Light enhanced tray type bridge stand

An enhanced, tray-type technology, applied in electrical components and other directions, can solve problems such as affecting the anti-corrosion performance and service life of the bridge, prone to gaps in the connection parts, and many processing procedures, so as to achieve firm and reliable welding parts, increase heat dissipation, and ensure The effect of assembly precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

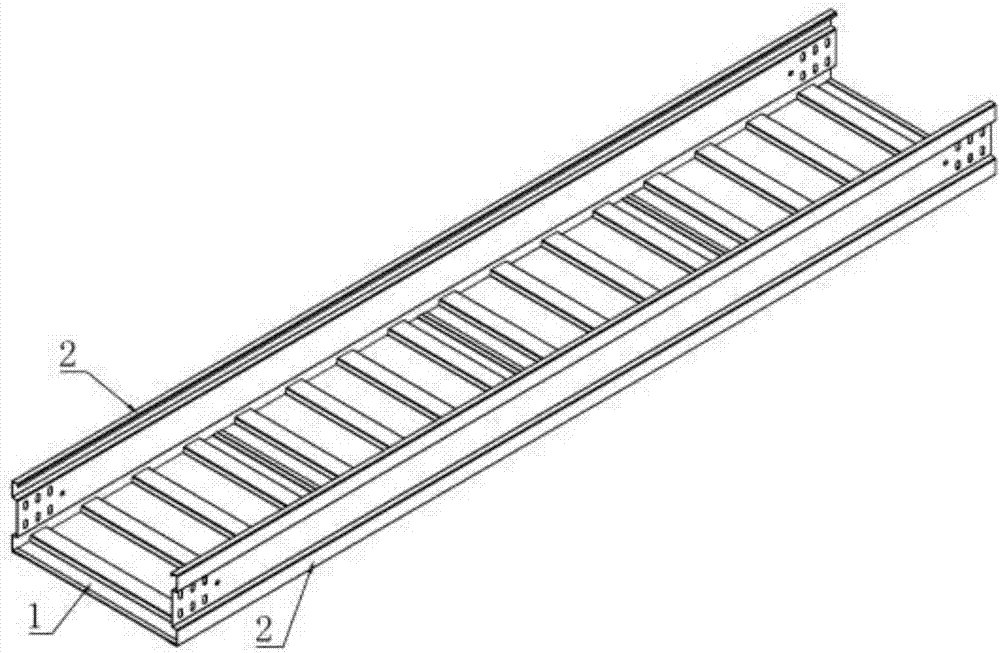

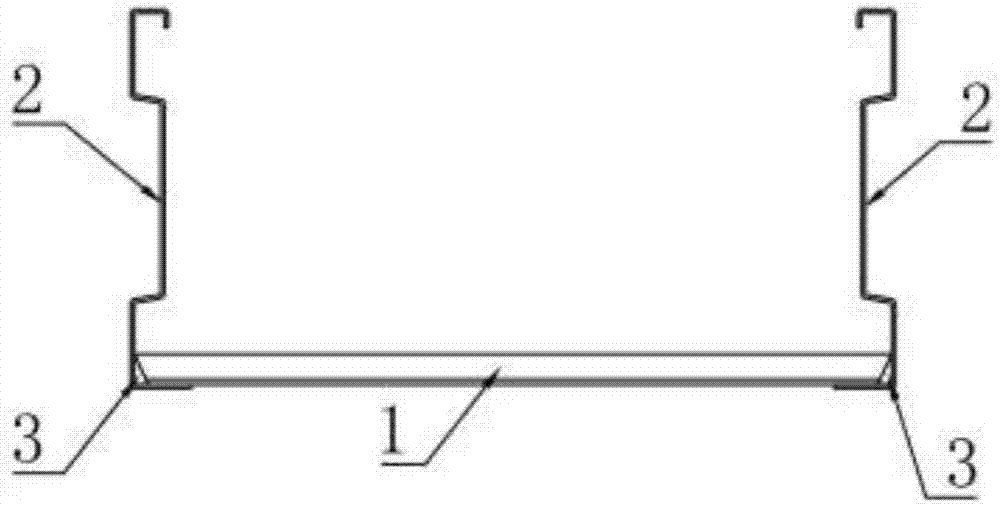

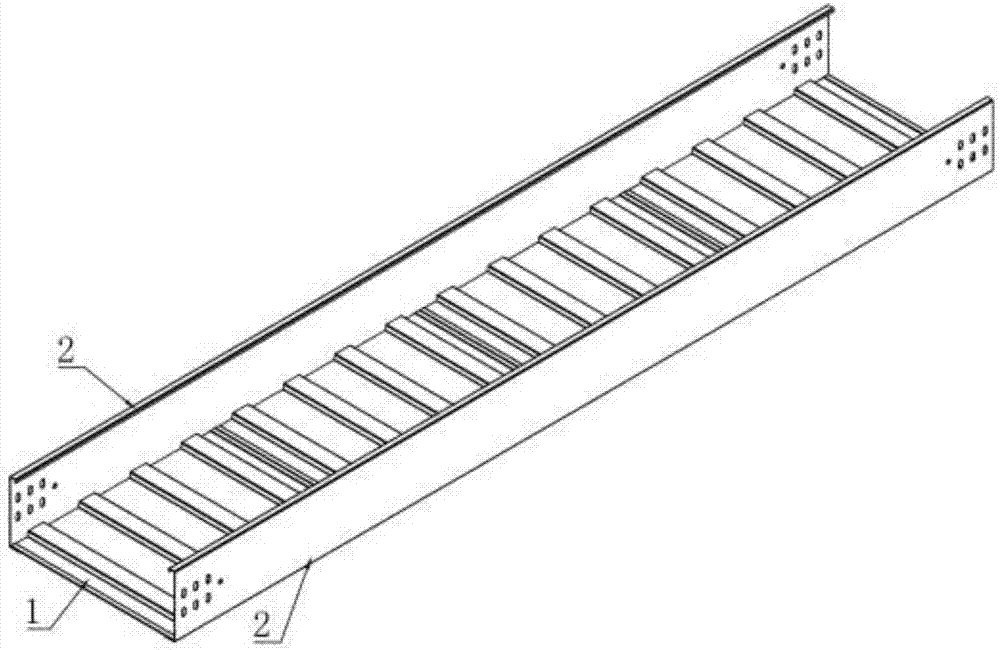

[0022] A light-duty reinforced pallet-type bridge frame of the present invention is composed of two side plates 2 and multiple bottom plates 1. The side plates 2 and bottom plates 1 are formed by cold bending. figure 2 , 4 , 6, 8 and other structures, the bottom plate 1 is spliced continuously along the length direction of the side plate 2 to form a bridge frame, the length of each bottom plate is 500mm, and there are four protrusions 11, and the two ends of the bottom plate are folded out 3 ~ 20mm The width of the bottom plate 1 is cut according to the specifications of the bridge, and the cutting angle is obliquely cut, that is, the width of the upper plane in the transverse direction of the base plate 1 is greater than the width of the lower plane, so that the transverse width of the bottom groove 12 is smaller than the transverse width of the protrusion 11. 15mm, so that there is a certain gap 3 at the bottom when the bottom plate 1 and the side plate 2 are connected, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com