Centering measurement apparatus for measuring center distance of two intersecting holes in intersecting hole system

A technology of measuring device and centering device, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of product center distance fluctuation, transmission efficiency fluctuation, abnormal noise torsion distance, etc., and achieves the reduction of manufacturing difficulty, Ensure the effect of use and eliminate the effect of machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with drawings and embodiments.

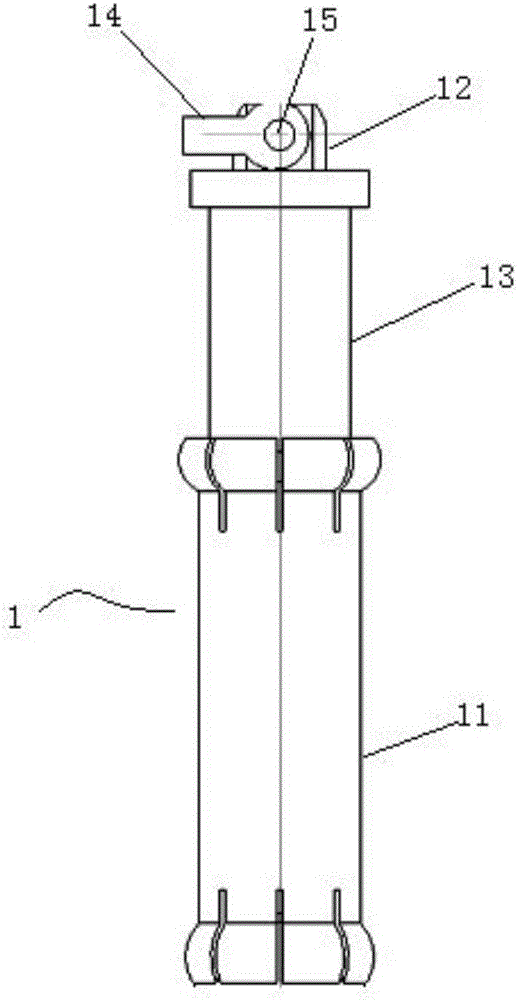

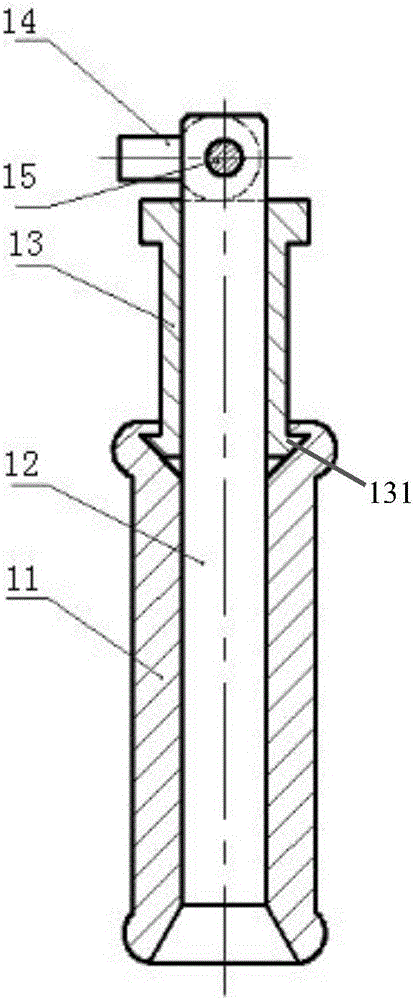

[0038] Such as Figure 5a-Figure 5e As shown, a centering measuring device for detecting the center distance of two intersecting holes in an intersecting hole system includes a two-hole positioning and centering device 1, which is used to give the first hole system 41 of the part 4 intersecting hole system to be measured. The two bearing holes are floating and centered, and the axis formed by the center of the two bearing holes is transferred to the outer circle of the centering expansion sleeve as a fixed end for detection.

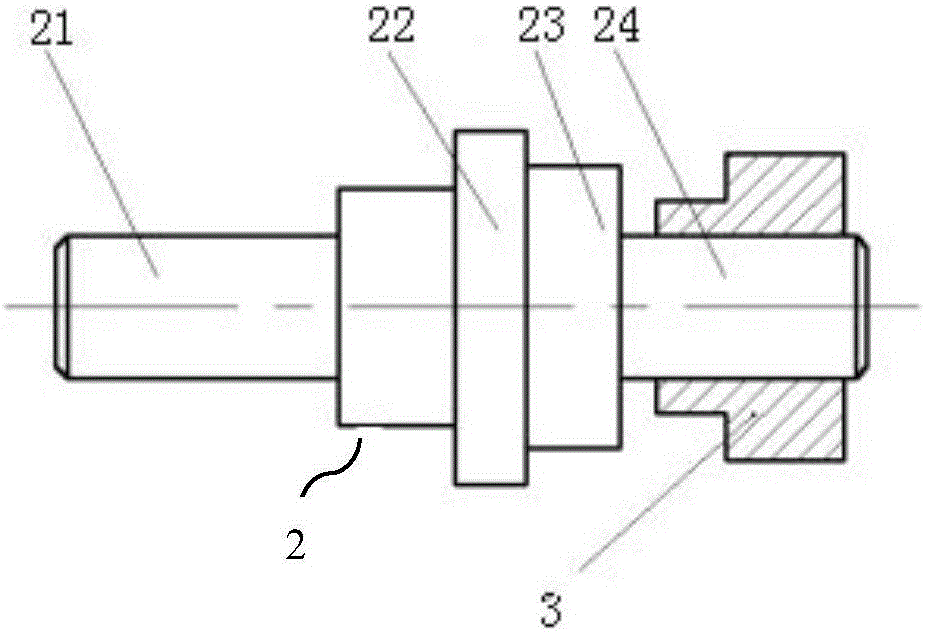

[0039] The variable pitch cam mechanism 2 and the auxiliary centering mechanism 3 are used to locate the second hole system 42 in the intersecting hole system of the part 4 to be measured. The variable pitch cam mechanism 2 and the auxiliary centering mechanism 3 are rotatable as a detection adjustment end.

[0040] Such as figure 1 and figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com