Gap-adjustable ultrasonic rolling device capable of stably outputting

A technology of ultrasonic rolling and stable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

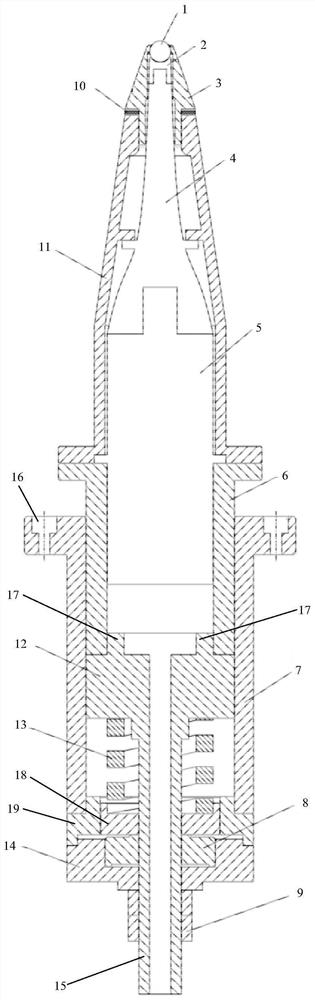

[0040] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

[0041] It should be noted that the "upper" and "lower" in the present invention refer to figure 1 as the base direction.

[0042] Such as figure 1 As shown, the embodiment of the present invention provides a stable output gap-adjustable ultrasonic rolling device, which includes a hollow inner pressure cap 3 connected in sequence along the axial direction, an adjustment ring 10, a fixed cover 11 and a sliding sleeve 6 and The tool seat 7 is sheathed on the outside of the sliding sleeve 6 , and the sliding sleeve 6 is slidably matched with the tool seat 7 so that the sliding sleeve 6 slides inside the tool seat 7 . The inner cavities of the pressure cap 3, the fixed cover 11 and the sliding sleeve 6 communicate with each other and form an installation room, in which the balls 1, the top cap 2, the horn 4 and the changer are arranged sequentially fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com