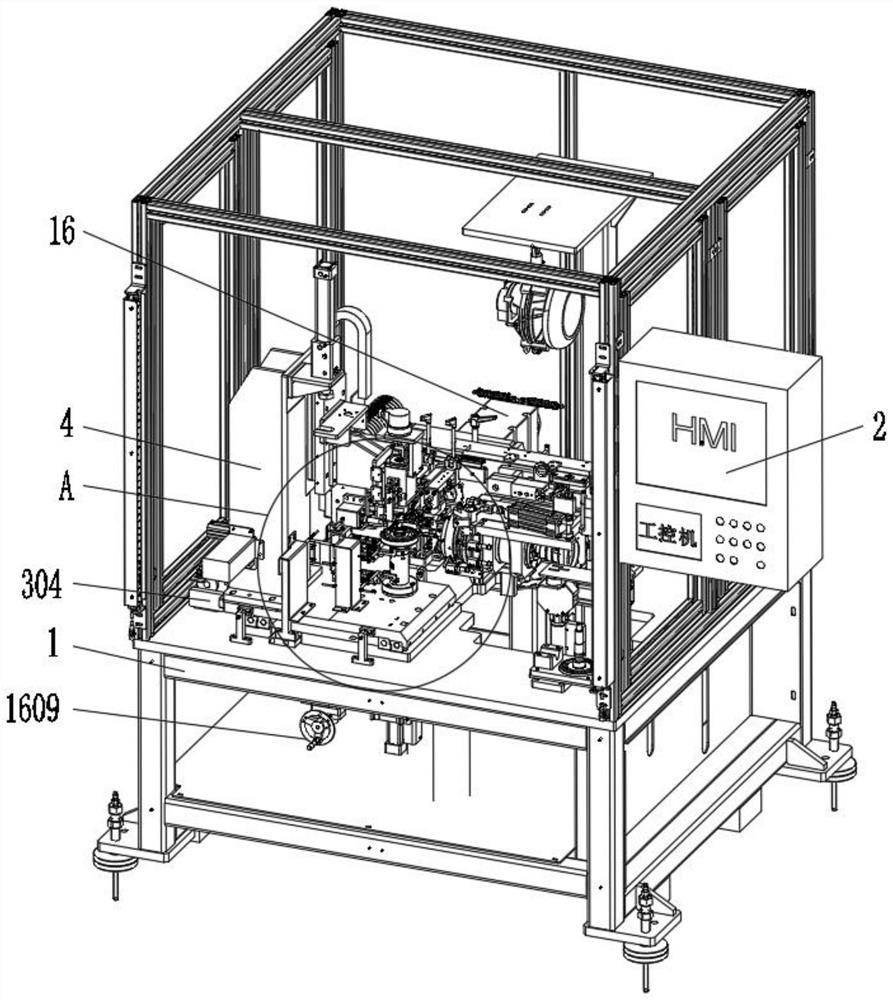

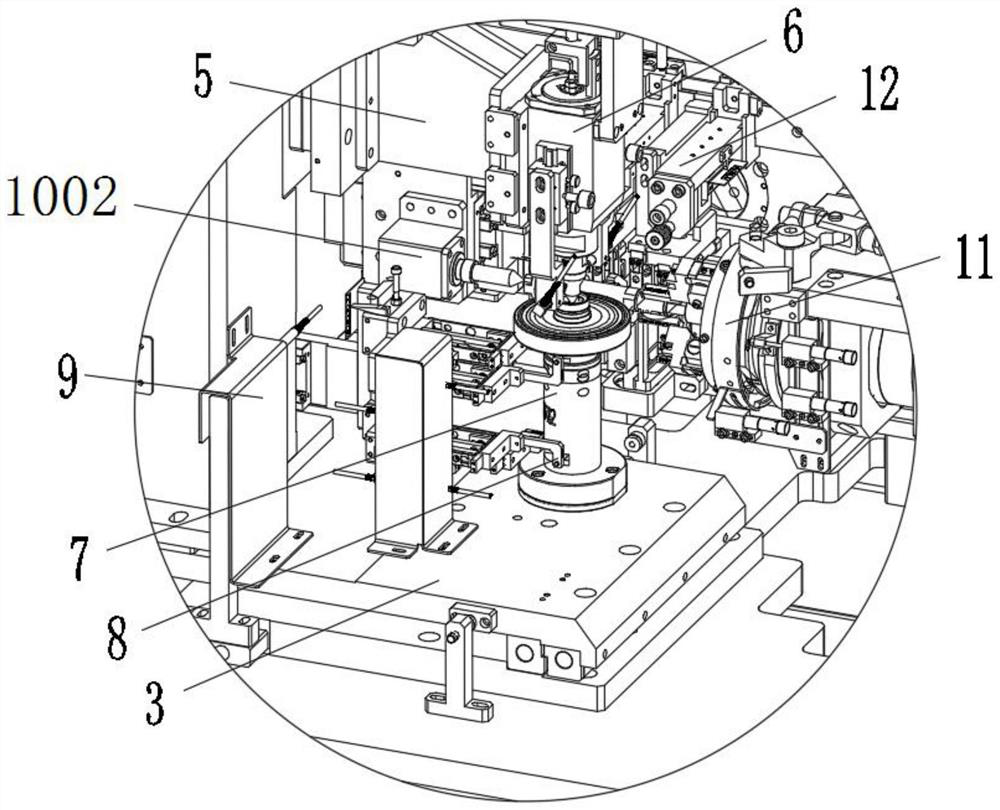

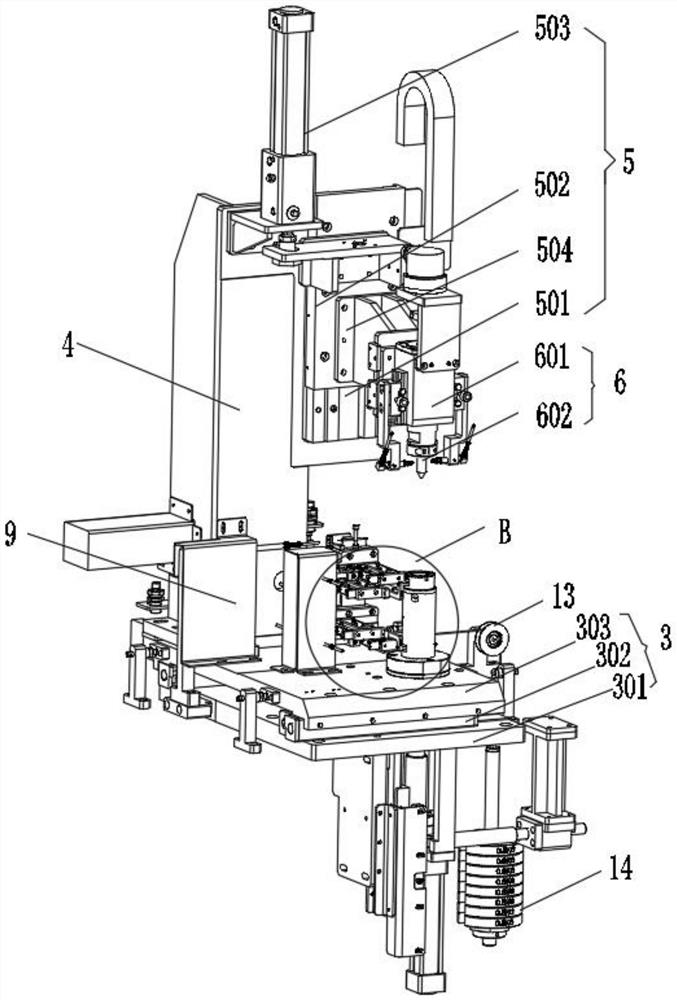

[0050] see Figure 1-9 , a worm gear meshing detection device, including a worm gear positioning cylinder 7 and a worm clamping mechanism, the worm gear positioning cylinder 7 is fixedly connected to a linear slide 3, and the linear slide 3 and the worm clamping mechanism are fixedly installed on a workbench 1 The measured worm gear is set on the worm gear positioning cylinder 7, and the standard worm is clamped on the worm clamping mechanism, or the standard worm gear is set on the worm gear positioning cylinder 7, and the measured worm is clamped on the worm gear clamping mechanism.

[0051] Such as Figure 1-6 As shown, the linear slide table 3 includes a slide seat 301 fixedly connected to the workbench 1, the slide seat 301 is fixedly connected with a first slide rail 302, and the first slide rail 302 is slidably connected with a first slide table 303; A first air cylinder 304 is also fixedly installed on the 301, the output shaft of the first air cylinder 304 is connect...

Embodiment 2

[0078] Such as Figure 7-9 , Figure 5 As shown, the second embodiment is an improvement on the basis of the first embodiment, mainly to make the device applicable to the detection of the meshing of the spur gear and the worm, and to enhance its versatility. Therefore, an angle adjustment mechanism 16 is added, and the angle adjustment mechanism 16 includes a base 1601 fixedly installed on the workbench 1, the second servo motor 1602 is fixedly installed on the installation base 1601, the output shaft of the second servo motor 1602 is fixedly connected with the back side of the mounting plate 15, and the second servo motor 1602 The rotation of the output shaft of the second servo motor 1602 drives the mounting plate 15 to rotate, thereby changing the angle of the turbine clamping mechanism; when the angle of the output shaft of the second servo motor 1602 changes, the angle of the mounting plate 15 connected to it will also change, and finally the mounting plate 15. The angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com